Magnesium-hercynite-structured heat-insulating integral composite brick and preparation method thereof

A magnesia-iron-aluminum spinel and composite brick technology, which is applied in the field of magnesia-iron-aluminum spinel structural heat insulation integrated composite bricks and its preparation, can solve the problem of thermal expansion of a cylinder body, increase of heat consumption of clinker, and kiln cylinder. It can solve the problems of increased heat dissipation and other problems, and achieve the effects of good thermal insulation performance, good structural strength and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

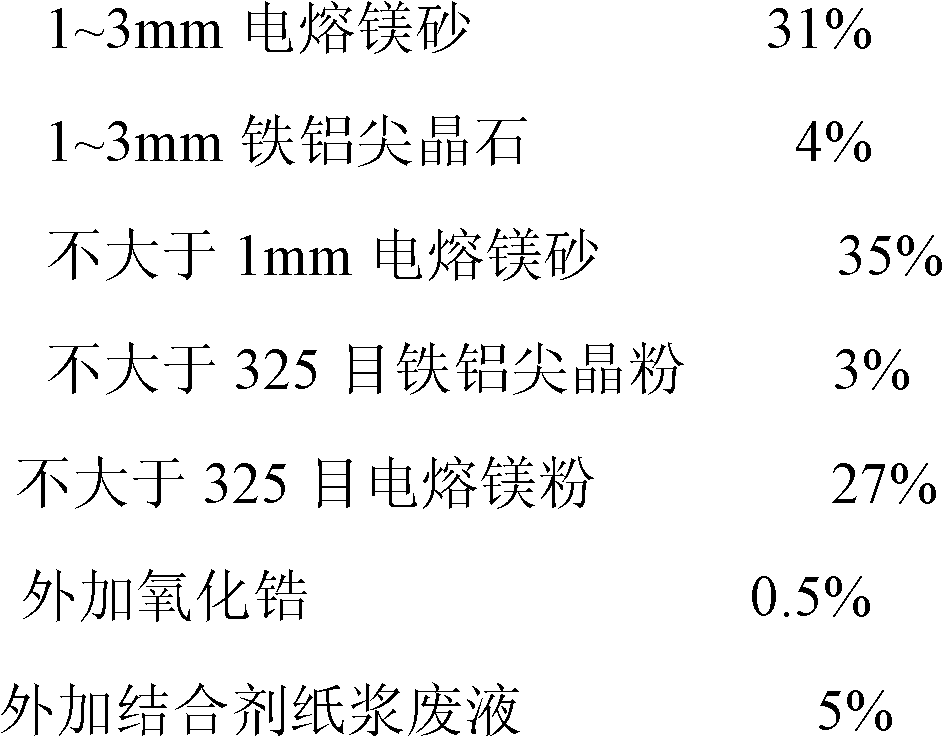

[0035] In this example, the heavy working layer 1 adopts DMS98 type fused magnesia and ferroaluminum spinel as raw materials, and the particle gradation and its mass percentage are as follows:

[0036]

[0037] According to the above ratio, the mass percentage of the MgO component in the heavy working layer is 96%, and the Al 2 o 3 Ingredient mass percentage is 2%, Fe 2 o 3 The composition mass percentage is 2%.

[0038] The raw materials used in the lightweight heat insulation layer 2 and their mass percentages are: 10% aluminum oxide hollow spheres, 10% magnesium aluminum hollow spheres, 10% corundum hollow spheres, 10% chromium corundum hollow spheres, and zirconium corundum hollow spheres. Ball 15%, 325 mesh fused spinel micropowder 45%, additional industrial lignosulfonate solution 6%, Al 2o 3 The mass percentage is 98%, Al in magnesium aluminum hollow sphere 2 o 3 The mass percentage content is 99.9%, the mass percentage content of MgO is 0.1%, and the Al in co...

Embodiment 2

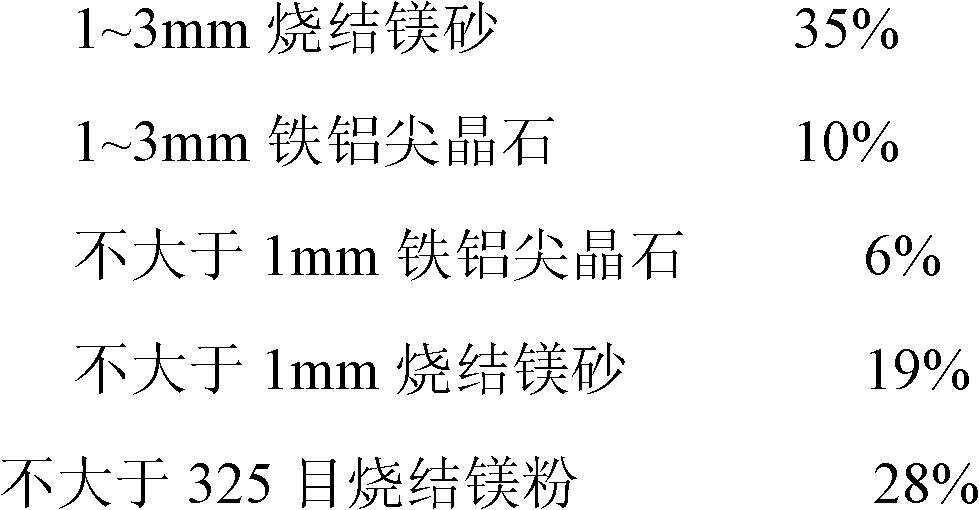

[0046] MS97A type sintered magnesia, α-Al 2 o 3 Powder and iron-aluminum spinel are used as raw materials, and the particle size distribution and its mass percentage are as follows:

[0047]

[0048]

[0049] According to the above ratio, the mass percentage of the MgO component of the heavy working layer is 85%, and the Al 2 o 3 The mass percentage of ingredients is 6.5%, Fe 2 o 3 The composition mass percentage is 7.5%.

[0050] The raw materials and their mass percentages used in the lightweight insulation layer 2 are: 65% of magnesium-aluminum hollow spheres, 35% of 325-mesh sintered spinel micropowder, 10% of lignosulfonate solution, and the magnesium-aluminum hollow spheres used Middle Al 2 o 3 The mass percent content is 70.5%, and the MgO mass percent content is 28.0%.

[0051] The manufacturing method of the magnesium-iron-aluminum spinel structure / heat insulation integrated composite brick of this embodiment includes the following steps:

[0052] (1) I...

Embodiment 3

[0058] The MS98A type sintered magnesia and ferroaluminum spinel used in the heavy working layer 1 of this example are raw materials, and the particle gradation and its mass percentage are as follows:

[0059]

[0060]

[0061] According to the above ratio, the mass percentage of the MgO composition of the heavy working layer obtained is 91%, and the Al 2 o 3 The mass percentage of ingredients is 3%, Fe 2 o 3 The composition mass percentage is 3.5%.

[0062] The raw materials and their mass percentages used in the lightweight heat insulation layer 2 are: 55% of magnesium-aluminum hollow spheres, 45% of 325-mesh fused spinel, 6% of methyl cellulose solution, and the magnesium-aluminum used Al in hollow sphere 2 o 3 The mass percentage is 50%, and the MgO mass percentage is 45%.

[0063] The manufacturing method of the magnesium-iron-aluminum spinel structure / heat insulation integrated composite brick of the present embodiment includes the following steps:

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com