Coating capable of enhancing kiln coating adherence of firing zone of rotary cement kiln and application of coating

A technology for strengthening cement and firing zone is applied in the field of refractory materials for firing zone of cement rotary kiln, which can solve the problems of easy falling off and difficulty in hanging kiln skin, so as to promote the development process, improve the performance of hanging kiln skin, and enhance the hanging kiln skin. The effect of skin properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

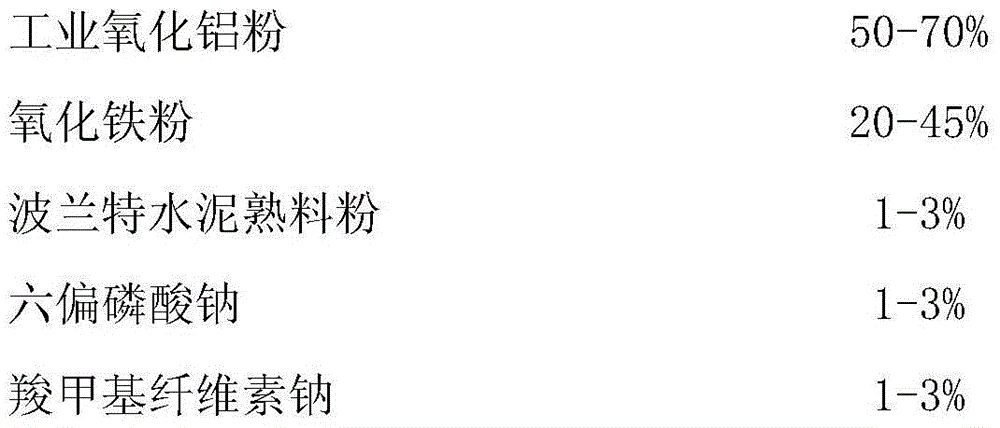

[0021] A coating for enhancing the performance of cement rotary kiln firing belt hanging kiln skin, its chemical composition and weight percentage composition are as follows:

[0022]

[0023] The coating that enhances the performance of cement rotary kiln firing with kiln skin is a slurry with uniform material distribution. After the slurry is fully mixed in the mixer with the above powder material, add 20% of the total weight of the powder material at room temperature. Drinking water is blended and stirred.

[0024] An application of a coating that enhances the performance of cement rotary kiln firing with kiln skin hanging, the steps of the application method are as follows:

[0025] a. Clean up the floating dust and impurities on the surface of the cement rotary kiln magnesia-iron-aluminum spinel brick;

[0026] b. Take the coating that enhances the performance of cement rotary kiln firing belt hanging kiln skin and spray it evenly on the surface of magnesium iron alum...

Embodiment 2

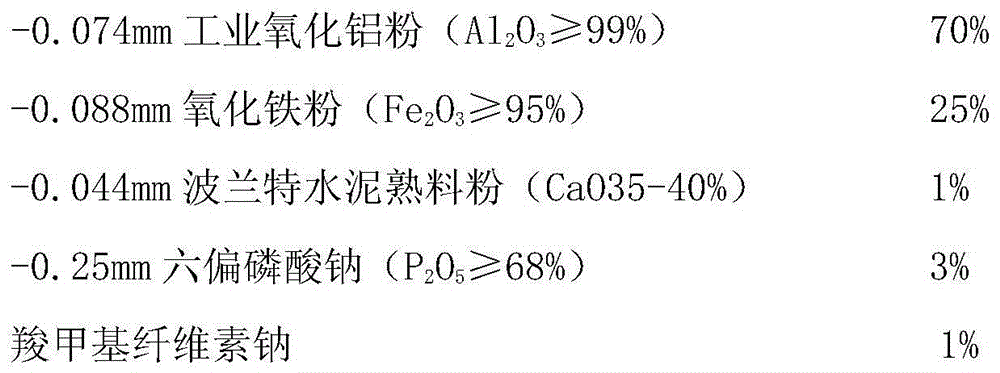

[0029] A coating for enhancing the performance of cement rotary kiln firing belt hanging kiln skin, its chemical composition and weight percentage composition are as follows:

[0030]

[0031] The coating that enhances the performance of cement rotary kiln firing with hanging kiln skin is a slurry with uniform material distribution. After the slurry is fully mixed in the mixer with the above powder material, add 25% of the total weight of the powder material at room temperature. Drinking water is blended and stirred.

[0032] An application of a coating that enhances the performance of cement rotary kiln firing with kiln skin hanging, the steps of the application method are as follows:

[0033] a. Clean up the floating dust and impurities on the surface of the cement rotary kiln fired with magnesium-iron-aluminum spinel brick;

[0034] b. Take the coating that enhances the performance of cement rotary kiln firing belt hanging kiln skin and spray it evenly on the surface of...

Embodiment 3

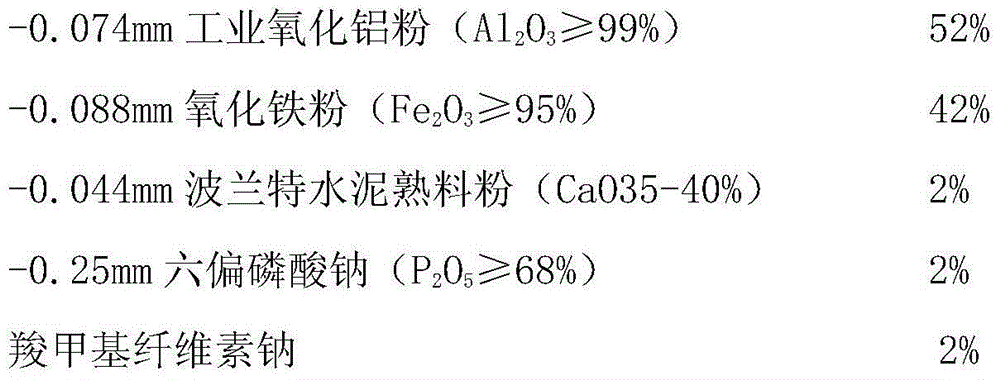

[0037] A coating for enhancing the performance of cement rotary kiln firing belt hanging kiln skin, its chemical composition and weight percentage composition are as follows:

[0038]

[0039] The coating that enhances the performance of cement rotary kiln firing with kiln skin is a slurry with uniform material distribution. After the slurry is fully mixed in the mixer with the above-mentioned powder material, add 30% of the total weight of the powder material at room temperature. Drinking water is blended and stirred.

[0040] An application of a coating that enhances the performance of cement rotary kiln firing with kiln skin hanging, the steps of the application method are as follows:

[0041] a. Clean the surface of the magnesia-iron-aluminum spinel brick after leaving the kiln and cooling in the production factory;

[0042] b. Take the coating that enhances the performance of cement rotary kiln firing belt hanging kiln skin and spray evenly on the surface of magnesia-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com