Cleaning agent and application thereof to cleaning of ceramic filter plates

A cleaning agent and ceramic technology, applied in the field of cleaning, can solve problems such as difficult to clean micropore blockages on ceramic plates, harm to human body and environment, and limited cleaning effect, and achieve strong penetration, environmental friendliness, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

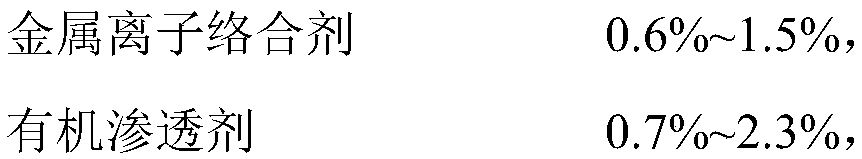

[0036] A kind of cleaning agent of the present invention is made up of the component of following percentage by weight:

[0037]

[0038] The preparation method of the cleaning agent in this example is as follows: weigh each component according to the above proportions, add it into the mixing tank, stir at room temperature for 10 minutes, discharge the material for later use, and obtain the cleaning agent of the present invention.

Embodiment 2

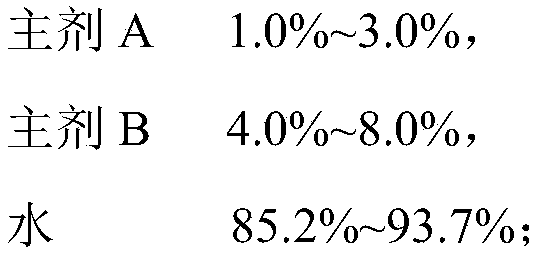

[0040] A kind of cleaning agent of the present invention is made up of the component of following percentage by weight:

[0041]

[0042] The preparation method of the cleaning agent in this example is as follows: weigh each component according to the above proportions, add it into the mixing tank, stir at room temperature for 10 minutes, discharge the material for later use, and obtain the cleaning agent of the present invention.

Embodiment 3

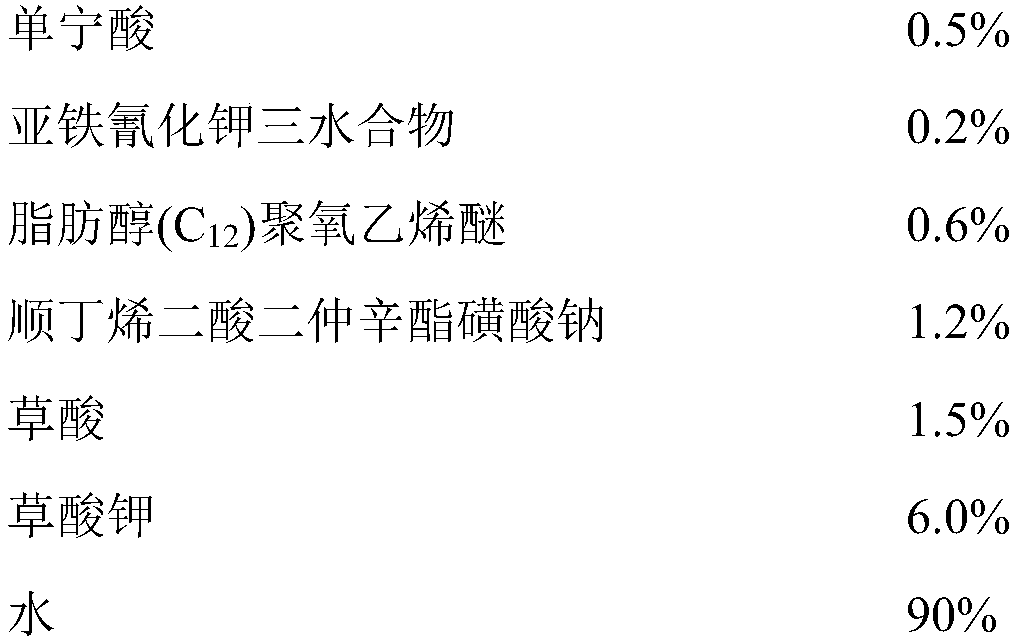

[0044] A kind of cleaning agent of the present invention is made up of the component of following percentage by weight:

[0045]

[0046]

[0047] The preparation method of the cleaning agent in this example is as follows: weigh each component according to the above proportions, add it into the mixing tank, stir at room temperature for 10 minutes, discharge the material for later use, and obtain the cleaning agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com