Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

An extrusion molding, microporous plastic technology, applied in the field of the preparation of open-celled microporous plastic products, can solve the problems of difficult micropore diameter and opening rate, complex process, long process, etc., and achieves easy degradation and simple process. , the effect of low molding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

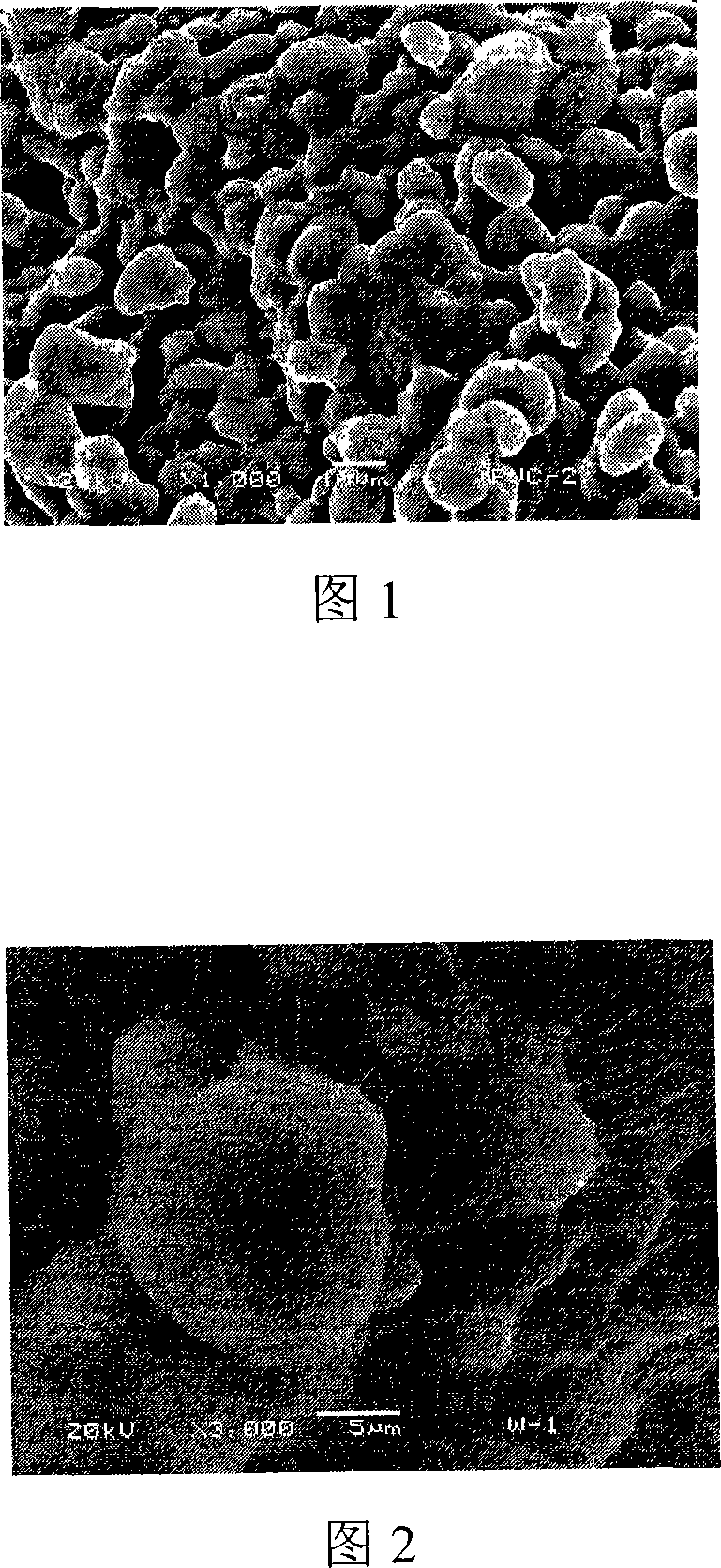

Image

Examples

Embodiment 1

[0036] Dry the 40-mesh ABS (Chimei 757) powder in an oven at a temperature of 90°C and a vacuum of 0.03MPa for 6 hours, then weigh 100 parts, and mix it with 2 parts of 10% ABS-tetrahydrofuran solution and 3 parts of sebacic acid Dibutyl ester and 3 parts of azodicarbonamide (ADC) are poured into an electric heating high-speed mixer and mixed for 5 minutes. At the same time, when the temperature is preheated to 80°C, discharge the material; put the preheated mixture into a dry insulator , at a temperature of 60°C and a relative humidity of 15%, the storage time is 1 hour; the stored mixture is placed in a vacuum suction feeding device with a constant temperature of 175°C, and a hydraulically driven double-plunger extruder is used. The raw material is extruded into a plate with a thickness of 4mm through the plate head, the die, the vacuum water tank for shaping, the crawler tractor, and the guillotine cutting device. Molding conditions: barrel temperature 180-210°C, head and d...

Embodiment 2

[0038] 100 parts of 120 mesh polyvinyl chloride resin powder and 3 parts of di-n-butyltin dilaurate, 2 parts of epoxy soybean oil, 3 parts of 20% PVC-dioctyl phthalate / tetrahydrofuran (=1:6) solution, 4 parts of methyl phenyl silicone oil and 6 parts of benzenesulfonyl hydrazide (BSH), pour into the electric heating high-speed mixer and mix for 8 minutes, and at the same time, when the temperature is preheated to 60 ° C, unload; put the preheated mixture into In a drying incubator, the storage time is 5 hours at a temperature of 45°C and a relative humidity of 50%. The stored mixture is placed in a blast-type feeding device with a constant temperature of 120°C, and squeezed by a hydraulic cylinder-driven double plunger. Out of the machine, the cross-section is a rectangular frame profile die, multi-plate type shaping, crawler tractor, and circular saw type cutting device to extrude a profile with a wall thickness of 1.5mm and a cross-section of a rectangular frame. Molding con...

Embodiment 3

[0040] Pour 100 parts of 60-mesh ultra-high molecular weight polyethylene powder, 3 parts of naphthenic oil and 2 parts of ethyl silicone oil into an electric heating high-speed mixer and mix for 8 minutes. Put the preheated mixture in a dry incubator at a temperature of 65°C and a relative humidity of 55%, and store it for 10 hours; put the stored mixture into a forced feeder device with a constant temperature of 120°C, and use a hydraulic cylinder The driven double-plunger extruder extrudes a pipe with a wall thickness of 2.0mm and an inner diameter of 10mm through a ring-shaped pipe die with a cross-section, a calibrating sleeve for shaping, a crawler tractor, and a circular saw cutting device. Molding conditions: barrel temperature 130-145°C, head and die temperature 145-180°C, pressurization pressure 100-150MPa, shaping section temperature 70-90°C, stretch ratio 1.5. The pore diameter of the obtained perforated microporous pipe is 5-50um, and the porosity is 20±5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com