Patents

Literature

45 results about "Microcellular plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

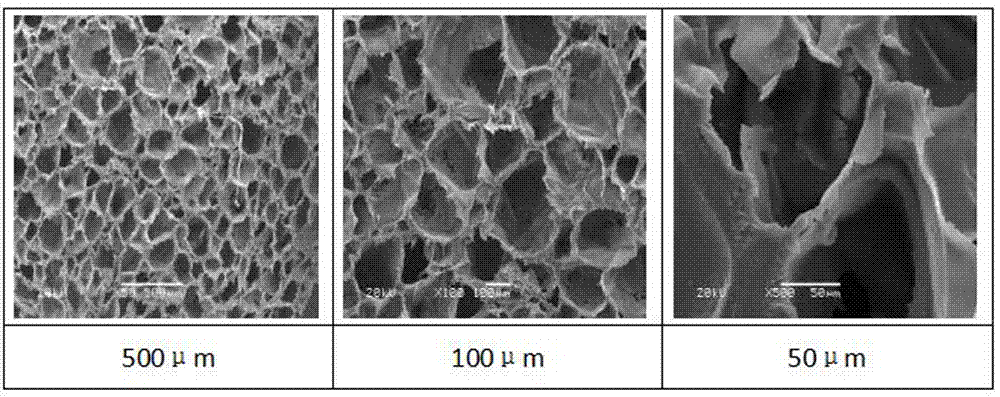

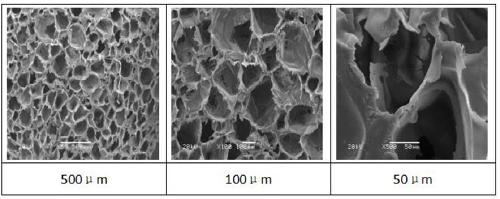

Microcellular plastics, otherwise known as microcellular foam, is a form of manufactured plastic, specially fabricated to contain billions of tiny bubbles less than 50 microns in size (typically from 0.1 to 100 micrometers). This type of plastic is formed by dissolving gas under high pressure into various polymers, relying on "thermodynamic instability phenomena" to cause the uniform arrangement of the gas bubbles, otherwise known as nucleation. Its main purpose was to reduce material usage while maintaining valuable mechanical properties. The main room for variance in these foams is the gas used to create them; the density of the finished product is determined by the gas used. Depending on the gas used, the density of the foam can lie between 5% and 99% that of the pre-processed plastic. Design parameters, focused more on the final form of the foam and the molding process afterward, include the type of die or mold to be used, as well as the dimensions of the bubbles, or cells, that classify this material as a foam. Since the size of cells is close to the wavelength of light, to the casual observer this foam retains the appearance of a solid light colored plastic.

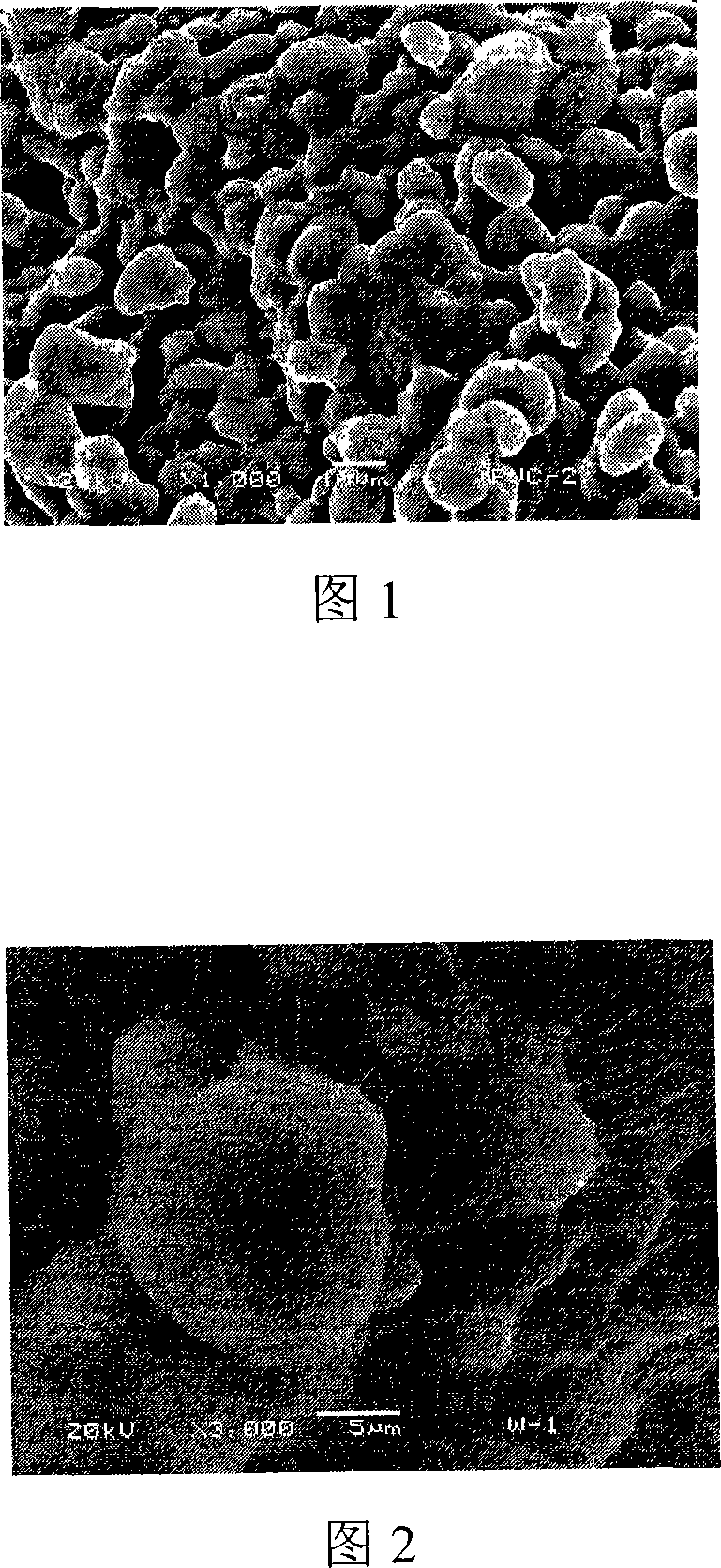

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

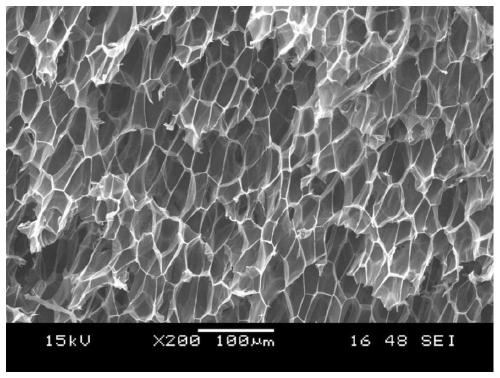

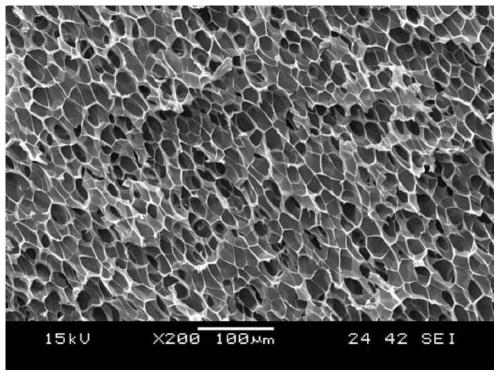

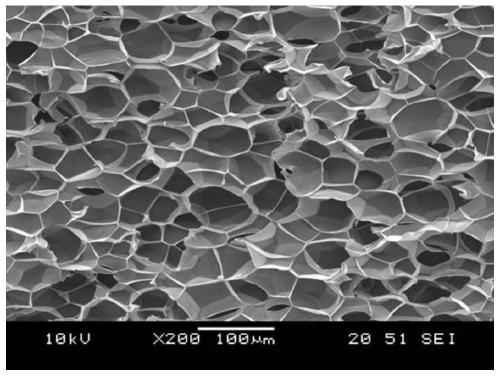

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

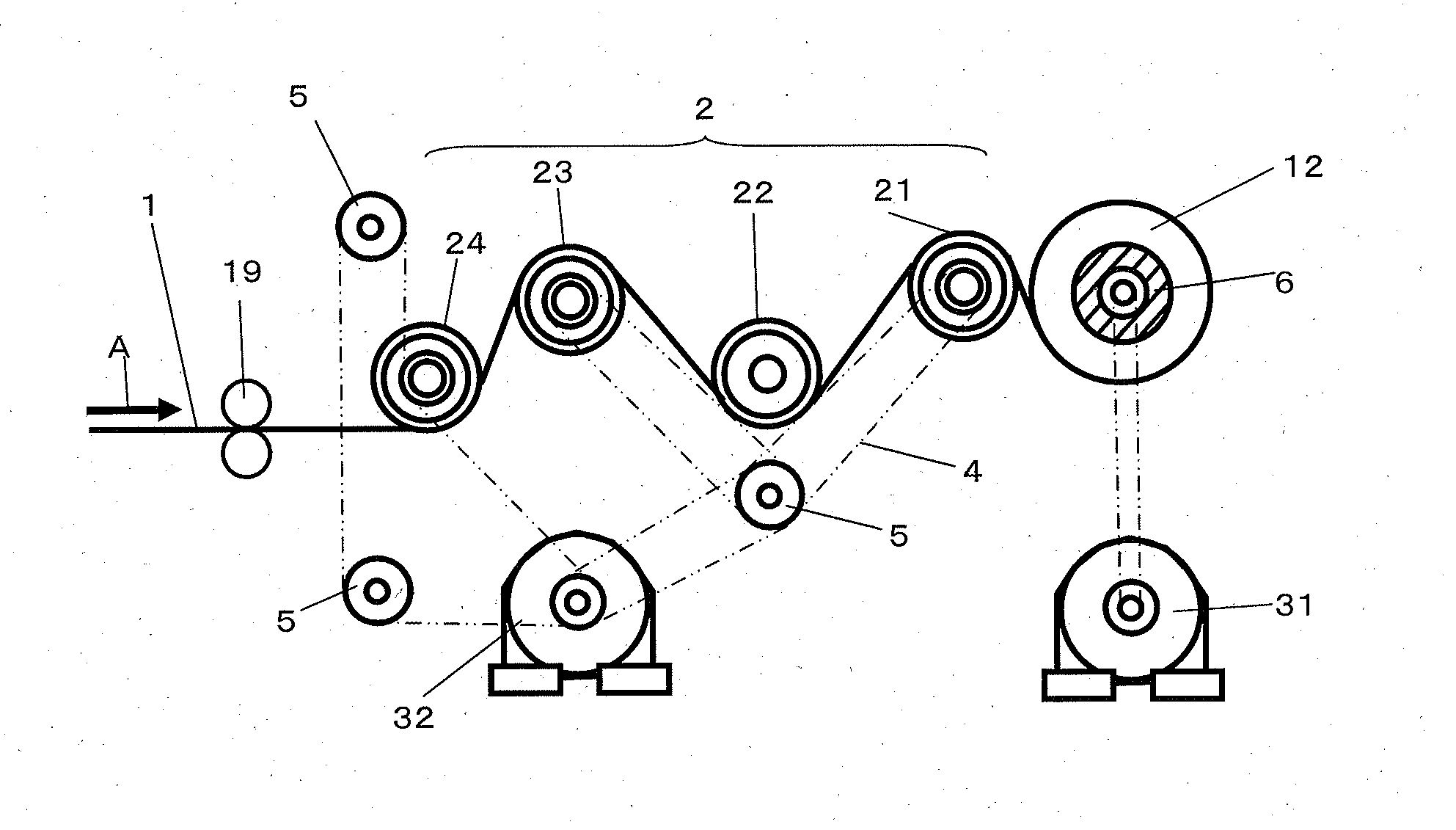

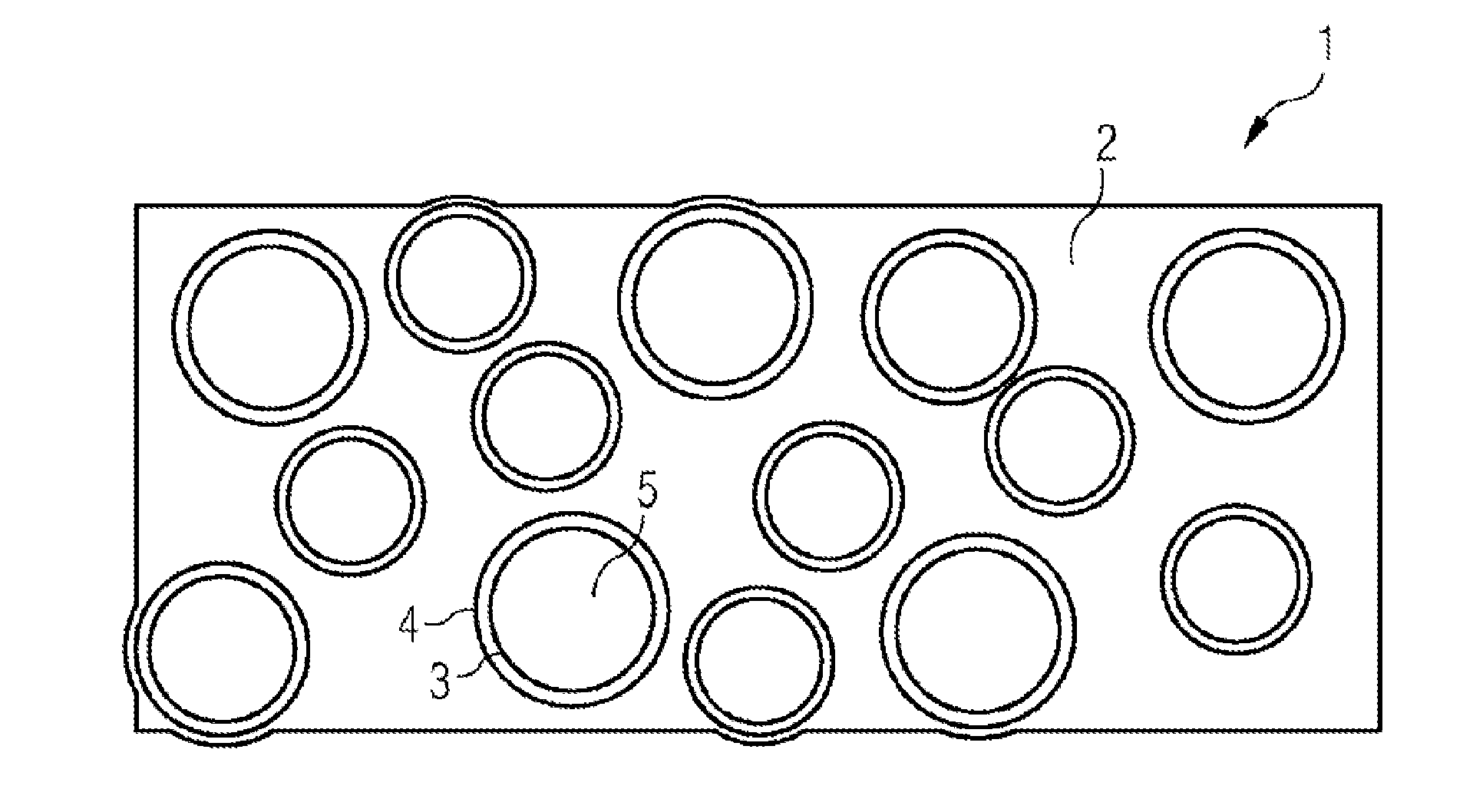

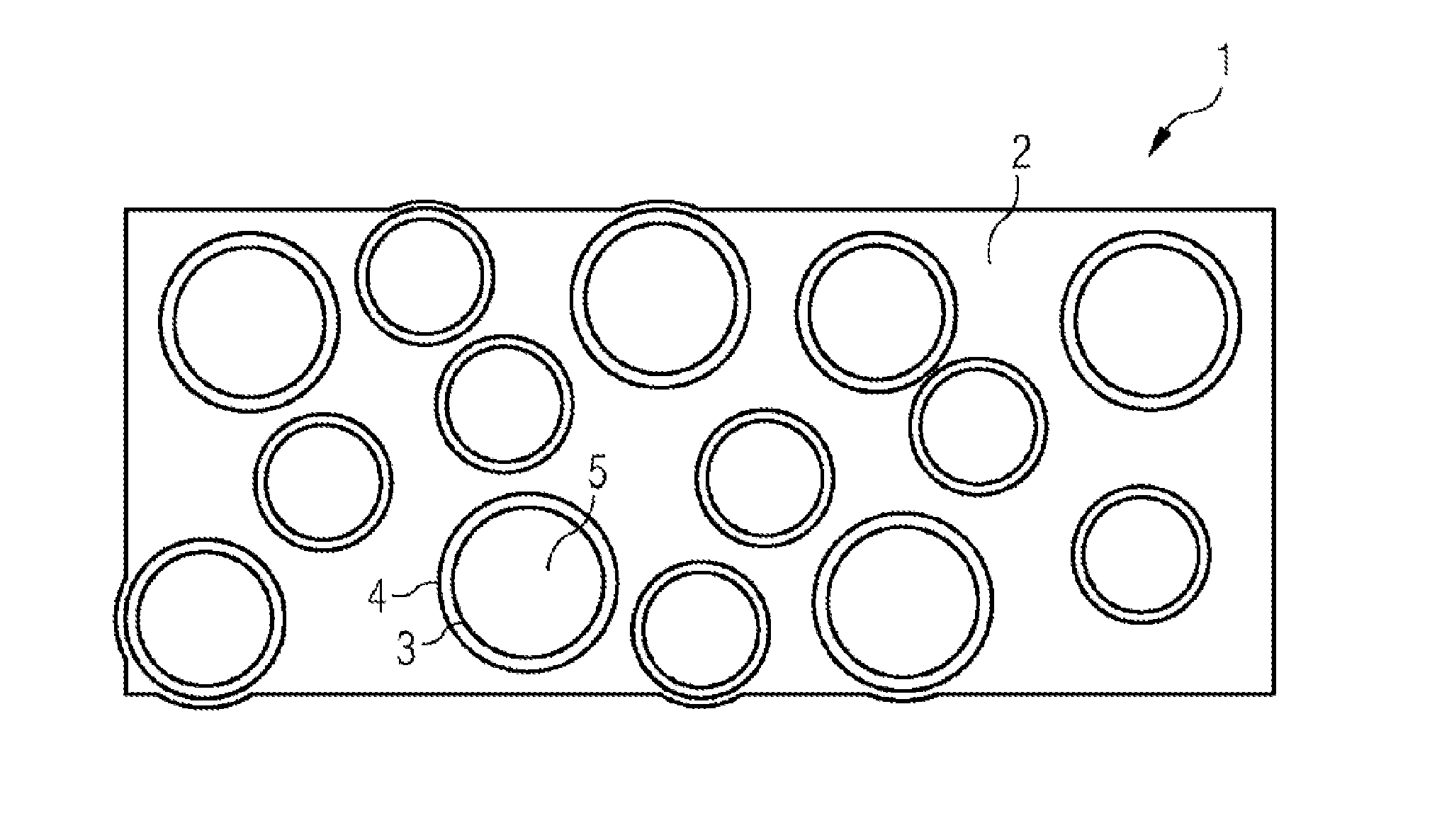

Process for producing roll of microporous plastic film

InactiveUS20140014762A1Lower average tensionPrevent from being easily brokenHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicrocellular plasticSurface roughness

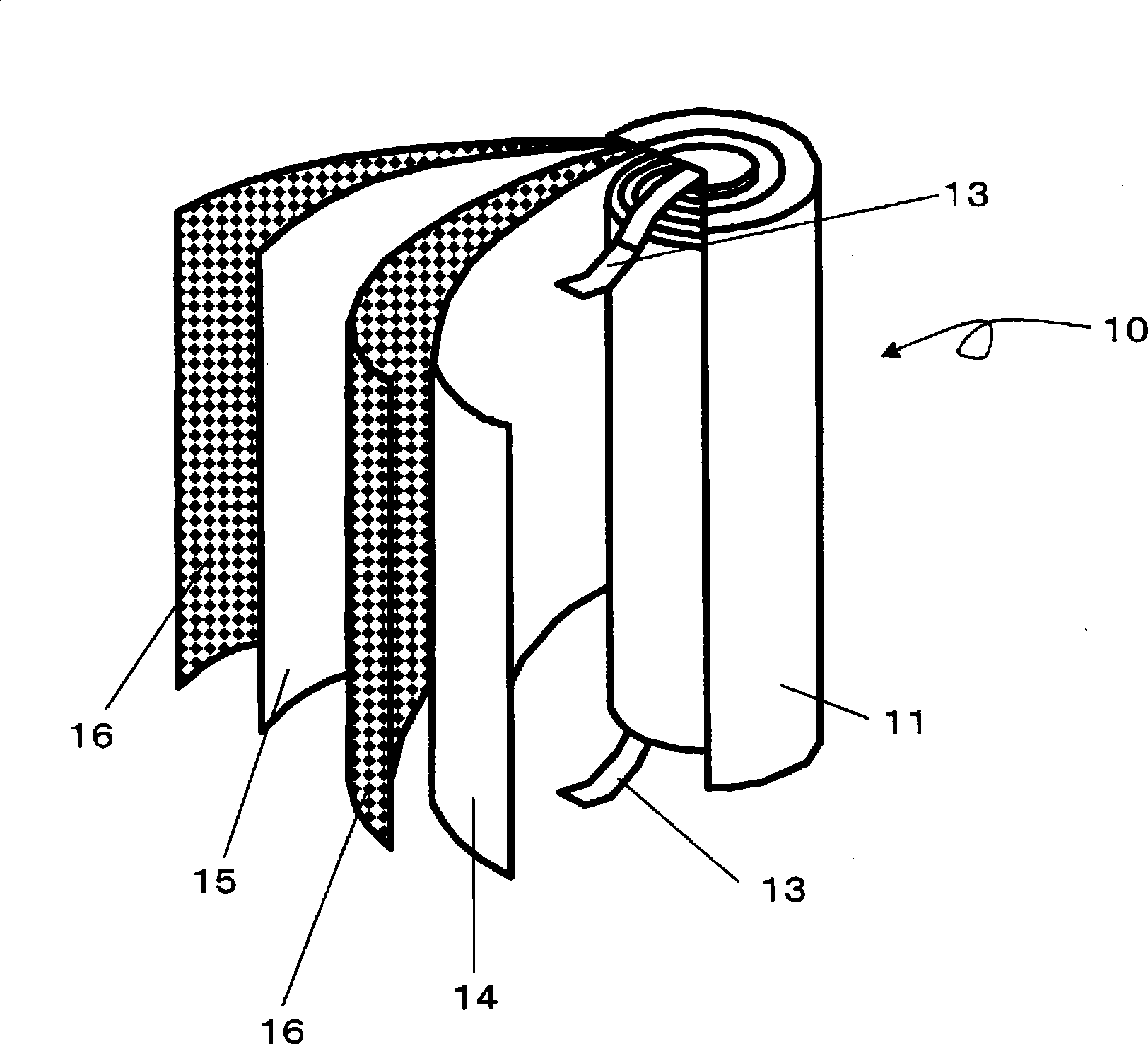

A microporous plastic film roll production method, comprising the steps of: conveying microporous plastic film having through-holes in its interior by using a plurality of conveyance rollers at least one conveyance roller of which has a surface roughness RzJIS (μm) of 0.3≦RzJIS≦30 and has a surface made of fluorine resin, silicone rubber, or a composite material containing one of them; and winding it up in a roll.

Owner:TORAY IND INC

Method of preparing apertured micropore plastic product semifusion mould press shaping method

A semi-fusing and die-pressing method for preparing the milliporous plastic product with open pores includes such steps as mixing the synthetic resin particles with at least one of plasticizer, viscosity increaser, foaming agent and disperser, preheating, storing in a temp and humidity constant container, filling in preheated die, hot die pressing, and cooling while holding the pressure.

Owner:SICHUAN UNIV

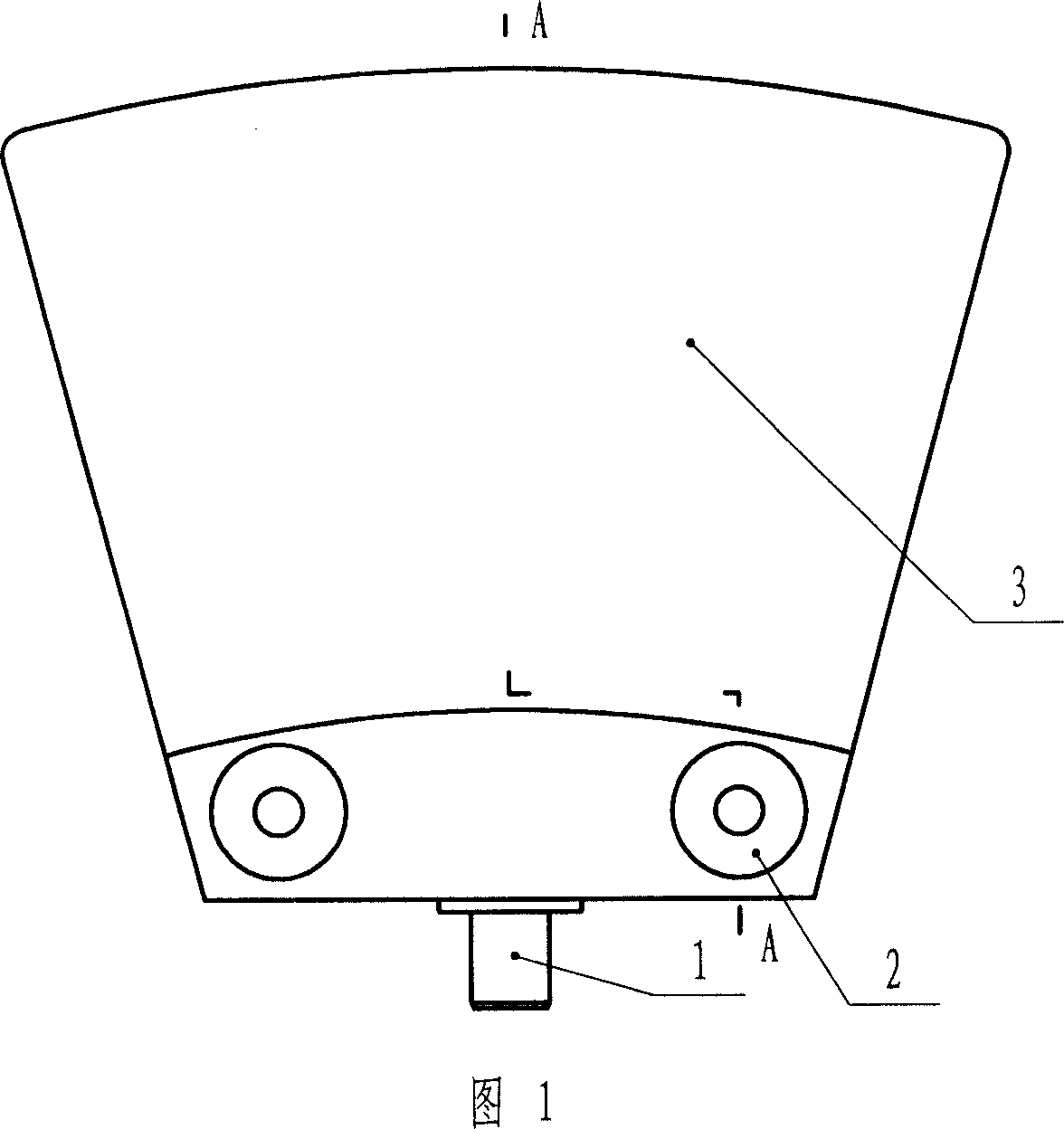

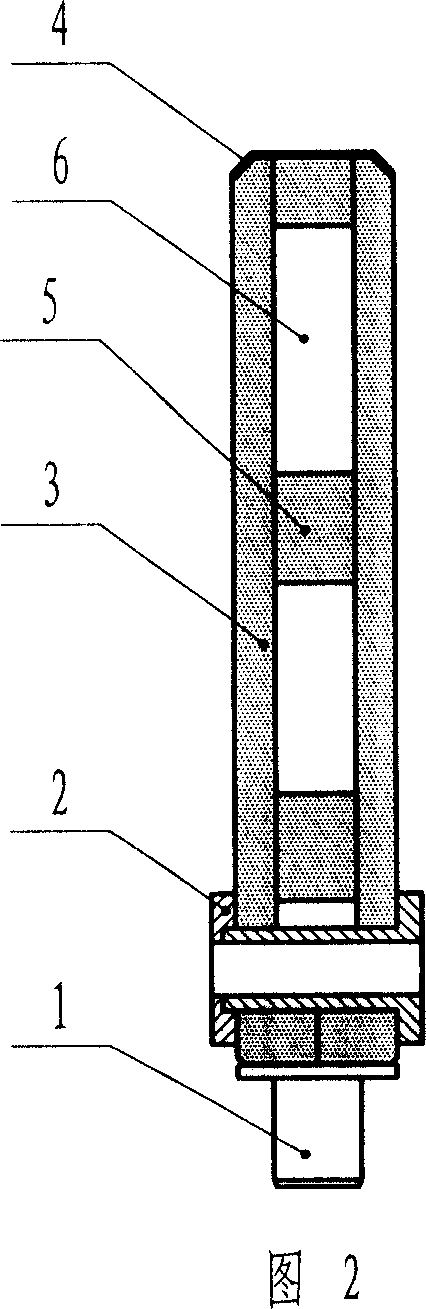

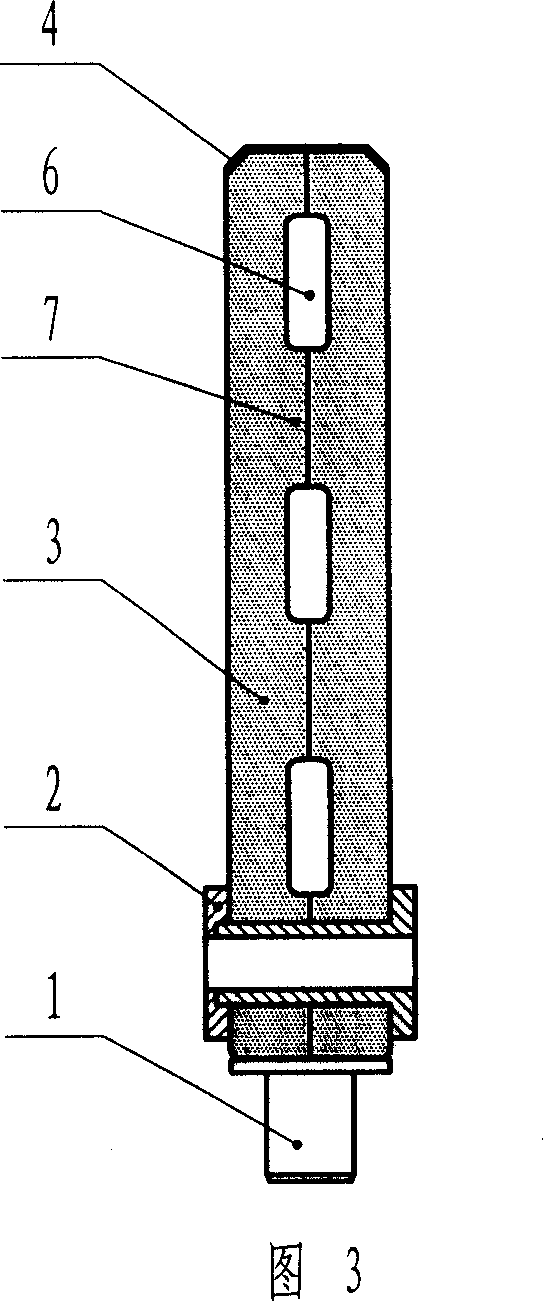

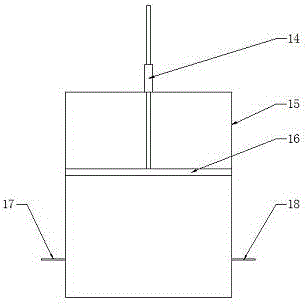

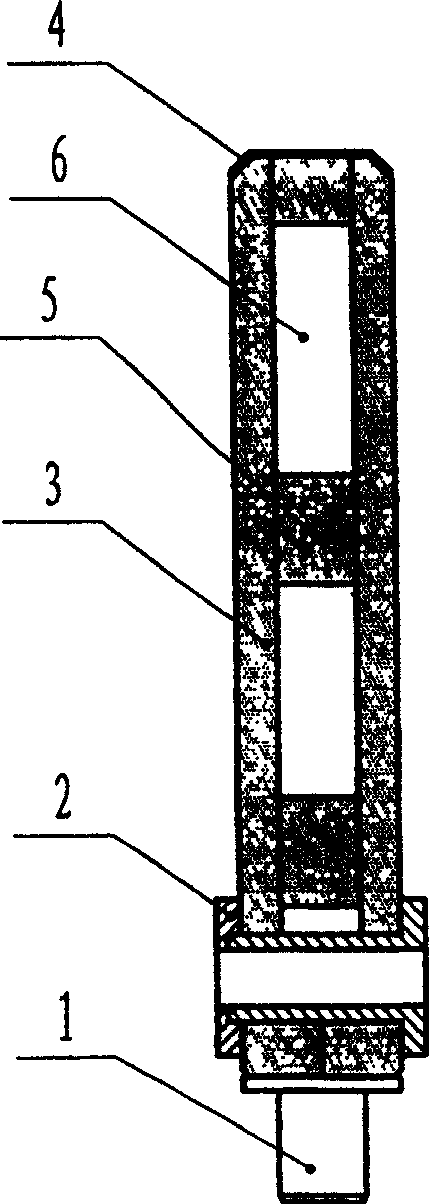

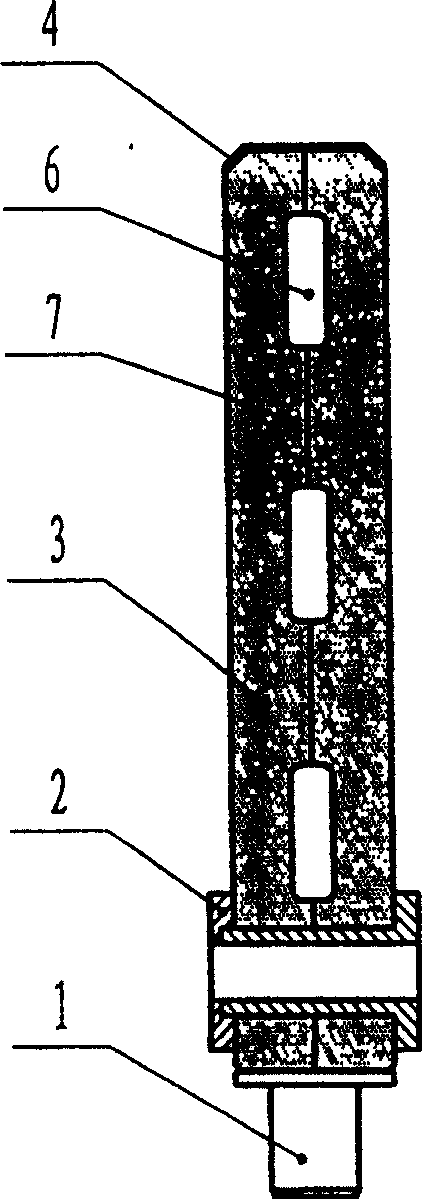

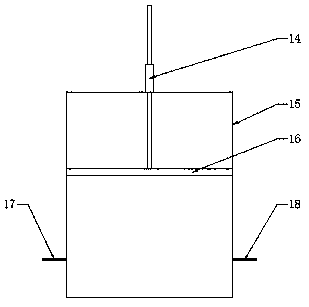

Micron-nano-sized aerator

InactiveCN102001719AIncrease contact areaIncrease the mass transfer rate coefficientTreatment using aerobic processesSustainable biological treatmentEngineeringOxygen

The invention discloses a micron-nano-sized aerator for sewage treatment and air flotation and the like. An air-water mixing chamber is arranged on the central side wall of a metal outer sleeve, a diffusion tube is communicated between the air-water mixing chamber and the metal outer sleeve, an air-water nozzle is arranged at the inlet end of the air-water mixing chamber, and a compression air inlet is arranged on the side part of the air-water mixing chamber, a micropore plastic round tube of which two ends are provided with spraying outlets is coaxially arranged at the center of the metal outer sleeve, a polytetrafluoroethylene plastic sheet is tightly matched between the micropore plastic round tube and the metal outer sleeve, micro pores the aperture of which is 1-3mum are distributed on the side wall of the micropore plastic round tube, a multi-layer cellular porous polytetrafluoroethylene plastic sheet is coated on the outer wall of the micropore plastic round tube, and the micro pores on each cellular porous polytetrafluoroethylene plastic sheet are arranged in a staggering way. The liquid sprayed from the spraying outlets is vaporous, the diameter of the air bubble is in nano level, the vaporized moisture is ascended together in water body, the contact area of the vaporized moisture and the water body is large, the retention period is long, the mass transfer rate coefficient is high and the concentration of the dissolved oxygen is high.

Owner:CHANGZHOU UNIV

Micron-nano-sized aerator

InactiveCN102001719BIncrease contact areaIncrease the mass transfer rate coefficientTreatment using aerobic processesSustainable biological treatmentEngineeringOxygen

The invention discloses a micron-nano-sized aerator for sewage treatment and air flotation and the like. An air-water mixing chamber is arranged on the central side wall of a metal outer sleeve, a diffusion tube is communicated between the air-water mixing chamber and the metal outer sleeve, an air-water nozzle is arranged at the inlet end of the air-water mixing chamber, and a compression air inlet is arranged on the side part of the air-water mixing chamber, a micropore plastic round tube of which two ends are provided with spraying outlets is coaxially arranged at the center of the metal outer sleeve, a polytetrafluoroethylene plastic sheet is tightly matched between the micropore plastic round tube and the metal outer sleeve, micro pores the aperture of which is 1-3mum are distributedon the side wall of the micropore plastic round tube, a multi-layer cellular porous polytetrafluoroethylene plastic sheet is coated on the outer wall of the micropore plastic round tube, and the micro pores on each cellular porous polytetrafluoroethylene plastic sheet are arranged in a staggering way. The liquid sprayed from the spraying outlets is vaporous, the diameter of the air bubble is in nano level, the vaporized moisture is ascended together in water body, the contact area of the vaporized moisture and the water body is large, the retention period is long, the mass transfer rate coefficient is high and the concentration of the dissolved oxygen is high.

Owner:CHANGZHOU UNIV

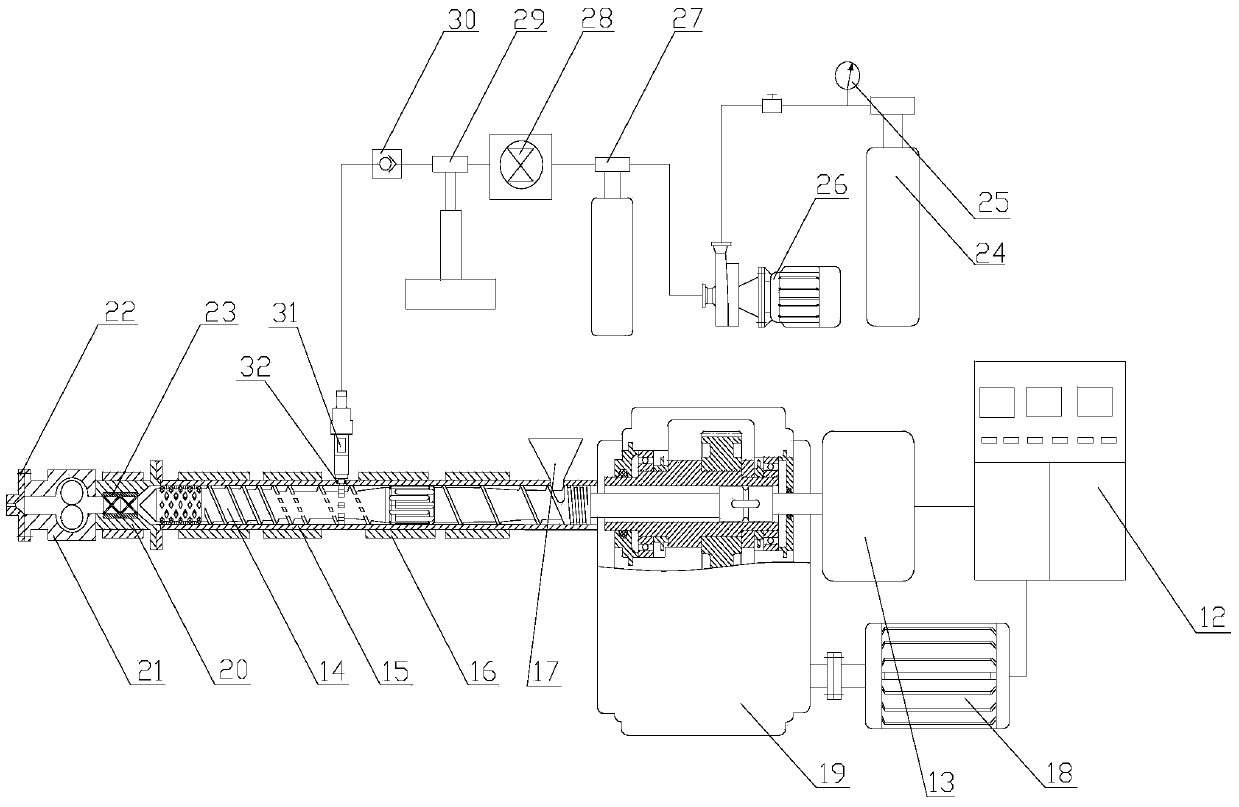

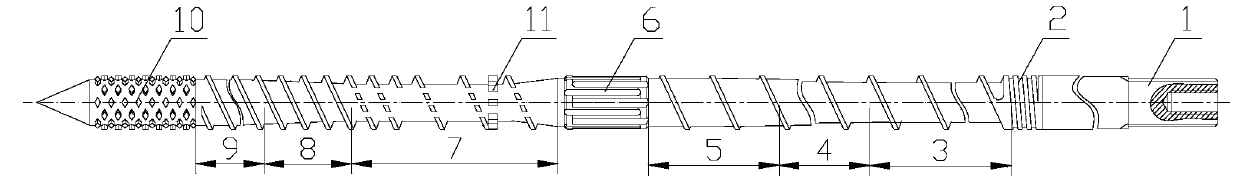

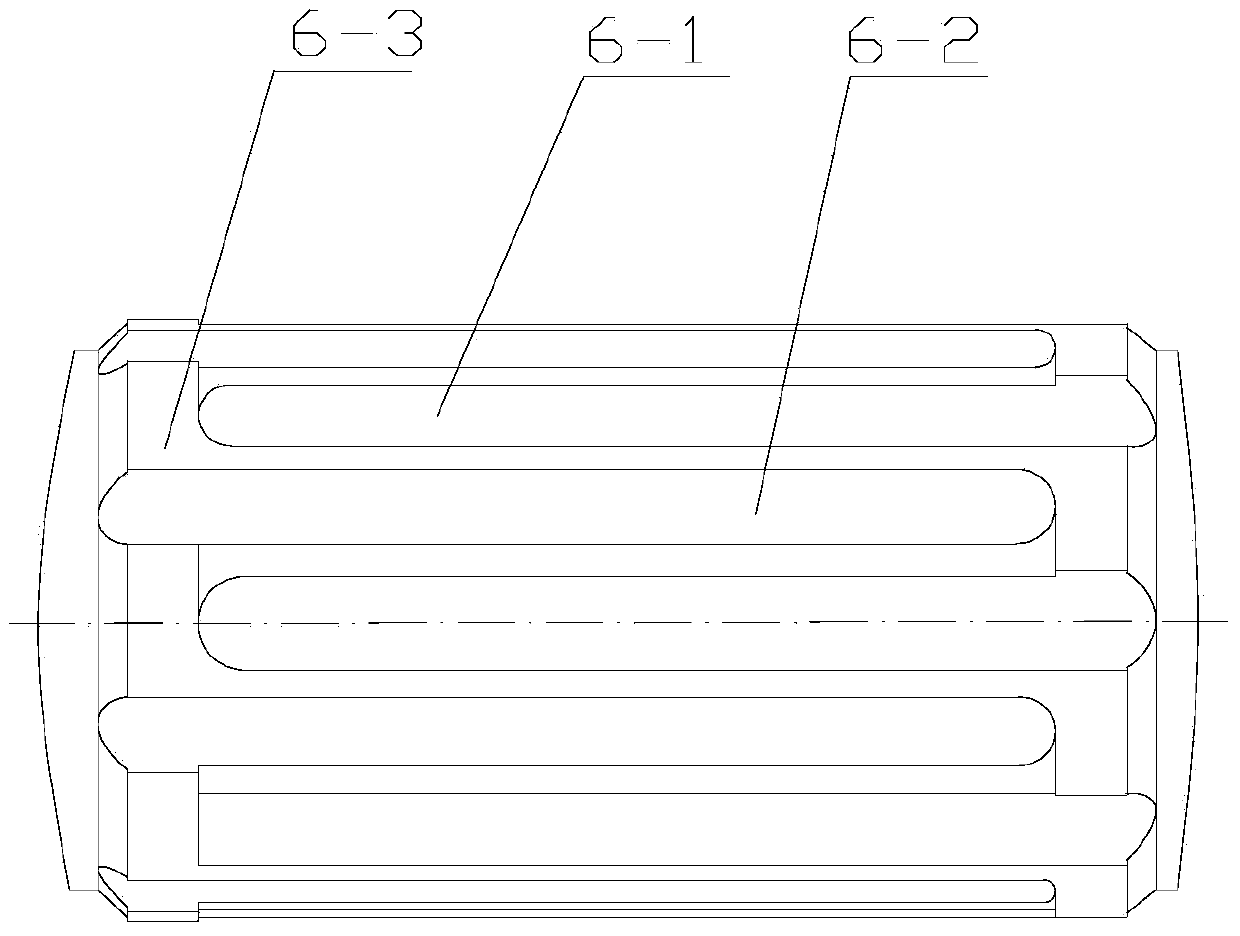

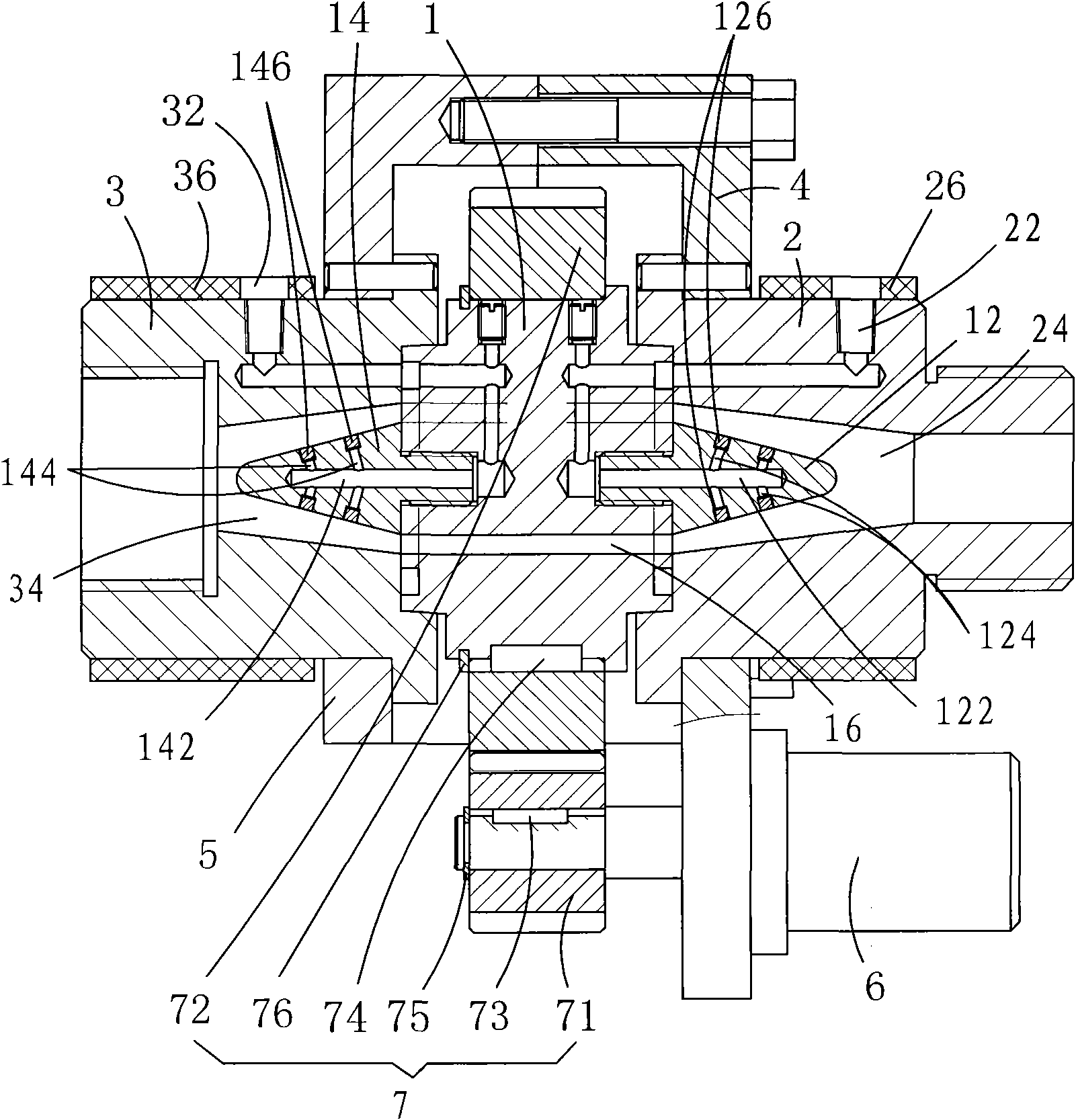

Apparatus and method for extrusion moulding of supercutical-fluid micropore plastic

The invention discloses an apparatus and a method for extrusion moulding of supercritical-fluid micropore plastic. The apparatus comprises an electric cabinet, a vibration exciter, a power unit, a plasticizing mixing unit, a supercritical fluid conveying unit and a moulding unit; the vibration exciter, the power unit, the plasticizing mixing unit and the moulding unit are in successive connection; the supercritical fluid conveying unit is arranged on the plasticizing mixing unit; and the vibration exciter, the power unit and the plasticizing mixing unit are all independently connected with the electric cabinet. The method comprises that the power unit drives a screw to rotate, the vibration exciter drives the screw to make periodic vibration at the axial direction; a material is plasticized and fused under the dual effects of shear force field and vibration force field of the screw; at the same time, the supercritical fluid conveying unit injects a supercritical fluid into a material barrel, and thus the supercritical fluid and the fused material rapidly form a single system of the supercritical fluid and a polymer melt under the dual force fields; and the single system finally enters the moulding unit for foaming fixing. The plasticizing mixing speed is fast, and the mixing effect of the supercritical fluid and the polymer melt is good.

Owner:SOUTH CHINA UNIV OF TECH

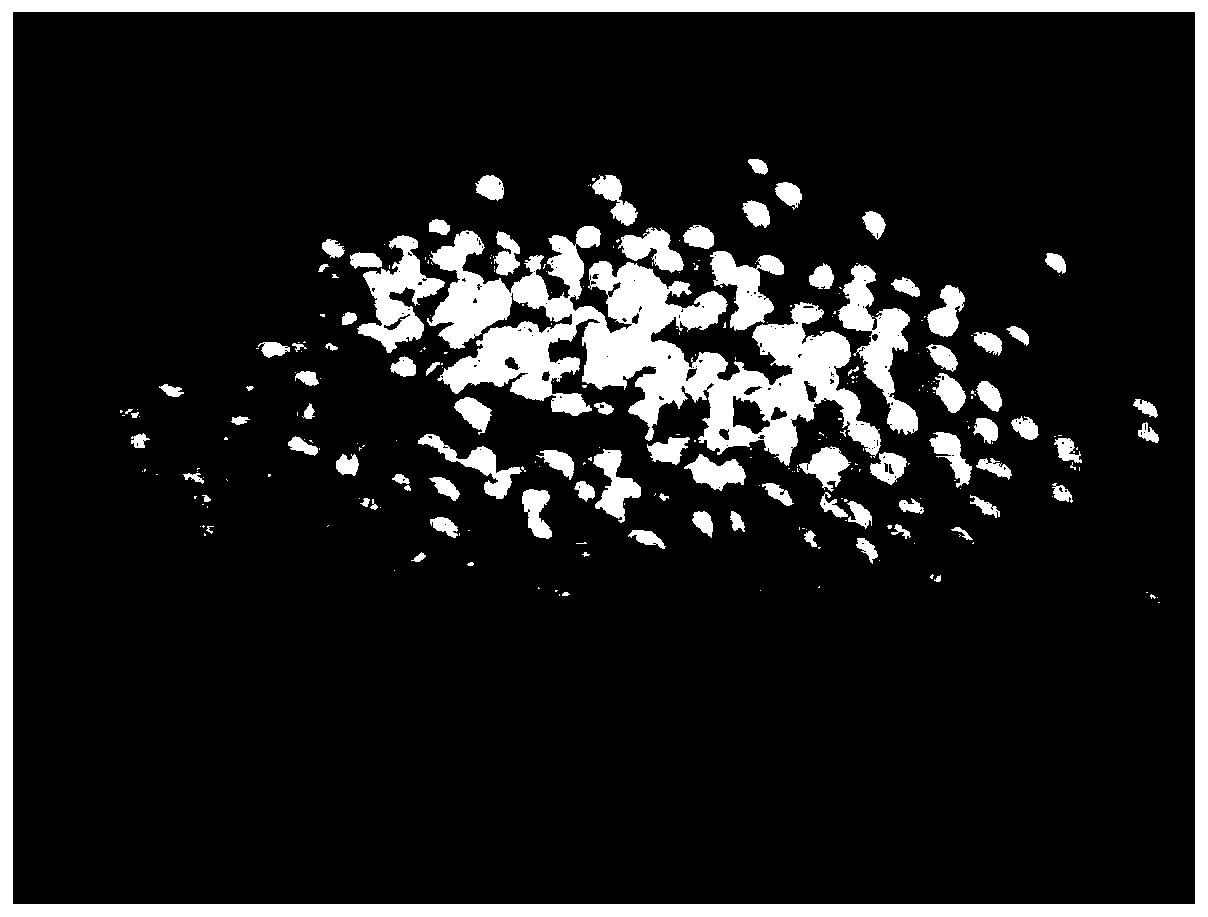

Low-density polypropylene bead foam as well as preparation method and application thereof

The invention belongs to the technical field of microporous plastic preparation, and particularly relates to low-density polypropylene bead foam as well as a preparation method and application thereof. The invention provides a method for preparing low-density polypropylene bead foam through extrusion foaming based on coupling modification of ultra-high molecular weight polyethylene and a nano carbon material. The preparation method comprises the following steps: mixing PP, UHMWPE and a nano carbon material in proportion, and then injecting a physical foaming agent into the mixture; fully and uniformly mixing the materials in a double-screw extruder, extruding the mixture, enabling the extruded mixture to sequentially flow through a static mixer, a gear pump, a melt cooler, an extrusion dieand the like which are arranged at the downstream of the double-screw extruder for extrusion foaming, and carrying out underwater pelletizing and drying to obtain the PP bead foam. The PP bead foam prepared by the method is low in density, uniform and full in appearance, small in shrinkage, uniform in cell structure, low in aperture ratio and easy for later steam molding.

Owner:福建鑫瑞新材料科技有限公司

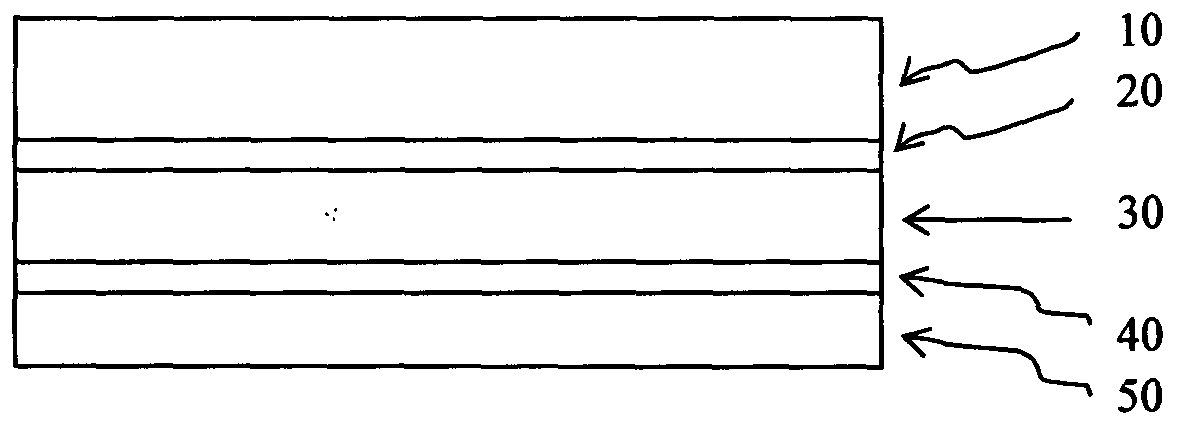

Electromagnetic shielding composite wallpaper and preparation method thereof

InactiveCN103572665AWith roughnessWith electromagnetic signalCovering/liningsSpecial paperAviationFiber

The invention discloses and provides an electromagnetic shielding composite wallpaper, which is characterized in that the wallpaper is composed of the following layers from the inner to the outer: fiber gridding cloth and metal coated on the surface thereof 10, an inner adhesive layer 20, a micro-porous plastic layer 30, an outer adhesive layer 40, and decoration paper 50, wherein the layers are connected through an adhesive. The invention also provides a manufacturing method of the electromagnetic shielding composite wallpaper. The electromagnetic shielding composite wallpaper provided by the invention has an electromagnetic shielding function, has the characteristics of alkali resistance, weatherability, and good fire resistant performance, does not carry out chemical reactions with alkaline cement plaster, and can be widely applied to fields that needs heat insulation under cold, hot, and damp environment, such as machinery, electronics, construction, aviation, aerospace, automobiles, and naval vessels.

Owner:SUZHOU V I P NEW MATERIAL

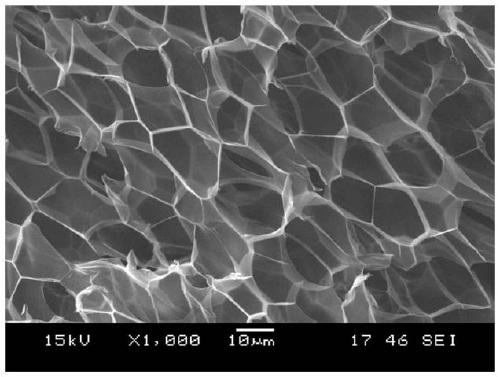

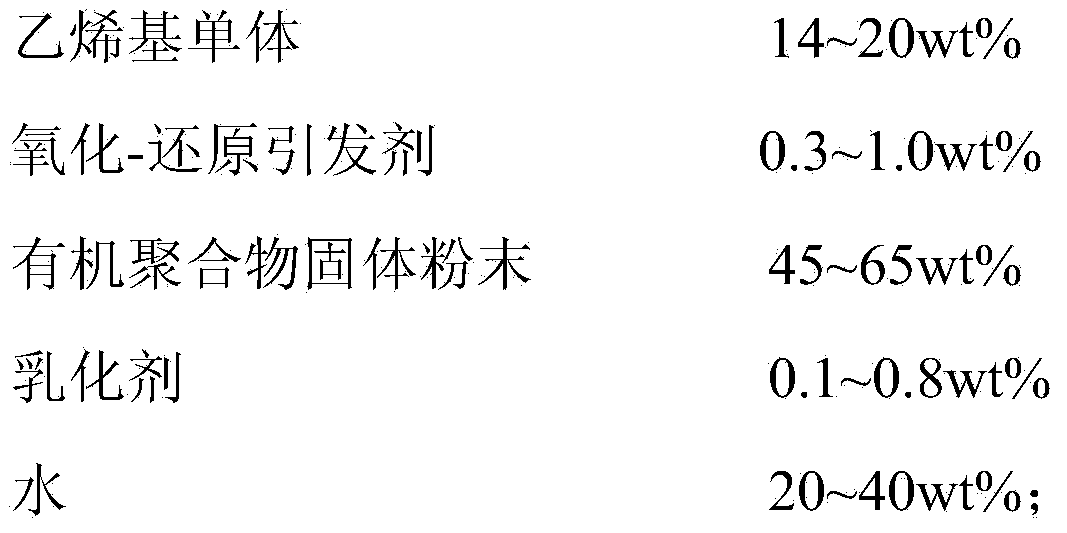

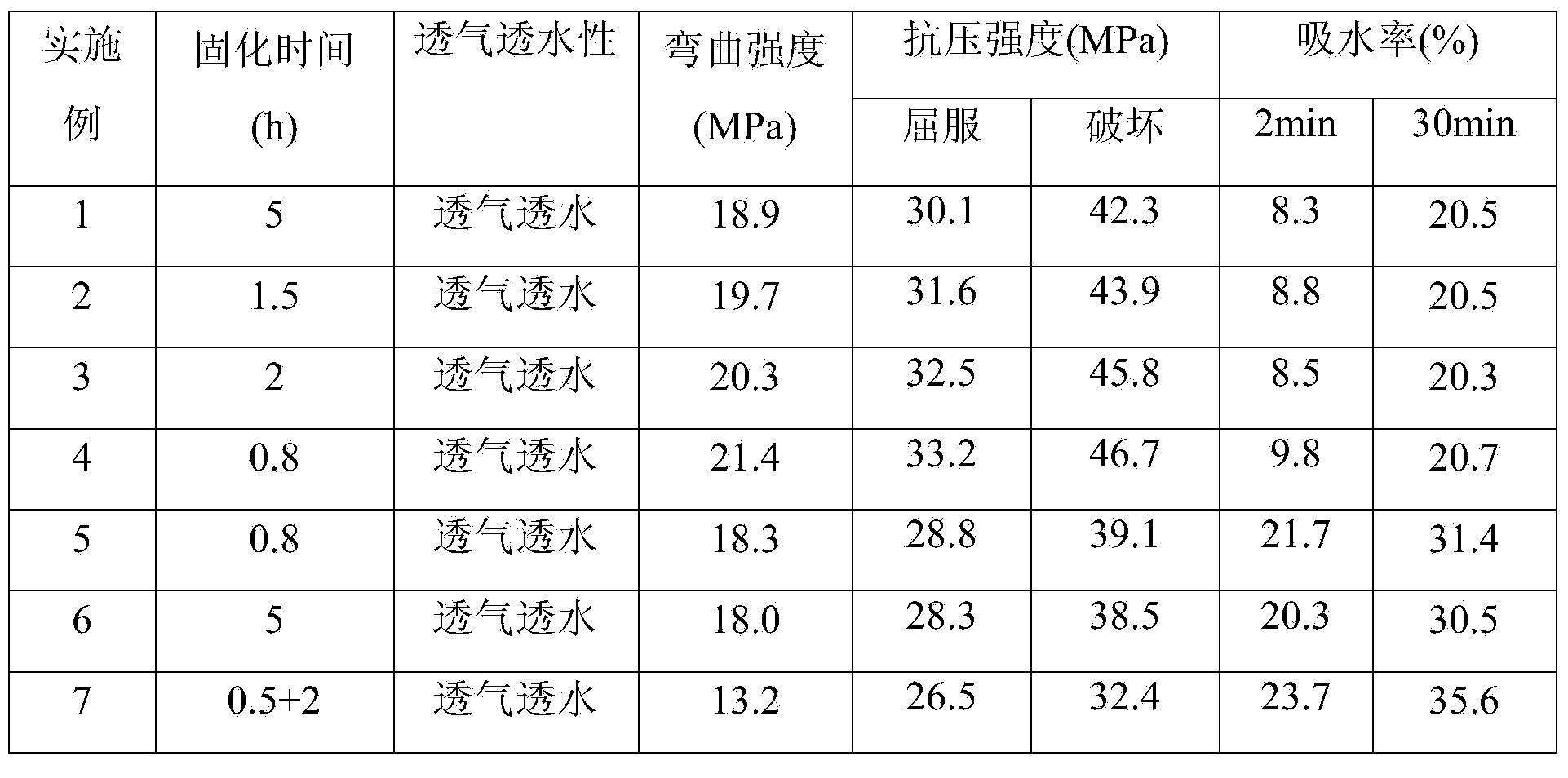

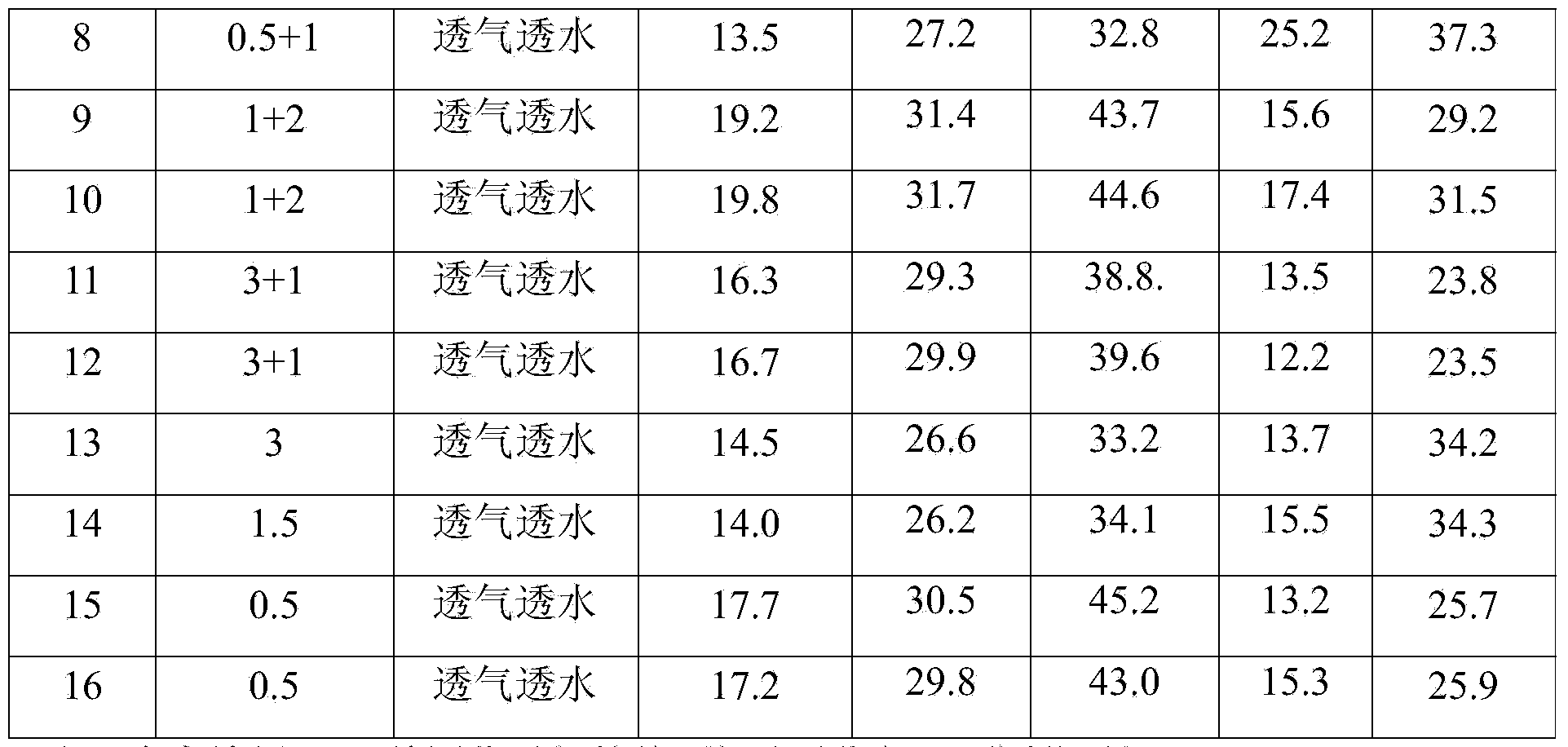

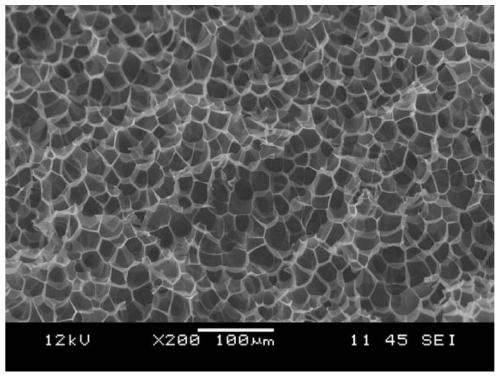

High-strength open-cell micro-porous plastic as well as preparation method and application thereof

ActiveCN103849096AGuaranteed mechanical strengthGuaranteed toughnessCompressive resistancePolymer science

The invention discloses high-strength open-cell micro-porous plastic as well as a preparation method and application thereof. The preparation method comprises the following steps: rapidly mixing 14-20 percent by weight of vinyl monomer, 0.3-1.0 percent by weight of an oxidation-reduction initiator, 45-65 percent by weight of organic polymer solid powder, 0.1-0.8 percent by weight of emulsifier and 20-40 percent by weight of water uniformly at the temperature of 1-15 DEG C; rapidly adding into a mold for curing to obtain the high-strength open-cell micro-porous plastic. The yield compressive strength of the high-strength open-cell micro-porous plastic is more than 26MPa, the bending strength is more than 13MPa, and the water absorption is more than 20 percent. The high-strength open-cell micro-porous plastic has remarkable air permeability and water permeability, and can be used repeatedly. The preparation method is simple and convenient in process, can be cured and molded quickly at room temperature or in a way of heating slightly, is easy for industrial production, can be taken as a filter material, and has a wide application prospect.

Owner:国科广化(南雄)新材料研究院有限公司

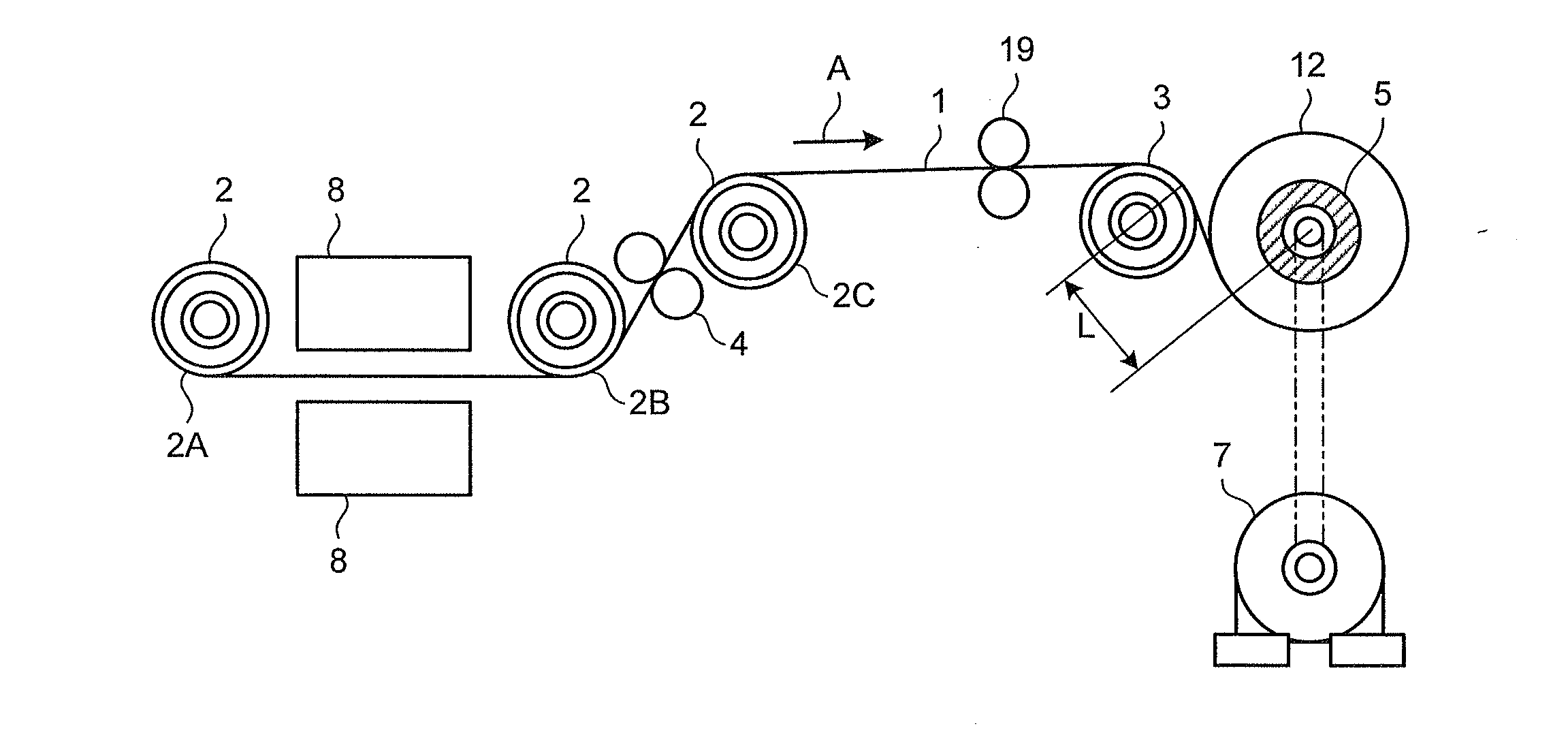

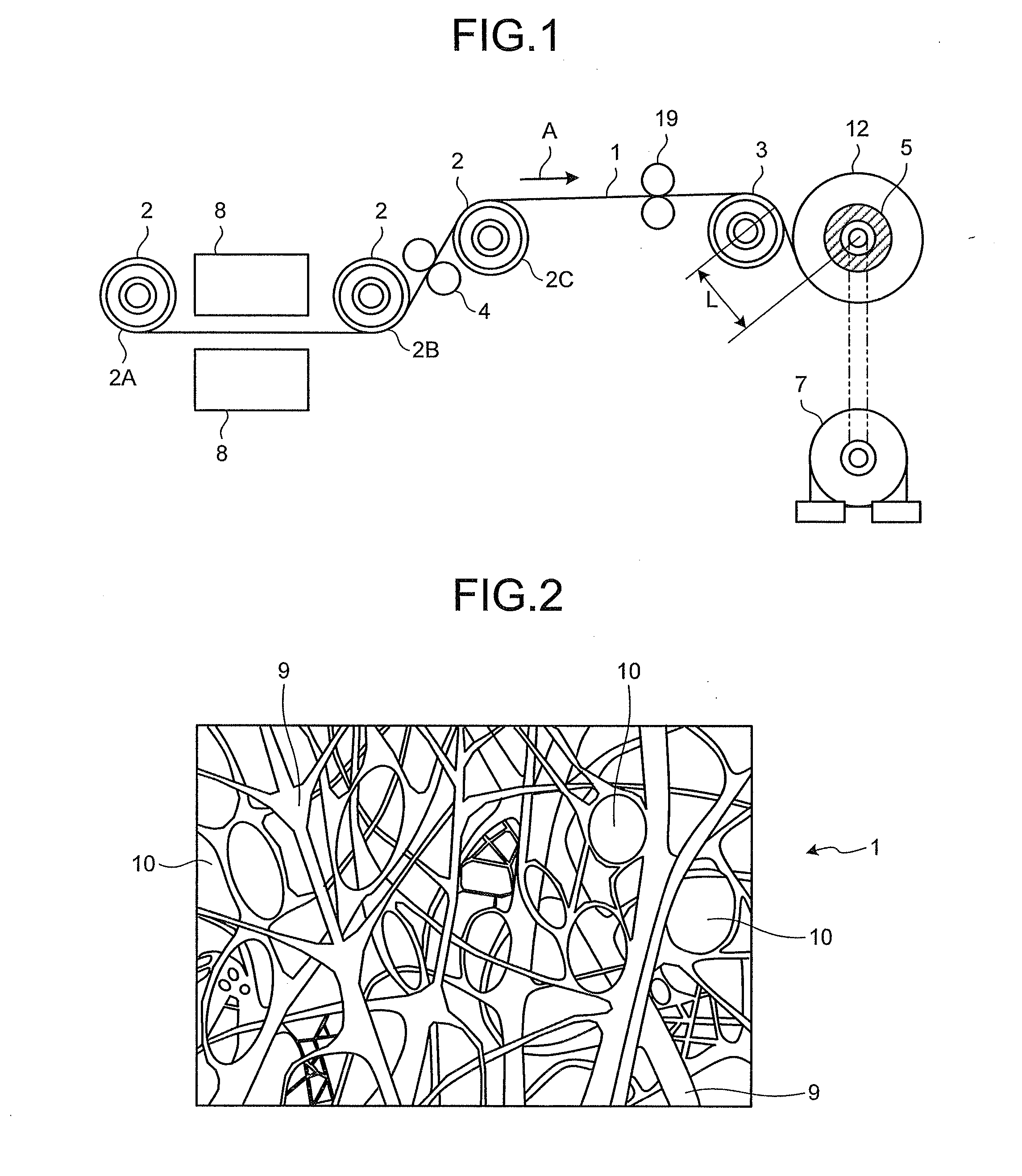

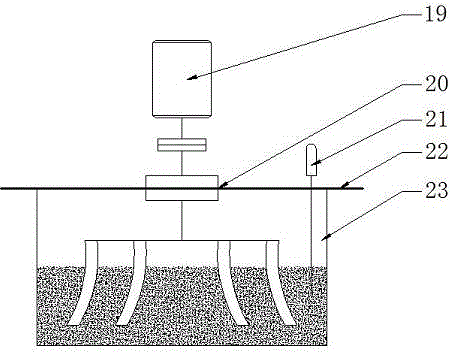

Apparatus and method for manufacturing microporous plastic film roll

InactiveUS20140374947A1Reduce generationEliminate riskDough-sheeters/rolling-machines/rolling-pinsConfectioneryMicrocellular plasticThin membrane

In an apparatus for manufacturing a microporous plastic film roll by conveying a microporous plastic film by conveying rollers and then winding the microporous plastic film in a roll shape while being brought close to a near roller or being brought into contact with a touch roller, a part of the touch roller to be in contact with the plastic film has a Vickers hardness of 100 to 2,000, and the microporous plastic film is conveyed so that a side of the microporous plastic film opposite the side being in contact with the conveying rollers is in a noncontact state in a range being in contact with the conveying rollers.

Owner:TORAY IND INC +1

Hollow extracting micro-hole filtering element

InactiveCN101032672AImprove toughnessStrong impact resistanceMoving filtering element filtersMicrocellular plasticMicroparticle

The present invention is improved filter plate for solid-liquid separating drier. The improved filter plate is hydrophilic microporous plastic plate with average pore size of 0.2-1.5 microns, and forms the sucking filter element walls. It is superior to available ceramic plate, and has pore opening rate of about 60 %, 20-30 % higher production capacity, high toughness, high impact resistance, and acid and base resistance.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Natural aromatic foam material and preparation method

The invention relates to a natural aromatic foam material and a preparation method, belonging to the technical field of foam materials and preparation methods. The natural aromatic foam material is prepared from a raw material polypropylene, and is characterized by also being prepared from natural aromatic plant materials and another additive. The raw material and materials are weighed in parts by weight: 8-20 parts of natural aromatic plant powder, 50-80 parts of the raw material polypropylene, and 1-10 parts of the other additive, wherein the other additive is a mixture of one or more of EPDM, modified talcum powder, monoglyceride and stearic acid. The natural aromatic plant powder is selected and is mixed with polypropylene to prepare a master batch, so as to prepare polypropylene-plant compound microporous plastic beads or sheets; the foam material can give out natural fragrance, and can be widely used in fields such as household consumer products and craft toys, the added value of the plastic foam material can be improved, and the use ratio of the natural aromatic plant can be improved.

Owner:义乌市中科院兰州化物所功能材料中心

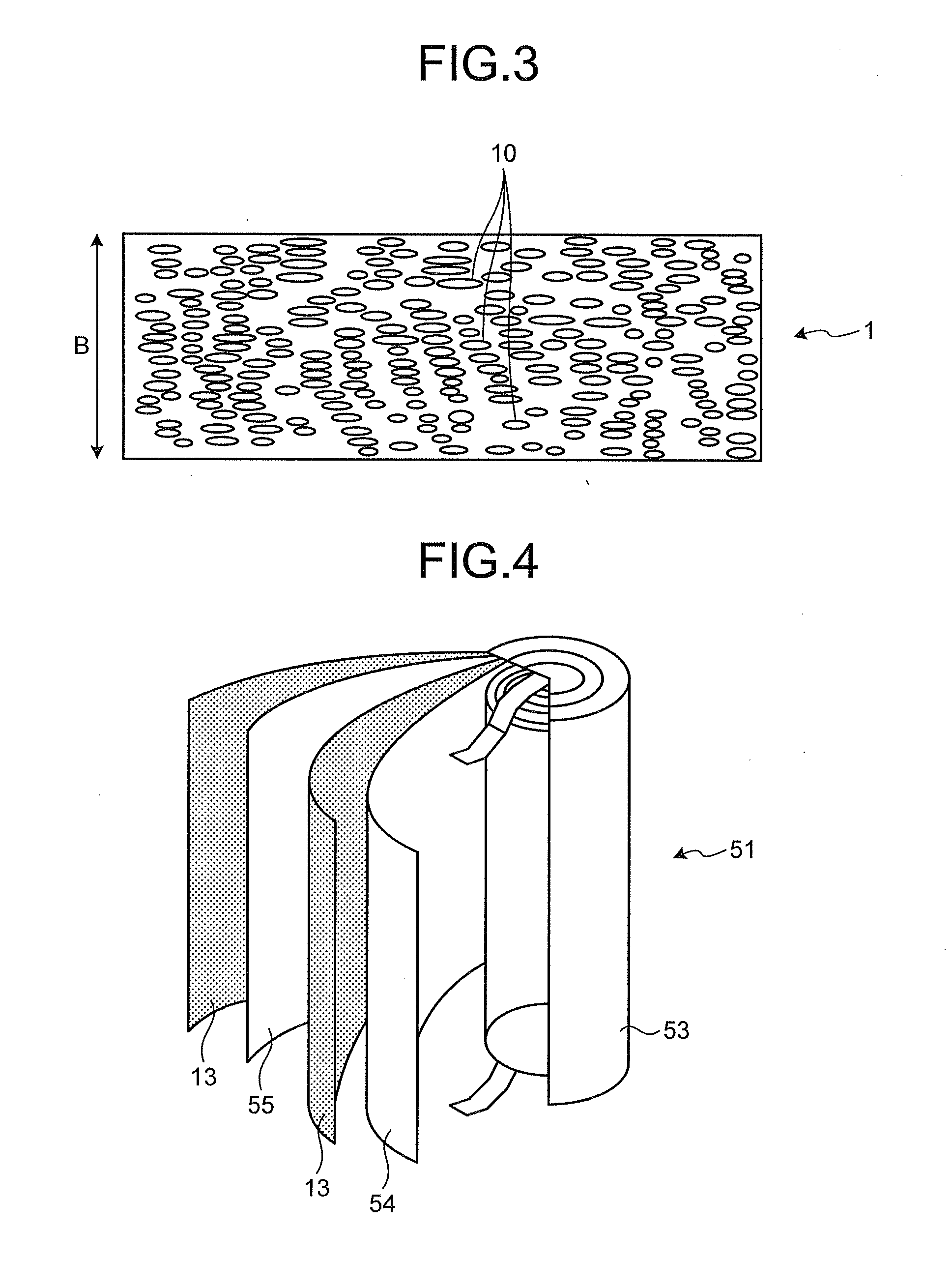

Power soft packaging lithium ion battery with high power

InactiveCN101752613AAvoid wrinklesAvoid Lithium AnalysisFinal product manufactureSecondary cellsMass ratioExternal encapsulating structure

The invention discloses a power soft packaging lithium ion battery with high power. The power soft packaging lithium ion battery is realized by the following technical scheme that a diaphragm has a structure for coiling according to the square battery pole group structure. The power soft packaging lithium ion battery is characterized in that a pole piece is inserted into an inflection point of each square surface of the diaphragm, and the pole piece has a two-way extraction lug structure; and the center of the pole group is provided with a micropore plastic plate skeleton. The lithium ion battery thoroughly changes the existing power battery mode, improves the mass ratio energy and the energy density of the battery by the external packaging structure of an aluminum plastics composite membrane, improves the afflux structure of an internal pole group by an innovative coiling lamination structure, and improves the defect of low strength of the aluminum plastics membrane by adding internally a micropore plastic skeleton structure so as to improve the safety performance of the battery.

Owner:TIANJIN LISHEN BATTERY

Novel light-weight high-strength low-density optical cable sheathing material and preparation method thereof

The invention relates to the technical field of optical cable sheathes, and particularly relates to an optical cable sheathing material and a preparation method thereof. The optical cable sheathing material is prepared from PE (Polyethylene), carbon black, thermal expansion microspheres or hollow glass microspheres, antioxidants and white oil. The preparation method comprises the steps of adding the raw materials to a mixing device according to an adding proportion, performing primary mixing and homogenization, then adding to an extruding machine, forming a homogeneous polymer / gas system by the thermal expansion microspheres or the hollow glass microspheres and PE polymers under the combined action of a shear mixing field and the processing temperature in a machine barrel, then conveying to a machine head, extruding, then cooling, dicing and drying, so as to obtain sheathing material granules of microcellular structures. By utilizing the characteristics of light weight, high strength and low density, the cost of a traditional optical cable sheathing material can be greatly reduced, obtained microcellular plastics have stable foaming properties and microcellular sizes, the process is simple, the manufacturing is easy, and industrial utilization is satisfied.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

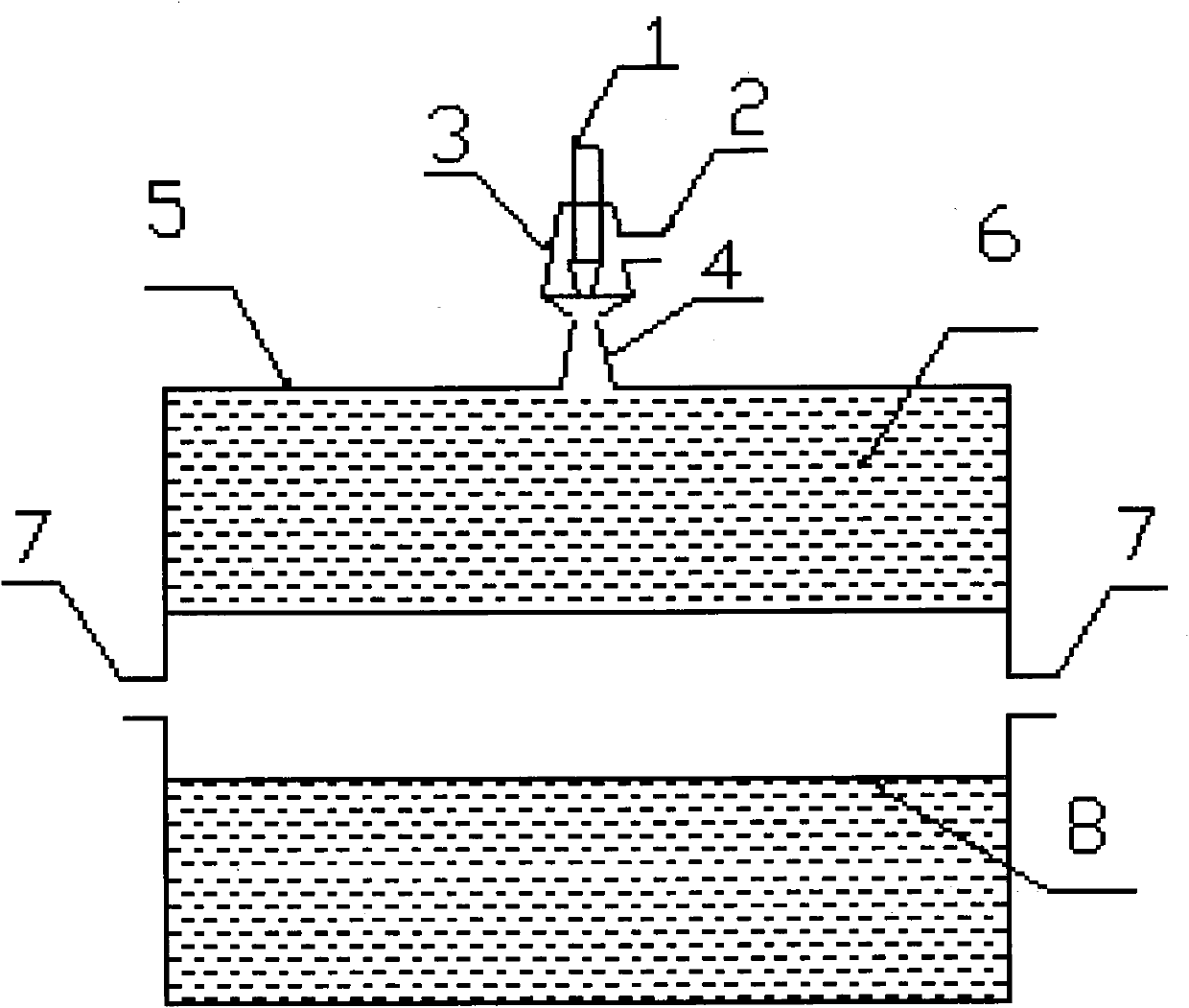

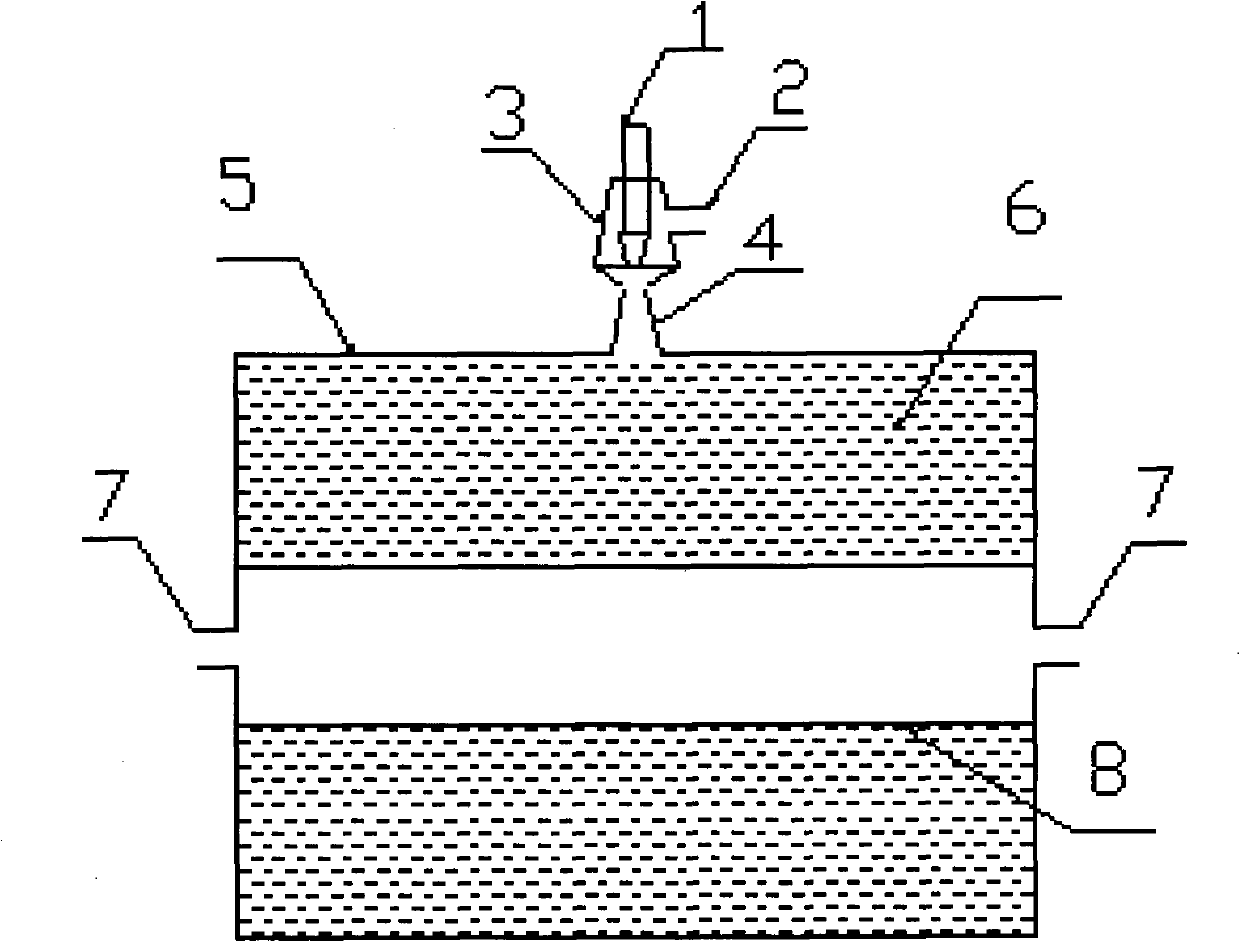

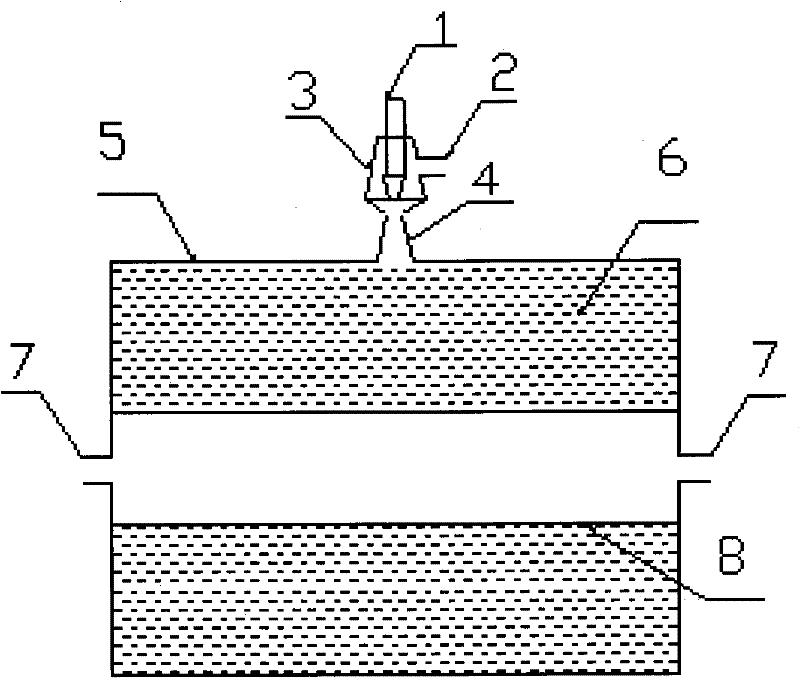

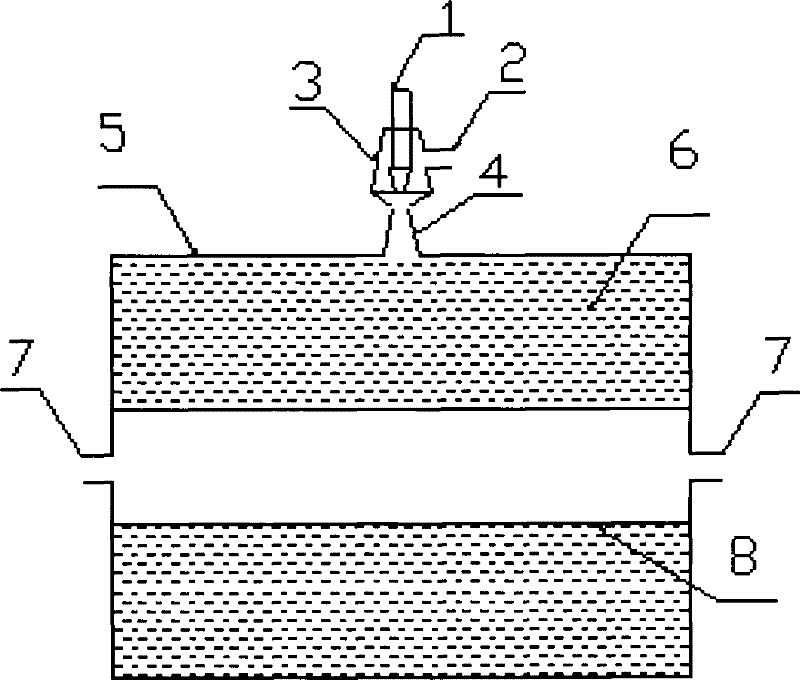

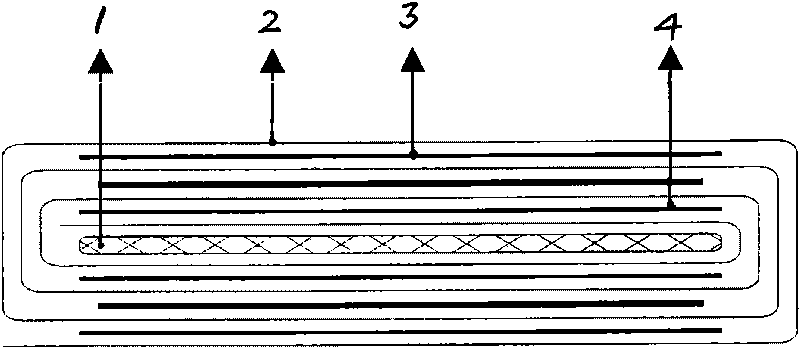

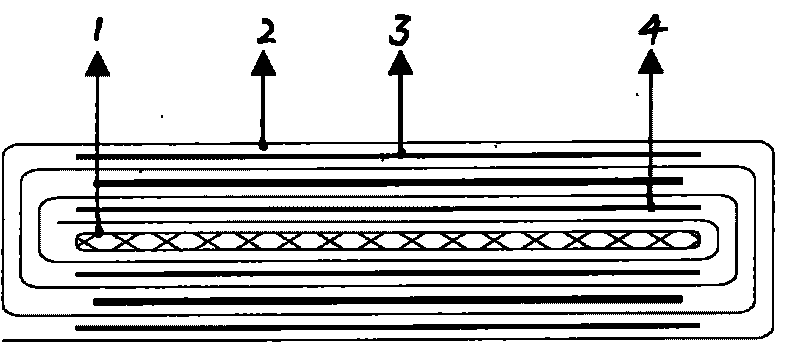

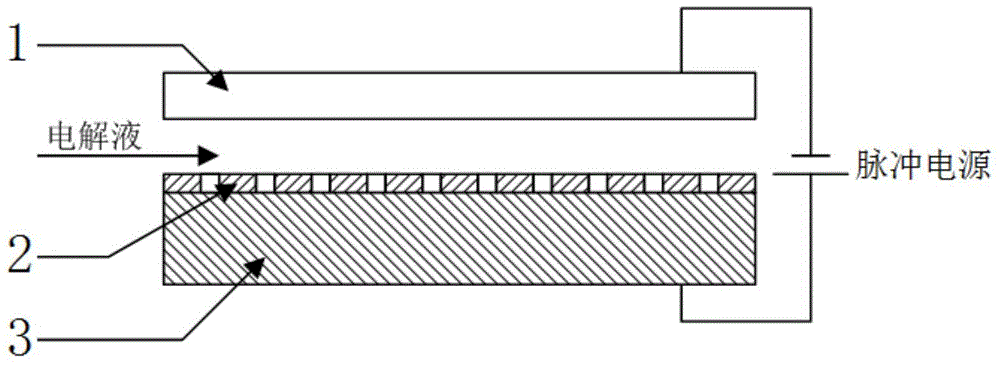

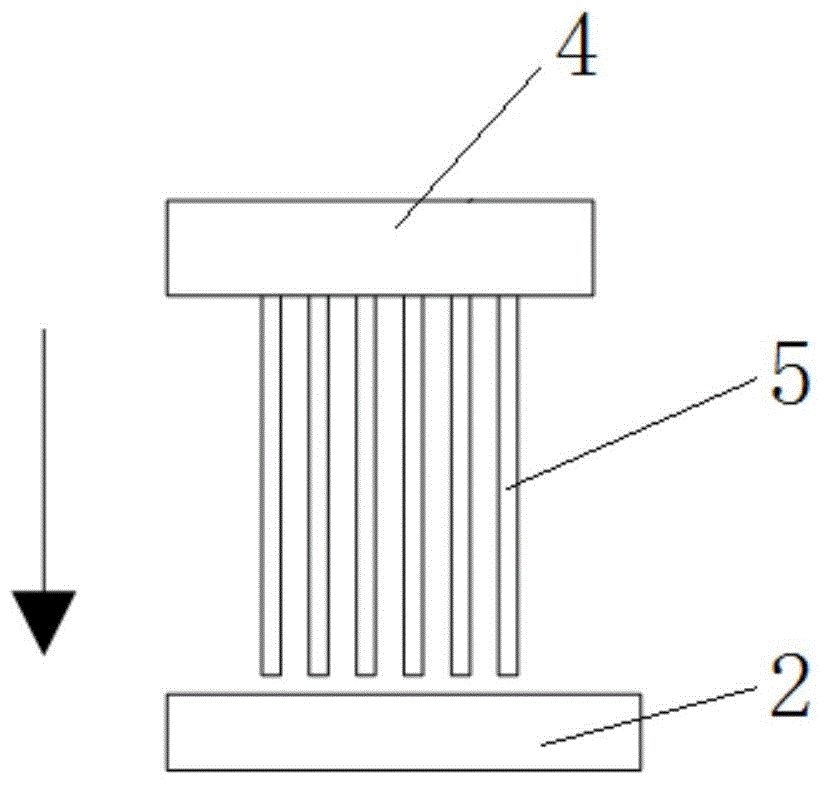

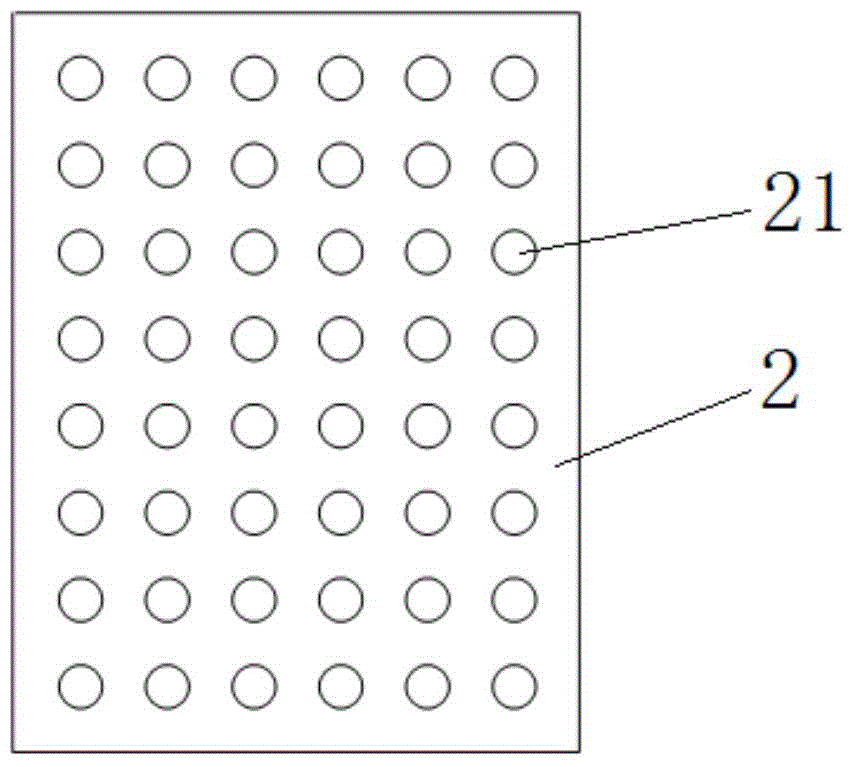

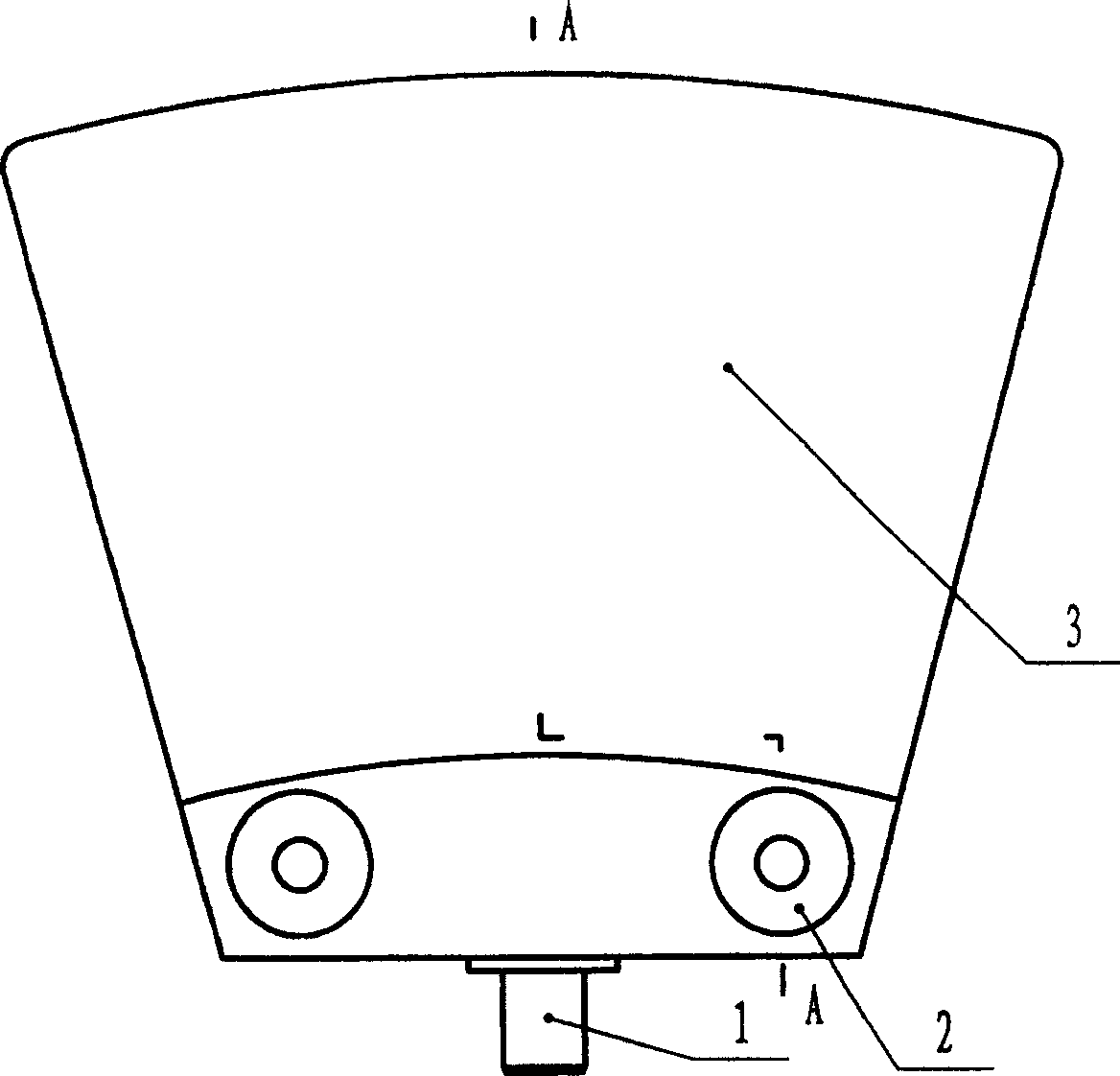

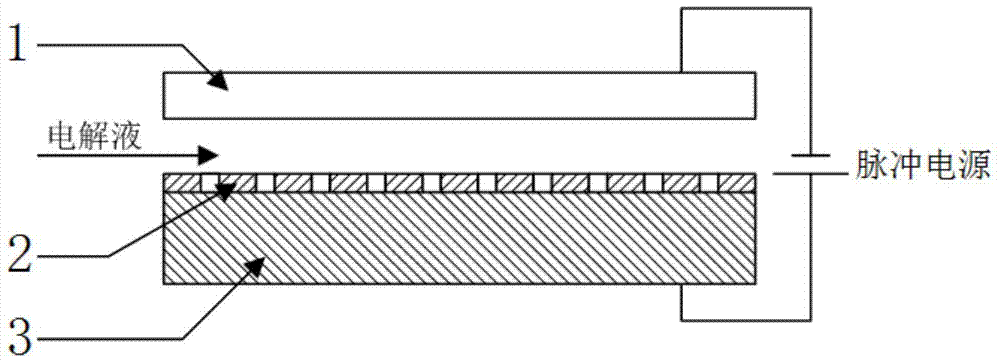

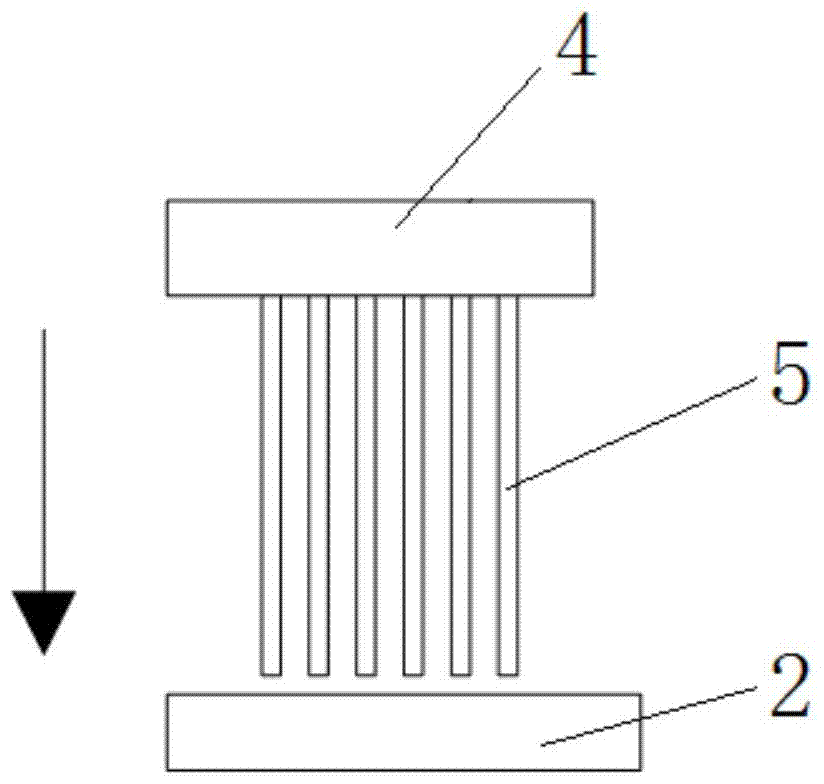

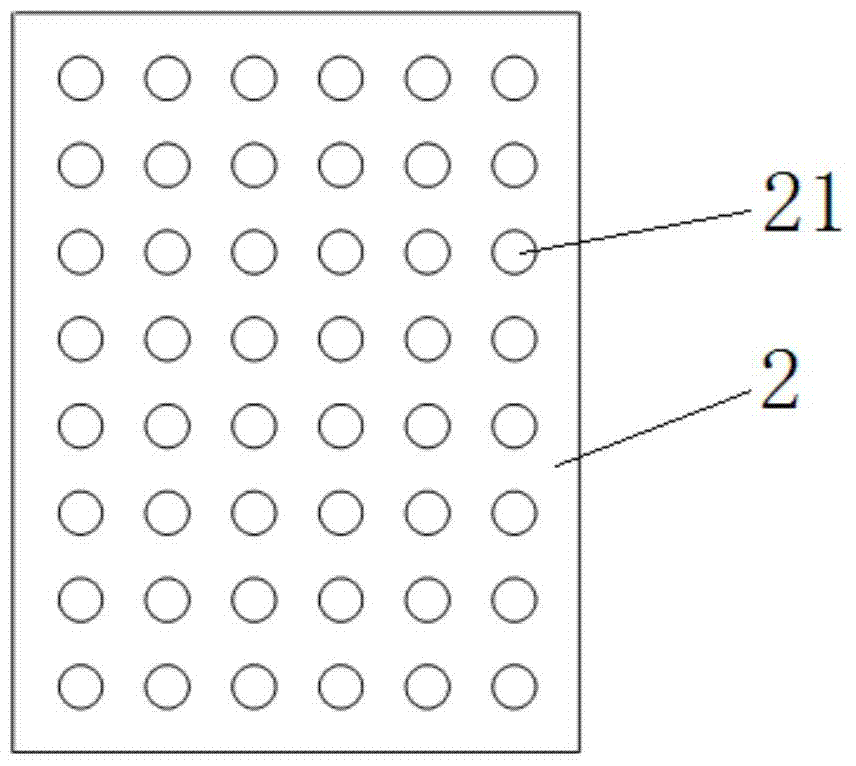

Electrolytic method for carrying out surface texturing by use of microporous plastic plate

ActiveCN104907654AImprove machining accuracyImprove processing efficiencyMetal working apparatusMicrocellular plasticInsulation layer

The invention discloses an electrolytic method for carrying out surface texturing by use of a microporous plastic plate, and belongs to the technical field of electrolytic processing. The method comprises the following steps: (a), manufacturing an insulation plate with array micropores; (b), flatly attaching the insulation plate on the processing surface of a workpiece; (3), introducing an electrolyte between a tool cathode and the insulation plate to enable the electrolyte to reach the processing surface of the workpiece, connecting the tool cathode with the cathode of a pulse power supply, and connecting the workpiece with the anode of the pulse power supply; and (d), turning on the pulse power supply to carry out electrolytic processing on a surface texture, wherein the insulation plate is a plastic plate, and the array microprobes in the plastic plate are processed by use of a hot melt method. According to the invention, the surface texturing of the workpiece is realized by use of the plastic plate with the array microprobes, the array microprobes are processed on the plastic plate by use of the hot melt method, the microprobe processing precision is high, the efficiency is high, and the pitch of the microprobes is conveniently controlled; and the plastic plate is taken as an insulation layer, the stray corrosion of the surface texture is small, the surface texturing precision is improved, the method is simple and practical, and therefore, the application prospect is wide.

Owner:CHANGZHOU INST OF TECH

Turbomachine with a coating, use of a plastic for coating and method for coating the turbomachine

InactiveUS20160290160A1Reduced coat weightTrend downLiquid surface applicatorsEngine manufactureMicrocellular plasticEngineering

A turbomachine includes an inner housing which radially defines the flow channel of the turbomachine. A thermal barrier coating is arranged about the inner housing. The thermal barrier coating of the inner housing is made of microporous plastic coating which can be added to hollow spheres made of different materials and have different sizes. A method for applying a thermal barrier coating to the inner casing of a turbomachine includes preparing a material having a base material which has a microporous plastic; coating the outside of the wall of the inner casing by applying the base material to the inner casing; and curing the applied material, thus forming the thermal barrier coating.

Owner:SIEMENS AG

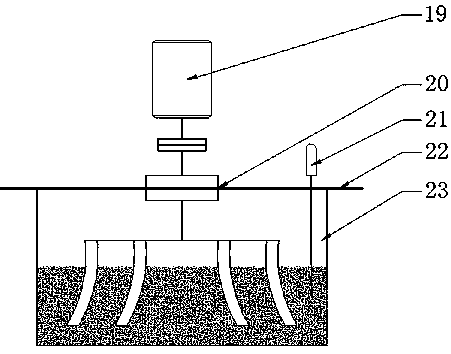

Rapid light curing DLP 3D printing device

PendingCN110625940AAchieve continuous growthAvoid deformationManufacturing platforms/substratesManufacturing enclosuresMicrocellular plasticOxygen ions

The invention discloses a rapid light curing DLP 3D printing device. The rapid light curing DLP 3D printing device comprises a machine frame and a light source, a reflector, a resin groove supportingplate, a resin groove and a Z-axis motion module, wherein the light source, the reflector, the resin groove supporting plate, the resin groove and the Z-axis motion module are installed on the machineframe. The light source and the reflector are located on a lower layer of the machine frame, the resin groove supporting plate is installed on an upper layer of the machine frame, the resin groove islocated right above the reflector, and the Z-axis motion module is connected with a motion molding platform. The center point of the lower surface of the motion molding platform coincides with the center point of the resin groove, and a microporous transparent film through which air can pass is arranged at the bottom of the resin groove. Air is used as a polymerization inhibitor, so that a molding dead zone is formed between the resin groove and the bottom surface of molding resin, so that the resin cannot adhere to the resin groove in the curing molding process of the resin, repeated tearingup and down of the molding platform is not required, and the resin can be continuously pulled up and quickly printed. Microporous glass or a microporous plastic film is used in the microporous transparent film, the air is used as the polymerization inhibitor, oxygen ions are not required to be prepared and a special oxidation and penetration window is not required, so that the input and use costof equipment is greatly reduced.

Owner:SHENZHEN ELEGOO TECH CO LTD

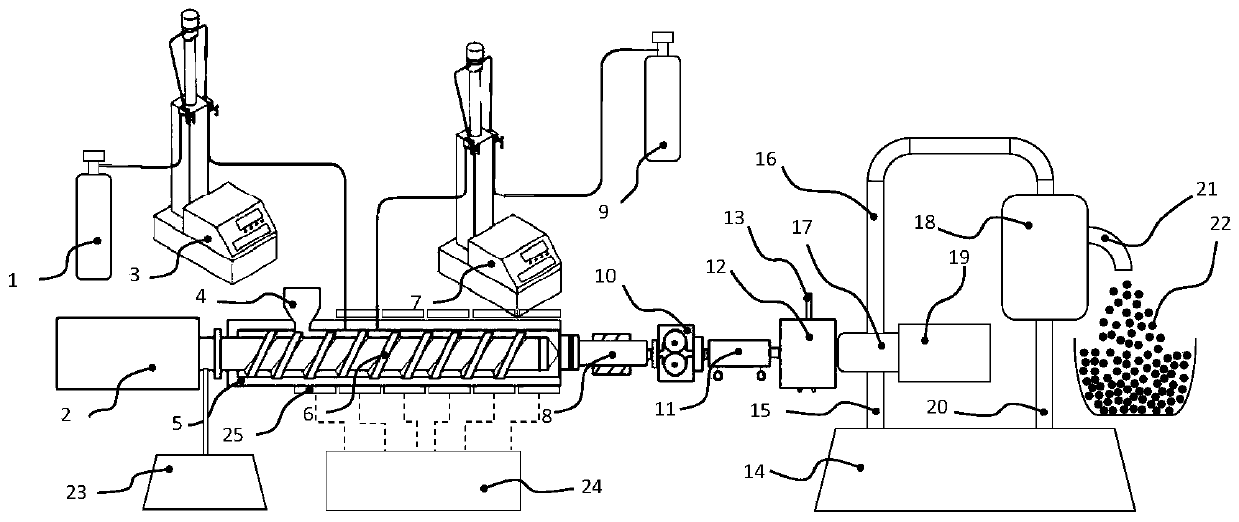

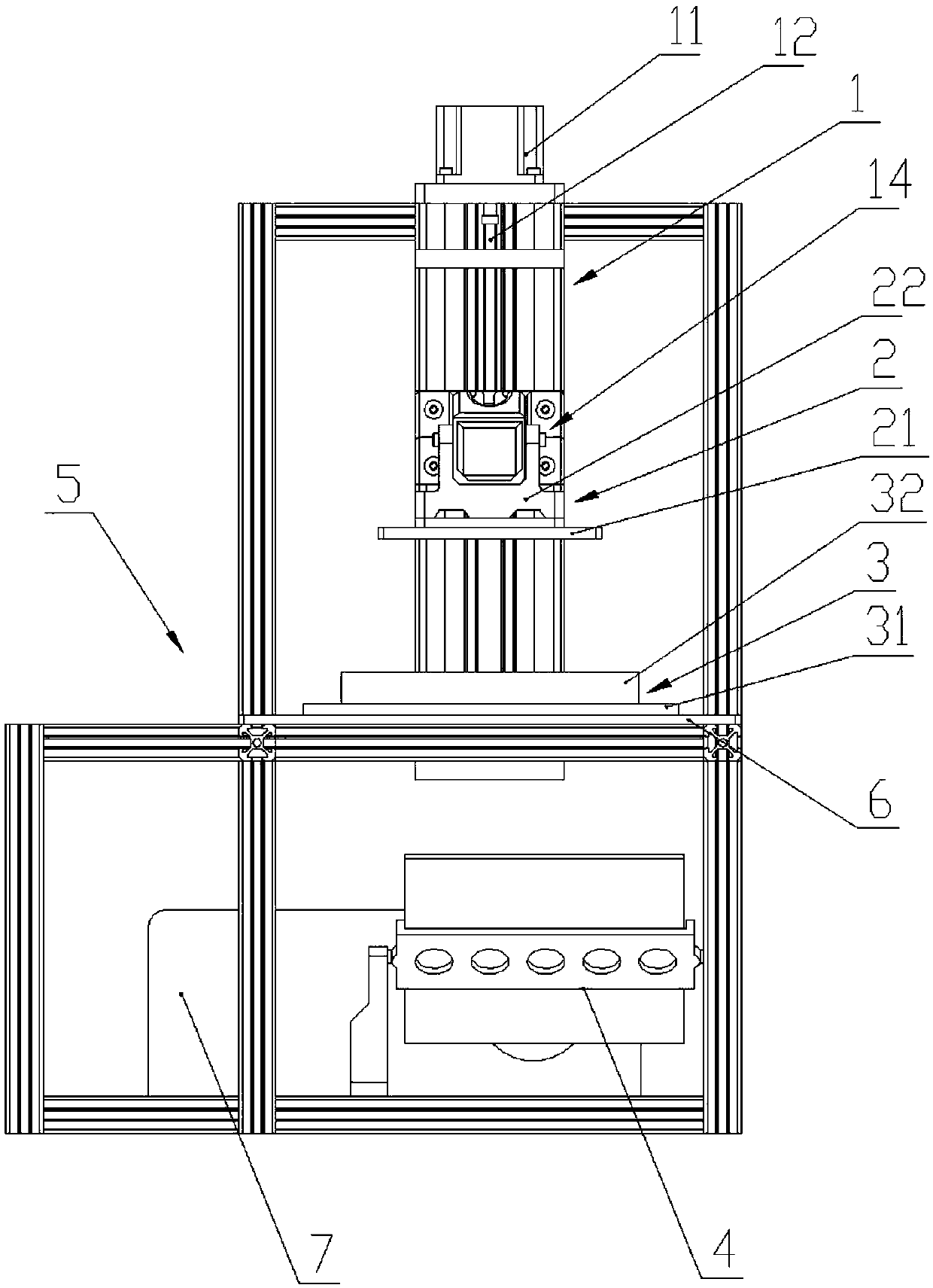

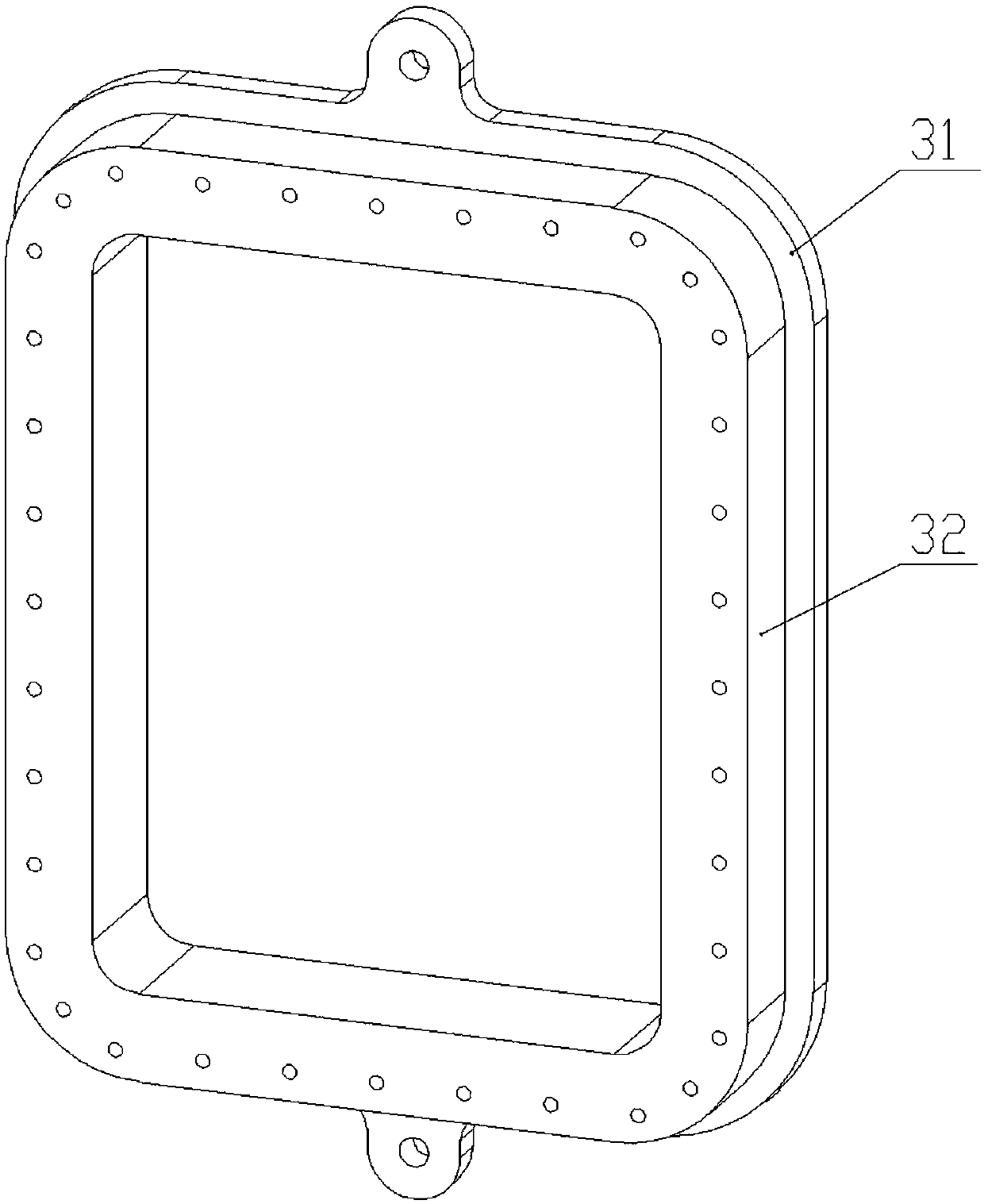

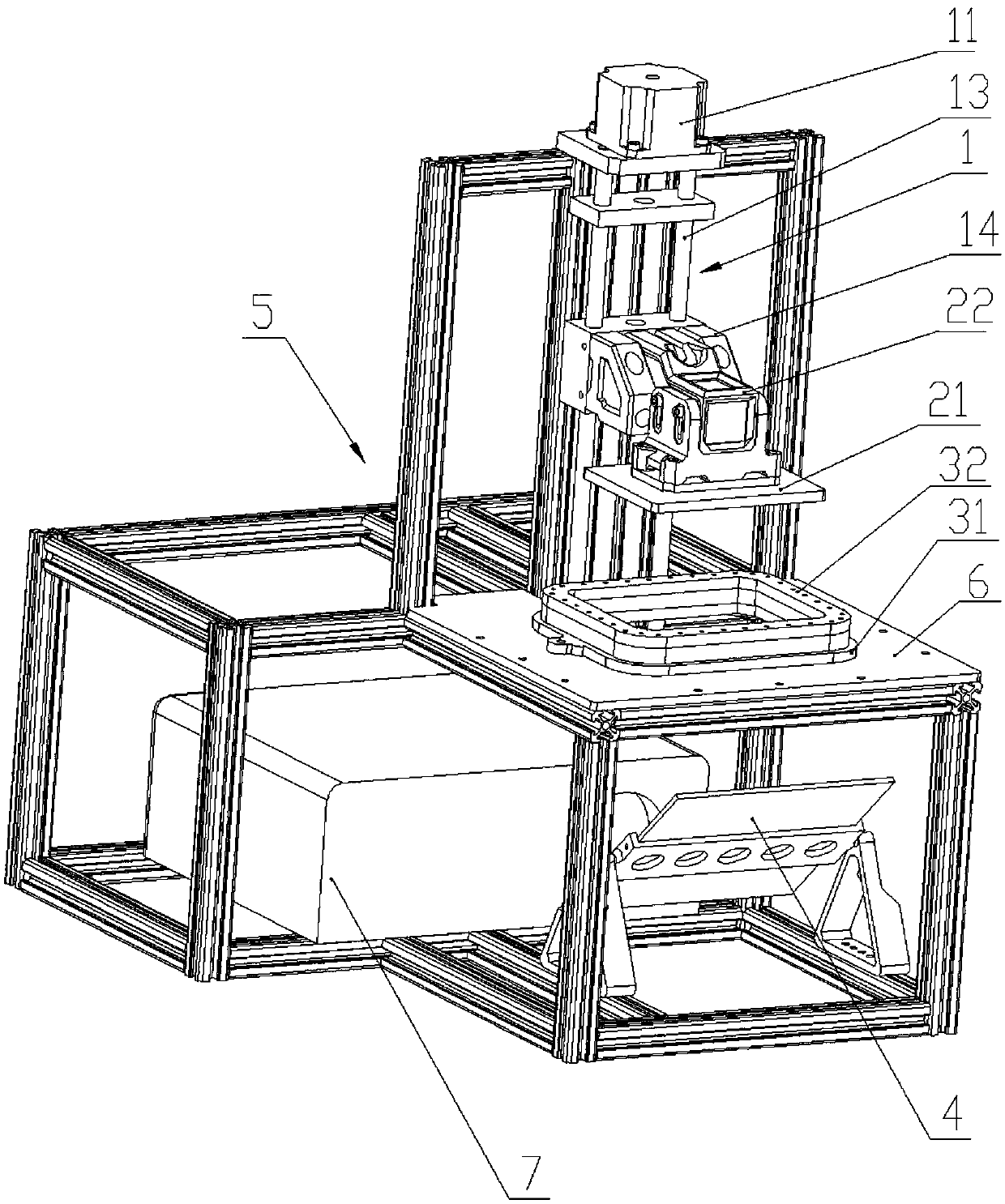

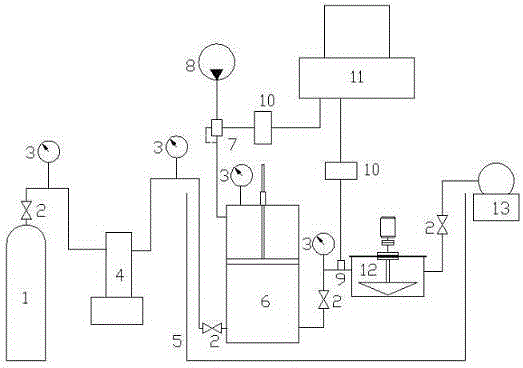

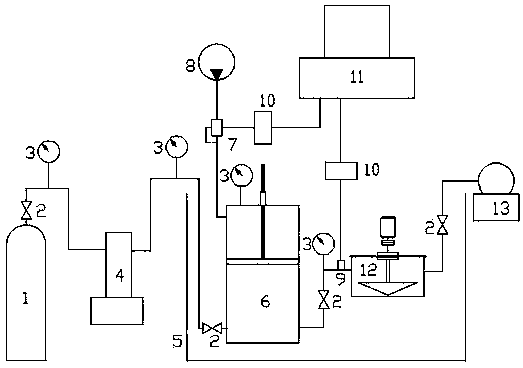

Experimental facility for dissolving supercritical CO2 in polymer melt under condition of interface updating

An experimental facility for dissolving supercritical CO2 in polymer melt under the condition of interface updating comprises a gas cylinder, a pressure reducing valve, a pressure data display instrument, a booster pump, an oil bath heating container, a pressure chamber 1, an overflow valve, an oil pump, a pressure sensor, a control system, a pressure chamber 2, a magnetic coupling, an external driving motor and a changeable mixing element. By the experimental facility, mutual effects of shearing rate and homogeneous body rheological properties under different temperature and pressure conditions, dissolvability and dissolved quantity as well as influences of process parameters such as temperature, pressure and revolving speed and the structure of the mixing element to the dissolving speed of the supercritical CO2 in the polymer melt are researched. A new theory of dissolving and dispersing of CO2 in the polymer melt is further verified, the formation characters of a homogeneous body in a micropore plastic continuous forming process can be known essentially, the process parameters are formulated reasonably, molds and equipment are improved reasonably, the novel technology is promoted to be mature as soon as possible, and the experimental facility has important practical significance.

Owner:NANCHANG UNIV

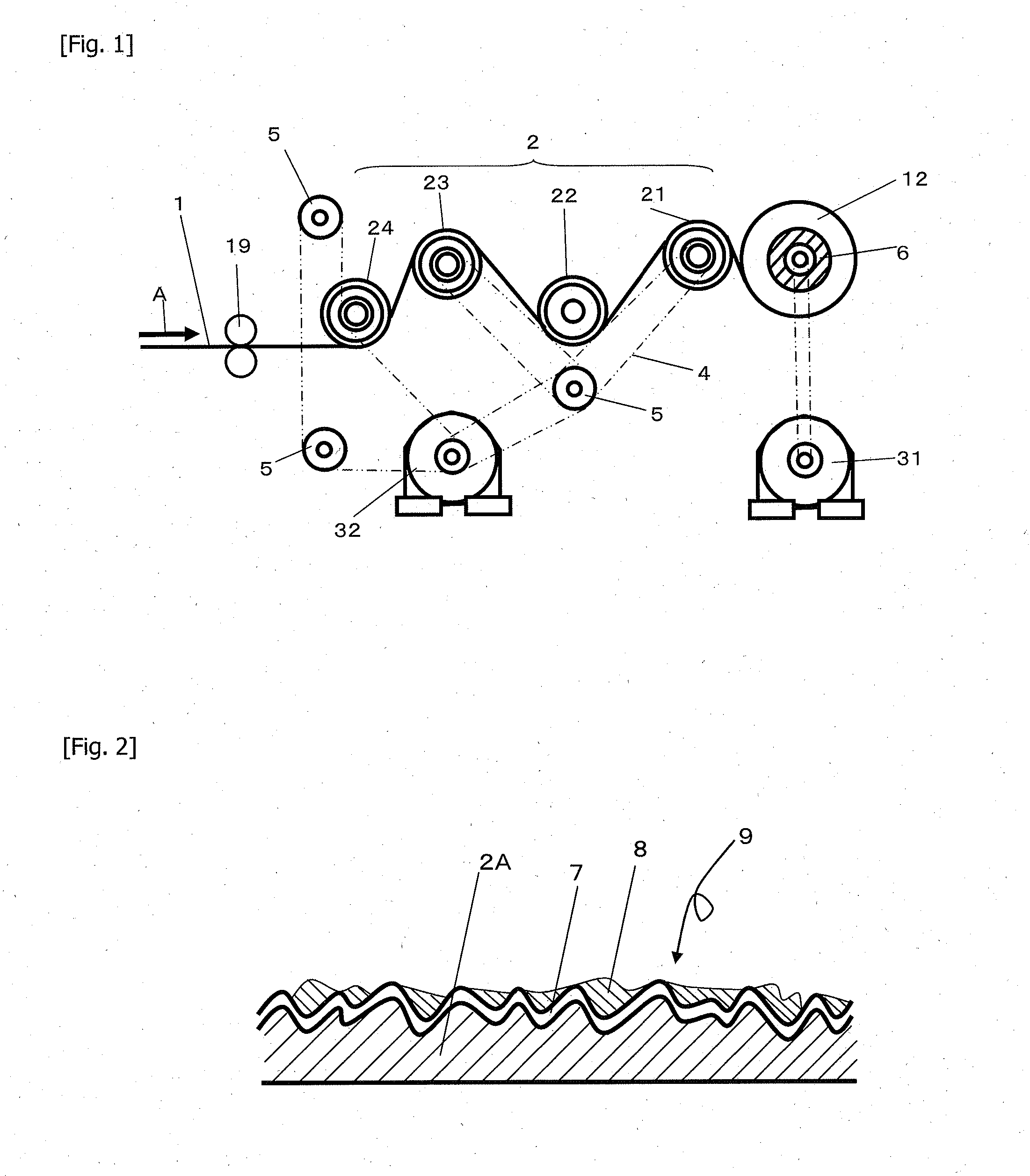

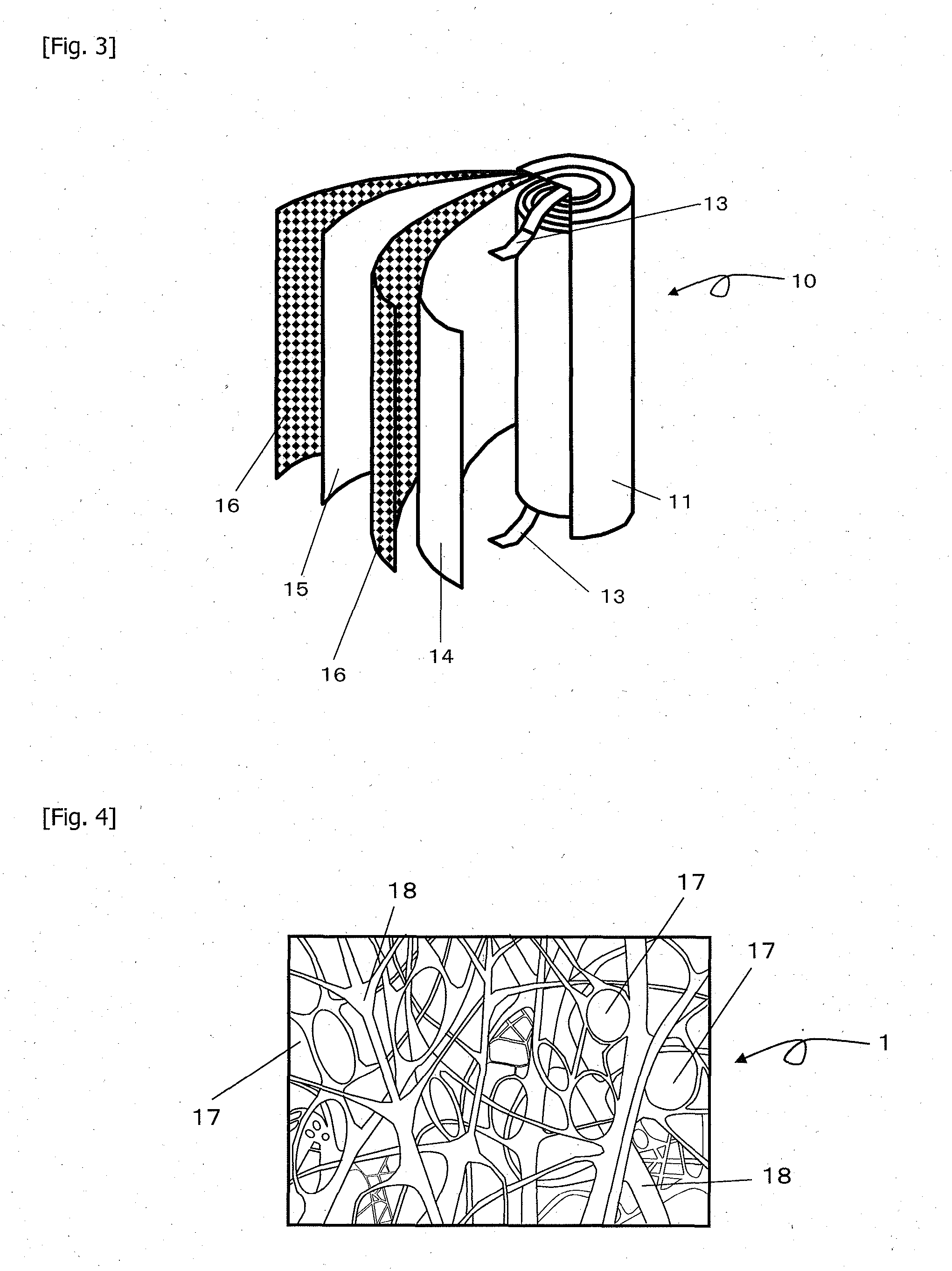

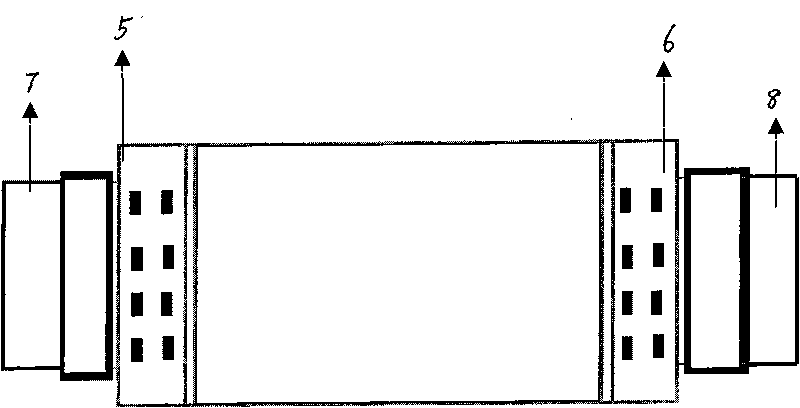

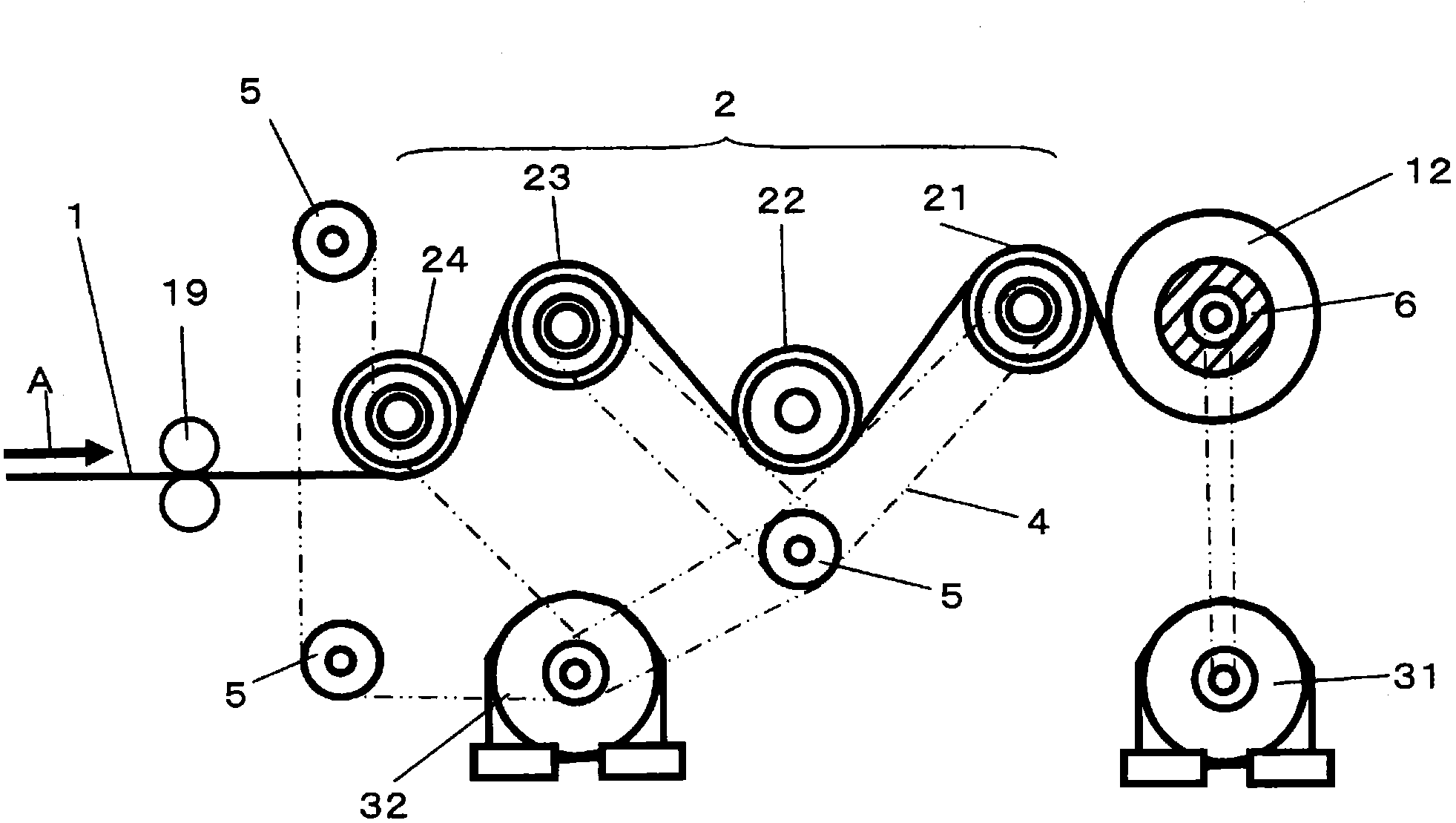

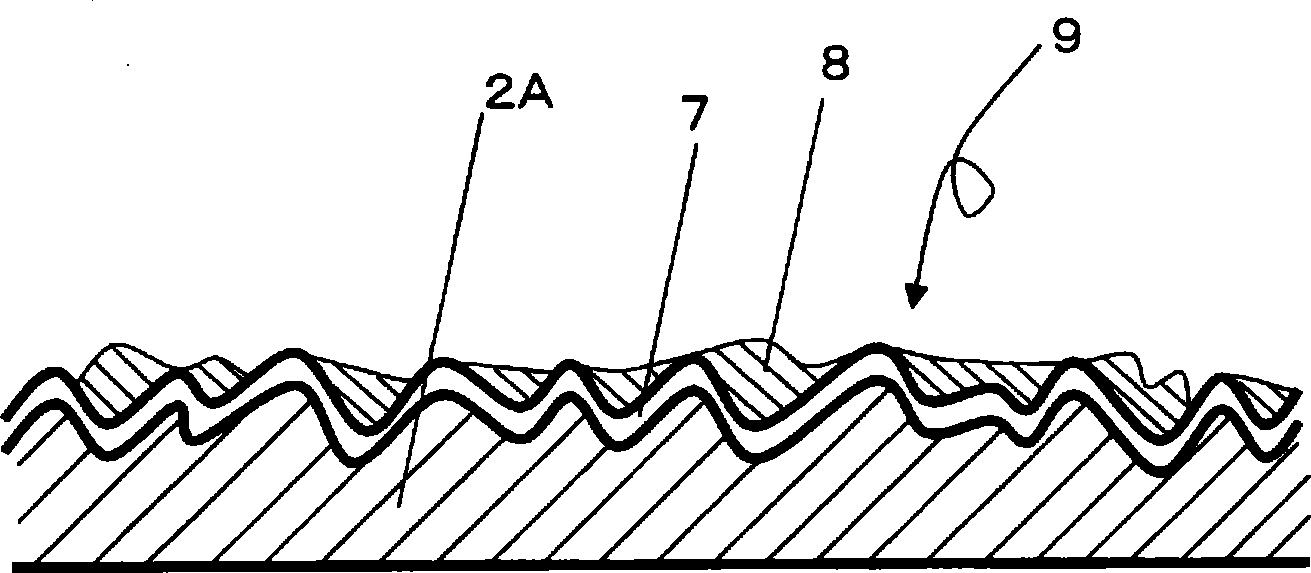

Process for producing roll of microporous plastic film

InactiveCN103459283AImprove manufacturing qualityImprove productivityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumMicrocellular plastic

A process for producing a roll (12) of a microporous plastic film which includes conveying a microporous plastic film (1) by means of a plurality of conveyor rollers (21-24) and winding the film on a core (6). At least one of the conveyor rollers (21-24) has a surface constituted of a fluororesin or a silicone rubber or of a composite material (9) containing either. The composite material (9) comprises a hard chromium layer (7) formed by plating and a fluororesin (8). The at least one roller has a surface roughness RzJIS of 0.3-30 [mu]m. The film (1) has a plurality of through-holes (17) therein and is for use as the separators (16) of a lithium-ion secondary battery (10) or as the separators of capacitors. The film (1) can be prevented from creasing or breaking, because the coefficient of friction between the film (1) and the conveyor rollers (21-24) is low.

Owner:TORAY IND INC

Continuous injecting and mixing method of micropore plastic physical foaming agent

The invention relates to a continuous injecting and mixing method of a micropore plastic physical foaming agent. A continuous injecting and mixing device of a micropore plastic physical foaming agent is additionally arranged between an injector charging barrel and a rotary-type locked charging nozzle, and a preprocessed physical foaming agent is continuously injected into a plastic melting body by the continuous injecting and mixing device of the micropore plastic physical foaming agent, and is mixed in a rotary moving mode to enable the physical foaming agent to be dissolved into the plastic melting body. The invention has the advantages that the continuous injection of the physical foaming agent is beneficial to the control of the injecting amount and the pressure of the foaming agent, the better and more uniform mixture of the physical foaming agent and the plastic melting body and the relative independence of the injecting and mixing process of the physical foaming agent and the injecting forming process of micropore plastic so as to reduce the synchronous requirement of the physical foaming agent and the micropore plastic and the control difficulty of equipment.

Owner:FUJIAN UNIV OF TECH

Method of preparing apertured micropore plastic product semifusion mould press shaping method

A semi-fusing and die-pressing method for preparing the milliporous plastic product with open pores includes such steps as mixing the synthetic resin particles with at least one of plasticizer, viscosity increaser, foaming agent and disperser, preheating, storing in a temp and humidity constant container, filling in preheated die, hot die pressing, and cooling while holding the pressure.

Owner:SICHUAN UNIV

Low-density polypropylene bead foam and preparation method and application thereof

ActiveCN111171366AImprove melt strengthIncrease nucleation densityPolymer scienceMicrocellular plastic

The invention relates to the technical field of microporous plastic preparation, in particular to low-density polypropylene bead foam and a preparation method and application thereof. The foam is prepared from the following raw materials in percentage by mass: 80-98% of PP, 0.5-12% of PTFE, 0.5-10% of talcum powder, 2-10% of supercritical carbon dioxide and 0.1-1% of supercritical nitrogen. The foaming ratio of a foaming product can reach 54 times, the density of the foaming product can be as low as 0.016 g / cm<3>, the average size of foam holes is smaller than 40 microns, the foaming product has a foam hole structure which is finer, more uniform, more regular and higher in porosity, and the closed pore rate can reach 95%.

Owner:福建鑫瑞新材料科技有限公司

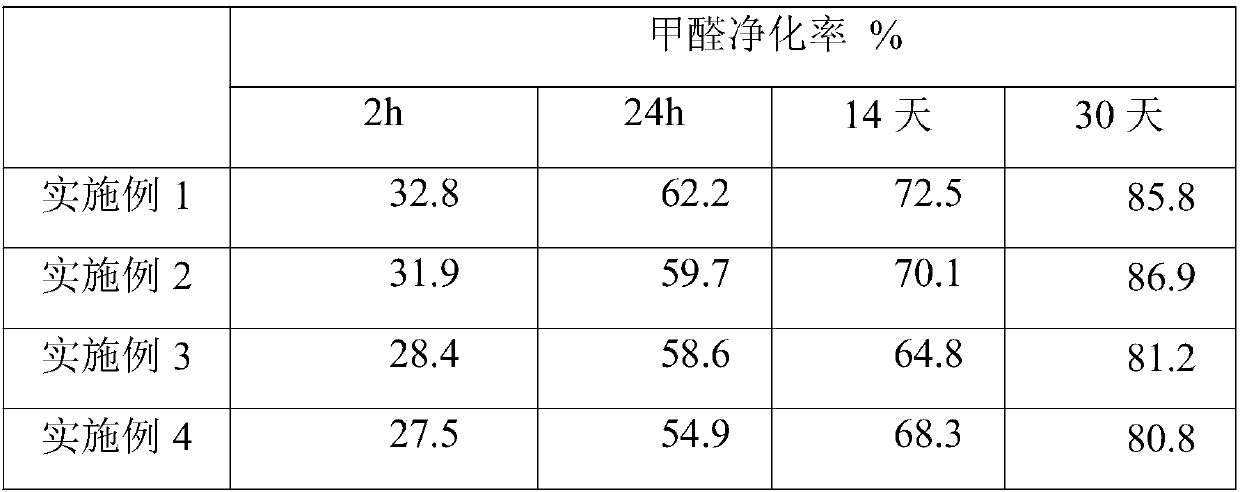

Preparation method of microporous plastic catalytically degrading formaldehyde

The invention relates to the technical field of formaldehyde scavengers, in particular to a preparation method of microporous plastic catalytically degrading formaldehyde. The preparation method comprises the following steps: (1), soaking plant fiber in an alkaline solution to obtain porous plant fiber; (2), uniformly mixing the porous plant fiber, negative ion powder and organic titanate in a solvent, and then performing a thermal reaction to obtain modified porous plant fiber; (3), adding metal powder and the modified porous plant fiber into phenolic resin, uniformly mixing to obtain composite phenolic resin, then adding a curing agent and an acidic solution into the composite phenolic resin, and then pouring into a mould, and performing curing moulding to obtain the microporous plasticcatalytically degrading the formaldehyde. The microporous plastic catalytically degrading the formaldehyde can be processed into parts with a variety of shapes, can permanently and thoroughly purify the formaldehyde in a room, and has a wide application prospect.

Owner:ANHUI LEJIN ENVIRONMENT TECH CO LTD

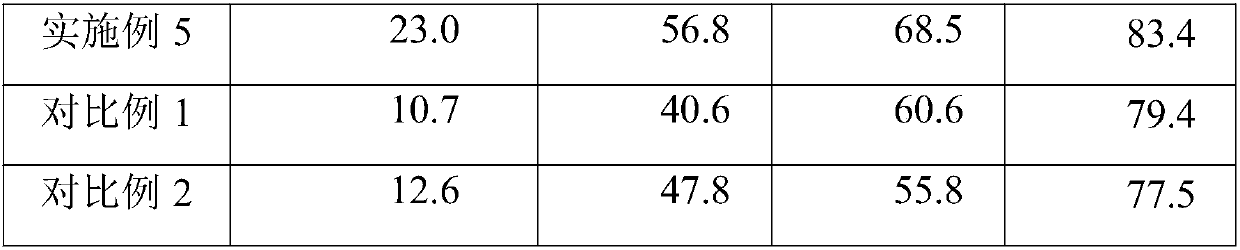

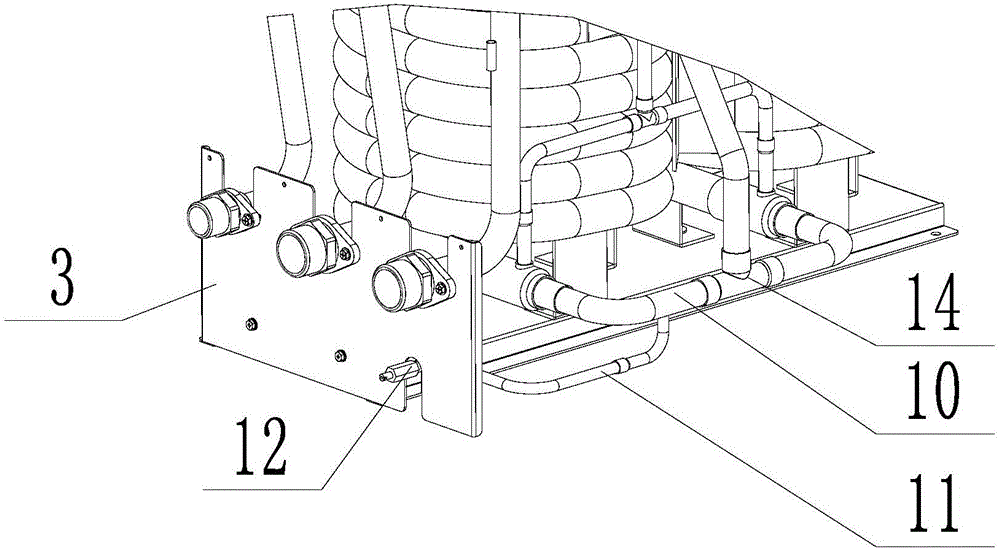

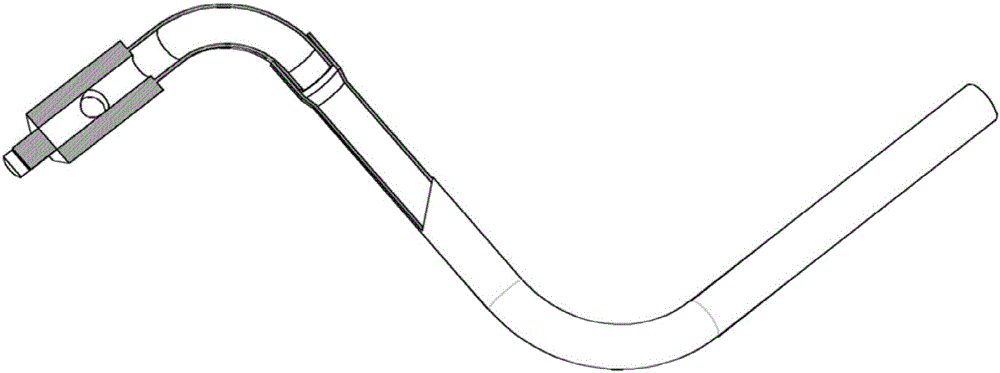

Frost crack resisting drainage pipeline and manufacturing method thereof

InactiveCN105090631APrevent frost crackingSimple assembly and manufacturing operationsGeneral water supply conservationPipe elementsFrost crackFrost

The invention provides a frost crack resisting drainage pipeline. The drainage pipeline is of a double-layer pipeline structure and comprises an outer pipeline body and an inner pipeline body which are tightly attached to each other and form a concentric pipeline structure. The outer pipeline body is made of metal material. The inner pipeline body is made of microcellular plastics. The invention further provides a method for manufacturing the frost crack resisting drainage pipeline. The method comprises the steps that the inner microcellular plastic pipeline body is located and punched, and a hole corresponds to a drain hole in a drain valve in position; the microcellular plastic pipeline body is placed in the metal pipeline body and made to be tightly attached to the inner wall of the metal pipeline body; and the double pipeline bodies which are tightly attached to each other are bent to form the frost crack resisting drainage pipeline. The frost crack resisting drainage pipeline is easy to assemble, manufacture and operate and can be effectively protected against frost cracks, and the safety of a water pipeline system of a water heater is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of natural aromatic foaming material and preparation method thereof

The invention relates to a natural aromatic foam material and a preparation method, belonging to the technical field of foam materials and preparation methods. The natural aromatic foam material is prepared from a raw material polypropylene, and is characterized by also being prepared from natural aromatic plant materials and another additive. The raw material and materials are weighed in parts by weight: 8-20 parts of natural aromatic plant powder, 50-80 parts of the raw material polypropylene, and 1-10 parts of the other additive, wherein the other additive is a mixture of one or more of EPDM, modified talcum powder, monoglyceride and stearic acid. The natural aromatic plant powder is selected and is mixed with polypropylene to prepare a master batch, so as to prepare polypropylene-plant compound microporous plastic beads or sheets; the foam material can give out natural fragrance, and can be widely used in fields such as household consumer products and craft toys, the added value of the plastic foam material can be improved, and the use ratio of the natural aromatic plant can be improved.

Owner:义乌市中科院兰州化物所功能材料中心

Hollow extracting micro-hole filtering element

InactiveCN100471544CImprove toughnessStrong impact resistanceMoving filtering element filtersMicrocellular plasticMicroparticle

The present invention is improved filter plate for solid-liquid separating drier. The improved filter plate is hydrophilic microporous plastic plate with average pore size of 0.2-1.5 microns, and forms the sucking filter element walls. It is superior to available ceramic plate, and has pore opening rate of about 60 %, 20-30 % higher production capacity, high toughness, high impact resistance, and acid and base resistance.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Low-density polypropylene foam with heat insulation performance and preparation method and application thereof

The invention relates to the technical field of microporous plastic preparation, in particular to low-density polypropylene foam with heat insulation performance and a preparation method and application thereof. The foam is prepared from the following raw materials in percentage by mass: 70-90% of PP, 1-15% of PTFE, 1-20% of flake graphite, 2-12% of supercritical carbon dioxide and 0.2-2% of supercritical nitrogen. The foaming ratio of the low-density polypropylene foam prepared by the invention can reach 65 times; the density of a foamed product can be as low as 0.014 g / cm <3>, the heat conductivity of the foamed product is as low as 0.029 W / (mK), and the foamed product has excellent heat insulation performance and can be used as a building outer wall and floor heat insulation material, an automobile anti-collision buffer filling material and a packaging protection material for logistics turnover.

Owner:福建鑫瑞新材料科技有限公司

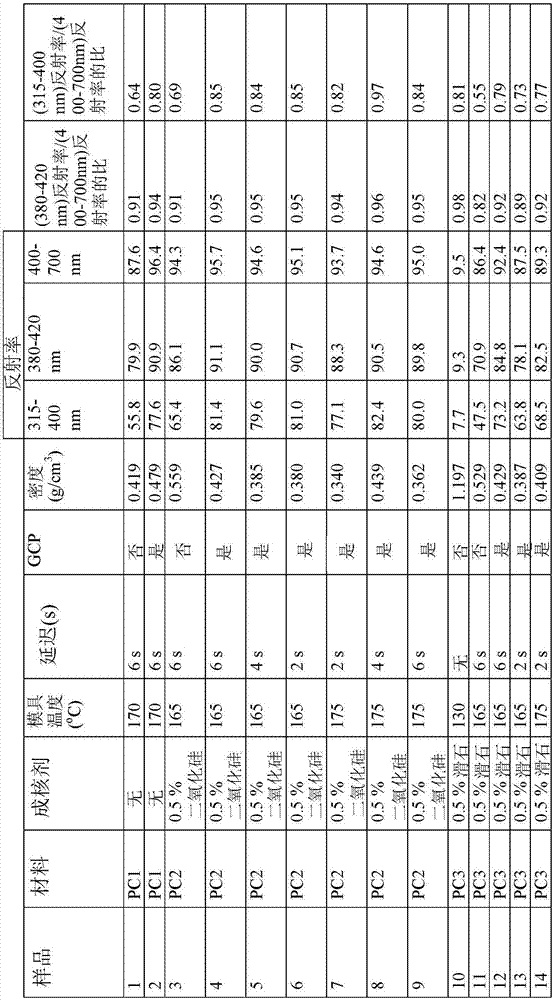

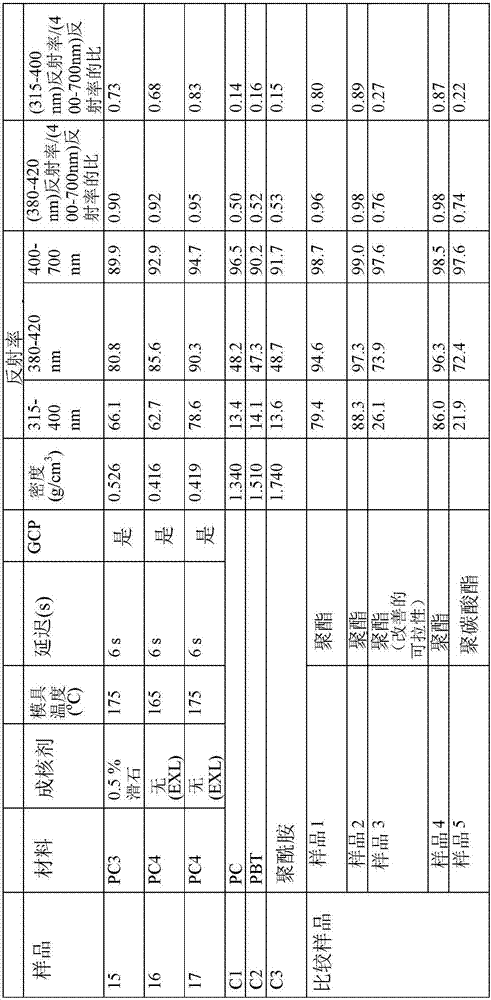

Reflective Articles Comprising A Micro-Cellular Structure And Having Improved Reflectivity

Provided are microcellular plastic articles having improved reflective properties. Also provided are methods of utilizing the disclosed articles.

Owner:SABIC GLOBAL TECH BV

An electrolytic method for surface texturing using microporous plastic plates

ActiveCN104907654BImprove machining accuracyImprove processing efficiencyMetal working apparatusElectrolysisMicrocellular plastic

The invention discloses an electrolytic method for carrying out surface texturing by use of a microporous plastic plate, and belongs to the technical field of electrolytic processing. The method comprises the following steps: (a), manufacturing an insulation plate with array micropores; (b), flatly attaching the insulation plate on the processing surface of a workpiece; (3), introducing an electrolyte between a tool cathode and the insulation plate to enable the electrolyte to reach the processing surface of the workpiece, connecting the tool cathode with the cathode of a pulse power supply, and connecting the workpiece with the anode of the pulse power supply; and (d), turning on the pulse power supply to carry out electrolytic processing on a surface texture, wherein the insulation plate is a plastic plate, and the array microprobes in the plastic plate are processed by use of a hot melt method. According to the invention, the surface texturing of the workpiece is realized by use of the plastic plate with the array microprobes, the array microprobes are processed on the plastic plate by use of the hot melt method, the microprobe processing precision is high, the efficiency is high, and the pitch of the microprobes is conveniently controlled; and the plastic plate is taken as an insulation layer, the stray corrosion of the surface texture is small, the surface texturing precision is improved, the method is simple and practical, and therefore, the application prospect is wide.

Owner:CHANGZHOU INST OF TECH

Experimental device for dissolution of supercritical CO2 in polymer melt under interface renewal conditions

An experimental facility for dissolving supercritical CO2 in polymer melt under the condition of interface updating comprises a gas cylinder, a pressure reducing valve, a pressure data display instrument, a booster pump, an oil bath heating container, a pressure chamber 1, an overflow valve, an oil pump, a pressure sensor, a control system, a pressure chamber 2, a magnetic coupling, an external driving motor and a changeable mixing element. By the experimental facility, mutual effects of shearing rate and homogeneous body rheological properties under different temperature and pressure conditions, dissolvability and dissolved quantity as well as influences of process parameters such as temperature, pressure and revolving speed and the structure of the mixing element to the dissolving speed of the supercritical CO2 in the polymer melt are researched. A new theory of dissolving and dispersing of CO2 in the polymer melt is further verified, the formation characters of a homogeneous body in a micropore plastic continuous forming process can be known essentially, the process parameters are formulated reasonably, molds and equipment are improved reasonably, the novel technology is promoted to be mature as soon as possible, and the experimental facility has important practical significance.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com