Natural aromatic foam material and preparation method

A foaming material and aromatic technology, which is applied in the field of natural aromatic foaming materials and preparation, can solve the problems of fragrance weakening, failure, plasticizer hazards, etc., and achieve the effect of lasting fragrance, low cost and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

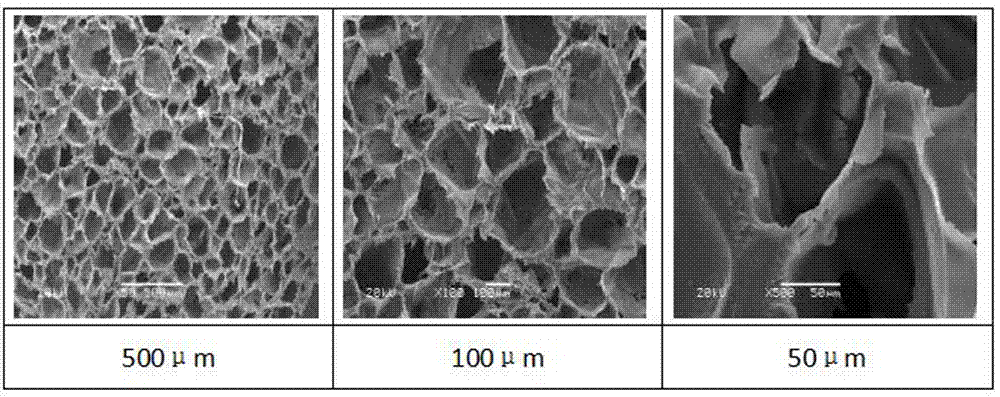

Image

Examples

Embodiment 1

[0013] A natural aromatic foaming material, lavender powder is selected as the natural aromatic plant powder, and the parts by weight are 20 parts by weight; the raw material of polypropylene is 80 parts by weight; other additives are a mixture of EPDM and monoglyceride , and its parts by weight are 10 parts; the above-mentioned raw materials are made into natural aromatic foaming materials by the following preparation method of Example 2.

Embodiment 2

[0015] A method for preparing a natural aromatic foaming material, comprising 20 parts by weight of natural aromatic plant matter powder-lavender powder, 80 parts by weight of polypropylene raw materials, 10 parts by weight of EPDM and monoglyceride The mixture is mixed by a high-speed mixer; measured by a weight loss scale, added to a φ25MM twin-screw extruder, heated, melted and pushed, and injected with supercritical CO 2 Fluid, mixed evenly, extruded into φ65 single-screw extruder, kneaded, cooled and extruded, finally extruded through a multi-hole die and then pelletized. Specific operating process parameters: The temperature of the first zone of the φ25MM twin-screw extruder is 175°C, the temperature of the second zone is 195°C, the temperature of the third zone is 211°C, the temperature of the fourth zone is 211°C, the temperature of the fifth zone is 201°C, and the temperature of the sixth zone is The temperature of the transition body is 195°C; the temperature of the ...

Embodiment 3

[0017] A kind of natural aromatic foaming material, select sandalwood powder as natural aromatic plant quality powder, its number of parts by weight is 20 parts by weight; raw material of polypropylene, its number of parts by weight is 76 parts by weight; other additives are EPDM, modified talcum powder , the mixture of stearic acid, its parts by weight are 9 parts; Above-mentioned raw material is made into natural aromatic type foaming material by following embodiment 4 preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com