Continuous injecting and mixing method of micropore plastic physical foaming agent

A technology of physical foaming agent and microporous plastic, which is applied in the field of plastic molding processing, can solve the problems of short mixing time of foaming agent and plastic melt, high difficulty of control, increased difficulty of equipment manufacturing and control, and achieve reduction Synchronization requirement, effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method for continuous injection and mixing of microporous plastic physical foaming agent. The difference from the prior art is that a microporous plastic physical foaming agent is continuously injected between the barrel of the injection machine and the rotary locking injection nozzle. With the mixing device, the pretreated physical foaming agent is continuously injected into the plastic melt through the microcellular plastic physical foaming agent and the mixing device is continuously injected into the plastic melt, and is mixed in a rotational motion, so that the physical foaming agent is dissolved in Plastic melt.

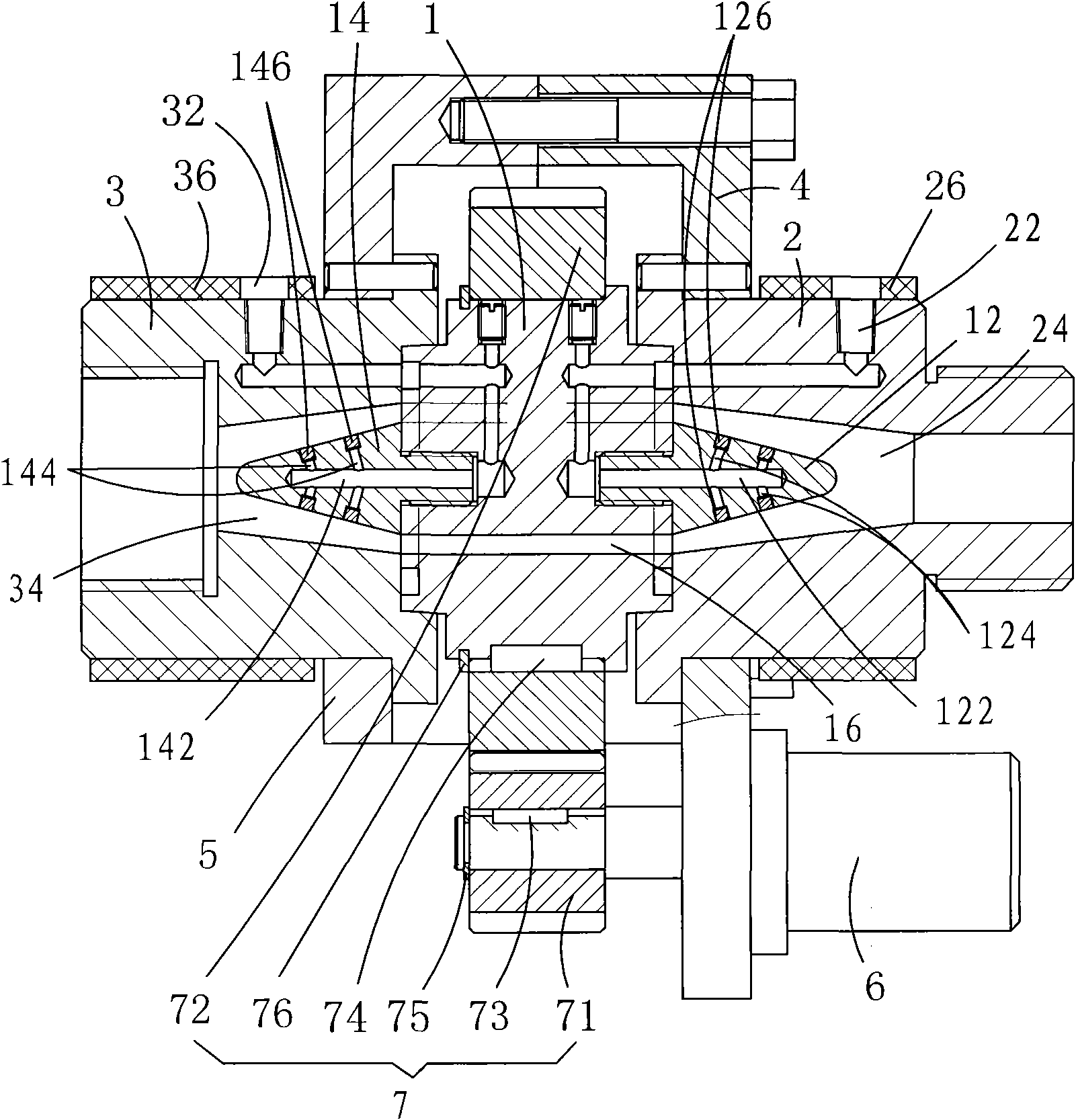

[0021] See figure 1 The continuous injection and mixing device for the microcellular plastic physical foaming agent used in the present invention includes a mixer 1, a front connector 2, a rear connector 3, a front housing 4, a rear housing 5, a hydraulic motor 6, and a gear drive Institution 7.

[0022] The front connector 2 and the rear connector 3 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com