Patents

Literature

32results about How to "Achieve continuous growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

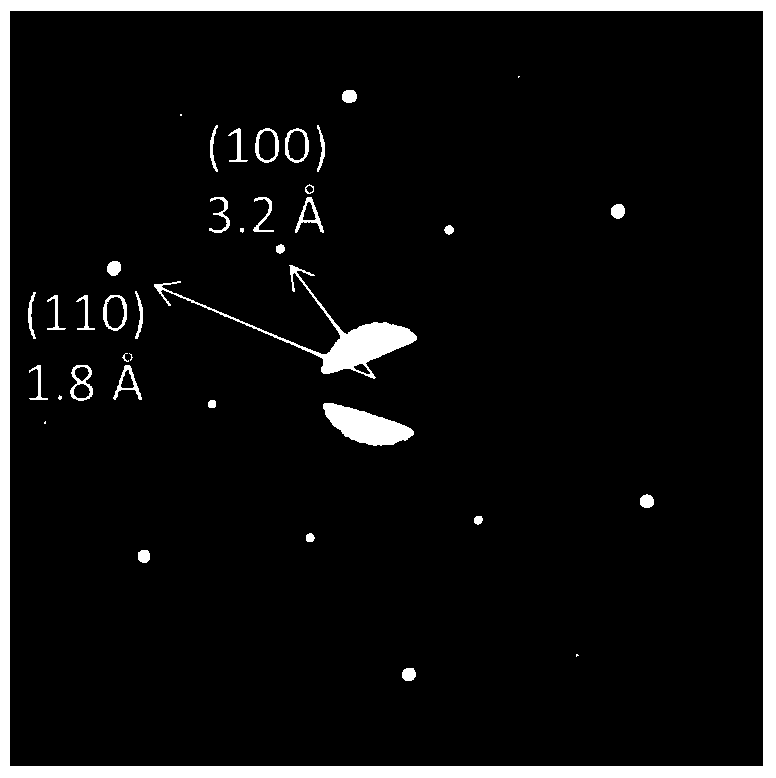

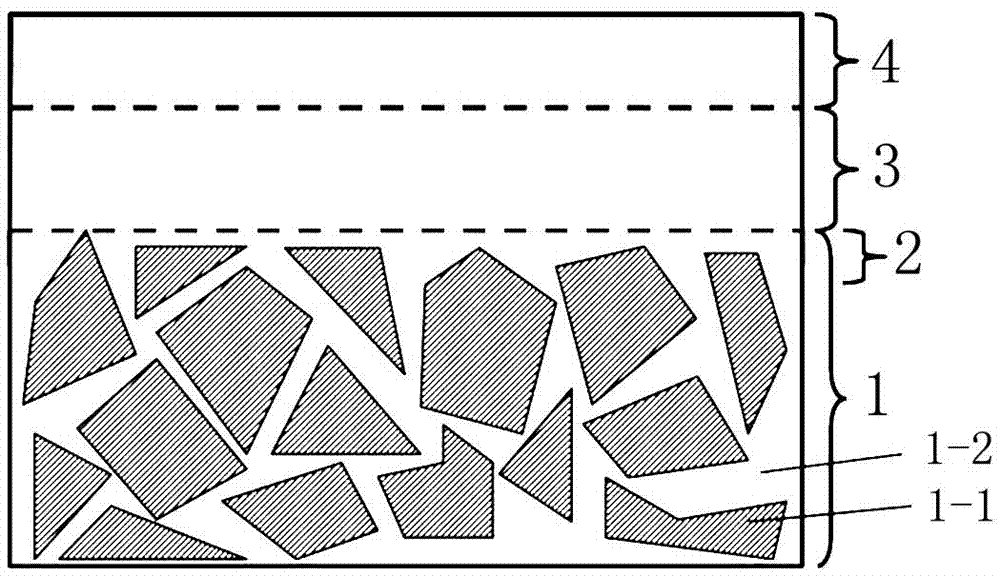

Transparent electrode based on ultra-thin metallic film and preparation method and application thereof

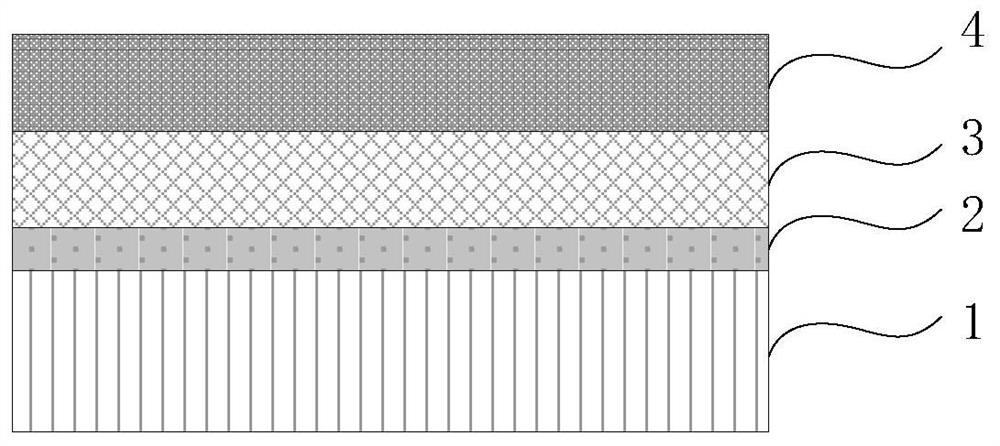

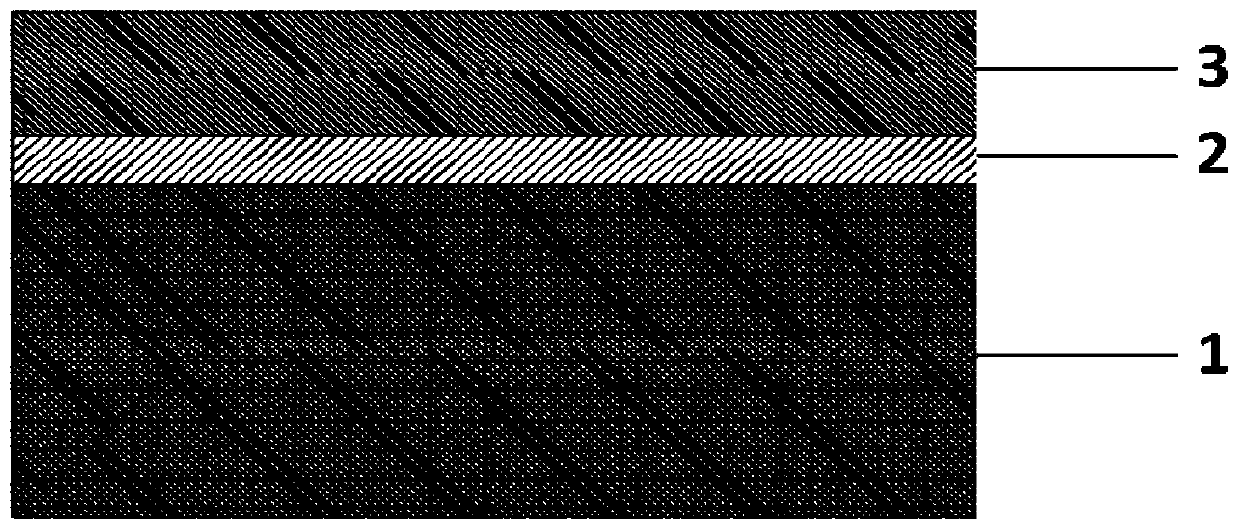

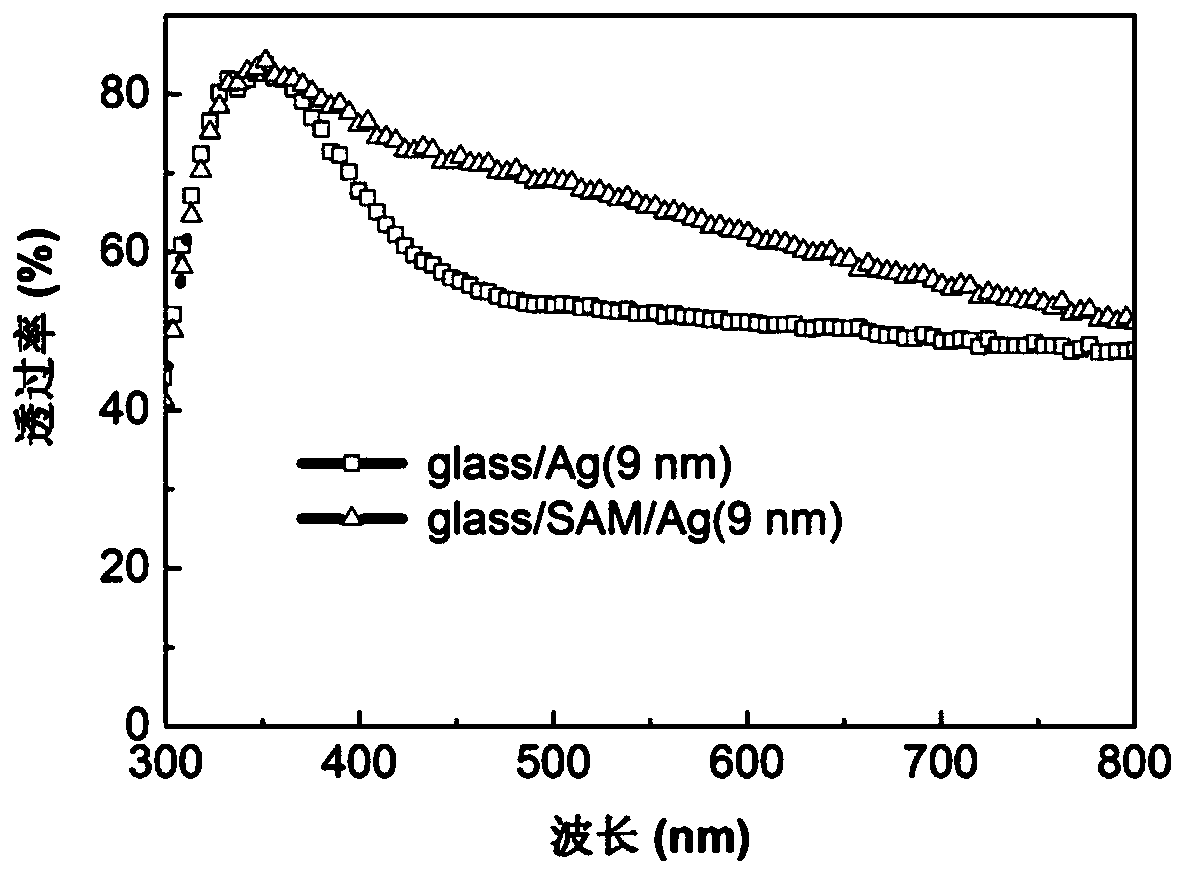

ActiveCN107393979AGood optical performanceControl conductivityFinal product manufactureSemiconductor devicesThin metalSystem structure

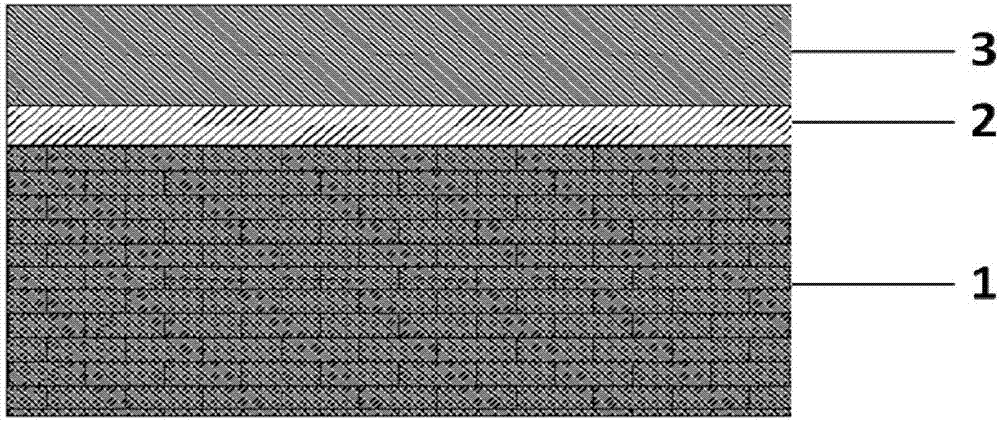

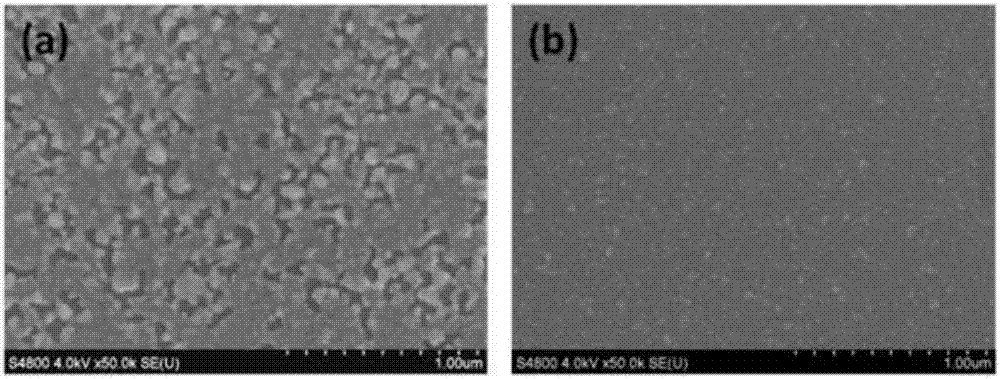

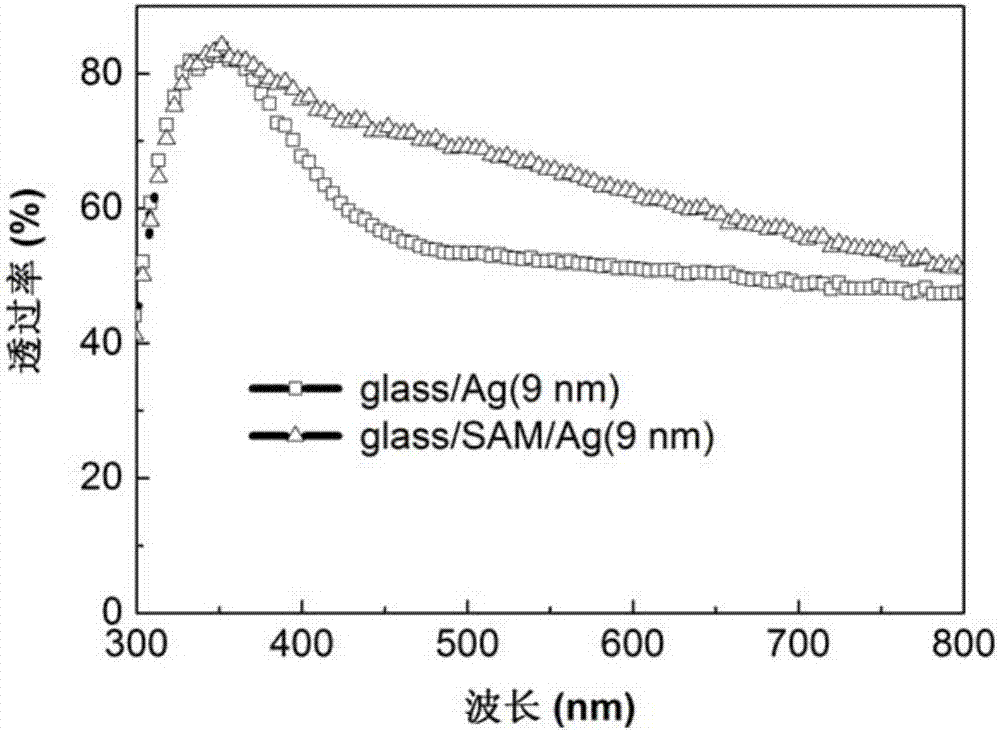

The invention discloses a transparent electrode based on an ultra-thin metallic film. The transparent electrode orderly comprises a transparent substrate, a metal layer and a metal oxide layer from bottom to top, wherein the thickness of the metal layer is 3 to 12nm. The substrate is modified by a monomolecular self-assembled layer; an ultra-thin metal layer is directly deposited on the substrate, and the continuity and conductivity of the ultra-thin metallic film are improved through the function of the monomolecular self-assembled layer; or through the co-deposition of metals, the continuous growth of the ultra-thin metallic film is realized directly on the substrate; and a metal oxide layer is deposited on the substrate as an antireflection layer, then a double-layer film system structure is obtained, and through the design and optimization of the double-layer film system structure, the maximization of transmittance is realized. The invention further discloses a preparation method of the transparent electrode based on the ultra-thin metallic film and an application thereof in photoelectric devices, wherein the transparent electrode can have good conductivity and high transmittance at the same time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

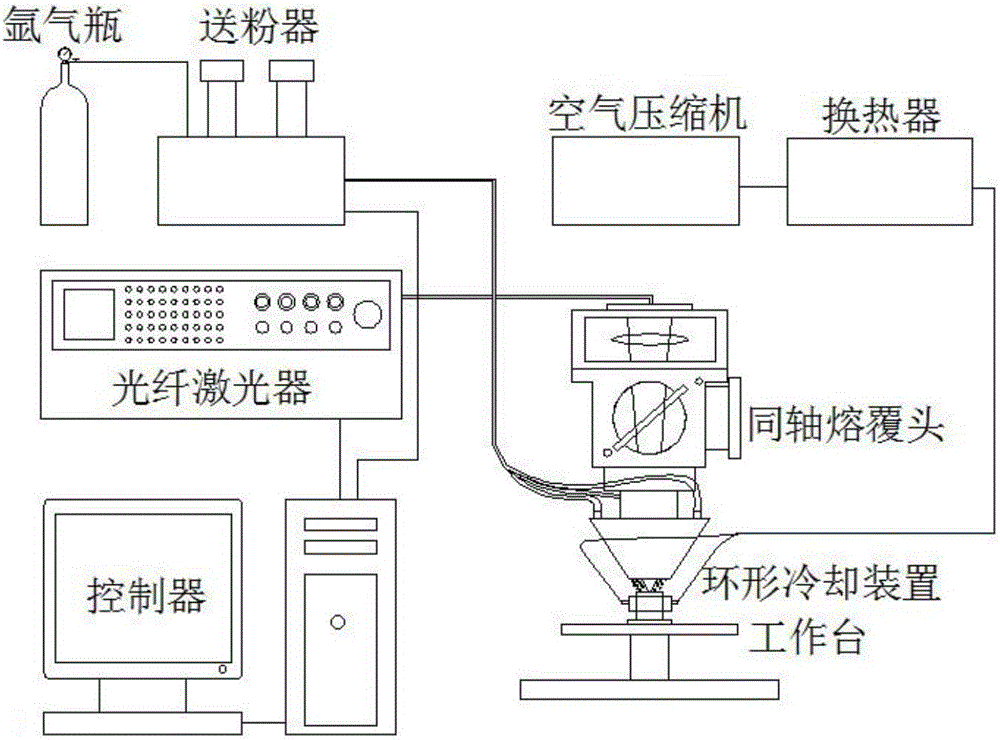

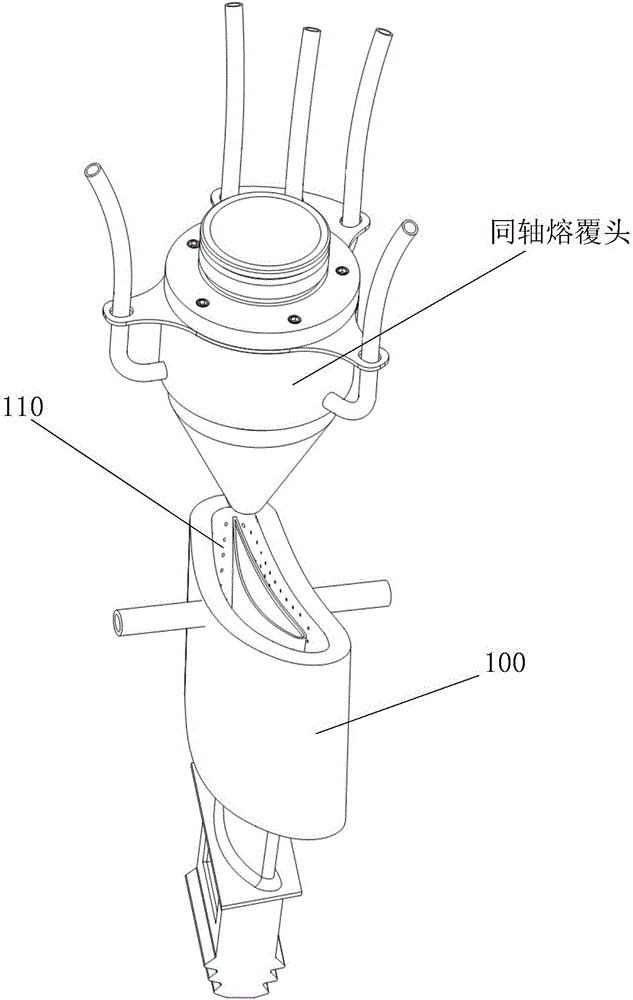

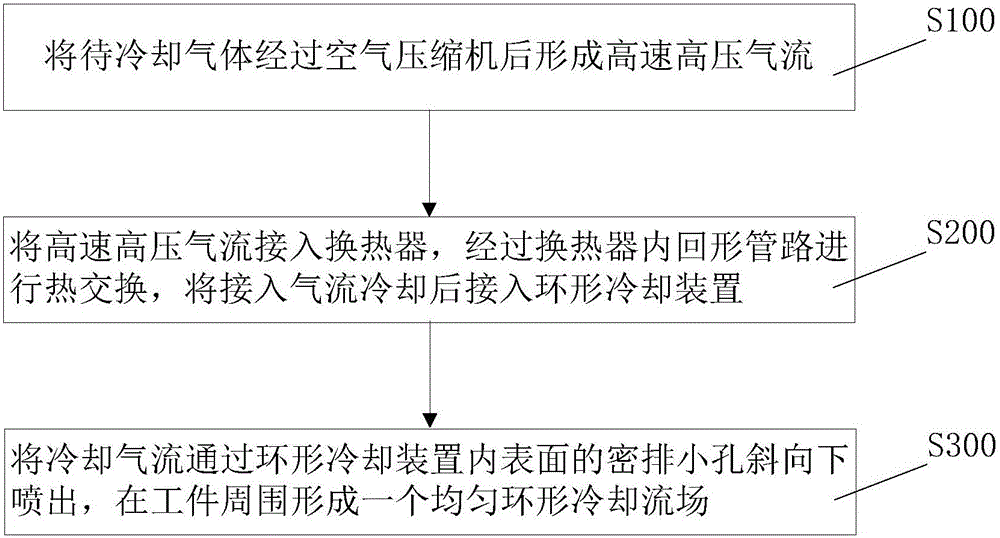

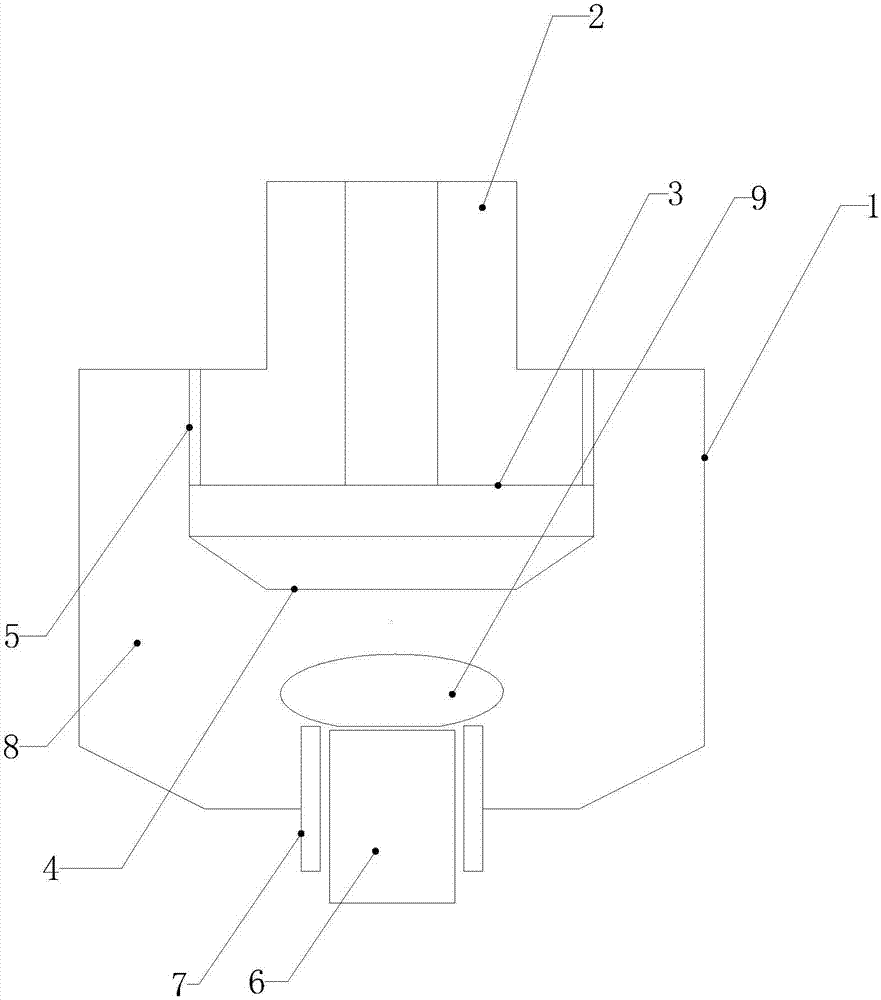

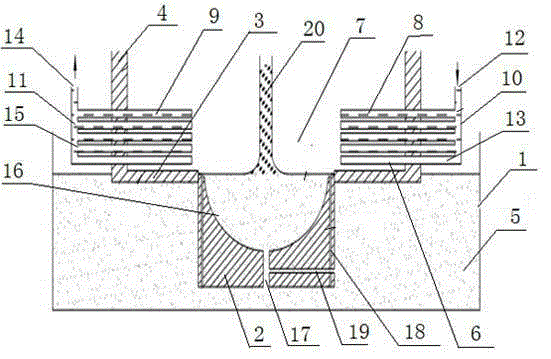

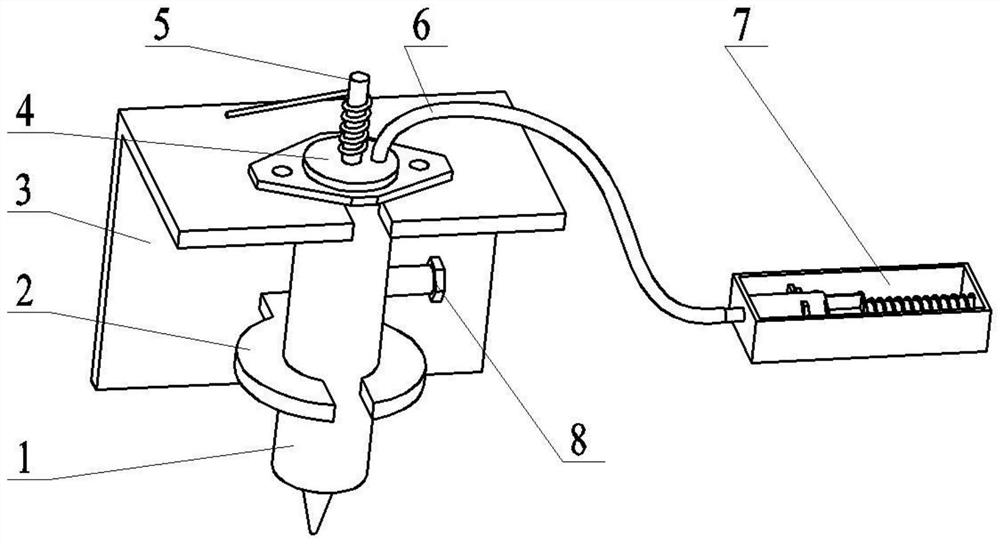

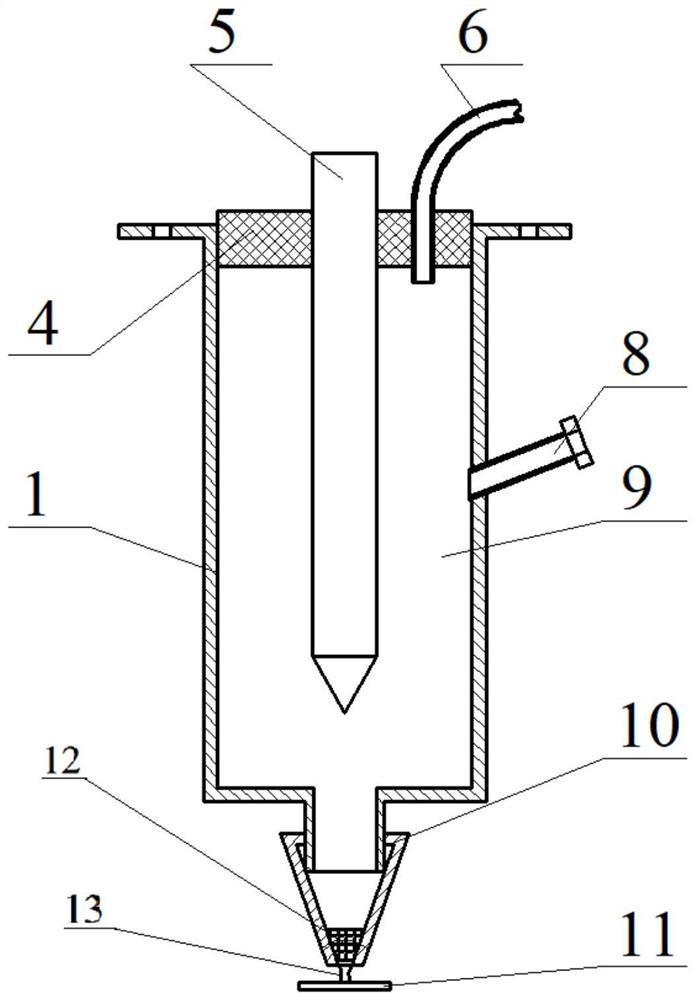

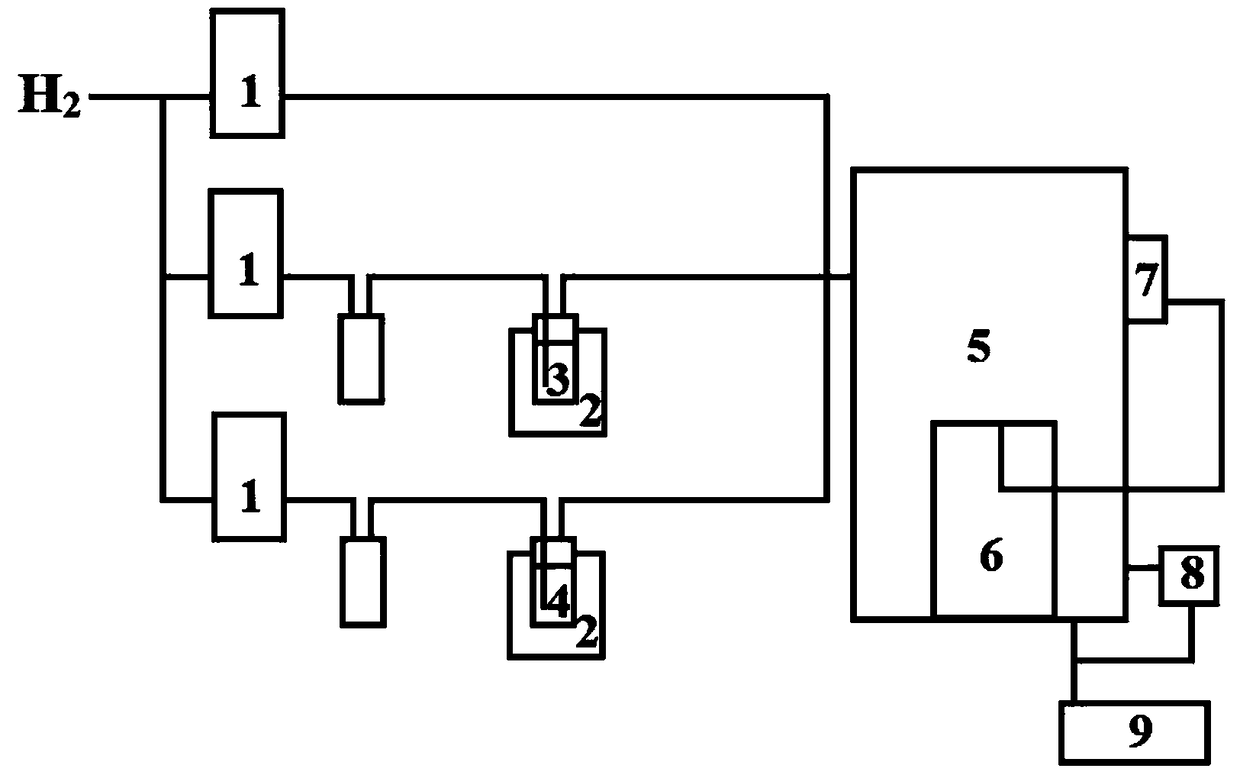

Active cooling device and method for laser repairing of single crystal turbine blade

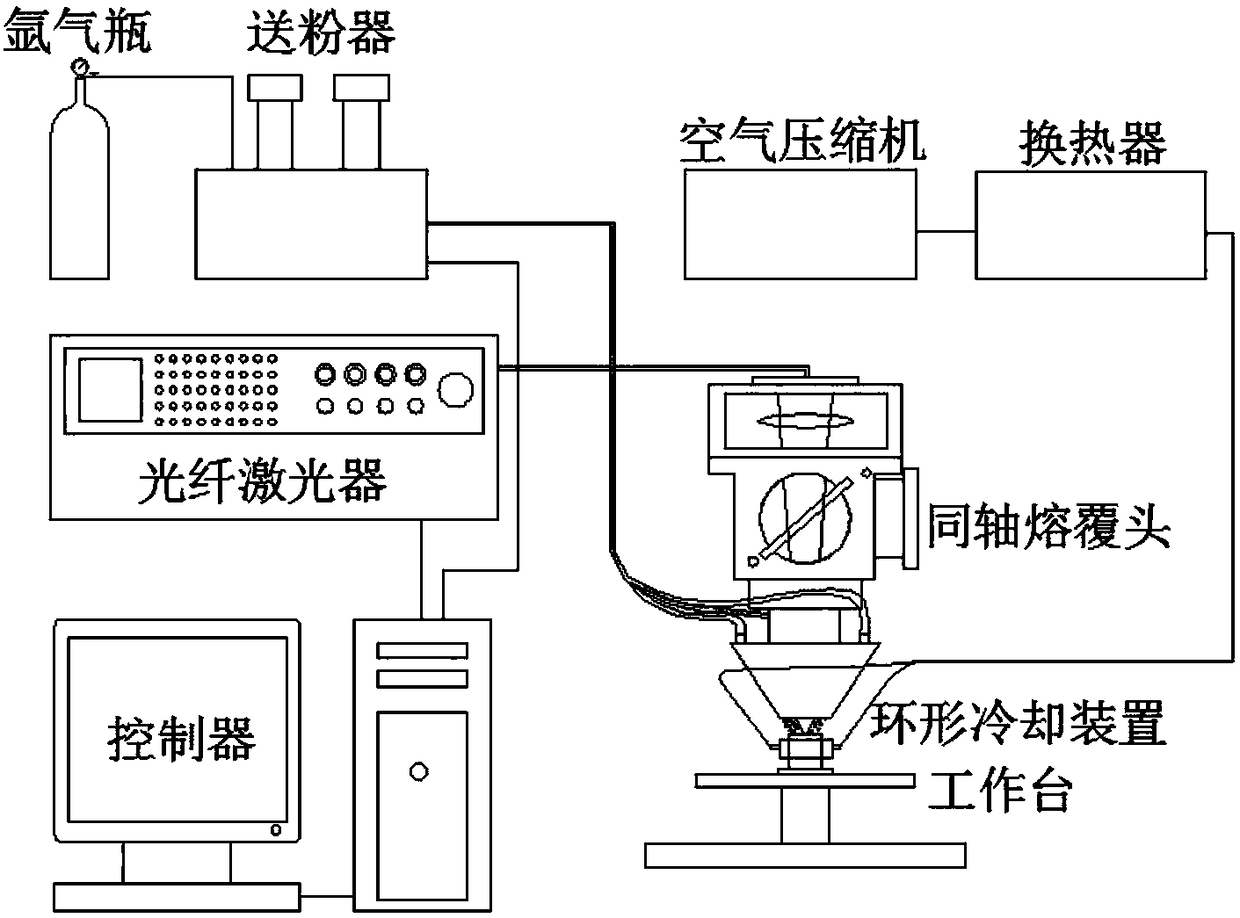

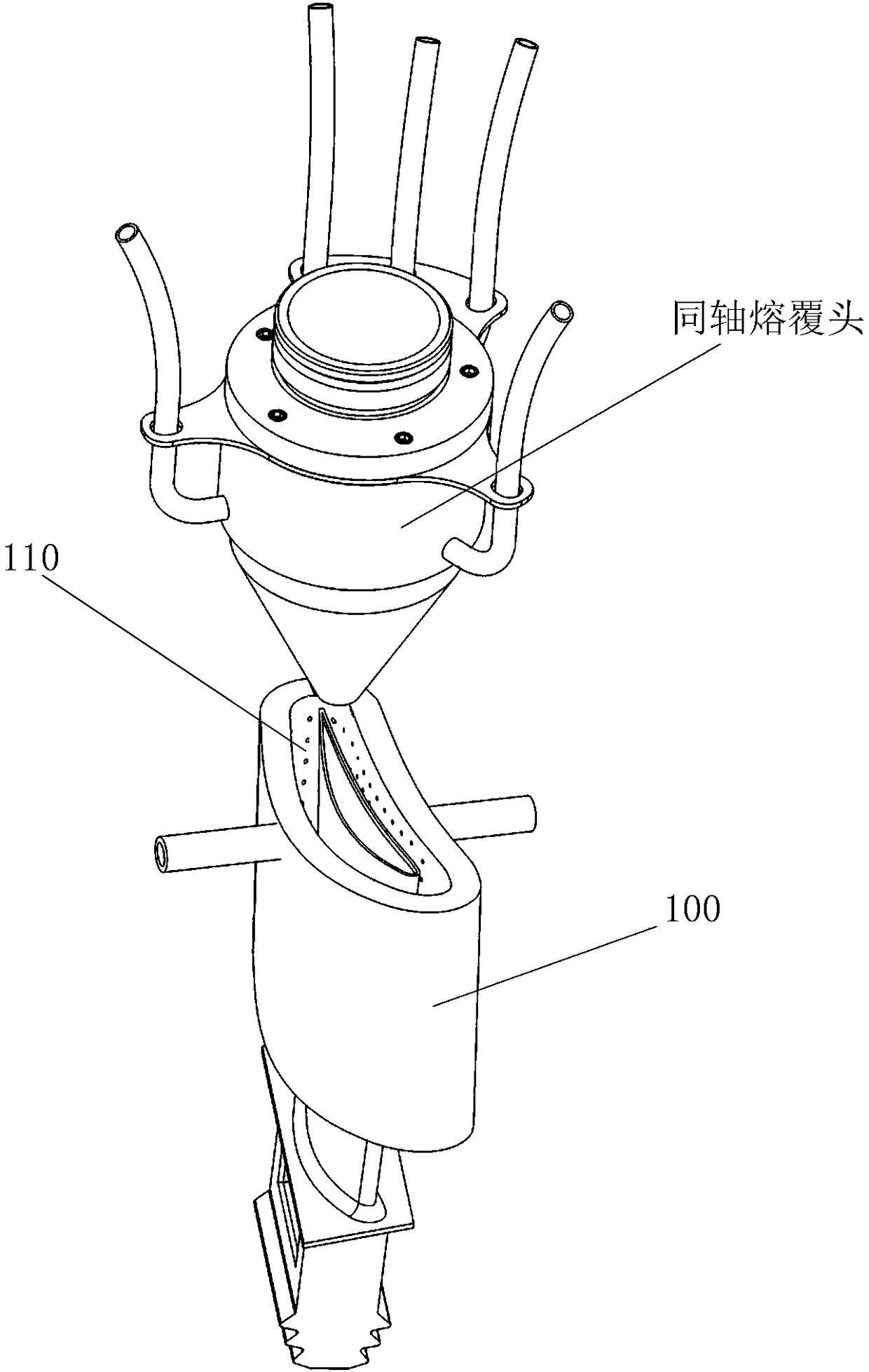

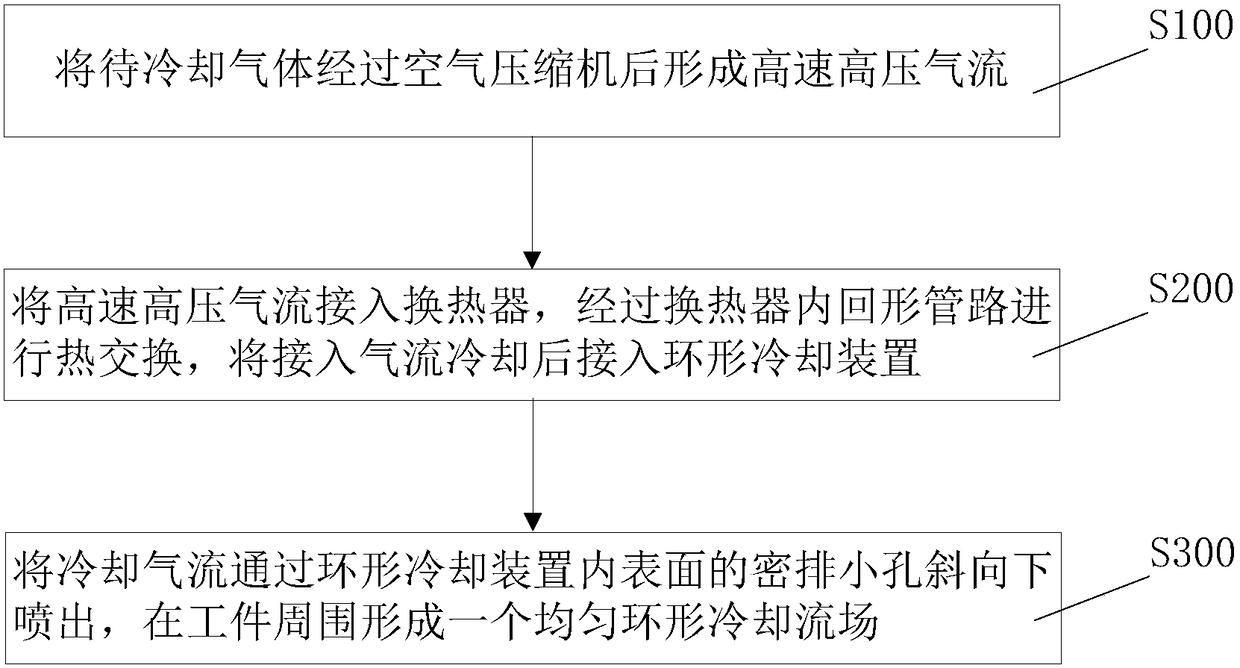

ActiveCN105671546ARaise the temperature gradientEnhanced Epitaxial Growth CapabilityFrom frozen solutionsMetallic material coating processesActive coolingTurbine blade

The invention provides an active cooling device and method for laser repairing of a single crystal turbine blade. The device comprises an air compressor, a heat exchanger and an annular cooling device. The air compressor compresses air to be cooled into high-speed and high-pressure airflow, and the airflow is introduced into the heat exchanger. After the introduced airflow is cooled by the heat exchanger, the airflow is introduced into the annular cooling device. The annular cooling device is arranged above a workbench of a laser cladding system and arranged around a workpiece. According to the active cooling device and method for laser repairing of the single crystal turbine blade, the volume and temperature of the cooled airflow and the position and angle of a cooling nozzle are adjusted, so that the best active cooling effect is achieved in the laser repairing process.

Owner:SHANGHAI JIAO TONG UNIV

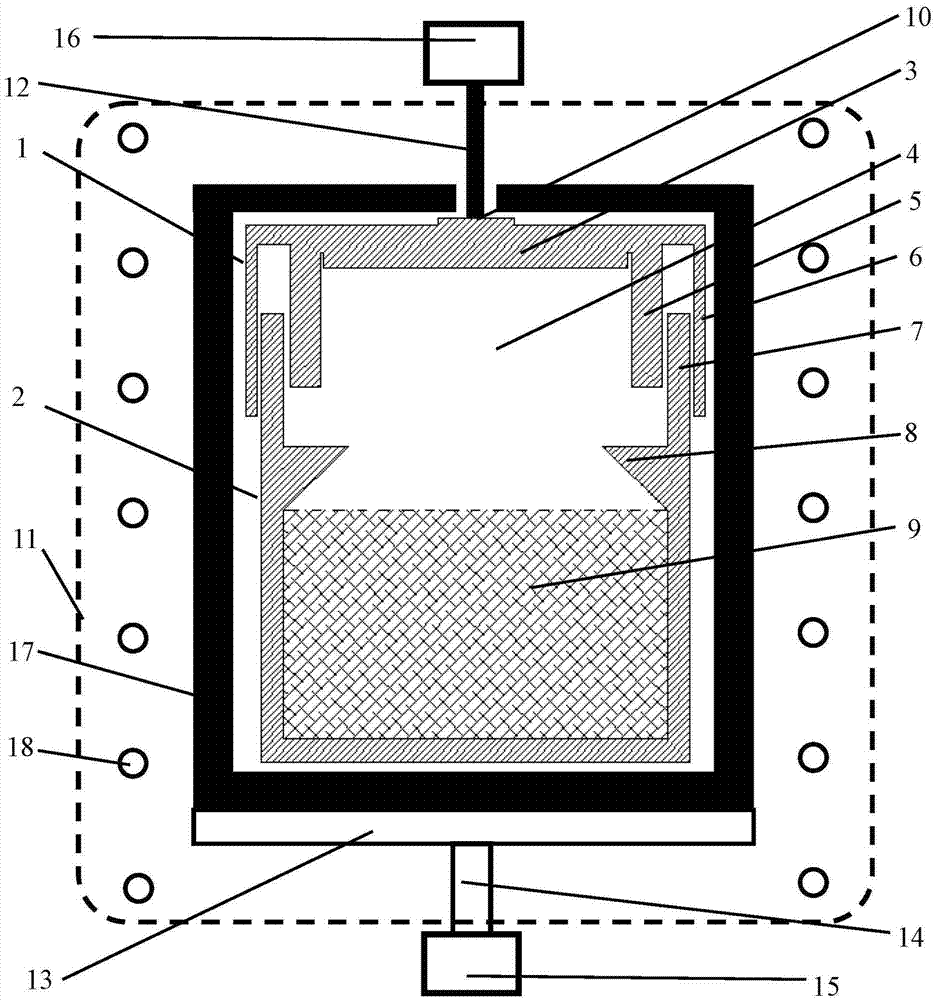

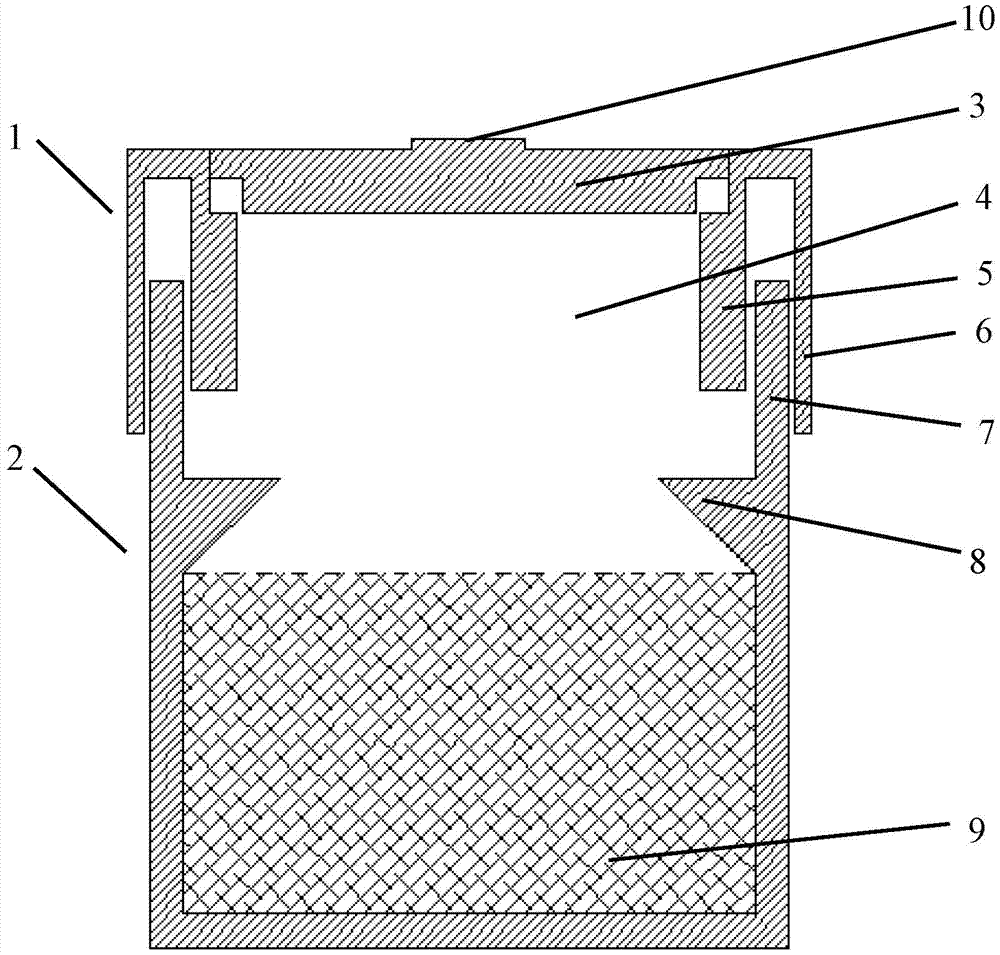

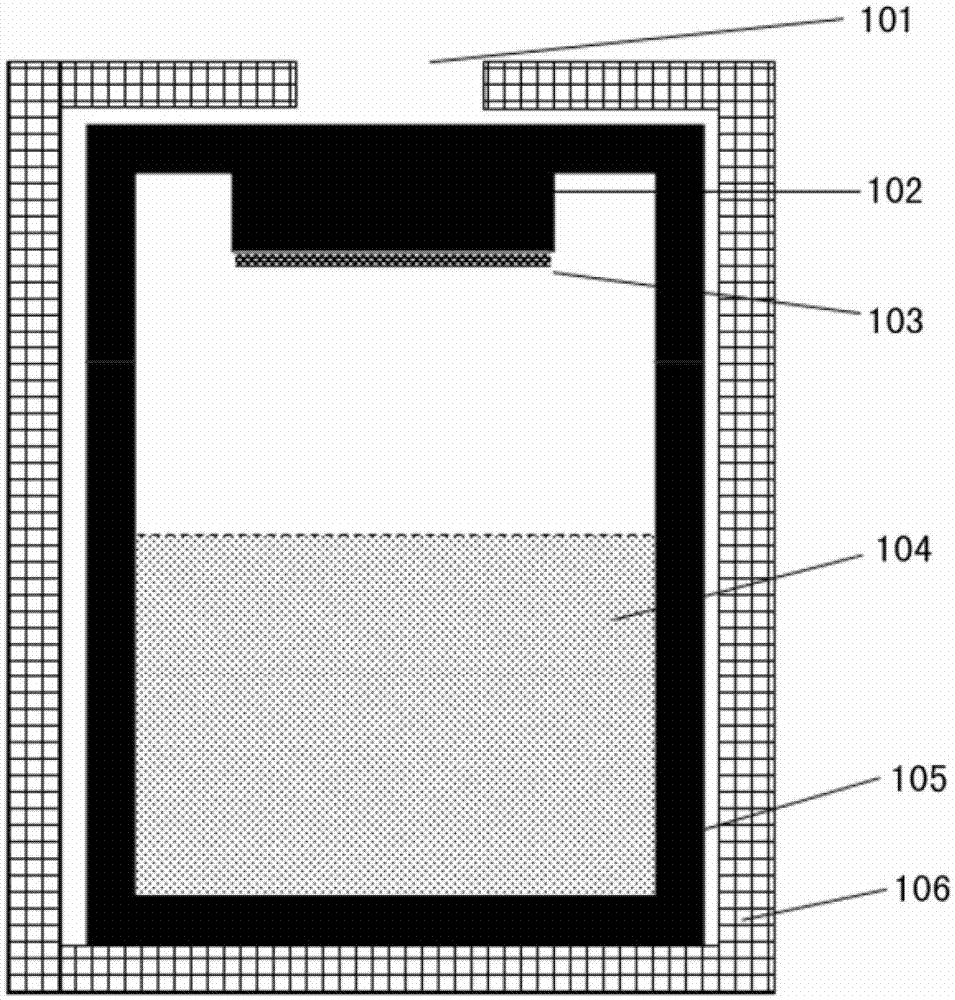

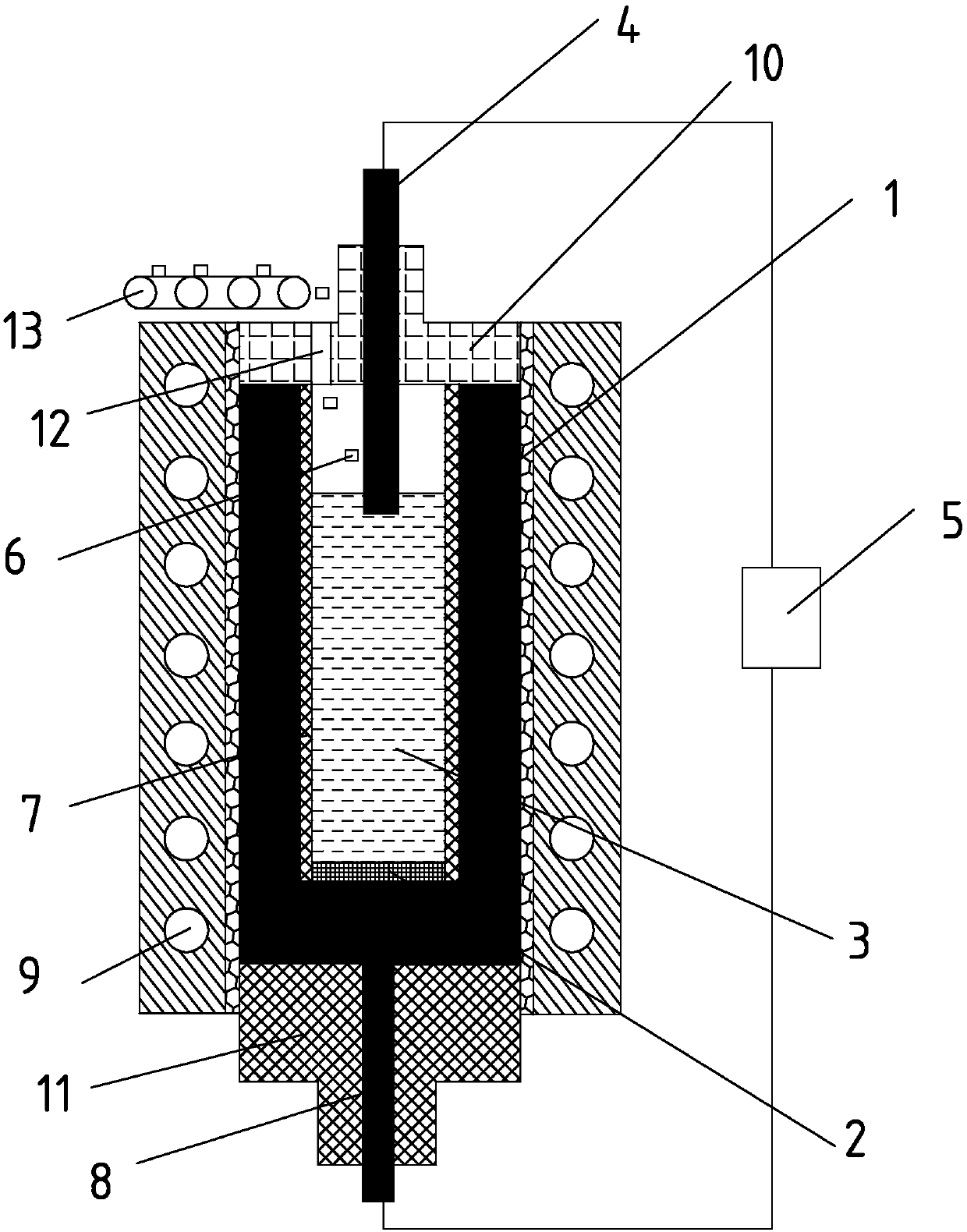

Split type crucible for crystal growth of silicon carbide

InactiveCN106929913AQuality improvementAvoid destructionPolycrystalline material growthFrom condensed vaporsCrucibleEngineering

The invention provides a split type crucible for crystal growth of silicon carbide. The crucible comprises the following components: a raw material chamber for containing raw materials for crystal growth of SiC; a growth chamber which is nested on the upper part of the raw material chamber in relative movement mode in order to form a crystallization area of crystal, wherein the growth chamber comprises a growth chamber, and a seed crystal holder which is arranged on a upper wall of the growth chamber; and a double layer structure which is formed by sidewalls of the growth chamber and comprises an inner cylinder and an outer cylinder. The crucible can be used for adjusting distance between the crystal surface and the raw material surface in a process of growth, and the stability of a temperature field is kept.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

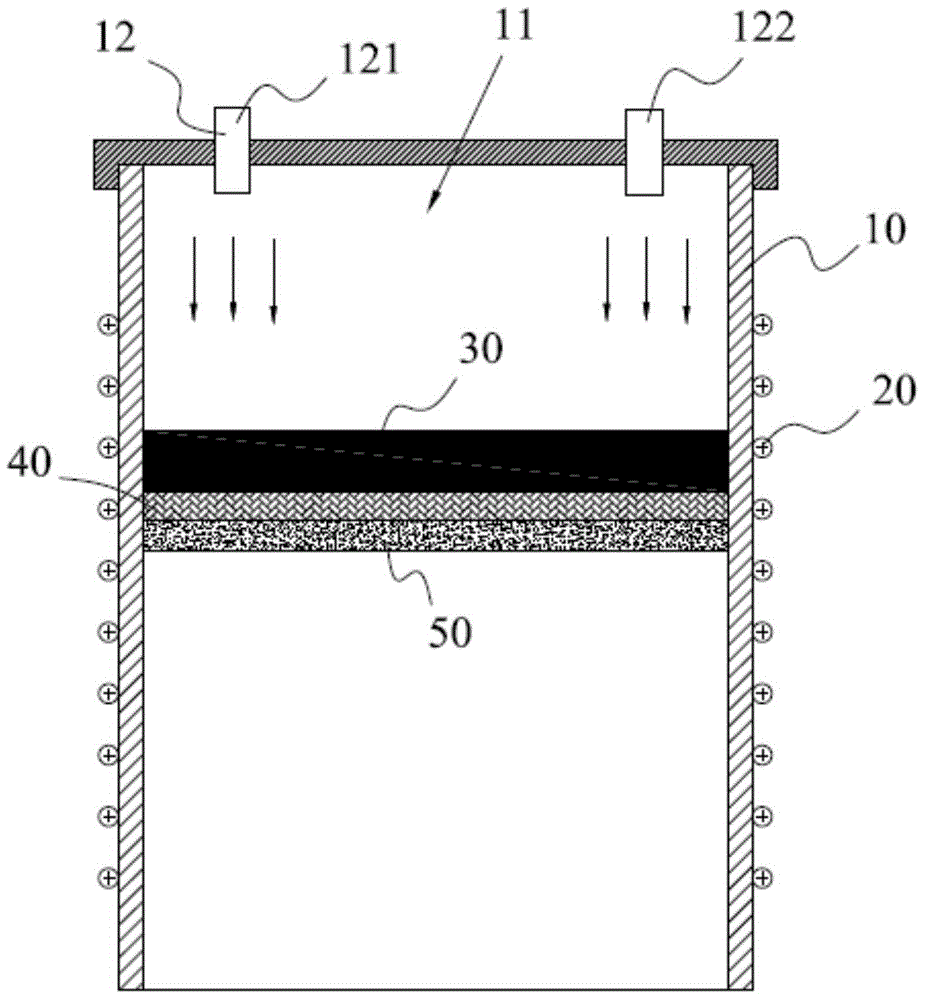

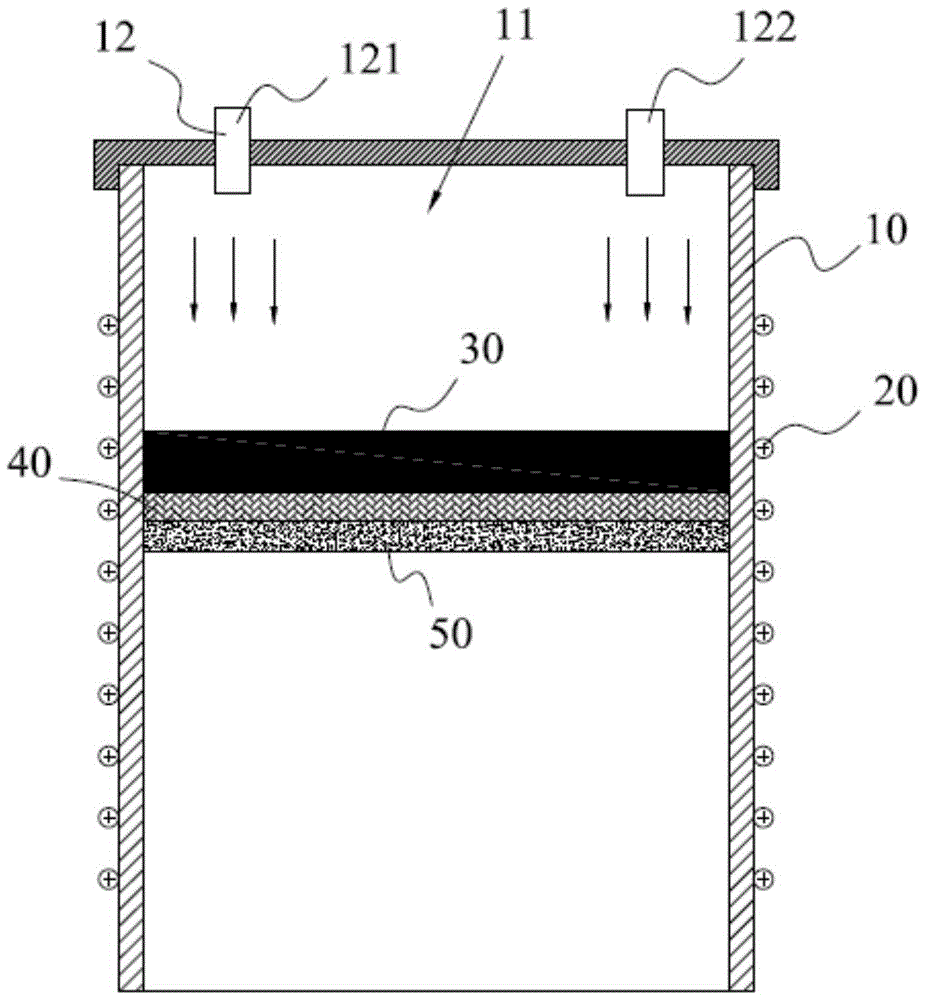

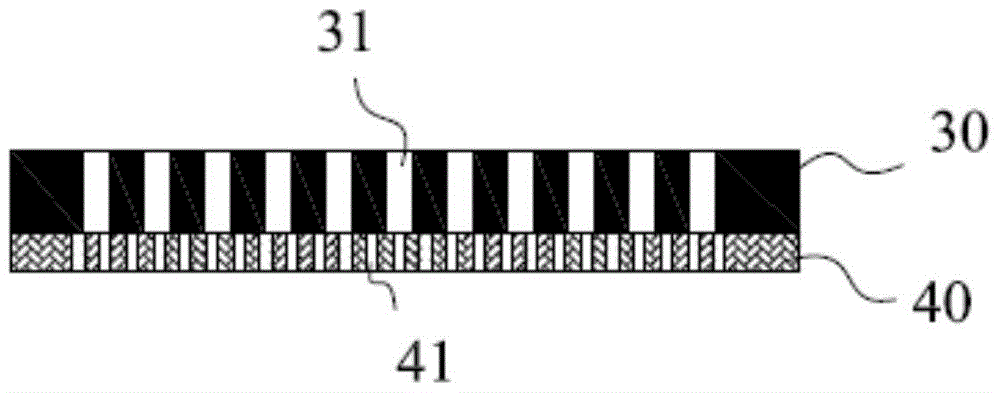

Microwave plasma chemical vapor deposition device and production method thereof

InactiveCN107227450ASimple structureReduce processing costsChemical vapor deposition coatingMicrowaveEngineering

The invention relates to a microwave plasma chemical vapor deposition device, which comprises a casing, a microwave input port is arranged on the upper surface of the casing, a substrate is arranged below the microwave input port, a loop antenna is arranged on the bottom surface of the substrate, and the connection between the substrate and the casing is A tubular microwave window made of microwave dielectric material is arranged in between, and a deposition platform is provided at the bottom of the shell, which is located below the loop antenna, and the deposition platform can move up and down driven by the first lifting device, and the deposition platform A plasma stabilizing ring with a tubular structure is arranged on the outer surface, and a closed resonant cavity is formed surrounded by the deposition table, the plasma stabilizing ring, the shell, the tubular microwave window and the substrate. The microwave plasma chemical vapor deposition device of the invention has the advantages of simple structure, low processing cost, high production efficiency and high quality of finished products. In addition, the present invention also designs the production method of the microwave plasma chemical vapor deposition device.

Owner:无锡远稳烯科技有限公司

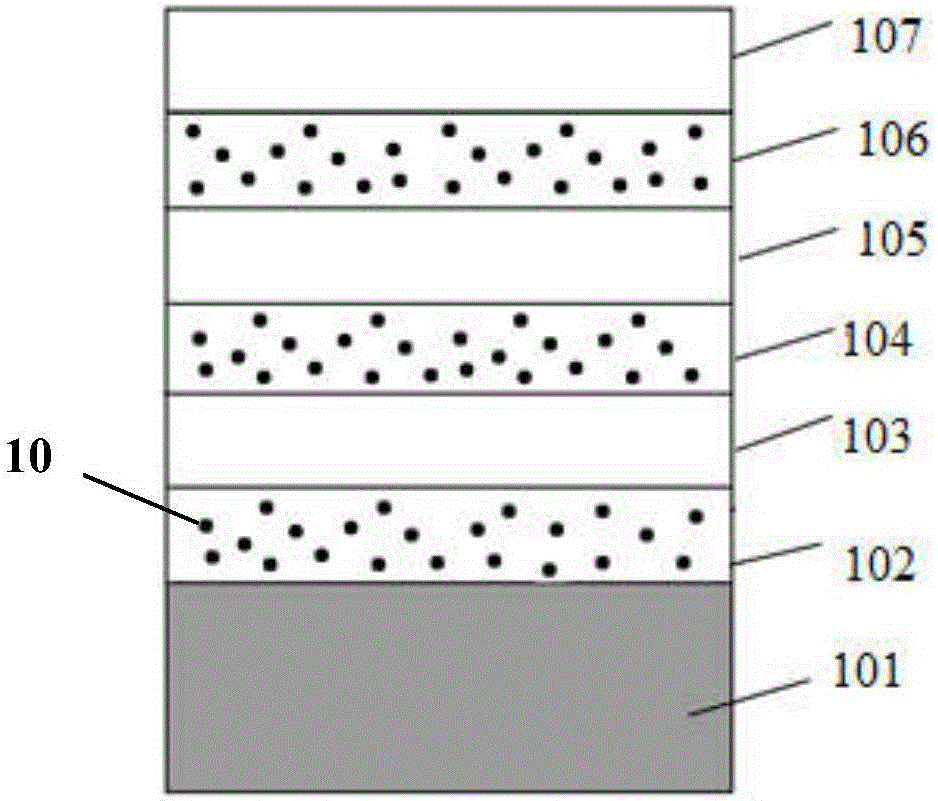

Tool provided with diamond/silicon carbide composite coating and preparation method thereof

ActiveCN106835064AEliminationHigh bonding strengthChemical vapor deposition coatingShear stressInterfacial binding

The invention provides a tool provided with a diamond / silicon carbide composite coating. The tool provided with the diamond / silicon carbide composite coating comprises a base body, and a multi-layer coating structure, wherein the multi-layer coating structure is arranged on the base body. The multi-layer coating structure comprises the silicon carbide / diamond composite coating and a diamond coating. The silicon carbide / diamond composite coating and the diamond coating are sequentially and alternately arranged upwards from the surface of the base body to form the multi-layer coating structure; and the diamond coating is arranged on the top layer of the multi-layer coating structure. Each layer of the multi-layer coating structure can achieve continuous growth of the diamond phase, and accordingly the interface bonding strength between the layers is strengthened, the internal stress of the coatings can be reduced effectively, the adhesion between a thin film and the base body can be strengthened, and particularly the multi-layer coating structure is beneficial for resisting the strong shear stress generated in the cutting process of the tool. In addition, the overall fracture toughness in the thickness direction of the coatings can be strengthened. The invention also provides a production method of the tool provided with the diamond coating.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

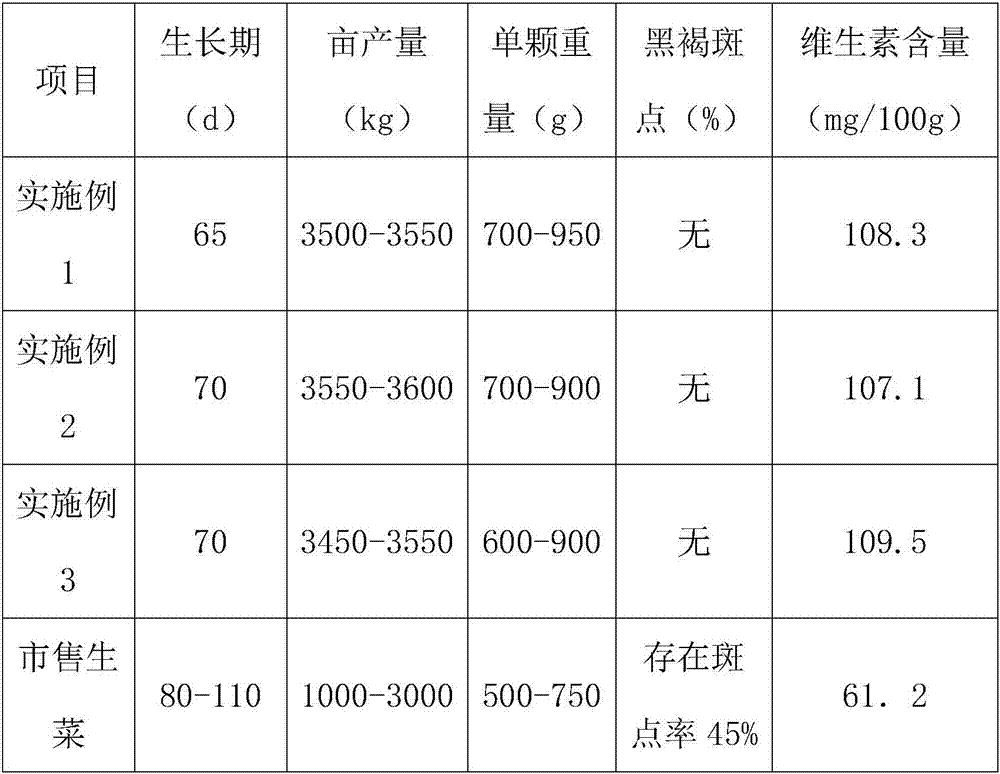

Lettuce plantation fertilizer and lettuce plantation method thereof

PendingCN107043298AReduce virus damageAvoid pollutionExcrement fertilisersBioloigcal waste fertilisersAmmonium sulfateNutrition

The invention discloses a lettuce plantation fertilizer and a lettuce plantation method thereof. The method is characterized in that plant leaves, sugarcane, urea, potassium dihydrogen phosphate, ammonium sulfate, calcium superphosphate, a carbendazim solution, a dimethomorph solution, and an antiviral preparation are mixed to prepare the fertilizer. The invention also provides a greenhouse plantation method by taking fermented bagasse as a main material and taking a phosphate fertilizer, a nitrogenous fertilizer, a potash fertilizer, polyether polyol and water as the auxiliary materials. The lettuce plantation fertilizer and the lettuce plantation method can guarantee the nutrition component required by the vegetation pollution due to an additional fertilizer applied during the lettuce plantation process can be avoided, humiture can be controlled by using greenhouse, virus disoperation is reduced; the lettuce plantation fertilizer has good water retention, can effectively reduce the water spray frequency, avoids the defect of seedling and transplant required during traditional plantation, shortens the growing period, realizes multiple plantation in one year, realizes a purpose of high yield, and has obvious effects for increasing yield, resisting virus, and disinfecting.

Owner:QINGDAO ACAD OF AGRI SCI

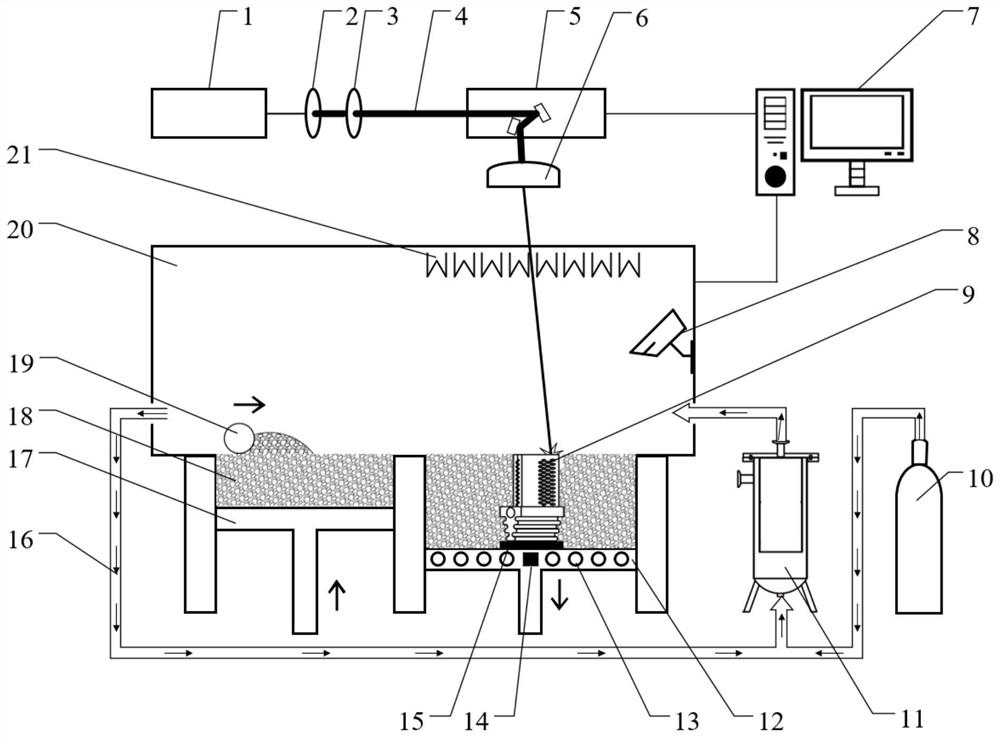

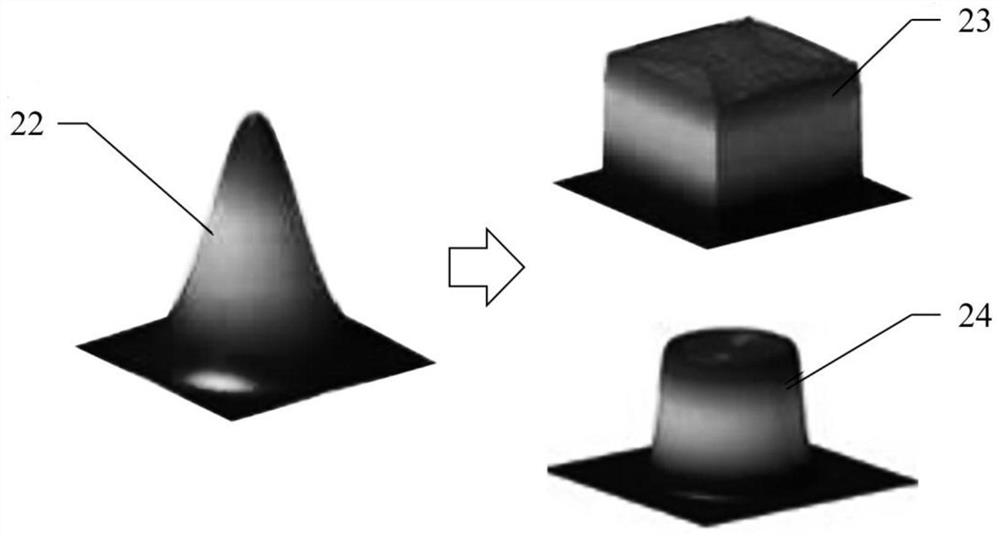

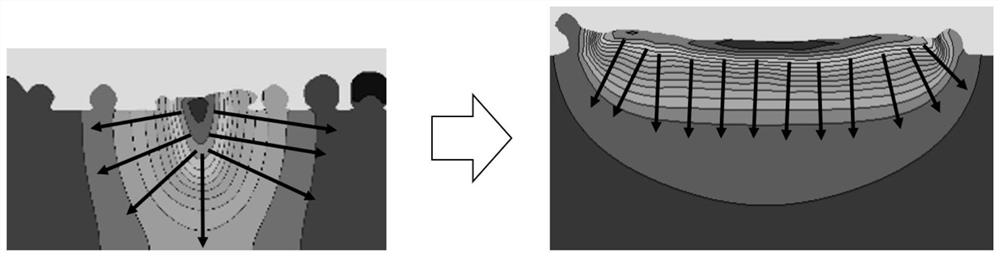

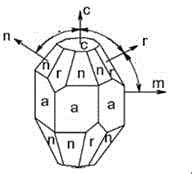

3D printing device and method for oriented crystal or single crystal high-temperature alloy and product

InactiveCN112893874AReduce energy variabilityReduce disruptionTurbinesPolycrystalline material growthSingle crystal superalloySingle crystal

The invention belongs to the related technical field of additive manufacturing, and discloses a 3D printing device and method for an oriented crystal or single crystal high-temperature alloy and a product. The device comprises a forming unit, a shape righting light path unit and a forced temperature difference unit; a DOE diffraction optical element is arranged in the shape righting light path unit, and the shape righting light path unit is used for converting laser spot energy generated by a laser emitting element into uniform distribution from Gaussian distribution; the forced temperature difference unit is arranged in the forming cavity and comprises an infrared heating pipe and a cooling pipeline, heating is conducted above a cooling substrate through the infrared heating pipe, cooling is conducted in the cooling substrate through the cooling pipeline, thus an environment temperature field with the temperature strictly and gradually reduced is formed above the cooling substrate, and then crystals grow in the opposite direction of gradually-reduced temperature when a molten pool is solidified. By means of the device and the method, the temperature gradient in the molten pool can be controlled from top to bottom strictly, mixed crystals such as isometric crystals and the like are reduced or even eliminated, and layer-by-layer stable epitaxial growth of oriented crystals or single crystals along [001] is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of epitaxially-growing silicon carbide-graphene film

InactiveCN106435723AReduce defectsQuality improvementPolycrystalline material growthFrom chemically reactive gasesHydrogen etchingCvd graphene

The invention relates to the technical field of function materials, in particular to a preparation method of an epitaxially-growing silicon carbide-graphene film. The preparation method of the epitaxially-growing silicon carbide-graphene film comprises steps as follows: (1) preparation of silicon carbide-graphene; (2) epitaxial growth of the silicon carbide-graphene film. Continuous growth of silicon carbide-graphene is realized, so that conventional common steps of hydrogen etching and silicon enrichment reproduction required for growing graphene on silicon carbide are omitted, the phenomena of lattice imperfection and severe reduction of surface silicon enrichment due to hydrogen etching are reduced, and graphene has fewer defects, has about four layers distributed uniformly and has better crystal quality.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

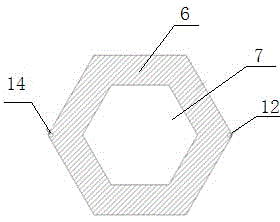

Growth device for sapphire crystal hemisphere cover and growth method for sapphire crystal hemisphere cover

InactiveCN104862775AAvoid situations where the interior of the growth interface cannot be cooled uniformlyImprove qualityPolycrystalline material growthBy pulling from meltCrucibleGas cooler

The invention relates to a growth device and a growth method for a sapphire crystal hemisphere cover by employing an edge-defined film-fed crystal growth method. The method specifically comprises the following main steps: respectively introducing a protective gas and a cooling gas into a crystal growth furnace and a cooler pan; heating the crystal growth furnace until a high-purity aluminum oxide material is fused; adjusting a hoist pan, so that aluminum oxide melt ascends to the top end of a mold along a center through hole and an annular capillary fissure in the symmetric axis of the mold; descending seed crystal to fuse with the aluminum oxide melt; under the action of affinity and surface tension, enhancing radiation heat exchange between a growth interface and the gas cooler pan by adjusting the flow of the cooling gas in the cooler pan, so as to quicken the expansion of the crystal; and finally limiting the expansion of the crystal by the top edge of the mold. The growth device has the advantages that supply of the melt in the mold is adjusted by controlling the relative positions of the mold and the crucible; continuous providing of the melt in the capillary fissure is ensured, so as to realize continuous growth; and a hexagonal annular cooler pan is prevented from being carbonized to deform by employing the cooling gas.

Owner:JIANGSU CEC ZHENHUA CRYSTAL TECH

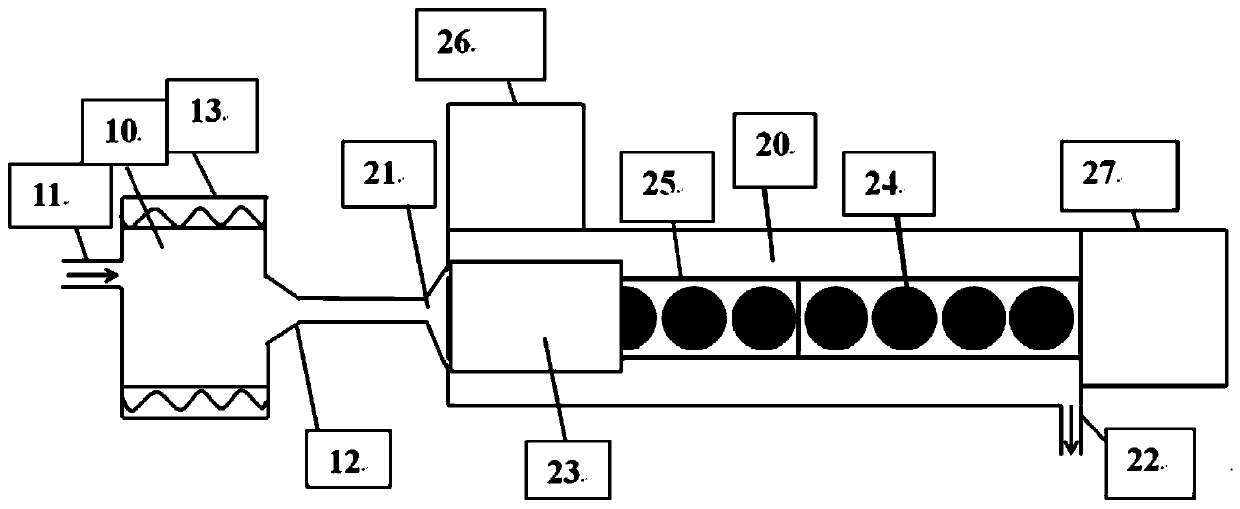

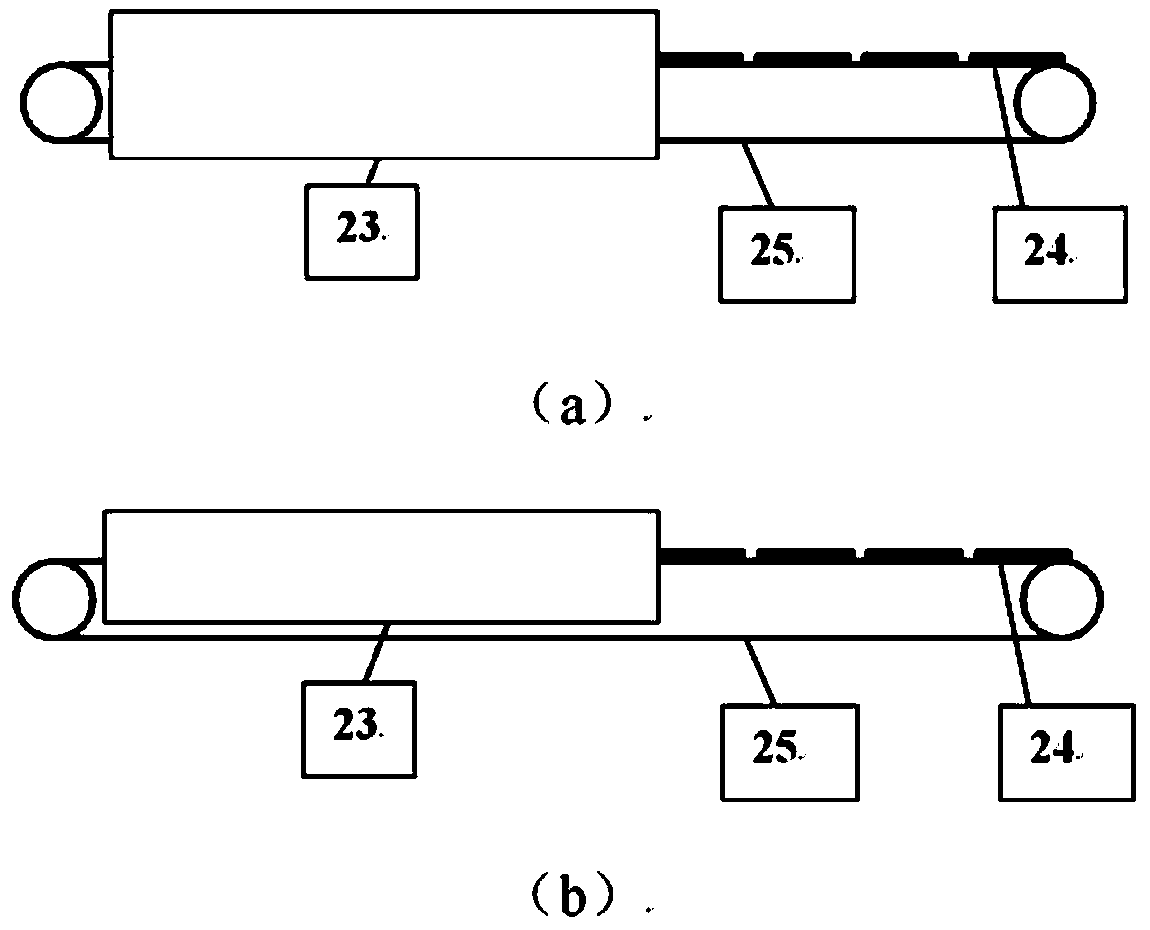

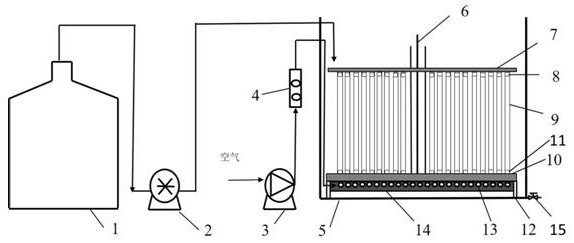

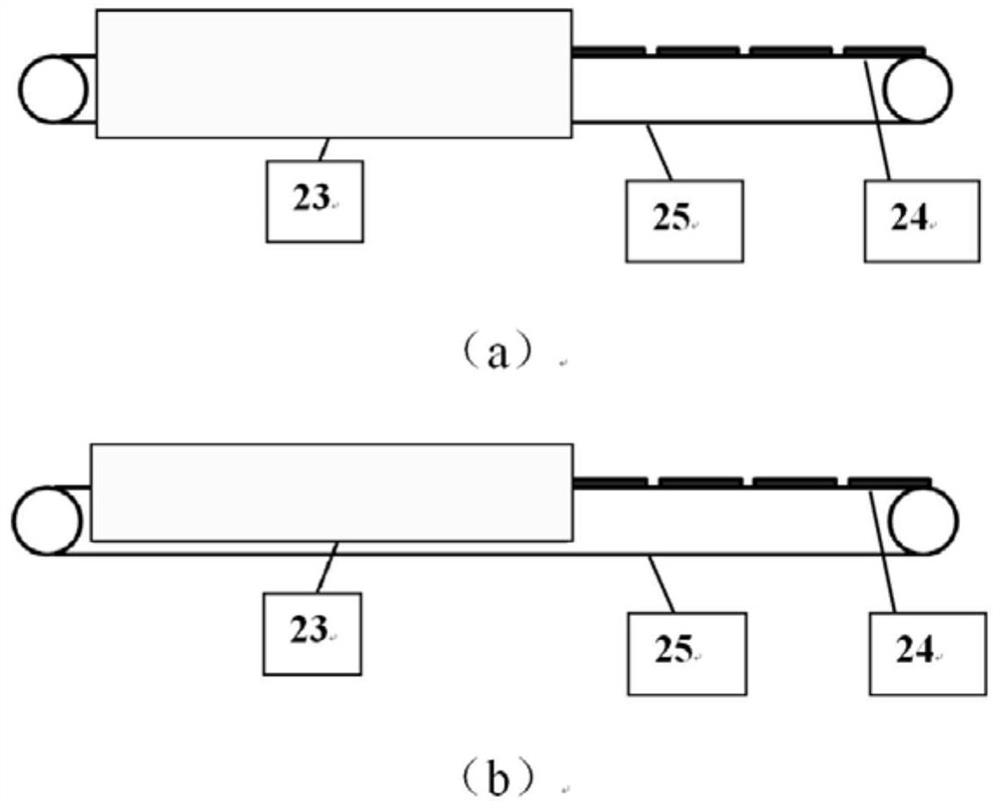

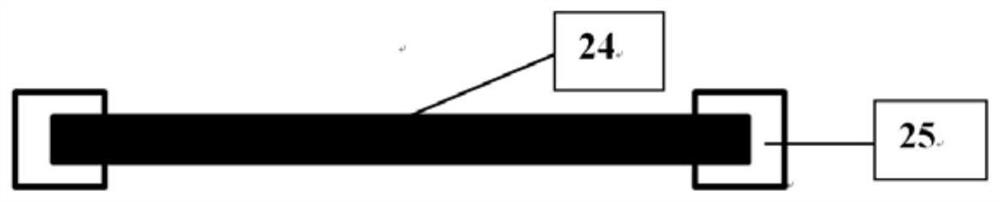

Carbon nanotube continuous lot production equipment

The invention belongs to the technical field of carbon nanotubes and especially relates to carbon nanotube continuous lot production equipment comprising a carbon source cracking apparatus and a carbon nanotube growing apparatus. The carbon source cracking apparatus includes a carbon source cracking chamber, a first heating assembly, a carbon source gas inlet and a carbon source gas outlet; the carbon nanotube growing apparatus includes: a carbon nanotube growing chamber, a transfer assembly, a second heating assembly, a gas inlet and a gas outlet. The transfer assembly is used for continuously transferring a carbon nanotube growing substrate. The carbon source gas outlet is communicated with the gas inlet of the carbon nanotube growing apparatus. The first heating assembly provides cracking temperature for the carbon source cracking chamber. The second heating assembly is provided with a heating channel. The transfer assembly penetrates through the heating channel. The heating channelis used for heating the carbon nanotube growing substrate entering the heating channel.

Owner:SHENZHEN XIWAN TECH CO LTD

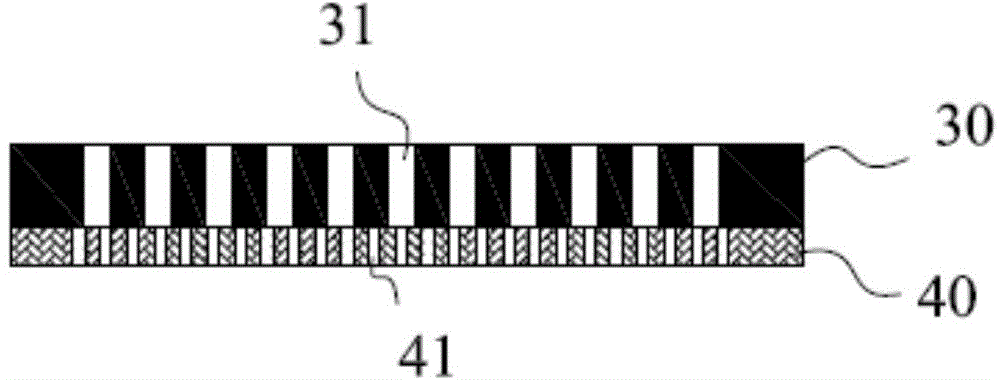

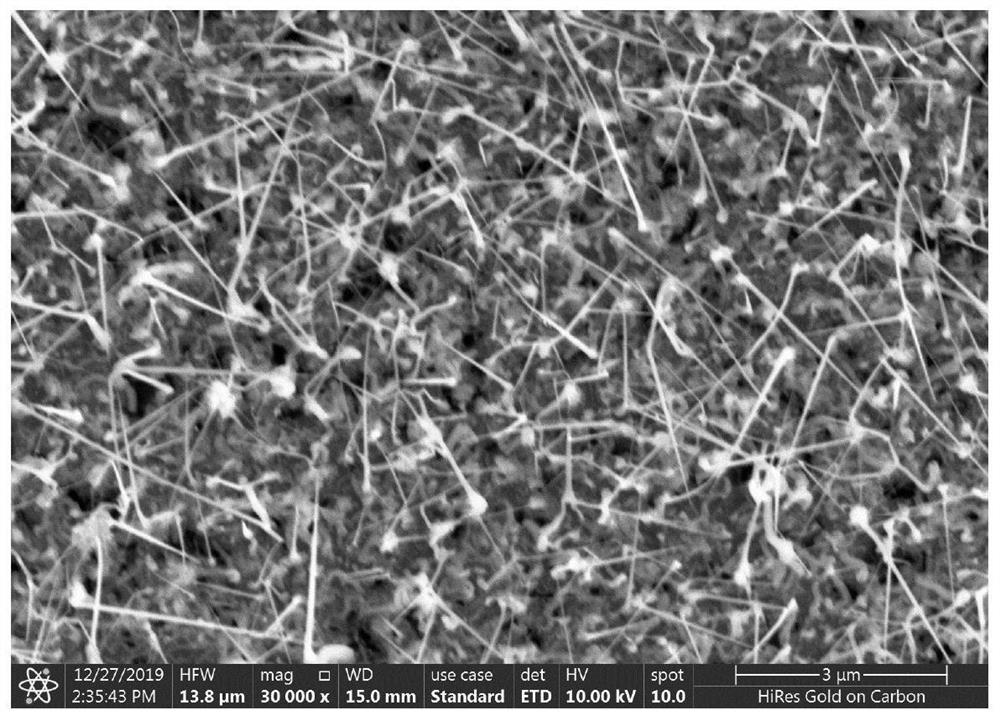

Continuous growth device for carbon nano-tube

ActiveCN104418318AAchieve continuous growthImprove growth efficiencyMaterial nanotechnologyPorous substrateCarbon nanotube

The invention discloses a continuous growth device for a carbon nano-tube. The continuous growth device comprises a heating room, a substrate, a catalyst film and a heating device, wherein the heating room is provided with a heating chamber, and a vent hole communicated to the heating chamber is formed in the heating room; the substrate is located inside the heating chamber, the catalyst film is formed on the surface of the substrate, first through holes are formed in the substrate, and the catalyst film comprises second through holes communicated to the first through holes; and the heating device is used for heating the heating chamber. The plurality of holes in the porous substrate are communicated with the plurality of holes in the catalyst film located below the porous substrate, and reactant gas is introduced from the upper part of the porous substrate and can continuously flow into the plurality of holes in the catalyst film through the plurality of holes in the substrate, so that the carbon nano-tube can continuously grow. Preferably, the growth direction of the carbon nano-tube in an improved device is changed to be vertical and downward, therefore, compared with the growth speed of the carbon nano-tube which vertically and upwards grows, the growth speed is increased under the action of gravity, and furthermore, the technical effect of continuous and rapid growth is achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method of single-layer transition metal sulfide

InactiveCN110607561AIncrease the saturated vapor pressureAchieve continuous growthPolycrystalline material growthFrom condensed vaporsPhysical chemistryMetallic sulfide

The invention provides a preparation method of single-layer transition metal sulfide. The preparation method comprises the following steps: mixing transition metal sulfide and alkali metal halide, andheating the mixture at high temperature to obtain the single-layer transition metal sulfide. According to the method, the alkali metal halide is used for assisting growth, the alkali metal halide andthe transition metal sulfide are heated to form the eutectic body, the saturated vapor pressure of the transition metal sulfide is increased; and continuous growth of large-area single-layer transition metal sulfide and controllable growth of a single domain region can be achieved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

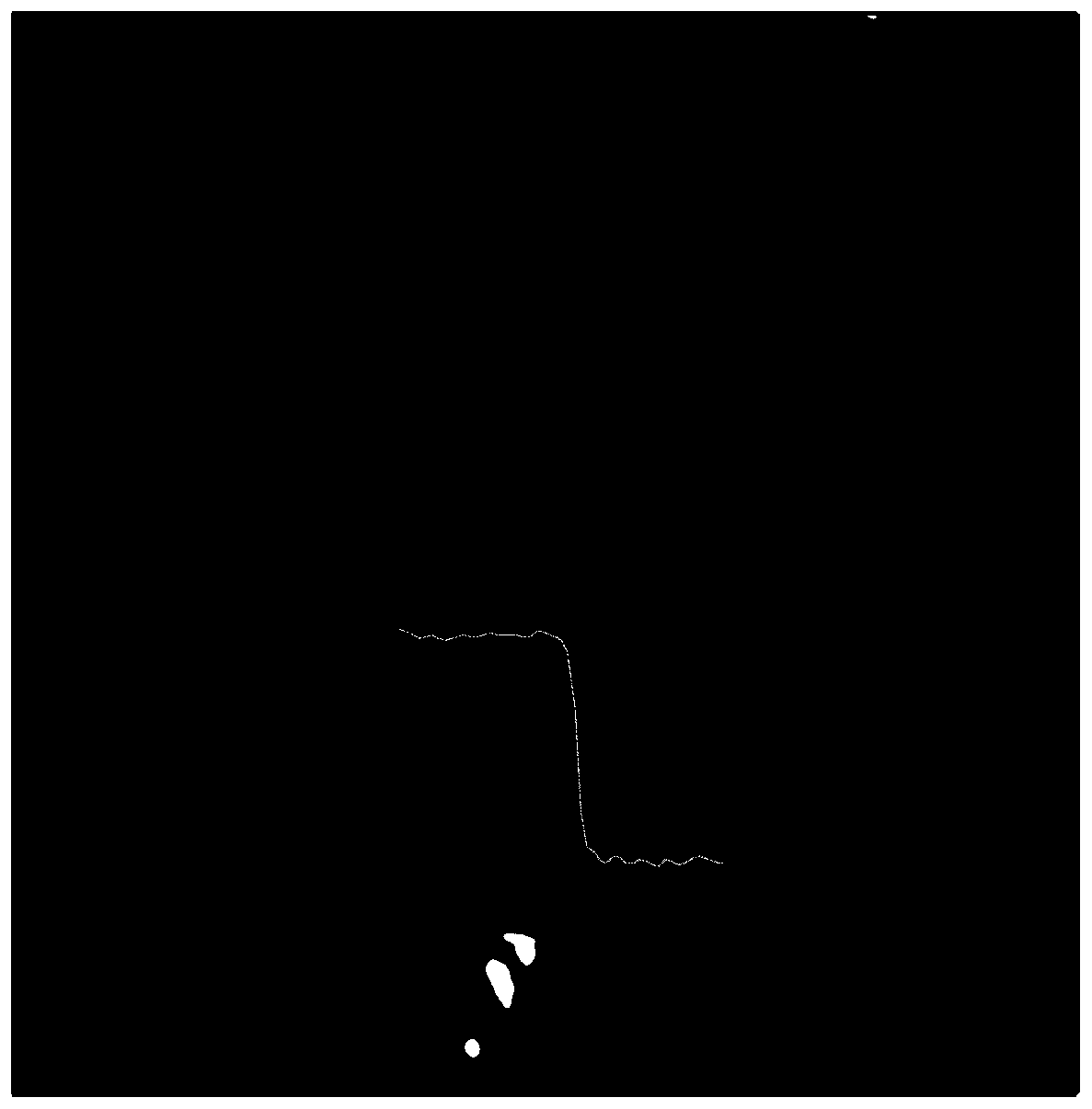

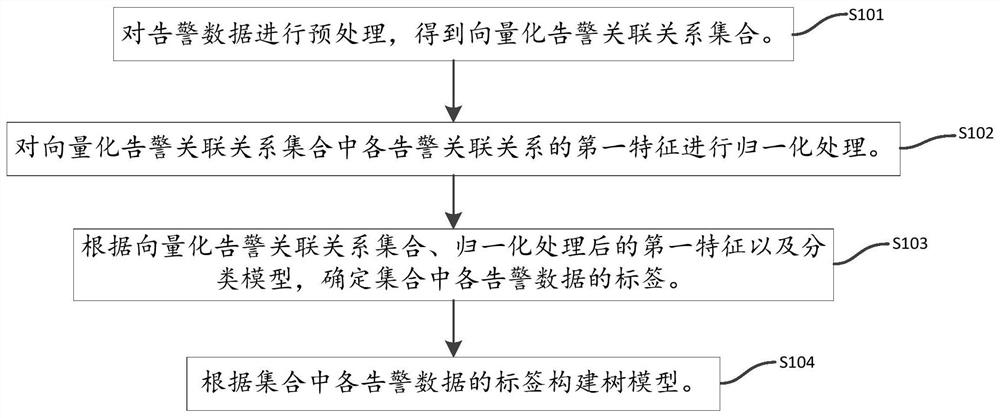

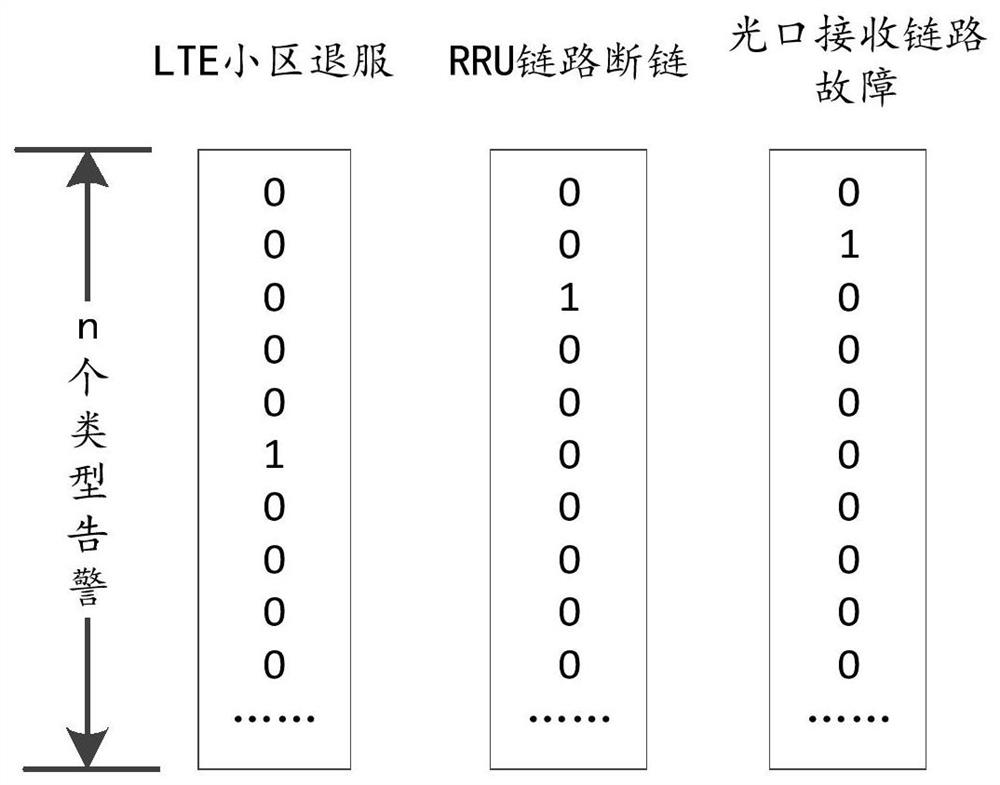

Tree model construction method and device, equipment and storage medium

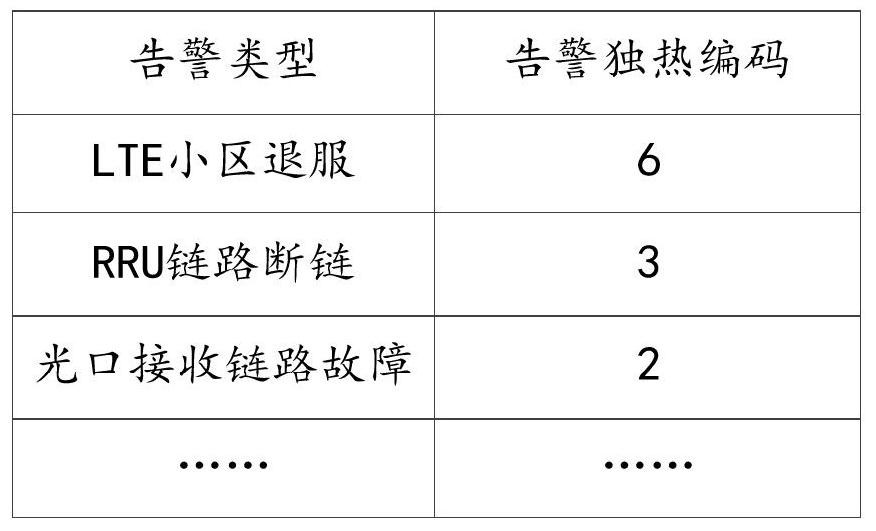

PendingCN113839802AAchieve continuous growthCharacter and pattern recognitionData switching networksEngineeringLearning analytics

The invention discloses a tree model construction method and device, equipment and a storage medium, and belongs to the technical field of data analysis and processing. The method comprises the following steps: pre-processing alarm data to obtain a vectorized alarm association relationship set; performing normalization processing on the first feature of each alarm association relationship in the vectorized alarm association relationship set; according to the vectorized alarm association relationship set, the normalized first feature and a classification model obtained by training, determining a label of each alarm data in the set; and constructing a tree model according to the label of each alarm data in the set. In this way, the primary and secondary incidence relation between alarms can be expressed through the tree model, the alarm data are learned and analyzed based on the classification model obtained through training, the corresponding tree model is dynamically generated, and therefore continuous growth of the tree is achieved.

Owner:ZTE CORP

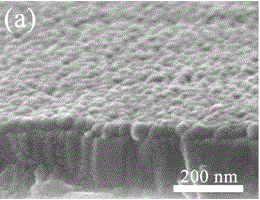

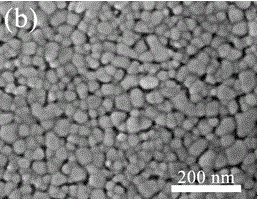

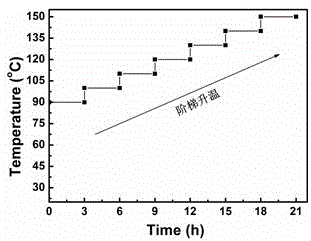

Preparation method of zinc oxide nanorod array thin film

InactiveCN103397382BImprove UV Luminescence PerformanceHigh UV Luminescence PerformancePolycrystalline material growthAfter-treatment detailsNanogeneratorHexamethylenetetramine

The invention belongs to the technical field of semiconductor film preparation, and particularly relates to a preparation method of a zinc-oxide nanorod array film. The technical scheme adopted by the invention is as follows: the preparation method comprises the following steps of: (1) on the basis of adopting height (001)-oriented ZnO as a seed layer, putting the ZnO seed layer into an aqueous solution of zinc nitrate (Zn(NO3)2), polyethyleneimine (PEI) and hexamethylenetetramine (HMT) for epitaxial growth to obtain a (001) preferred-orientation ultralong ZnO nanorod array film; (2) carrying out fast annealing treatment on the film, and improving the photoluminescence performance of the ZnO array film. The technology has the advantages that the continuous growth of the ZnO nanorod at the temperature higher than 100 DEG C can be realized; due to the high-temperature growth condition, the crystallization quality of the nanorod is improved, the internal defects are obviously reduced; the zinc-oxide nanorod array film has excellent photoelectric performance, and is more conductive to being applied in photoelectric devices such as dye-sensitized solar batteries, ultraviolet detectors, field-effect transistors, light-emitting diodes and nanogenerators.

Owner:UNIV OF JINAN

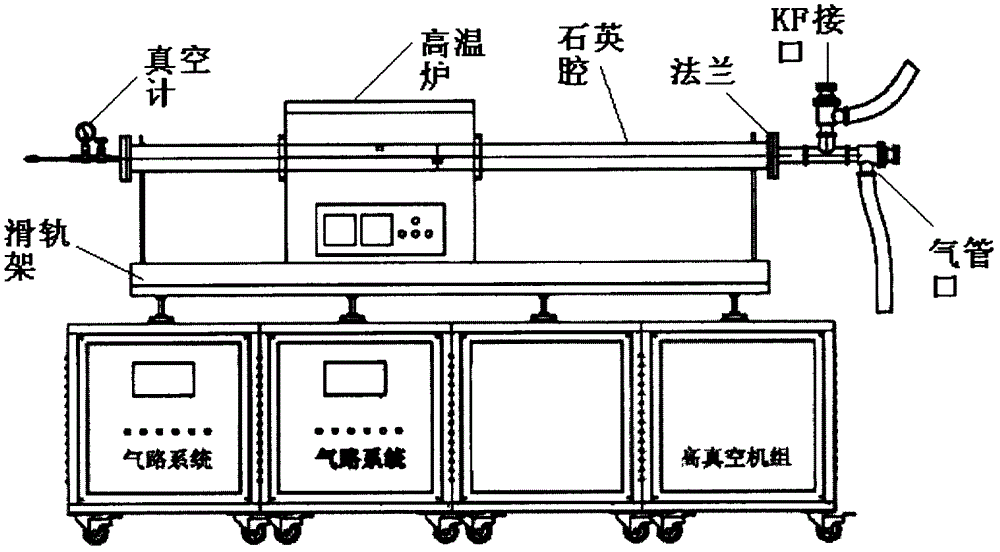

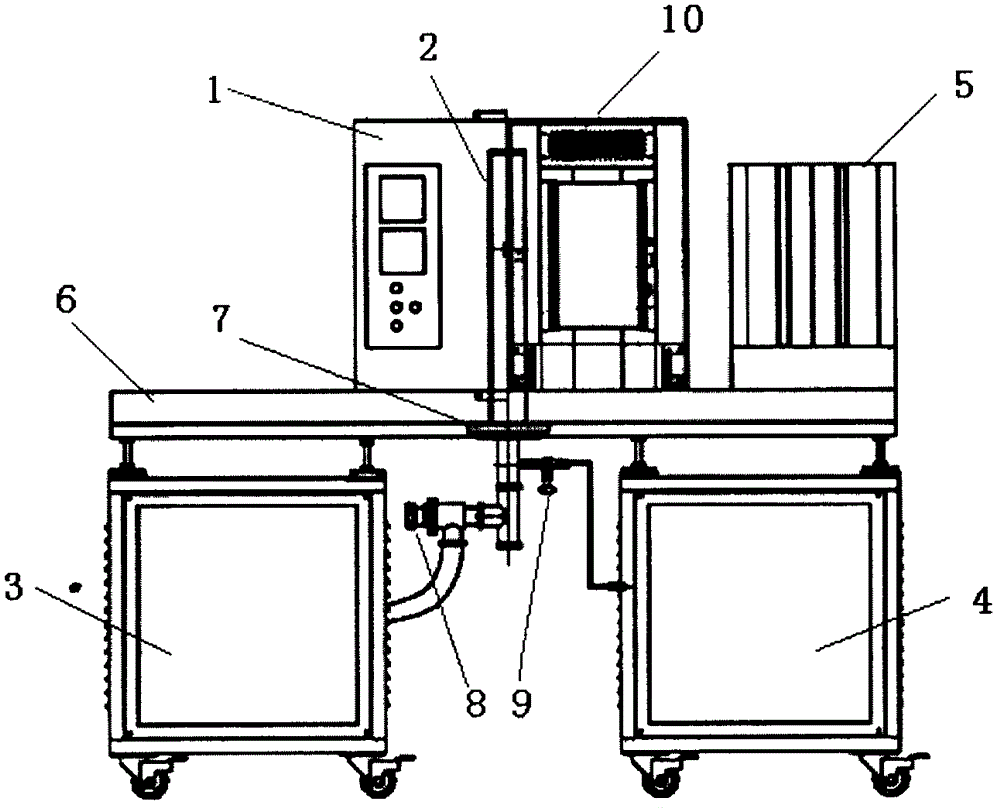

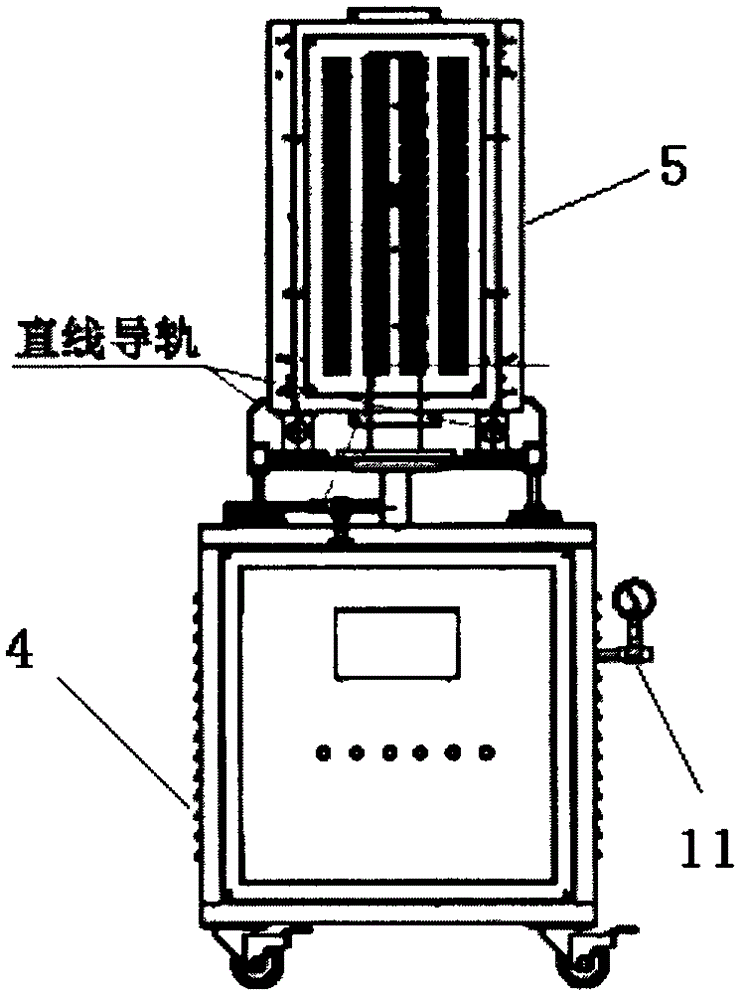

Graphene device capable of achieving continuous growth

InactiveCN104860305AAchieve continuous growthSolve the problem of rapid coolingLiquid nitrogen coolingGraphene

The invention discloses a graphene device capable of achieving continuous growth, and relates to the technical field of graphene. The graphene device comprises a high temperature furnace, a quartz cavity, a high vacuum unit, a gas path system, a liquid nitrogen cooling box and a sliding rail support, wherein the quartz cavity is perpendicularly fixed at the middle end of the sliding rail support, the high temperature furnace and the liquid nitrogen cooling box are installed on the left and right ends of the sliding rail support respectively and both connected with the sliding rail on the sliding rail support in a sliding manner, and the high temperature furnace adopts a vertical folio structure. The graphene device can achieve the integration and automation of quick warming and quick cooling, and solves the quick cooling problem after the graphene material is subjected to high temperature treatment; the vertical movable furnace structure allows the quartz cavity to be shorter, thus being compact in structure, and capable of achieving vertical replacement of growing cavities and achieving continuous growth.

Owner:ANHUI BEQ EQUIP TECH

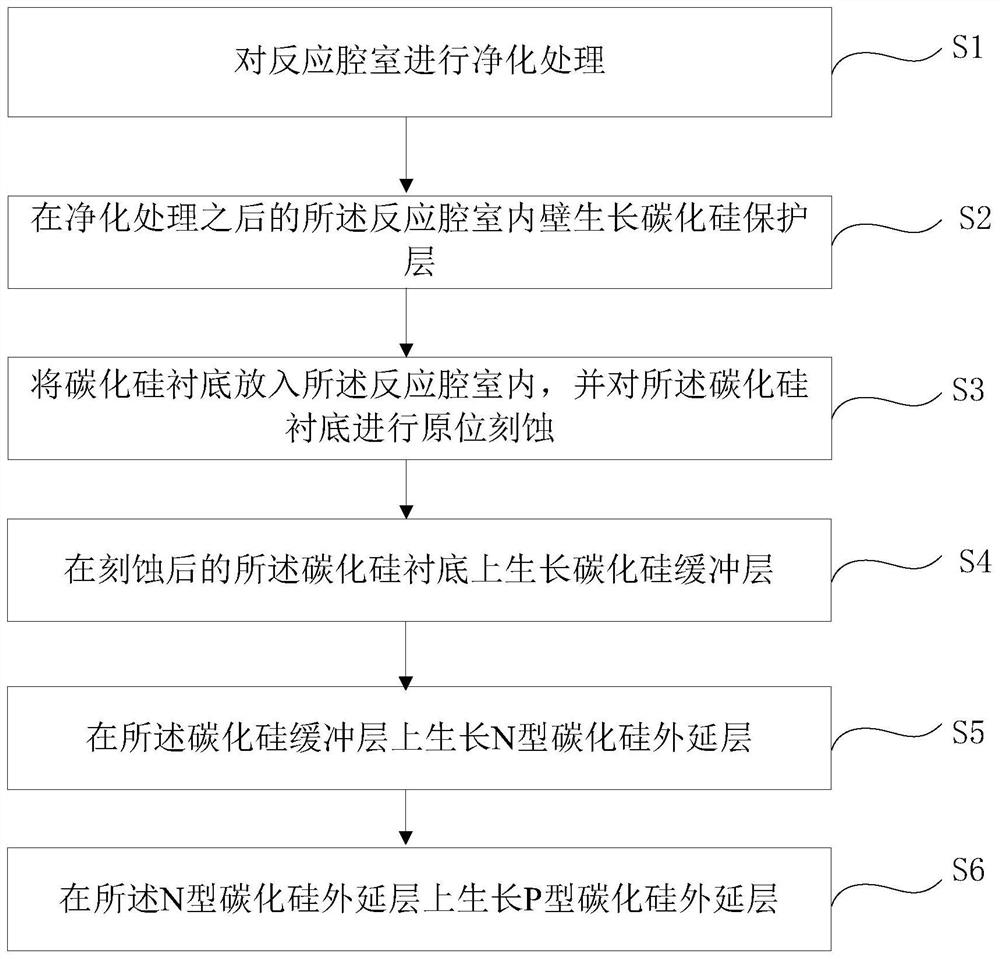

Preparation method of silicon carbide epitaxial structure and semiconductor equipment

PendingCN112885709AReduce surface defectsGrowth impactSemiconductor/solid-state device manufacturingCarbide siliconMetallurgy

The invention provides a preparation method of a silicon carbide epitaxial structure. The preparation method comprises the following steps: purifying a reaction chamber; growing a silicon carbide protection layer on the inner wall of the reaction chamber after purification treatment; putting a silicon carbide substrate into the reaction chamber, and performing in-situ etching on the silicon carbide substrate; growing a silicon carbide buffer layer on the etched silicon carbide substrate; growing an N-type silicon carbide epitaxial layer on the silicon carbide buffer layer; and growing a P-type silicon carbide epitaxial layer on the N-type silicon carbide epitaxial layer. The preparation method is simple, growth of epitaxial layers of different doping types can be completed in the same chamber, continuous growth of the epitaxial layers of different doping types is achieved, surface defects of a silicon carbide epitaxial structure are reduced, and the yield of silicon carbide devices is improved.

Owner:CEC COMPOUND SEMICON CO LTD

Active cooling device and cooling method for laser repairing single crystal turbine blade

ActiveCN105671546BRaise the temperature gradientEnhanced Epitaxial Growth CapabilityFrom frozen solutionsMetallic material coating processesActive coolingTurbine blade

The invention provides an active cooling device and method for laser repairing of a single crystal turbine blade. The device comprises an air compressor, a heat exchanger and an annular cooling device. The air compressor compresses air to be cooled into high-speed and high-pressure airflow, and the airflow is introduced into the heat exchanger. After the introduced airflow is cooled by the heat exchanger, the airflow is introduced into the annular cooling device. The annular cooling device is arranged above a workbench of a laser cladding system and arranged around a workpiece. According to the active cooling device and method for laser repairing of the single crystal turbine blade, the volume and temperature of the cooled airflow and the position and angle of a cooling nozzle are adjusted, so that the best active cooling effect is achieved in the laser repairing process.

Owner:SHANGHAI JIAOTONG UNIV

A reactor for static culture and continuous growth of aerobic filamentous biofilm

ActiveCN109354208BImprove liquidityAvoid shearingBiological treatment apparatusSustainable biological treatmentPeristaltic pumpBiofilm

The invention discloses a reactor for realizing static culture and continuous growth of aerobic filamentous biofilm, which comprises a feed tank, a peristaltic pump, an aeration pump, a gas flow meter, a reaction tank, a carrier bracket, an upper partition, an upper conduit, Vessel carrier, lower baffle, downcomer, support, microporous aeration tube, enclosure; the gas pumped by the present invention enters the microporous aeration tube through the adjustment of the gas flow meter to form air bubbles, enclosure and support The bubbles are gathered, and the bubbles pass through the hollow channel formed by the downcomer, the vascular carrier, and the upper catheter, which promotes and drives the waste water to flow upward through the inside of the vascular carrier, avoiding the direct impact of the air bubbles and waste water on the aerobic filamentous biofilm, and realizing the reactor The aerobic filamentous biofilm in the vascular carrier obtains oxygen and nutrients from the inside of the vascular carrier, thereby avoiding the aging and death of the filamentous biofilm close to the vascular carrier in the reactor due to hypoxia and nutrition, and solving the problem of filamentous The problem of complete detachment of biofilms from vascular supports.

Owner:KUNMING UNIV OF SCI & TECH

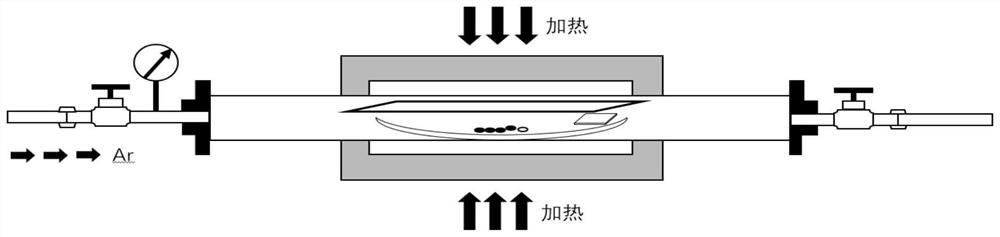

Preparation method of germanium and tin nano material under normal pressure

ActiveCN111893454AFast preparationContinuous productionFinal product manufactureNanotechnologyPtru catalystMetal catalyst

The invention provides a preparation method of a germanium and tin nano material under normal pressure, and belongs to the technical field of semiconductor nano materials. The preparation method comprises the following steps that S1, a silicon wafer is taken, and a metal catalyst is sprayed to the surface of the silicon wafer to achieve treatment; and S2, the silicon wafer treated in the step S1 is flatly placed at one end in a round-bottom porcelain boat, the face, with the metal catalyst sprayed, of the silicon wafer is upward, germanium powder and tin powder with the mass ratio being (20-10):1 are put at the other end in the round-bottom porcelain boat, the round-bottom porcelain boat is placed in a heating cavity of a tube furnace, inert gas is continuously introduced into the end withthe germanium powder and the tin powder with the gas flow being 200 sc.cm, after the temperature of the tube furnace is increased to 800-850 DEG C from the room temperature with the rate of 5 DEG C / min, heat preservation is carried out for 50 min to 110 min, then the temperature is reduced to the room temperature with the rate of 5 DEG C / min, and the germanium and tin nano material is obtained onthe surface of the silicon wafer. By means of the preparation method, the germanium and tin nano material can be rapidly and directly prepared, no waste gas treatment is needed in the whole preparation process, continuous production can be achieved, equipment is simple, and operation is easy.

Owner:SHAANXI UNIV OF SCI & TECH

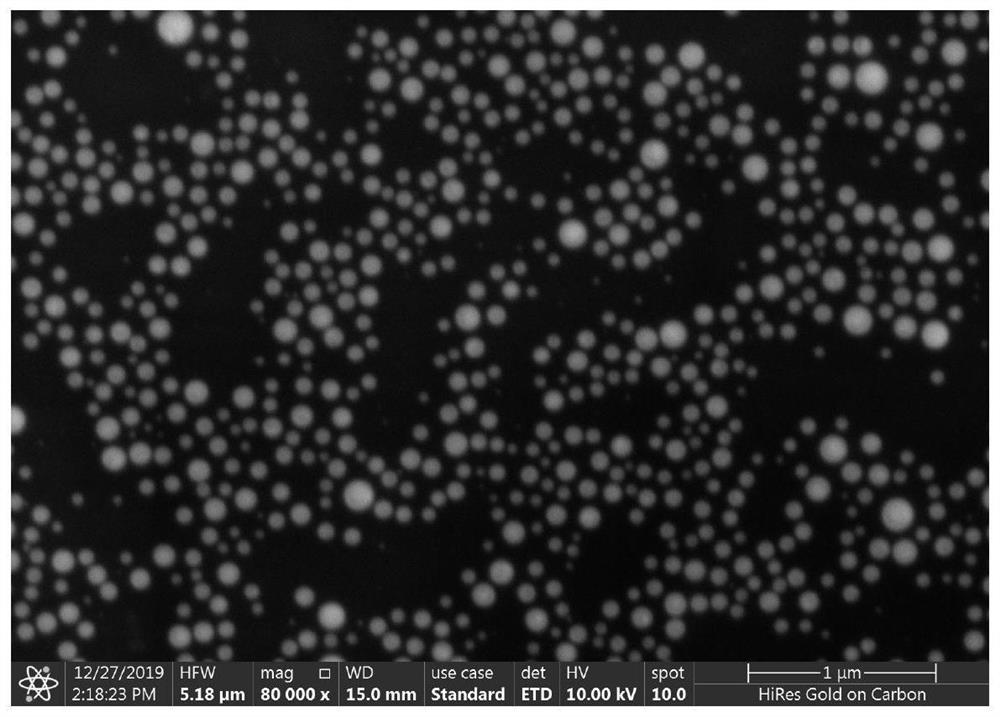

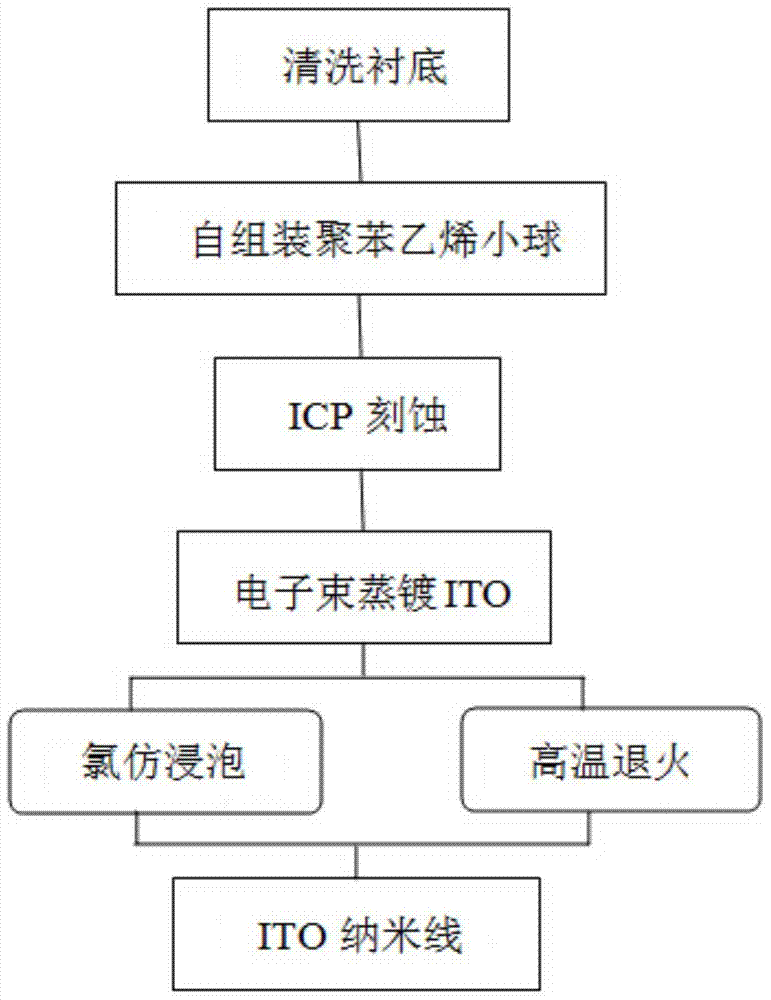

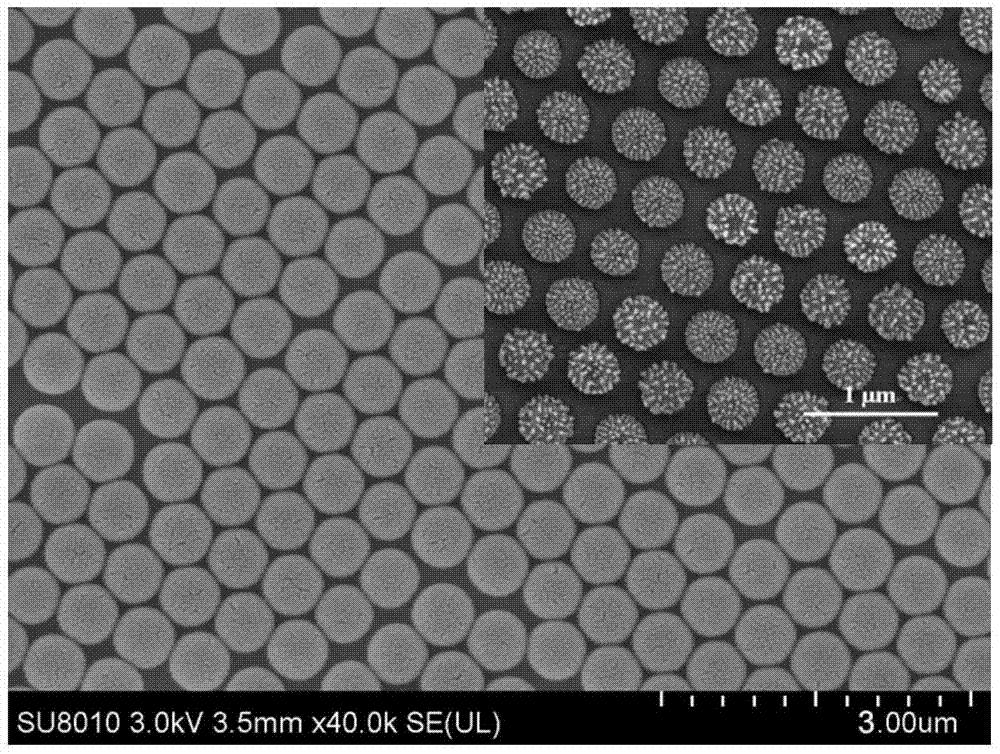

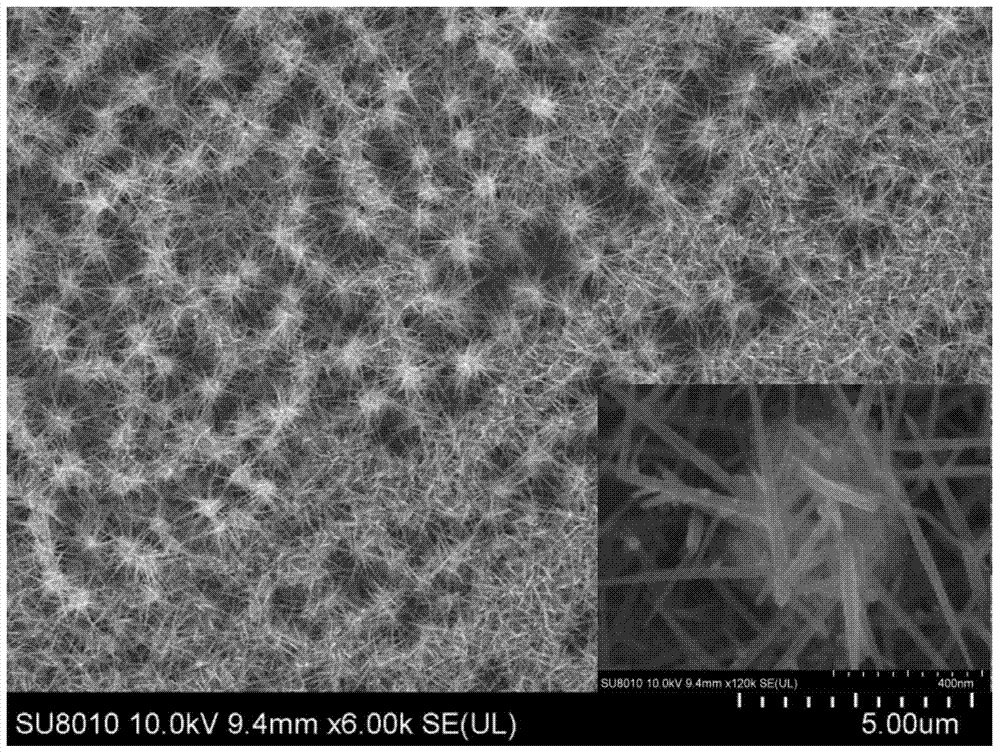

A kind of method that utilizes organic macromolecule material as catalyst to prepare ito nanowire

ActiveCN104761154BImprove adsorption capacityGood adhesionMaterial nanotechnologyNanowirePolystyrene bead

Owner:XI AN JIAOTONG UNIV

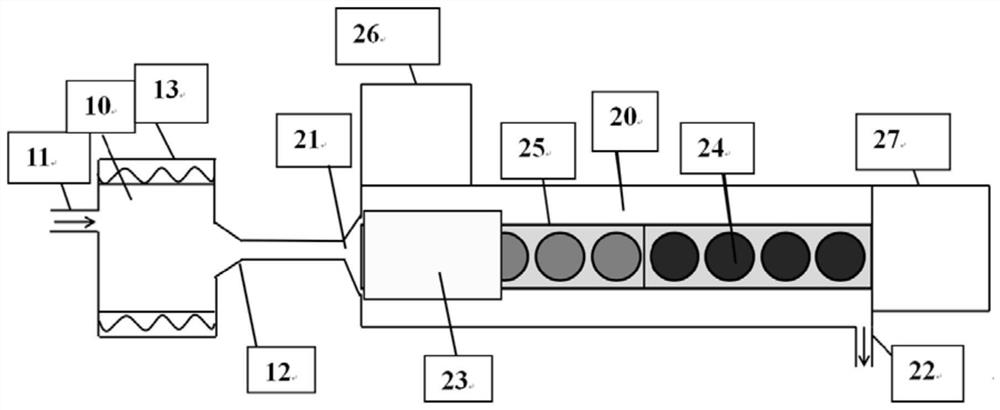

Carbon nanotube batch continuous production equipment

The invention belongs to the technical field of carbon nanotubes, and in particular relates to a batch continuous production equipment of carbon nanotubes, which includes a carbon source cracking device and a carbon nanotube growth device; the carbon source cracking device includes: a carbon source cracking cavity, a first heating component , carbon source air inlet and carbon source air outlet; the carbon nanotube growth device includes: a carbon nanotube growth chamber, a transmission assembly, a second heating assembly, an air inlet and an air outlet; wherein the transmission assembly is used to continuously convey carbon The nanotube growth substrate, the carbon source air outlet is connected to the air inlet of the carbon nanotube growth device; the first heating component provides cracking temperature for the carbon source cracking chamber; the second heating component has a heating channel, and the transmission component Disposed in the heating channel, the heating channel is used to heat the carbon nanotube growth substrate entering the heating channel.

Owner:SHENZHEN XIWAN TECH CO LTD

Method for preparing printing electron by adopting catalytic type nano particles

InactiveCN101873768BIncrease printing areaReduce processing costsConductive pattern formationChemical platingNanoparticle

The invention discloses a method for preparing printing electron by adopting catalytic type nano particles. The method adopts the following steps of: printing resin on a substrate, printing the catalytic type nano particles onto the resin after the resin is solidified or half solidified to form a circuit with electric conductivity and catalytic property, then carrying out chemical plating treatment on the circuit and plating a metal layer with high electric conductivity so as to obtain an electronic circuit. The printing electron prepared by the method lowers the processing cost greatly, the obtained electronic circuit has the advantages of high electric conductivity, high stability and the like, and the application of electron for printing and manufacturing in a plurality of fields of a battery, a display, a sensor, an RFID tag, an interactive package, a solar panel, a loudspeaker and the like can be pushed.

Owner:SUN YAT SEN UNIV

Continuous carbon nanotube growth device

ActiveCN104418318BAchieve continuous growthImprove growth efficiencyMaterial nanotechnologyPorous substrateCarbon nanotube

The invention discloses a continuous growth device for a carbon nano-tube. The continuous growth device comprises a heating room, a substrate, a catalyst film and a heating device, wherein the heating room is provided with a heating chamber, and a vent hole communicated to the heating chamber is formed in the heating room; the substrate is located inside the heating chamber, the catalyst film is formed on the surface of the substrate, first through holes are formed in the substrate, and the catalyst film comprises second through holes communicated to the first through holes; and the heating device is used for heating the heating chamber. The plurality of holes in the porous substrate are communicated with the plurality of holes in the catalyst film located below the porous substrate, and reactant gas is introduced from the upper part of the porous substrate and can continuously flow into the plurality of holes in the catalyst film through the plurality of holes in the substrate, so that the carbon nano-tube can continuously grow. Preferably, the growth direction of the carbon nano-tube in an improved device is changed to be vertical and downward, therefore, compared with the growth speed of the carbon nano-tube which vertically and upwards grows, the growth speed is increased under the action of gravity, and furthermore, the technical effect of continuous and rapid growth is achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A kind of transparent electrode based on ultra-thin metal film and its preparation method and application

ActiveCN107393979BAchieve continuous growthImprove continuityFinal product manufactureSemiconductor devicesThin metalSystem structure

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

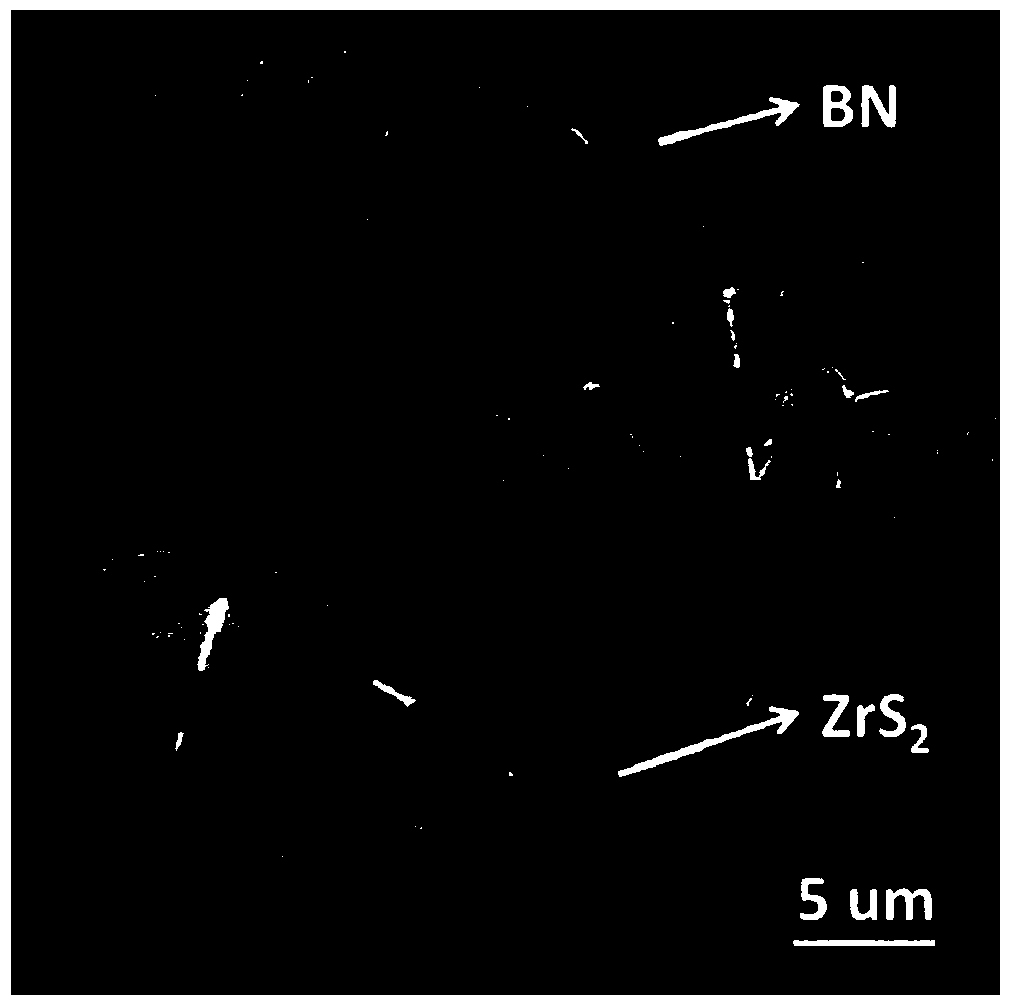

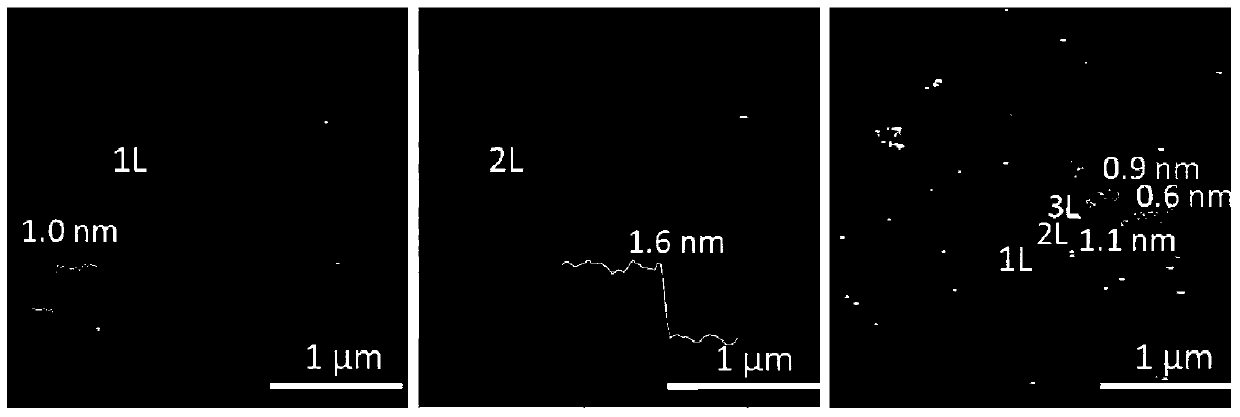

A kind of two-dimensional transition metal chalcogenide film and its preparation method and application

ActiveCN104894530BAchieve continuous growthOptimize deposition methodChemical vapor deposition coatingBoron nitrideChemical vapor deposition

The invention relates to a two-dimensional transition metal chalcogenide film, a preparation method and application thereof. The two-dimensional transition metal chalcogenide refers to: ZrS2, ZrSe2, HfS2 and HfSe2; Monolayer or few-layer two-dimensional transition metal chalcogenides are deposited on boron substrates. The method provided by the invention can controllably synthesize a hexagonal or triangular two-dimensional transition metal chalcogenide film with a thickness of about 1 nm and a thickness of more than 1 μm on a boron nitride substrate, and realizes two-dimensional ZrS2, ZrSe2, HfS2 and controlled growth of large-area continuous thin films and monodomain regions of HfSe2.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

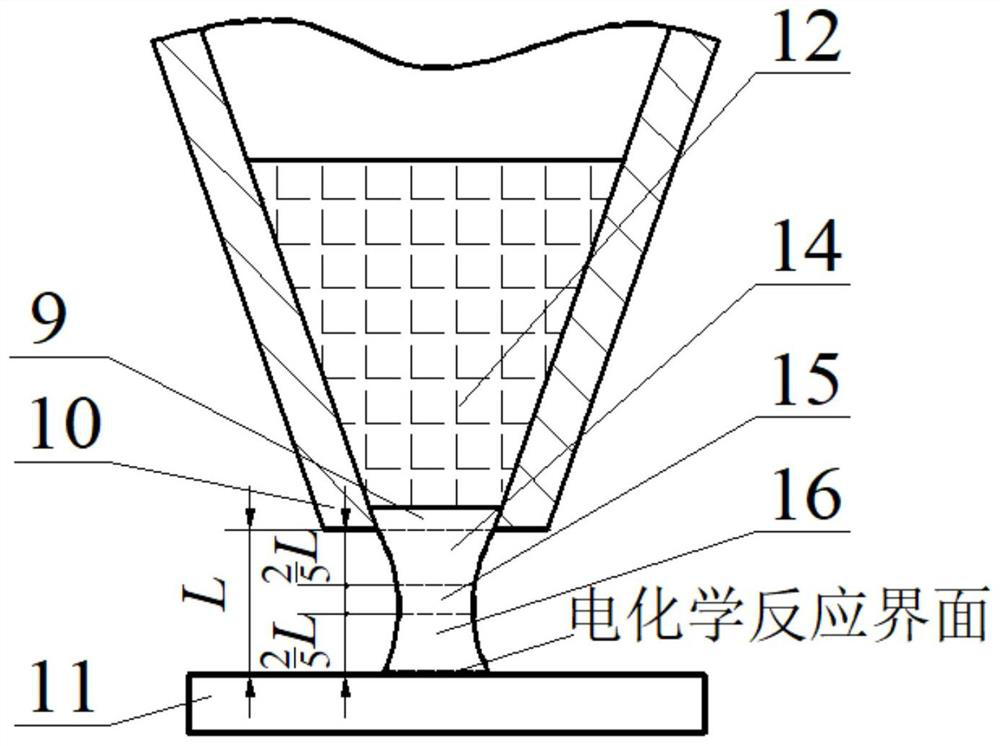

An electrochemical metal 3D printing method for processing serial variable diameter metal pillar structures

ActiveCN113215625BAchieve continuous growthPrevent extrusion/suctionAdditive manufacturing apparatus3D structure electroformingElectrochemical responseElectrolytic agent

Owner:DALIAN UNIV OF TECH

A process for inducing alloy directional solidification growth and strengthening alloy refining process by direct current electric field

ActiveCN105819451BAchieve continuous growthReduce segregation coefficientGlass severing apparatusSilicon compoundsDirectional solidificationNucleation

The invention discloses a technology for inducing alloy directional solidification growth and reinforcing an alloy refining process by an direct current electric field. The technology comprises the following steps: heating a Si-M mother alloy to a corresponding liquidus temperature in order to obtain a Si-M alloy melt, introducing the direct current electric field to the Si-M alloy melt to realize directional movement of silicon atoms in the Si-M alloy melt, enrichment at the bottom of a graphite crucible and formation of a supersaturated area in order to achieve nucleation and growth on a crystal silicon substrate; continuously adding raw material silicon from the top of the graphite crucible in the growth process in order to realize continuous growth of the crystalline silicon; and powering off a heat source after the growth ends to cool and solidify, and powering off a direct current power supply. The technology realizes a highly-accurate directional growth mode, effectively reduces the refining temperature and the fractional condensation coefficients of various impurities, reduces energy consumption, enhances the purifying effect, makes different impurities be afresh distributed under the action of an electric field, and allows silicon to be solidified and precipitated and the silicon atoms to be continuously provided through continuously adding the raw material silicon in order to realize continuous growth of silicon.

Owner:DALIAN UNIV OF TECH

A method for preparing amorphous silicon carbide ceramics-diamond composite coating

The invention discloses a method for preparing an amorphous silicon carbide ceramic-diamond composite coating. The method comprises the steps of cracking macromolecular organic silane serving as a precursor on the surface of a substrate by adopting a macromolecular precursor cracking method to generate an amorphous silicon carbide ceramic film, and then performing in-situ deposition on the micro diamond film by adopting a hot filament chemical vapor deposition method to obtain the amorphous silicon carbide ceramic-diamond composite coating. Compared with the prior art, the amorphous silicon carbide transition layer prepared by adopting the macromolecular precursor cracking method can be used for effectively blocking residual cobalt phase on the surface of a hard alloy matrix after two-step treatment and improving the rough surface of the hard alloy matrix; and the prepared amorphous silicon carbide ceramic-diamond composite coating has excellent adhesion and extremely high abrasion resistance, and is suitable for preparing high-quality diamond coating cutters.

Owner:SHANGHAI JIAOTONG UNIV

A preparation method of large-scale core-shell structure quantum dots

ActiveCN109504367BSmall sizeAchieve continuous growthMaterial nanotechnologyNanoopticsQuantum dotMaterials science

The invention belongs to the technical field of luminescent quantum dot materials and particularly relates to a preparation method of a large-size core-shell structured quantum dot. The preparation method comprises steps as follows: a dispersion liquid of a shell source is added to a dispersion liquid of a core in a mode of dropwise adding at intervals in a protective atmosphere, and the core-shell structured quantum dot is obtained through in-situ growth. With the adoption of the mode of dropwise adding at intervals, matching from the inner layer of shell components to crystal lattices of themiddle layer is realized, influence of lattice imperfection on quantum yield is avoided, continuous growth of the shell is realized, and the core-shell structured quantum dot with large size and highyield is obtained finally. A result of an embodiment indicates that when the core-shell structured quantum dot with grain size being 15 nm is prepared with the method, the yield is as high as 80%; when the core-shell structured quantum dot with the grain size being 60 nm is prepared, the yield still keeps 50% or higher.

Owner:HENAN UNIVERSITY

A method for preparing gradient hard composite coating on the surface of cemented carbide

ActiveCN105386049BSmall coefficient of thermal expansionHigh bonding strengthSuperimposed coating processGlow plasmaThermal expansion

The invention relates to a method for manufacturing a gradient hard composite coating on the surface of a hard alloy. A dual-layer glow plasma surface alloying device is used, argon serves as plasma stimulation gas, a composite target manufactured through a refractory metal wire and a graphite plate serves as a source electrode, and refractory metal and a carbide composite cementation layer of the refractory metal are manufactured on the surface of the hard alloy; then mixed gas of tetramethylsilane and hydrogen is led in, and the gradient composite coating comprising refractory metal carbide and silicon carbide is prepared by continuously increasing the flow of the tetramethylsilane; and finally methane is led in, the flow of the methane is gradually increased, the flow of the tetramethylsilane is reduced at the same time, and the silicon carbide and diamond gradient hard composite coating is prepared. The coating prepared with the method and a base body are in metallurgical bonding, the coefficients of thermal expansion from the base body to the coating are distributed in a gradient manner, and the method has the characteristics of being small in stress, high in binding intensity and the like. Meanwhile, the overall coating is continuously prepared in one device, the process is simple, and the cost is low.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com