Carbon nanotube batch continuous production equipment

A technology for carbon nanotubes and production equipment, which is applied in the field of batch continuous production equipment for carbon nanotubes, can solve the problems of poor quality of carbon nanotubes, low degree of continuity, and low utilization rate of raw materials, etc., and achieve stable growth temperature and save energy. Energy consumption, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In some embodiments, the method for preparing carbon nanotubes can be carried out in the batch continuous production equipment of carbon nanotubes in the above embodiments, including the following steps:

[0072] S10. Cracking the carbon source and the protective gas in a carbon source cracking device at a temperature of 400-600° C. to obtain the hydrocarbon gas;

[0073]S20. Adding the mixture of the hydrocarbon gas and the protective gas to the carbon nanotube growth device to grow carbon nanotubes, the carbon nanotube growth device also includes a transmission component and a second heating component, The conveying assembly is used to convey the carbon nanotube growth substrate, and the second heating assembly provides a heating temperature of 400-700° C. for the carbon nanotube growth substrate.

[0074] The preparation method of carbon nanotubes in the embodiments of the present invention can be realized in the batch continuous production equipment of carbon nanotu...

Embodiment 1

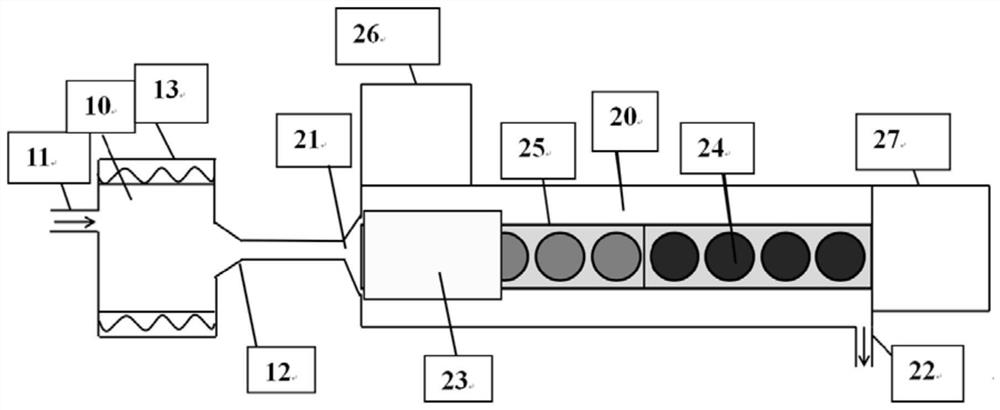

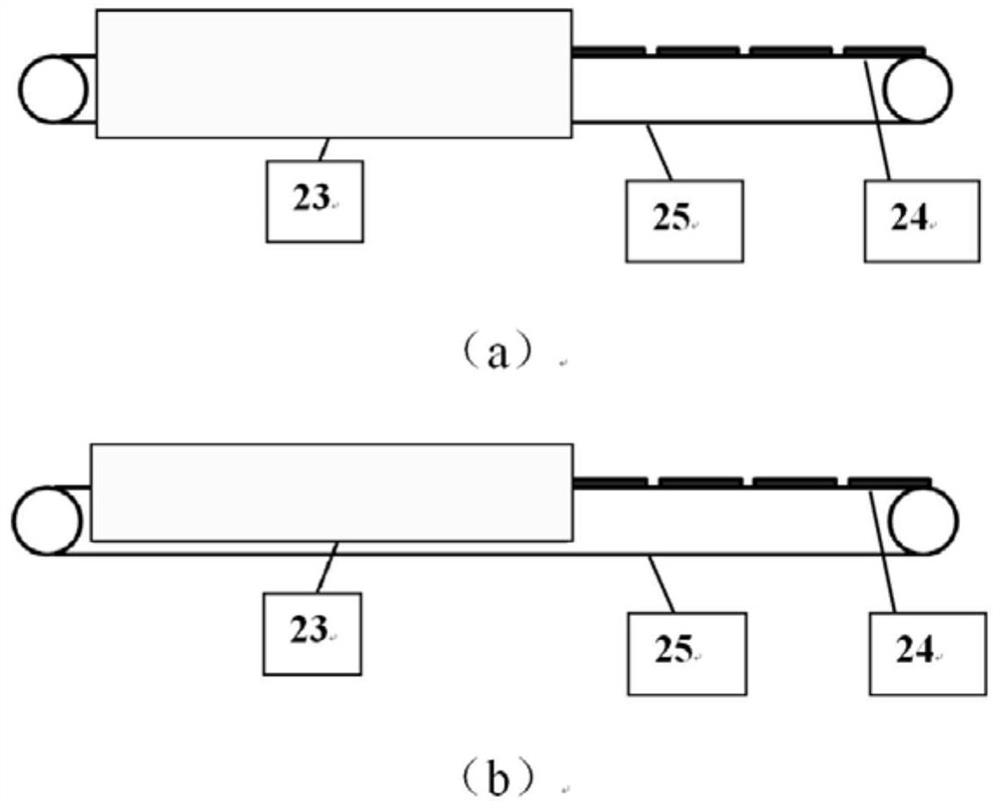

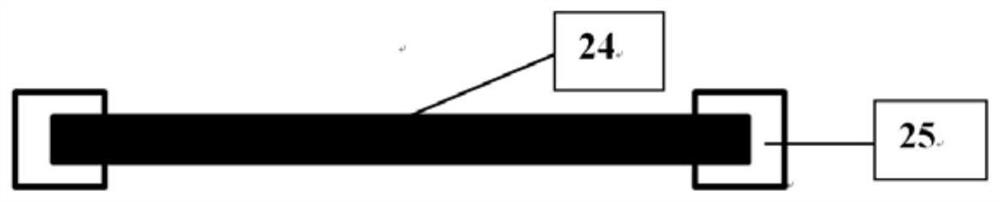

[0087] A batch continuous production equipment for carbon nanotubes, as attached figure 1 As shown, it includes a carbon source cracking device and a carbon nanotube growth device, and the carbon source cracking device includes: a first heating assembly 13, a carbon source inlet 11 and a carbon source gas outlet 12, and the carbon nanotube growth device includes : transport unit 25, several carbon nanotube growth substrates 24, second heating assembly 23, air inlet 21 and air outlet 22; wherein, the temperature in the carbon source cracking device is 500 ℃, as attached Figure 4 As shown, the transmission unit 25 is two stainless steel guide rails, the track is a straight line, the transmission unit 25 drags the two opposite sides of the carbon nanotube growth substrate 24, and the length of the transmission belt is 1.2 meters; the second heating assembly 23 is a spiral The quartz heating tube is arranged around the conveying assembly, and the surrounding direction is perpend...

Embodiment 2

[0094] A batch continuous production equipment for carbon nanotubes, as attached figure 1 As shown, it includes a carbon source cracking device and a carbon nanotube growth device, and the carbon source cracking device includes: a first heating assembly 13, a carbon source inlet 11 and a carbon source gas outlet 12, and the carbon nanotube growth device includes : transport unit 25, several carbon nanotube growth substrates 24, second heating assembly 23, air inlet 21 and air outlet 22; wherein, the temperature in the carbon source cracking device is 500 ℃, as attached Figure 5 As shown, the transmission unit 25 is two stainless steel guide rails, the track is a serpentine curve, the transmission unit 25 drags the two opposite sides of the carbon nanotube growth substrate 24, and the length of the transmission belt is 8 meters; the second heating assembly 23 is The spiral quartz heating tube is arranged around the conveying assembly, the winding direction is perpendicular to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com