Preparation method of zinc oxide nanorod array thin film

A technology of zinc oxide nanorods and nanorod arrays, which is applied in the field of preparation of zinc oxide nanorod array thin films, can solve the problems of inability to meet the performance requirements of ZnO nanorod array thin film devices, poor crystal quality, weak emission peaks, etc., and achieve improved Photoluminescent properties, improved crystal quality, effects of uniform diameter and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Prepare the seed layer precursor solution: Dissolve equimolar amounts of zinc acetate and ethanolamine 0.3M in sequence in ethanol, stir well, seal and homogenize for more than 4 hours;

[0059] (2) Cleaning of the deposition substrate: The ITO conductive glass was ultrasonically cleaned for 30 minutes with a 1:1:1 solution of ethanol:isopropanol:acetone, then ultrasonically cleaned with deionized water for 10 minutes and dried.

[0060] (3) Spin-coating ZnO precursor solution: transfer the deposition substrate to a homogenizer, add the precursor solution prepared in step (1) dropwise, and spin at a speed of 6000 rpm for 30 seconds after uniform dispersion.

[0061] (4) Evaporation of the solvent: transfer the spin-coated substrate to an electric heating plate, and evaporate the solvent or pyrolyze it at 180-300° C. for more than 5 minutes.

[0062] (5) Crystallization of the ZnO seed layer thin film: transfer to a rapid annealing furnace, perform rapid heat treatme...

Embodiment 2

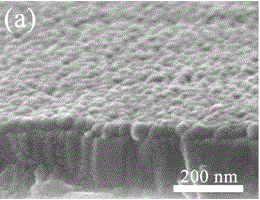

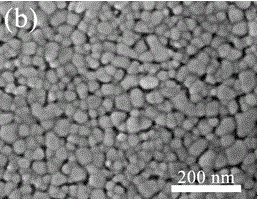

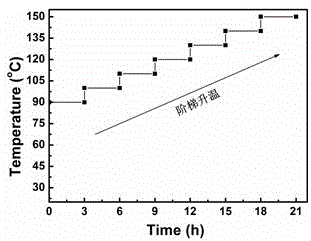

[0069] The preparation method and test are the same as in Example 1, but the programmed heating process is changed, as Figure 7 Schematic diagram of step heating. Figure 8 is in equimolar amount of Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine at a concentration of 0.15 mol L -1 , add 60mmol·L -1 Polyethylenimine growth solution, using Figure 7 According to the step heating process, the FESEM image of the cross-section of the obtained ZnO nanorod array film was grown under the condition of 80-150°C step heating for 16 hours. The ZnO nanorods prepared by the method have a diameter of 50-150 nm and a length of about 50 μm. It shows that the length of ZnO nanorods will decrease if the temperature rises too fast.

[0070] The photoluminescent performance of the ZnO nanorods obtained by this method is the same as that of the ZnO nanorods array thin film obtained by step heating in Example 1, which has good high intrinsic emission.

Embodiment 3

[0072] Preparation method and test are identical with embodiment 1, but the concentration of growth solution is 3 times of embodiment 1, the Zn(NO 3 ) 2 ·6H 2 O and hexamethylenetetramine at a concentration of 0.15 mol L -1 , add 60mmol·L -1 Polyethyleneimine as epitaxial growth regulator of ZnO nanorods. Figure 9 For the cross-sectional FESEM diagram of the ZnO array film prepared by this method, the diameter of the ZnO nanorods is 100-250nm and the length is about 150 μm, indicating that increasing the concentration is beneficial to the increase of the length of the ZnO nanorods, but the diameter of the ZnO nanorods also increases.

[0073] The photoluminescent performance of the ZnO nanorods obtained by this method is the same as that of the ZnO nanorods array thin film obtained by step heating in Example 1, which has good high intrinsic emission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com