Ultraviolet light-emitting diode based on n-ZnO/n-GaN alloplasm nN node and preparation method thereof

A light-emitting diode and heterogeneous technology, applied in the field of nanomaterials and optoelectronic devices, can solve the problems of high threshold voltage and low luminous intensity, and achieve the effects of reducing threshold voltage, improving performance, and improving ultraviolet luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (2) Preparation of i-type intermediate layer. RF magnetron sputtering process conditions: The target material is a Mg metal target or a ZnO small ceramic sheet or a ZnO ceramic target stacked on a Mg metal target. The background vacuum during sputtering is better than 10 -3 Pa, the substrate temperature is 150-400°C, the gas pressure during deposition is 0.5-5.0Pa, and the relative oxygen partial pressure is O 2 / (O 2 +Ar)=1 / 5~1 / 2, the sputtering power range is 80~130W, and the sputtering time is 8~15 minutes;

[0031] (3) growing n-type ZnO thin film layer. The condition parameters used in radio frequency magnetron sputtering are: the target material is a ZnO ceramic target. The background vacuum degree during sputtering is better than 5×10 -3 Pa, the substrate temperature is 150-450°C, the gas pressure during deposition is 0.5-5.0Pa, and the relative oxygen partial pressure is O 2 / (O 2 +Ar)=1 / 9~1 / 6, the sputtering power range is 80~130W, and the sputtering tim...

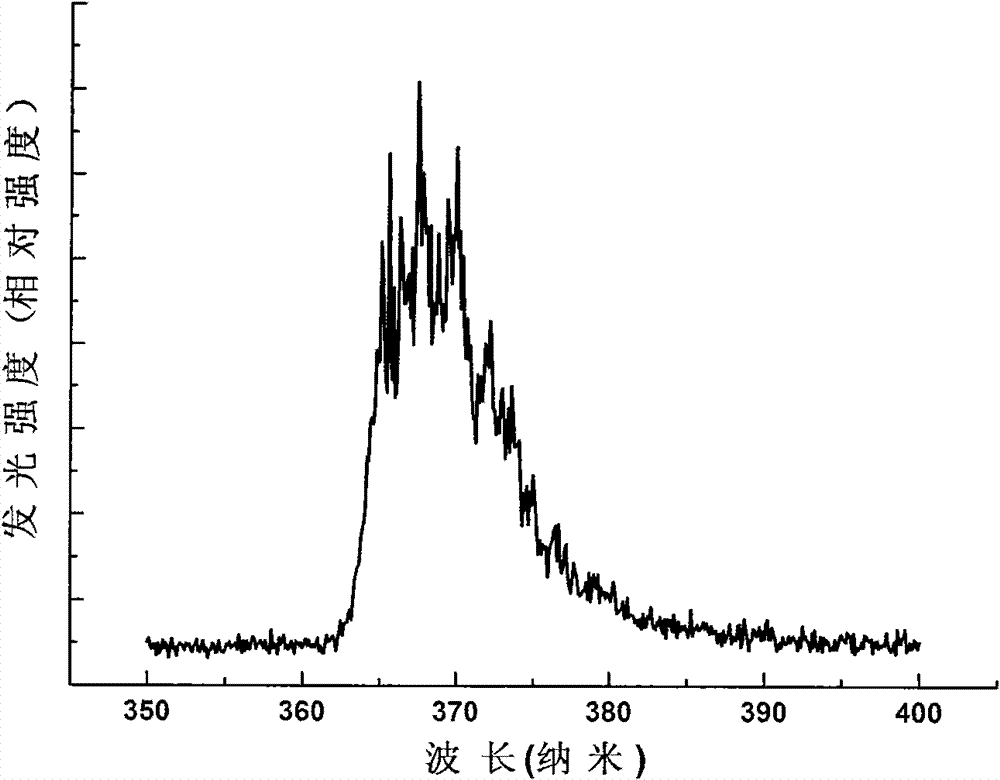

Embodiment 1

[0037] 1. Substrate cleaning: use n-type gallium nitride / sapphire as the substrate, cut it into a size of 25mm×30mm,

[0038]Use acetone, alcohol, and deionized water to ultrasonically clean for 3 minutes, and finally blow dry with a nitrogen gun.

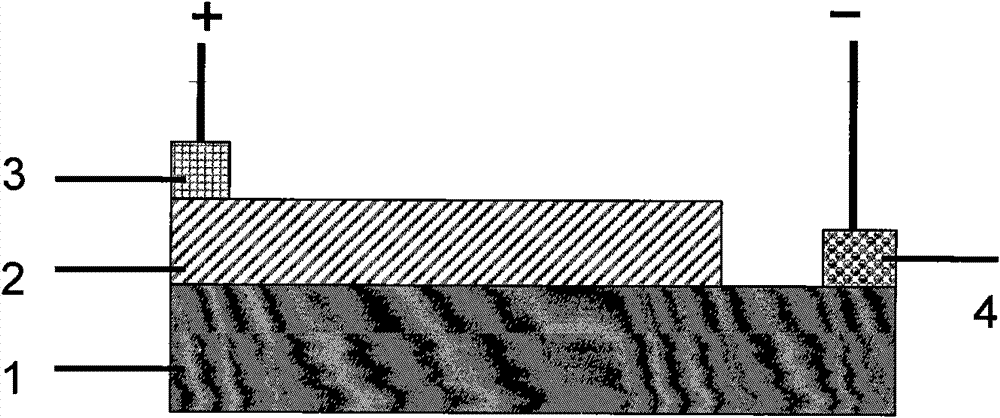

[0039] 2. Growth of n-type layer ZnO: use radio frequency magnetron sputtering method to deposit ZnO thin film (2) on GaN layer (1). The target material is ZnO ceramic target, and the background vacuum is 1.0×10 -3 Pa, the deposition substrate temperature is 300°C, the gas pressure during deposition is 1.0Pa, and the relative oxygen partial pressure is O 2 / (O 2 +Ar)=1 / 6, power 80W, sputtering time 45 minutes.

[0040] 3. Electrode preparation: Au electrodes (3) were prepared on the surface of the ZnO thin film by DC sputtering method, the substrate temperature was 120° C., and the deposition time was 1 minute. The Al electrode (4) is prepared on the surface of the GaN thin film by thermal evaporation process, and the depositio...

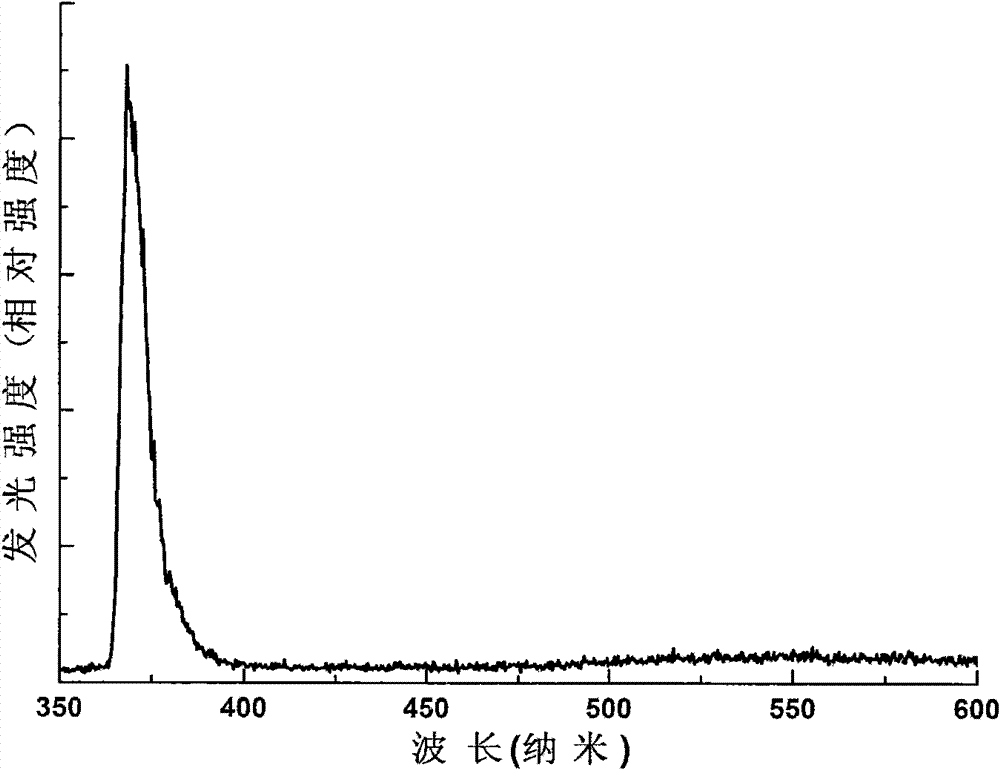

Embodiment 2

[0043] 1. Substrate cleaning: use n-type gallium nitride / sapphire as the substrate, cut it into a size of 25mm×30mm,

[0044] Use acetone, alcohol, and deionized water to ultrasonically clean for 3 minutes, and finally blow dry with a nitrogen gun.

[0045] 2. Growth of n-type layer ZnO: use radio frequency magnetron sputtering method to deposit ZnO thin film (2) on GaN layer (1). The target material is ZnO ceramic target, and the background vacuum is 1.0×10 -3 Pa, the deposition substrate temperature is 150°C, the gas pressure during deposition is 0.5Pa, and the relative oxygen partial pressure is O 2 / (O 2 +Ar)=1 / 9, power 130W, sputtering time 30 minutes.

[0046] 3. Electrode preparation: The Ag electrode (3) was prepared on the surface of the ZnO thin film by DC sputtering method, the substrate temperature was 100° C., and the deposition time was 2 minutes. An In electrode (4) is prepared on the surface of the GaN thin film by a thermal evaporation process, and the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com