Patents

Literature

173 results about "Ag electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solder Paste and Solder Joint

ActiveUS20090301607A1Improve wettabilityLow melting pointPrinted circuit aspectsPrinted circuit manufactureAlloyMetal powder

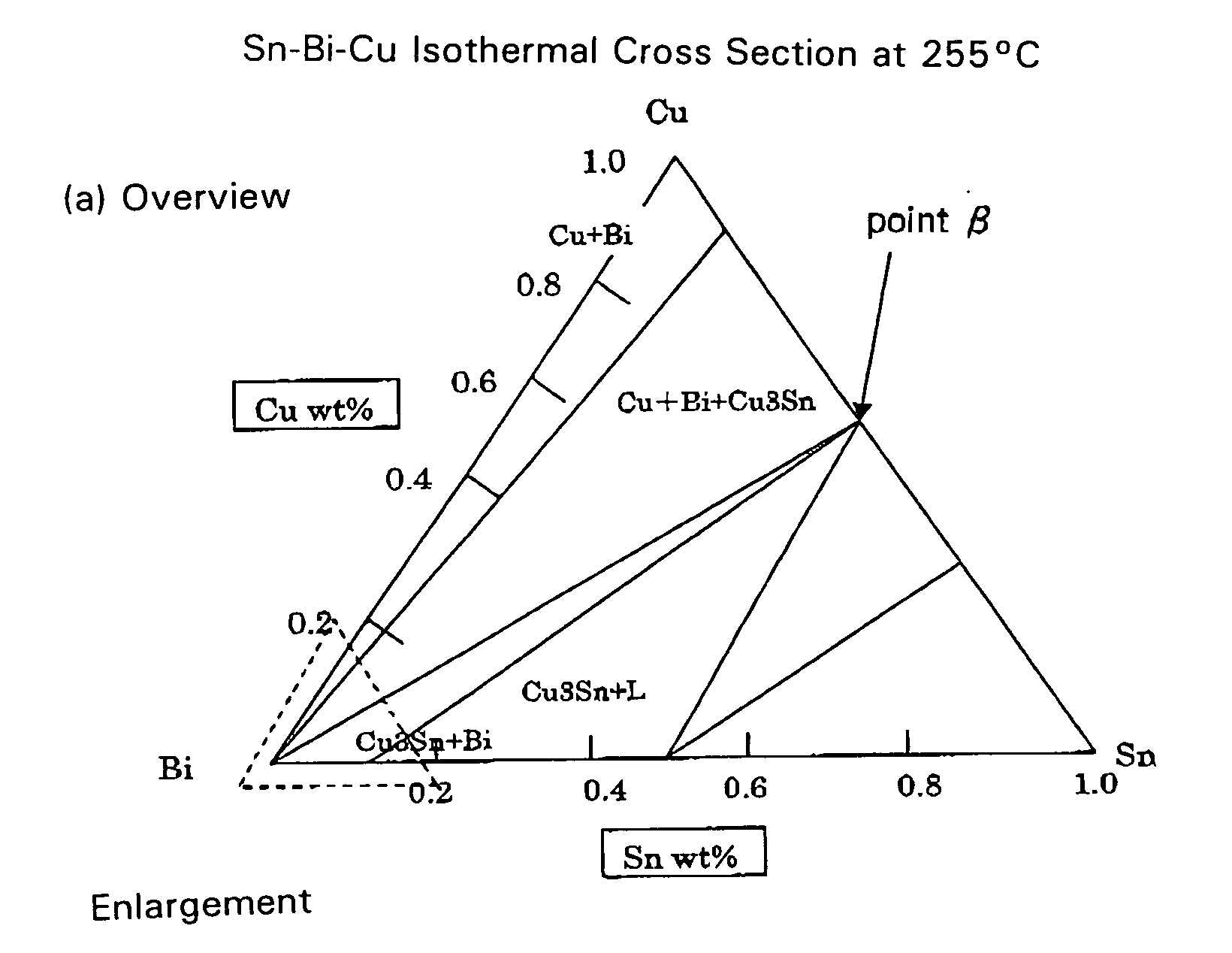

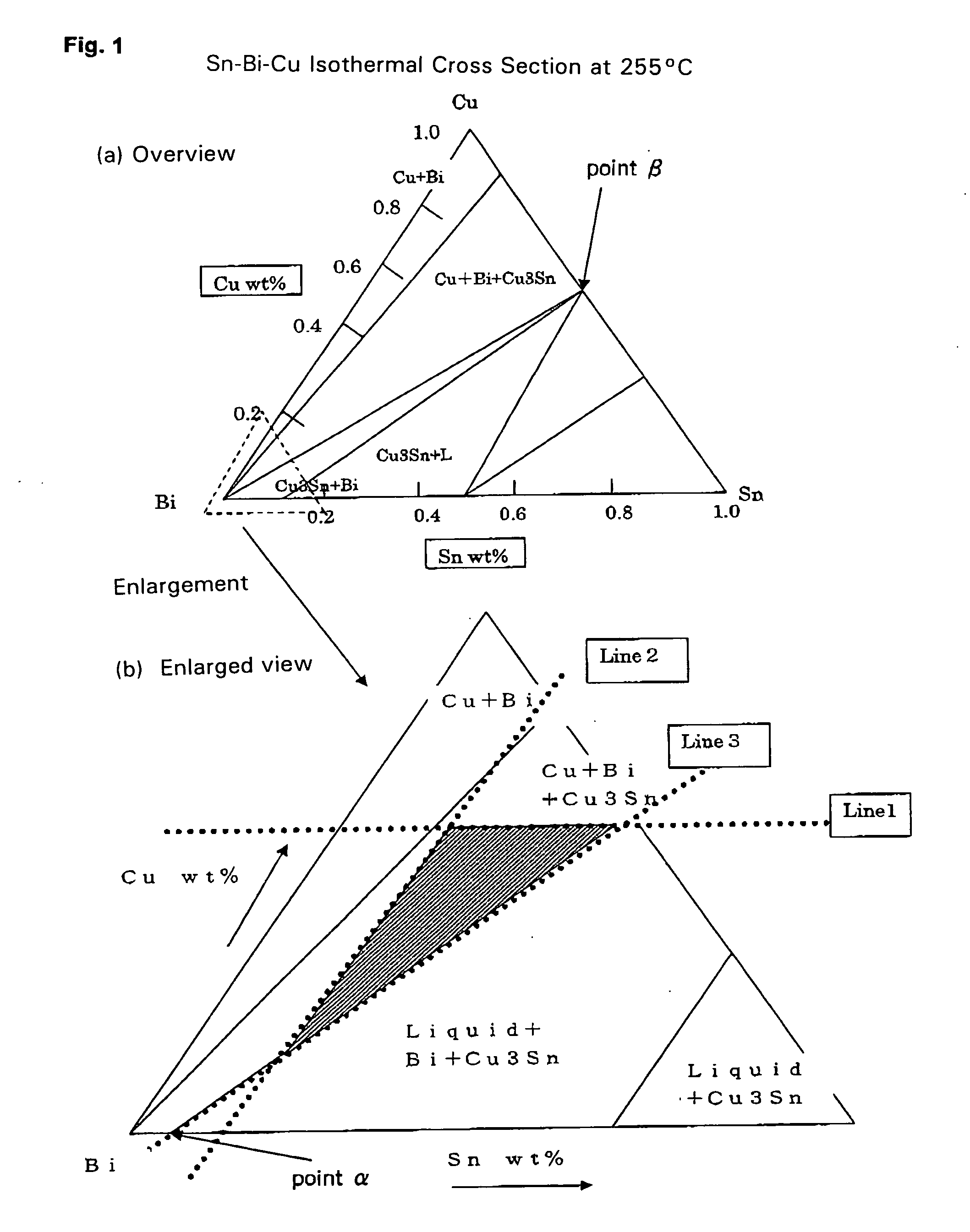

The invention provides a solder paste which has a solidus temperature of 255° C. or above and is improved in the wettability between Bi and Cu or Ag electrode to attain approximately equivalent wettability to those of Pb-containing high-temperature solders even in low-temperature soldering. The solder paste comprises a metal powder component consisting of Bi or a Bi alloy, a solidus temperature lowering metal for Bi, and a solid-phase metal capable of forming an intermetallic compound with the solidus temperature lowering metal, and a flux component.

Owner:SENJU METAL IND CO LTD +1

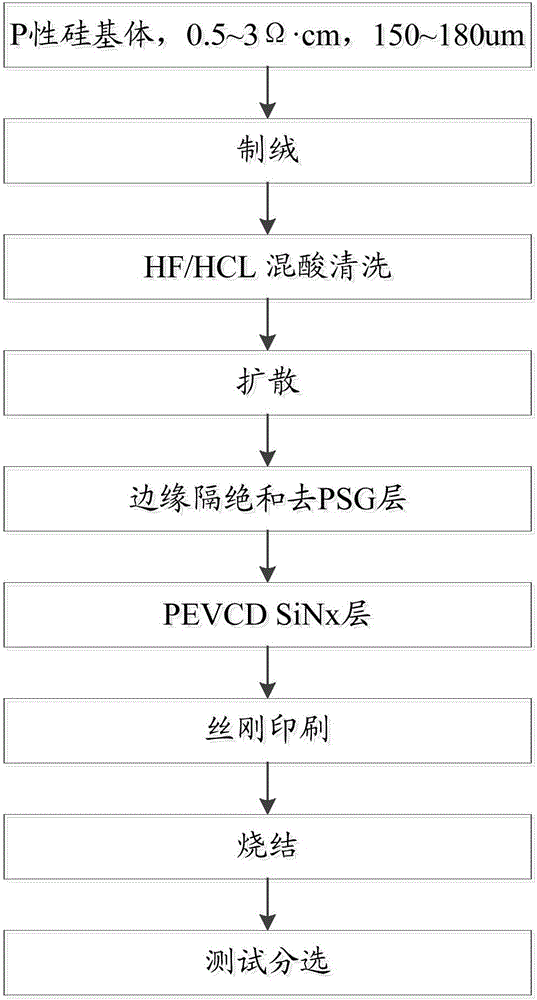

Preparation method of solar cell

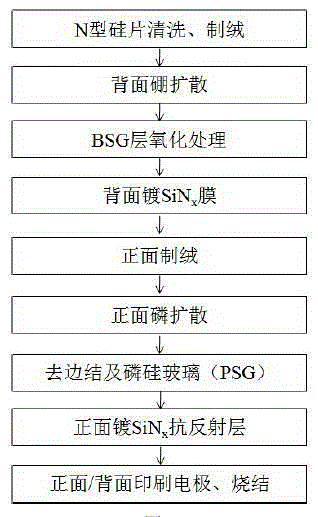

InactiveCN101937945AOvercome defilementOvercome defectsFinal product manufactureSemiconductor devicesScreen printingSilicon oxide

The invention discloses a preparation method of a solar cell. The method comprises the following steps: providing a plurality of polycrystalline silicon wafers for texturization; overlapping the textured silicon wafers, depositing a silicon nitride or silicon oxide masking film on the periphery of the silicon wafers, then diffusing a phosphorus doping layer on the front surface of the to-be-prepared positive electrode of the silicon wafers to form a PN junction, wherein the periphery of the silicon wafers can not form the diffusion PN junction owning to the existence of the masking film; removing the peripheral masking film and the surface phosphosilicate glass; preparing a passivation layer and an antireflection layer; and performing screen printing and sintering to form a back Ag electrode, a back Al-back surface and a front Ag electrode. In the preparation method of the solar cell provided by the invention, the masking film is formed before the impurity source diffusion used for preparing the PN junction; owning to the existence of the masking film, the periphery of the silicon wafers can not form the PN junction; and the silicon wafers after diffusion is washed with acid to remove the masking film on the periphery of the silicon wafers and the phosphosilicate glass on the diffusion surface, thus achieving the aim of replacing the etching step.

Owner:百力达太阳能股份有限公司

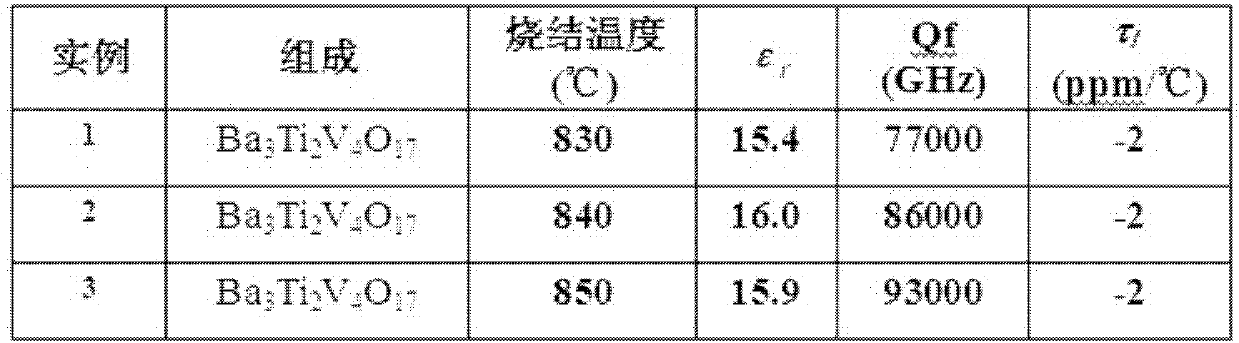

Double-sided N-type crystalline silicon cell and preparation method thereof

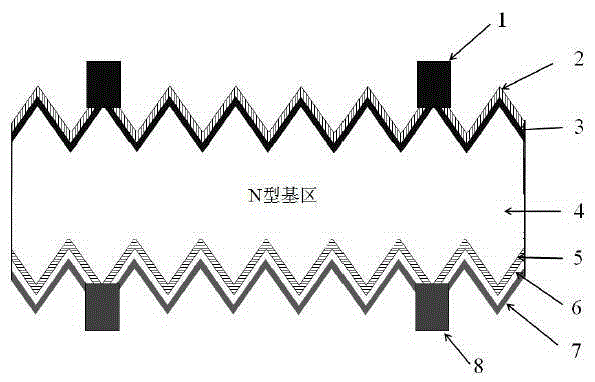

InactiveCN105047742AIncrease the open circuit voltageImprove current efficiencyFinal product manufacturePhotovoltaic energy generationChemical solutionBack surface field

The invention discloses a double-sided N-type crystalline silicon cell comprising a front AgAl electrode, a front antireflection film, a boron emitter passivation layer, a boron emitter p+ layer, an N-type silicon wafer, a phosphorus diffusion n+ back surface field layer, a back passivation layer, a back antireflection film, and a back Ag electrode. The front and the back of the cell are textured surfaces, and both sides can receive light and generate electricity. The boron emitter passivation layer and the back passivation layer are prepared at the same time by growing SiO2 layers through thermal oxidation in a low-temperature dry method, which reduces the interface-state density and the rate of interface recombination. A laminated film composed of a borosilicate glass layer and a silicon nitride layer formed in the diffusion process is used as a boron emitter protection layer. Therefore, boron diffusion surface etching and phosphorous diffusion cross contamination caused by chemical solution are prevented effectively, multiple times of etching and mask deposition in the process are reduced, and the technological process is simplified.

Owner:中国东方电气集团有限公司

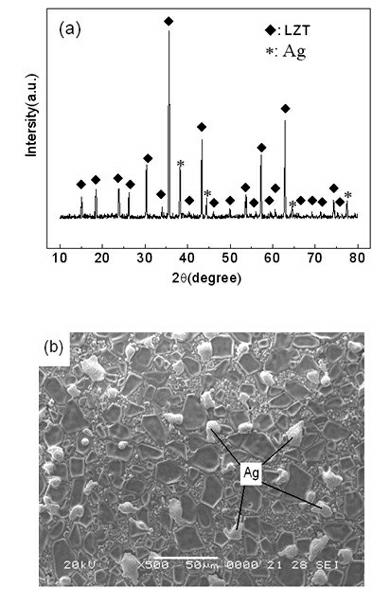

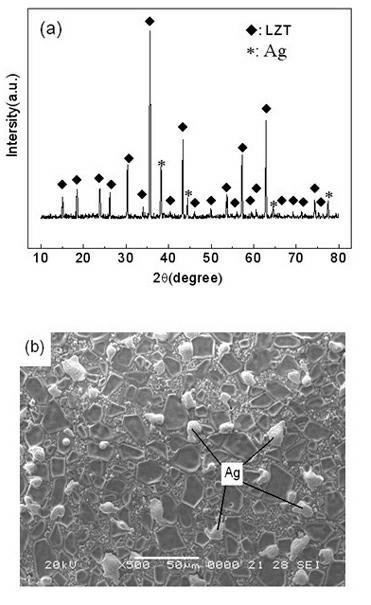

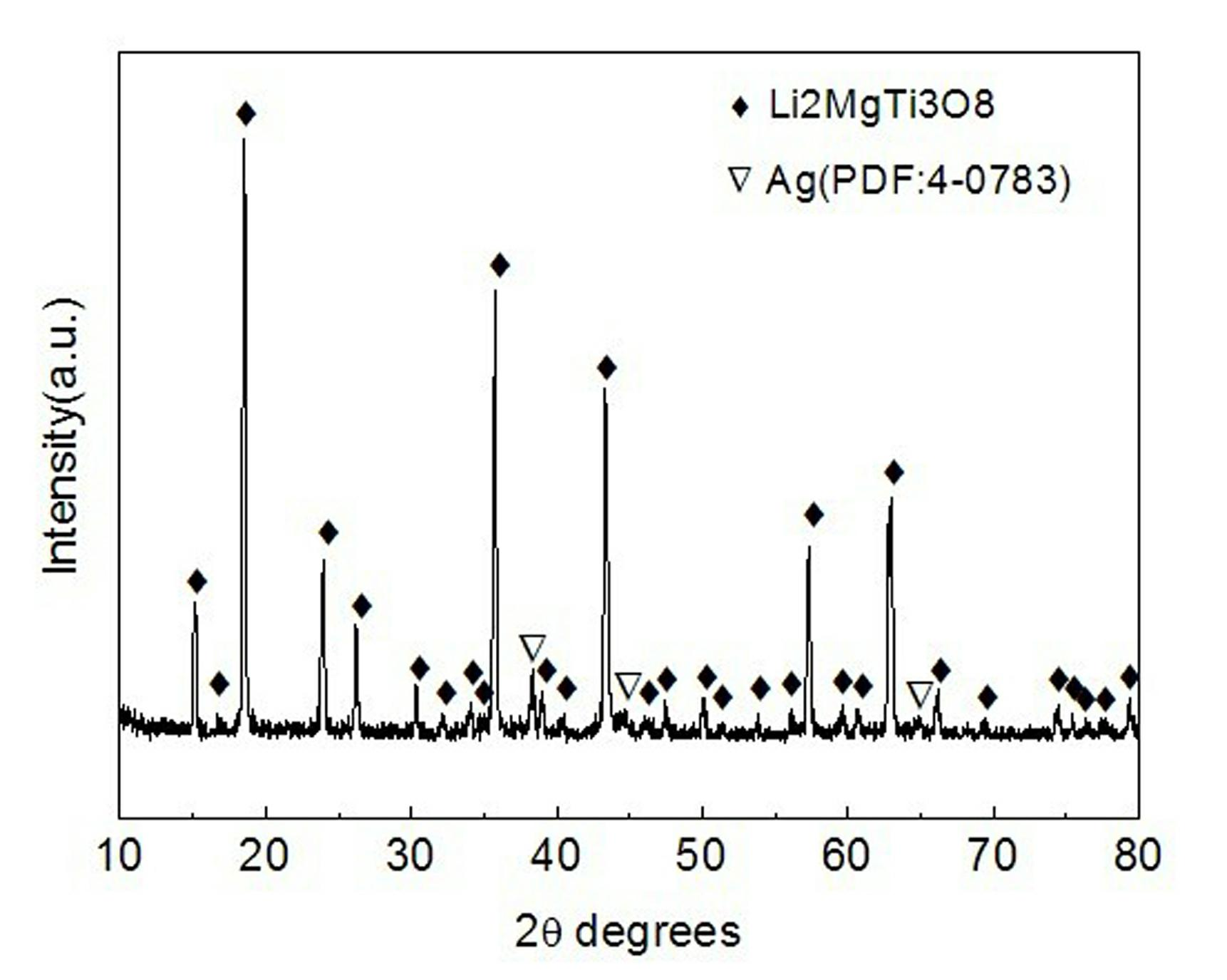

Low temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveCN102381874ALower sintering temperatureThe sintering temperature drops toCeramicsDielectric resonatorSolid state reaction method

The invention discloses a low temperature co-fired microwave dielectric ceramic material and a preparation method thereof. The ceramic material comprises a main powder material Li2ZnTi3O8, an auxiliary component TiO2 and low-melting-point LZB (Li2O-ZnO-BiO2) or LBS (Li2O-B2O3-SiO2) glass powder. The preparation method comprises the following steps of: adding TiO2 and the glass powder into the Li2ZnTi3O8 powder in a powder form; and then evenly mixing in a ball mill, drying, pelleting and sintering so as to obtain the ceramic material. In the invention, based on the Li2ZnTi3O8 powder as a reference, batching is carried out according to the proportions that the mass of the glass powder is 0.5-3wt% of that of Li2ZnTi3O8 and the mass of the TiO2 powder is 0-5wt% of that of Li2ZnTi3O8; and thematerial of the invention can be obtained by a traditional solid phase reaction method. The low temperature co-fired microwave dielectric ceramic material prepared by the method of the invention has low sintering temperature (about 875 DEG C) and good microwave dielectric property, and can be well co-fired with a Ag electrode; pure silver with high electricity conductivity and low cost is used asan electrode material, thus the manufacturing cost of a device can be greatly reduced; and the low temperature co-fired microwave dielectric ceramic material can be used for a low temperature co-fired ceramic (LTCC) system and manufacturing of microwave devices such as multilayer dielectric resonators, microwave antennas, filters and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

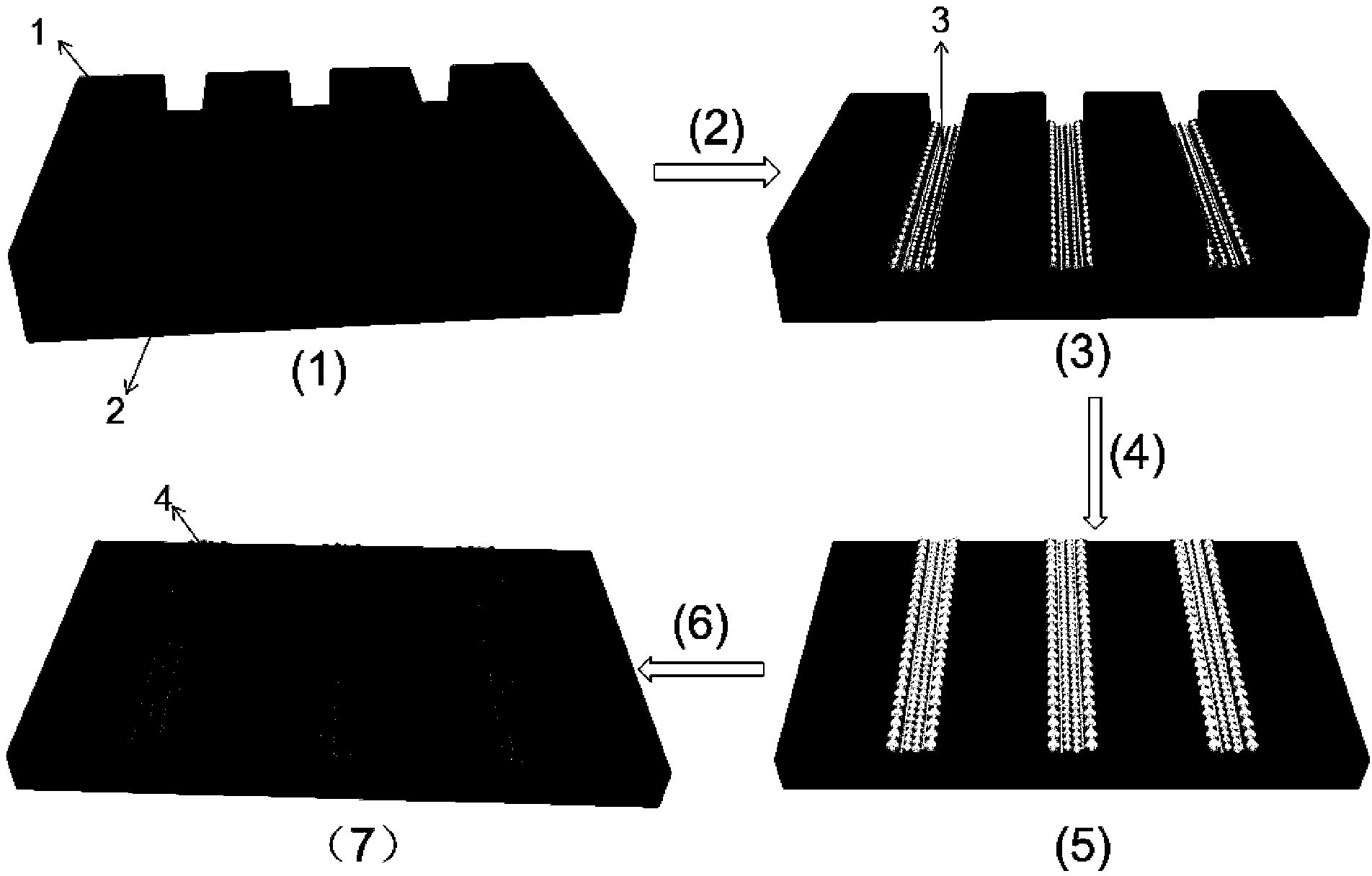

Method for preparing solar cell silver wire grid electrode based on photolithographic mask method and liquid phase method

ActiveCN103367541AFlexible patterns and sizesGood light transmittance and conductivityFinal product manufacturePhotomechanical exposure apparatusSolar cell efficiencyElectrochemical response

The invention discloses a method for preparing a solar cell silver wire grid electrode based on a photolithographic mask method and a liquid phase method. The method disclosed by the invention comprises the following steps: (1) a photoresist template is manufactured: photoresist is uniformly coated on the surface of a silicon substrate by using a spin-coating method, and designed specific graphics on a mask are copied on the silicon substrate through the steps of exposure, development, hardening and the like; (2) Ag particles are deposited by using a chemical method: an electrochemical reaction method is used for depositing the Ag particles on the photoresist template; (3) the photoresist template is removed: the photoresist is removed by using a photoresist remover; and (4) the annealing and sintering are carried out, and after the closely arrayed Ag particles are heated at high temperature, the Ag electrode is formed by mutual communication. The micron-level Ag electrode prepared according to the method has excellent electroconductive performance and a lower reflecting rate, moreover, the preparation process is simple, resource consumption is less, the Ag electrode can well replace a silk screen printed electrode, the efficiency of a solar cell can be improved, and the cost can be lowered.

Owner:SOUTH CHINA NORMAL UNIVERSITY

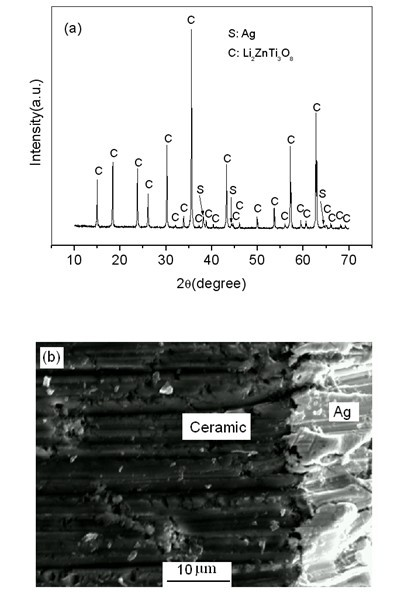

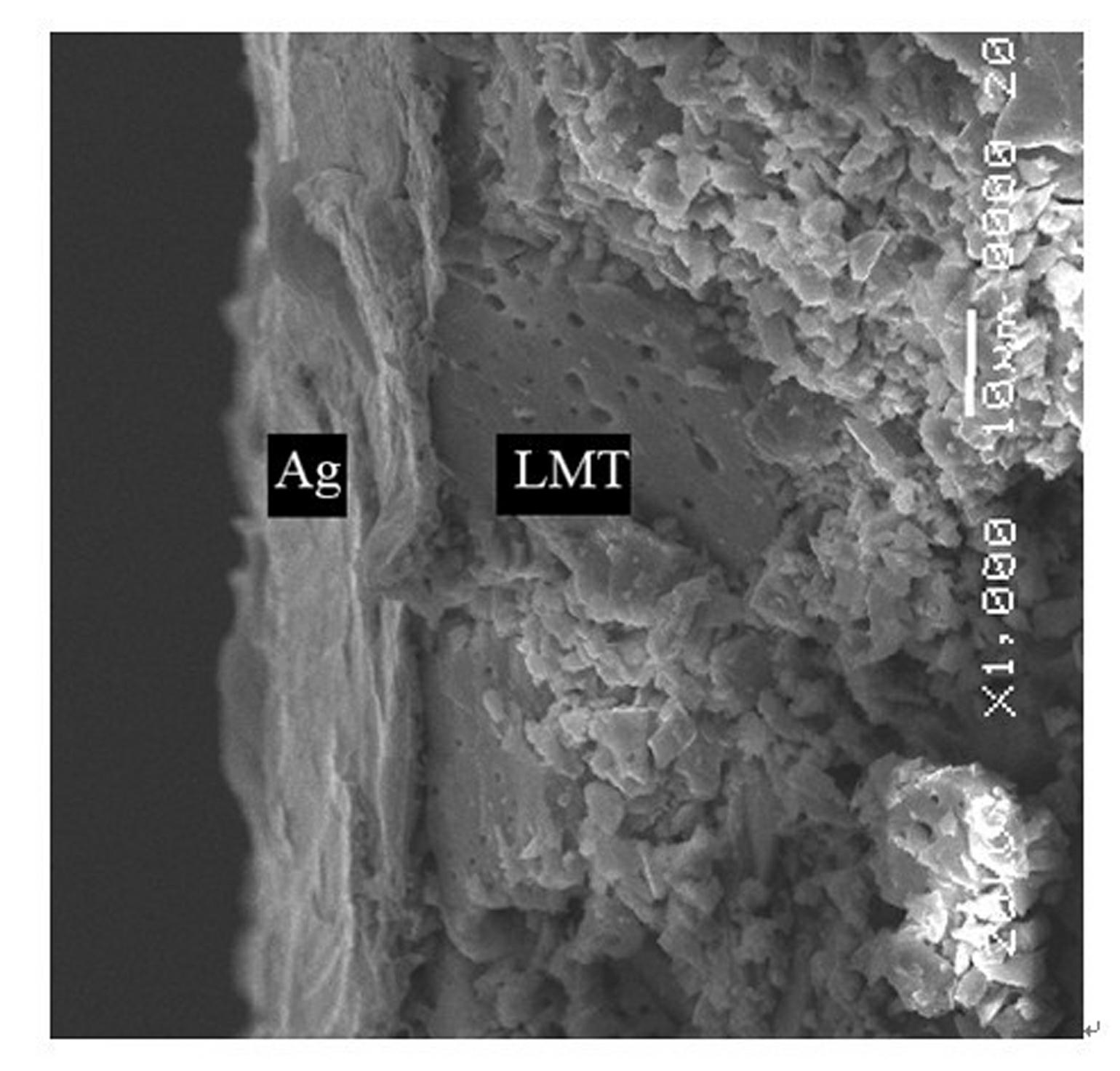

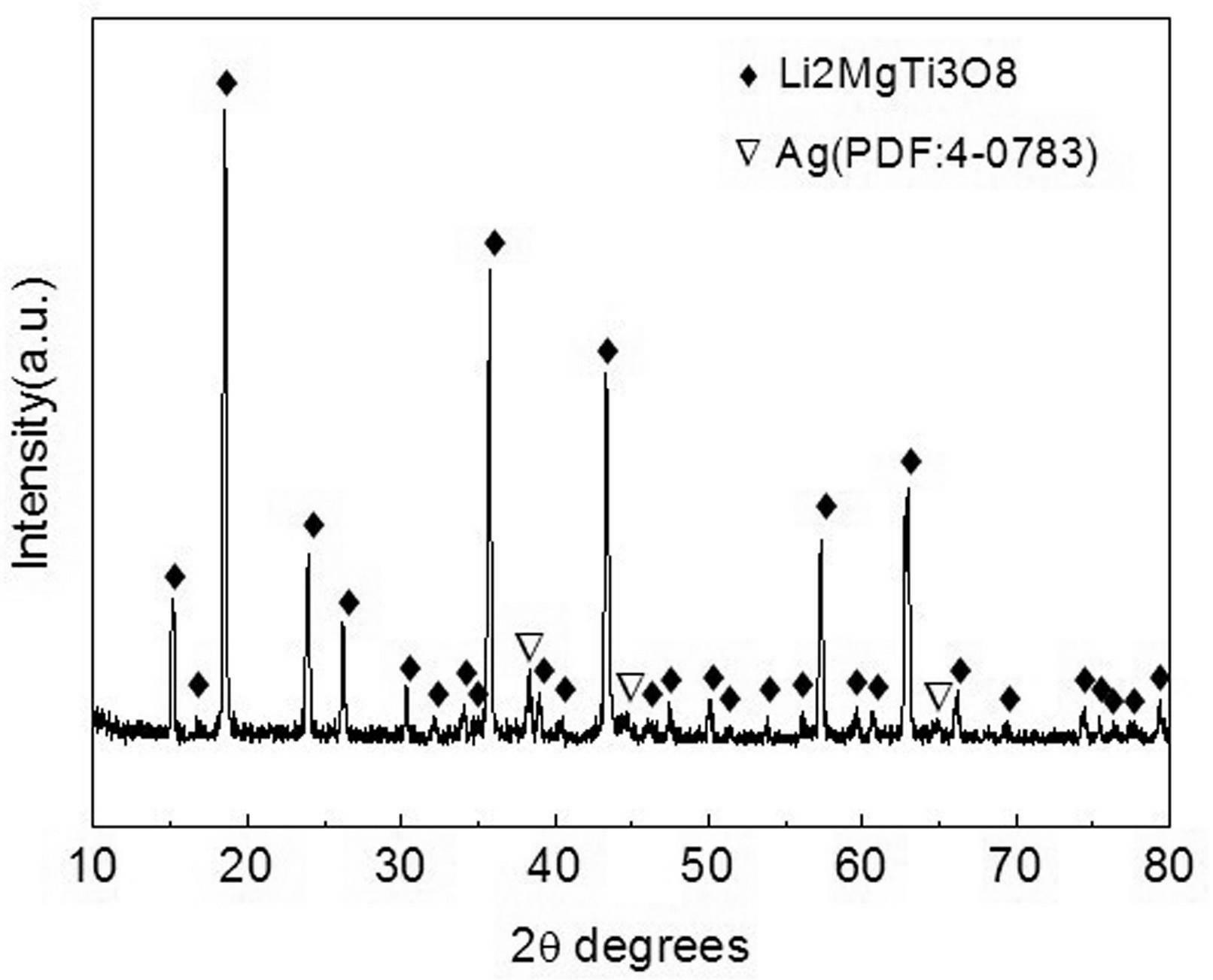

Low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and preparation method thereof

InactiveCN102674829ALower sintering temperatureImprove Microwave PerformanceCeramicsDielectric resonatorAg electrode

The invention discloses a low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and a preparation method thereof. The material comprises a main powder material Li2MgTi3O8 and low-melting-point Li2O-MgO-B2O3 (LMB) glass powder. The glass powder is added into Li2MgTi3O8 powder in the form of powder and then the mixture is evenly mixed in a ball mill and is dried, granulated and fired to obtain the material. The proportions of components for preparing the material are determined by taking the Li2MgTi3O8 powder as a reference, wherein the weight of the glass powder accounts for 0.5-3 percent of the weight of Li2MgTi3O8 powder. The material can be obtained through the traditional solid-phase reaction synthesis method. The low-temperature co-fired microwave dielectric ceramic material prepared by adopting the preparation method has the advantages that the firing temperature is low (approximate 875 DEG C), the microwave dielectric performance is excellent, the dielectric constant (epsilon r) is large, the quality factor (Q-f) is high, the resonant frequency-temperature factor (tf) is close to zero, the effect of co-firing with an Ag electrode is good, high-conductivity low-cost pure silver can be used as an electrode material, the manufacturing cost of devices can be greatly reduced, and the low-temperature co-fired microwave dielectric ceramic material can be used for manufacturing microwave devices such as low-temperature co-fired ceramic (LTCC) systems, multilayer dielectric resonators, microwave antennas and filters.

Owner:GUILIN UNIV OF ELECTRONIC TECH

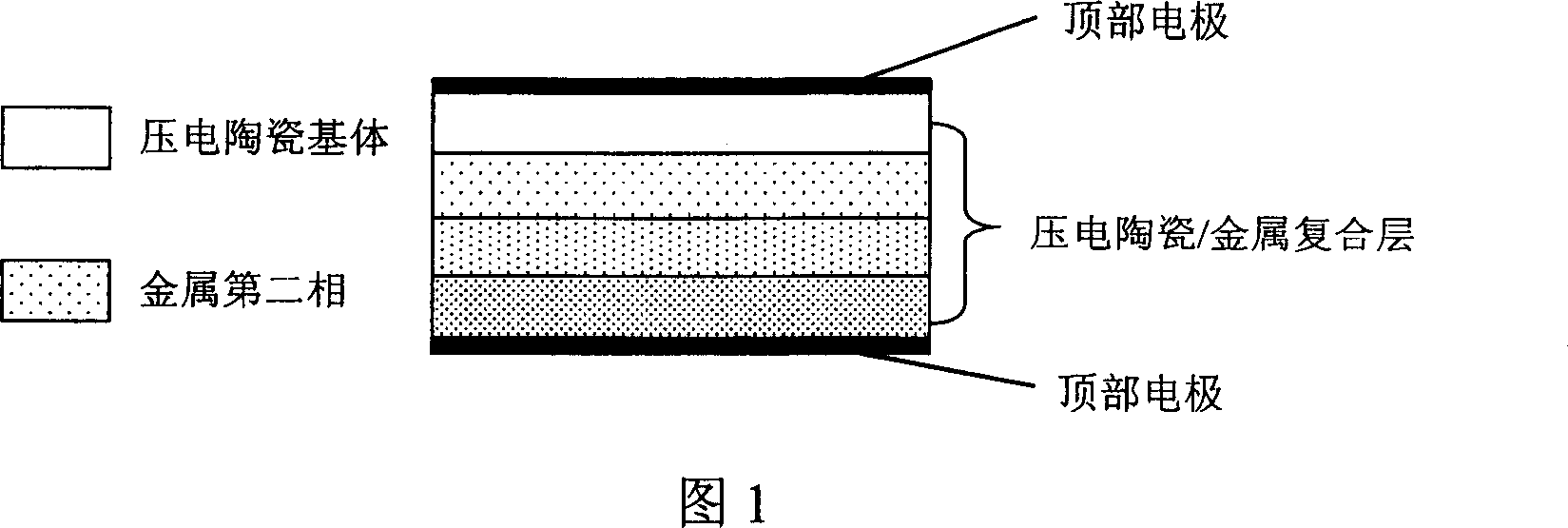

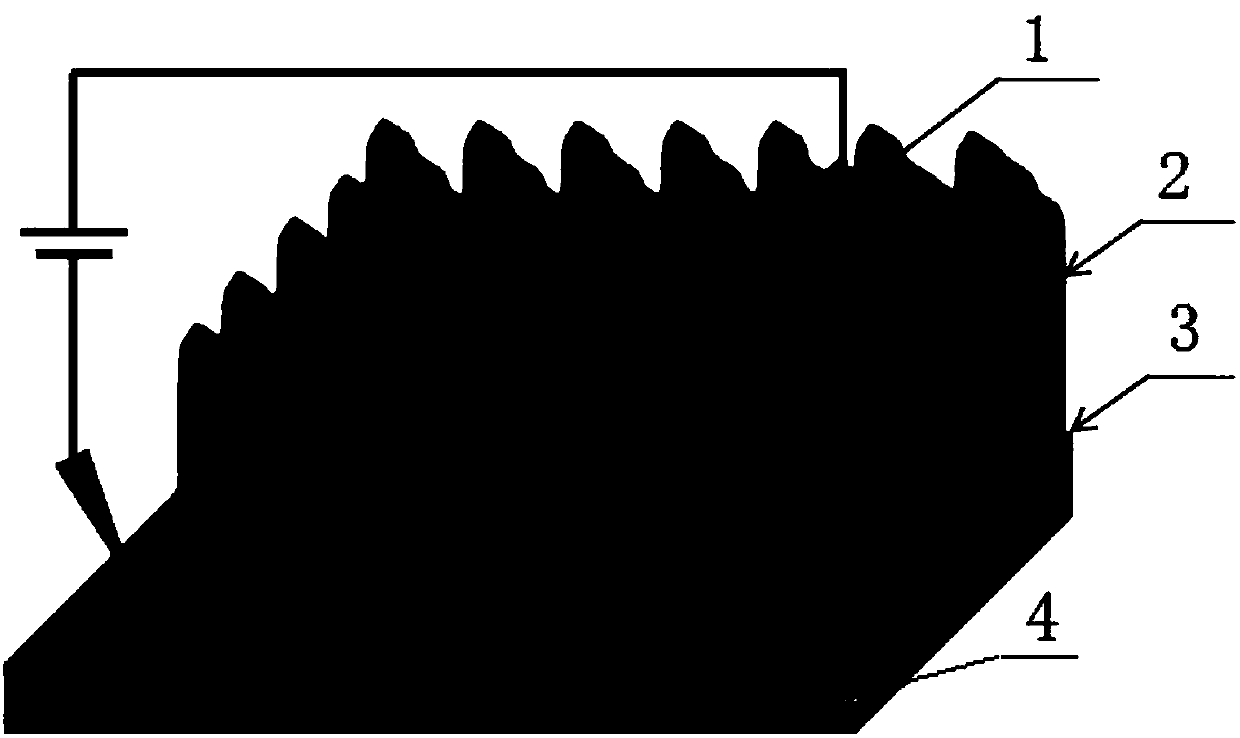

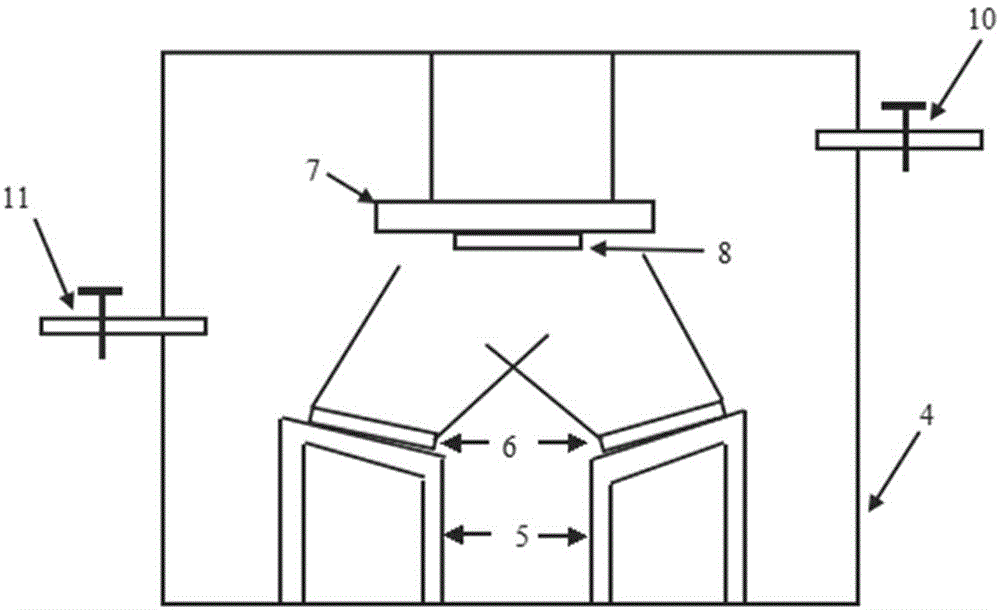

Piezoelectric driving device of functional gradient structure and its preparing method

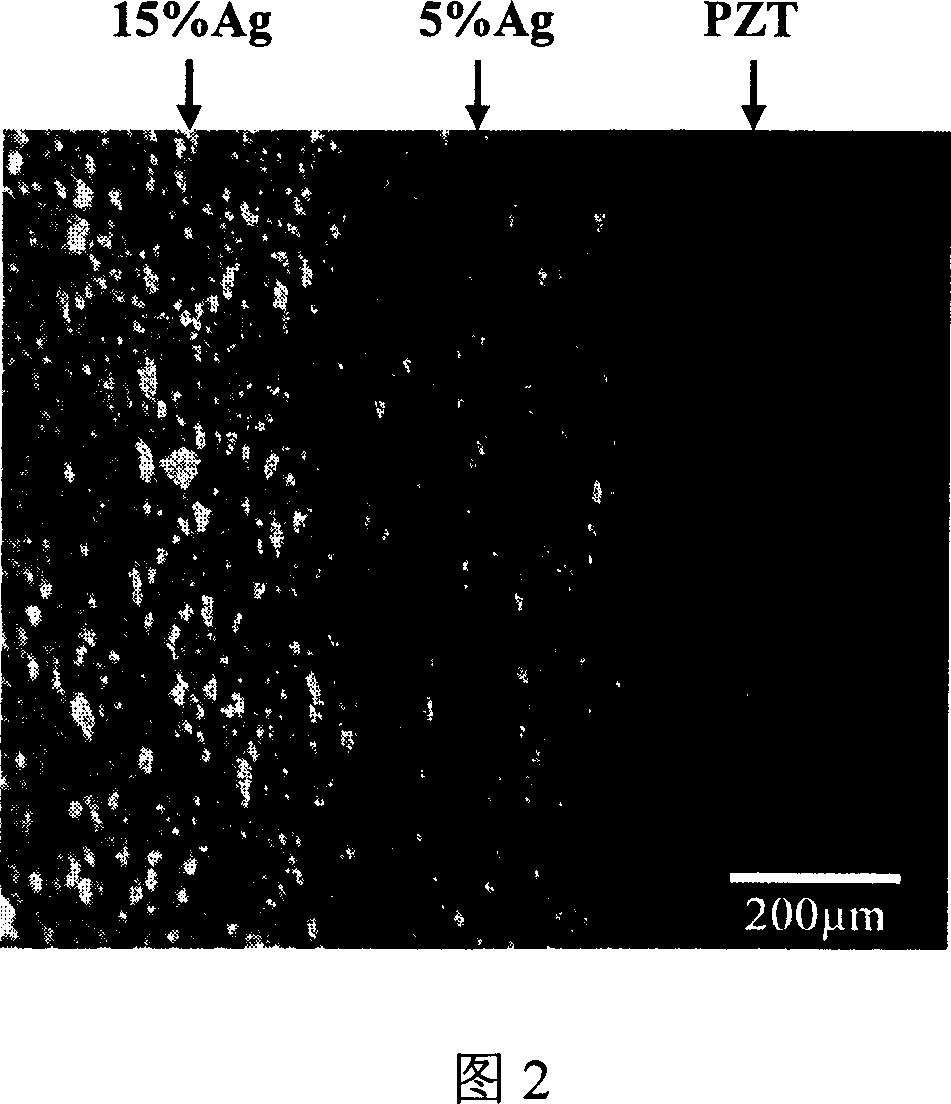

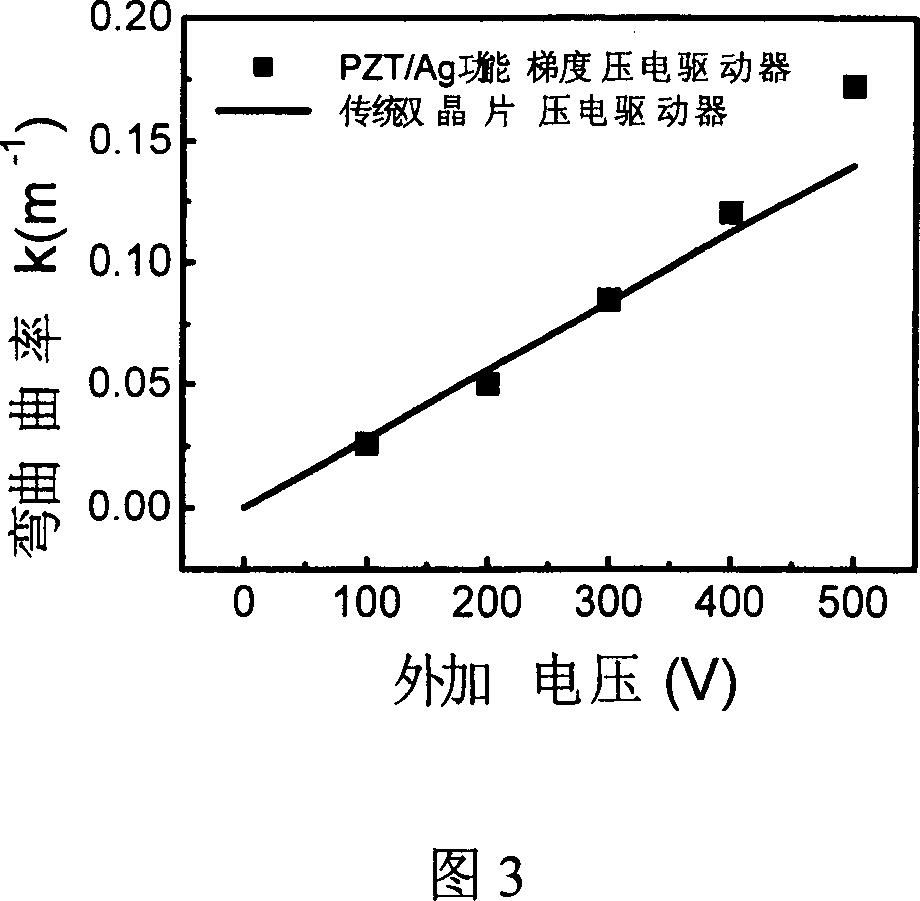

InactiveCN1945869AImprove job stabilityExtended service lifePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesLead zirconate titanatePiezoelectric composite

This invention relates to a piezoelectric drive device and its preparation method for a function grads structure, which applies a powder sinter method to composite PZT piezoelectric ceramics and Ag to form a piezoelectric ceramic compound material with varied Ag composition grads by altering Ag content one layer by one layer, coats Ag electrode on the up and down surfaces of the material and cuts it to molding to get a piezoelectric driver of the PZT / Ag functional grads structure, the sinter temperature of the material is 900-1200deg.C and the maximum content of Ag is 15vol%.

Owner:UNIV OF SCI & TECH BEIJING

Method for manufacturing high-performance perovskite solar energy cell in humid air

ActiveCN106025075AEasy to operateEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrical battery

The invention discloses a method for manufacturing a high-performance planar structure CH3NH3PbI3-X(SCN)x-based perovskite solar energy cell in the humid air. The method comprises steps that hydrolysis of titanium tetrachloride solution is firstly carried out to acquire TiO2 colloid, the colloid acquired through hydrolysis of the titanium tetrachloride solution is deposited on FTO electro-conductive glass to acquire a TiO2 compact layer, a CH3NH3PbI3-X(SCN)x perovskite layer is prepared on the TiO2 compact layer by employing a two-step solution method, a cavity conduction layer is coated on the perovskite layer in a spinning mode, a Ag electrode is prepared through thermal evaporation, and the perovskite cell is finally acquired. Compared with the prior art, the method is advantaged in that the production process is simple, and cost is low.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Back surface junction N-type double-sided crystal silicon cell and preparation method thereof

InactiveCN105206699AImprove life expectancyImprove efficiencyFinal product manufacturePhotovoltaic energy generationAg electrodeSunlight irradiation

The invention provides a back surface junction N-type double-sided crystal silicon cell and a preparation method thereof. The cell comprises a front surface Ag electrode, a front surface antireflection film, a phosphorus diffusion N+ front surface field layer, an N-type substrate, a boron diffusion emission electrode P+ layer, a back surface passivation composite film and a back surface AgAl electrode. The front surface and the back surface of the cell have a textured structure. The back surface passivation composite film comprises a borosilicate glass layer and a silicon nitride layer. The borosilicate glass layer is arranged on the boron diffusion emission electrode P+ layer. The silicon nitride layer is deposited on the borosilicate glass layer. Both of the front surface and the back surface of the cell can effectively receive sunlight irradiation for power generation so that comprehensive efficiency of the cell can be enhanced; and the laminated film of the borosilicate glass layer and the silicon nitride layer through oxidation treatment is adopted to act as a boron emission electrode passivation layer and a diffusion masking layer of subsequent phosphorus diffusion so that boron emission electrode passivation and diffusion masking functions can be realized simultaneously, and the process of multiple times of etching and mask deposition in the manufacturing process can be reduced. The back surface junction N-type double-sided crystal silicon cell is simple in technology, high in production efficiency and low in production technology cost.

Owner:中国东方电气集团有限公司

Preparation method of selective emitter solar cell

InactiveCN101950780AReduce one high temperature diffusion processThe process path is simpleFinal product manufactureSemiconductor devicesScreen printingSolar cell

The invention discloses a preparation method of a selective emitter solar cell, comprising the following steps: providing a silicon wafer for carrying out surface texturization; printing a diffusion permeable membrane on the silicon wafer by a first silk-screen printing plate; covering a non-electrode region by using the diffusion permeable membrane printed by the first silk-screen printing plate, exposing an electrode region to be printed; forming a light diffusion layer for the silicon wafer in the non-electrode light-affected region with the permeable membrane, and forming a heavy diffusion layer in the electrode region without the permeable membrane to be printed; carrying out corrosion for removing peripheral PN nodes, washing the membrane, and removing phosphosilicate glasses; preparing a passivation layer and an antireflection layer; and printing by the printing screen printing plate and sintering to form a back Ag electrode, a back Al-BSF and a front Ag electrode. The preparation method for the selective emitter solar cell provided by the invention adopts one-time diffusion to form the light and heavy doping required by the selective emitter solar cell, thereby reducing one-time high-temperature diffusion process, simplifying processes of the technology, and lowering the cost.

Owner:百力达太阳能股份有限公司

Silicon solar cell and manufacturing method thereof

ActiveCN102157624AEfficient removalImprove conversion efficiencyFinal product manufactureSemiconductor devicesResistIndium

The invention relates to a silicon solar cell and a manufacturing method thereof. the method comprises the following steps: (1) carrying out wet-type chemical cleaning on a silicon wafer, and drying; (2) carrying out single-side phosphorus source diffusion on the silicon wafer; (3) placing the silicon wafer into an oxide furnace, and forming an oxide layer; (4) carrying out primary photoetching on the frontage of the silicon wafer; (5) removing the oxide layer of the photoetching graphics part of the silicon wafer; (6) carrying out whirl coating protection on the diffusion surface of the silicon wafer, and then corroding the oxide layer at the back surface; (7) carrying out single-side phosphorus source anew partial diffusion on the silicon wafer; (8) removing the oxide layer at the back surface of the silicon wafer; (9) evaporating a Ti / Pd / Ag electrode on the back surface of the silicon wafer, and then annealing; (10) firstly carrying out whirl coating protection on the back surface of the silicon wafer, and removing an optical resist at the back surface of the silicon wafer; (11) evaporating an indium tin film at the frontage of the silicon wafer by utilizing a magnetic control sputtering device; (12) carrying out secondary photoetching on the frontage of the silicon wafer; (13) carrying out tertiary photoetching on the frontage of the silicon wafer; and (14) removing the optical resist at the frontage of the silicon wafer, and annealing. According to the invention, the cell conversion efficiency can be improved effectively; and the cell and method provided by the invention can be widely used in the field of solar cells.

Owner:CECEP SOLAR ENERGY TECH

Doping agent for dielectric material of ceramic capacitor, dielectric material, and preparation method

InactiveCN1873862ACompliant with large capacityCompliance with reliabilityFixed capacitor dielectricCeramicsRare-earth elementDielectric

The invention is related to technique of electronic material, especially, to technique of capacitor material including dopant of dielectric materials of ceramic capacitor, dielectric materials, and preparation method. The bases of dopant are composite oxides including following elements expressed in formula: aR+bA +cB+dC, where R as oxides of rare earth elements including Nd2O3; A as alkali oxide / alkaline earth including Li2O, Na2O etc.; B as oxide of transition metal including MnO2; C as non-metallic oxide including B2O3, SiO2; a, b, c, d as coefficients in weight percent. Useful effects are: easy to control agglomeration technology, good evenness of produced material, good repeatability. The disclosed material is applicable to prepare X7R type MLCC of miniaturized Pd-Ag electrode with large capability.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

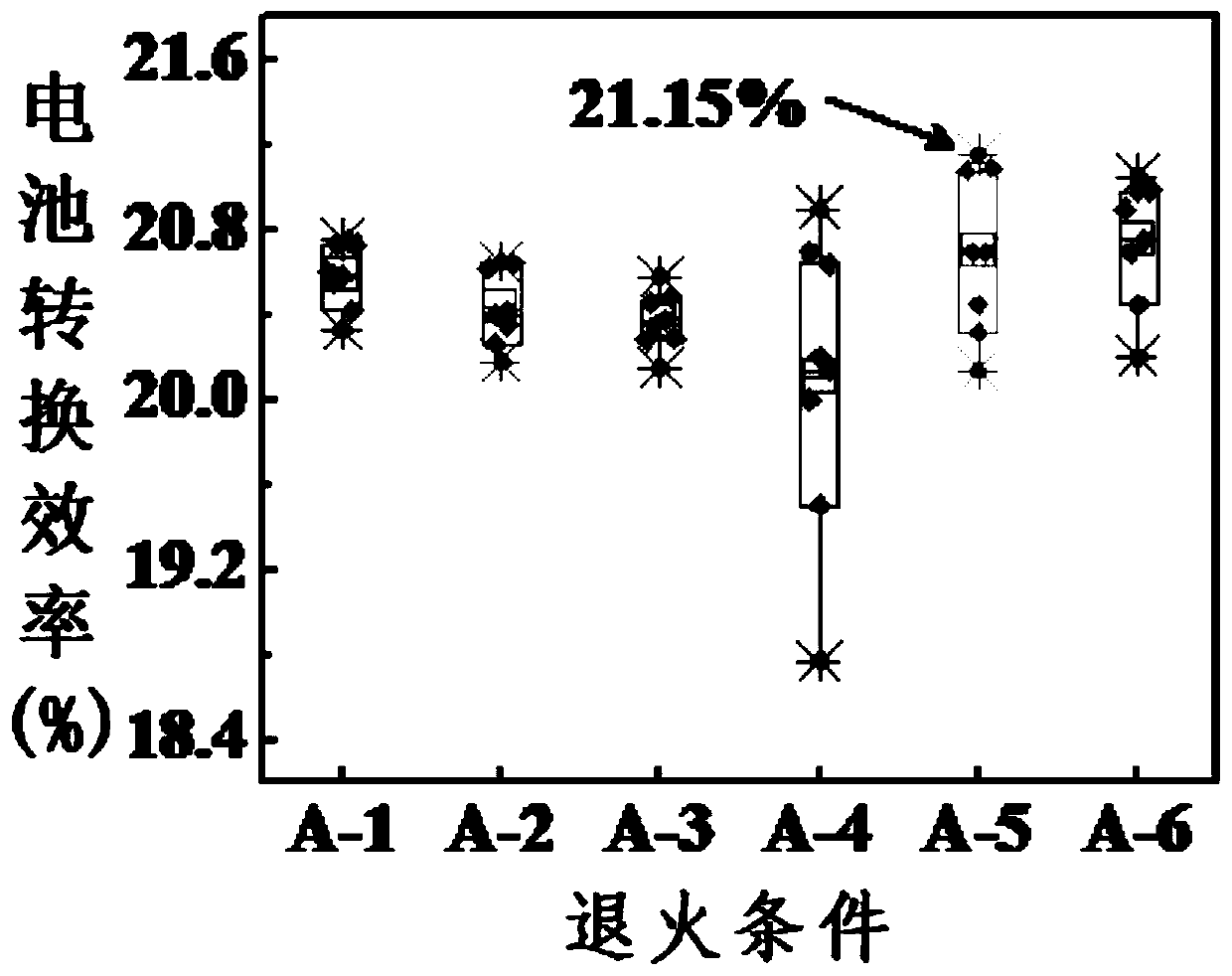

N-type crystalline silicon PERT double-sided battery with new structure and preparation method of n-type crystalline silicon PERT double-sided battery

InactiveCN110880541AReduce compoundingImprove compactnessFinal product manufacturePhotovoltaic energy generationSilicon solar cellSilicon oxide

The invention discloses an n-type crystalline silicon PERT double-sided battery with a new structure and a preparation method of the n-type crystalline silicon PERT double-sided battery, and relates to the silicon solar cell field. A p + emitter layer, a hydrogenated silicon nitride antireflection layer and an Ag / Al electrode are sequentially formed on the front surface of a n-type crystalline silicon substrate, a p + + selective emitter region is locally formed on the p + emitter layer, and a silicon oxide layer, a p-doped polycrystalline silicon layer, a hydrogenated silicon nitride passivation layer and an Ag electrode are sequentially formed on the rear surface of the n-type crystalline silicon substrate. According to the present invention, the laser doping is carried out on the surface of the borosilicate glass subjected to conventional diffusion to reduce the carrier recombination of a metal contact area, and the devices, such as the low-pressure diffusion devices, etc., are notneeded for making high sheet resistance; an ultrathin silicon oxide layer with good performance is prepared in a simple, easy-to-control and extremely-low-cost nitric acid chemical oxidation mode; after the proper side insulation and high-temperature annealing processing, the characteristics of the front side structure and the rear side structure of the battery can be improved at the same time, the mutual interference is avoided, the follow-up lifting space is large, and the important significance is achieved.

Owner:SHANGHAI JIAO TONG UNIV

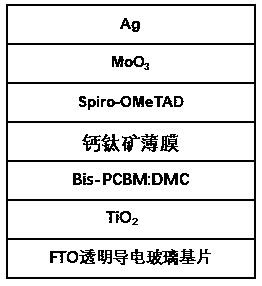

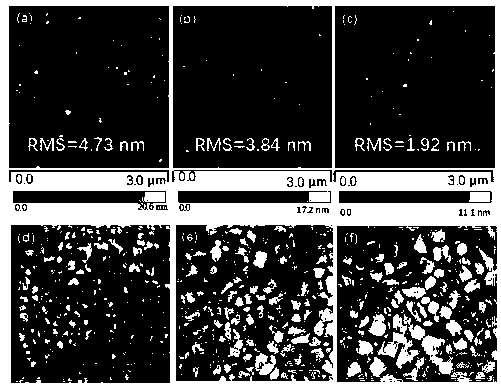

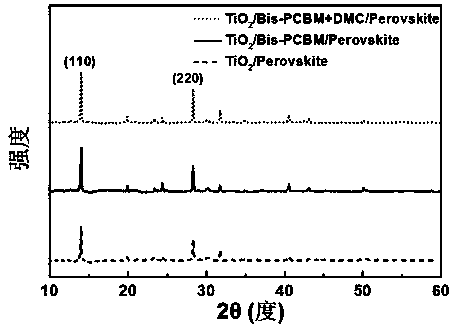

Preparation method of perovskite battery with n-type doped electron transport layer and TiO2 layer

ActiveCN108091766AIncrease short circuit currentImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEvaporation (deposition)Electrical battery

The invention provides a preparation method of a perovskite battery with an n-type doped electron transport layer and a TiO2 layer. The method comprises the following steps of: (1) FTO transparent conductive glass substrate cleaning and TiO2 thin film preparation: an upper TiO2 layer is deposited on a treated FTO transparent conductive glass substrate, and the FTO transparent conductive glass substrate with the deposited upper TiO2 layer is arranged in a drying oven for later use; (2) Bis-PCBM and DMC composite film preparation; (3) spin coating treatment on the FTO transparent conductive glass substrate with the deposited upper TiO2 layer; (4) perovskite film preparation; (5) Spiro-OMeTAD thin film preparation: a Spiro-OMeTAD solution is spin coated on the FTO transparent conductive glass substrate in step (4); and (6) MoO3 and Ag electrode preparation: an MoO3 electrode and Ag electrode are formed on a Spiro-OMeTAD thin film through evaporation. With the method of the invention adopted, the electron mobility and conductivity of a thin film can be improved; the photoelectric conversion efficiency of a device can be improved; the surface of the thin film is smoother, so that the thin film can be used as a good substrate for the deposition and growth of a perovskite layer in subsequent processes; and the degradation process of the perovskite layer can be slowed down, and the stability of the device can be improved.

Owner:SUZHOU UNIV

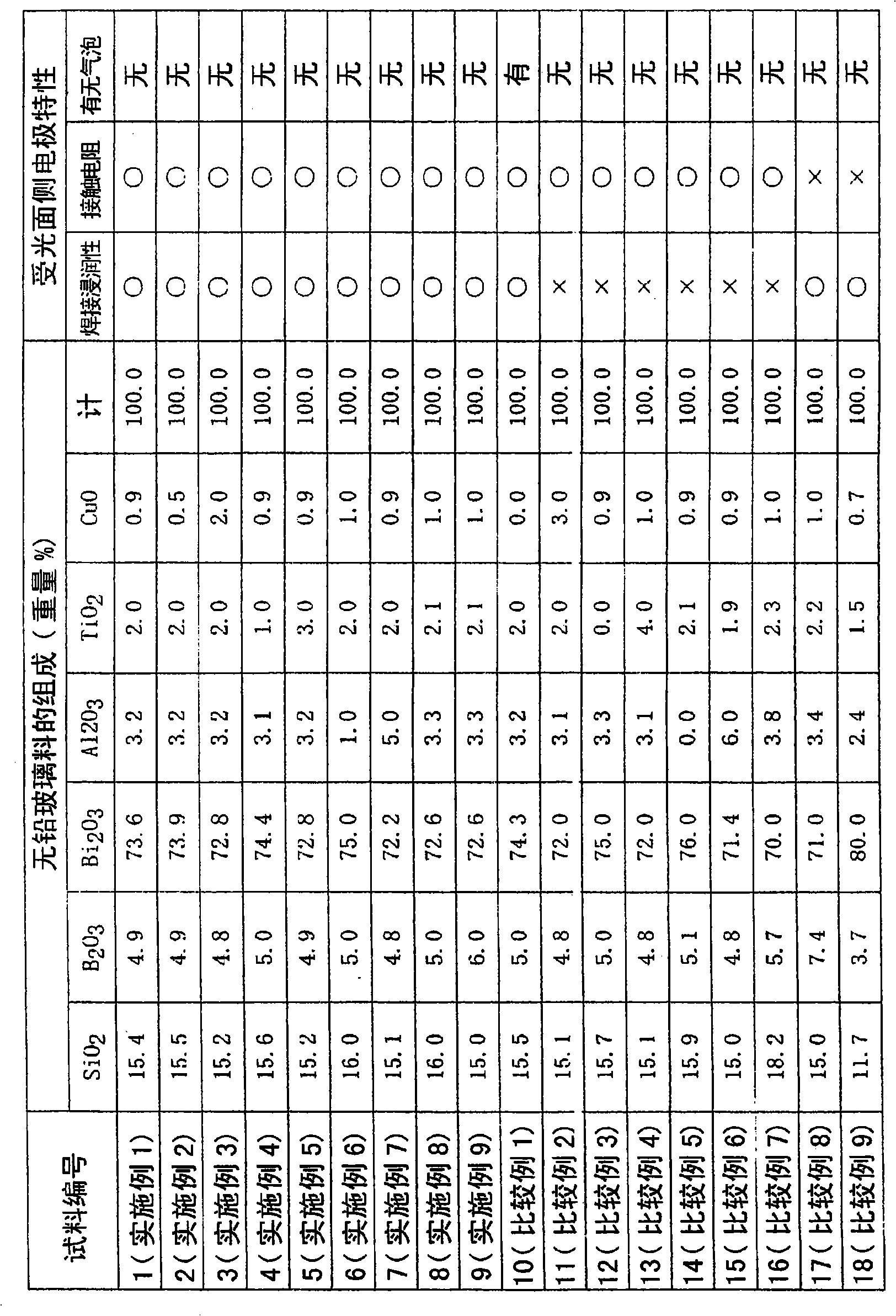

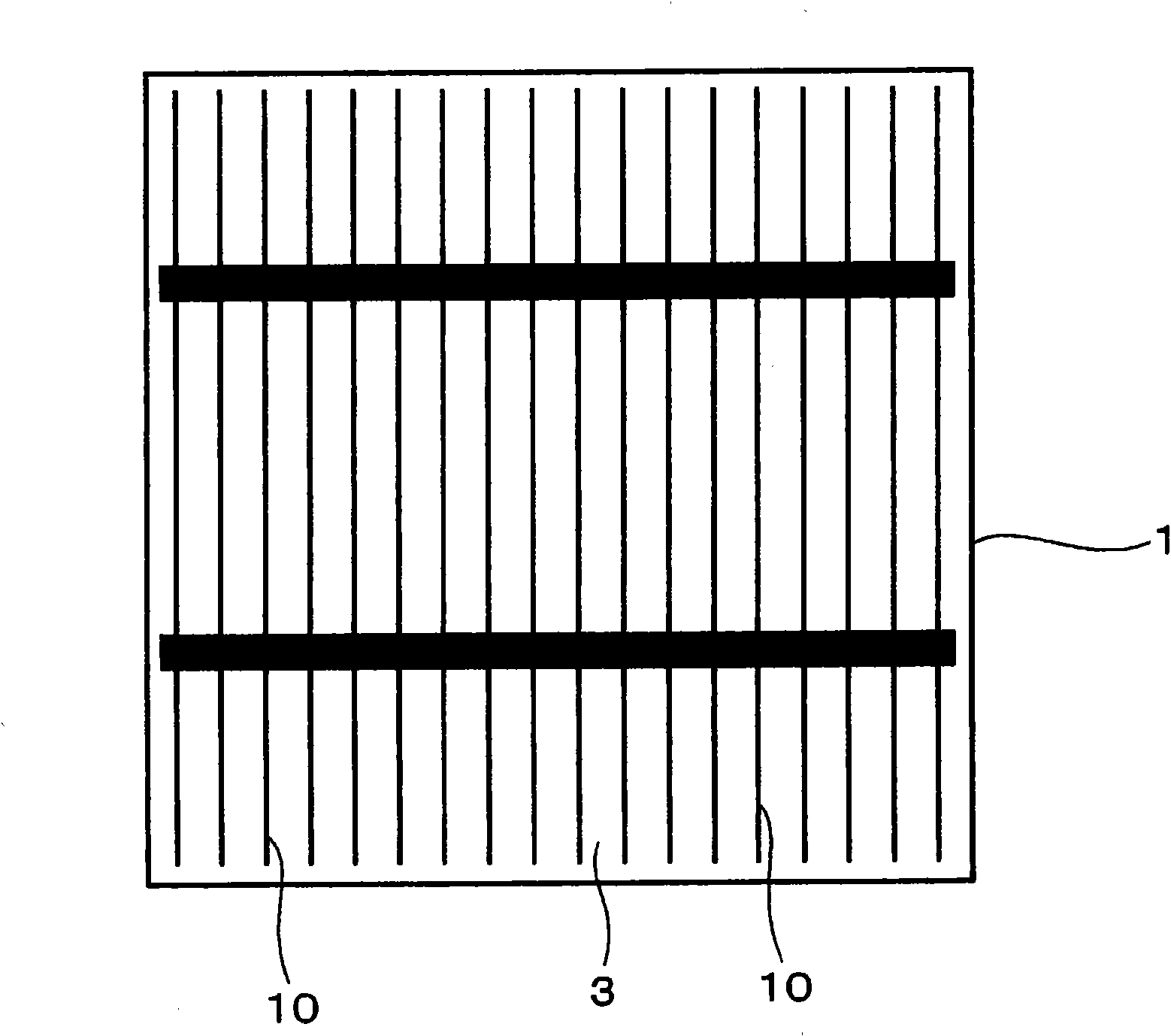

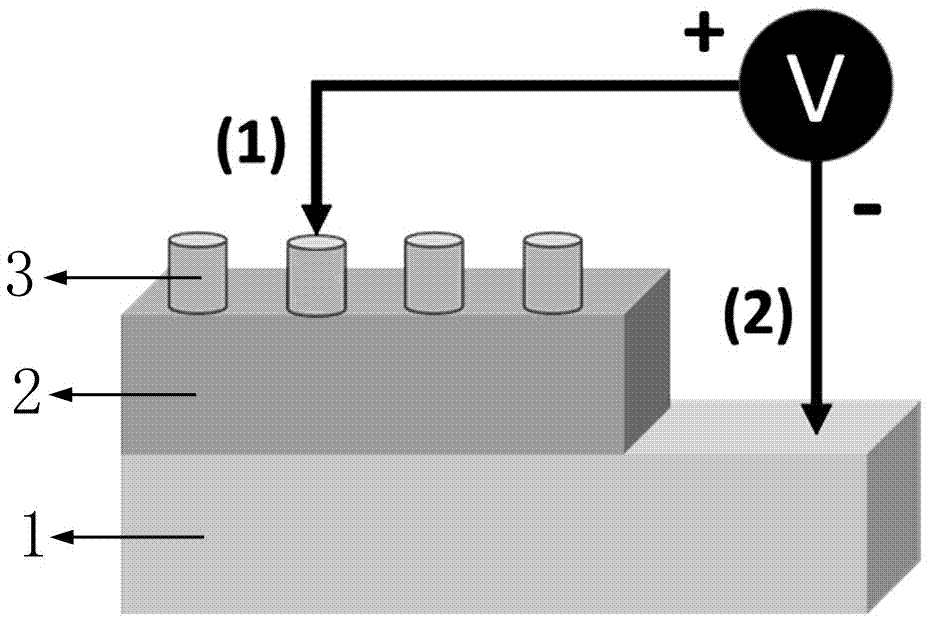

Ag electrode paste, solar battery cell, and process for producing the solar battery cell

ActiveCN101809758AAvoid it happening againLower resistanceNon-conductive material with dispersed conductive materialPrinted circuitsSolar batteryAg electrode

Owner:MURATA MFG CO LTD

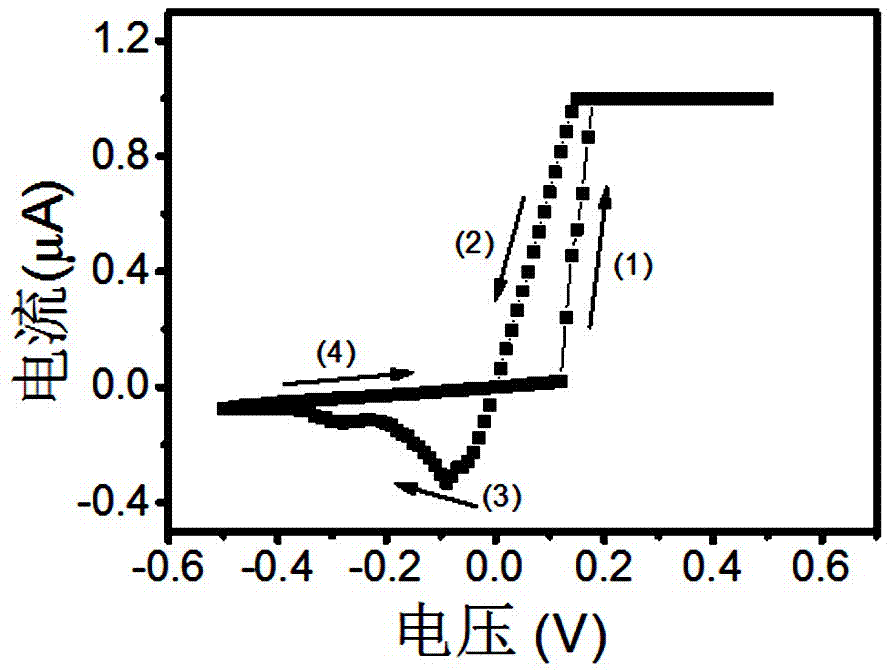

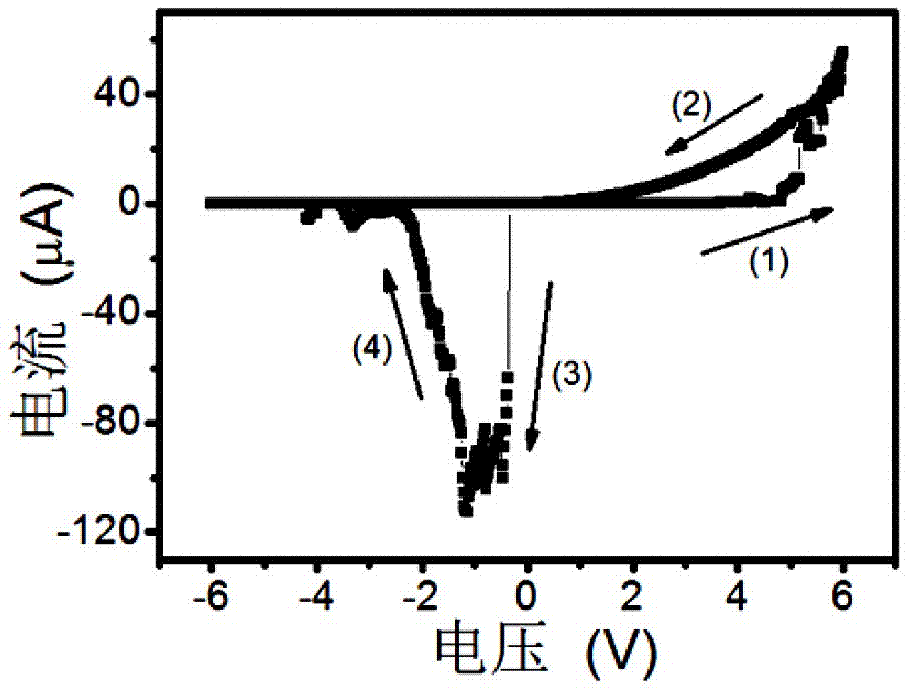

Resistance-changing nerve simulation device having organic biocompatibility and preparation method and application thereof

ActiveCN107425119AStable resistance changeOvercome compatibilityElectrical apparatusProtein solutionHigh resistance

The invention discloses a resistance-changing nerve simulation device having organic biocompatibility. The resistance-changing nerve simulation device comprises an ITO glass substrate, wherein a composite organic protein film and an Ag electrode film are sequentially grown on an ITO film of the ITO glass substrate, and the composite organic protein film is composite film of silver-doped wool keratin and silk protein. The preparation method comprises the steps of a) preparing a wool keratin solution; b) preparing a silk protein solution; c) preparing the silver-doped wool keratin solution; d) preparing the composite organic protein solution; e) cleaning the substrate; f) forming the composite organic protein film; and g) growing the Ag electrode film. Moreover, the invention discloses application of the device. The device prepared by a special method shows relatively stable resistance value change, difference between a high-resistance value and a low-resistance value is relatively large, and a switch voltage is relatively concentrated; and moreover, the resistance-changing nerve simulation device has a nerve simulation function, is simple in process, is easy to operate and has a wide application prospect.

Owner:HEBEI UNIVERSITY

Preparation method of solar cell with elimination of printing wave line

InactiveCN102437241AEasy to operateEasy to industrializeFinal product manufactureOther printing apparatusBack surface fieldSlurry

The invention relates to a preparation method of a solar cell with elimination of a printing wave line. The method is characterized in that the method comprises the following steps that: a silicon wafer is inserted into a petal basket along the downward direction of a cutting trace of the silicon wafer; the monocrystalline silicon wafer is provided and surface texturing is carried out; the processed silicon wafer is inserted into a quartz boat along the downward direction of the cutting trace of the silicon wafer; a diffusion layer is formed on the surface of the silicon wafer that has been processed by texturing; the diffused silicon wafer is placed in a bearing box along a certain direction; etching is carried out to remove PN nodes around the silicon wafer as well as the etched silicon wafer is inserted into the petal basket along the downward direction of the cutting trace of the silicon wafer; pickling is carried out to remove phosphosilicate glass; a passivation and antireflection layer is manufactured; and the silicon wafer that has been processed by film coating is placed in a to-be-printed bearing box along a certain direction, so that after printing, a fine grid line direction is vertical to a cutting line direction; and a cell back side slurry and a right side slurry are successively printed as well as sintering is carried out to form a back side Ag electrode, a back side aluminium back surface field and a right side Ag electrode. According to the invention, the method can be operated simply and conveniently; and compared with a traditional production mode, the industrialized production mode enables no extra production cost to be generated.

Owner:百力达太阳能股份有限公司

Solar cell structure with anti-potential induced degradation (PID) effect and production method of solar cell structure

ActiveCN105140306ALattice coefficient matchingGood passivation effectFinal product manufactureSemiconductor devicesPotential induced degradationSolar cell

The invention relates to a solar cell structure with an anti-potential induced degradation (PID) effect and a production method of the solar cell structure. The solar cell comprises a base layer, a P+ layer, a silicon base body, a diffusion layer, a thermal oxidation SiOx layer, a dual-layer plasma enhanced chemical vapor deposition (PECVD) SiNx film and an Ag electrode, wherein the thermal oxidation SiOx layer is used for improving the anti-PID capacity of the solar cell; and the production method of the solar cell with the anti-PID effect comprises a pretreatment step, a high-temperature quartz tube cleaning saturation step, a high-temperature oxidation step, a growth step of the dual-layer PECVD SiNx film and a post-treatment step. The physical structure of SiOx is applied to the surface of the solar cell to form a stable film layer, so that the influenceon the solar cell caused by the outside iseffectively isolated; and the anti-PID effect is reached. The anti-PID effect can be realized without inputting of lot of money for equipment purchasing and gas path transformation; an oxidation layer grown by the method is good in compactness; and the anti-PID attenuation test result at an assembly end shows that the assembly power attenuation is kept at 0.5%-1.5% and bettter-than-expected anti-PID effects are achieved.

Owner:선테크파워컴퍼니리미티드

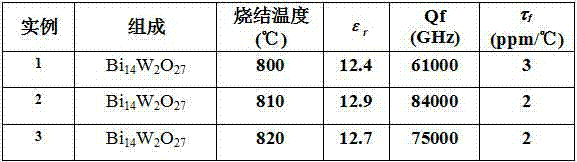

Low-temperature sintering temperature-stable microwave dielectric ceramic Bi14W2O27 and preparation method thereof

ActiveCN103496981APromote sinteringResonant frequency temperature coefficient is smallAir atmosphereDielectric

The invention discloses a low-temperature sintering temperature-stable microwave dielectric ceramic and a preparation method thereof. The composition formula of the low-temperature sintering temperature-stable microwave dielectric ceramic is Bi14W2O27. The preparation method comprises the steps of (1) weighing and batching original powder of Bi2O3 and WO3 with the purity being over 99.9% according to the chemical formula Bi14W2O27; (2) carrying out wet ball-milling and mixing on raw materials obtained in the step (1) for 12 hours, taking distilled water as a solvent, drying, and then, pre-sintering in an air atmosphere for 6 hours at the temperature of 700 DEG C; (3) adding a binder into powder prepared in the step (2), granulating, then, carrying out compression molding, and finally, sintering in the air atmosphere for 4 hours at the temperature of 800-820 DEG C, wherein a polyvinyl alcohol solution with the mass concentration of 5% is adopted as the binder, and the dosage of the binder accounts for 3% of the total mass of the powder. According to the ceramic prepared by the preparation method, the sintering at the temperature of 800-820 DEG C is good, the dielectric constant reaches 12-13, the quality factor (Qf) reaches up to 61,000-84,000GHz, the temperature coefficient of resonance frequency is small, and the ceramic can be subjected to low-temperature co-sintering together with a Ag electrode, so that the ceramic has a great application value in industries.

Owner:苏州弘吴科技中介服务有限公司

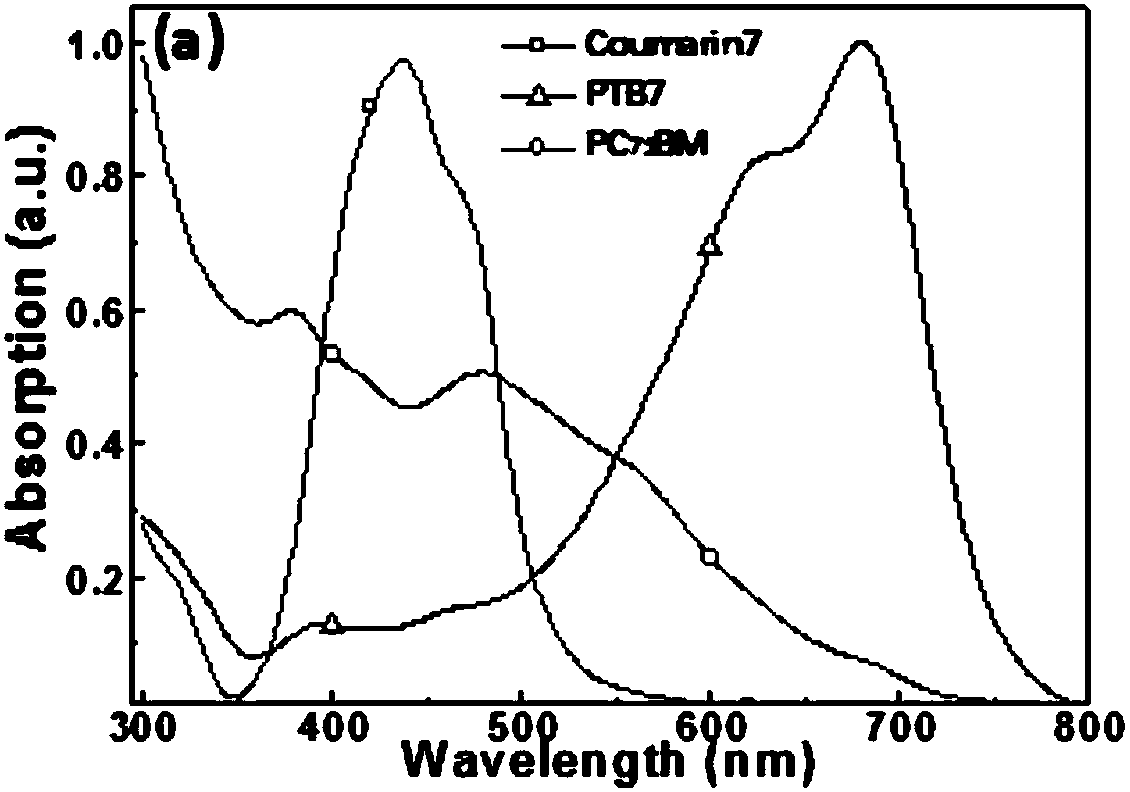

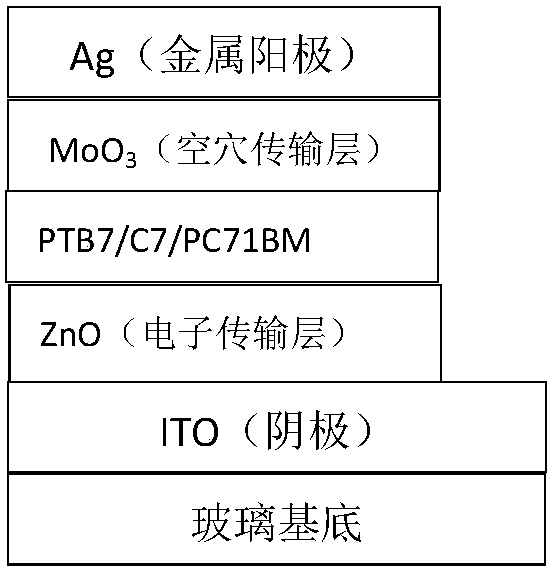

Preparation method of ternary organic solar cell

InactiveCN108288674ALow efficiencyImprove air stabilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellSpins

The invention discloses a preparation method of a ternary organic solar cell, and belongs to the field of the solar cell. The preparation method comprises the following steps of (1) configuration of an active layer material: taking CB as a solvent, taking PTB7 and a coumarin derivative as a donor material based on the mass ratio of PTB7 to the coumarin derivative of 0.7:0.1-1:0.l; taking PC71BM asan acceptor material at the mass ratio of the donor material to the acceptor material of 1:1-1:3; enabling the donor material, the acceptor material and the solvent to be mixed into an active layer solution with the concentration of 7-15mg / ml; (2) performing ZnO solution configuration; (3) performing cleaning on ITO glass, and then carrying out plasma ozone treatment; (4) spin coating the surfaceof the ITO glass with ZnO, and then carrying out heating and annealing; (5) spin coating the annealed ITO glass with the active layer material, and then carrying out heating and annealing to form anactive layer; and (6) evaporating an MoO<3> layer on the surface of the active layer and then evaporating an Ag electrode. By virtue of the preparation method, efficiency improvement of the device canbe facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

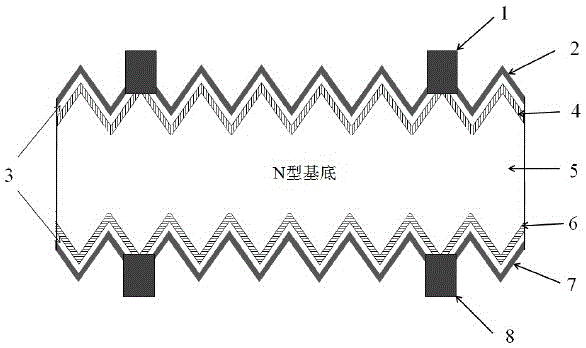

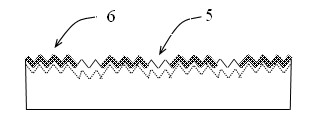

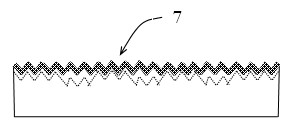

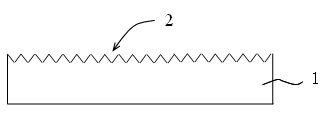

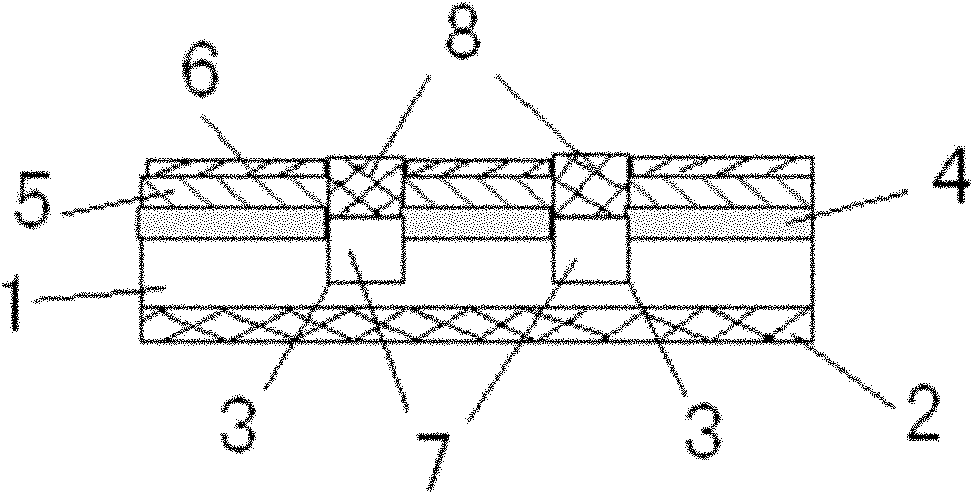

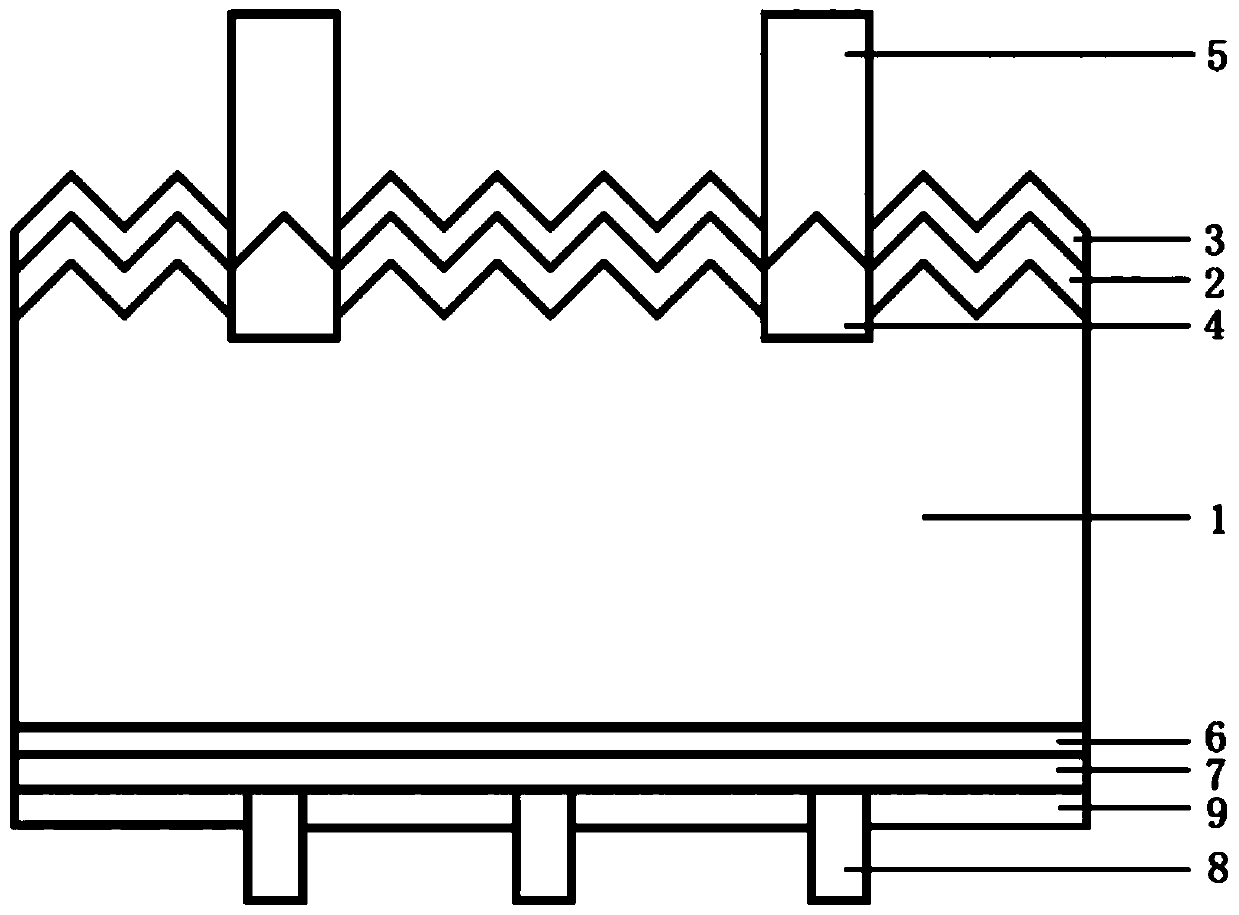

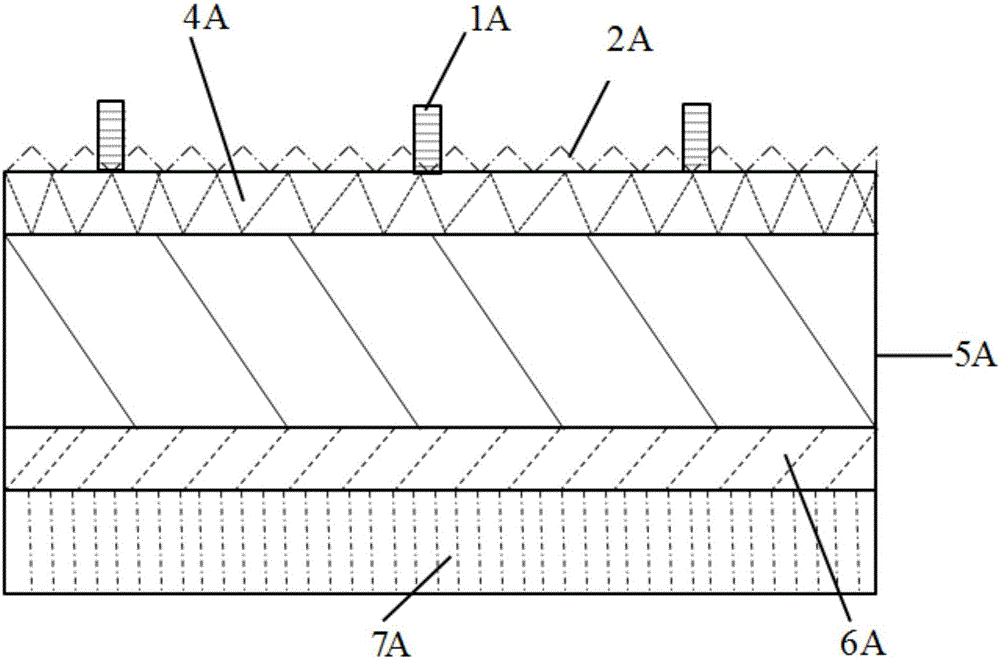

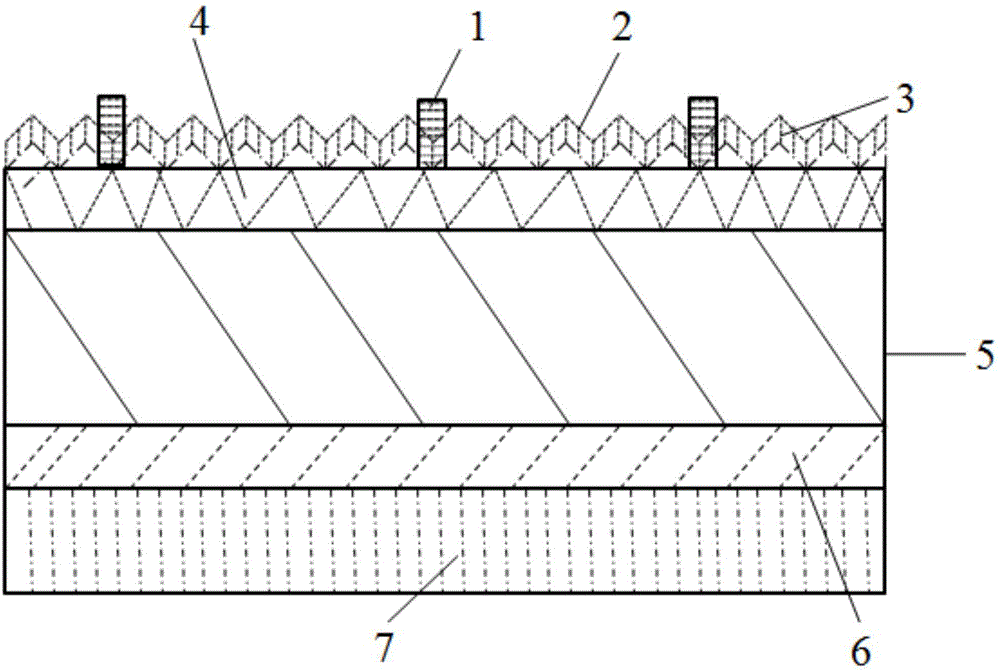

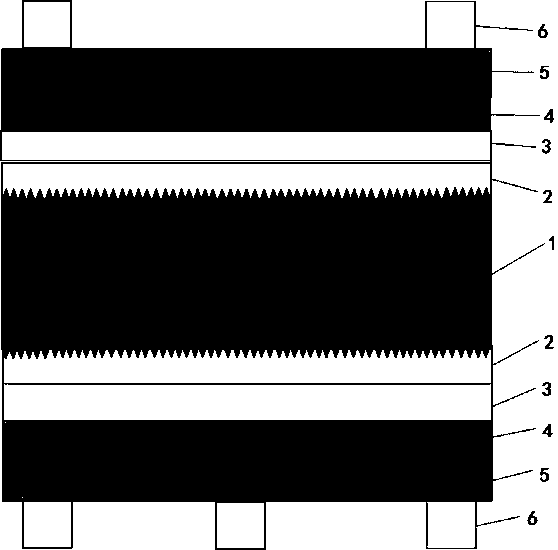

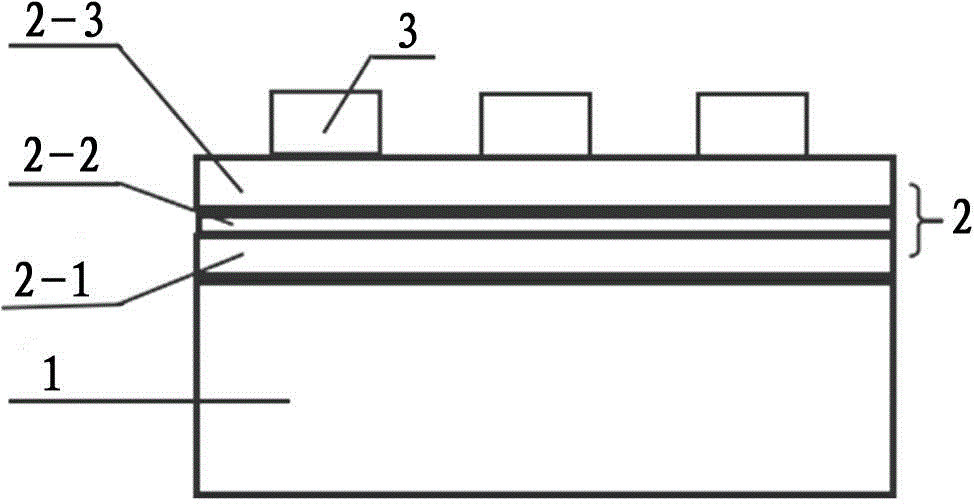

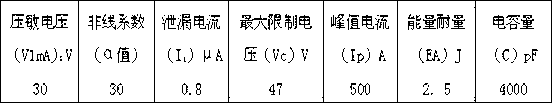

High-efficiency heterojunction battery intrinsic amorphous silicon passivation layer structure and preparation method thereof

InactiveCN109638094AIncreased film hydrogen contentAvoid epitaxial growthFinal product manufacturePhotovoltaic energy generationHeterojunctionSilanes

The invention relates to a high-efficiency heterojunction battery intrinsic amorphous silicon passivation layer structure and a preparation method thereof, the high-efficiency heterojunction battery intrinsic amorphous silicon passivation layer structure comprises an N-type crystal silicon wafer (1), and the front surface and the back surface of the N-type crystal silicon wafer (1) are respectively provided with a plurality of amorphous silicon intrinsic layers. An amorphous silicon doping layer (4) is arranged on the outer side of a second amorphous silicon intrinsic layer (3), a TCO conductive film (5) is arranged on the outer side of the amorphous silicon doping layer (4), and a plurality of Ag electrodes (6) are arranged on the outer side of the TCO conductive film (5). The amorphous silicon intrinsic layer adopts lamination, the first layer adopts pure silane deposition, epitaxial growth caused by initial deposition of a crystalline silicon / amorphous silicon interface is effectively avoided, and the second layer adopts high-hydrogen diluted silane deposition, so that the hydrogen content of a thin film of the first layer of amorphous silicon is increased, and interface passivation is enhanced at the same time.

Owner:SUZHOU AIKANG LOW CARBON TECH INST

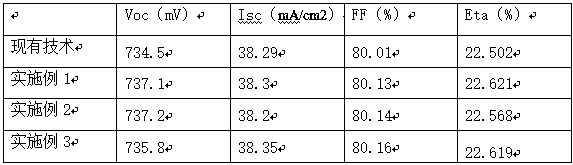

Microwave dielectric ceramic Ba3Ti2V4O17 capable of realizing low temperature sintering and preparation method thereof

ActiveCN103342558APromote sinteringResonant frequency temperature coefficient is smallDielectricPolyvinyl alcohol

The invention discloses a microwave dielectric ceramic Ba3Ti2V4O17 capable of realizing low temperature sintering and a preparation method thereof. A vanadate microwave dielectric ceramic material capable of realizing low temperature sintering has the composition of Ba3Ti2V4O17. The preparation method comprises the following steps of: (1) weighing and dosing original powder of BaCO3, TiO2 and V2O5 with the purity of over 99.9 percent according to a chemical formula of Ba3Ti2V4O17; (2) performing wet ball milling and mixing the raw materials in the step (1) for 12 hours, wherein the solvent is distilled water, and pre-sintering at the temperature of 750 DEG C in atmosphere for 6 hours after drying; and (3) adding an adhesive into the powder prepared in the step (2) and pelleting, pressing and forming, and finally, sintering at the temperature of 830-850 DEG C in atmosphere for 4 hours, wherein the adhesive is a polyvinyl alcohol solution with the mass concentration of 5 percent, and the dose accounts for 3 percent of the total mass of the powder. The prepared ceramic has good sintering performance at the temperature of 850-900 DEG C and has the dielectric constant of 15-16, quality factor Qf is up to 77000-93000GHz, the resonant frequency temperature coefficient is low, the microwave dielectric ceramic can be subjected to low-temperature co-firing with an Ag electrode, and the microwave dielectric ceramic has extremely high application value in industry.

Owner:苏州弘吴科技中介服务有限公司

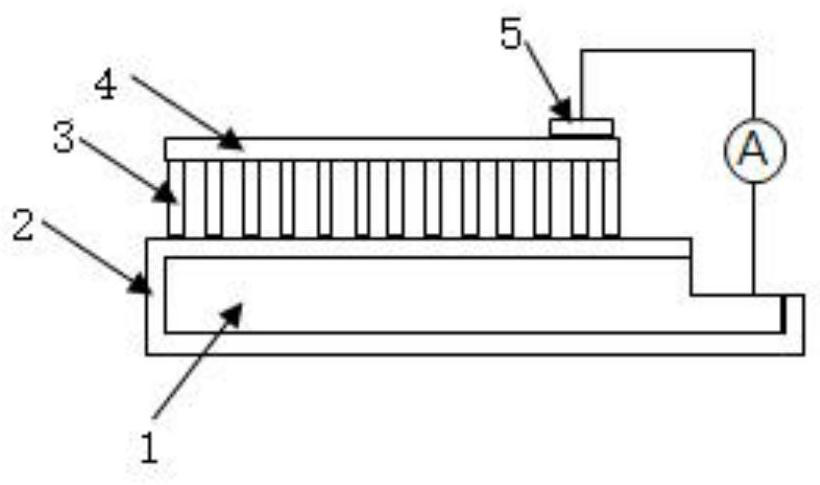

Cu2O/GaOOH nano core-shell pn junction photoelectric detector and preparation method thereof

ActiveCN107819076AImprove utilization efficiencyStrong absorption capacityMaterial nanotechnologySolid-state devicesPhotovoltaic detectorsNanocrystal

The invention belongs to the field of photoelectric detectors, and specifically relates to a Cu2O / GaOOH nano core-shell pn junction photoelectric detector and a preparation method thereof. The Cu2O / GaOOH nano core-shell pn junction photoelectric detector comprises an Ag electrode, Cu2O nano-crystals, a GaOOH nano-column array, a Ga2O3 seed crystal layer and FTO conductive glass, and is characterized in that the Ga2O3 seed crystal layer is located on the FTO conductive glass, the Cu2O / GaOOH nano-column array is located on the Ga2O3 seed crystal layer, Cu2O / GaOOH nano-columns are formed by GaOOHnano-columns and the Cu2O nano-crystals, the GaOOH nano-column array is located on the Ga2O3 seed crystal layer, and the Cu2O nano-crystals wrap the outer periphery of the GaOOH nano-columns. The Cu2O / GaOOH nano core-shell pn junction prepared according to the invention has a large specific surface area, is strong in absorption for light, can achieve wide-spectrum detection and provides an effective method for constructing a high-performance photoelectric detector. The preparation method is simple to operate, low in cost and good in repeatability, and certainly has great application prospectsin the photoelectric field in the future.

Owner:ZHEJIANG SCI-TECH UNIV

Double-clotted-layer solar cell and making method

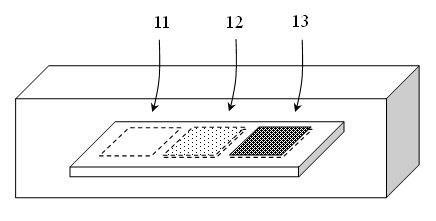

InactiveCN1851935AAvoid the phenomenon of photoelectric performance degradationImprove efficiencyFinal product manufacturePhotovoltaic energy generationSolar cellMicrocrystalline silicon

This invention discloses a double-layer solar energy battery and its manufacturing method, in which, the structure of which includes a substrate-a Ag electrode layer, a metal oxide transparent conduction layer / type-n micro-crystal silicon-type-I non-crystal (12)-p-micro-crystal silicon (13) / ITO transparent conduction layer, the I layer in the bottom layer p-i-n junction is formed by micro-crystal silicon to avoid decline of photoelectric performance due to the long time illumination and layer-I in the p-i-n junction at the top is plated with non-crystal silicon to strengthen the spectrum absorption.

Owner:姜堰新金太阳能光伏制造有限公司

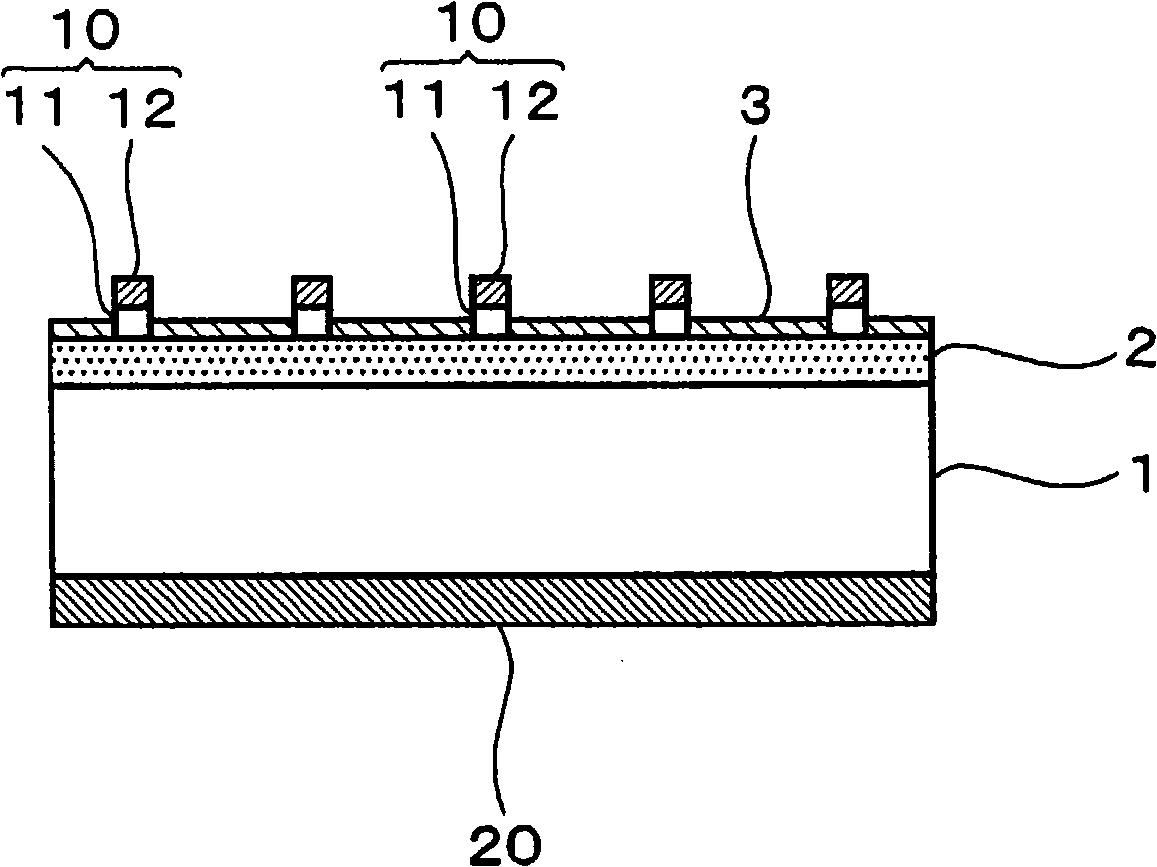

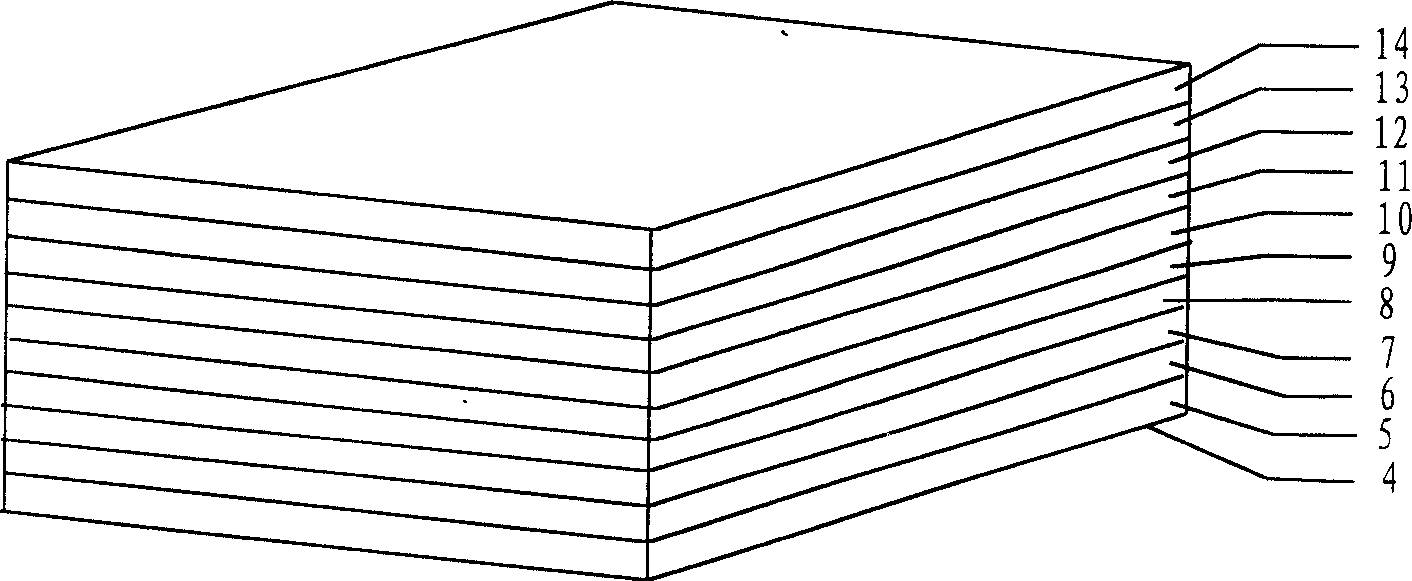

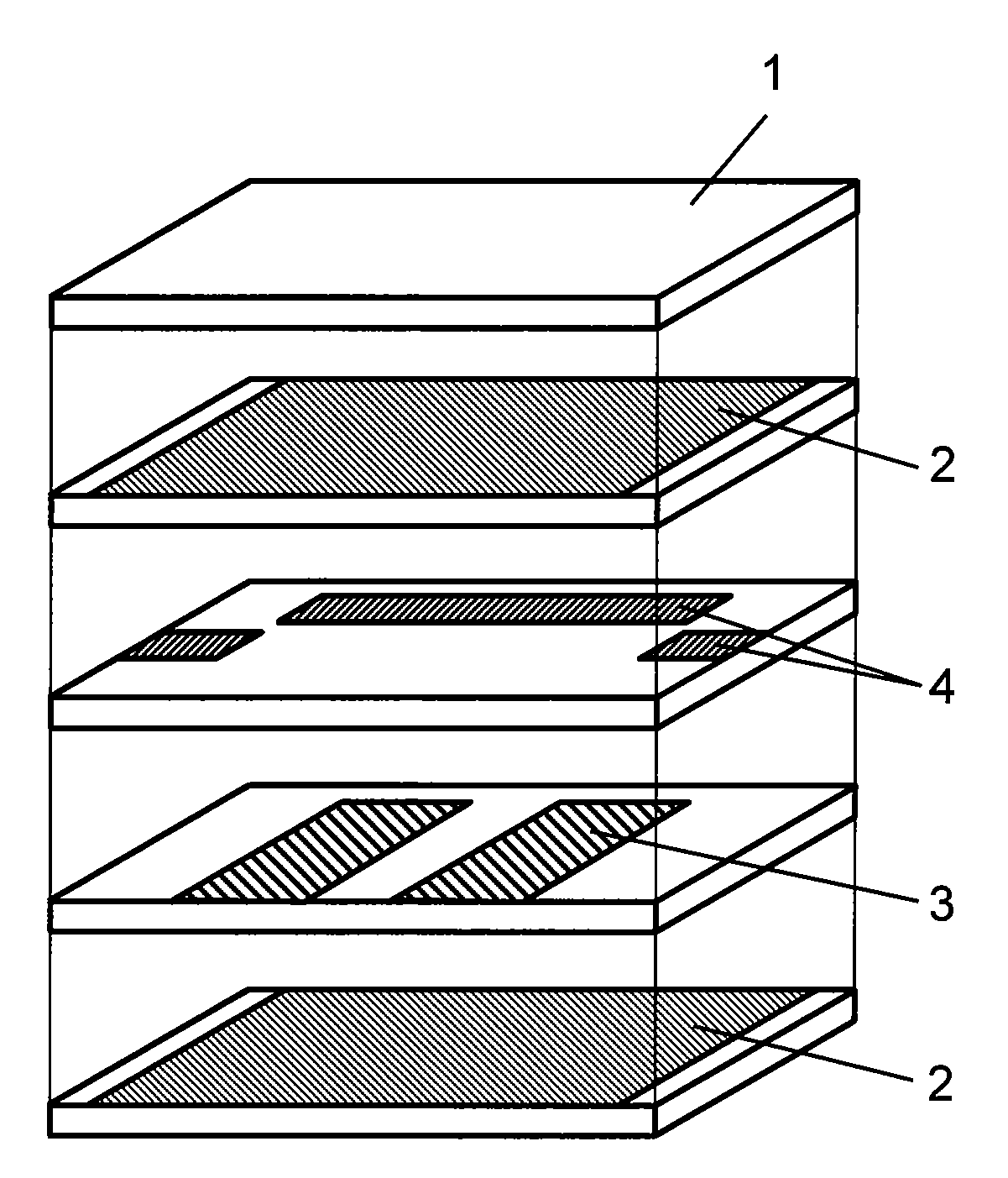

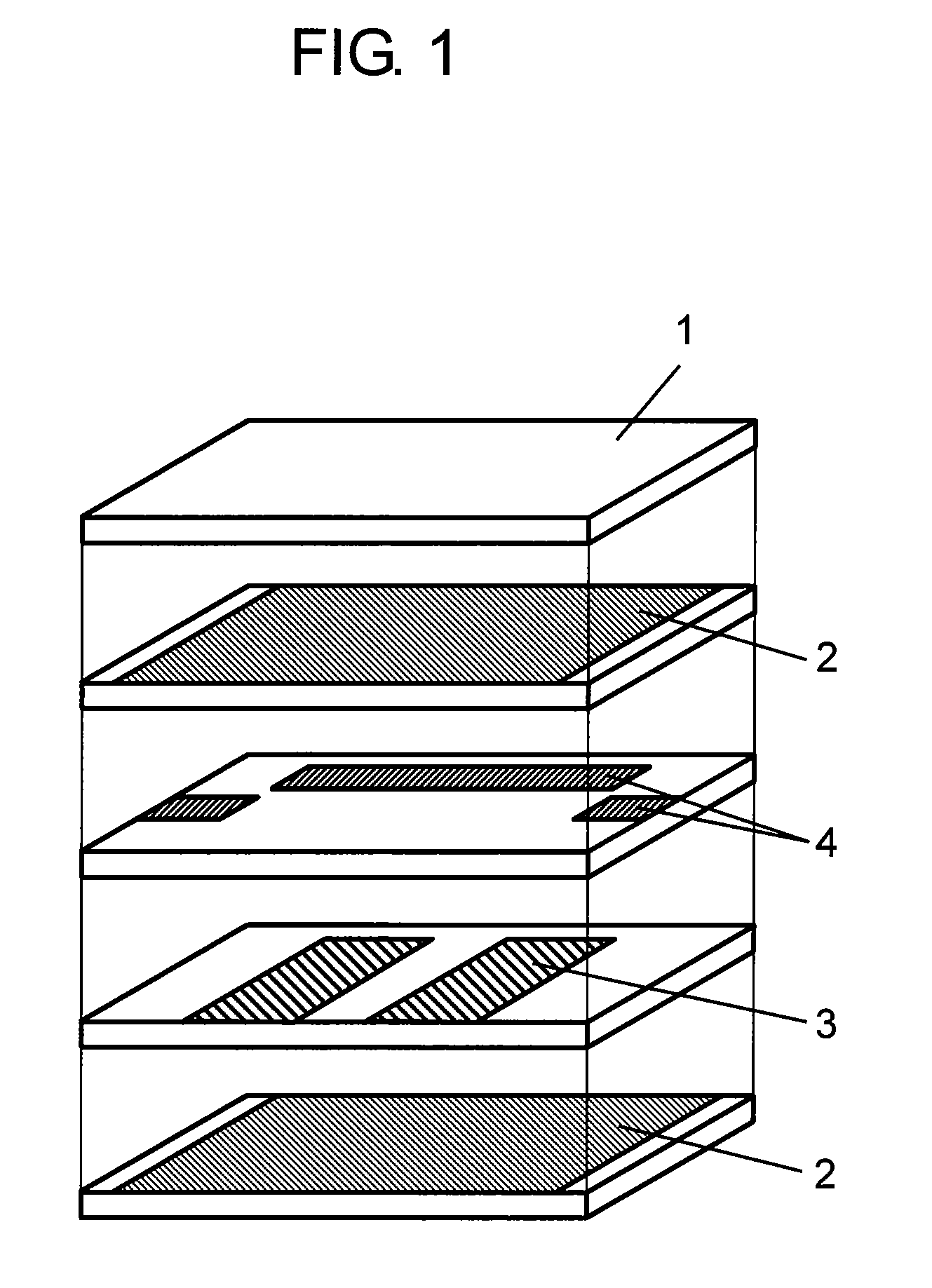

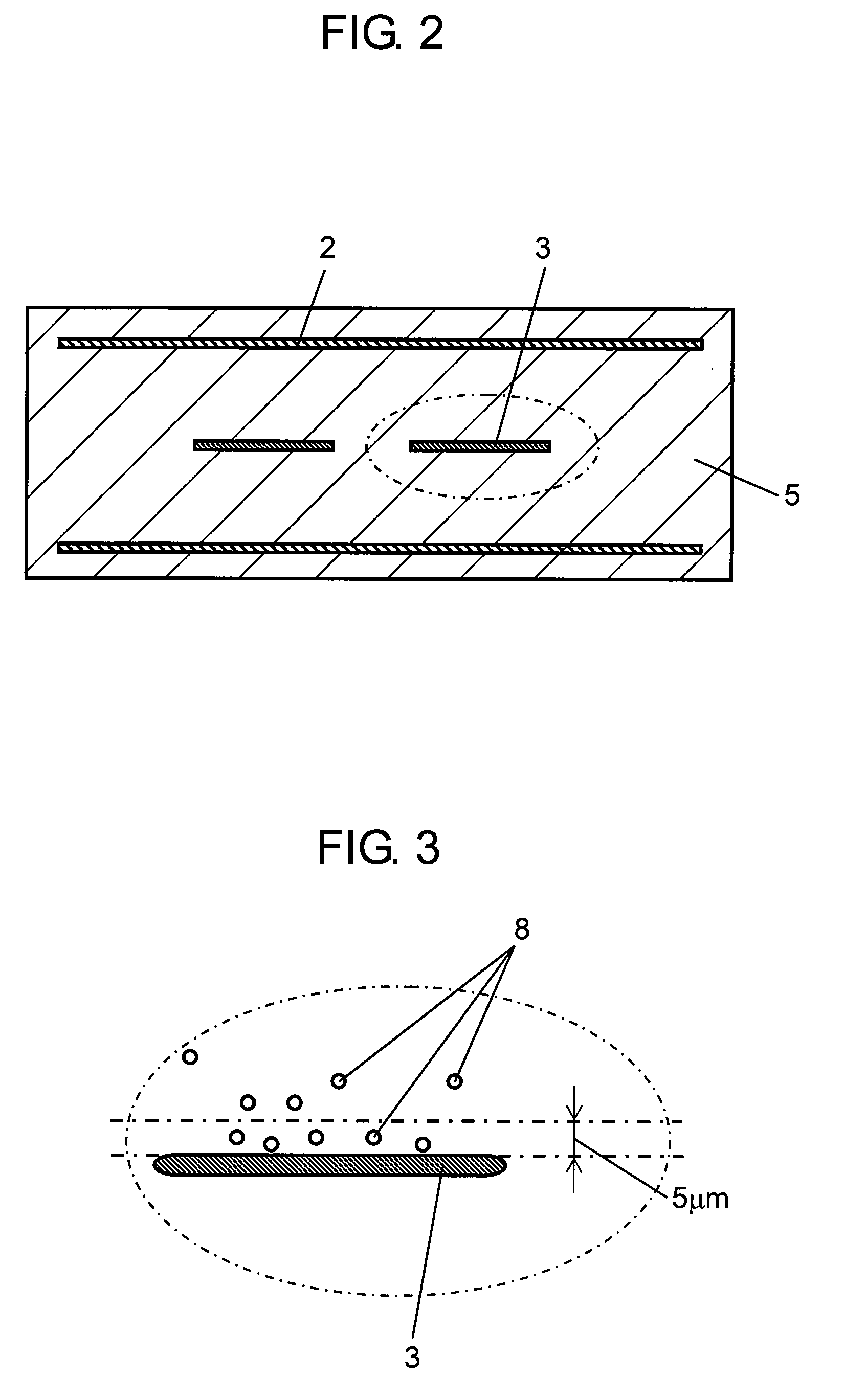

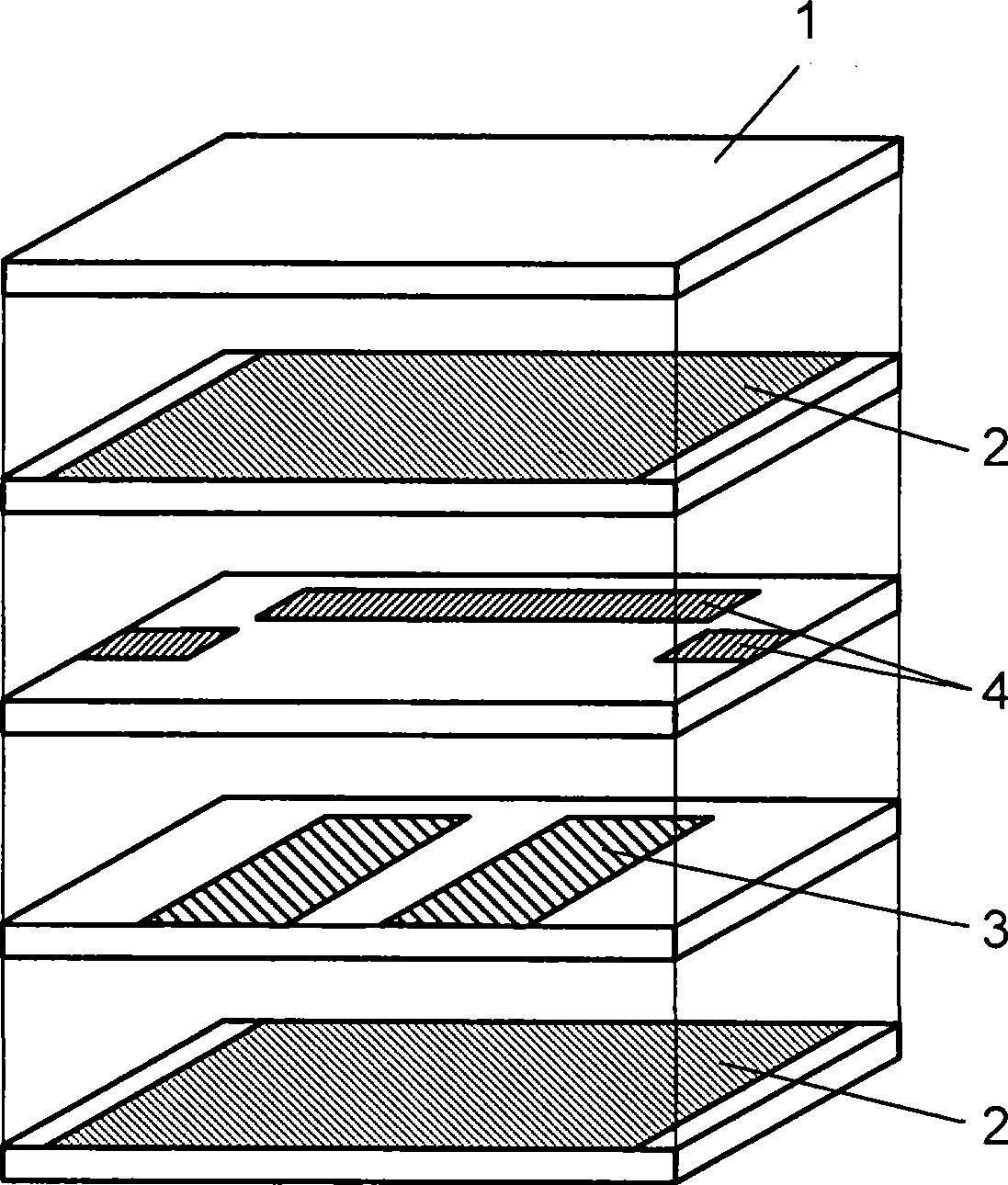

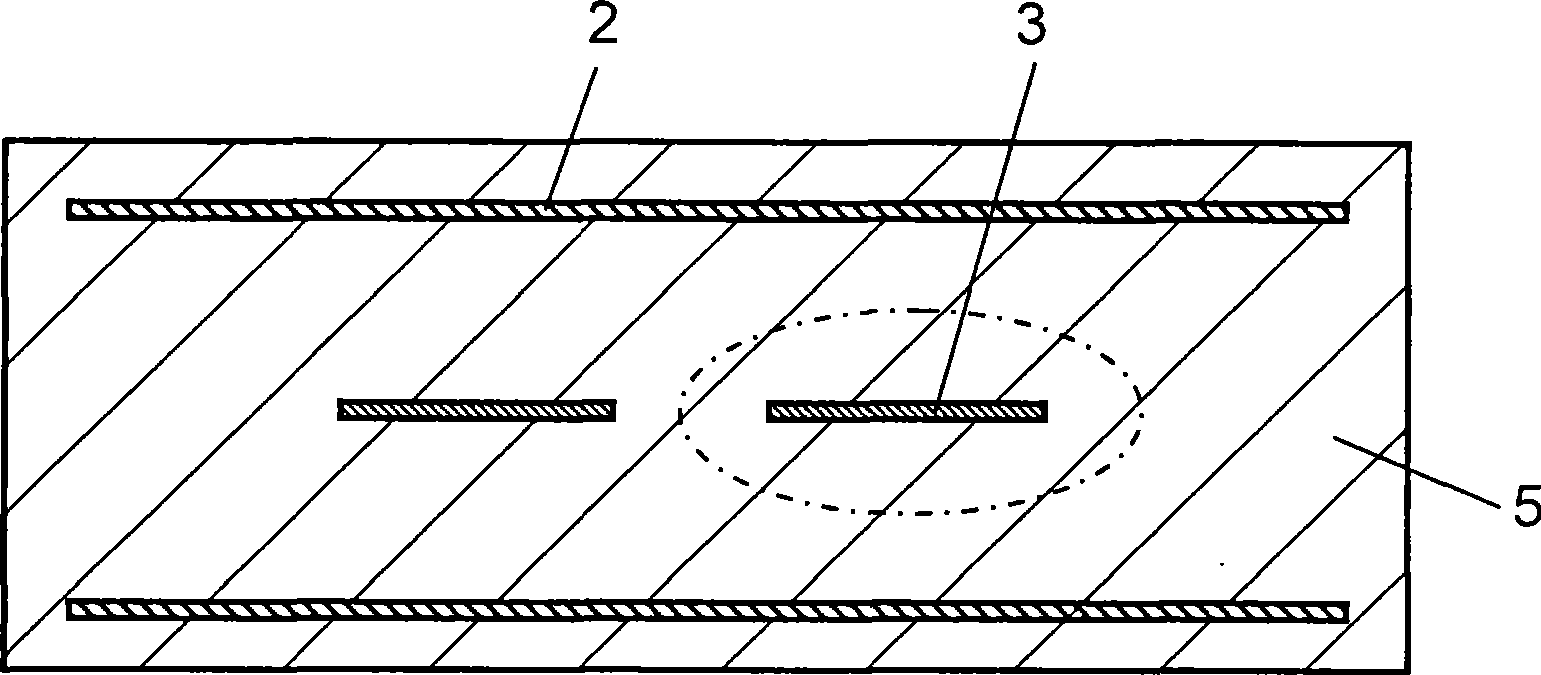

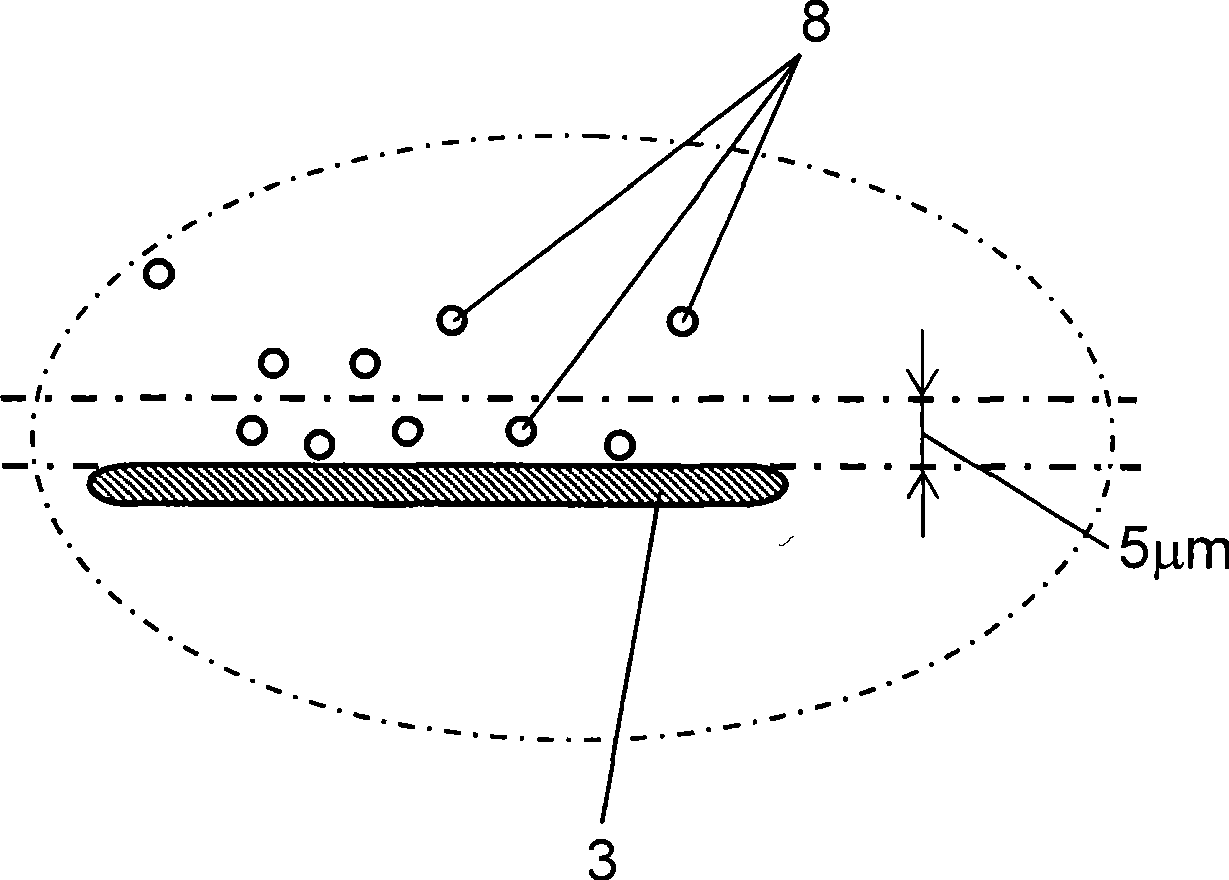

Ceramic laminated device and method for manufacturing same

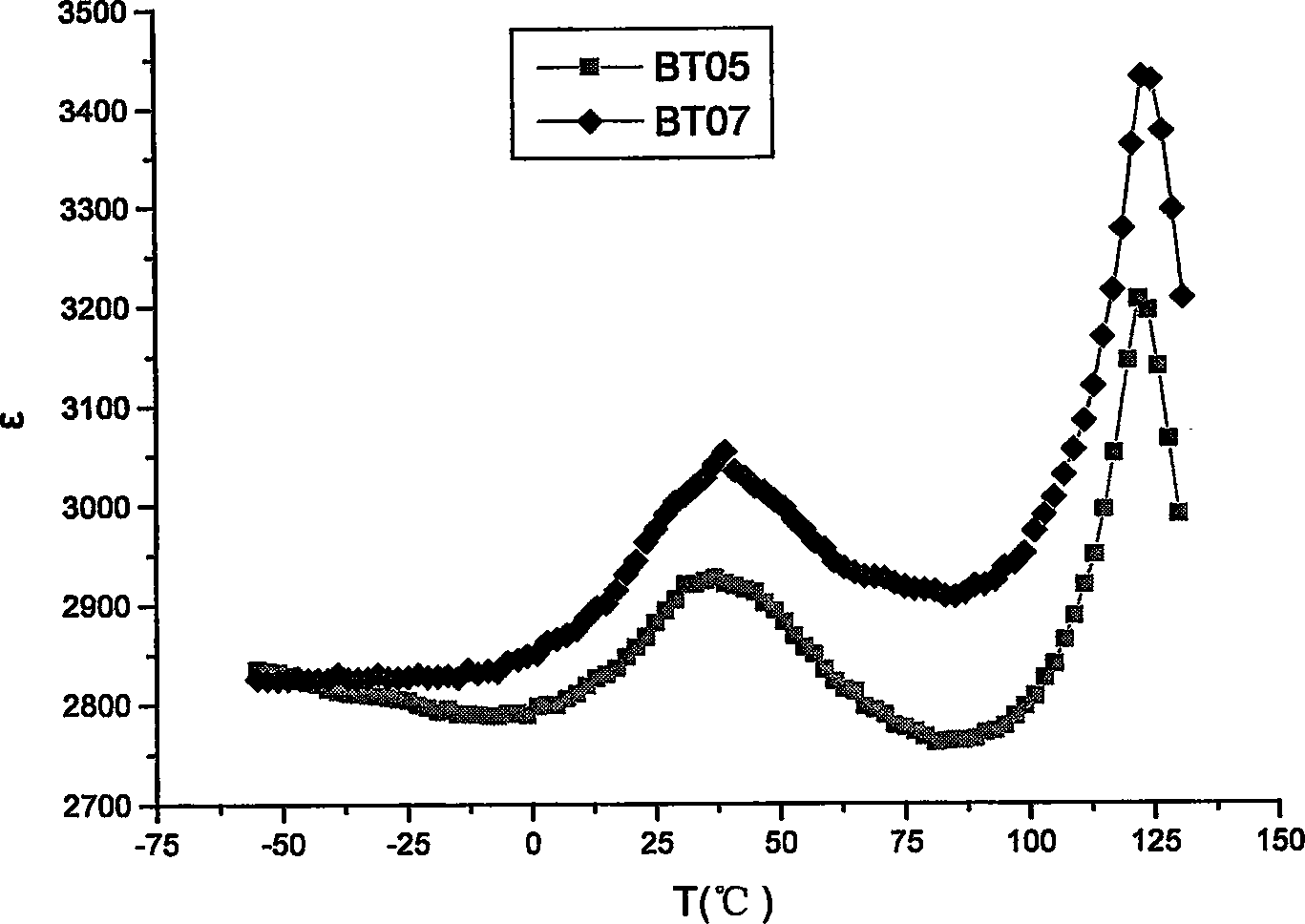

InactiveUS20090034157A1Suppress reactivityHigh valueMultiple-port networksFixed capacitor electrodesCeramicHigh dielectric permittivity

The present invention relates to a ceramic laminated device including a dielectric ceramic and an Ag electrode. In a dielectric ceramic that can be sintered at low temperatures and has a high dielectric constant and Q value, reactivity between the ceramic and Ag during sintering is suppressed low and segregation of specific elements in the proximity of the electrode is controlled. Thus, a filter having a high Q value and low loss is produced stably. For this purpose, in a ceramic laminated body including at least a ceramic and a Si-containing glass, a ratio of A / B, i.e. a ratio of a Si element concentration (A) within a range at a distance of 5 μm or smaller from the Ag electrode to a Si element concentration (B) within a range at a distance larger than 5 μm from the Ag electrode, is set equal to or smaller than 2.

Owner:PANASONIC CORP

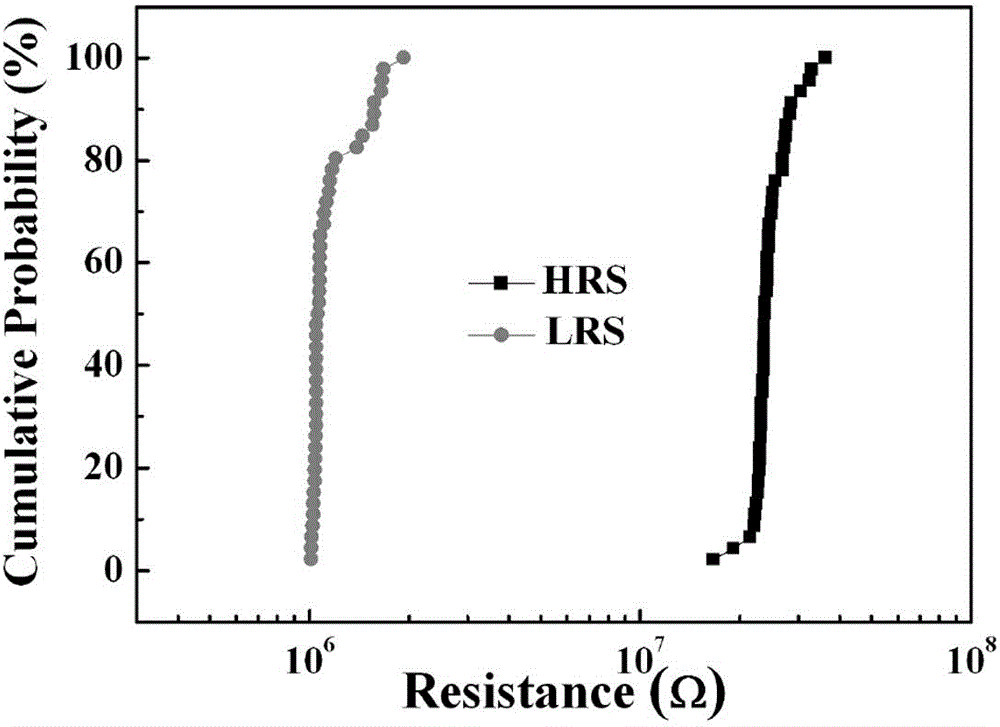

Misunderstanding prevention resistance random access memory and production method thereof

ActiveCN104810477AStable resistance changeGood switching effectElectrical apparatusVacuum evaporation coatingHigh resistanceElectrical resistance and conductance

The invention provides a misunderstanding prevention resistance random access memory and a production method thereof. The structure of the resistance random access memory lies in that a resistance random medium layer and an Ag electrode membrane layer are sequentially formed on a Pt membrane layer of a Pt / Ti / SiO2 / Si substrate; the resistance random medium layer comprises a first ferrite bismuth membrane layer, a second ferrite bismuth doped silver membrane layer and a third ferrite bismuth membrane layer which are sequentially formed. By the arrangement, stable resistance changes are presented, resistances of high-low resistance states are quite concentrated in distribution, and the high resistance and the low resistance are large in difference, so that confusion of the high and low resistances is less prone to occurrence, and misunderstanding is not easy to occur during data reading. The resistance random access memory is remarkable in switch effect and quite beneficial to readout of the memory. In addition, anti-fatigue performance of the resistance random access memory under the high-low resistance states is quite good.

Owner:HEBEI UNIVERSITY

Dielectric ceramic composition

A dielectric ceramic composition of high dielectric constant and low dielectric loss, which can be co-fired with Ag electrodes, is provided for use in various parts of electric and electronic appliances. The composition is represented by the following chemical formula:a wt. % {x BaO-y1 Nd2O3-y2 Sm2O3-w Bi2O3-z TiO2}+b wt. % (ZnO-B2O3-SiO2-PbO based glass frit)+c wt. % CuOwherein, 10.0 mol %<=x<=20.0 mol %; 7.0 mol %<=y1+y2<=20.0 mol %; 0.5 mol %<=w<=5.0 mol %; 60.0 mol %<=z<=80.0 mol %, with the proviso that x+y1+y2+w+z=100; 80.0 wt. %<=a<=98.0 wt. %; 1.0 wt. %<=b<=10.0 wt. %; 1.0 wt. %<=c<=10.0 wt. %.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

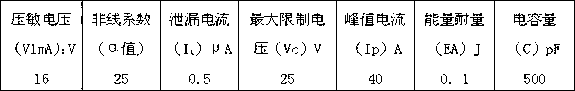

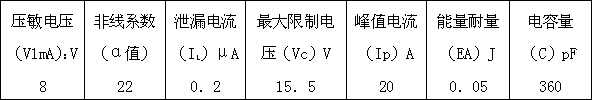

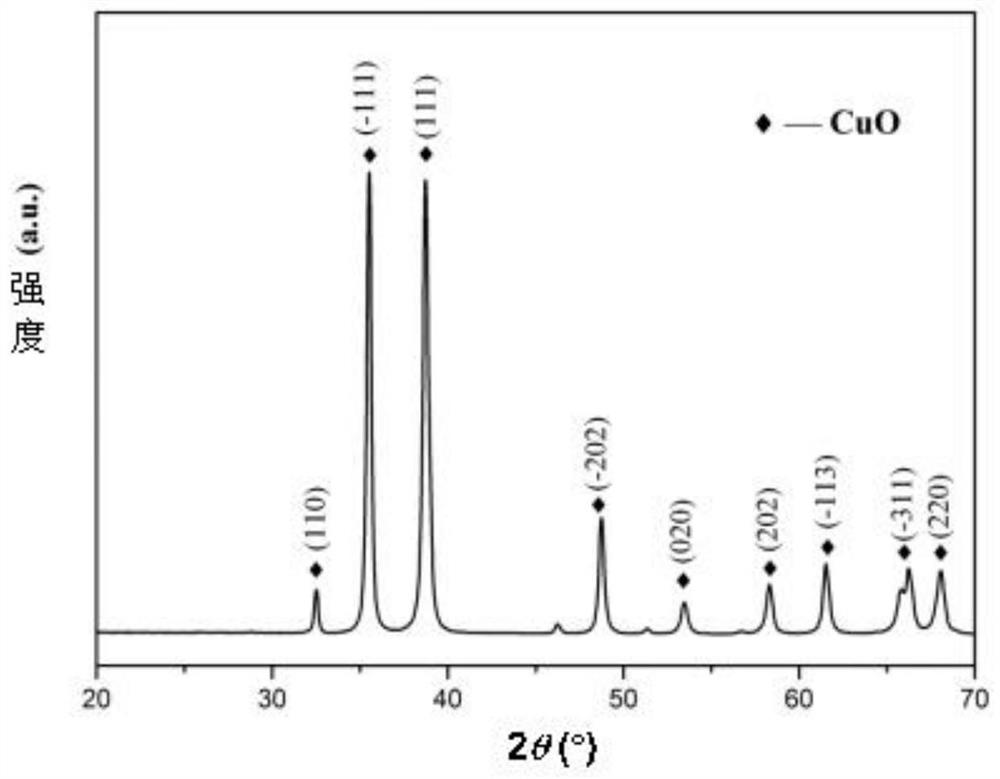

Multilayer varistor and preparation method for same

ActiveCN102709010ALower sintering temperatureSimple processResistor manufactureVaristor coresPhysical chemistryEngineering

The invention discloses a multilayer varistor and a preparation method for the same. The multilayer varistor comprises a varistor body and an internal electrode in a porcelain body, wherein the varistor body consists of a ZnO-Bi2O3-SiO2-SnO2 porcelain system; and the internal electrode is a pure Ag electrode. The varistor is high in electrical property and low in production cost.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

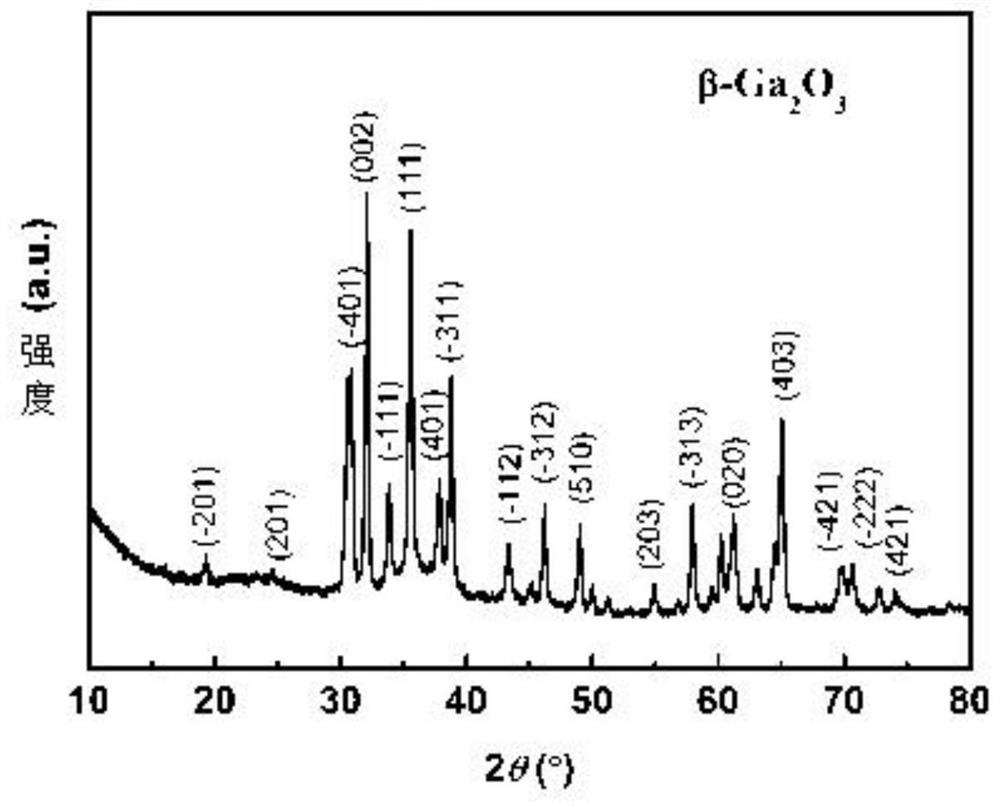

Flexible ultraviolet detector based on copper oxide/gallium oxide nanopillar array pn junction and preparation method thereof

ActiveCN111613691AGood size controlLow costFinal product manufactureNanotechnologyHeterojunctionNanowire

The invention relates to a flexible ultraviolet detector based on a copper oxide / gallium oxide nanopillar array pn junction and a preparation method. The detector comprise the orderly arranged parts of a flexible copper sheet substrate, wherein at least one side of the flexible copper sheet substrate is provided with a copper oxide layer, and a beta-Ga2O3 nanorod array is arranged on the copper oxide layer positioned at one side of the copper sheet substrate; a graphene / Ag nanowire composite layer which is positioned on the beta-Ga2O3 nano column array; an Ag electrode which is located on thegraphene / Ag nanowire composite layer, wherein a copper oxide / gallium oxide nanopillar array pn junction is formed between the copper oxide and the beta-Ga2O3 nanopillar array, and the flexible coppersheet substrate serves as a copper electrode to form an access with the Ag electrode. The ultraviolet detector provided by the invention has a three-dimensional space heterojunction interface structure and a solar blind characteristic, has the excellent chemical and thermal stability, is flexible and bendable, is high in pressure resistance, low in working temperature and power consumption and good in repeatability, and can directionally identify the ultraviolet light with the wavelength of 200-280nm in a solar blind waveband.

Owner:ZHEJIANG SCI-TECH UNIV

Ceramic laminated device and method for manufacturing same

InactiveCN101401495AImprove featuresReduced responseMultiple-port networksStacked capacitorsDielectric ceramicsAg electrode

The present invention relates to a ceramic laminated device including a dielectric ceramic and an Ag electrode. In a dielectric ceramic that can be sintered at low temperatures and has a high dielectric constant and Q value, reactivity between the ceramic and Ag during sintering is suppressed low and segregation of specific elements in the proximity of the electrode is controlled. Thus, a filter having a high Q value and low loss is produced stably. For this purpose, in a ceramic laminated body including at least a ceramic and a Si-containing glass, a ratio of A / B, i.e. a ratio of a Si element concentration (A) within a range at a distance of 5 [mu]m or smaller from the Ag electrode to a Si element concentration (B) within a range at a distance larger than 5 [mu]m from the Ag electrode, is set equal to or smaller than 2.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com