Cu2O/GaOOH nano core-shell pn junction photoelectric detector and preparation method thereof

A technology of photodetectors and nano-core shells, applied in the field of photodetectors, can solve the problems of relatively high pH requirements, poor repeatability, and high cost, and achieve the effects of uniform distribution, low cost, and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

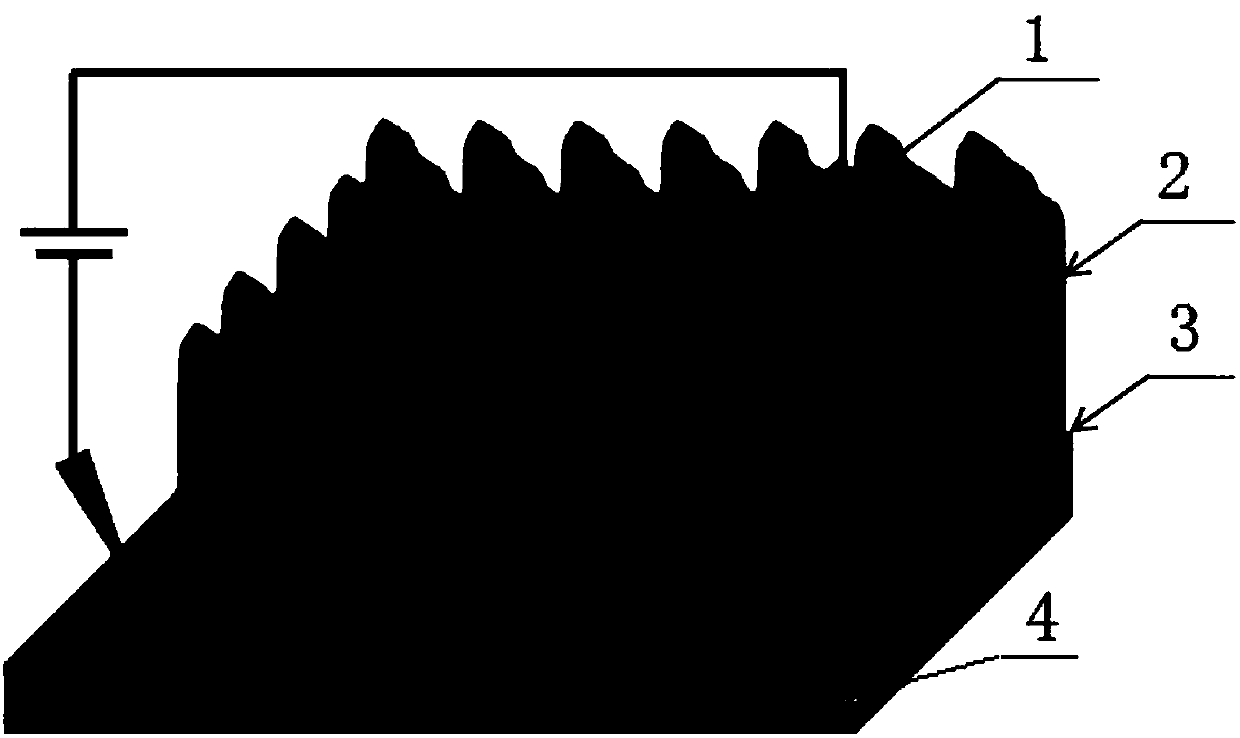

[0034] a Cu 2 Preparation method of O / GaOOH nano core-shell pn junction photodetector, coating a layer of Ga on FTO conductive glass 2 o 3 seed layer, using a hydrothermal method on Ga 2 o 3 GaOOH nanocolumn arrays are grown on the seed layer, and copper salt solution is added to the water bath to grow Cu 2 O nanocrystals, forming Cu 2 O / GaOOH nano-core-shell nanoarrays. Also included in Cu 2 O / GaOOH nano-core-shell nano-array coated with silver electrodes.

[0035] Cu 2 The specific steps of the preparation method of the O / GaOOH nano core-shell pn junction photodetector are as follows:

[0036] (1) Pretreatment of FTO conductive glass substrate: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 10 minutes, and then drying in an oven;

[0037] (2) Preparation of the seed layer solution: Take 18 μL of ethanolamine, 0.0741 g of gallium isopropoxide, and 2.98 mL of ethylene glycol methyl ether into a 5 mL beaker, heat in a water bath at 60 °C fo...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that the Ga(NO 3 ) 3 The concentration of the growth solution was 0.3g / 30mL, and the growth time was 12 hours at 150°C in a stainless steel autoclave, and the rest were the same as in Example 1.

[0045] Specifically, Cu 2 The specific steps of the preparation method of the O / GaOOH nano core-shell pn junction photodetector are as follows:

[0046] (1) Pretreatment of FTO conductive glass substrate: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 10 minutes, and then drying in an oven;

[0047] (2) Preparation of the seed layer solution: Take 18 μL of ethanolamine, 0.0741 g of gallium isopropoxide, and 2.98 mL of ethylene glycol methyl ether into a 5 mL beaker, heat in a water bath at 60 °C for 60 min, cool and place in a refrigerator for later use ;

[0048] (3) Preparation of the seed crystal layer: the FTO conductive glass substrate after step 1) is fixed on the glue homogenizin...

Embodiment 3

[0054] The difference between this example and Example 1 is that the amount of 80% hydrazine hydrate solution added in step (6) is 300 μL, and the rest are the same as Example 1.

[0055] Specifically, Cu 2 The specific steps of the preparation method of the O / GaOOH nano-core-shell pn junction photodetector are as follows: (1) Pretreatment of the FTO conductive glass substrate: ultrasonic cleaning with acetone, absolute ethanol, and deionized water for 10 min, and then drying in an oven ;

[0056] (2) Preparation of the seed layer solution: Take 18 μL of ethanolamine, 0.0741 g of gallium isopropoxide, and 2.98 mL of ethylene glycol methyl ether into a 5 mL beaker, heat in a water bath at 60 °C for 60 min, cool and place in a refrigerator for later use ;

[0057] (3) Preparation of the seed crystal layer: the FTO conductive glass substrate after step 1) is fixed on the glue homogenizing sample stage of the rubber homogenizing / glue drying machine, drips a certain amount of 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com