Double-clotted-layer solar cell and making method

A technology for solar cells and manufacturing methods, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as short service life, photoelectric performance degradation, etc., to optimize interface conditions, improve crystalline properties, and improve conversion efficiency. and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

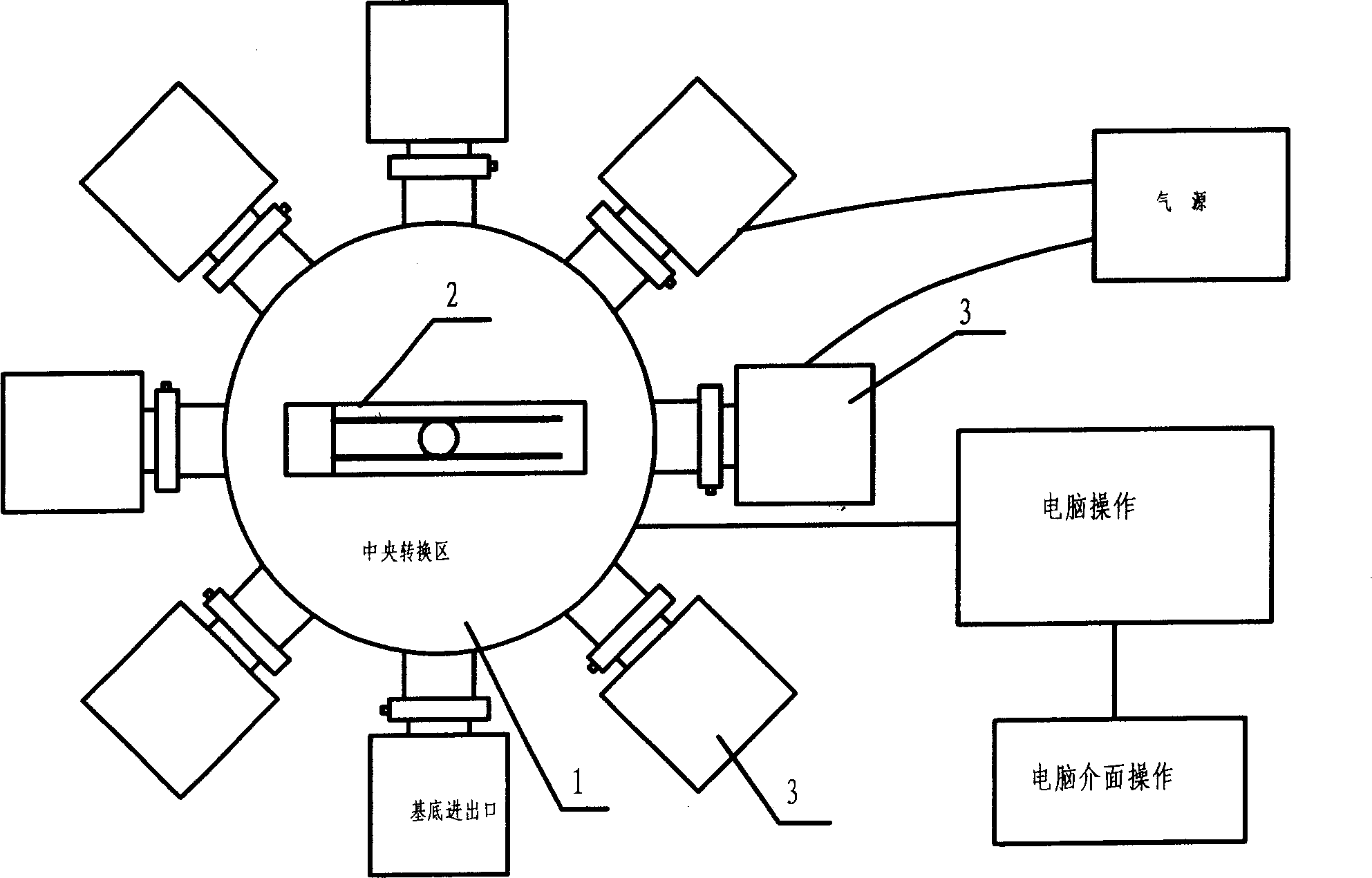

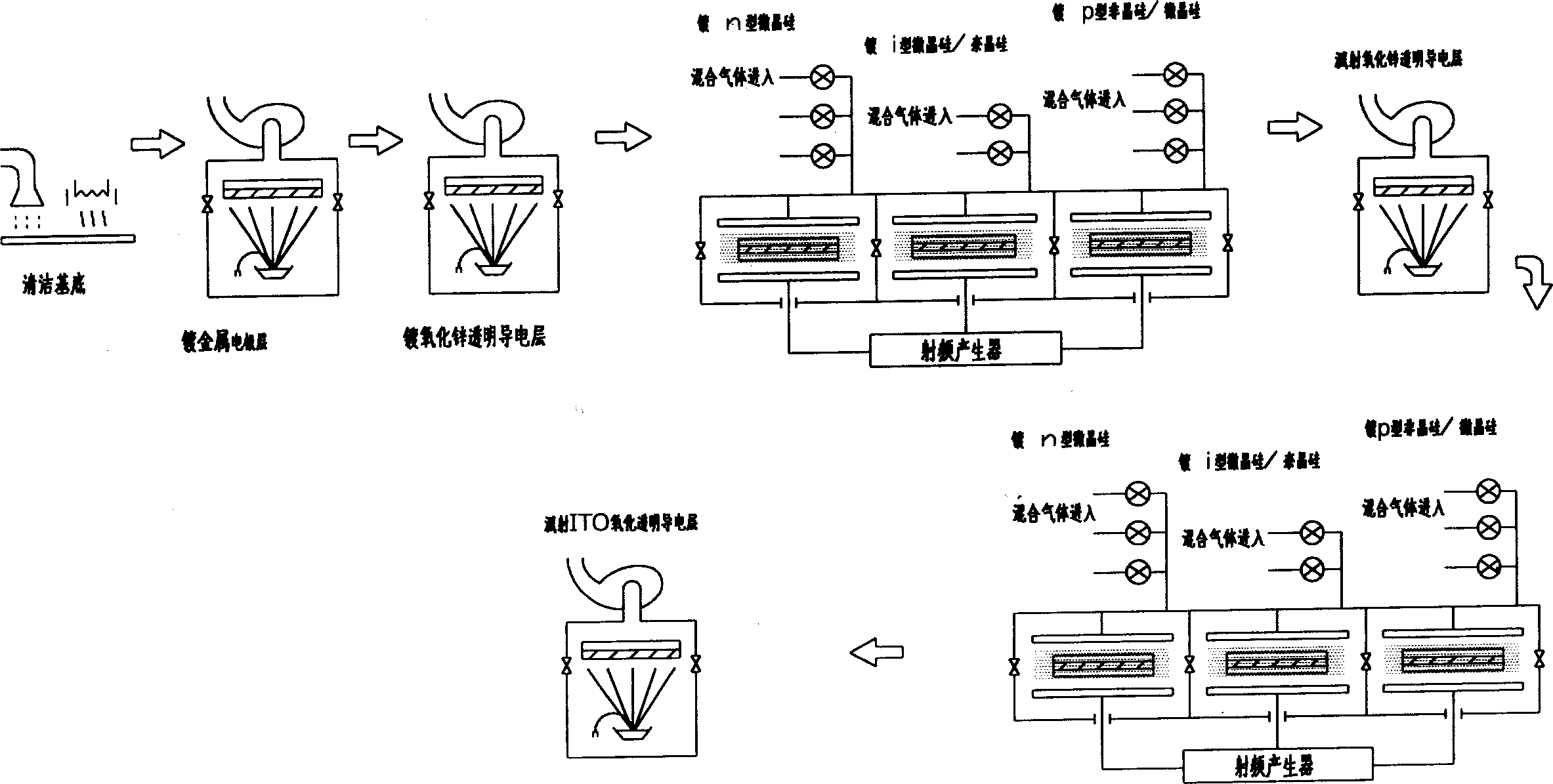

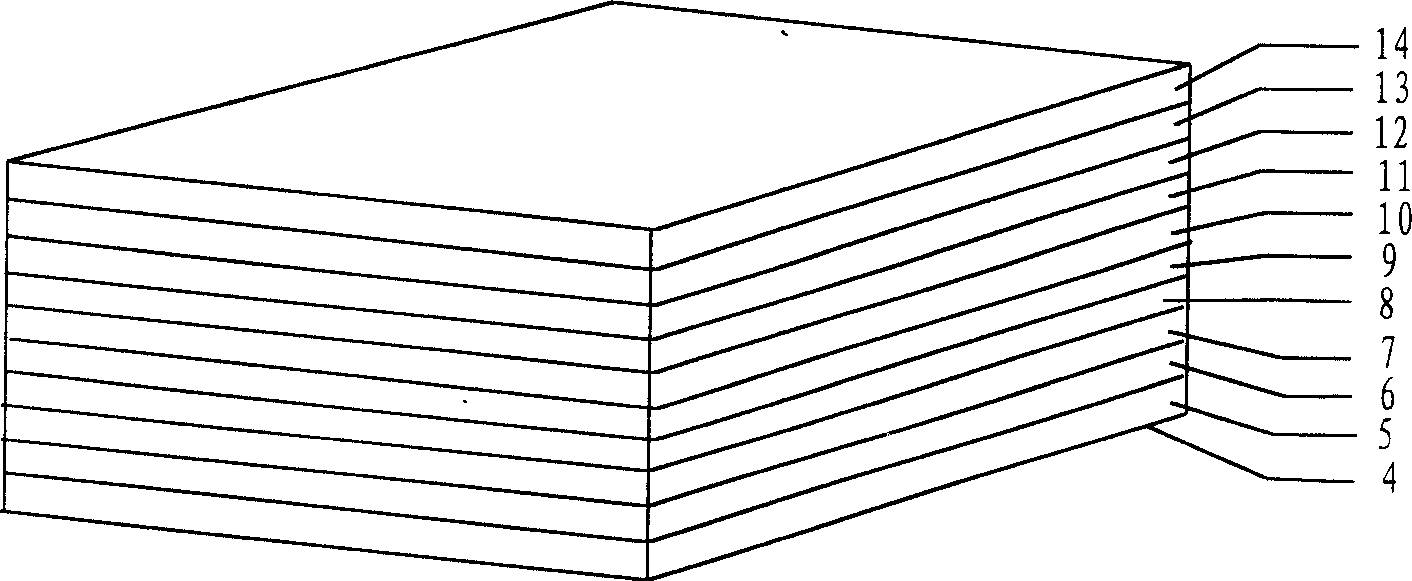

[0014] figure 1 A device for producing double-junction solar cells. This device is very closely related to the coating of amorphous silicon / microcrystalline silicon solar cells on the substrate of the present invention. In the circular (square) central transfer area 1, there is a set of automated robotic arms 2, which can operate in any order with any of the eight surrounding coating areas 3, and insert or take out the cassettes with substrates. All the operation processes are controlled by switch software, and the eight coating areas 3 are connected to the central conversion area 1 by vacuum valves, which can maintain an independent vacuum state, avoid cross-contamination of coating gas generated during substrate conversion, and improve solar cells. effectiveness. One coating area 3 is used as the entrance and exit of the substrate, and the remaining seven areas have three coating areas 3 used for sputtering electrode layer, which are silver plating and metal oxide transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com