Patents

Literature

42results about How to "The process path is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for collecting nickel and cobalt from laterite-nickel ore lixivium

ActiveCN101298638AHigh extraction rateReduce energy consumptionProcess efficiency improvementPregnant leach solutionSlag

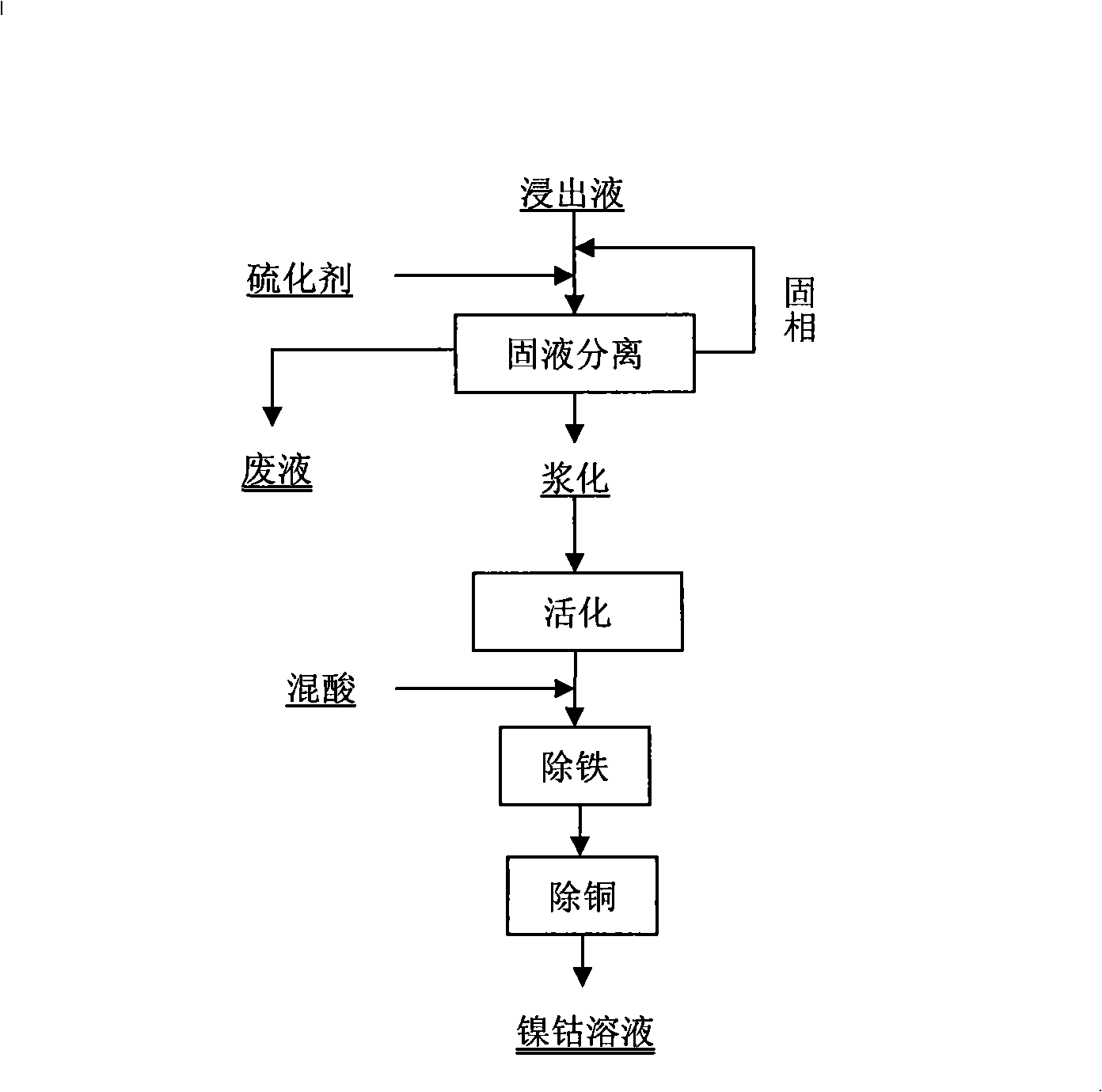

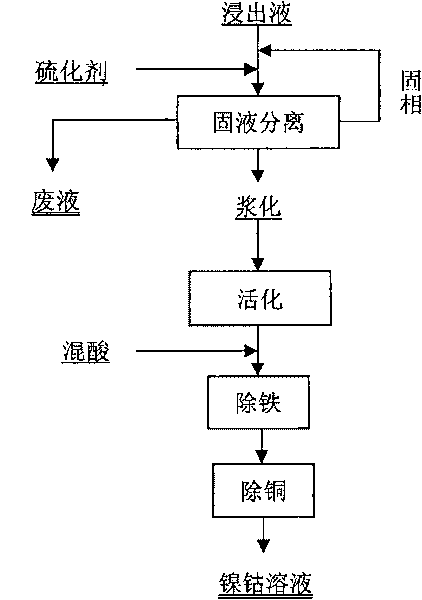

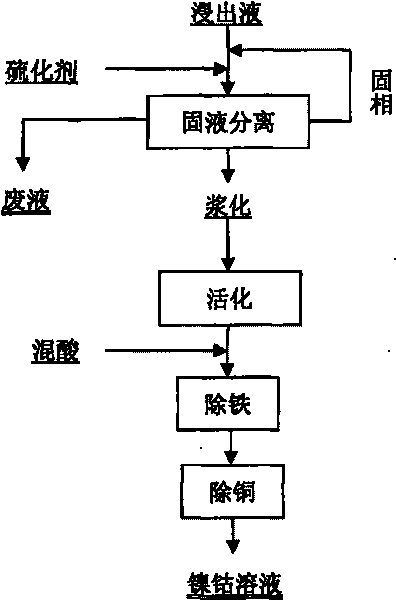

The invention discloses a method for separating enriched nickel and cobalt from a laterite nickel ore lixivium, which comprises the following steps: after solid and liquid separation between the laterite nickel ore lixivium and ore slag is implemented, a vulcanizing agent is added into the lixivium, the solid and the liquid are separated after reaction precipitation, and precipitated solid is washed by a new lixivium, thus obtaining sulfide precipitate; after the sulfide precipitate is pulpified, sulphuric acid and solution of nitric acid and mixed acid are added so as to implement oxidizing leaching; the goethite method is adopted for removing iron from a superior pickle liquor; a sodium thiosulfate solution is added so as to implement copper removing; a filtering liquor that is the enriched nickel and cobalt solution is obtained. Compared with the prior art, the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium is implemented at normal temperature and normal pressure, does not need a high-pressure caldron, has less device investment, low running cost, simple technical path, short process and controllable production scale; the vulcanizing agent and acids that are used in the technique can be recycled to the utmost extent and do not have emissions and environment pollution; the extraction yield of nickel and cobalt can achieve over 95 percent, and the method for separating enriched nickel and cobalt from the laterite nickel ore lixivium has low production cost and easy industrialization.

Owner:福建常青新能源科技有限公司

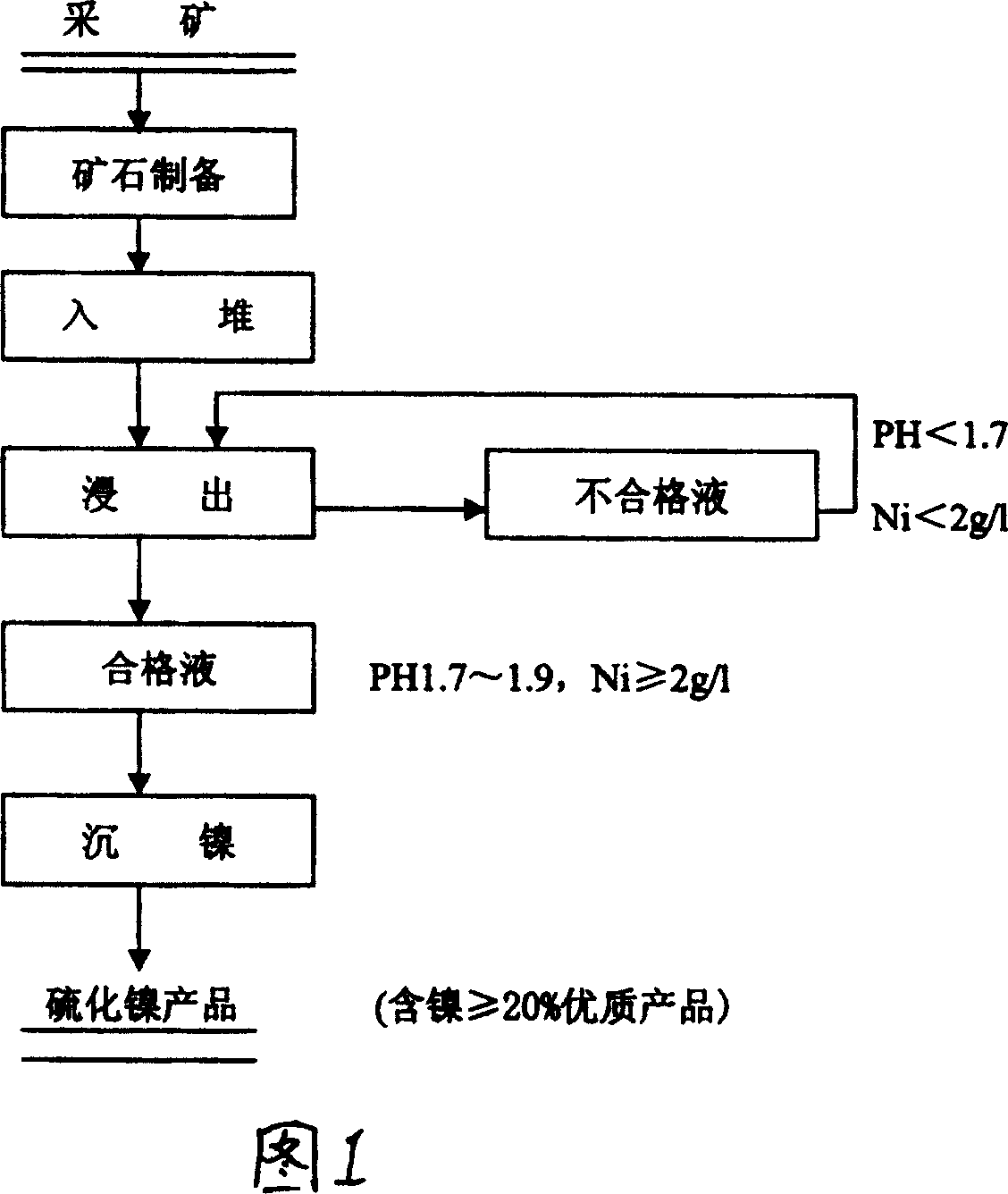

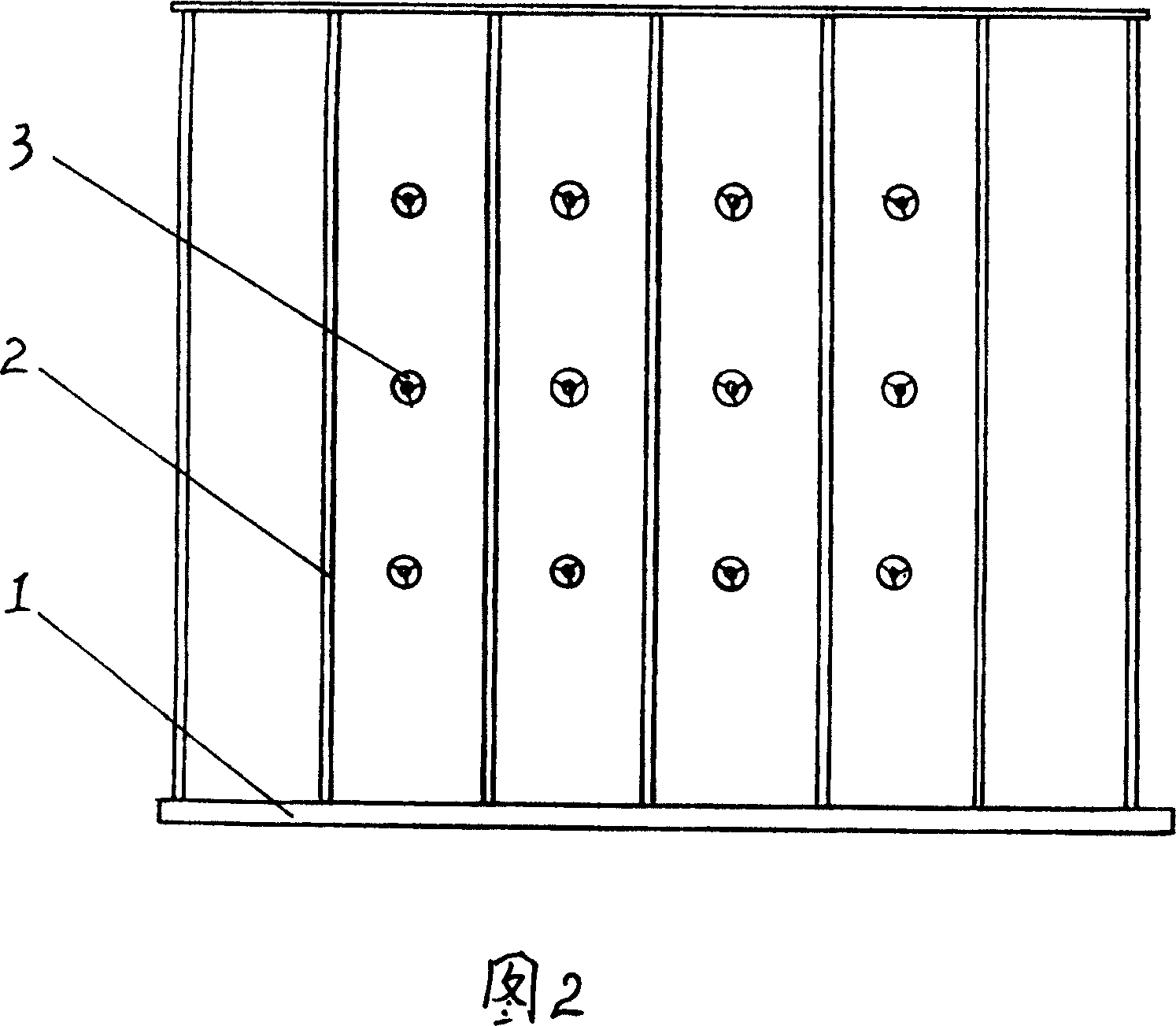

Method of bulk infusion extracting nickel cobalt from low grade red soil nickel ore

InactiveCN1718787AImprove leaching rateNo pollutionProcess efficiency improvementPregnant leach solutionGranularity

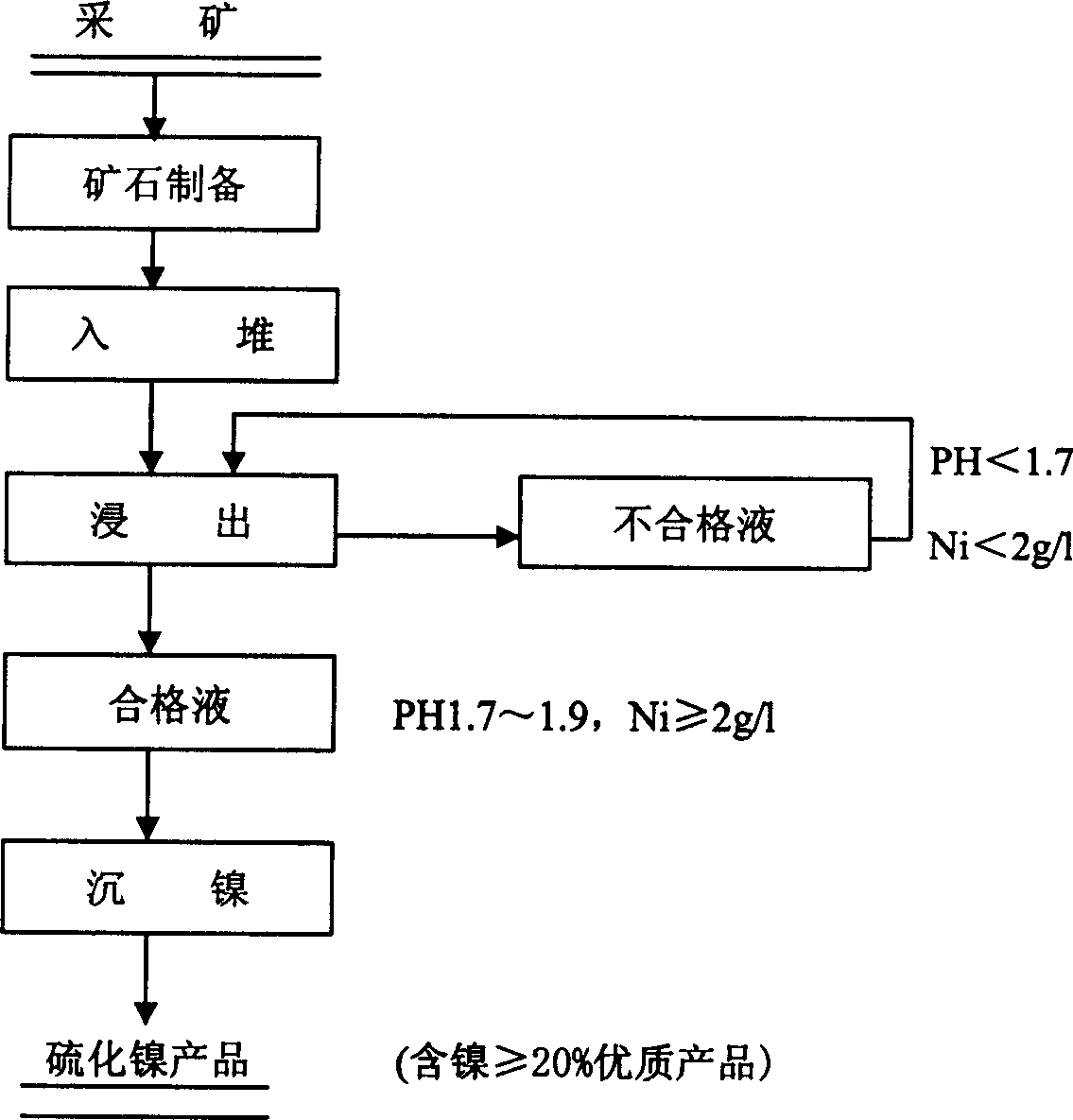

A process for extracting Ni and Co from the low-grade Ni-contained laterite ore includes such steps as crushing to make its average granularity less than 2 cm, stacking the ore particles with granularity of 100 mesh-1.5 cm, proportionally mixing others, adding them to the stack, shrinkling acidic extracting liquid, collecting the extracting liquid, and concentrating until the concentration of Ni ions is 2-4g / L.

Owner:广西赛可昱新材料科技有限公司

Method for separating enriched nickel and cobalt from battery waste leaching solution

InactiveCN102492858AHigh extraction rateReduce energy consumptionProcess efficiency improvementPregnant leach solutionVulcanization

The invention discloses a method for separating enriched nickel and cobalt from battery waste leaching solution. The method comprises the following steps of: (1) soaking battery waste with acidic leaching solution, adding a reducing agent for treatment, adjusting pH value by using sodium carbonate and then heating and adding hydrogen peroxide or sodium hypochlorite to stir for ruction so as to obtain FeOOH precipitate; then adding a vulcanizing agent for vulcanization treatment; and finally adding water to prepare slurry, adding mixed acid solution for treatment and performing solid-liquid separation to obtain nickel and cobalt-enriched solution. The method for separating the enriched nickel and cobalt from the battery waste leaching solution provided by the invention has the advantages of less investment, simple process, low energy consumption, low production cost, high nickel and cobalt recovery rate and low impurity content in obtained nickel and cobalt-enriched solution.

Owner:河南省冶金研究所有限责任公司

Light-emitting diode package structure manufacturing method

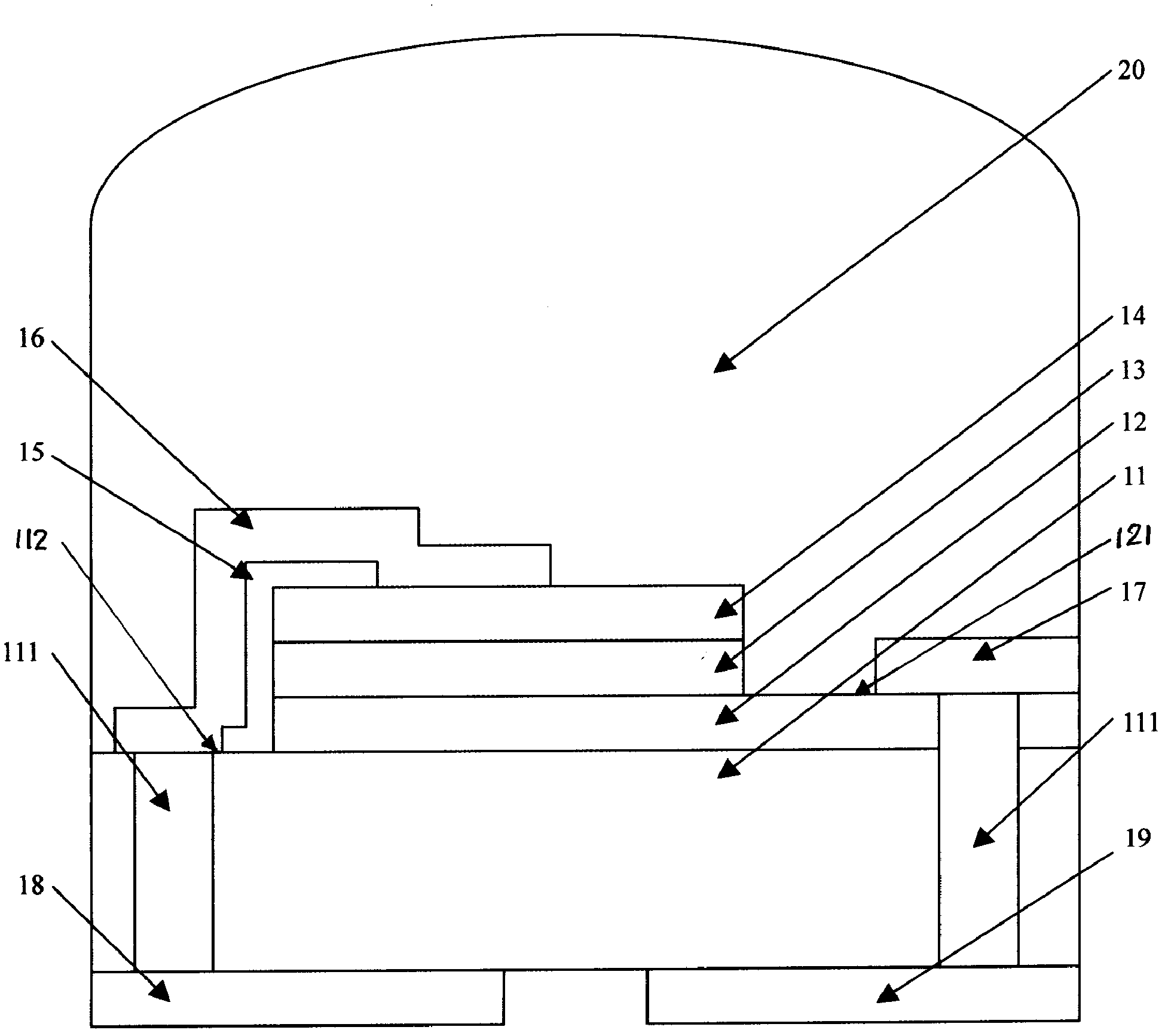

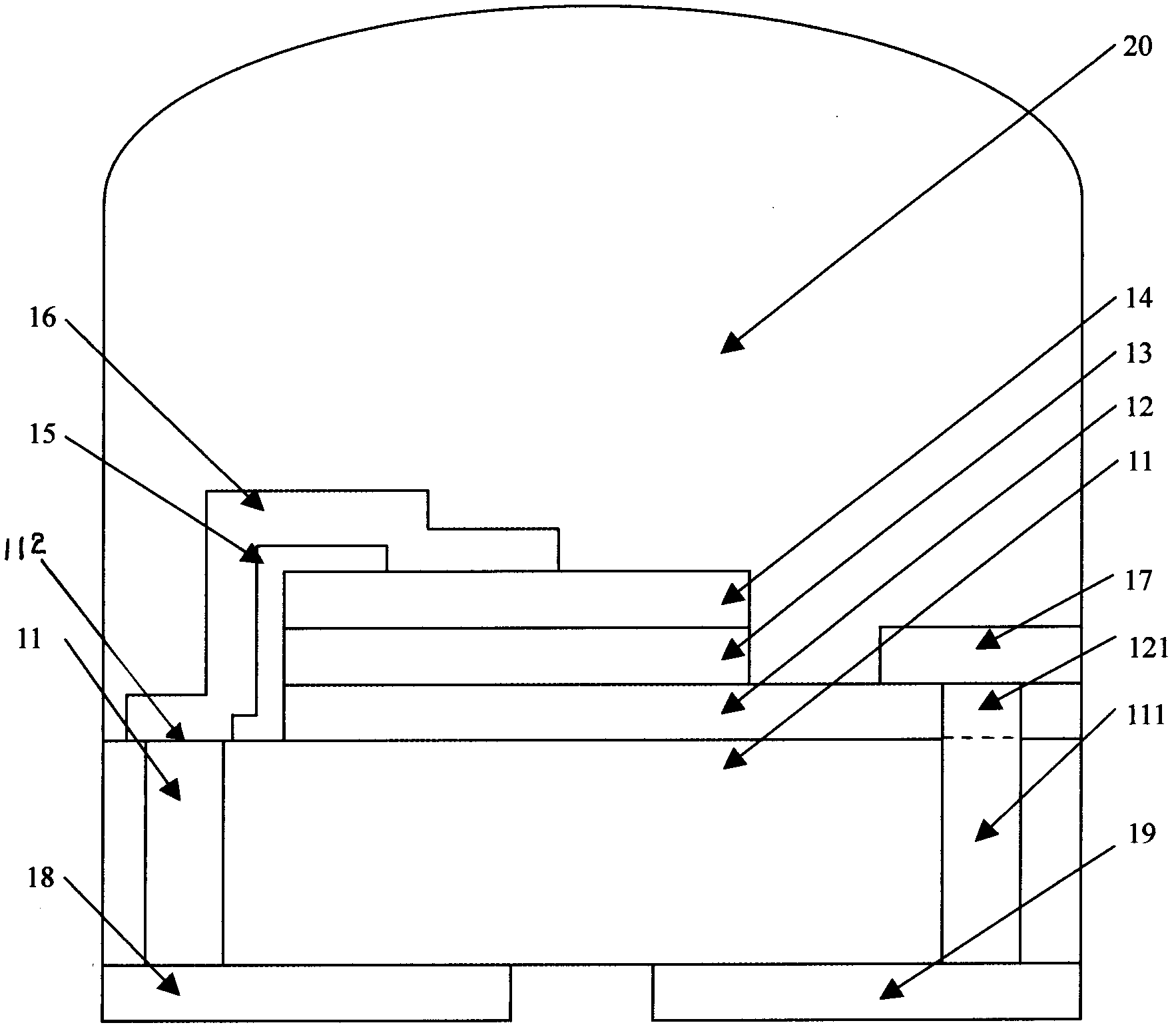

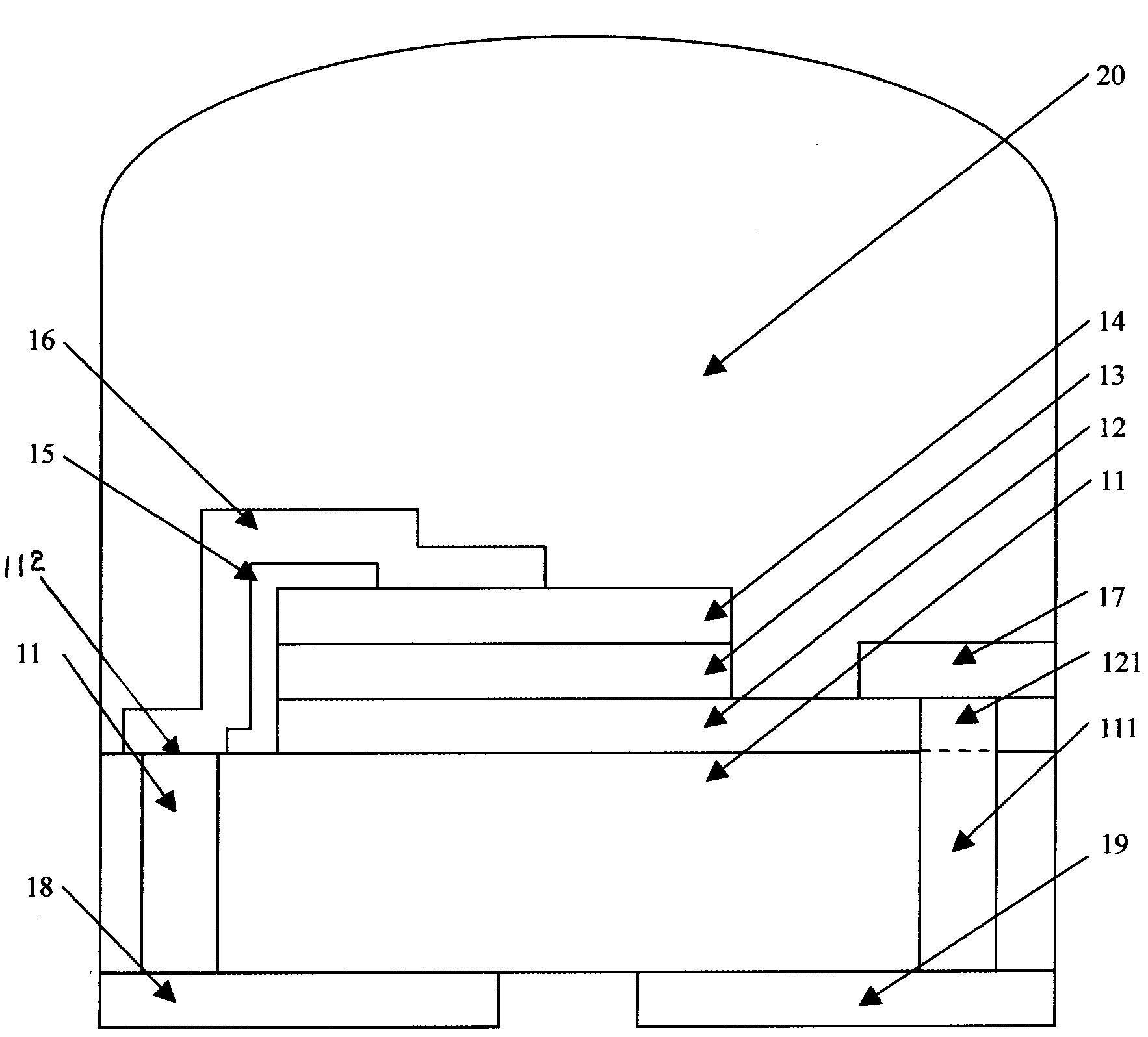

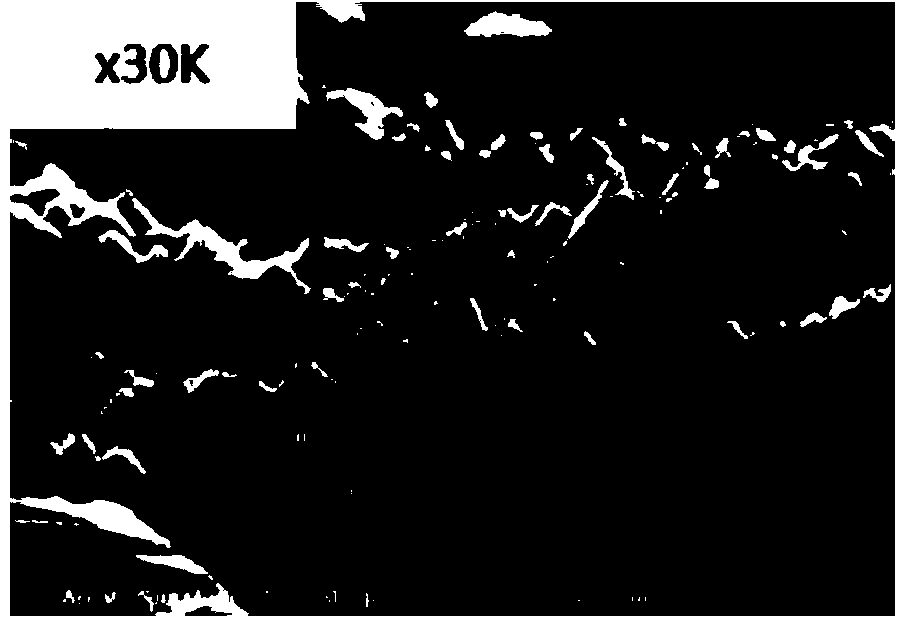

ActiveCN102231421AThe process path is simpleReduce package sizeSemiconductor devicesActive layerLight-emitting diode

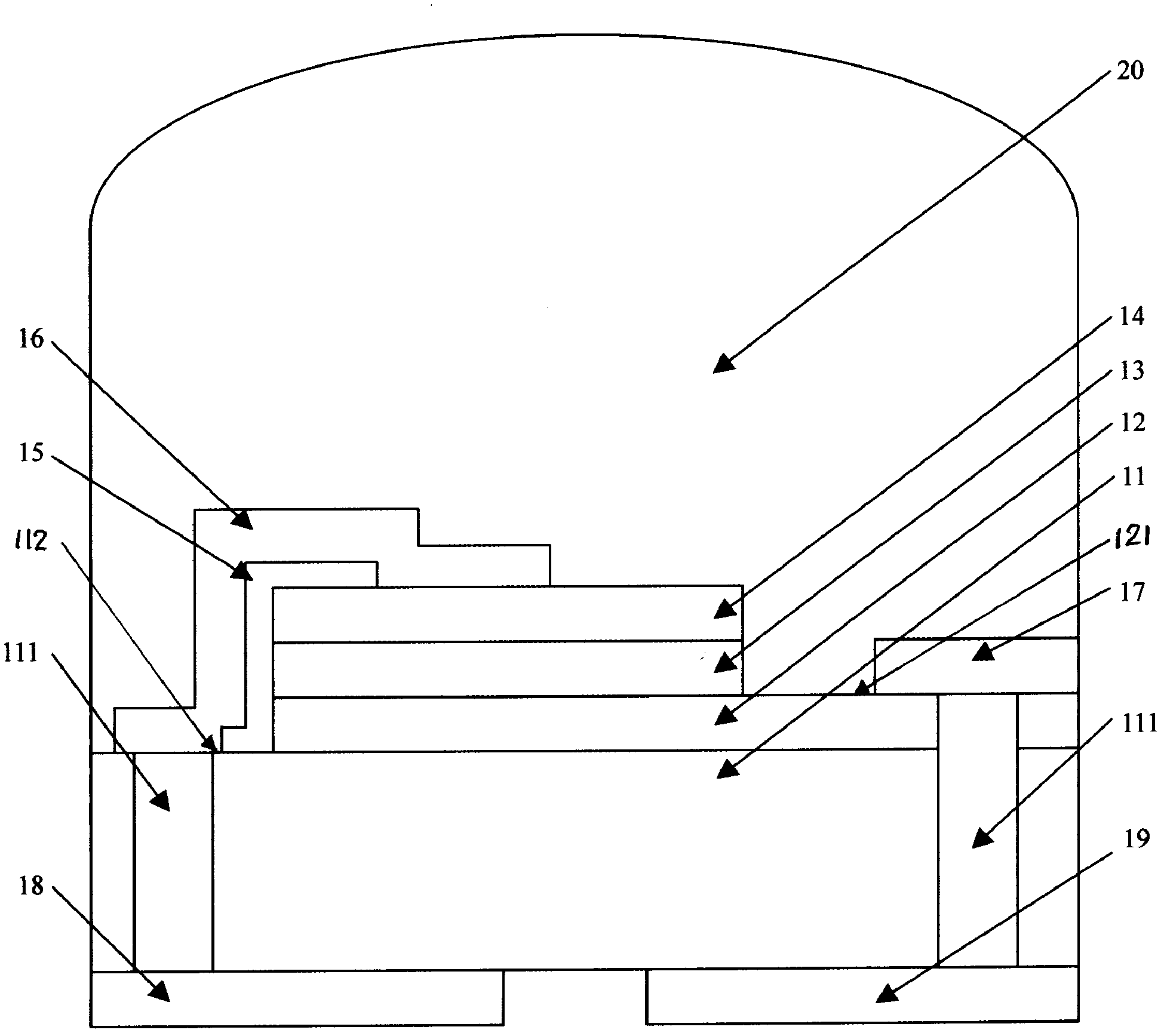

The invention discloses a light-emitting diode package structure manufacturing method, which comprises the following steps of: sequentially growing an n-type layer, an active layer and a p-type layer on an insulating substrate by utilizing a metal organic vapor phase epitaxial method; downwards photoetching one side of the upper surface of the p-type layer with the photoetching depth of reaching the surface of the n-type layer to form a first tabletop, downwards etching the other side with the etching depth of reaching the surface of the insulating substrate to form a second tabletop; manufacturing conductive through holes on the first and second tabletops, and filling conductive metals; manufacturing an insulating layer partially covering the upper surface of the p-type layer on the sideclose to the second tabletop; manufacturing a p electrode covering the insulating layer on the insulating layer; manufacturing an n electrode on the conductive through hole on the first tabletop; thinning the insulating substrate; manufacturing a first back electrode and a second back electrode on the two sides of the back of the insulating substrate to form a substrate of a device; packaging an optical element on the substrate of the device to finish manufacturing the device on the substrate; and cutting the device on the substrate into independent devices in a mechanical way.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for leaching nickel-cobalt from low-grade laterite nickel ore

InactiveCN101255494AImprove leaching rateNo pollutionProcess efficiency improvementLower gradeReducer

The invention provides a method for leaching nickel and cobalt from low-grade laterite-nickel ore, comprising the steps that: smash, grinding and size mixing the ore, controlling the ore granule -100 mesh; adding ore pulp into a reaction kettle for atmospheric pressure acid leaching; strengthening by a reducer during the leaching process. The leaching condition is: the ratio of acid to material is 0.2:1-0.5:1; the ratio of solid to liquid is 3:1-5:1; the temperature is 60 to 95 DEG C; electroequivalent of the reducer according to Fe in the ore is 0.5-1.0; the leaching time is 60 to 240 minutes; and the lixivium is partially cycled during the leaching process to control the nickel concentration greater than 2g / L. In the method for processing low-grade laterite-nickel ore, the leaching rate of nickel is greater than 90%, the leaching rate of cobalt is greater than 85%, and the leaching rate of ferrum is lower than 30%.

Owner:CENT SOUTH UNIV

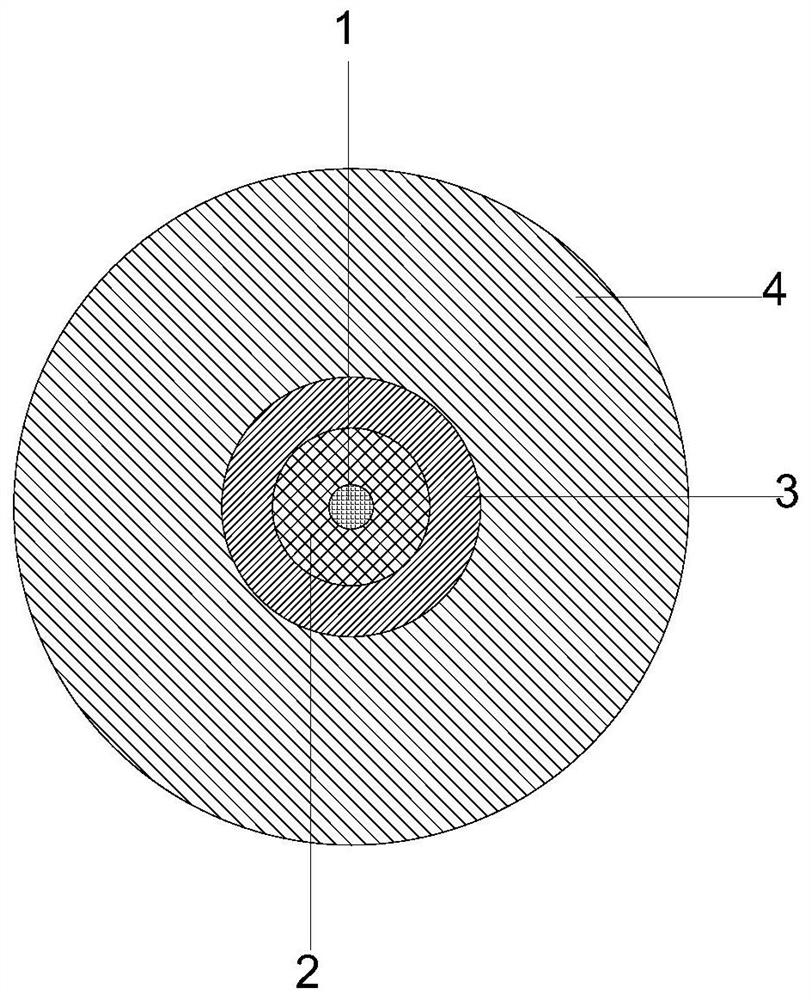

Light emitting diode (LED) packaging structure

ActiveCN102255034AThe process path is simpleReduce package sizeSemiconductor devicesIsolation layerActive layer

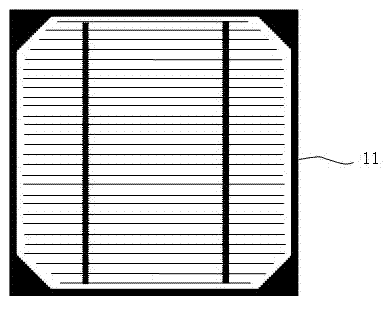

The invention relates to a light emitting diode (LED) packaging structure. The LED packaging structure comprises an insulating substrate, an n-shaped layer, an active layer, a p-shaped layer; an isolating layer, a p electrode, an n electrode, a first back electrode and a second back electrode, wherein through holes are formed on both sides of the insulating substrate and are filled with conductive metal; the n-shaped layer is arranged on the insulating substrate, and a hole is formed in the n-shaped layer and is filled with conductive metal; the active layer is arranged on the n-shaped layer;the p-shaped layer is arranged on the active layer; the isolating layer is positioned on one side of the n-shaped layer, the active layer and the p-shaped layer and is used for covering a part of upper surface of the p-shaped layer; the p electrode is used for covering the isolating layer and covering a part of upper surface of the p-shaped layer; the n electrode is arranged on one side of the upper side of the n-shaped layer and is connected with the conductive metal in the through holes in the insulating substrate; the first back electrode is arranged on one side of the rear side of the insulating substrate and is connected with the p electrode through the conductive metal in the through holes in the insulating substrate; and the second back electrode is arranged on the other side of the rear side of the insulating substrate and is connected with the n electrode through the conductive metal in the through holes in the insulating substrate. A substrate of a device is formed by all the parts, and an optical element is packaged on the substrate to complete the production of the device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost

InactiveCN102560109AImprove leaching rateNo pollutionProcess efficiency improvementIron(II) oxideCrusher

The invention relates to a method for extracting copper, nickel and cobalt intermediate products from copper and cobalt ore at low cost. The method comprises the following steps of: crushing copper and cobalt ore by using a crusher, grinding by using an ore gridding machine into powder with the particle size of less than or equal to 100 meshes; placing the ore powder with the particle size of less than or equal to 100 meshes in a reaction kettle, performing agitation leach by using hydrochloric acid at normal temperature and normal pressure, and allowing copper, nickel, cobalt, iron, magnesium, and calcium in a form of chloride in the ore to enter lixivium; adjusting the pH value to be 0.5 to 1.5, and adding iron powder in an amount which is not less than 1.5 times that of the copper in the solution and replacing to remove copper; dropwise adding ammonia water and hydrogen peroxide simultaneously at the temperature of 90DEG C with continuous stirring to adjust the pH and ferrous oxide ions to generate goethite and remove iron; and extracting nickel and cobalt by using an organic extracting agent P204. The method is low in investment, energy consumption and production cost, and simple and reasonable; and leaching rate is high.

Owner:JIANGXI UNIV OF SCI & TECH

Method for precipitating iron from goethite containing ferro-nickel mixed solution

ActiveCN103740931AEasy to separateNo pollutionProcess efficiency improvementSulfateReaction temperature

The invention discloses a method for precipitating iron from goethite containing a ferro-nickel mixed solution. The method comprises the following steps: slowly adding a mixed solution containing nickel sulfate and ferric sulfate into a solution of which the Fe<3+> content is less than or equal to 1g / L, and stirring while controlling the reaction temperature to be 20-80 DEG C and the PH to be 2.5-4.0, so that goethite precipitate is generated through Fe<3+>. The chemical precipitation is good in filtering performance and easy to wash, and complete ferro-nickel separation can be realized. The precipitated goethite is high in iron content and can serve as coarse iron ore for sales. The process is variable in production scale, wide in application, simple in process route, low in investment, low in energy consumption, good in nickel-iron separation effect, simple and convenient to operate and low in production cost, the environment is not polluted, nickel-iron separation is realized in the process of precipitating iron from the nickel sulfate and ferric sulfate mixed solution, and an extremely effective and economic and applicable way is provided for iron recycling.

Owner:江苏仁欣环保科技有限公司

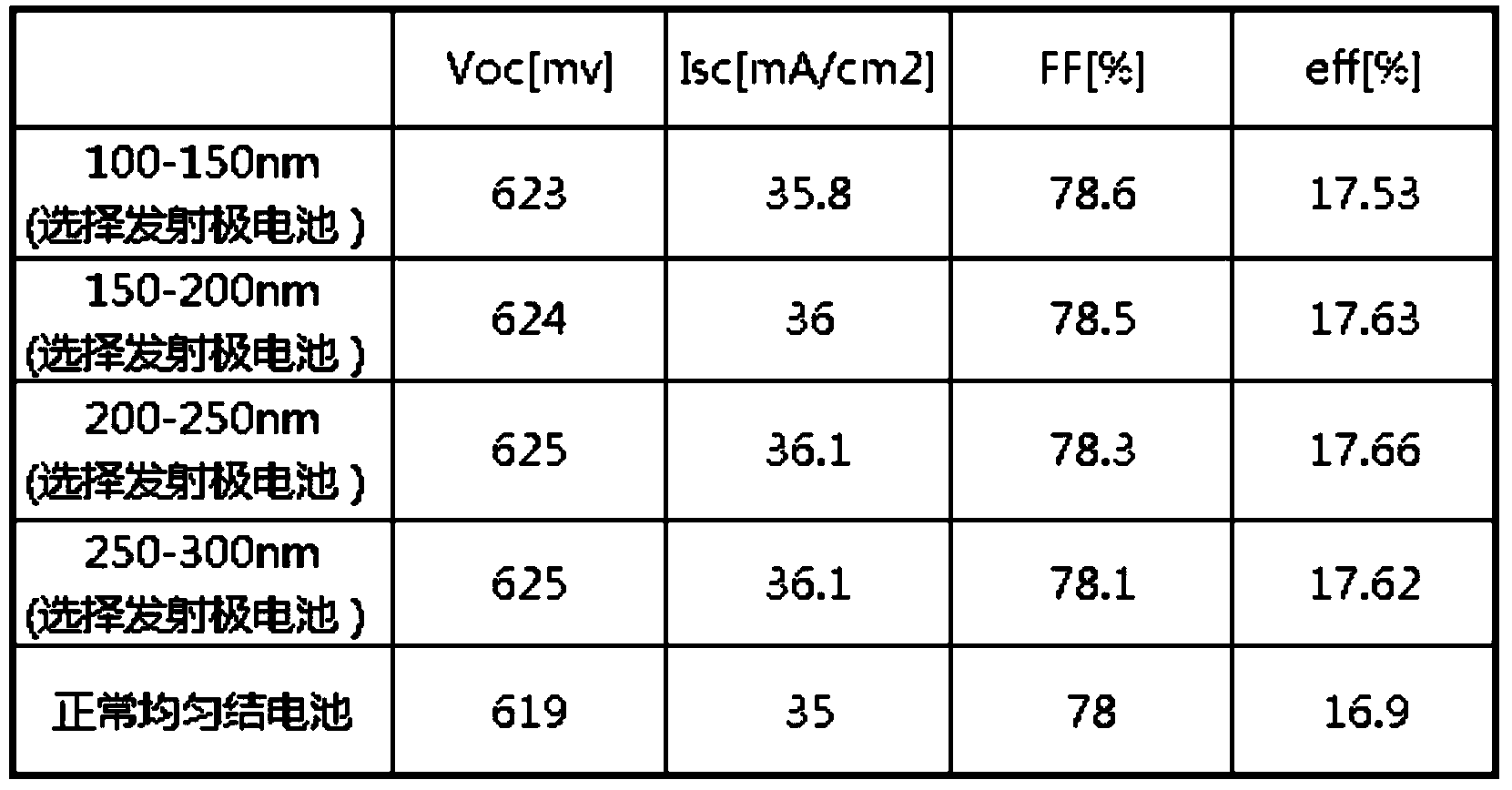

Preparation method for polycrystal/monocrystal-like solar cell selective emitting electrode structure

InactiveCN103531657AImprove conversion efficiencyReduce heat treatment processFinal product manufacturePhotovoltaic energy generationOptoelectronicsSolar cell

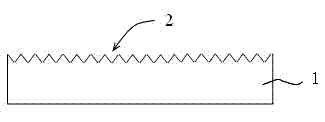

The invention discloses a preparation method for a polycrystal / monocrystal-like solar cell selective emitting electrode structure. The preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure comprises the following steps: (1) chemically removing a surface energy affected layer; (2) carrying out heavy doping by the one-time diffusion technology to form a PN junction; (3) growing or forming a dielectric layer or a mask layer on the surface of a silicon wafer; (4) corroding the dielectric layer of a non-electrode grid line area with a chemical corrosion method, and keeping the mask layer under an electrode grid line area; (5) etching a pyramid matte structure of 100-300nm in the non-electrode grid line area by reactive ion etching (RIE), and meanwhile, forming a shallow doped area in one time; and (6) removing a surface affected layer formed by RIE and a lower mask layer under the electrode grid line area with a wet chemistry method to obtain the selective emitting electrode structure. According to the preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure, which is disclosed by the invention, the light doping and the heavy doping required by the selective emitting electrode polycrystal / monocrystal-like solar cell and a low-reflectivity nanoscale surface texture can be finished by one-time diffusion combined with the RIE technology, the process path is simplified, the conversion efficiency is high, and the preparation method for the polycrystal / monocrystal-like solar cell selective emitting electrode structure is suitable for industrial volume production.

Owner:CHINA SUNERGY CO LTD

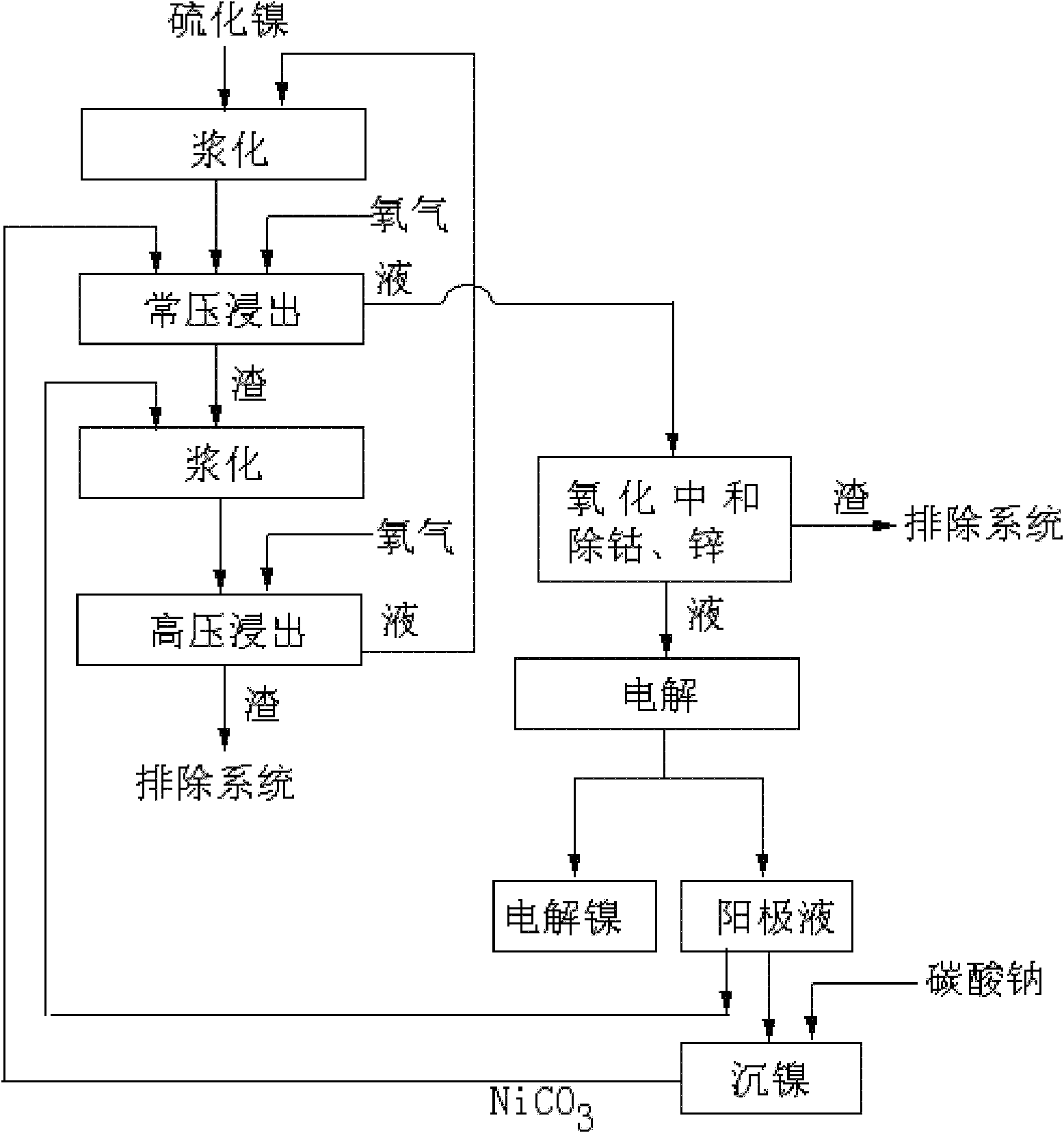

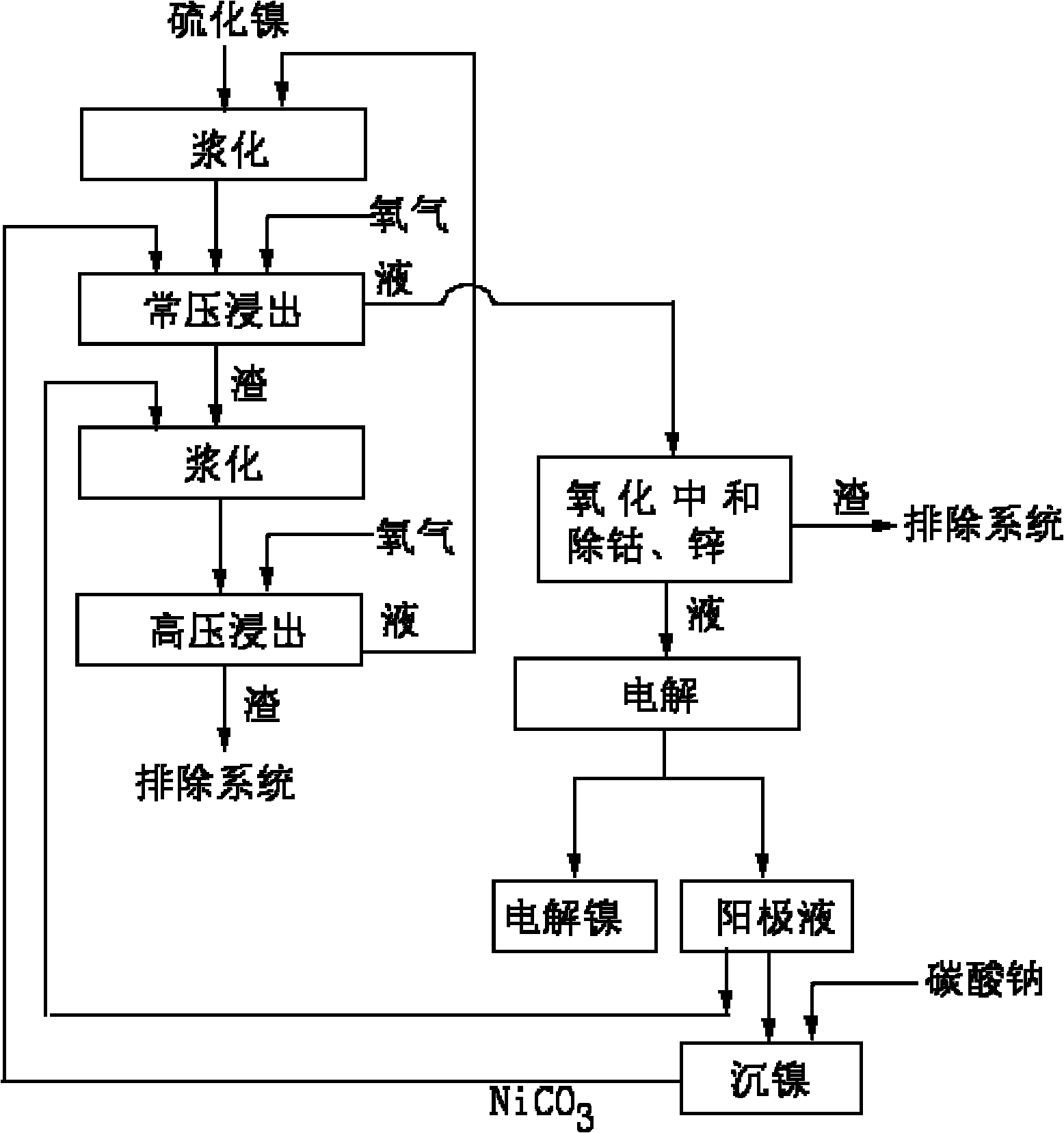

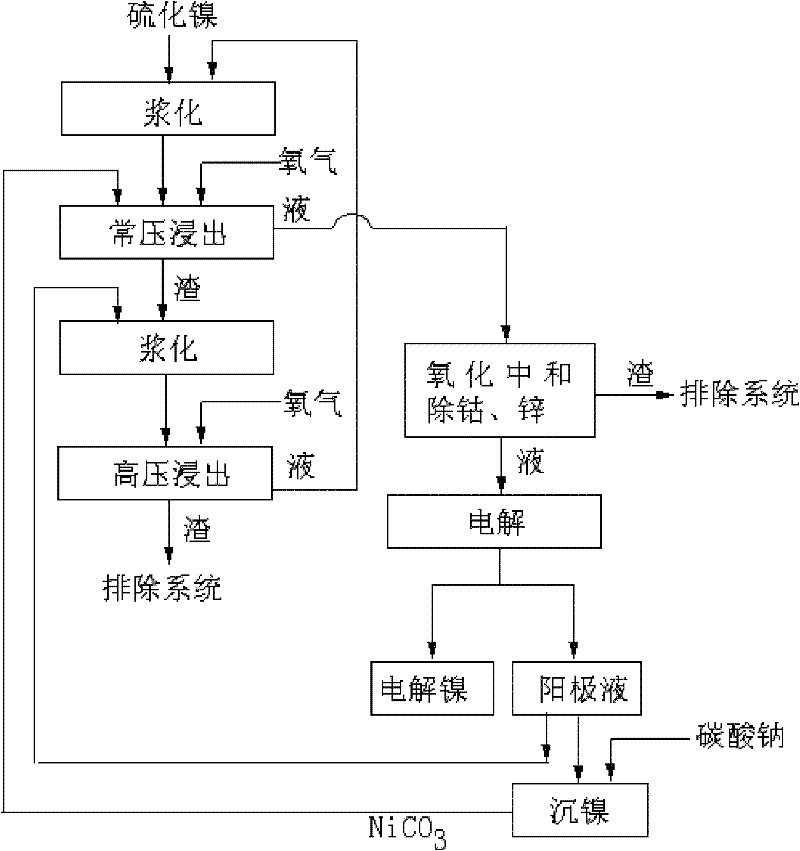

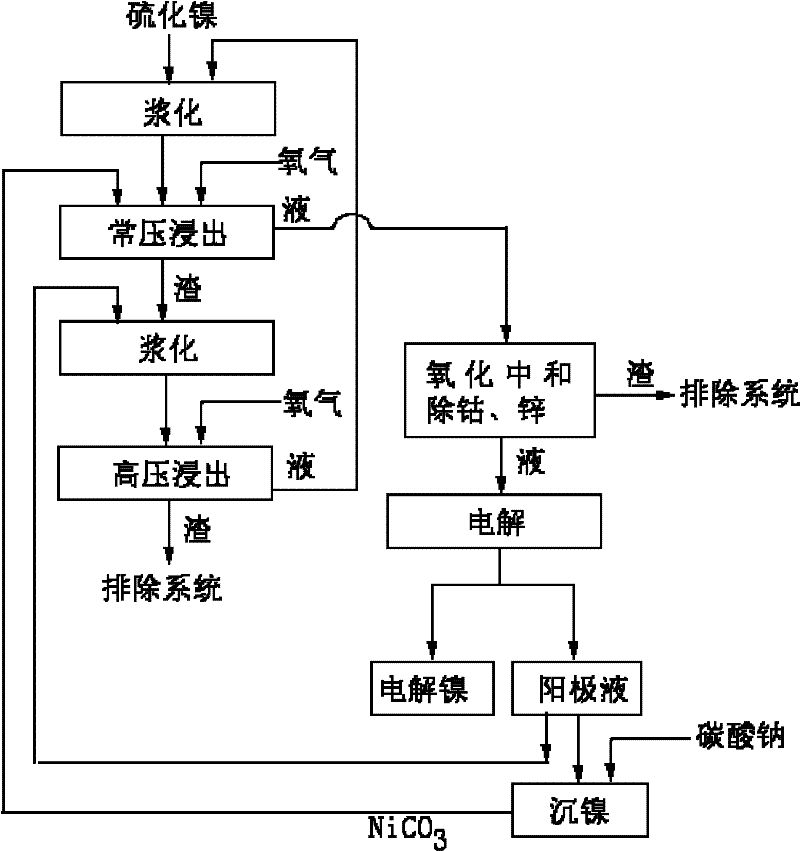

Method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen

InactiveCN101899568AImprove leaching rateWide range of resource utilizationPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel sulfide

The invention discloses a method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen, comprising the following steps: mixing and pulpifying chemically precipitated nickel sulfide and high pressure leachate based on the mass ratio of (8-10):1, performing one-stage atmospheric pressure leaching on the pulpified material, removing impurities from one-stage leachate and electrolyzing, producing electrolytic nickel and anolyte, mixing one-stage leached residue with anolyte for secondary pulpifying, further leaching by two-stage high pressure, and returning the obtained leached filtrate to one-stage pulpifying for utilization. The process technique has widely utilized resources, simple technical route, small investment, low energy consumption, no environment pollution, high leaching rate of nickel and cobalt, simple and convenient operation and low production cost, and provides an effective and economical way for producing electrolytic nickel in nickel sulfide concentrates.

Owner:SHAANXI HUAZE NICKEL & COBALT METAL

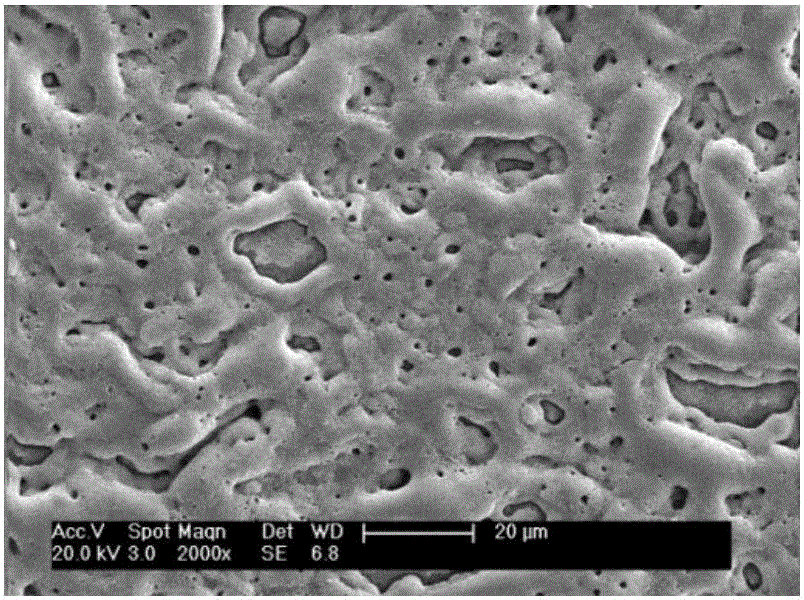

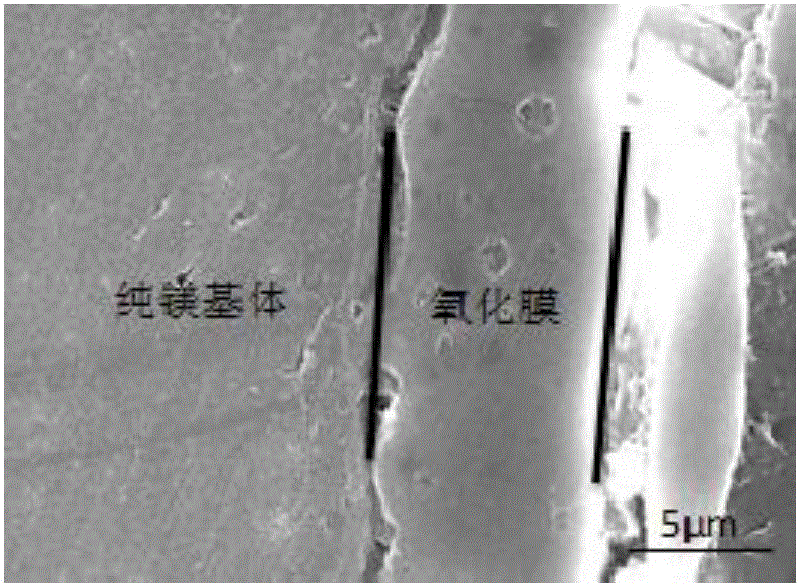

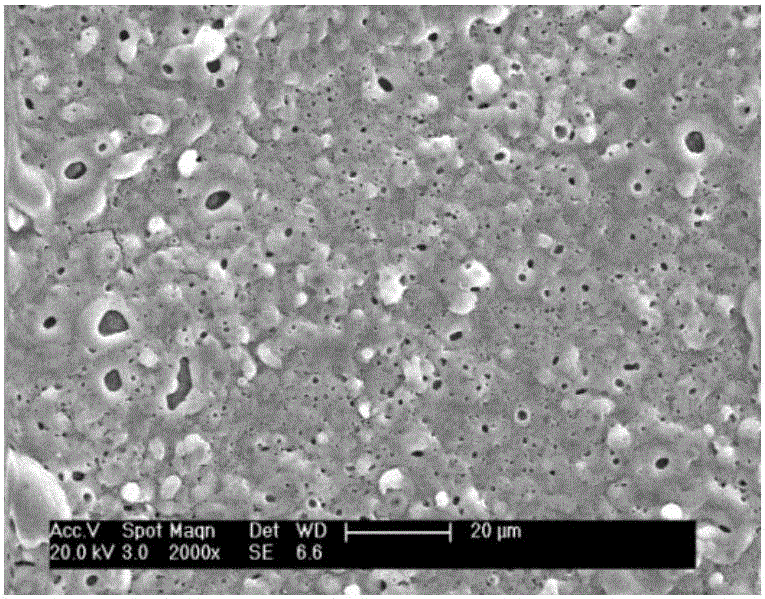

Method for preparing anti-microbial, mildew-resistant and corrosion-resistant membrane layer on magnesium metal surface

InactiveCN106480487AReduce porosityFacilitate depositionAnodisationAlternating currentMaterials science

The invention discloses a method for preparing an anti-microbial, mildew-resistant and corrosion-resistant membrane layer on a magnesium metal surface. Firstly a magnesium metal is pretreated, and then is put in an oxidation fluid. An alternating current with a current density of 0.5-2.5 A / dm<2> is connected. A layer of oxidation functional membrane is formed after the treatment is carried out for 10-40 minutes at the temperature of 15-30 DEG C. Then the magnesium metal is rinsed by deionized water and is sealed t in the pure water. The oxidation membrane layer with the thickness of 3-15[mu]m is obtained on the magnesium metal surface. The oxidation fluid contains the following solute: 40-80g / L NaOH, 50-90g / L Na2SiO3, 40-80g / L Na2B4O7, and 8-16g / L citric acid, and also contains soluble anti-microbial and mildew-resistant functional element salts. The magnesium metal surface after treatment by the method of the invention has a layer of the oxide membrane which takes a magnesia ceramic phase as a matrix. The anti-microbial and mildew-resistant functional elements Ag and Ni are dispersed and distributed in a matrix phase. The membrane layer has the good anti-microbial and mildew-resistant performance and good corrosion resistance, and can be used in many fields such as package and storage of food and clothing, and human body implantation medical instruments.

Owner:SOUTHEAST UNIV

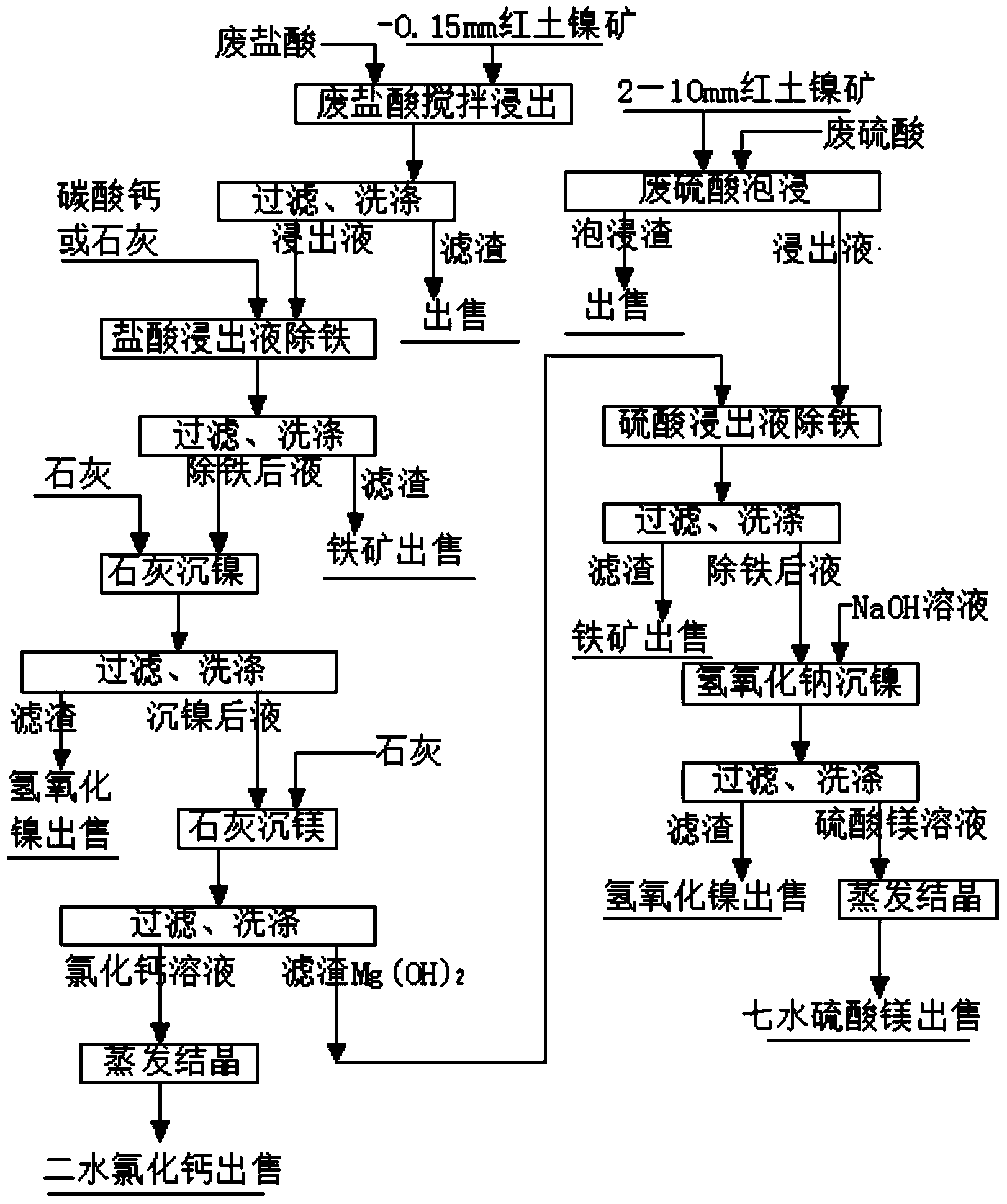

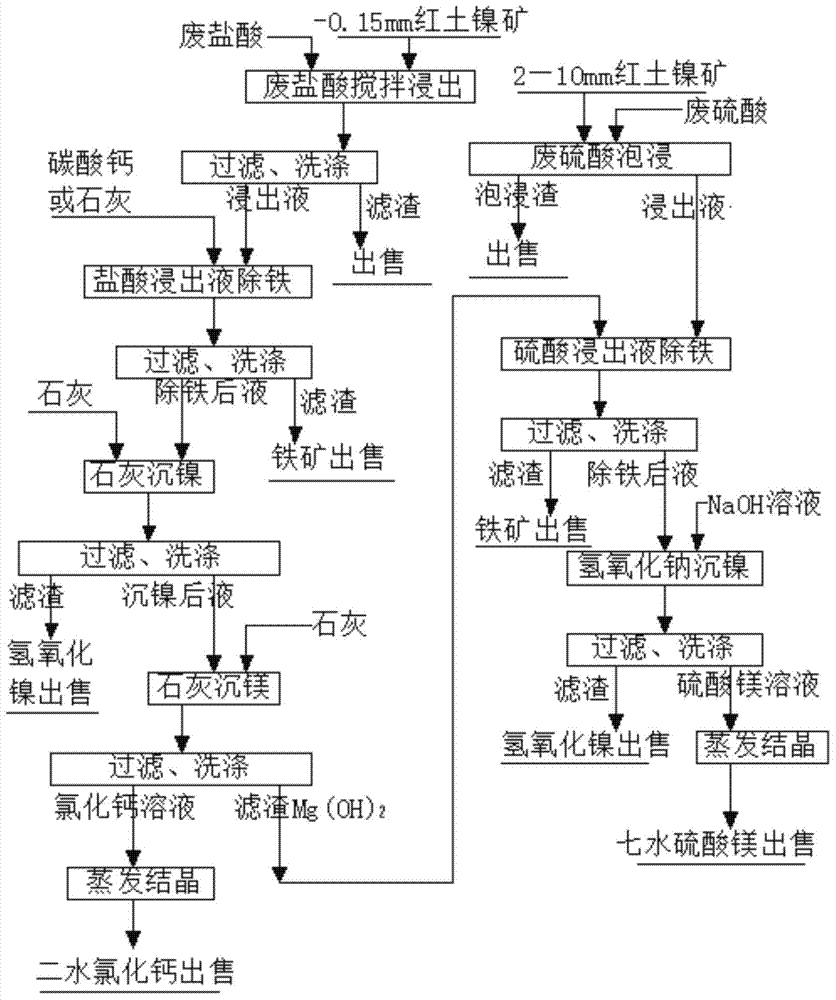

Method for comprehensive reclaiming elements by treating laterite-nickel ore by combination of chemical waste sulfuric acid and hydrochloric acid

ActiveCN103757259AWide range of resource utilizationIncrease concentrationProcess efficiency improvementResource utilizationLaterite

The invention discloses a method for comprehensive reclaiming elements by treating laterite-nickel ore by combination of chemical waste sulfuric acid and waste hydrochloric acid. The method comprises the following steps: stirring and extracting the prepared laterite-nickel ore with granularity of less than 0.15mm in a solid-liquid ratio that waste hydrochloric acid to minerals is (3-5):1; neutralizing extract with calcium carbonate or lime to remove iron, and precipitating nickel with lime; precipitating magnesium by adding lime after nickel is precipitated to obtain magnesium hydroxide, evaporating and crystallizing the liquid after magnesium is precipitated to produce calcium chloride dehydrate; soaking the prepared laterite-nickel ore of 2-10mm in a liquid-solid ratio of 0.5:1 for multiple times in a countercurrent manner, and neutralizing the extract with magnesium hydroxide to remove iron, and precipitating magnesium with sodium hydroxide; evaporating and crystallizing the solution after nickel is precipitated to produce magnesium sulfate heptahydrate. The process is adjustable in production scale, wide in resource utilization, simple in process flow, small in investment and low in energy consumption, can be used for comprehensively reclaiming elements, does not pollute the environment, has the advantages of high nickel reclaiming rate, simple operation and low production cost, and provides an extremely effective and economical way to effective utilization of waste sulfuric acid and waste hydrochloric acid and comprehensive reclaiming of laterite-nickel ore.

Owner:江苏仁欣环保科技有限公司

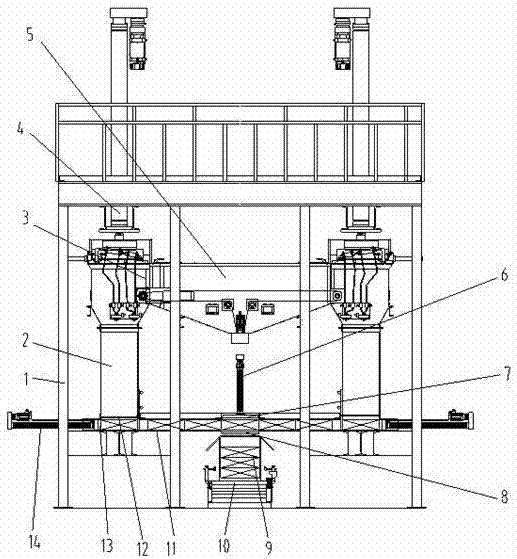

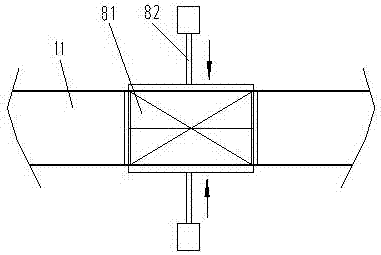

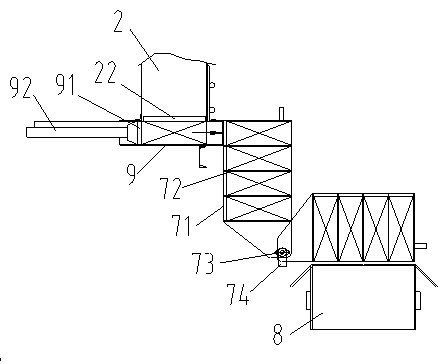

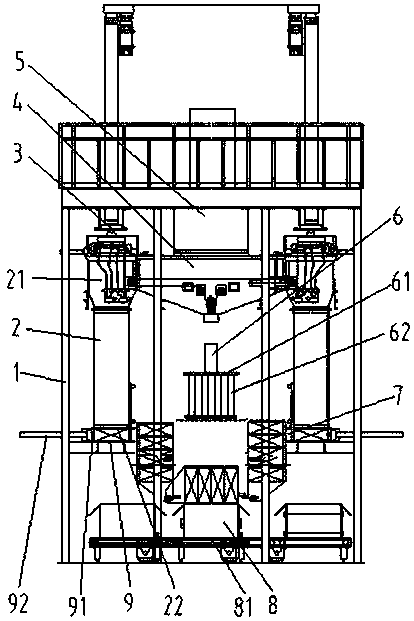

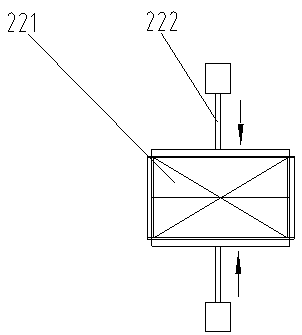

Cigarette sheet compressing blocking and packing machine

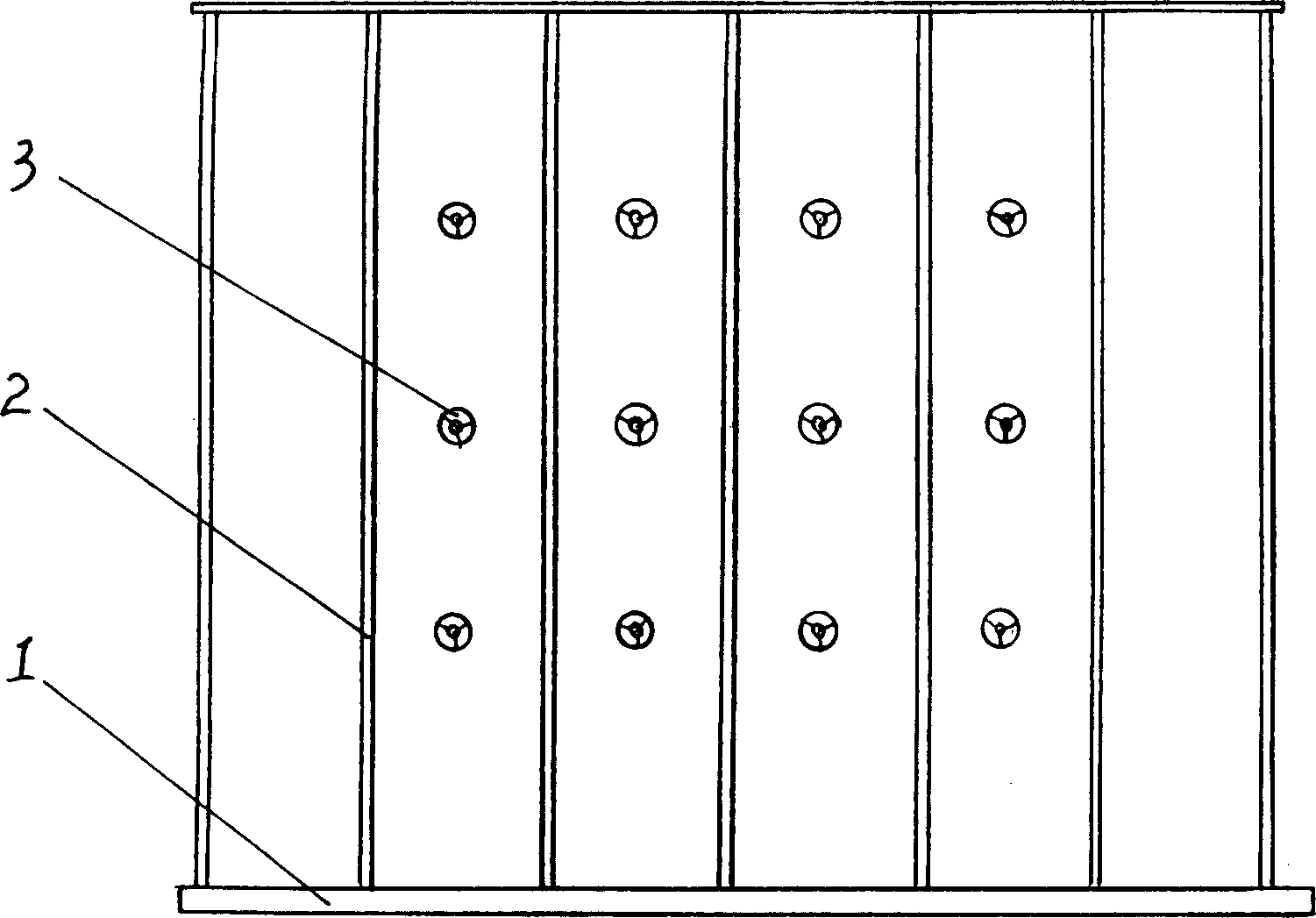

PendingCN107380575ASame density up and downImprove breathabilityTobacco preparationIndividual articlesEngineeringCigarette pack

The invention provides a cigarette sheet compressing blocking and packing machine which comprises a rack and a vertical material box arranged on the rack. A feeding inlet is formed in one side of the upper portion of the vertical material box; a compression power machine is arranged at the top of the vertical material box, and an opening-closing-type bottom plate is arranged at the bottom of the vertical material box. The cigarette sheet compressing blocking and packing machine is characterized in that a blanking flat plate is arranged on the lower portion of the vertical material box; one end of the blanking flat plate is provided with a horizontal push connected with a horizontal power cylinder, and the other end of the blanking flat plate is provided with a discharging outlet; and the upper portion of the discharging outlet is provided with a longitudinal push connected with a lifting power cylinder, and the lower portion of the discharging outlet is provided with a packing box. The up-down density of packed finished product cigarette packs is consistent, the ventilation rate and heat dissipation rate of the finished product cigarette packs are greatly increased, the finished product density uniformity of the finished product cigarette packs is greatly improved, the cigarette leaf loss is reduced, the problems of mildew and pack burning in the cigarette pack alcoholization process are fundamentally solved, the whole machine height is greatly decreased, the plant space can be reasonably used for flexible layout, the process path and equipment are simplified, and the characteristic threshing and redrying process technology is enhanced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

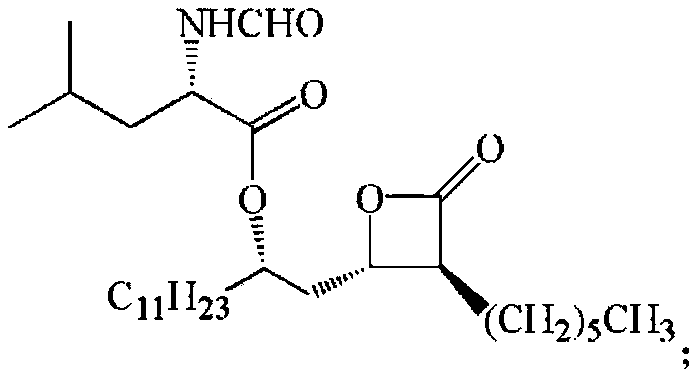

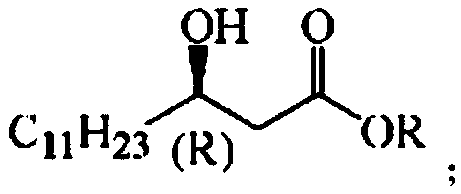

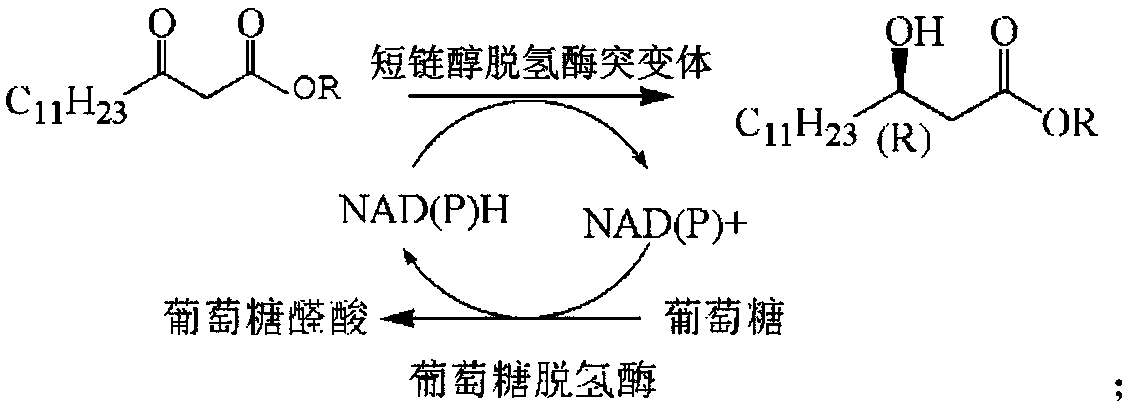

Novosphingobium short-chain alcohol dehydrogenase mutant and application thereof

ActiveCN109097344AMild preparation conditionsThe process path is simpleOxidoreductasesFermentationEnzyme catalysisSite-directed mutagenesis

The invention relates to the technical field of dehydrogenase mutants, in particular to a novosphingobium short-chain alcohol dehydrogenase mutant and an application thereof. The novosphingobium short-chain alcohol dehydrogenase mutant adopts the amino acid sequence of novosphingobium short-chain alcohol dehydrogenase NA-ADH as a template. The short-chain alcohol dehydrogenase mutant of a marine origin is obtained by site-directed mutagenesis. The mutuant is transferred into an expression strain BL21 (DE3) to obtain thalli containing the recombinant short-chain alcohol dehydrogenase after recombination by an expression vector, and then beta-hydroxytetradecanoate is used as a substrate to prepare (R)-beta-hydroxytetradecanoate by bio-enzyme catalysis, the chiral ee value of the obtained (R)-beta-hydroxytetradecanoate can reach above 99, and the substrate conversion rate is above 95%. The preparation conditions are mild, and the process way is simple.

Owner:ZHEJIANG OCEAN UNIV

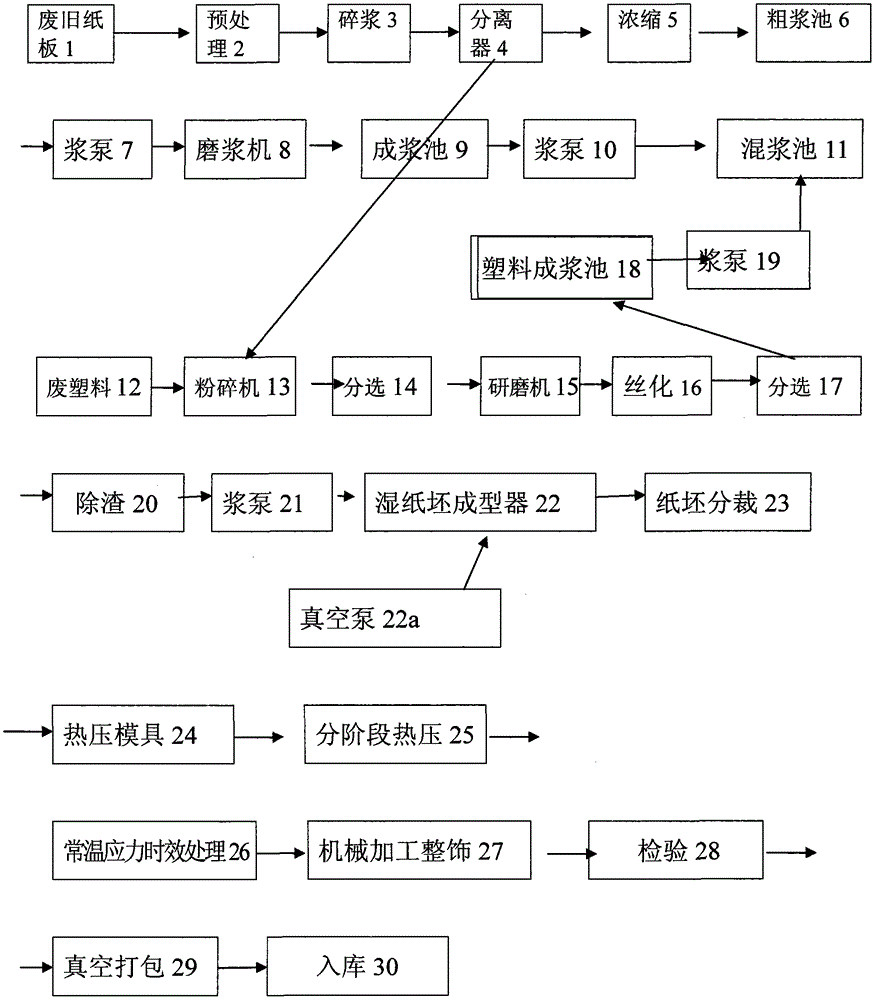

Process for producing shaping plates by using waste paper, plates and waste plastics

InactiveCN103603222AThe process path is simpleReduce investmentPaper-making machinesSlagFilamentation

The invention relates to a process for producing shaping plates by using waste paper, plates and waste plastics. The process includes that subjecting the waste paper and plates to purifying pretreatment prior to pulping; concentrating pulp subjected to size degradation to 4.0+ / -0.5% in concentration before allowing the same to enter a pulp chest, delivering the pulp to a pulping machine through a pulp pump, delivering ground pulp into a full pulp chest prior to delivering the same to a mix pulp chest through the pulp pump; pulverizing the waste plastics through a pulverizer, separating the ground plastic through a separating screen, delivering plastic particles conforming to grinding standard to a grinding machine for grinding and refining prior to delivering to the mix pulp after filamentation; mixing paper pulp and plastic pulp prior to purifying through a slag separator, forming, splitting, drying, cooling, releasing, edge cutting, mechanical processing and finishing, testing, vacuum packaging and vacuum packaging and warehousing. The process is simple in process path, and special equipment can be partially added by utilizing existing equipment, so that equipment investment is less, and commercial value of products is high.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

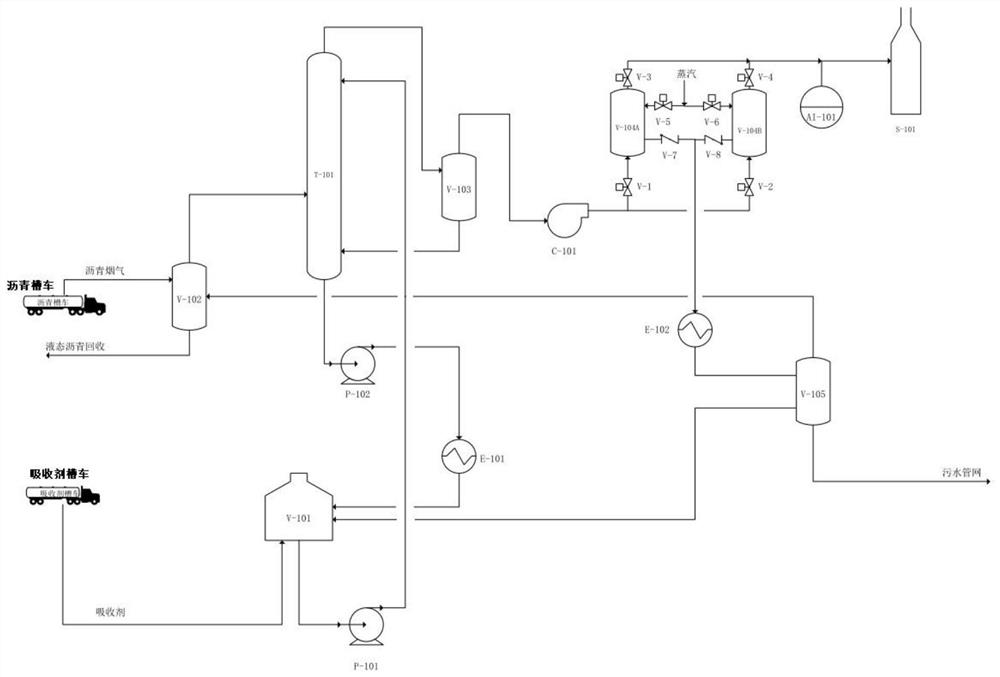

Recovery system and method for escaping flue gas in liquid asphalt loading process

PendingCN114053842AThe process path is simplePrevent precipitationGas treatmentDispersed particle separationProcess equipmentFlue gas

The invention provides a special recovery system and method for escaping flue gas in a liquid asphalt loading process. High-temperature liquid asphalt flue gas passes through a buffer tank, an absorption tower, a coalescer and an adsorption tank, and liquid-phase recovery of organic matters contained in the asphalt flue gas is completed through absorption mass transfer, gas-liquid separation and adsorption trapping. The industrial method not only can effectively solve the problems of adsorption failure and overhigh energy consumption caused by high temperature of flue gas, but also can recycle sulfur-containing, chlorine-containing and other macromolecular organic matters which are easy to block and solidify through an effective absorption method, so that downstream process equipment and materials are effectively protected, the process route of flue gas treatment is shortened, the asphalt flue gas treatment cost is reduced, and the continuous up-to-standard emission of the asphalt tail gas can be ensured.

Owner:QINGDAO NUOCHENG CHEM SAFETY SCI & TECH CO LTD

Method for producing magnesium hydroxide from mixed solution containing magnesium chloride and calcium chloride by lime seeding method

InactiveCN103754901ANo pollutionEasy to separateCalcium/strontium/barium chloridesMagnesium hydroxideFiltrationChloride

The invention discloses a method for producing magnesium hydroxide from a mixed solution containing magnesium chloride and calcium chloride by a lime seeding method. The method is capable of producing high-purity magnesium hydroxide through the steps of adding the magnesium hydroxide to the mixed solution containing magnesium chloride and calcium chloride, stirring and then slowly adding lime milk, wherein the produced high-purity magnesium hydroxide is good in filtration performance, easy to wash and capable of completely separating calcium from magnesium. The calcium chloride solution left after the magnesium hydroxide precipitates can be used for producing crystalline calcium chloride through evaporative crystallization. The method is changeable in production scale, wide in application, simple in process route, low in investment, low in energy consumption, free of pollution to environment, good in calcium-magnesium separation effect, simple and convenient to operate and low in production cost; and therefore, a quite effective, economical and practicable way is provided for producing the magnesium hydroxide from the mixed solution of magnesium chloride and calcium chloride.

Owner:江苏仁欣化工股份有限公司

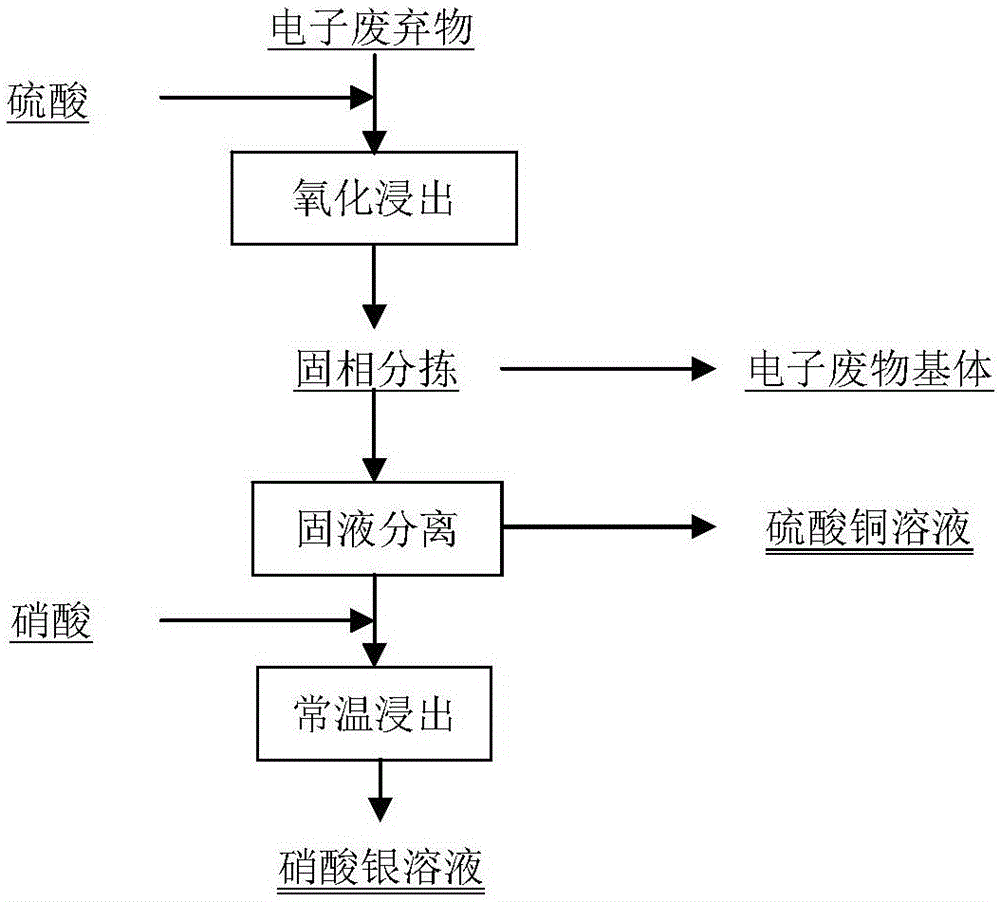

Method for recycling valuable metal from electronic waste

ActiveCN105087944AReduce manufacturing costCopper leaching at low acidity and temperature regulation (silver has less production costProcess efficiency improvementEconomic benefitsElectronic waste

The invention discloses a method for recycling valuable metal from electronic waste. The method comprises the following steps that 1, the electronic waste is immersed into sulfuric acid to obtain a mixture A; 2, ozone is introduced to react with the mixture A after the mixture A is heated to 40-60 DEG C, and a mixture B is obtained after the reaction is completed, wherein the amount of the introduced ozone corresponding to every one kg of electronic waste is not less than 2 L / h, and the reaction time is not less than 2 h; and 3, the mixture B is subjected to solid-liquid separation, and obtained liquid is copper sulfate solution. According to the method, the electronic waste does not need to be smashed before being subjected to acid immersion; the method is implemented at low temperature and normal pressure, investment is less relatively, and the operating cost is low; the process is simple, energy consumption is low, the production cost is low, the recovery rate of the valuable metal is high, and the method is applicable to large-scale industrial production; the ozone used for the method cannot pollute the environment, no pollutants such as sulfur dioxide can be produced in the leaching process, and good economic benefits and environmental benefits are realized.

Owner:河南省冶金研究所有限责任公司

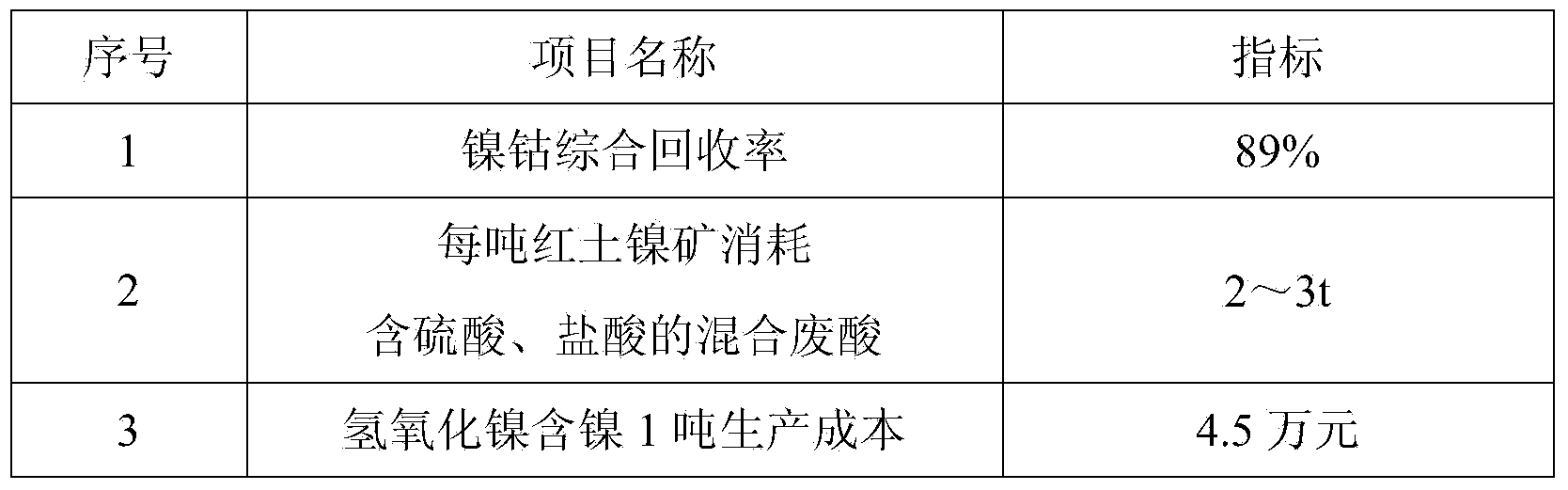

A method for comprehensively recovering various elements of chemical waste sulfuric acid and waste hydrochloric acid combined treatment of laterite nickel ore

ActiveCN103757259BWide range of resource utilizationIncrease concentrationMetal recyclingProcess efficiency improvementResource utilizationLaterite

The invention discloses a method for comprehensive reclaiming elements by treating laterite-nickel ore by combination of chemical waste sulfuric acid and waste hydrochloric acid. The method comprises the following steps: stirring and extracting the prepared laterite-nickel ore with granularity of less than 0.15mm in a solid-liquid ratio that waste hydrochloric acid to minerals is (3-5):1; neutralizing extract with calcium carbonate or lime to remove iron, and precipitating nickel with lime; precipitating magnesium by adding lime after nickel is precipitated to obtain magnesium hydroxide, evaporating and crystallizing the liquid after magnesium is precipitated to produce calcium chloride dehydrate; soaking the prepared laterite-nickel ore of 2-10mm in a liquid-solid ratio of 0.5:1 for multiple times in a countercurrent manner, and neutralizing the extract with magnesium hydroxide to remove iron, and precipitating magnesium with sodium hydroxide; evaporating and crystallizing the solution after nickel is precipitated to produce magnesium sulfate heptahydrate. The process is adjustable in production scale, wide in resource utilization, simple in process flow, small in investment and low in energy consumption, can be used for comprehensively reclaiming elements, does not pollute the environment, has the advantages of high nickel reclaiming rate, simple operation and low production cost, and provides an extremely effective and economical way to effective utilization of waste sulfuric acid and waste hydrochloric acid and comprehensive reclaiming of laterite-nickel ore.

Owner:江苏仁欣环保科技有限公司

Method of bulk infusion extracting nickel cobalt from low grade red soil nickel ore

InactiveCN1311089CImprove leaching rateNo pollutionProcess efficiency improvementPregnant leach solutionGranularity

A process for extracting Ni and Co from the low-grade Ni-contained laterite ore includes such steps as crushing to make its average granularity less than 2 cm, stacking the ore particles with granularity of 100 mesh-1.5 cm, proportionally mixing others, adding them to the stack, shrinkling acidic extracting liquid, collecting the extracting liquid, and concentrating until the concentration of Ni ions is 2-4g / L.

Owner:广西赛可昱新材料科技有限公司

Method for recovering nickel and cobalt through leaching laterite-nickel ore by using sulfuric and hydrochloric acid containing mixed waste acid

InactiveCN103773951ARealize comprehensive utilizationHigh recovery rateProcess efficiency improvementChemical industrySulfuric acid

The invention discloses a method for recovering nickel and cobalt through leaching laterite-nickel ore by using sulfuric and hydrochloric acid containing mixed waste acid. The method comprises the processes of carrying out stirred leaching on sulfuric and hydrochloric acid containing mixed waste acid, de-ironing a leachate and precipitating nickel and cobalt. According to the method, sulfuric and hydrochloric acid containing mixed waste acid generated during chemical industry production can be treated, meanwhile, the comprehensive utilization of sulfuric and hydrochloric acid containing mixed waste acid is realized, the waste is changed into the valuable, the laterite-nickel ore is leached, nickel and cobalt are recovered simultaneously, the recovery ratio of nickel and cobalt is high, the production scale can be large and small, and the range of used sulfuric and hydrochloric acid containing mixed waste acid is large; the method disclosed by the invention has the characteristics of simple process path, small investment, low energy consumption, low operating cost, no environmental pollution, comprehensive utilization in sulfuric and hydrochloric acid containing mixed waste acid, simplicity and convenience in operation, low production cost and the like, so that an extremely effective, economical and applicable way for the treatment and comprehensive utilization of sulfuric and hydrochloric acid containing mixed waste acid and the recovery of nickel and cobalt through laterite-nickel ore leaching is provided.

Owner:江苏仁欣化工股份有限公司

Method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen

InactiveCN101899568BImprove leaching rateWide range of resource utilizationPhotography auxillary processesProcess efficiency improvementPregnant leach solutionNickel sulfide

The invention discloses a method for producing electrolytic nickel by leaching chemically precipitated nickel sulfide with pure oxygen, comprising the following steps: mixing and pulpifying chemically precipitated nickel sulfide and high pressure leachate based on the mass ratio of (8-10):1, performing one-stage atmospheric pressure leaching on the pulpified material, removing impurities from one-stage leachate and electrolyzing, producing electrolytic nickel and anolyte, mixing one-stage leached residue with anolyte for secondary pulpifying, further leaching by two-stage high pressure, and returning the obtained leached filtrate to one-stage pulpifying for utilization. The process technique has widely utilized resources, simple technical route, small investment, low energy consumption, no environment pollution, high leaching rate of nickel and cobalt, simple and convenient operation and low production cost, and provides an effective and economical way for producing electrolytic nickel in nickel sulfide concentrates.

Owner:SHAANXI HUAZE NICKEL & COBALT METAL

Smoke sheet compression block flip packing machine

PendingCN107585375ASame density up and downImprove breathabilityTobacco preparationIndividual articlesEngineeringVolumetric Mass Density

The invention provides a smoke sheet compression block flip packing machine. The flip packing machine comprises a rack, and a vertical material box arranged on the rack; a feeding port is formed in one side of the upper part of the vertical material box, a compression power machine is arranged on the top and an open-closed type bottom plate is arranged on the bottom; the flip packing machine is characterized in that a blanking flat plate is arranged on the lower side of the vertical material box, a horizontal push which is connected with a power cylinder is arranged on one end of the blankingflat plate, the other end of the blanking flat plate is connected with an elevating and flipping buffer mechanism, a longitudinal push which is connected with the power cylinder is arranged on the upper side of the horizontal position of the elevating and flipping buffer mechanism, and a packaging box is arranged on the lower side. The packed finished cigarette packets are consistent in upper andlower density, the air permeability, heat dissipation and density uniformity of the finished cigarette packets are greatly improved, the problems of mildew and burn bags in the alcoholization processof cigarette packets are fundamentally solved, the height of the whole machine is reduced, flexible layout of workshop space is facilitated, the processing route and equipment are simplified, and theprocess of featured threshing and redrying is improved.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

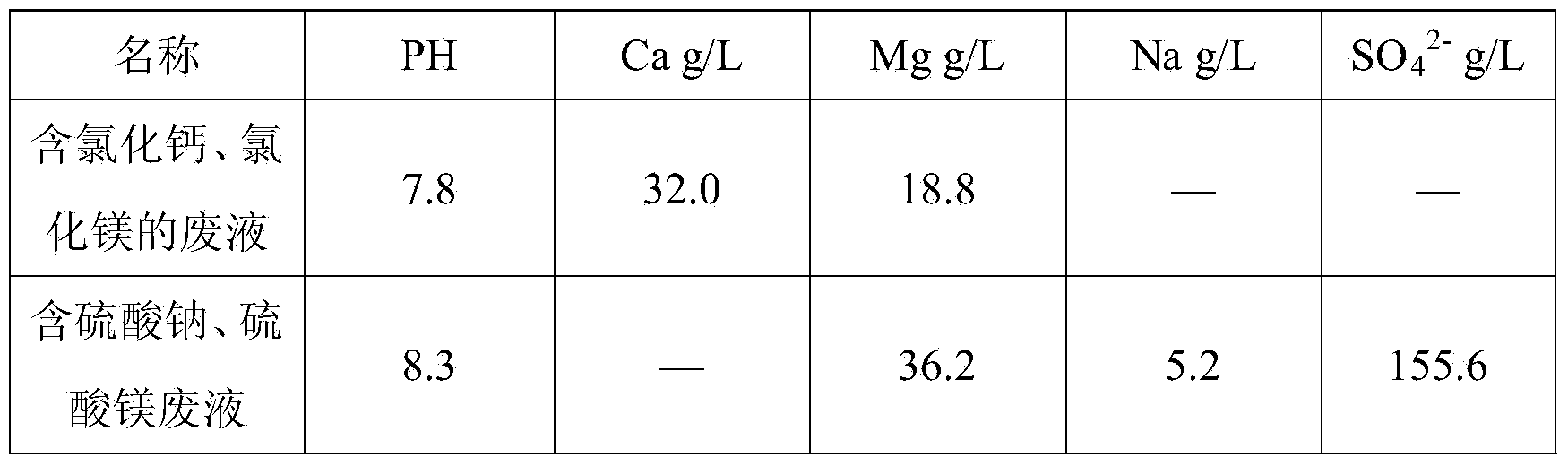

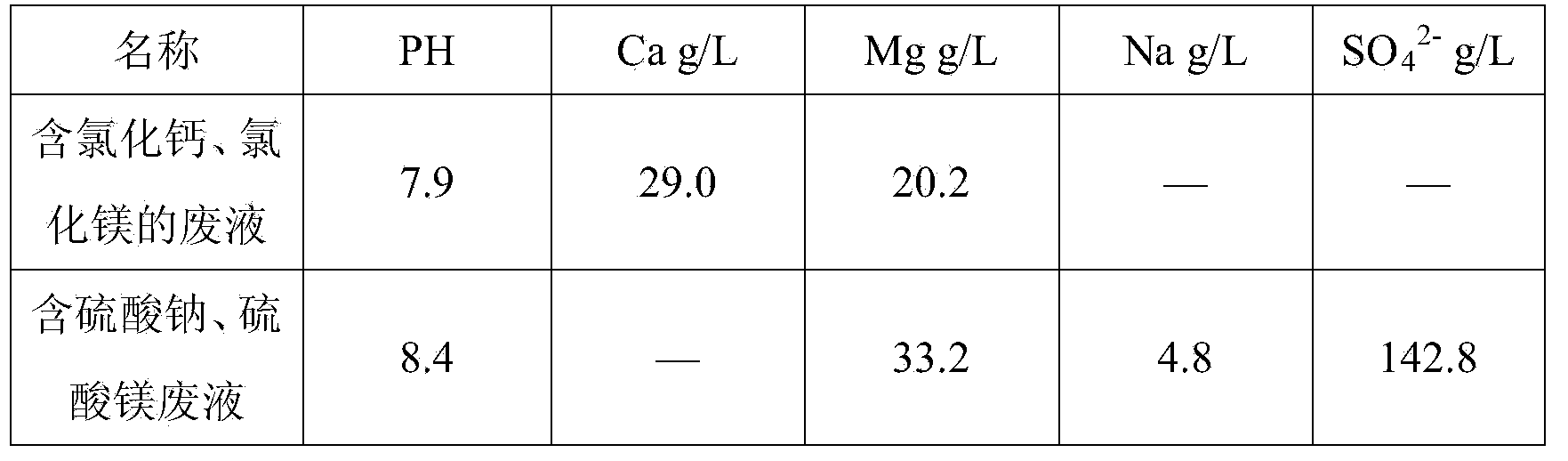

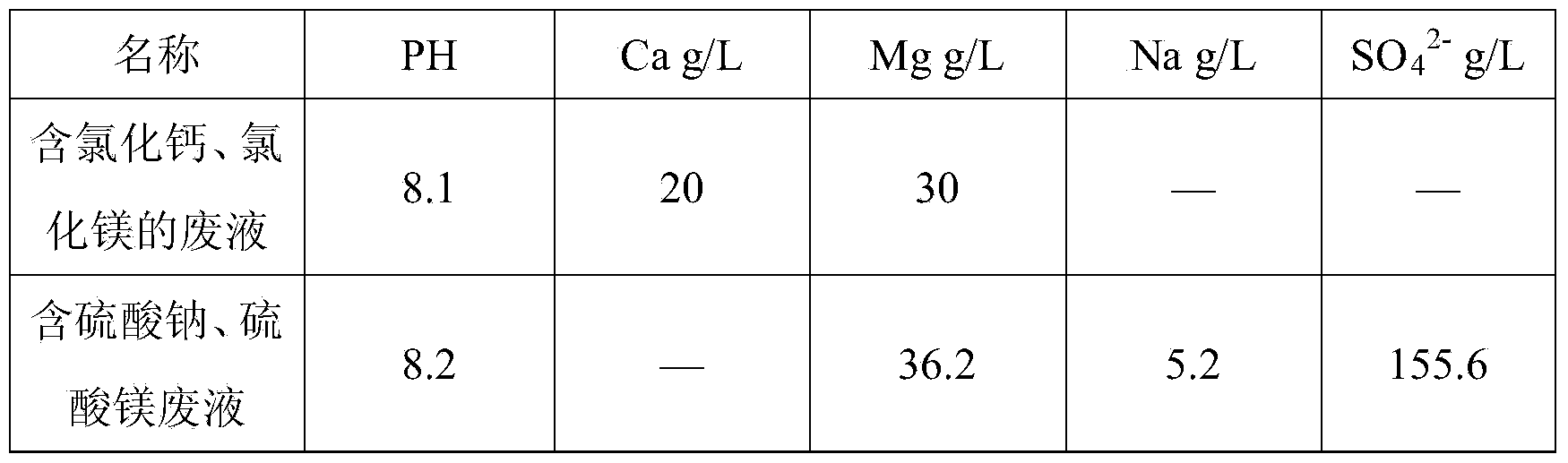

A process of producing a snow melting agent from waste liquids obtained by subjecting laterite nickel ore to leaching with sulfuric acid and hydrochloric acid and to nickel precipitation

ActiveCN103833054AThe process path is simpleLess investmentOther chemical processesMagnesium chloridesMagnesium chloride hexahydratePrecipitation

The invention discloses a process of producing a snow melting agent from waste liquids obtained by subjecting laterite nickel ore to leaching with sulfuric acid and hydrochloric acid and to nickel precipitation. According to the process, a waste liquid obtained by subjecting laterite nickel ore to leaching with hydrochloric acid, iron removal with calcium carbonate and nickel precipitation with lime, which contains calcium chloride and magnesium chloride, and a waste liquid obtained by subjecting the laterite nickel ore to leaching with sulfuric acid, iron removal with calcium carbonate and nickel precipitation with sodium hydroxide are mixed according to a molar ratio that is Ca<2+>:SO4<2->=1:1 to produce calcium sulphate dihydrate, and to produce a magnesium chloride hexahydrate type snow melting agent by evaporative crystallization, wherein the second waste liquid contains sodium sulfate and magnesium sulfate. The process can either be big or small in production scale, and is simple in process route, low in investment, low in energy consumption, free of pollution to the environment, simple in operation, and low in production cost. The process provides an effective and economical route for treating the waste liquid containing the calcium chloride and the magnesium chloride, treating the waste liquid containing the sodium sulfate and the magnesium sulfate, reducing pollution and achieving comprehensive utilization.

Owner:江苏仁欣化工股份有限公司

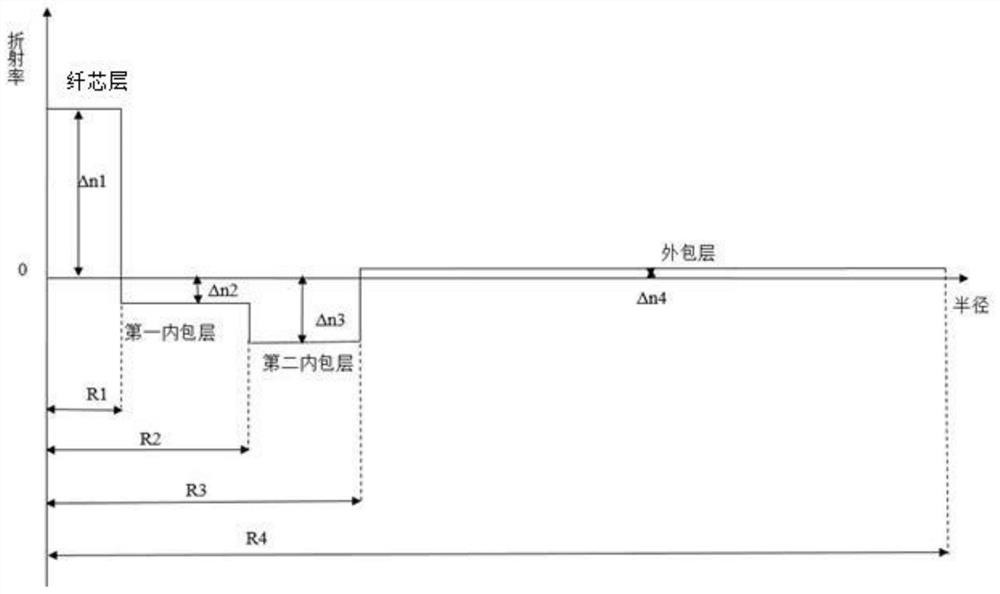

Total-synthesis low-loss single-mode optical fiber

PendingCN112230331AReduce stressLow viscosityGlass optical fibreOptical fibre with multilayer core/claddingFiberRefractive index

The invention discloses a total-synthesis low-loss single-mode optical fiber which comprises a fiber core layer, a first inner cladding layer, a second inner cladding layer and an outer cladding layerfrom inside to outside. The fiber core layer is a germanium-doped quartz glass layer, and the refractive index difference deltan1 of the fiber core layer relative to pure quartz glass is 0.300%-0.340%; the first inner cladding layer and the second inner cladding layer are both quartz glass layers doped with a fluorine element; the refractive index difference deltan2 of the first inner cladding relative to the pure quartz glass is -0.04%- -0.02%; the refractive index difference deltan3 of the second inner cladding relative to the pure quartz glass is -0.07%- -0.04%; the outer cladding is a micro-doped aluminum quartz cladding, and the refractive index difference deltan4 of the outer cladding relative to the pure quartz glass satisfies deltan1 > deltan4 > deltan2 > deltan3. The attenuationcoefficient of the optical fiber in the 1550 nm waveband is smaller than or equal to 0.180 db / km, the purpose of low loss attenuation is achieved, the manufacturing cost is low, and the process difficulty is low.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

Wood charcoal produced from processed waste paper scraps of insulating paper plates and producing process thereof

InactiveCN102757798AThe process path is simpleSmall footprintBiofuelsSolid fuelsCompression moldingCardboard

The invention relates to wood charcoal produced from processed waste paper scraps of insulating paper plates and a producing process thereof. The producing process comprises the steps of: adding the dry processed waste paper scraps of the dry insulating paper plates and clean clay into purified water to be mixed and stirred fully; placing the well mixed raw material in a purpose-made hollow mould for compression molding under pressure; putting blanks obtained after the compression molding into a firing kiln to be fired, flame-hardened and cooled so as to obtain finished products; packaging the finished products with bags to form commercial wood charcoal which can be used as hotpot fuel. The wood charcoal produced from the processed waste paper scraps of the insulating paper plates and the producing process thereof, disclosed by the invention, have the advantages of simple processing way, small floor area, low equipment investment and high commercial value of the product.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

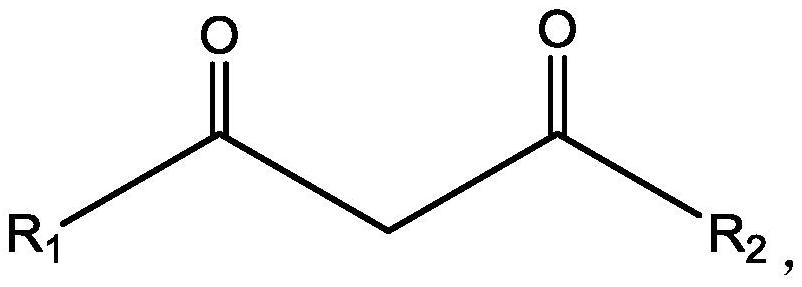

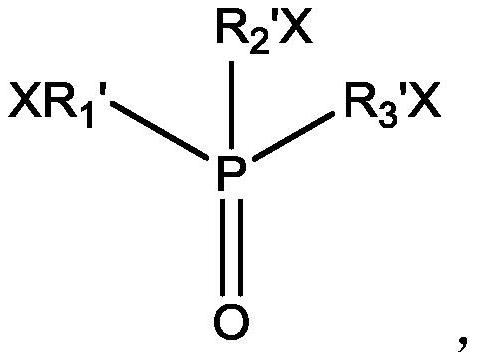

Method for extracting and separating lithium and alkaline earth metal from salt lake brine with high sodium-lithium ratio

PendingCN113981243AReduce usageAvoid densityProcess efficiency improvementHigh sodiumAlkaline earth metal

The invention discloses a method for extracting and separating lithium and alkaline earth metal from salt lake brine with a high sodium-lithium ratio, which comprises the following steps of providing an extraction water phase: taking the salt lake brine with the high sodium-lithium ratio as the extraction water phase which contains Li<+>, Na<+>, Ca<2+> and Mg<2+>, wherein the mass ratio of Na<+> to Li<+> is (10: 1)-(200: 1), providing anextraction organic phase: mixing an extraction agent, a synergistic extraction agent and kerosene, and preparing the extraction organic phase, wherein the extraction agent is a diketone compound, and the synergistic extraction agent is a halogen-containing organic phosphine compound, in an extraction step, mixing the extraction organic phase and the extraction water phase, performing counter-current extraction of more than one stage, and performing phase splitting after the extraction is balanced to obtain raffinate and a first loaded organic phase, and sequentially conducting sodium reverse extraction, lithium reverse extraction, calcium reverse extraction and magnesium reverse extraction on the first loaded organic phase, so that a sodium salt solution, a lithium salt solution, a calcium salt solution and a magnesium salt solution are obtained through separation. Sodium, lithium, calcium, magnesium and other alkaline earth metals are effectively separated from the salt lake brine with the high sodium-lithium ratio.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for collecting nickel and cobalt from laterite-nickel ore lixivium

ActiveCN101298638BHigh extraction rateReduce energy consumptionProcess efficiency improvementPregnant leach solutionSlag

Owner:福建常青新能源科技有限公司

Preparation method of selective emitter solar cell

InactiveCN101950780BReduce one high temperature diffusion processThe process path is simpleFinal product manufactureSemiconductor devicesScreen printingSolar cell

The invention discloses a preparation method of a selective emitter solar cell, comprising the following steps: providing a silicon wafer for carrying out surface texturization; printing a diffusion permeable membrane on the silicon wafer by a first silk-screen printing plate; covering a non-electrode region by using the diffusion permeable membrane printed by the first silk-screen printing plate, exposing an electrode region to be printed; forming a light diffusion layer for the silicon wafer in the non-electrode light-affected region with the permeable membrane, and forming a heavy diffusion layer in the electrode region without the permeable membrane to be printed; carrying out corrosion for removing peripheral PN nodes, washing the membrane, and removing phosphosilicate glasses; preparing a passivation layer and an antireflection layer; and printing by the printing screen printing plate and sintering to form a back Ag electrode, a back Al-BSF and a front Ag electrode. The preparation method for the selective emitter solar cell provided by the invention adopts one-time diffusion to form the light and heavy doping required by the selective emitter solar cell, thereby reducing one-time high-temperature diffusion process, simplifying processes of the technology, and lowering the cost.

Owner:百力达太阳能股份有限公司

Method for leaching nickel-cobalt from low-grade laterite nickel ore

The invention provides a method for leaching nickel and cobalt from low-grade laterite-nickel ore, comprising the steps that: smash, grinding and size mixing the ore, controlling the ore granule -100mesh; adding ore pulp into a reaction kettle for atmospheric pressure acid leaching; strengthening by a reducer during the leaching process. The leaching condition is: the ratio of acid to material is0.2:1-0.5:1; the ratio of solid to liquid is 3:1-5:1; the temperature is 60 to 95 DEG C; electroequivalent of the reducer according to Fe in the ore is 0.5-1.0; the leaching time is 60 to 240 minutes; and the lixivium is partially cycled during the leaching process to control the nickel concentration greater than 2g / L. In the method for processing low-grade laterite-nickel ore, the leaching rateof nickel is greater than 90%, the leaching rate of cobalt is greater than 85%, and the leaching rate of ferrum is lower than 30%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com