Total-synthesis low-loss single-mode optical fiber

A single-mode optical fiber, low-loss technology, applied in glass optical fiber, clad optical fiber, multi-layer core/clad optical fiber, etc., can solve the problem of unfavorable long-term stable operation of optical fiber, low-loss mandrel process is difficult, not elaborated Attenuation level and other issues to achieve the effect of reducing Rayleigh scattering loss, reducing internal defects, and suppressing fundamental mode leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

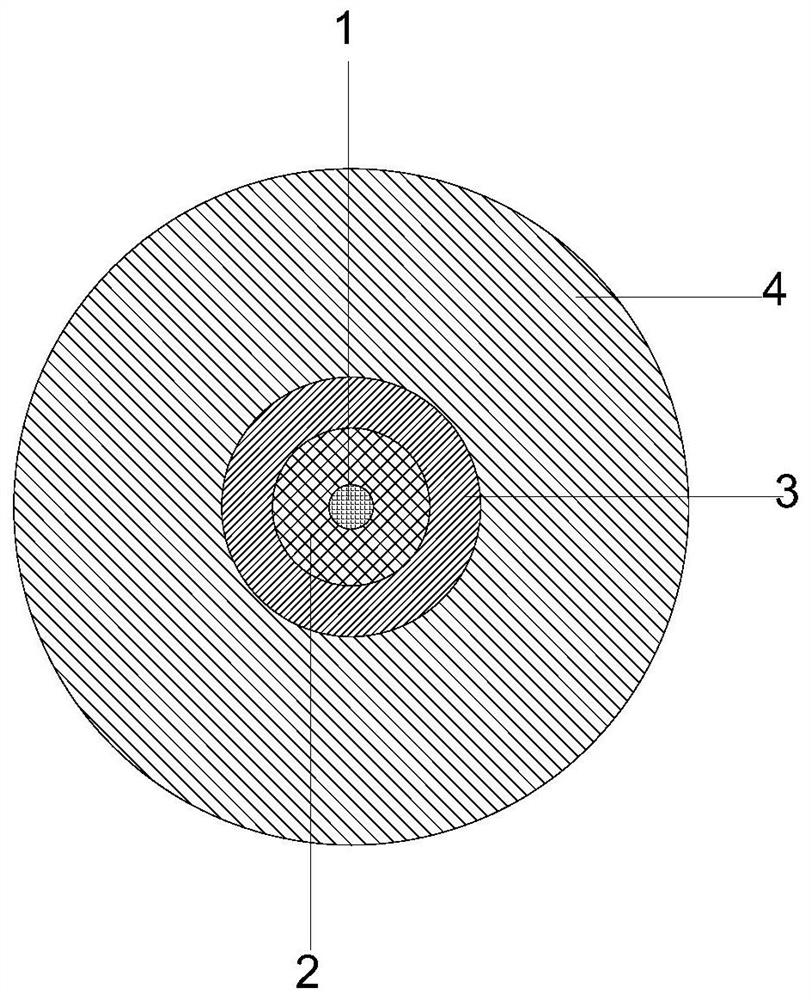

[0024] Such as figure 1 A preferred embodiment of a fully synthetic low-loss single-mode fiber is shown, and its fiber structure includes a core layer 1, a first inner cladding layer 2, a second inner cladding layer 3 and an outer cladding layer 4 from inside to outside;

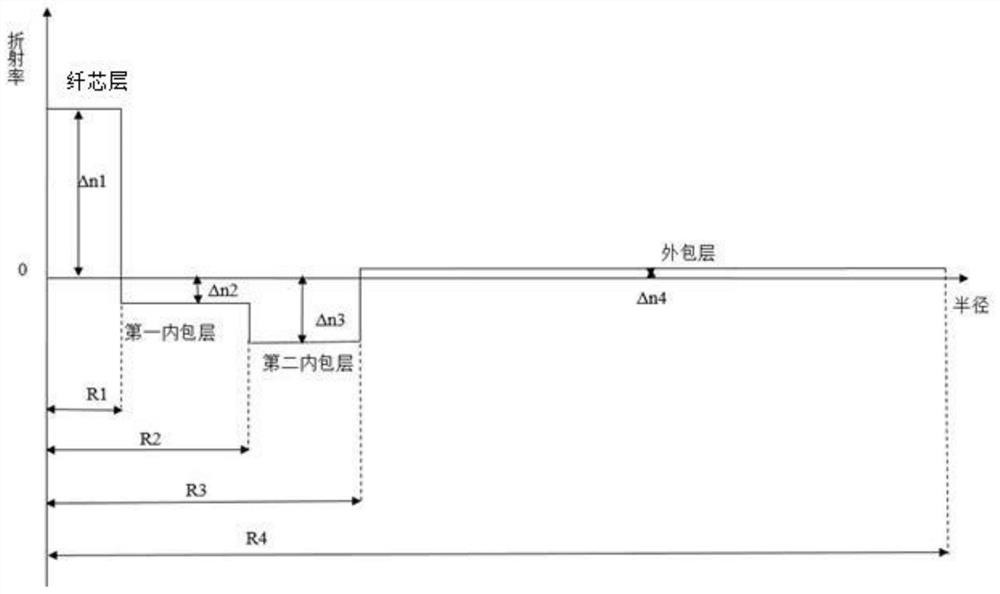

[0025] Such as figure 2 As shown, the core layer 1 is a silica glass layer doped with germanium, which is deposited in one step by vapor phase axial deposition (VAD); the radius R1 of the core layer is 4.3 μm, and the core layer is relatively pure silica glass The refractive index difference Δn1 is 0.310%;

[0026] Such as figure 2 As shown, both the first inner cladding layer 2 and the second inner cladding layer 3 are quartz glass layers doped with fluorine; the radius R2 of the first inner cladding layer is 13.5 μm, and the refractive index difference between the first inner cladding layer and pure quartz glass is Δ n2 is -0.02%; the radius R3 of the second inner cladding is 22.1 μm, and the refracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com