Patents

Literature

440results about How to "Reduce internal defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

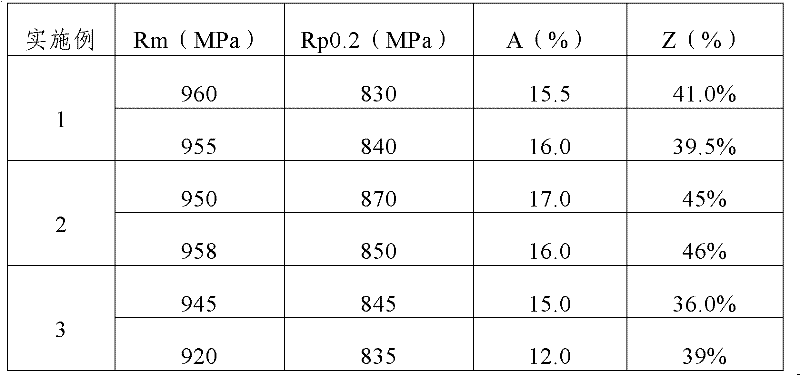

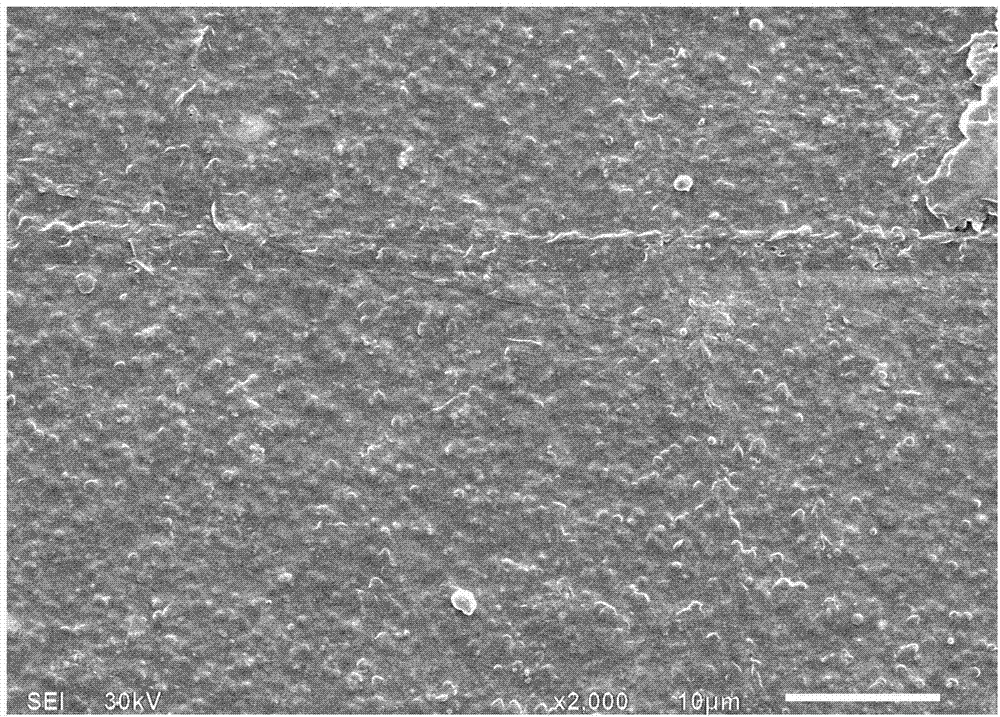

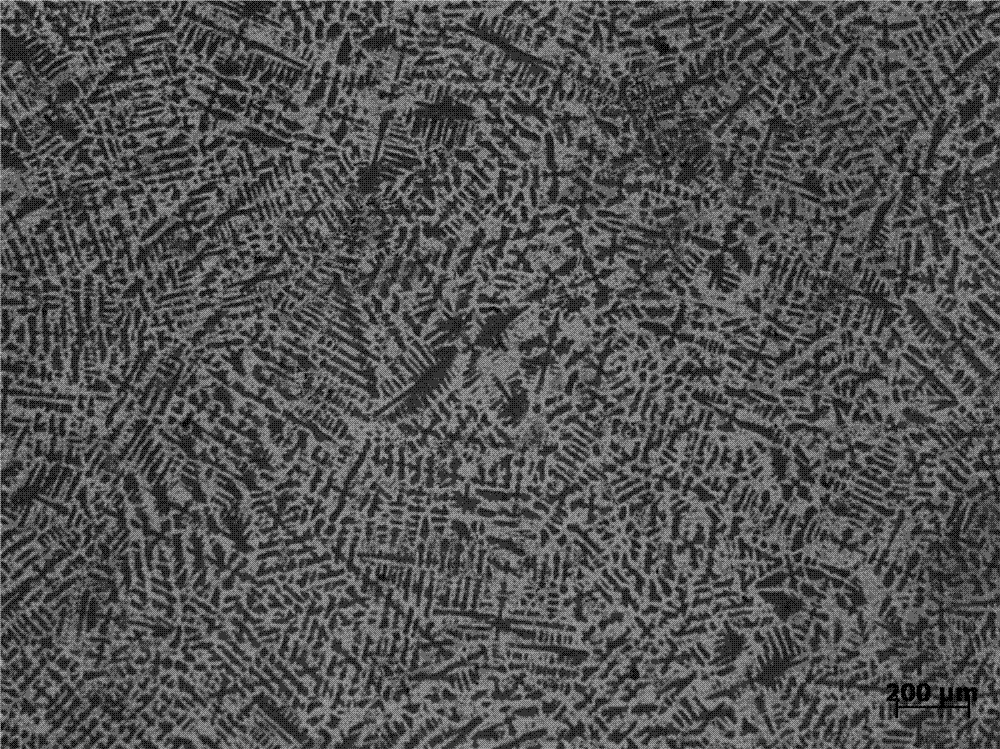

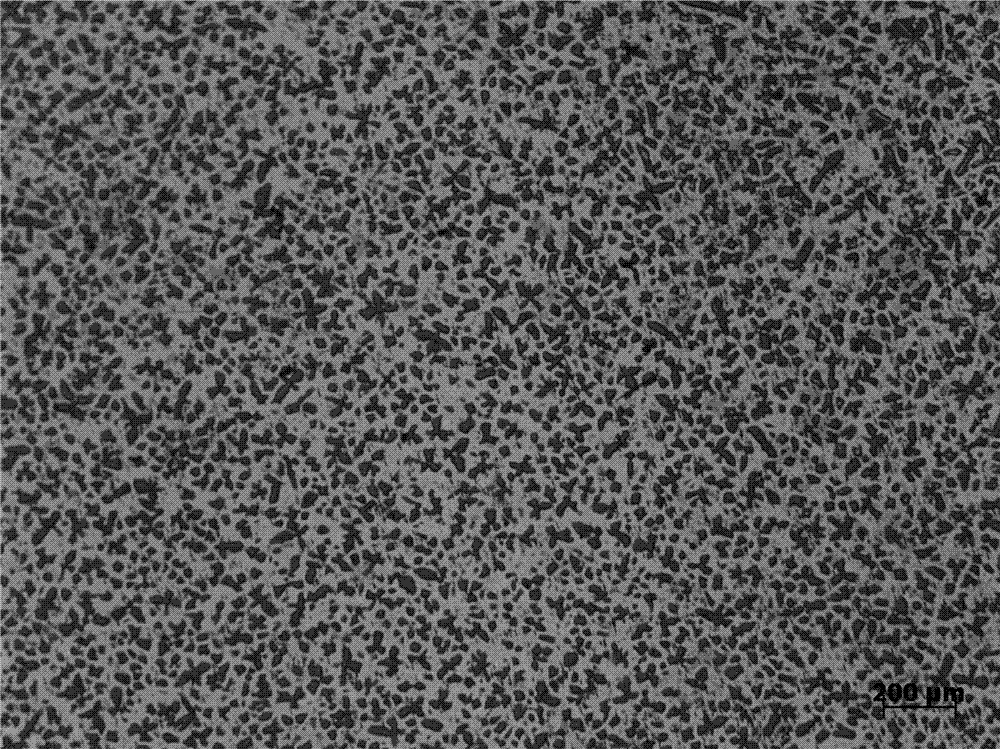

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

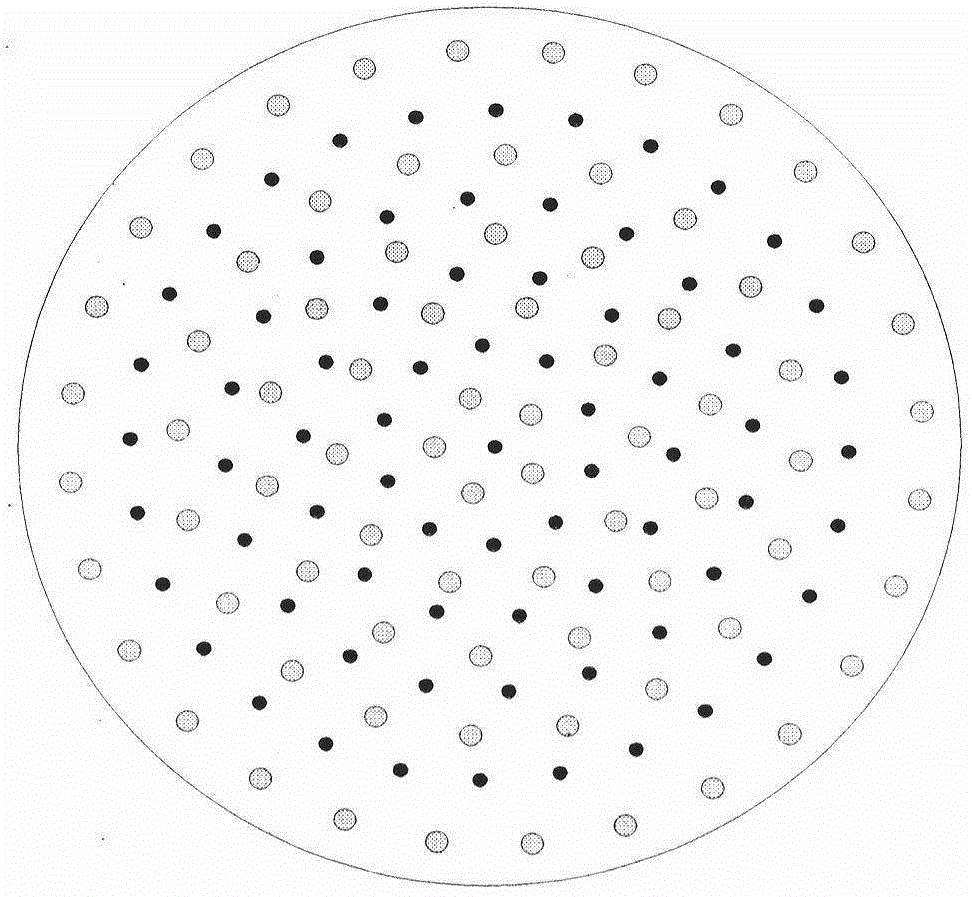

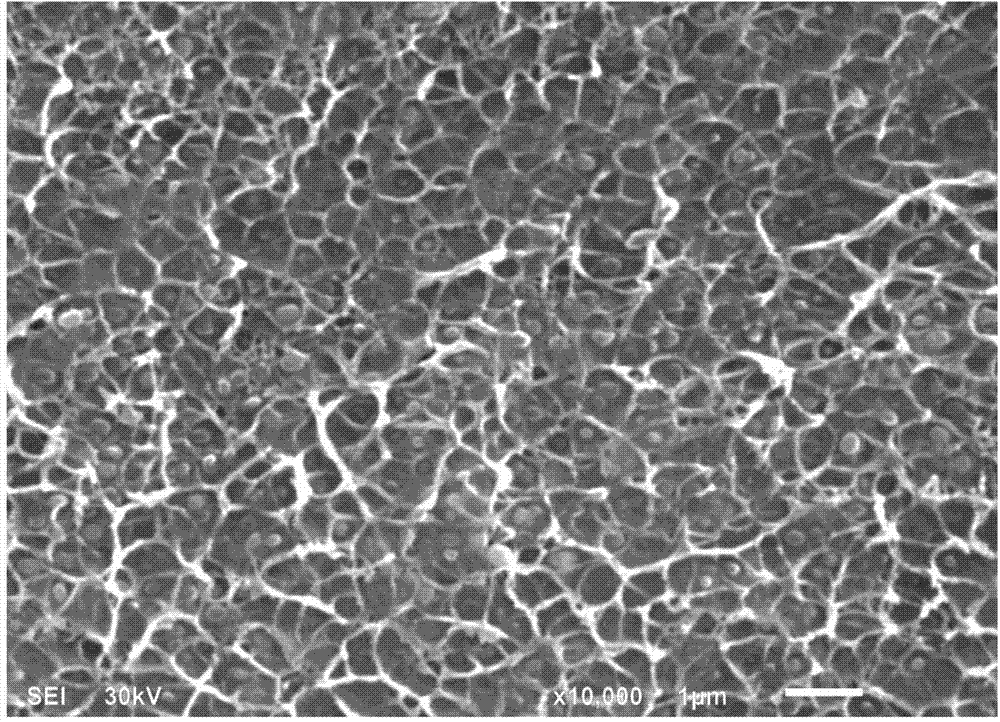

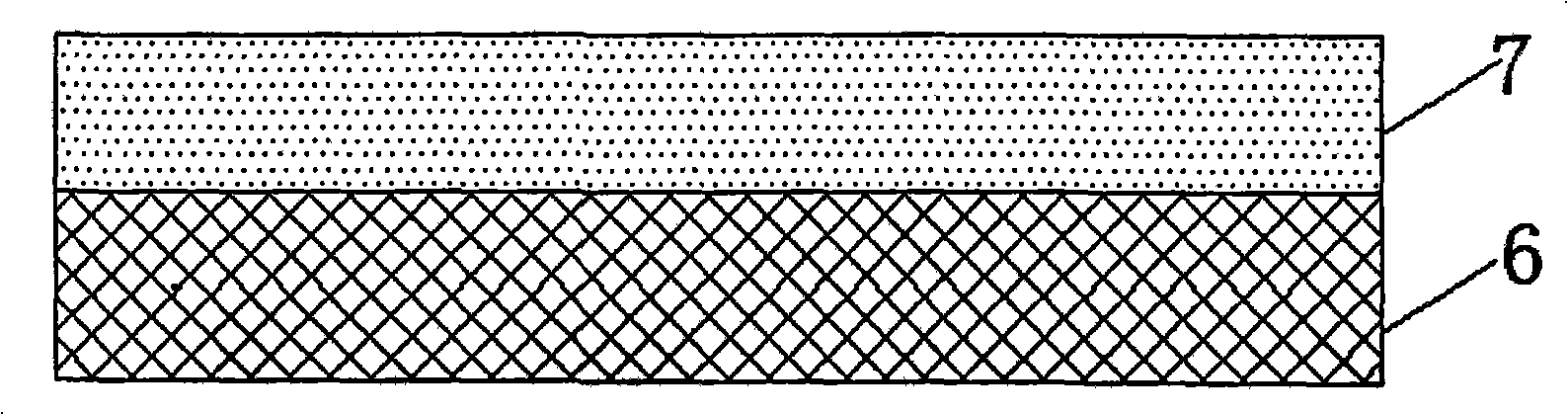

Fiber-reinforced resin-based composite material core and preparation method thereof

InactiveCN104672782AImprove promotion effectPromote the stability of the effectGlass fiberResin-Based Composite

The invention provides a fiber-reinforced resin-based composite material core. The composite material core is prepared from a fiber-reinforced composite material core in the inner part and an insulating layer on the outer layer, wherein the insulating layer is a glass fiber layer and has the thickness of 0.2-2mm. According to the fiber-reinforced resin-based composite material core, the internal structure is uniform, a layering phenomenon difficultly occurs, the strength is high, the toughness is high, and the cost is reduced.

Owner:STATE GRID CORP OF CHINA +3

Polymer-matrix electric conduction gradient function material and preparation method thereof

The invention discloses a polymer-matrix electric conduction gradient function material and a preparation method thereof. The content of electric conduction filler in the prepared polymer-matrix electric conduction gradient function material shows continuous gradient change along the thickness direction of the material from low to high, and the performance also changes correspondingly. The preparation of the material mainly uses rheology principle to realize the gradient of distribution of material components by controlling and influencing thermodynamic factor and dynamic factor in the deposition process.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

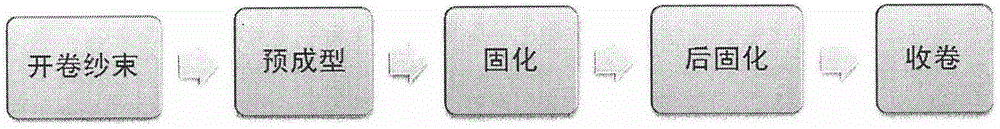

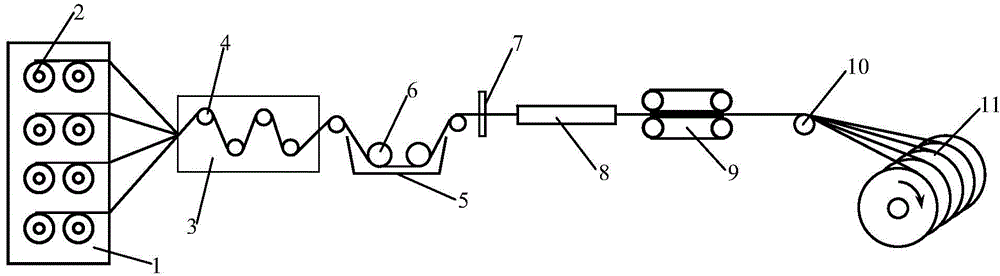

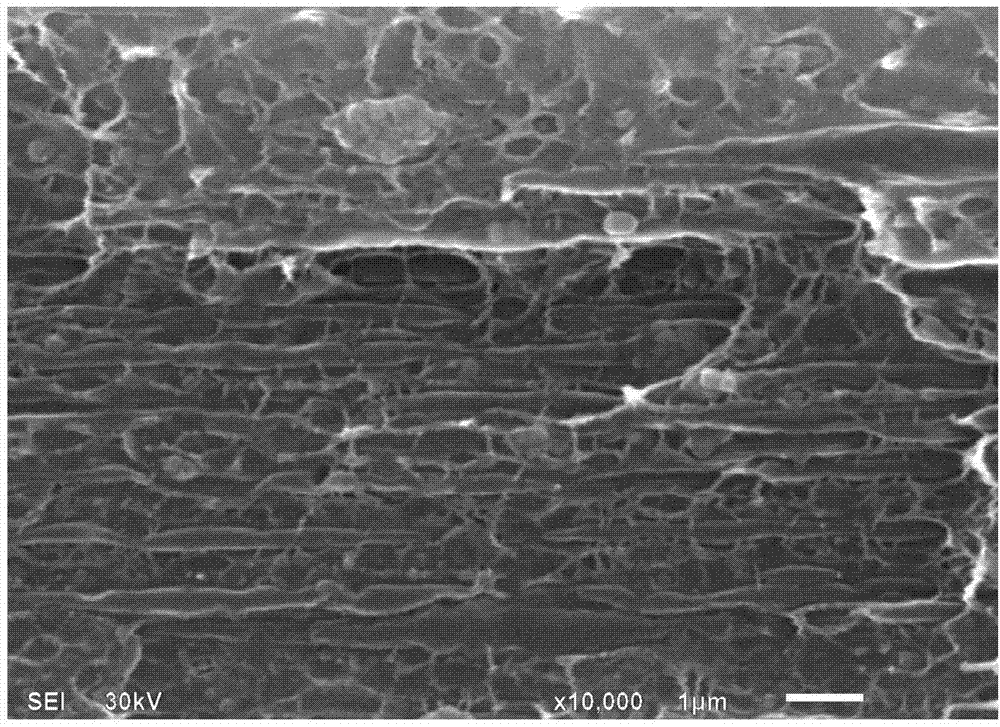

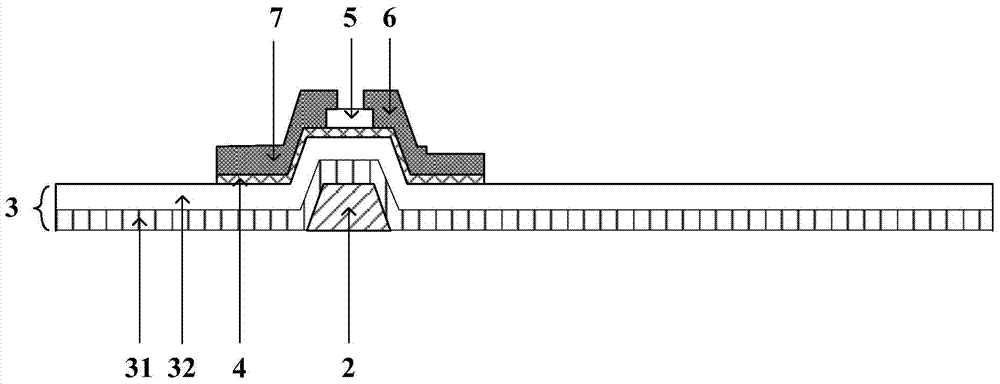

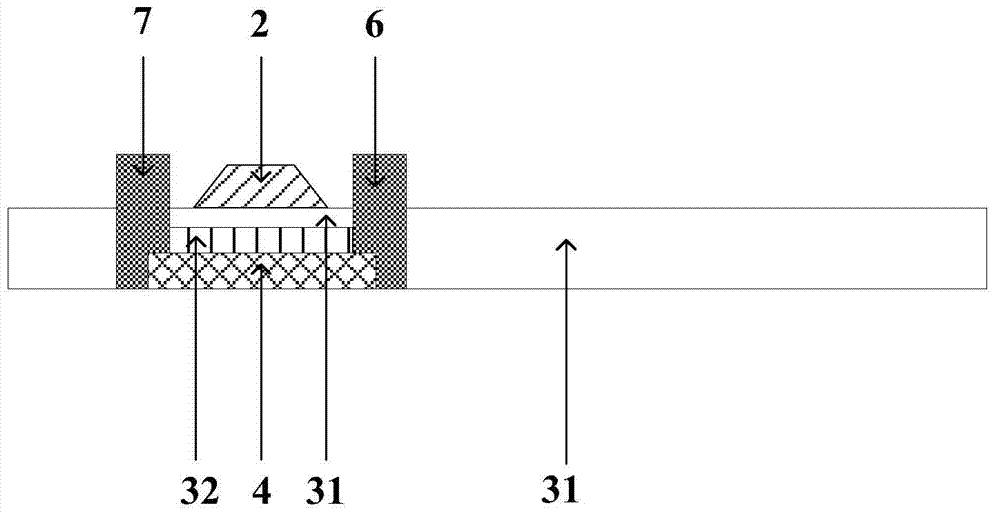

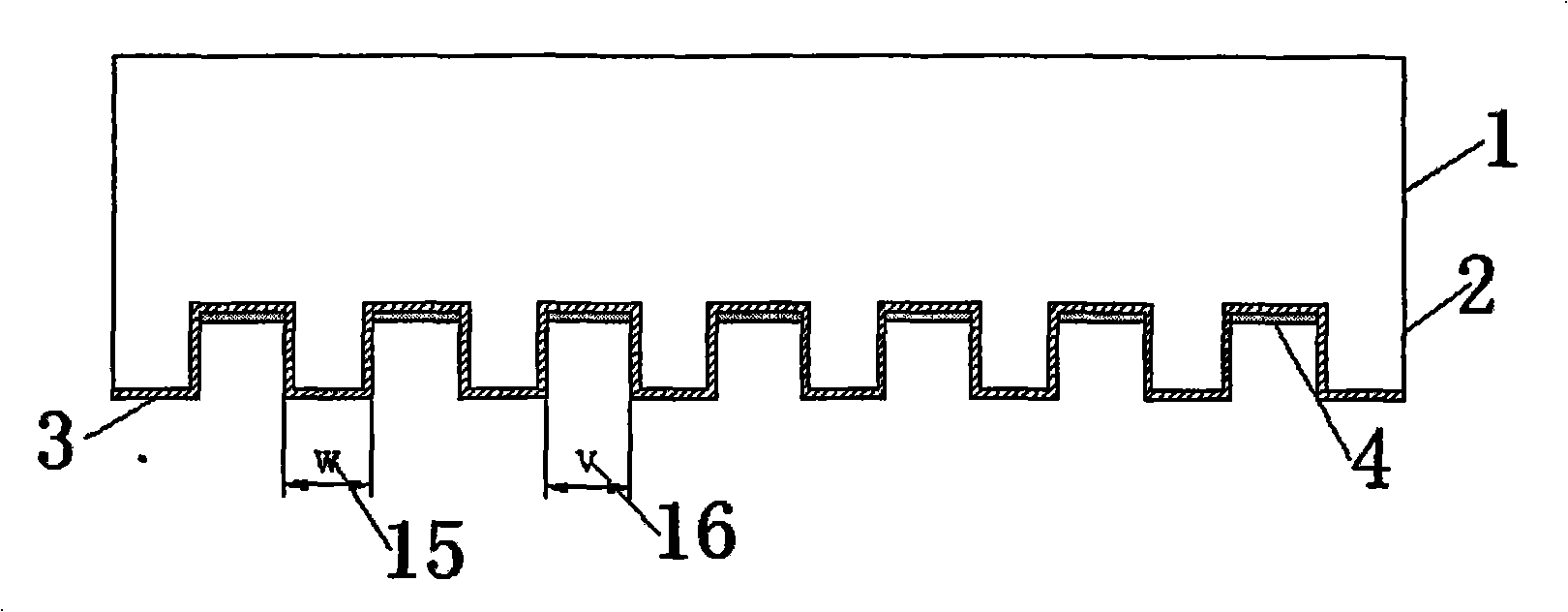

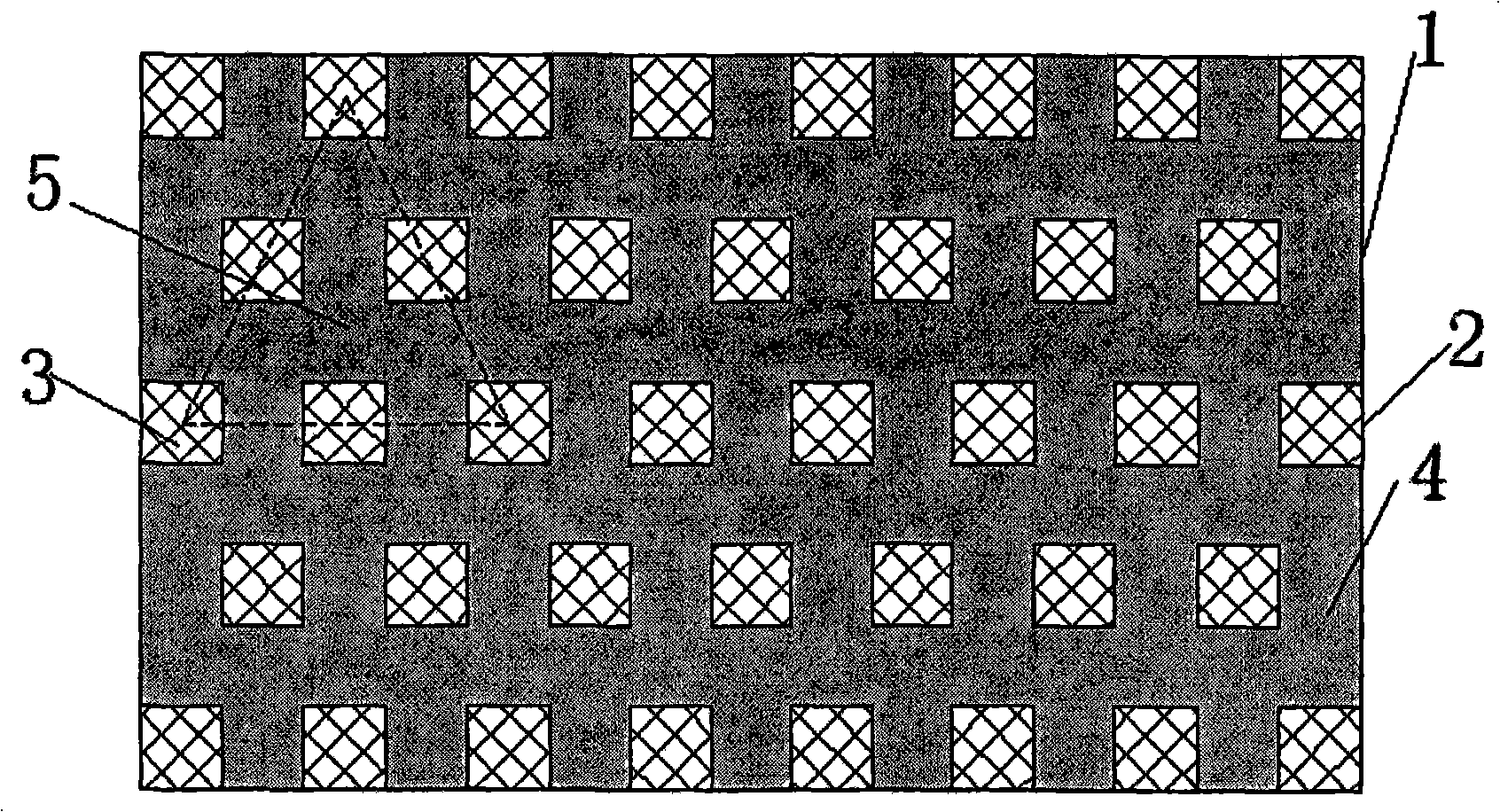

Preparation method and preparation system for ultralight composite traction belt

ActiveCN104552988AReduce internal defectsImprove tensile propertiesRope making machinesBeltsYarnAgricultural engineering

The invention discloses a preparation method and a preparation system for an ultralight composite traction belt, and provides a preparation method and a preparation system for the ultralight composite traction belt with uniform bearing and long service life. The preparation method comprises the following steps: a twist-free continuous monofilament is led out of a fiber yarn group, unfolded uniformly, and introduced into an impregnation tank for impregnation, wherein the impregnation tank is added with a glue solution, then arrangement is performed, and composite enhanced pieces are obtained after pultrusion and curing; the composite enhanced pieces are led out respectively, preheated and introduced into a head die of an extruder, an extruding die core corresponding to the section of the traction belt is arranged in the head die, the composite enhanced pieces are uniformly coated with molten thermoplastic resin in the head die and led out of the head die of the extruder, preliminary forming is realized, and the traction belt is obtained after cooling setting and cooling. The prepared traction belt is light in weight, high in strength, easy to bend, anti-fatigue, long in service life, low in maintenance cost and more applicable to a long-distance elevator.

Owner:TIANJIN GOLDSUN WIRE ROPE

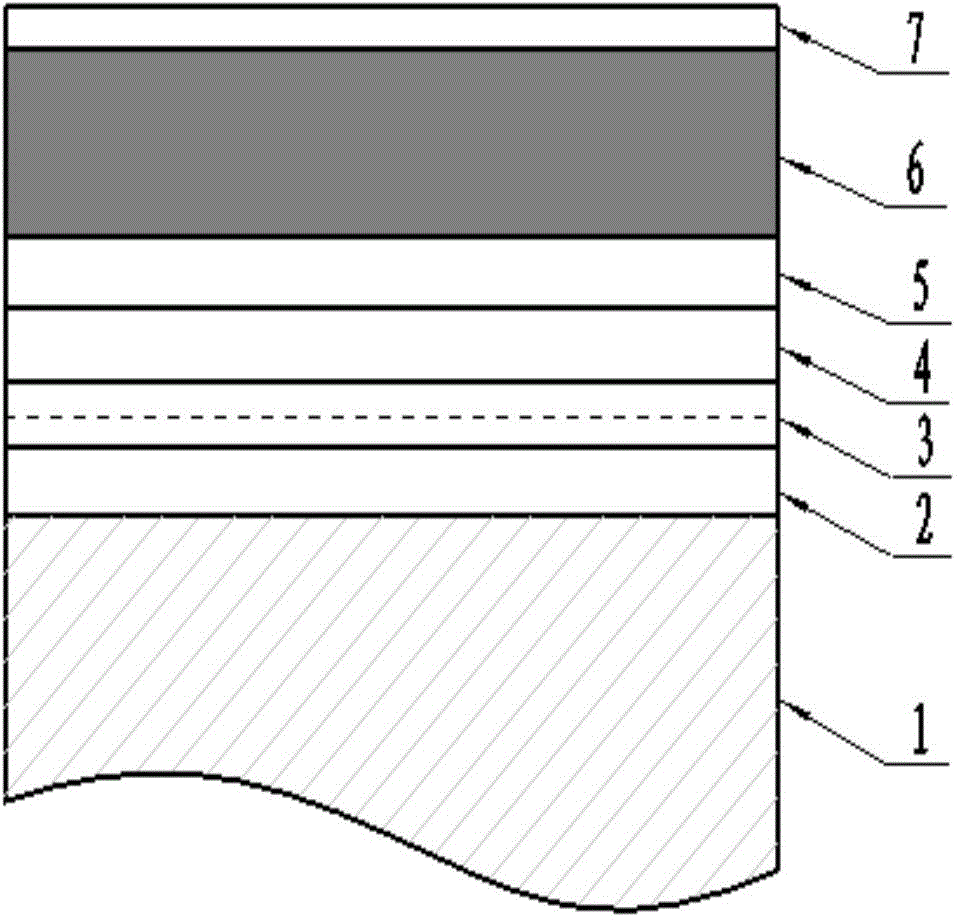

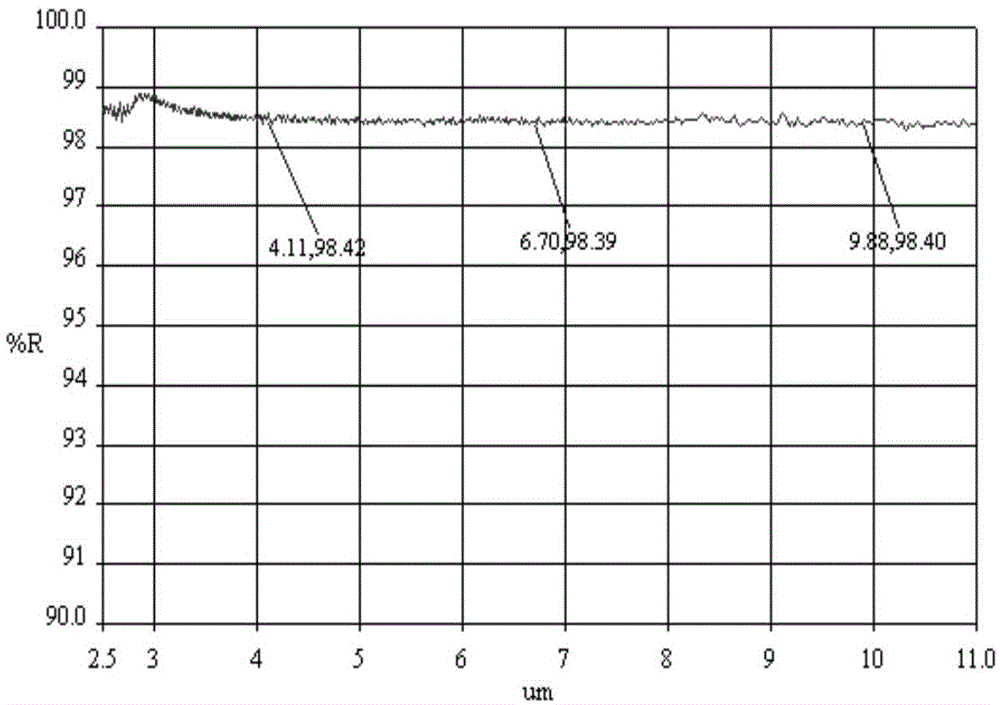

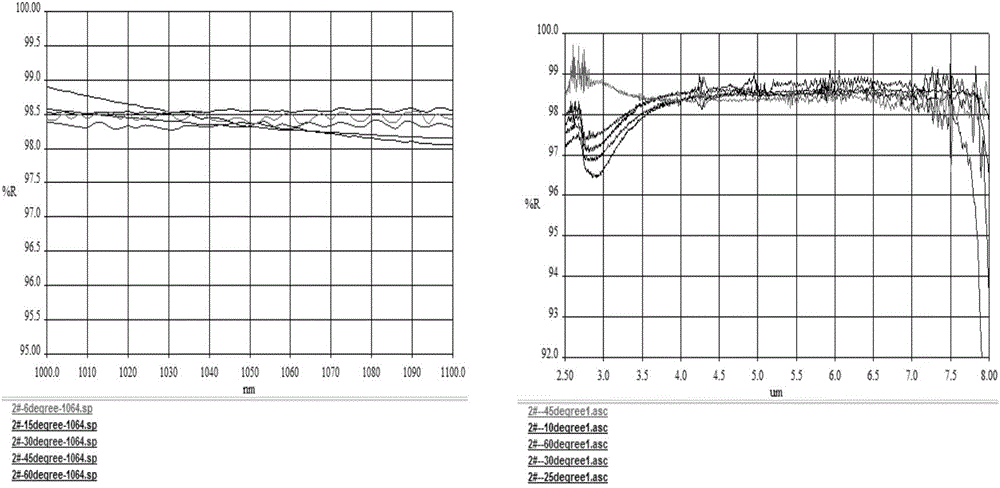

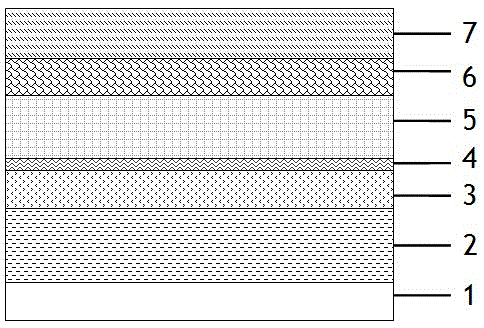

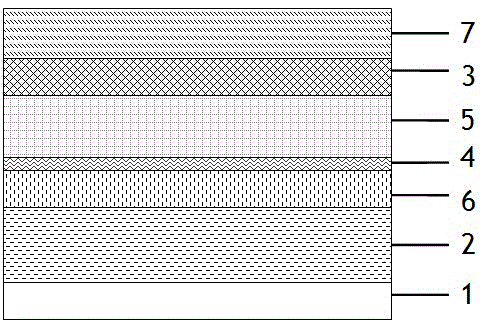

Infrared metal reflecting film with high adhesive force and manufacturing method thereof

ActiveCN104090312AGood physical occlusionImprove adhesionVacuum evaporation coatingSputtering coatingAdhesiveWear resistant

The invention provides an infrared metal reflecting film with high adhesive force and a manufacturing method thereof, wherein the infrared metal reflecting film with high adhesive force is plated on substrates of optical components such as glass, metal and silicon crystals. The infrared metal reflecting film with high adhesive force comprises a substrate, and is characterized in that a first transition layer, a holding-on bonding layer, a metal layer, a stress matching layer, a dielectric enhancement protecting layer and a hard wear-resistant layer are sequentially arranged on the substrate in an evaporation mode. The infrared metal reflecting film has the advantages of being good in film adhesive force, high in reflectivity, resistant to wear and high in environmental suitability, has a high laser damage resistance threshold value level, and can be widely applied to military and civilian photoelectron technical fields such as infrared lasers, refraction-reflection type optical systems and laser / infrared universal photoelectric equipment.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

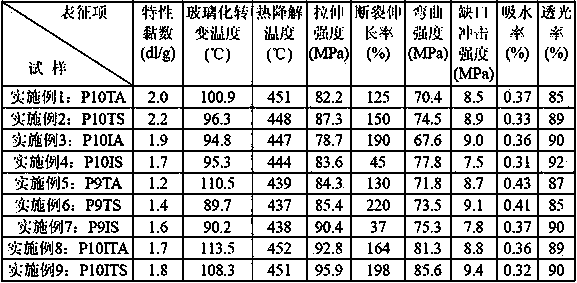

Semi-aromatic transparent polyamide material and preparation method thereof

The invention discloses a semi-aromatic transparent polyamide material and a preparation method thereof, belonging to the field of high-molecular materials. The material consists of a random copolymer of semi-aromatic amide salt and aliphatic amide salt and necessary auxiliaries; the intrinsic viscosity is 1.0-2.2dl / g, and the degree of crystallinity is less than 15%; the semi-aromatic amide salt is selected from amide salt 9T, amide salt 9I, amide salt 10T and amide salt 10I; and the aliphatic amide salt is selected from amide salt 610 and amide salt 1010. The preparation method comprises the following steps: adding the semi-aromatic amide salt, aliphatic amide salt and auxiliaries into a polymerization kettle; adding water which is 0.3-1.0 times the total mass of the semi-aromatic amide salt and aliphatic amide salt; in a protective gas atmosphere, stirring and heating to 160-210 DEG C within 1-2 hours, and performing constant-temperature pre-polymerization for 1-3 hours; heating to 240-300 DEG C, increasing pressure to 1-3MPa, and maintaining the pressure for reaction for 1-3 hours; slowly degassing to normal pressure within 1-4 hours; continuously stirring at constant temperature for 1-4 hours; and discharging after the reaction.

Owner:ZHENGZHOU UNIV

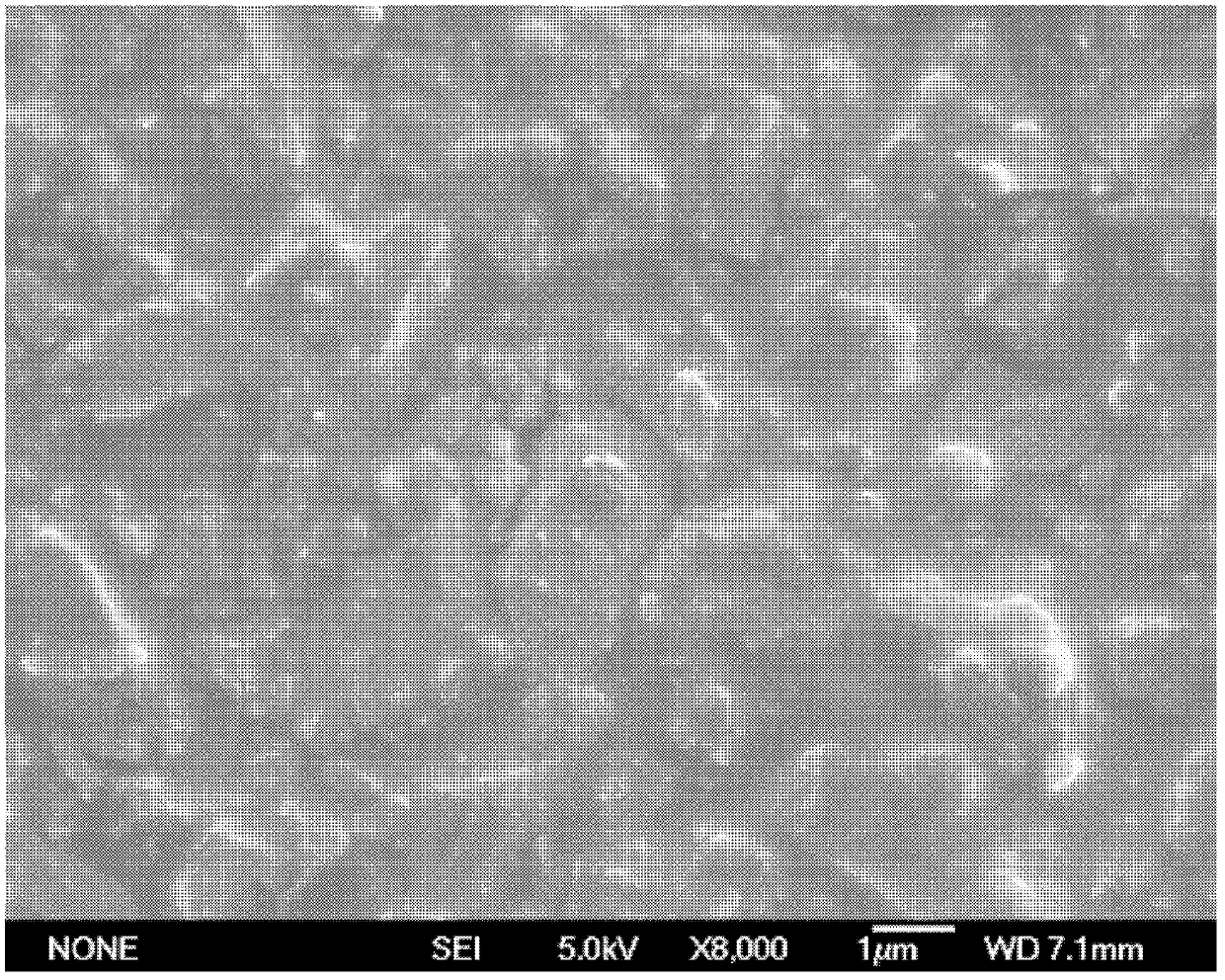

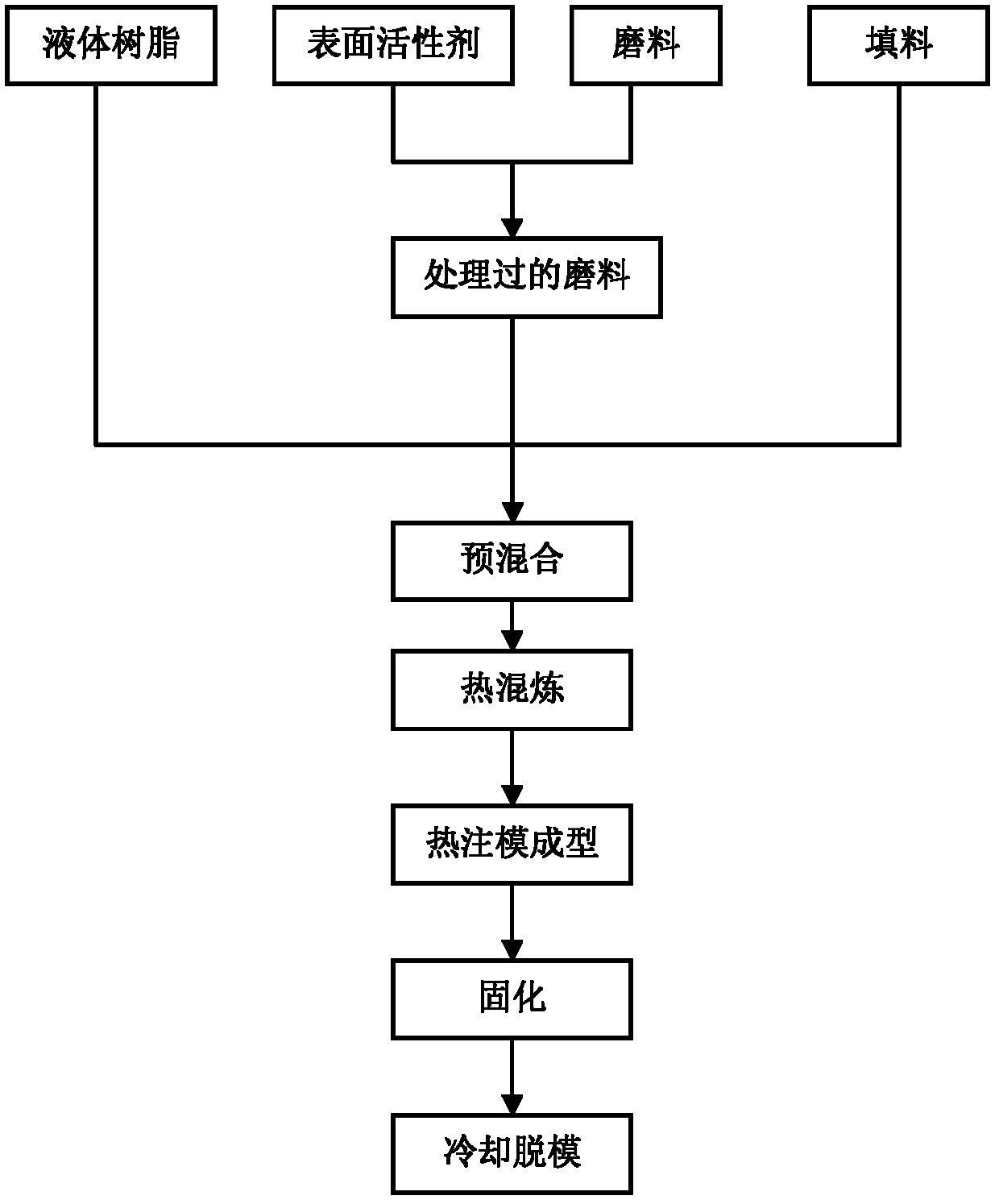

Preparation method of resin binder diamond abrasive product used for accurate grinding

ActiveCN102601745AImprove plasticityUniform tissueAbrasion apparatusGrinding devicesTemperature controlGranularity

The invention discloses a preparation method of a resin binder diamond abrasive product used for accurate grinding. The preparation method comprises the following steps: firstly, surface treatment is carried out on diamond abrasive material by a surfactant, the diamond abrasive material is pre-mixed with liquid resin, filler and the like, then the mixture is added into a material mixing device with accurate temperature control, and thermal mixing is carried out on the mixture at a certain temperature, so that uniform forming material with better plasticity is formed, finally, the forming material is poured into a grinding wheel forming die at a certain temperature and under a certain pressure and then is solidified under a certain condition, so that the resin binder diamond abrasive product is prepared. The resin binder diamond abrasive product prepared in the invention has the advantages that the tissues are uniform, the internal defects are less, the reliability is high, and the like, and therefore, the preparation method is particularly suitable for preparing diamond grinding wheels with fine granularity and super fine granularity in complex shapes.

Owner:HUNAN UNIV

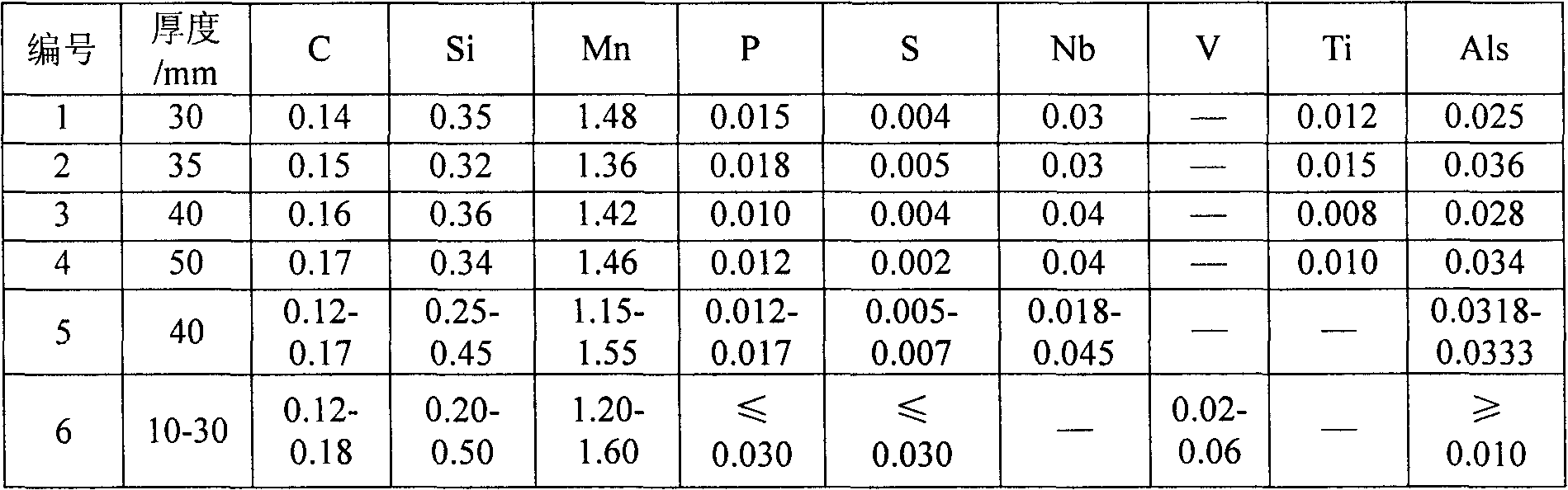

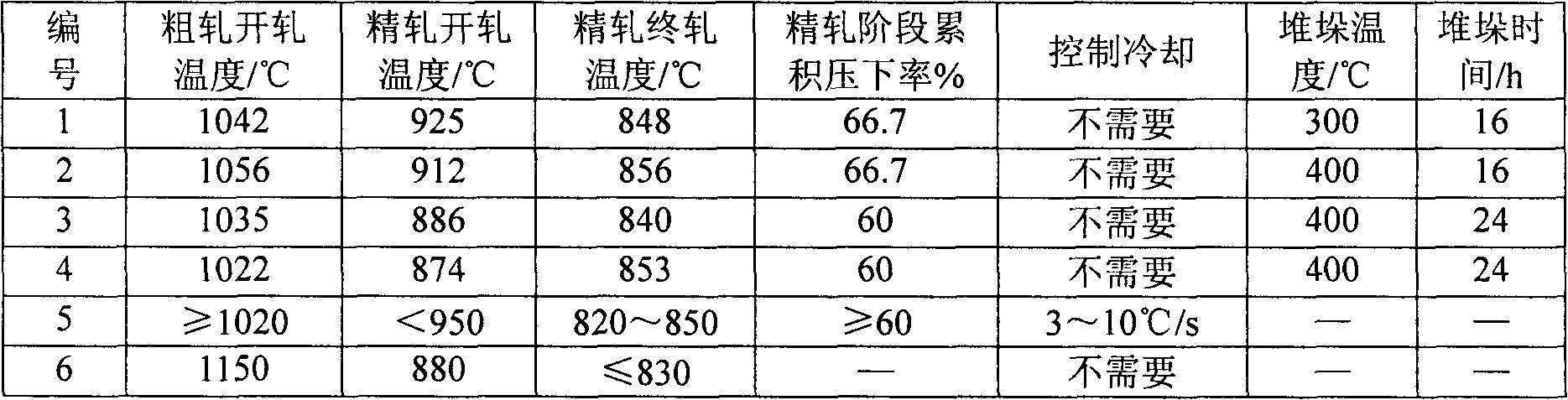

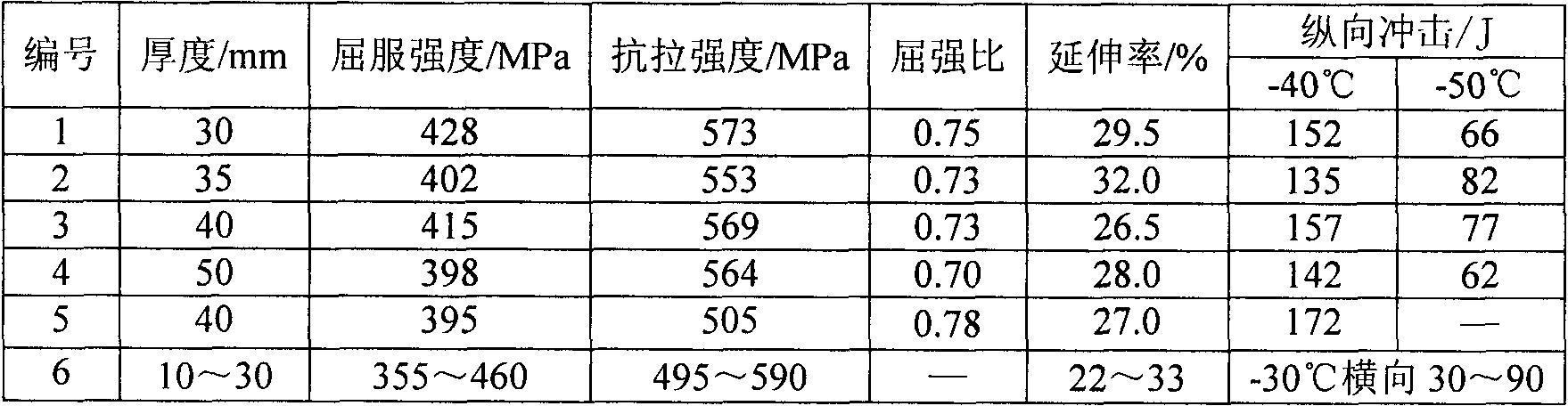

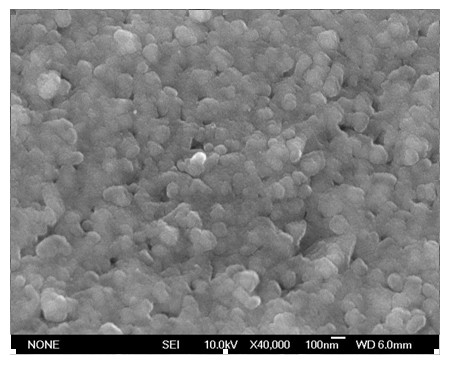

Steel plate for wind power tower in low temperature and manufacturing method thereof

The invention discloses a steel plate for a wind power tower in a low temperature and a manufacturing method thereof. The chemical constituent of the steel plate comprises, by weight, 0.14%-0.17% of C, 0.25%-0.40% of Si, 1.35%-1.50% of Mn, not more than 0.020% of P, not more than 0.005% of S, 0.020%-0.045% of Al, 0.02%-0.04% of Nb, 0.005%-0.015% of Ti, and the balance being iron and ineluctable impurities. The heating temperature of the slab is 1150-1250 DEG C. Time is 0.5-1.1 min / mm. The rough rolling temperature is 970-1060 DEG C. The screwdown ratio of a single pass in each pass is not less than 8%. The screwdown ratio of the single pass in back 4-5 passes is not less than 10%. During finish rolling, the initial rolling temperature is between 870 DEG C and 930 DEG C and the final rolling temperature is between 830 DEG C and 860 DEG C. The screwdown ratio of the single pass in frontal 3 passes is not less than 12%. The cumulative screwdown ratio is not less than 60%. Hot straightening is carried out after finish rolling, stowing and slow cooling is carried out after hot straightening. The temperature is between 300 and 400 DEG. Time is between 16 and 24 h. The yield strength of the steel plate in the invention is not less than] 390 MPa. The tensile strength of the steel plate is not less than 520 MPa. The elongation rate is not less than 25%. The yield ratio is lower than 0.78. The Charpy impact energy at the vertical -40 DEG C V-shaped gap is not less than 120 J. The Charpy impact energy at the vertical -50 DEG C V-shaped gap is not less than 60 J.

Owner:ANGANG STEEL CO LTD

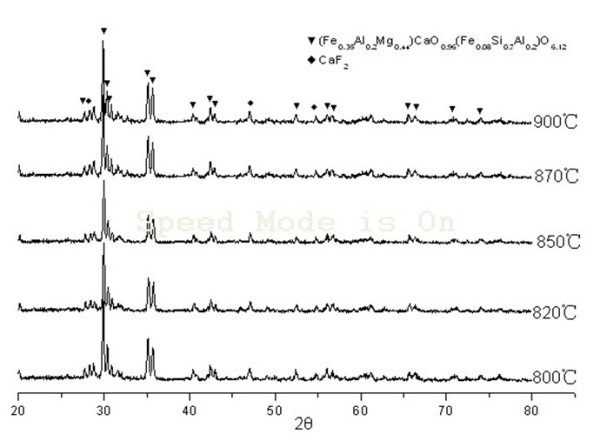

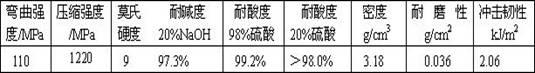

Slag glass ceramic pipe and preparation method thereof

The invention relates to a glass ceramic pipe and a preparation method thereof. The glass ceramic pipe is prepared from the following raw materials in percentage by weight: 20 to 40 percent of coal ash, 20 to 50 percent of slag obtained by separating Baiyunebo tailings again, 0 to 40 percent of blast furnace slag or steel slag, 15 to 30 percent of quartz sand, 2 to 5 percent of sodium carbonate, 2 to 7 percent of borax, 0 to 5 percent of dolomite or lime stone, and 0 to 6 percent of albite or potash feldspar; and the preparation method comprises the following steps of: measuring the raw materials according to the ratio and then adding into a ball-milling mixing machine and mixing uniformly and melting the mixture at the temperature of between 1,350 and 1,450 DEG C; and performing centrifugal casting and molding; annealing, coring and crystallizing the molded pipe, and reducing the temperature at a speed of 1 to 5 DEG / min to the temperature of less than 100 DEG C and then discharging. The product has good performance, the abrasive resistance of the product is three times higher than that of a glass-ceramic tube, the weight of the product is only one third that of a glass-ceramic composite tube, the service life of the product is 3 to 5 times that of the glass-ceramic composite tube, and the cost performance of the product is high. The utilization rate of industrial waste residue in the raw materials is more than and equal to 70 percent, and the pipe is energy-saving and environment-friendly, has low production cost, is suitable for large-scale industrial production and has a wide application range.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

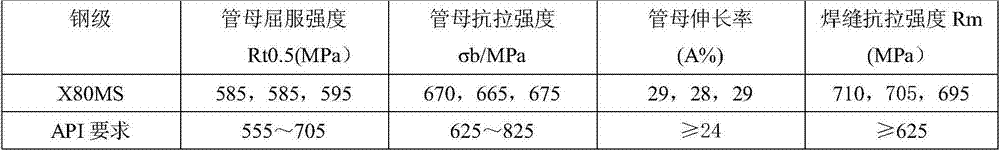

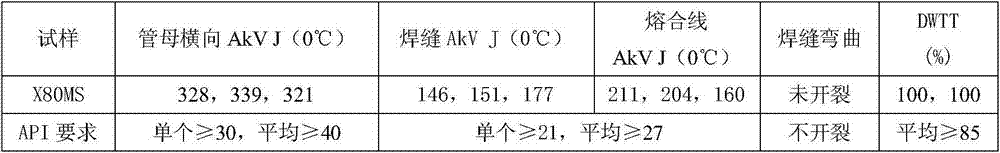

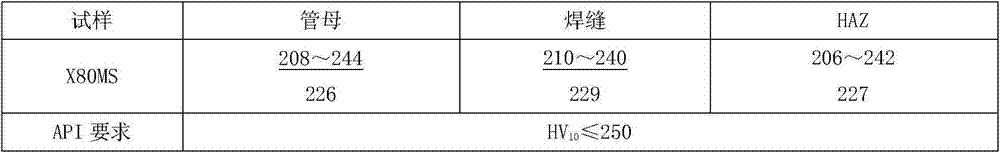

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

The invention discloses an X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as a manufacturing method thereof. The straight seam submerged-arc welded pipe comprises a welding seam and a welded pipe body, and is characterized in that the welded pipe body consists of the following elements in percent by mass: not greater than 0.04% of C, 0.20%-0.40% of Si, 1.20%-1.80% of Mn, not greater than 0.008% of P, not greater than 0.002% of S, 0.10%-0.30% of Ni, not greater than 0.15% of Cr, not greater than 0.15% of Cu, 0.01%-0.10% of Nb, 0.01%-0.10% of Ti, 0.10%-0.30% of Mo, 0.04%-0.10% of Al, not greater than 0.0005% of B, not greater than 0.002% of Ca, and the balance of Fe and inevitable impurities. According to the X80-level straight seam submerged-arc welded pipe and the manufacturing method thereof disclosed by the invention, the X80 straight seam submerged-arc welded pipe disclosed by the invention has good strength, toughness, welding performance, ductility and corrosion resistance through reasonably deploying and controlling material components, a manufacturing process, a manufacturing technology and subsequent processing. Besides, high-pressure large-flow conveying requirements of oil gas under an acidic environment are satisfied.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

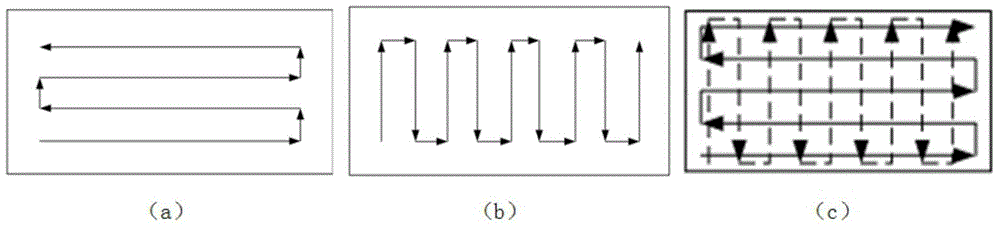

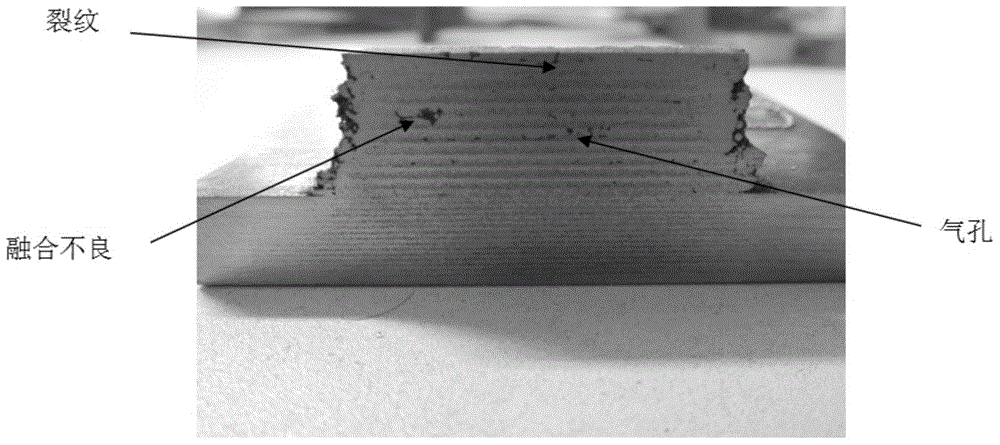

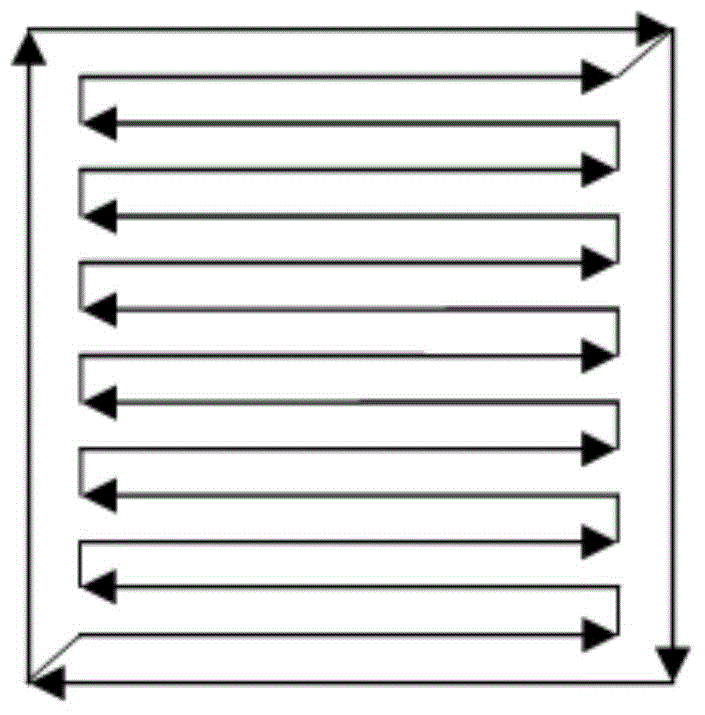

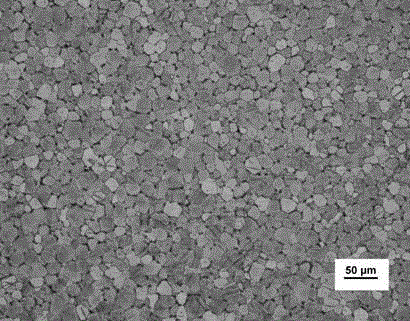

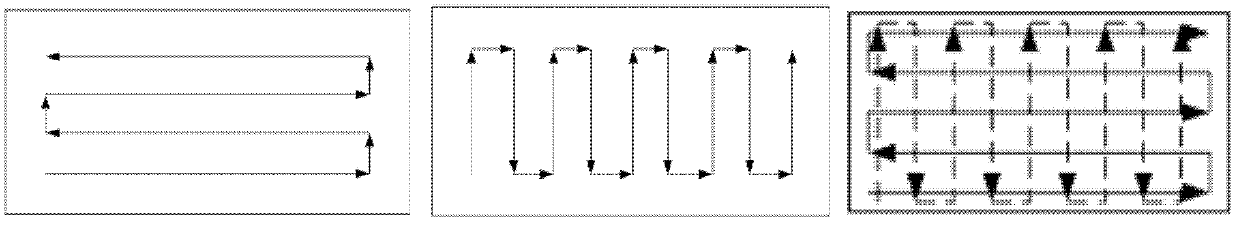

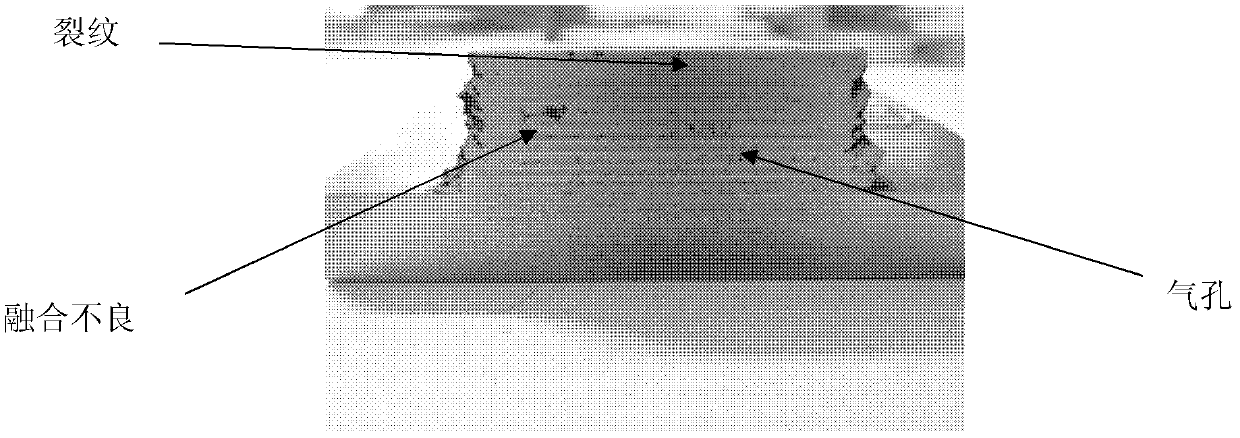

Laser additive manufacturing technology of high-temperature alloy parts

InactiveCN104785778AImplement defect controlControl internal defectsIncreasing energy efficiencyManufacturing technologyLaser scanning

The invention discloses a laser additive manufacturing technology of high-temperature alloy parts, and belongs to the technical field of laser additive manufacturing of metal powder. According to the invention, the technological parameter ranges of different high-temperature alloy materials are determined through basic technological experiments, and then additive manufacturing is carried out by adopting specific laser scanning paths and related internal defect control methods in the manufacturing process. The parts manufactured through the technology have the advantages that the forming efficiency is high, the cost is low, the internal quality is high, the automation degree is high and operation is easy. The high-temperature alloy parts capable of being applied industrially can be directly manufactured by adopting the technology, so that a new approach for manufacturing the high-temperature alloy parts is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Preparation method of polyvinylidene fluoride-based thin film

The invention relates to a preparation method of a polyvinylidene fluoride (PVDF)-based thin film. According to the thin film forming process, through an extrusion casting and drawing method, PVDF, polymethyl methacrylate (PMMA), a rubber elastomer, titanium dioxide as well as other auxiliaries and fillers are mixed according to a certain ratio and are melted and extruded at certain temperature, and then the PVDF-based thin film is formed under guiding and stretching effects of casting traction equipment. The PVDF-based thin film prepared by the invention is uniform and easily controllable in thickness, good in barrier property as well as excellent in mechanical property and environmental aging resistance, and is easy to realize industrialization; the PVDF-based thin film, through modification treatment, is significantly improved in surface caking property and guarantees good adhesion with a solar cell packaging material; the thin film brings high convenience for assembly of a solar cell backboard film and is compact in structure; and the thin film has good application prospect in solar cell industry.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

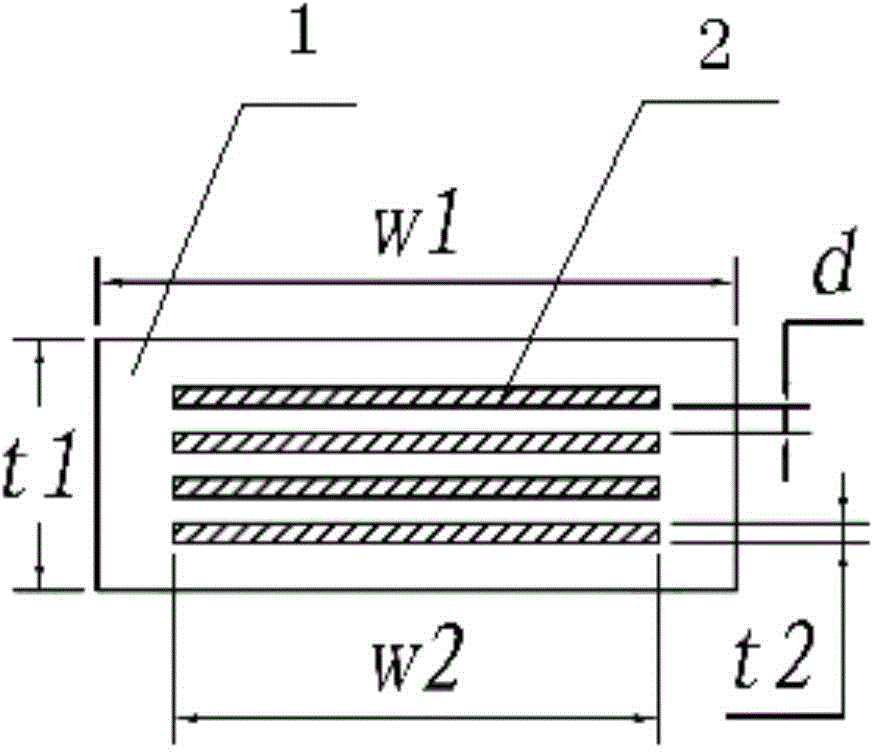

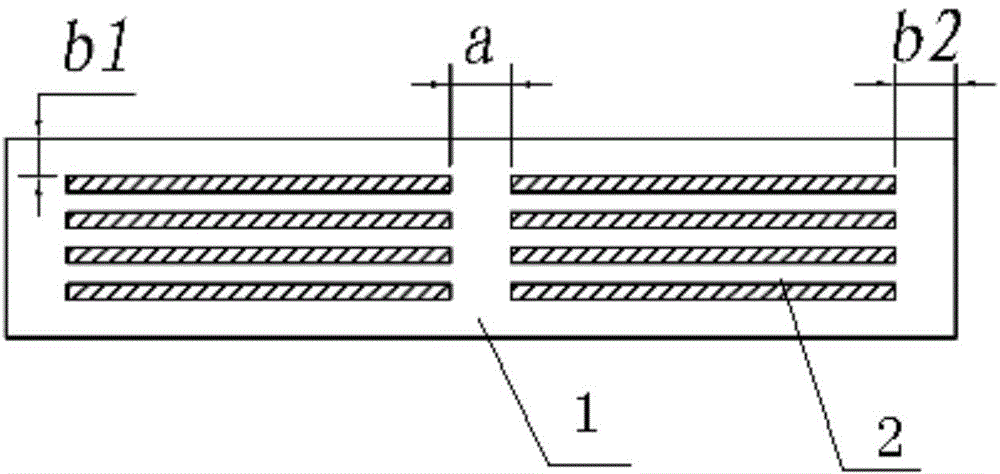

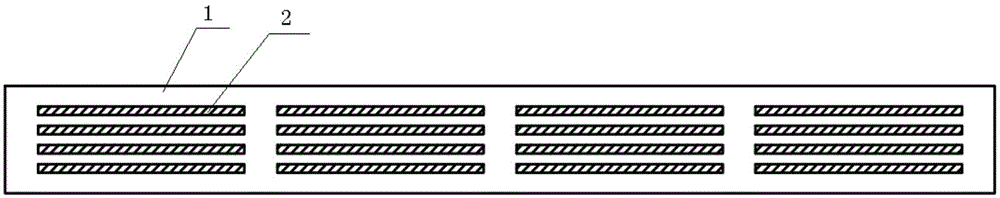

Dragging belt of composite materials

InactiveCN104528498AReduce the bending radius of curvatureEasy to bendRope making machinesElevatorsFiberThermoplastic polyurethane

The invention discloses a dragging belt of composite materials. The dragging belt is light in weight and good bending performance. The dragging belt comprises a plurality of inner bearing body layers and abrasion-resisting elastic bodies wrapped outside the inner bearing body layers. The inner bearing bodies are in a sheet shape which is continuous in the single length direction of the dragging belt. Each inner bearing body comprises a base body. A plurality of nonmetal non-twist continuous fiber monofilaments are arranged in the base bodies, the nonmetal non-twist continuous fiber monofilaments are not in contact, the base bodies of inner bearing body layers are made of thermosetting resin materials or thermoplastic resin materials, the abrasion-resisting elastic bodies are thermoplastic polyurethane or rubber elastic bodies. At least two inner bearing body layers are arranged in the thickness direction of the dragging belt. The thickness of the inner bearing body layers of the sheet-shaped structure of the dragging belt is small, under the premise that good bearing is achieved, bending curvature radius is greatly lowered, the obtained dragging belt is light in weight, high in intensity and easy to bend, abrasion resistance and whether resistance are achieved, anti-fatigue performance is achieved, service life is long, maintaining cost is low, and the dragging belt can be used for lifting of long-distance heavy objects.

Owner:TIANJIN GOLDSUN WIRE ROPE

High-efficiency low-cost solar cell diffusion technology

InactiveCN103681976AReduce internal defectsImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingNitrogenEngineering

The invention provides a high-efficiency low-cost solar cell diffusion technology, which is a multi-step variable temperature diffusion and annealing technology under the protection of small-flow nitrogen, and is characterized by adopting the following eight steps of diffusion processes under the protection of small-flow nitrogen: step 1, ultralow temperature boat entering process; step 2, constant temperature field process; step 3,variable temperature oxidation process; step 4, fixed temperature diffusion process; step 5, variable temperature diffusion process; step 6, knot pushing diffusion process; step 7, variable temperature annealing process; step 8, ultralow temperature boat exiting process. Compared with traditional constant temperature diffusion technology, the high-efficiency low-cost solar cell diffusion technology provided by the invention shortens diffusion technology time, reduces technology gas cost, improves uniformity and repeatability of diffusion sheet resistor.

Owner:百力达太阳能股份有限公司

Degradable magnesium alloy plate and bar for fracture internal fixation and preparation methods thereof

InactiveCN104630587AReduce the chance of infectionGood biocompatibilitySurgeryFernicoPhysical chemistry

The invention relates to a degradable magnesium alloy plate and a bar for fracture internal fixation. The degradable magnesium alloy plate and bar are prepared by adding one or two of Sr, Ca and Ag based on a Mg-Zn-Zr alloy, wherein the degradable magnesium alloy plate comprises the following components in percentage by mass: 3.0wt% of Zn, 0.5wt% of Zr, 0.0-1.0 wt% of Ca, 0.0-1.0wt% of Ag, 0.0-1.5wt% of Sr, and the balance of Mg, wherein the content of each of iron, nickel, copper, aluminum single impurity element is less than 0.05% and the total amount of the impurities is not more than0.4%. The degradable magnesium alloy plate and the bar have the advantages of high purity, good uniformity composition and microstructure and higher strength and corrosion resistance; the contained elements such as calcium and strontium can promote bone growth so that the alloy has better biocompatibility; the silver element is added so as to improve antibacterial property of an implant; and the degradable magnesium alloy plate and the bar is suitable for being applied in fracture fixation materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

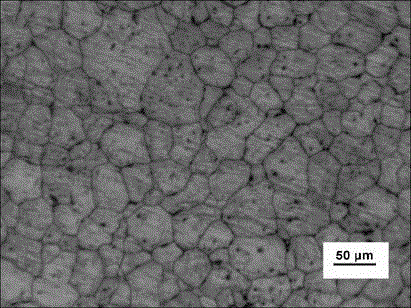

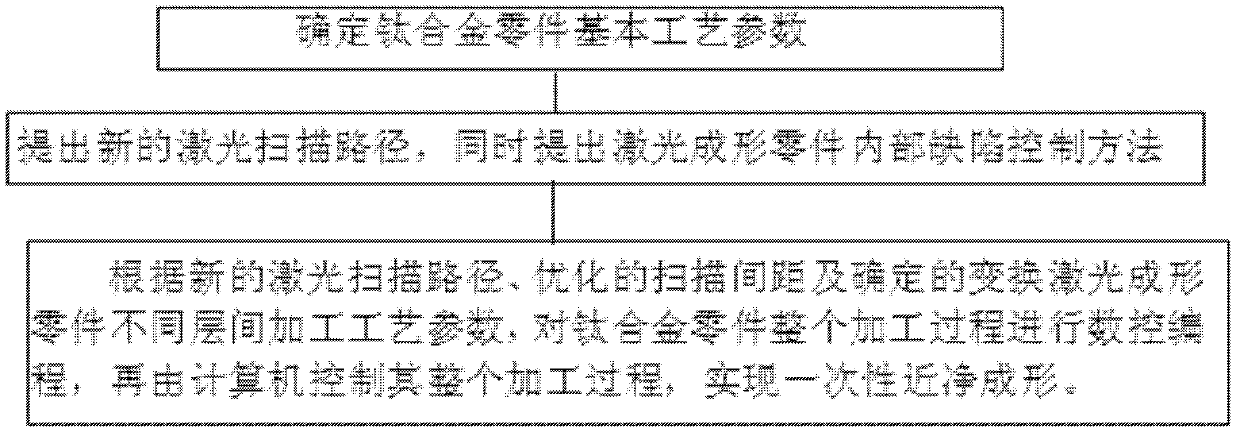

Laser direct forming process for titanium alloy part

ActiveCN103302292AImprove forming efficiencyLow costIncreasing energy efficiencyLaser scanningMetal powder

The invention discloses a laser direct forming process for a titanium alloy part, and relates to a laser rapid forming technology for metal powder. The process mainly comprises the following steps of determining basic process parameters of the titanium alloy part, and disclosing a new laser scanning path and a method for controlling an internal defect of a laser formed part, i.e. firstly determining a process parameter range of spherical TA15 powder by a basic process experiment, and transforming processing process parameters of different layers of the laser formed part to form the titanium alloy part by adopting the laser scanning path and the related internal defect control method, namely by adopting an optimal scanning interval. The part formed by the process has the advantages of high forming efficiency, low cost, high internal quality, high automation degree, easiness in operation and the like. The process can be used for directly forming the titanium alloy part at an industrial application level, and a novel way for the production of a titanium alloy structural part is provided.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

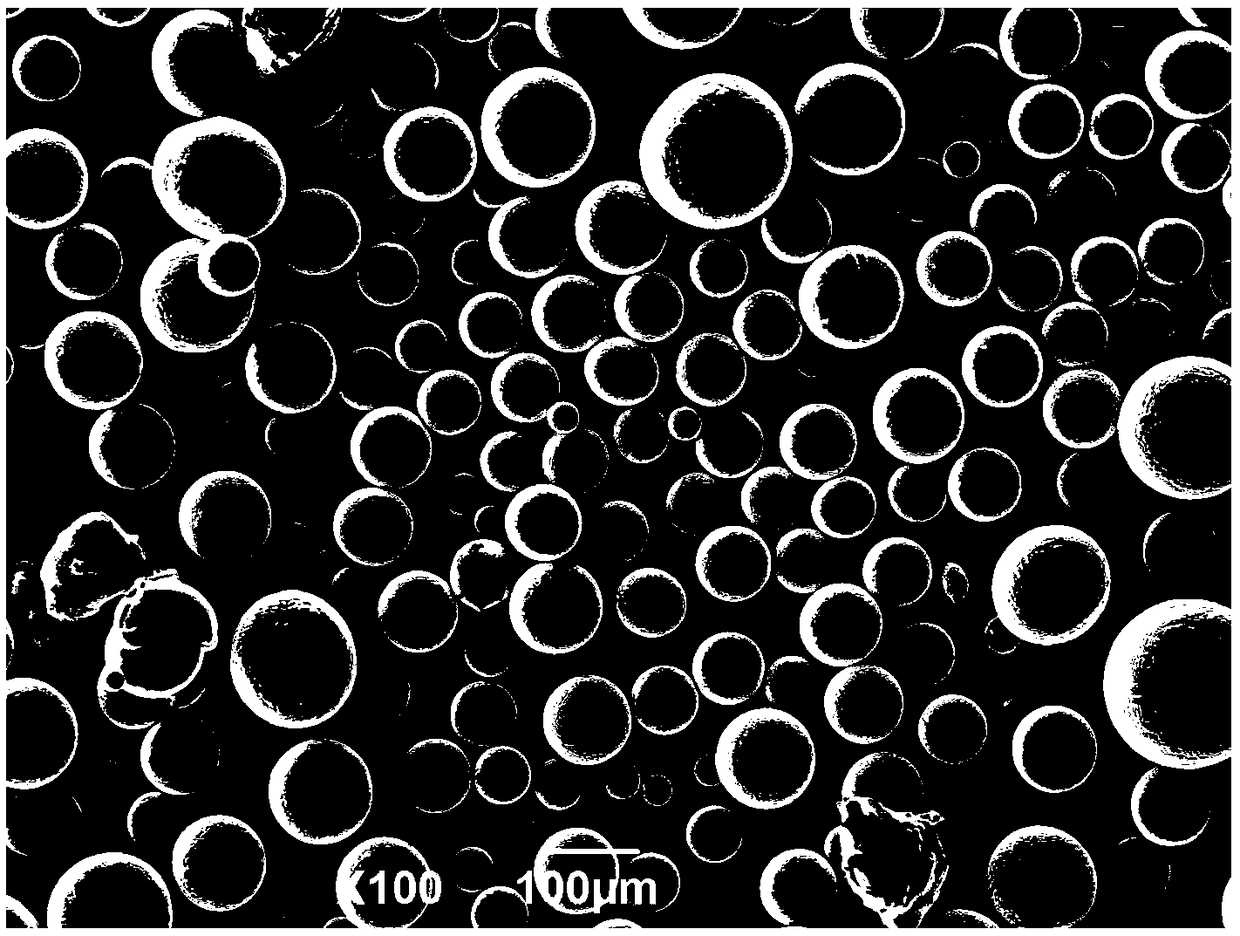

Preparation method of copper alloy powder for manufacturing of additional materials

ActiveCN109112346AUniform compositionReduce internal defectsAdditive manufacturing apparatusTransportation and packagingCentrifugal forceOxygen

The invention discloses a preparation method of a copper alloy powder for manufacturing of additional materials. The preparation method specifically comprises the following steps of firstly, accordingto components of copper alloy, smelting the materials, casting, annealing, forging, machining, and finely turning, so as to obtain a copper alloy electrode rod; loading the copper alloy electrode rodinto a reaction chamber, heating an end part of the copper alloy electrode rod by plasma, uniformly melting the end part of the copper alloy electrode rod, enabling atomized liquid droplets to be thrown out from the end part of the copper alloy electrode rod under the function of centrifugal force and form fine liquid droplets, quickly cooling the fine liquid droplets into spherical particles under an inert gas protection atmosphere, and enabling the spherical particles to fall into a collector at the bottom part of the reaction chamber; finally, screening obtained copper alloy powder under the inert gas protection environment, and packaging. The preparation method can be used for preparing the copper alloy powder with high degree of sphericity, high degree of purity, excellent fluidity,low content of oxygen, and uniform components.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Thin film transistor, preparation method of thin film transistor, array substrate and display device

ActiveCN103489920AImprove featuresImprove compactnessTransistorSolid-state devicesDisplay deviceSilicon oxide

The invention discloses a thin film transistor. The thin film transistor comprises a grid electrode, a semiconductor layer and an insulating layer. The thin film transistor is characterized in that the insulating layer comprises a first insulating layer body composed of a first silicon oxide thin film and a second silicon oxide thin film, the second silicon oxide thin film directly makes contact with the semiconductor layer, and the compactness of the second silicon oxide thin film is larger than that of the first silicon oxide thin film. A good interface is formed between the second silicon oxide thin film and the semiconductor layer, defect states are reduced, and the features of the thin film transistor are improved. The embodiment of the invention further provides a preparation method of the thin film transistor, an array substrate and a display device.

Owner:BOE TECH GRP CO LTD

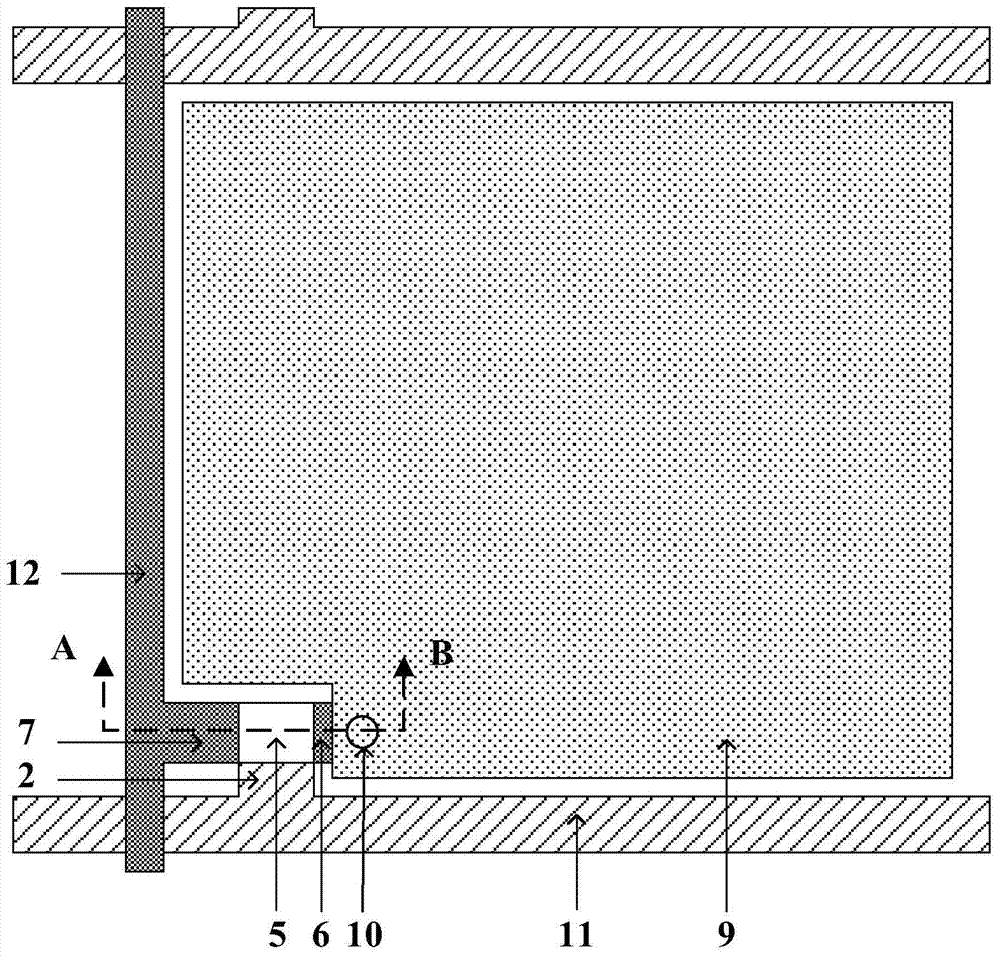

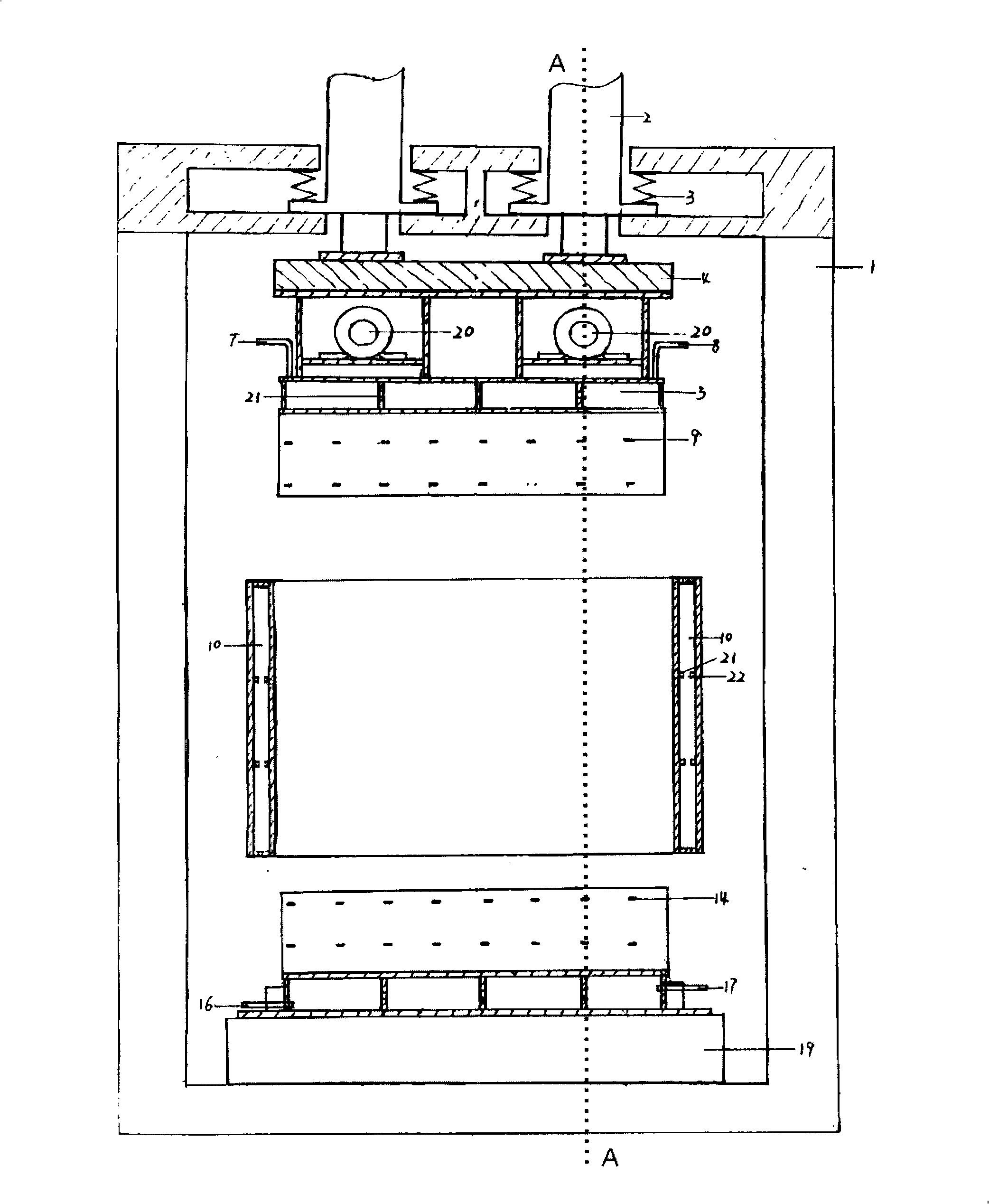

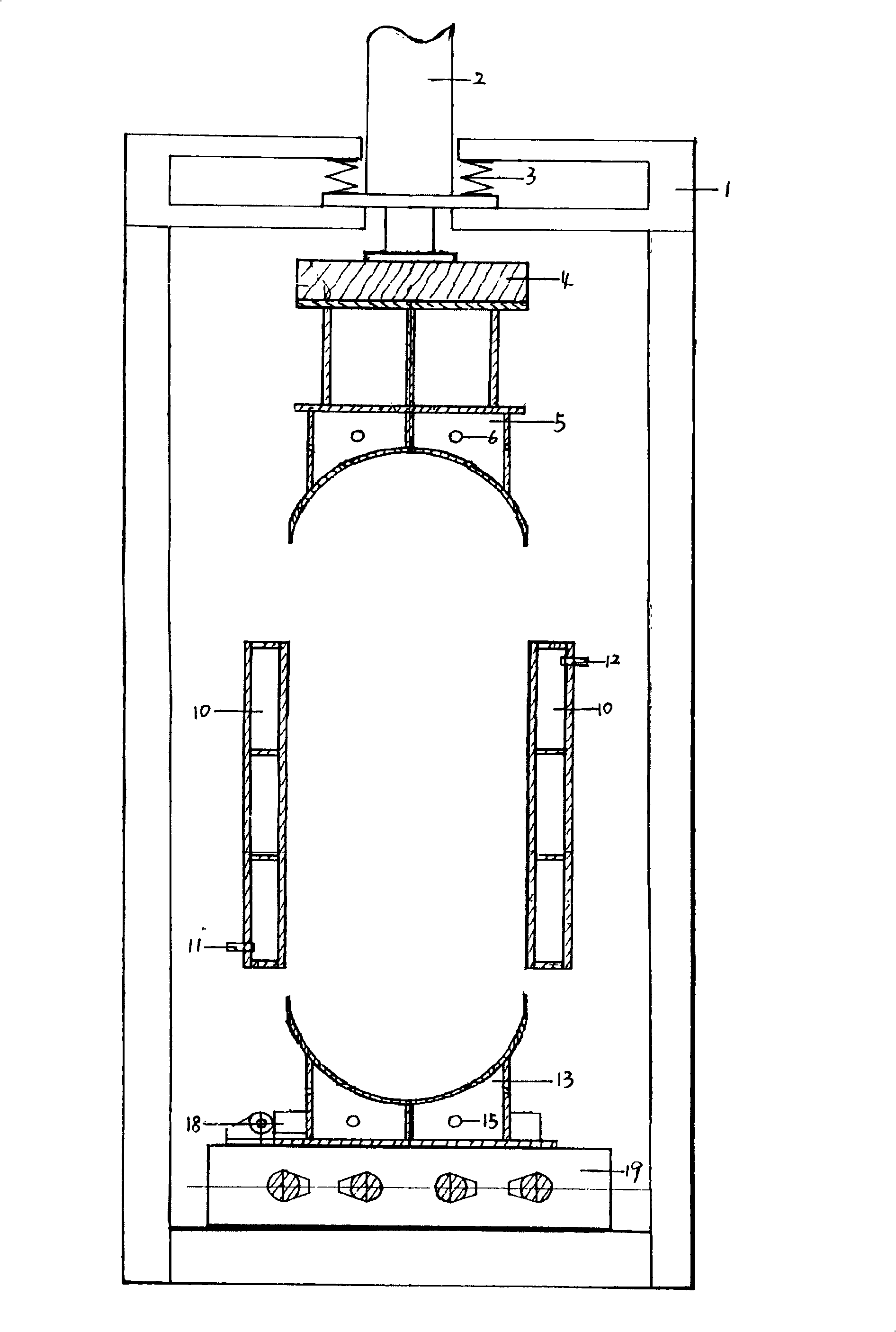

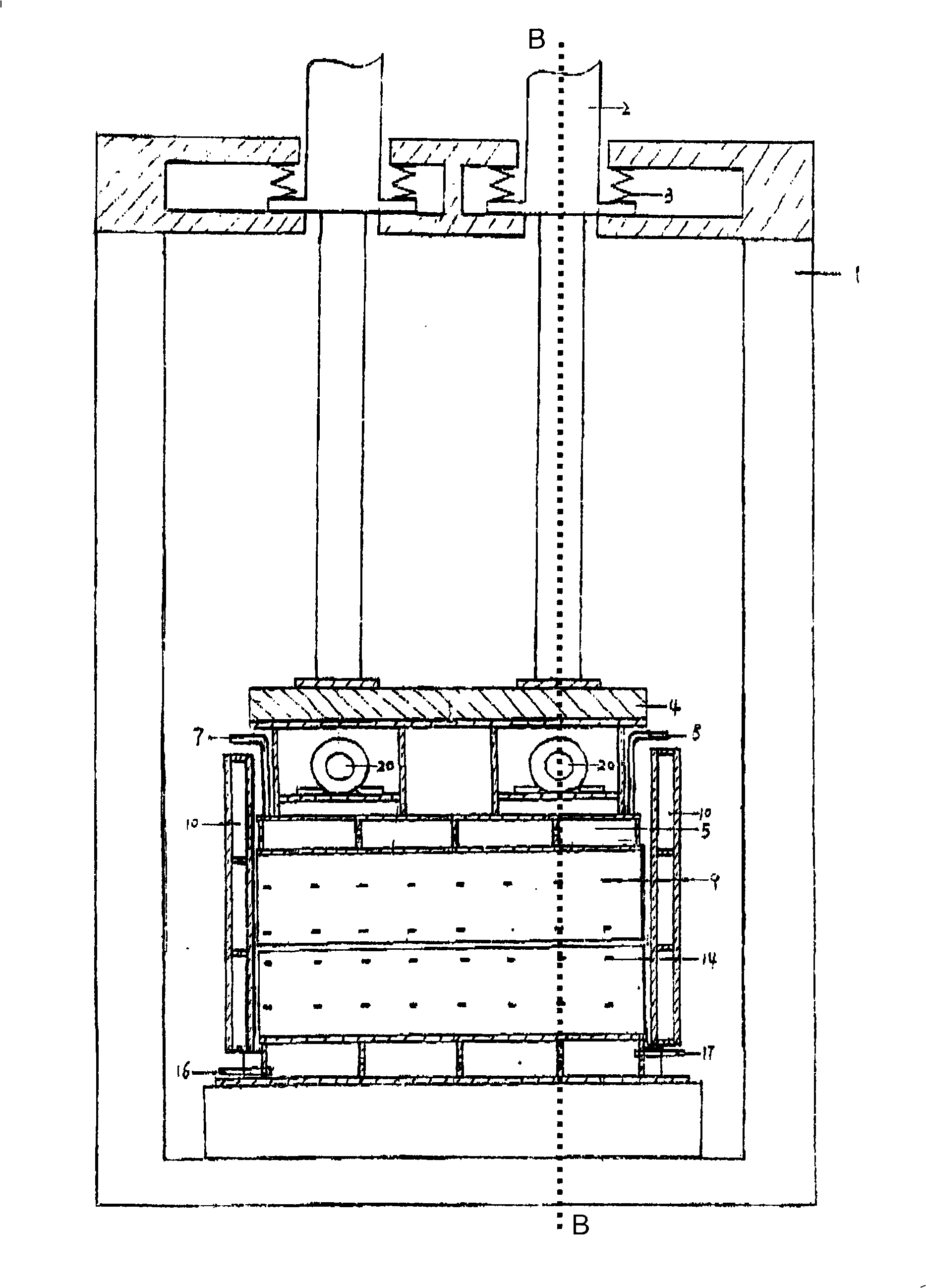

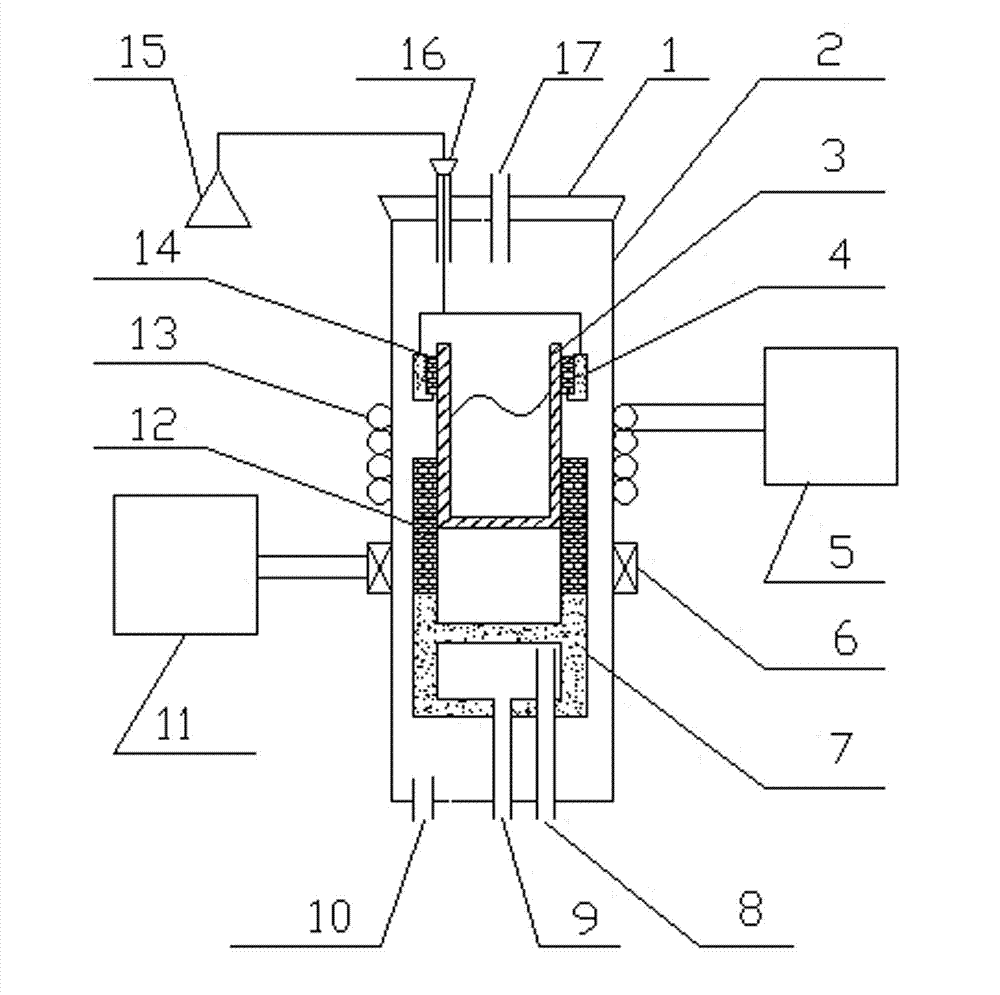

Carbon electrode horizontal type bidirectional vibration molding technique and special forming equipment

InactiveCN101254614AHigh strengthHigh densityCell electrodesCeramic extrusion diesVolumetric Mass DensityEnergy conservation

The invention relates to a horizontal two-way vibration forming process of carbon electrode and special forming equipment. The forming process comprises following steps: selecting materials, heating, mixing, kneading, air-drying, adding materials, pre-vibrating, pressurizing, two-way vibrating, and de-molding. The special forming equipment consists of a four-axis amplitude modulation vibration table, a frame, a mold, a pressure-bearing conductive connector, a hydraulic piston, a vibration energy-storage spring, a hydraulic mechanism, etc., wherein the mold consists of an upper mold, a middle mold and a lower mold; a vibration motor is fixed on the upper mold; the upper mold, the pressure-bearing conductive connector and the hydraulic piston on the hydraulic mechanism constitute a pressure conductive device and are fixed on the frame through the two-way vibration energy-storage spring; the lower mold is horizontally fixed on the four-axis amplitude modulation vibration table through a flip hinge; and the middle mold is below the upper mold and above the lower mold. Carbon electrode manufactured by the process has the advantages of high strength and density, good consistency, less internal defects, high forming efficiency, and reduced energy consumption.

Owner:焦作市东星炭电极有限公司

Perovskite solar cell and preparation method thereof

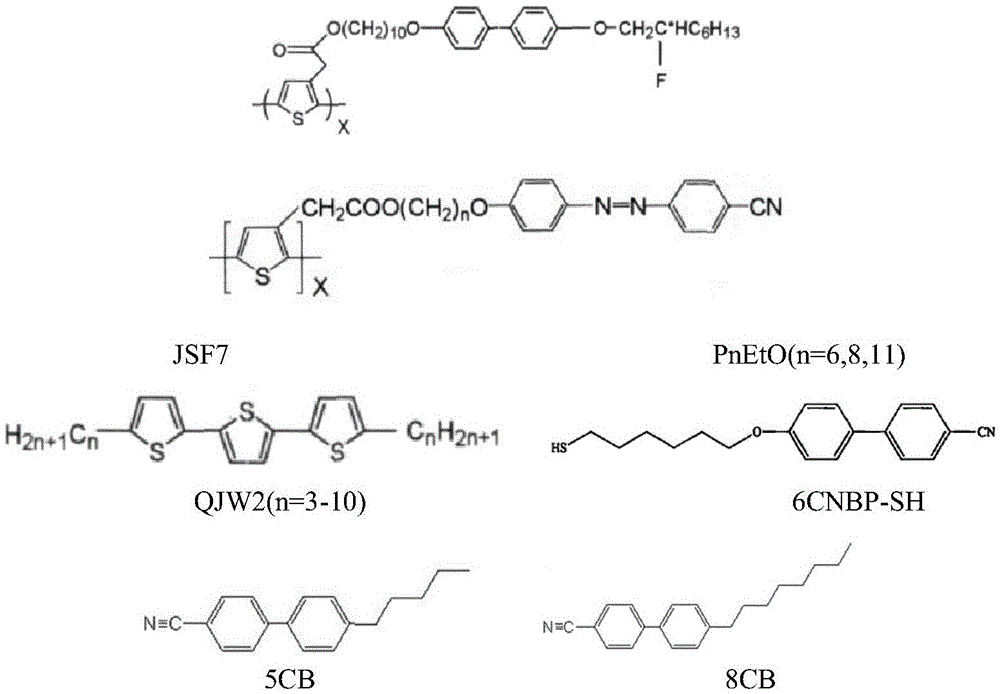

ActiveCN105609641AImprove film morphologyReduce surface defectsFinal product manufactureSolid-state devicesThin film morphologyLiquid-crystal display

The invention relates to a perovskite solar cell and a preparation method thereof. By arranging a liquid crystal layer on the surface of an electron transmission layer or a hole transmission layer, the thin film morphology of the electron transmission layer or the hole transmission layer is improved, the defect on the surface of the electron transmission layer or the hole transmission layer is passivated, the transmission of reverse current carriers is effectively blocked, the electric leakage generation is prevented, the combination probability of electrons and holes which are generated in a perovskite light absorption layer is reduced, and the photoelectric conversion efficiency and the stability of the cell are improved; and meanwhile, the liquid crystal layer is prepared by a low-temperature solution method, and the preparation method is suitably used for roll-to-roll industrial production of the perovskite photovoltaic cell, and is simple in process and low in fabrication cost.

Owner:CHINA LUCKY FILM CORP

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

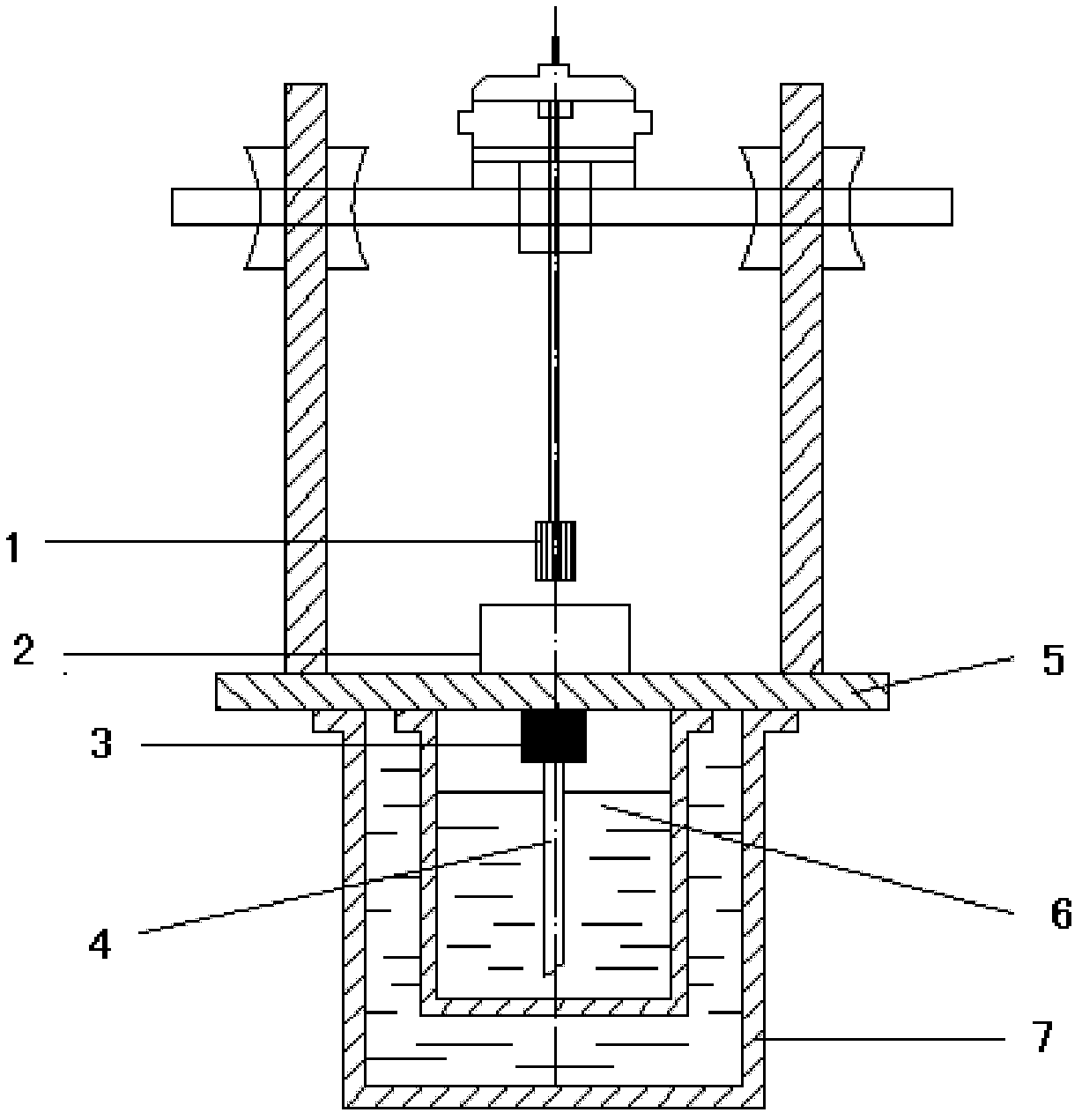

Gold base alloy casting blank melting and casting integrated device and utilization method thereof

ActiveCN103691912AReduce the number of oxide inclusionsEliminate severe oxidationIntegrated devicesCrucible

The invention discloses a gold base alloy casting blank melting and casting integrated device and a utilization method thereof. The gold base alloy casting blank melting and casting integrated device comprises a melting pot, a fireproof material cylinder, a cooling base, an outer cylinder, a heating induction coil and a magnetic stirring device. The utilization method of the gold base alloy casting blank melting and casting integrated device comprises putting gold into the melting pot and inserting the melting pot into the fireproof material cylinder; piping inert gas or reducing gas into the outer cylinder; heating the metal inside the melting pot to be melted through magnetic fields, adding other metal or alloy and performing alloying; enabling the melting pot with the fusant to descend to an annual boss of the cooling base and cooling the fusant to cast the fusant which is gradually solidified from bottom to upper during the cooling process. The gold base alloy casting blank melting and casting integrated device has the advantages of being simple in structure, convenient to operate and low in integral cost and enabling prepared gold base alloy to be uniform in ingredient and less in internal defect. The gold base alloy casting blank melting and casting integrated device and the utilization method thereof have good application prospects.

Owner:NORTHEASTERN UNIV

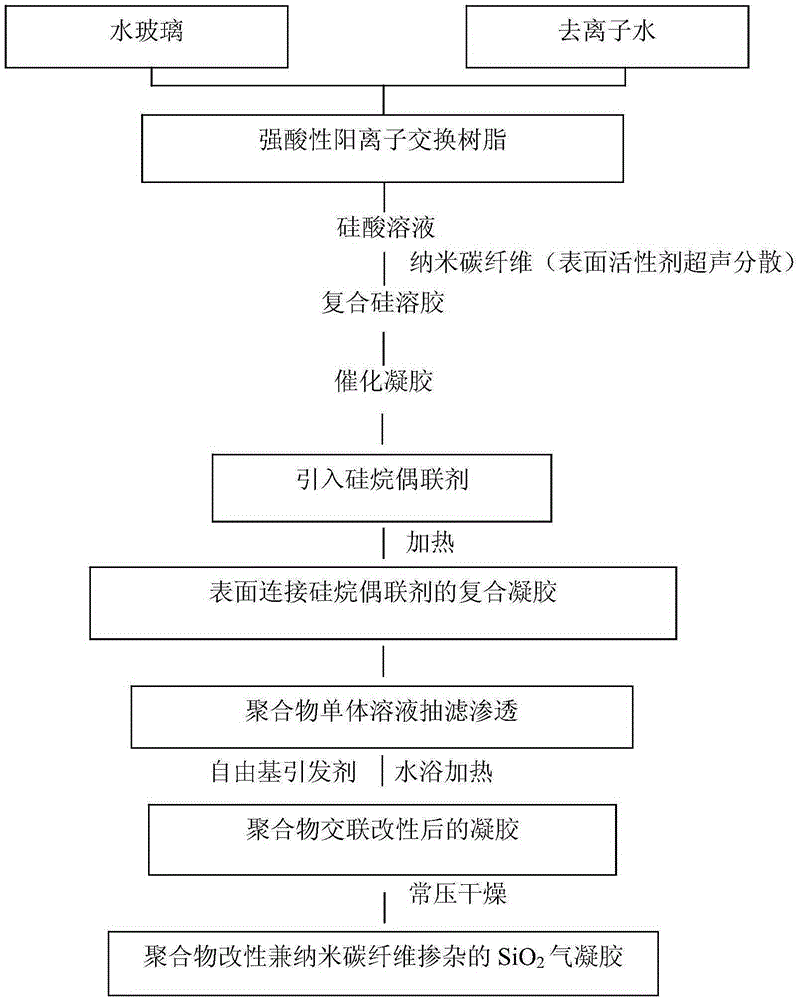

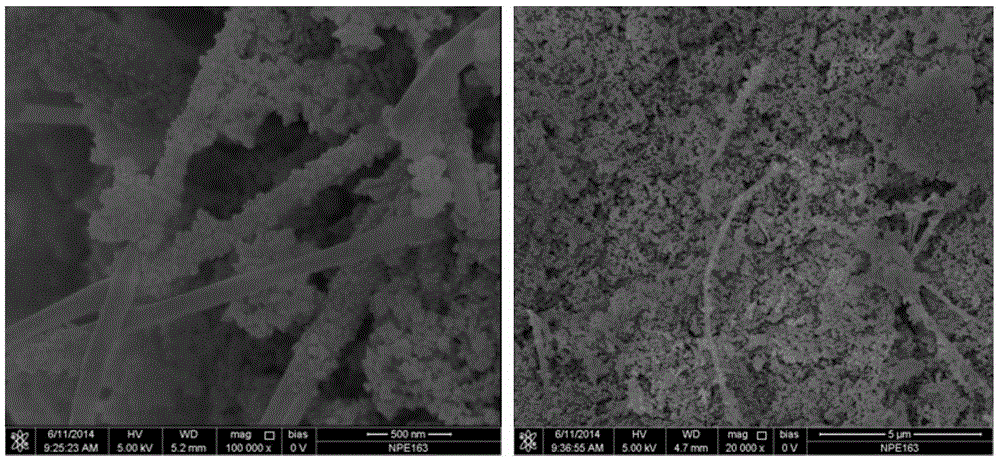

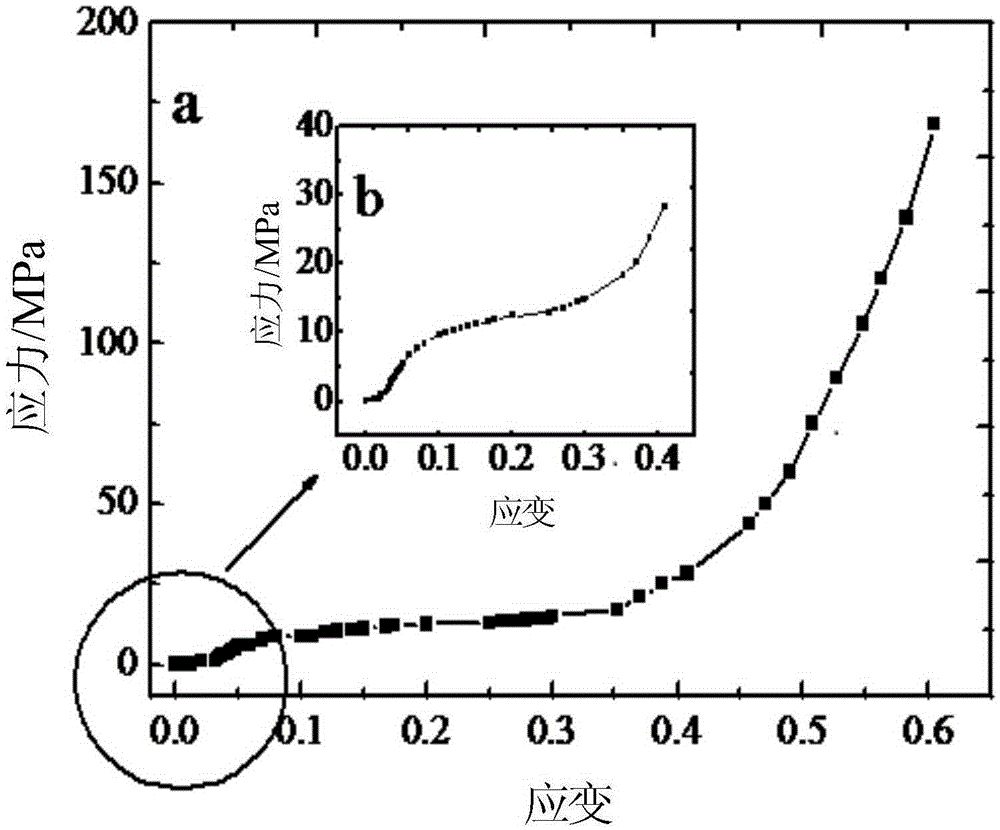

Polymer modified and nano-carbon fiber doped SiO2 aerogel and preparation method thereof

ActiveCN105236426AReduce internal defectsImprove high temperature insulation performanceSilicaFiberPolymer modified

The invention provides a polymer modified and nano-carbon fiber doped SiO2 aerogel and a preparation method thereof. The preparation method comprises: subjecting a water glass solution to ion exchange to obtain a silicic acid solution; dissolving a surfactant and nano-carbon fiber in the silicic acid solution, and carrying out ultrasonic dispersion to obtain nano-carbon fiber / SiO2 composite sol; adjusting the pH value of the composite sol, conducting standing at room temperature to obtain nano-carbon fiber / SiO2 gel; aging the gel at room temperature, and then transferring the gel into an aqueous solution of an organic solvent to conduct soaking; dissolving the soaked gel in an organic solvent of a silane coupling agent to carry out reaction under a heating condition; immersing the gel into a polymer monomer solution, conducting pumping filtering by a vacuum pump, and then carrying out polymerization reaction; and then performing washing and drying, thus obtaining the polymer modified and nano-carbon fiber doped SiO2 aerogel. The technical scheme provided by the invention has the advantages of safe operation and simple process, and the prepared SiO2 aerogel has excellent mechanical and thermal performance.

Owner:PETROCHINA CO LTD

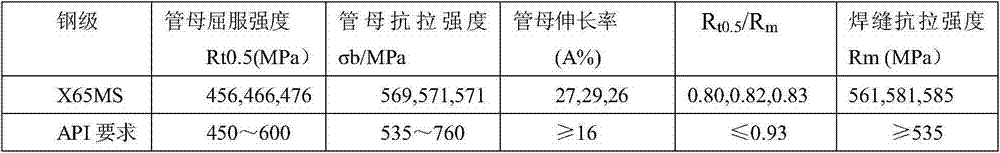

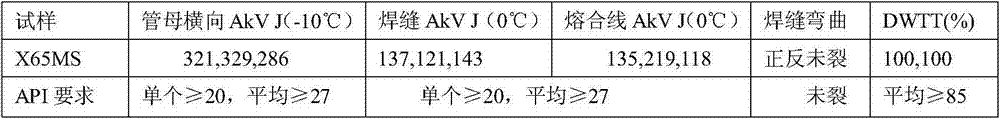

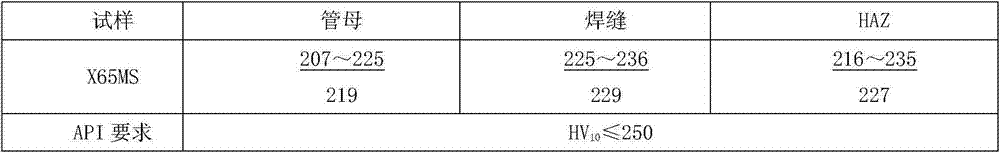

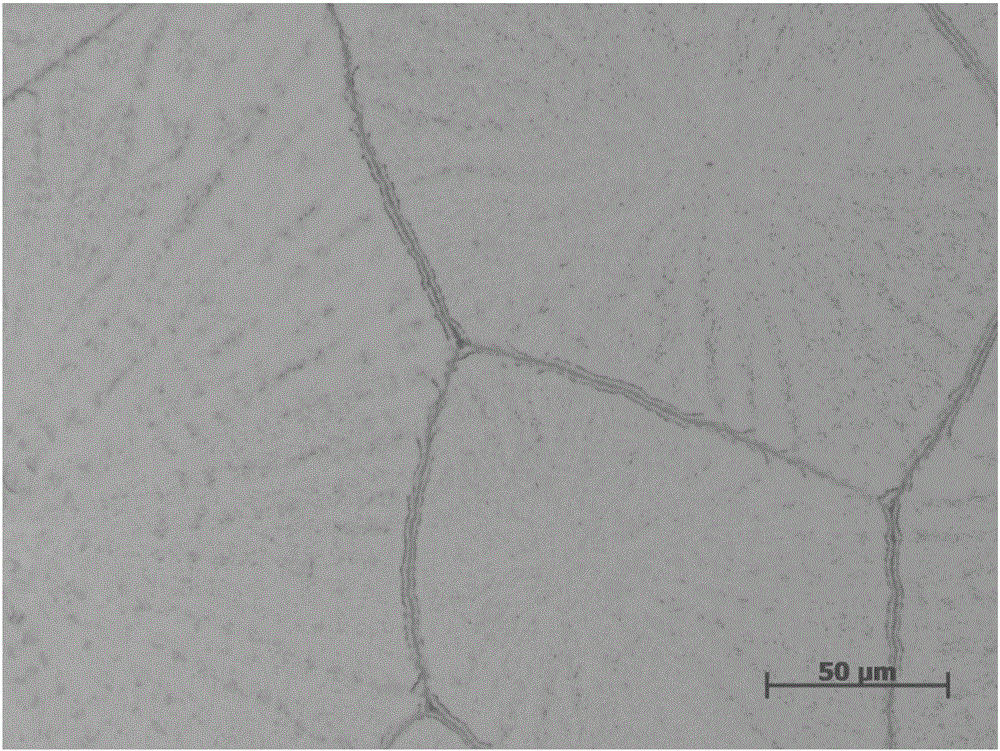

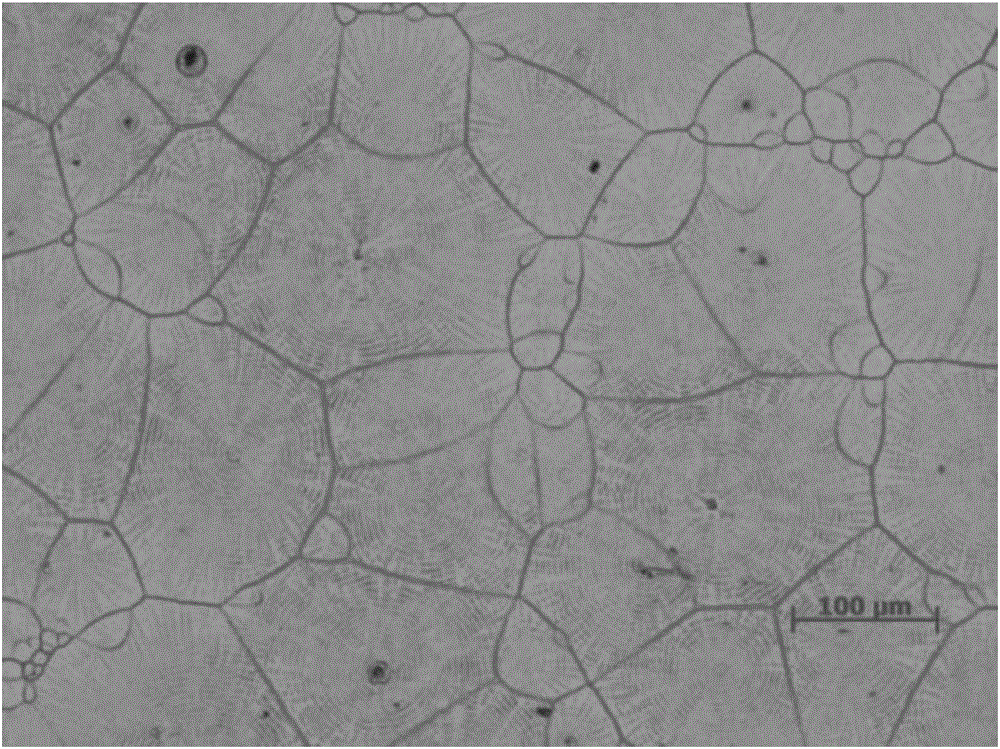

X65MS/X70MS spiral submerged-arc welded pipe with excellent SSCC (Sulfide Stress Corrosion Cracking) stress corrosion resistance as well as manufacturing method thereof

ActiveCN103540834AUniform tissueImprove anti-SSCC performanceFurnace typesHeat treatment furnacesEnergy controlTest sample

The invention discloses an X65MS / X70MS spiral submerged-arc welded pipe with excellent SSCC (Sulfide Stress Corrosion Cracking) stress corrosion resistance as well as a manufacturing method thereof. In a welded pipe manufacturing process, the X65MS / X70MS steel-level spiral submerged-arc welded pipe with high strength, high toughness and excellent SSCC stress corrosion resistance can be obtained by mainly adopting technologies such as low-stress forming, anti-corrosion wire welding and flux welding and heat input line energy control. The X65MS / X70MS steel-level spiral seam submerged-arc welded pipe disclosed by the invention has excellent H2S corrosion resistance; an SSCC test is carried out in liquor A by adopting NACE (National Association of Corrosion Engineer) TM0177 standards, specified yield strength stress level of over 90% sigma s is applied, a stretching surface of a test sample is perfect without appearing any cracks, and therefore, the X65MS / X70MS spiral submerged-arc welded pipe is suitable for a high-pressure large-flow oil field gathering pipeline or being used for conveying an acidic oil-gas medium.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

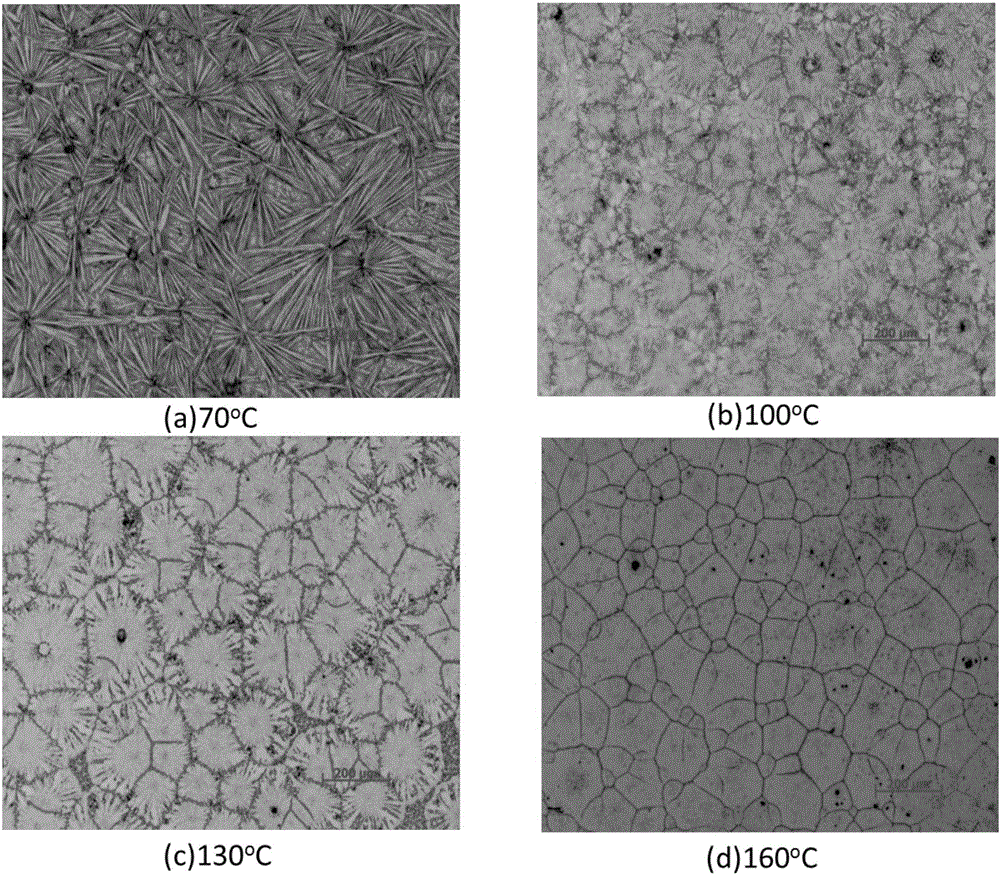

Large grain organic and inorganic hybrid perovskite film preparation method

ActiveCN106159088AEasy to controlEasy preparation of controlled substrate temperatureSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSolar battery

The invention discloses a large grain organic and inorganic hybrid perovskite film preparation method, belonging to the perovskite type solar battery and correlated photoelectric semiconducting material field, and can prepare a uniform and compact large grain film through the steps of configuration of an organic and inorganic hybrid perovskite precursor solution, stirring and heating, spin coating, annealing, etc. The method requires no spin coating in a multistep approach, ca easily control the temperature of a room temperature substrate, has no strict requirements on an annealing and cooling rate, and can manufacture a film efficiently. The method realizes virtual grain film growth through adjusting the grain dimension of a perovskite light-absorption layer, thereby reducing grain inner defects, and increasing the carrier transport efficiency; in addition, the method controls grain boundary defects, greatly improves perovskite crystal film environment stability, and enhances perovskite thin-film device performances. A perovskite type virtual monocrystalline film prepared in the low temperature solution method can assemble hysteresis free, efficient and stable perovskite type solar batteries and correlated film transistor, electroluminescent and laser emission photoelectric semiconductor devices.

Owner:NANJING UNIV OF TECH

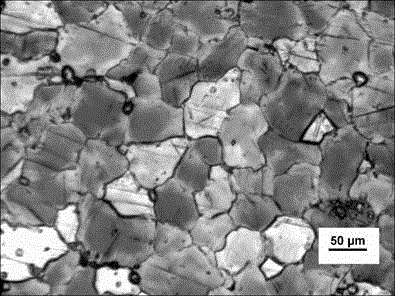

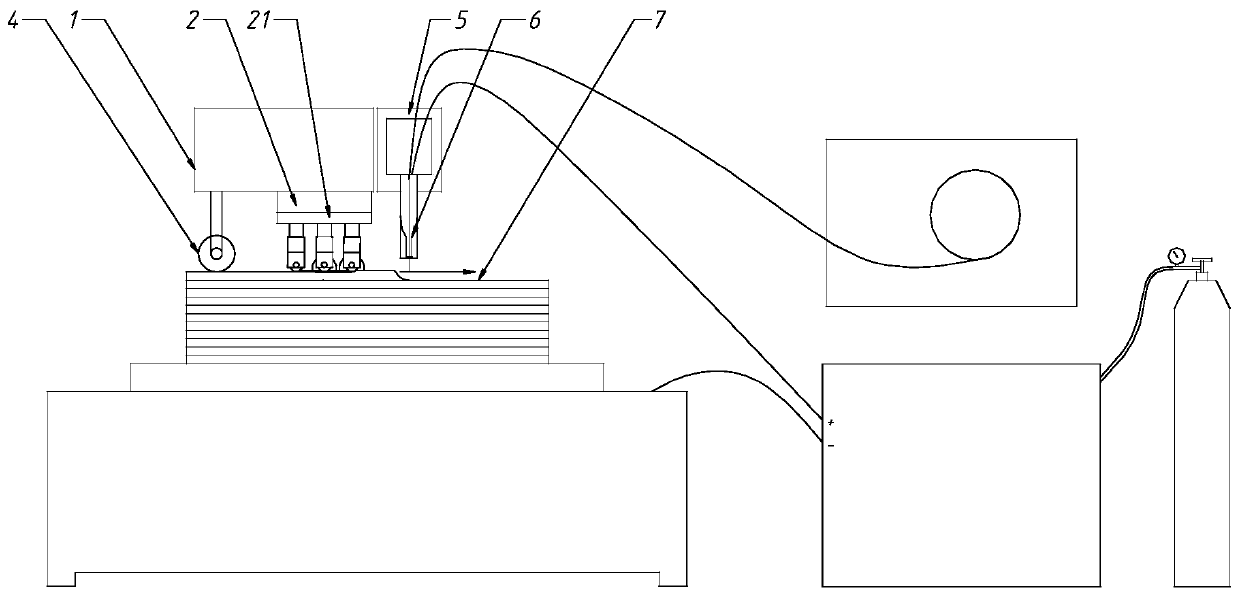

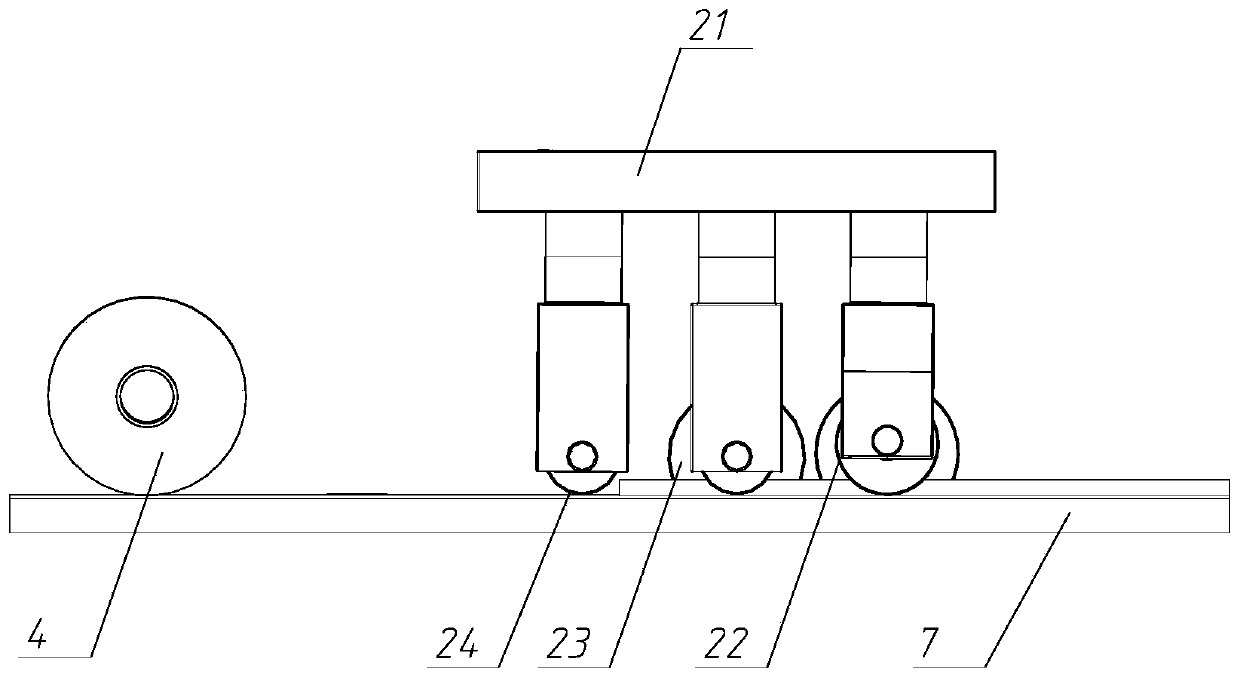

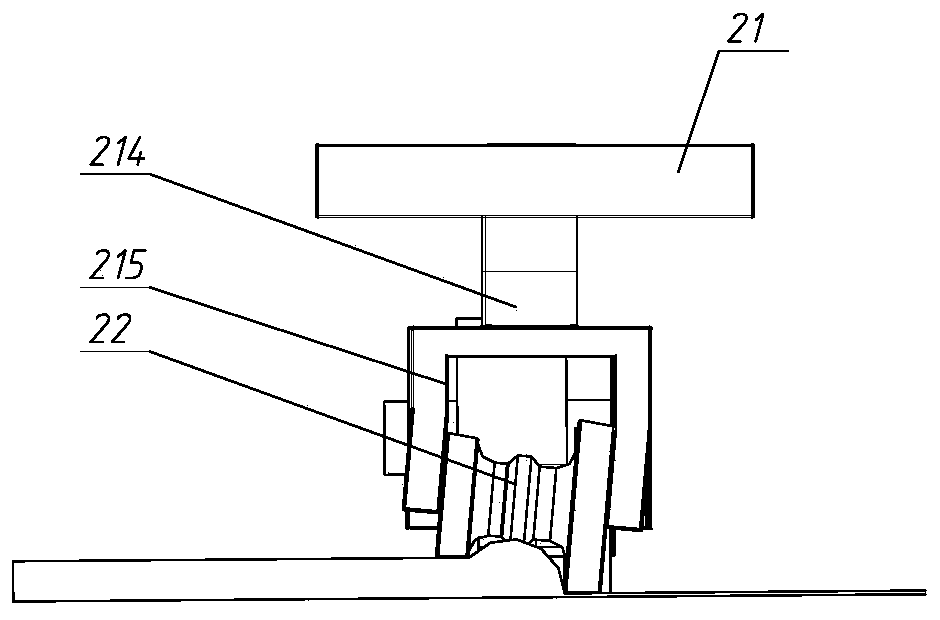

Arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device

ActiveCN111215843ARapid coolingPreventing Dimensional Distortion ProblemsAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringShearing deformation

The invention discloses an arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device, and relates to the technical field of 3D printing. The wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device are exquisite in structure, high in processing efficiency and good in processing effect, and can refine crystal grains ofan arc additive manufacturing formed part, improve compactness and reduce internal defects, thereby finally improving mechanical properties. The technical scheme of the invention is as follows: the manufacturing method comprises the following steps: (1) initialization; (2) arc wire feeding and material adding; (3) rolling; (3.1) strong shear deformation of an oblique roller; (3.2) primary flattening; (3.3) full flattening; (4) cooling; and (5) cutting of waste edges. The crystal grains of the arc wire feeding additive manufacturing formed part can be refined, the compactness is improved, internal defects are reduced, and the mechanical properties of the part are finally improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cobalt-based high-temperature alloy wire and preparation method thereof

InactiveCN110983113ADecreased high temperature strengthImprove high temperature strengthDouble phaseOxidation resistant

The invention provides a cobalt-based high-temperature alloy wire which is prepared from the following chemical components in percent by mass: 0.06-0.12% of C, less than or equal to 0.3% of Si, 1-1.8%of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 19.2-20% of Cr, 9.5-10.5% of Ni, 14.2-15.5% of W, less than or equal to 2.8% of Fe, less than or equal to 0.4% of other impurities and the balance Co. By adding 19.2-20% of Cr, the cobalt-based high-temperature alloy wire has excellent corrosion resistance, and a condition that high-temperature strength is decreased as aresult of a double phase area as the content of Cr is too high to promote generation of an epsilon-Co phase and a sigma phase is avoided. Elements such as massive Co, 14.2-15.5% of W and 19.2-20% ofCr and the like in the cobalt-based alloy can reduce stacking fault energy, so that the high-temperature strength of the alloy is improved. The content of W is controlled at 19.2-20%, so that it is ensured that a condition of prominent work hardening of the alloy, difficulty in cold processing and poor stability as the too high W content is avoided. As the cobalt-based high-temperature alloy wirecontains 9.5-10.5% of Ni, the tissue stability of the alloy is improved favorably, and precipitation of a Co7W6 phase is reduced. By adding 1.1-1.8% of Mn, the oxidation resistance of a Ni-Cr alloy isimproved effectively.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

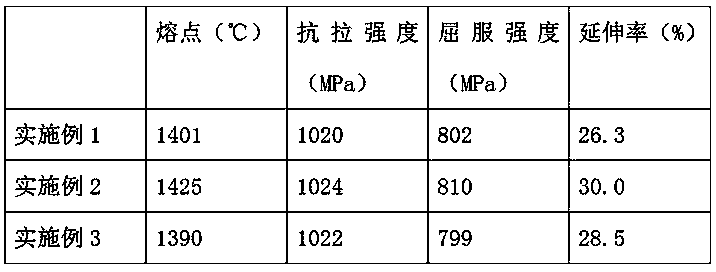

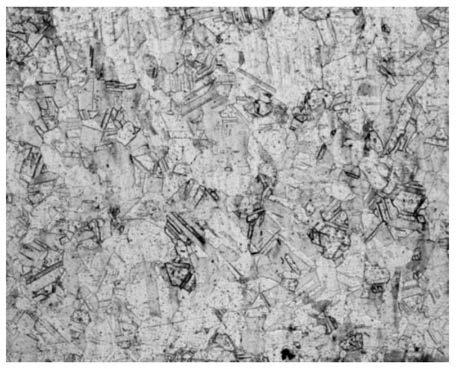

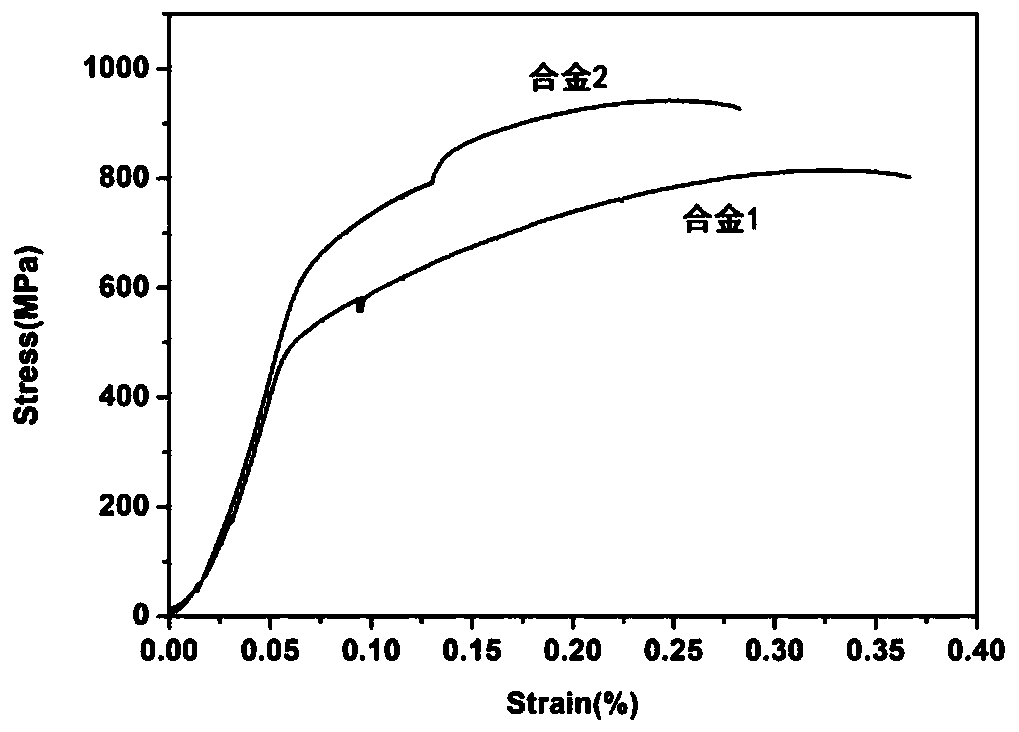

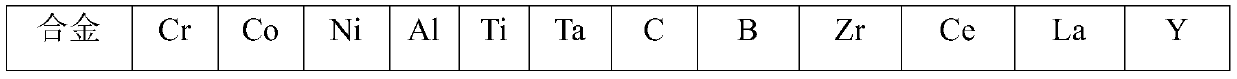

High-toughness medium entropy high temperature alloy and preparing method thereof

ActiveCN111500917AHigh strengthImprove high temperature mechanical propertiesIndustrial gasManufactured material

The invention discloses a high-toughness medium entropy high temperature alloy and a preparing method thereof. The alloy comprises chemical components including, by weight percent, 28.5 to 32.5% of Cr, 31.5 to 33.4% of Co, 32 to 35% of Ni, 0.5 to 6% of Al, 0 to 6% of Ti, 0 to 3% of Ta, 0.02 to 0.12% of C, 0.002 to 0.015% of B, 0.005 to 0.12% of Zr, 0.005 to 0.15% of RE, and larger than or equal to2% and smaller than or equal to 6% of Al+Ti+Ta, wherein Re is one of Ce, La and Y. The preparing method of the alloy comprises the steps that the raw materials are burdened and smelted according to the proportion, an electrode bar is forged and subjected to remelting, forging is carried out, an alloy bar is prepared, and the alloy bar is subjected to solid solution and aging heat treatment. The alloy is provided with a reasonable component ratio, a wide heat machining window and a heat processing system, the prepared alloy bar has the higher temperature strength, good heat machining and oxidation resistance properties, and the alloy is a candidate material of aero-engine and industrial gas turbine heat end parts.

Owner:UNIV OF SCI & TECH BEIJING +1

Full forbidden region three-dimensional photon crystal stamp molding method and full forbidden region three-dimensional photon crystal structure

InactiveCN101303524AReduce internal defectsSmall cell structurePhotomechanical apparatusPolystyreneCrystal

The invention relates to the technical field of micro-nano manufacturing, introducing a manufacturing method of a full forbidden-band three-dimensional photonic crystal which is molded through impressing and full forbidden-band three-dimensional photonic crystal structure. The manufacturing method takes polymer silicone rubber or polymethyl methacrylate as base material, adopts the method of nano-imprint to fill monodisperse colloidal particles (such as polystyrene, titanium dioxide or silica) in the polymer base material, causing the monodisperse colloidal particles in the polymer base material to form face-centered cubic structure. The monodisperse colloidal particles are adsorbed in raised part of an impressing template, and micro-contacting type nano-imprint technique is adopted to cause monodisperse colloidal particles in the base material of liquid polymer to form two-dimension structure with the 111 surface of a face-centered cube, wherein, the monodisperse colloidal particles are the element on the 111 surface of the face-centered cube and then the particles on the surface are accumulated layer by layer to finally form the full forbidden-band three-dimensional photonic crystal with the face-centered cubic structure.

Owner:XI AN JIAOTONG UNIV

New ultrafine sand concrete

ActiveCN102093001AReduce internal defectsImprove structural featuresSolid waste managementWater reducerFiber

The invention discloses new ultrafine sand concrete. The new ultrafine sand concrete comprises the following components in parts by weight: 1.3 parts of cementing material, 1.5 parts of fine aggregate, 4 parts of coarse aggregate, 0.01 part of high efficiency water reducing agent and 0.32 part of water. The ultrafine sand concrete also contains expanding agent, water reducing agent, grinding aid, surfactant and reinforced fiber. By adopting the coordination of various components, particularly adding the reinforced fiber in the ultrafine sand concrete disclosed by the invention, the technical defect of the prior art that concrete is easy to crack can be overcome, the anti-seepage function of concrete can be enhanced and the cracking of concrete can be inhibited.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com