Polymer modified and nano-carbon fiber doped SiO2 aerogel and preparation method thereof

A nano-carbon fiber and polymer technology, which is applied in the preparation of functional materials and thermal insulation materials, nanoporous materials, can solve the limitations of large-scale industrial production and application of airgel materials, poor mechanical properties of airgel, airgel Low bulk density and other issues, to achieve the effect of improving high temperature heat insulation performance, improving mechanical properties, and avoiding polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

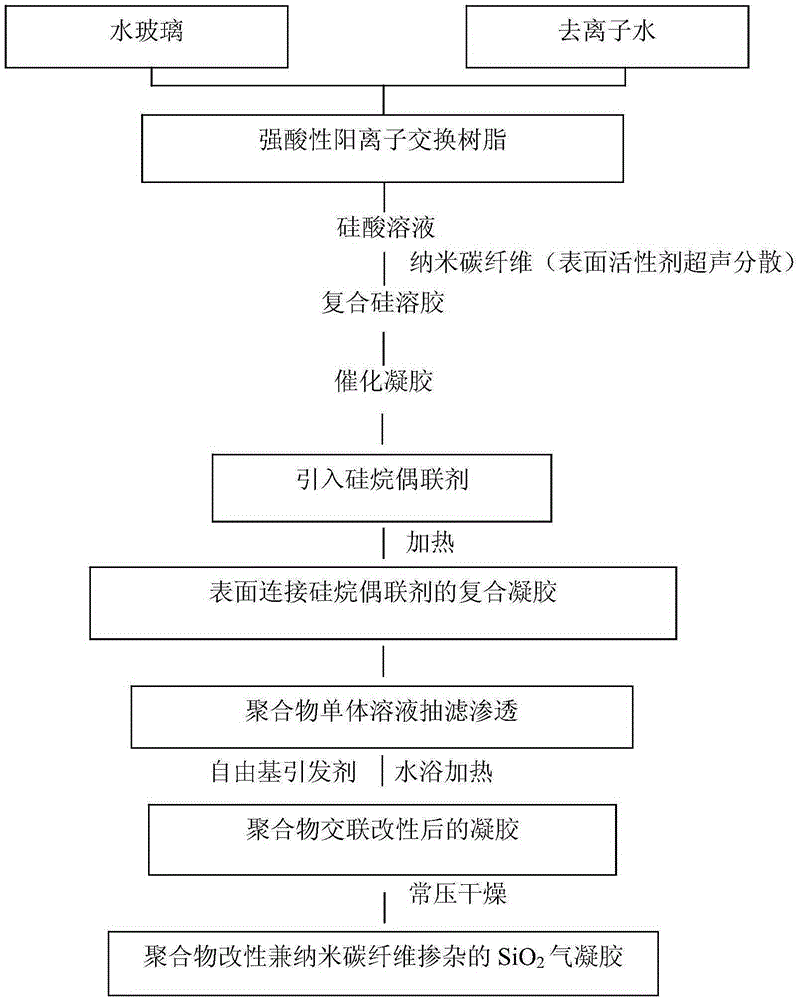

[0039] This embodiment provides a polymer modified and nano-carbon fiber doped SiO 2 The preparation method of airgel (operating process such as figure 1 ), which includes the following steps:

[0040] 1) Dilute water glass (modulus about 3.1, Baume degree about 40) with deionized water at a volume ratio of 1:2, perform ion exchange through a strongly acidic styrene-based cation exchange resin, and remove sodium ions to obtain silicon acid solution;

[0041] 2) Using sodium dodecyl sulfate (SDS) as a dispersant, according to the mass ratio of SDS:CNFs (Carbonnanofibers, carbon nanofibers)=4:1, ultrasonically disperse in silicic acid solution for 60min to obtain uniformly dispersed carbon nanofibers / SiO 2 Composite sol;

[0042] 3) Catalyze the above carbon nanofiber / SiO with 3.0mol / L ammonia water 2 Composite sol, adjusting the pH value of the composite sol to 5-6;

[0043] 4) Aging the gel at room temperature for 12 hours, then moving it into a methanol solution with a...

Embodiment 2

[0049] This embodiment provides a polymer modified and nano-carbon fiber doped SiO 2 The preparation method of airgel, it comprises the following steps:

[0050] 1) Dilute water glass (modulus about 2.9, Baume degree about 30) with deionized water at a volume ratio of 1:6, and ion-exchange through strong acidic styrene-based cation exchange resin drop by drop to remove sodium ions to obtain a silicic acid solution;

[0051] 2) Using methylcellulose (MC) as the dispersant, according to the mass ratio of MC:CNFs=1:1, ultrasonically disperse in the silicic acid solution for 30min to obtain uniformly dispersed carbon nanofibers / SiO 2 Composite sol;

[0052] 3) Catalyze the above carbon nanofiber / SiO with 1.0mol / L sodium hydroxide solution 2 Composite sol, adjusting the pH value of the composite sol to 5-6;

[0053] 4) Aging the gel at room temperature for 12 hours, then moving it into an ethanol solution with a volume percentage concentration of 50% and soaking for 12 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com