Full forbidden region three-dimensional photon crystal stamp molding method and full forbidden region three-dimensional photon crystal structure

A photonic crystal, bandgap technology, applied in optics, optomechanical equipment, instruments, etc., to achieve high flexibility, elimination of internal defects, and fewer internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

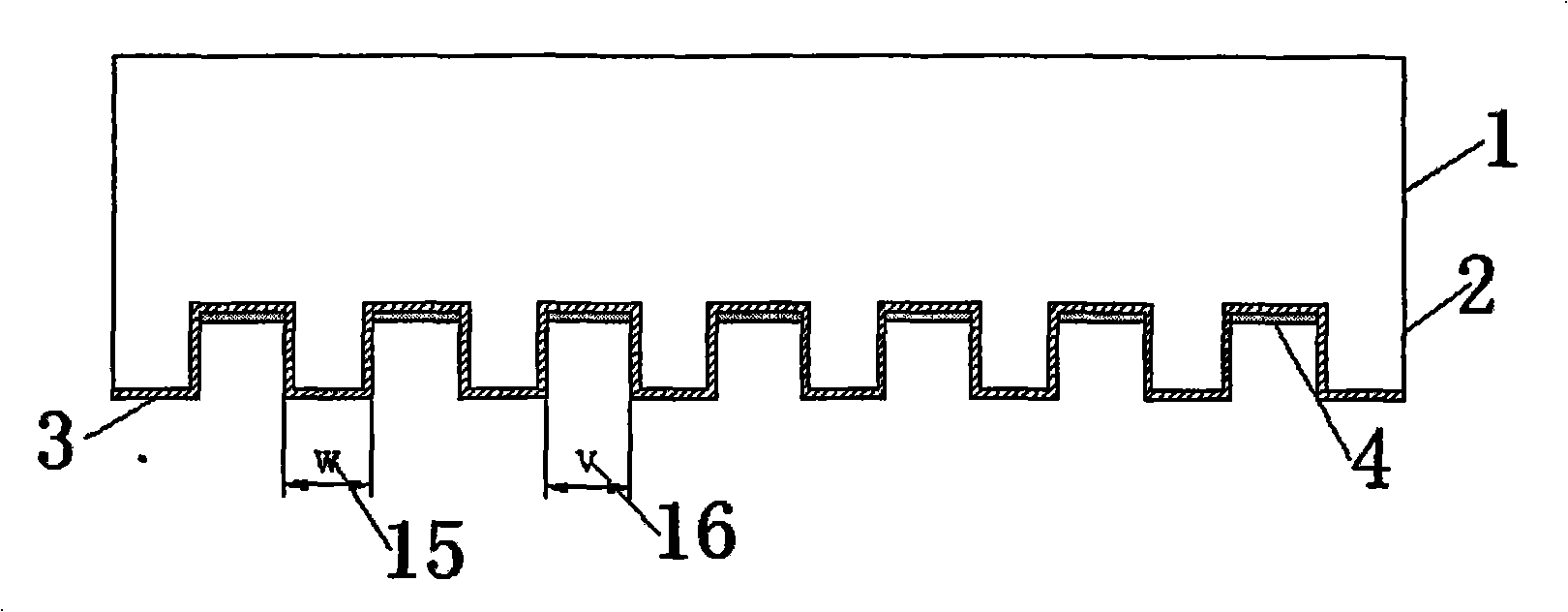

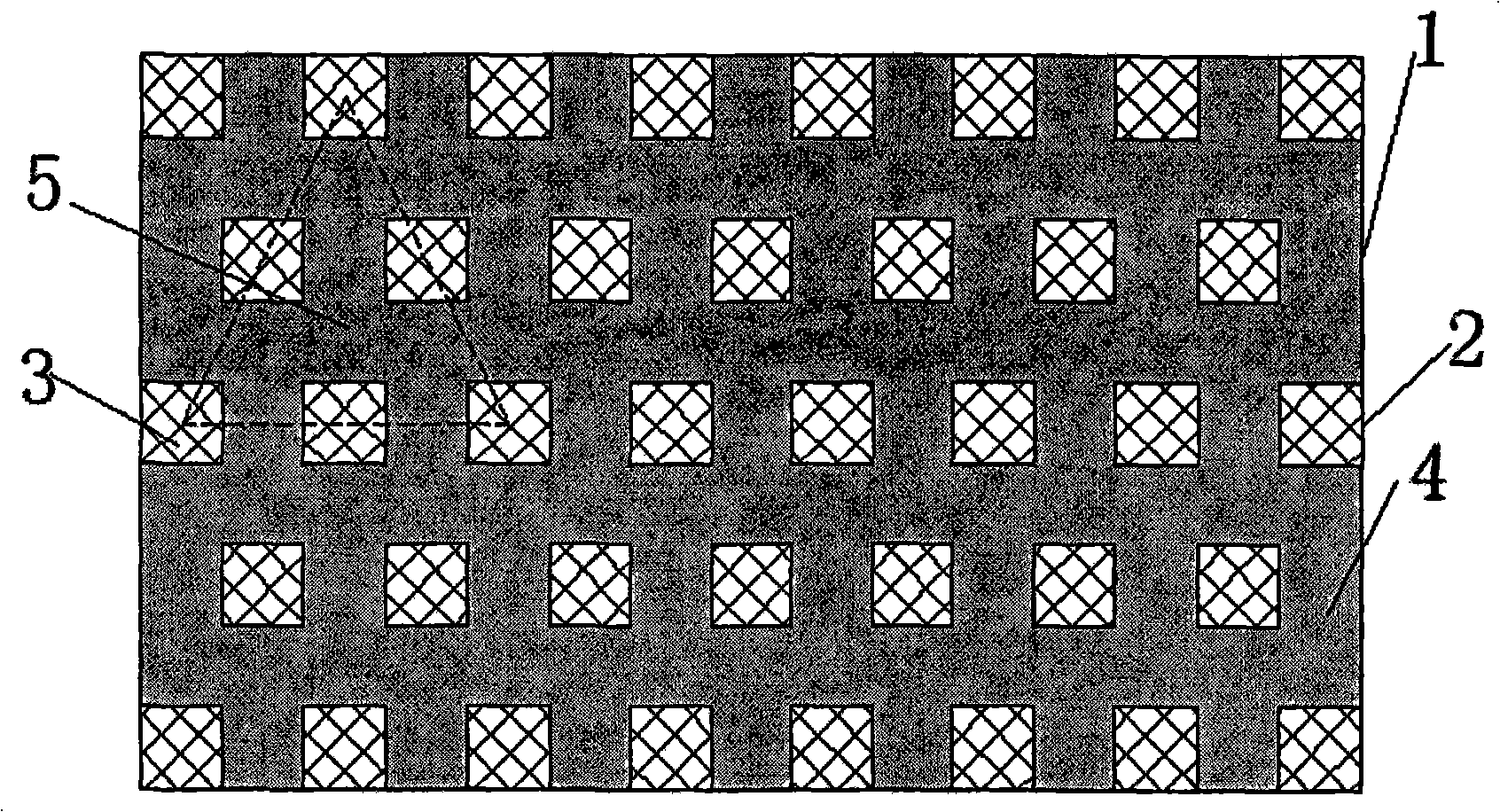

[0029] In the following, the nanoimprint manufacturing method of the total forbidden band three-dimensional photonic crystal will be described in detail in combination with the accompanying drawings.

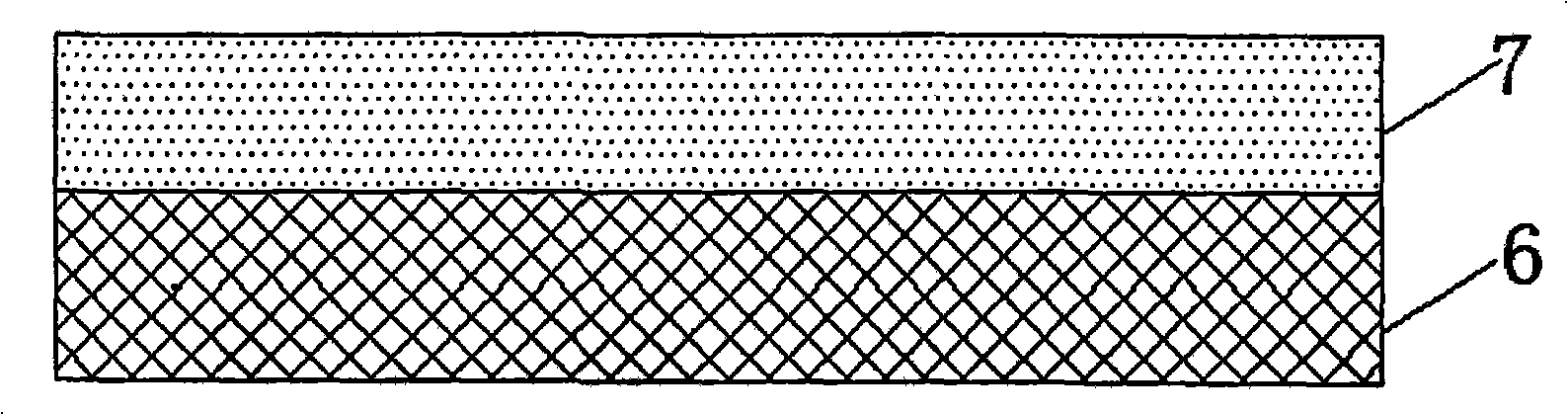

[0030] The full-gap three-dimensional photonic crystal is a three-dimensional photonic crystal with a face-centered cubic structure formed by embedding monodisperse colloidal particles 8 in a polymer matrix material 7 after solidification.

[0031] The basic working principle of the present invention is: select suitable material, select polystyrene as the monodisperse colloid particle, select silicon rubber as the polymer matrix material; Methyl acrylate. A dielectric constant ratio greater than 2 is generated between the monodisperse colloidal particles and the polymer matrix material. At the same time, monodisperse colloidal particles form a face-centered cubic structure in three-dimensional space, and these two points meet the physical conditions for photonic crystals to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com