Large grain organic and inorganic hybrid perovskite film preparation method

A perovskite, large-grain technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problems of restricting development, high energy consumption, and high cost, achieve low equipment requirements, improve device performance, The effect of reducing internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

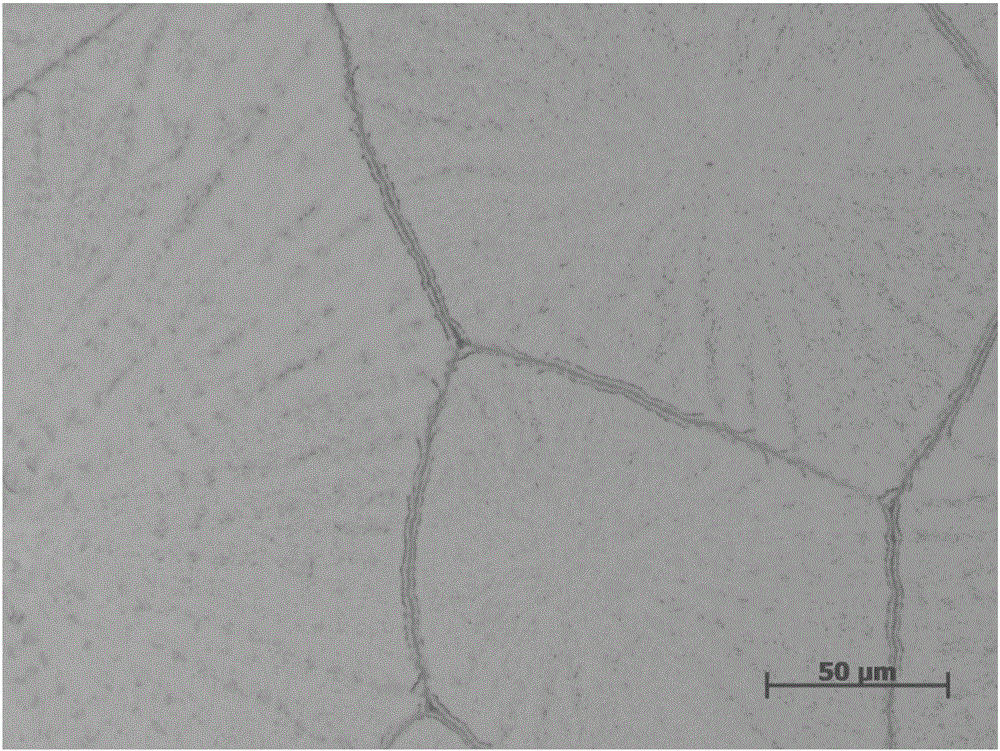

[0039] A method for preparing a large-grain organic-inorganic hybrid perovskite film, the preparation method comprising the following steps:

[0040] (1) Solvent DMSO with a certain mass fraction is configured as the perovskite precursor liquid for standby;

[0041] (2) The precursor material CH 3 NH 3 I·PbI 2 Dissolved in the perovskite precursor solution in the step (1), forming a yellow solution for subsequent use;

[0042] (3) Configure the perovskite precursor solution in the step (2) into a chemical formula of CH 3 NH 3 PB 3-x Br x Organic-inorganic hybrid perovskites, where 0≤x≤3.

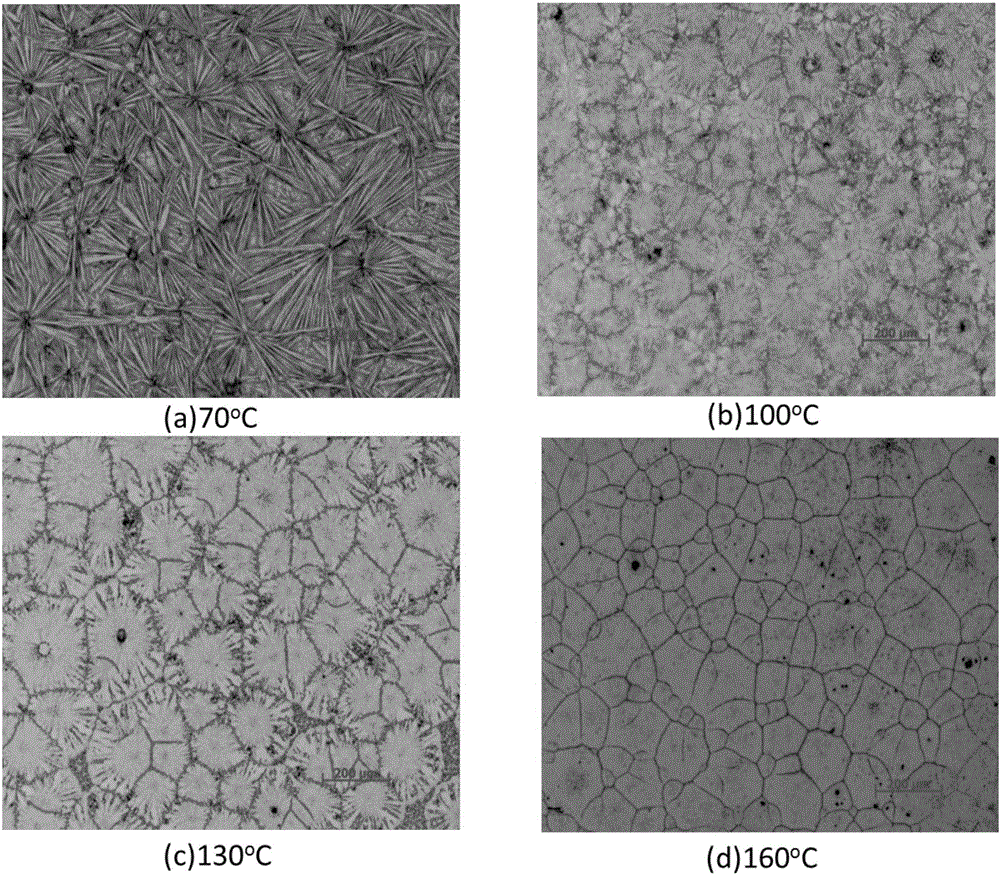

[0043] (4) heating the organic-inorganic hybrid perovskite obtained in the step (3) to above 130° C. under magnetic stirring conditions, and keeping it for 1 to 3 minutes;

[0044] (5) drop the solution obtained in the step (4) onto the prepared substrate, and spin-coat at a speed of 2500rpm for 25s to obtain a perovskite film;

[0045] (6) The perovskite film was annealed at 150°C ...

Embodiment 2

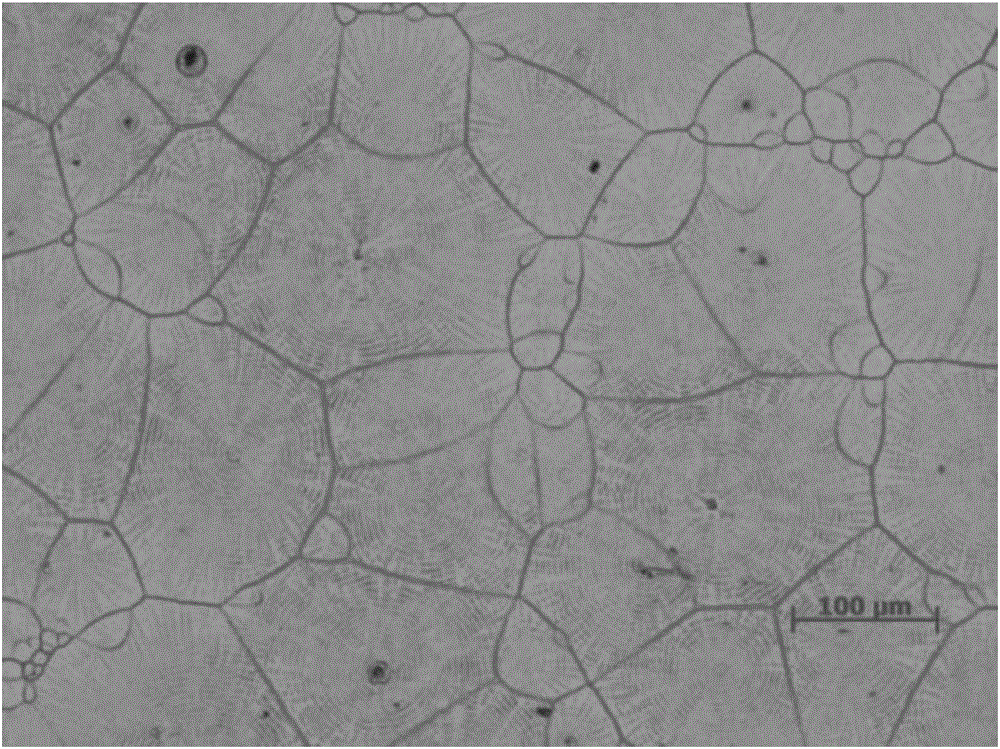

[0056] A method for preparing a large-grain organic-inorganic hybrid perovskite film, the preparation method comprising the following steps:

[0057] (1) configure the mixed solution of DMSO and DMF of a certain mass fraction as a solvent, and use the solvent as a perovskite precursor solution for subsequent use;

[0058] (2) The precursor material CH 3 NH 3 I, PbI 2 Dissolved in the perovskite precursor solution in the step (1), forming a yellow solution for subsequent use;

[0059] (3) Configure the perovskite precursor solution in the step (2) into a chemical formula of CH 3 NH 3 PB 3-x Br x The organic-inorganic hybrid perovskite, where 0≤x≤3.

[0060] (4) heating the organic-inorganic hybrid perovskite obtained in the step (3) to above 130° C. under magnetic stirring conditions, and keeping it for 1 to 3 minutes until the spin coating is completed;

[0061] (5) drop the solution obtained in the step (4) onto the prepared substrate, and spin-coat for 30s at a rotat...

Embodiment 3

[0067] A method for preparing a large-grain organic-inorganic hybrid perovskite film, the preparation method comprising the following steps:

[0068] (1) Configure a mixed solution of DMSO and GBL with a certain mass fraction as a solvent, and use the solvent as a perovskite precursor solution for subsequent use;

[0069] (2) The precursor material CH 3 NH 3 I·PbI 2 Dissolved in the perovskite precursor solution in the step (1), forming a yellow solution for subsequent use;

[0070] (3) Configure the perovskite precursor solution in the step (2) into a chemical formula of CH 3 NH 3 PB 3-x Cl x The organic-inorganic hybrid perovskite, where 0≤x≤3.

[0071] (4) heating the organic-inorganic hybrid perovskite obtained in the step (3) to above 130° C. under magnetic stirring conditions, and keeping it for 1 to 3 minutes until the spin coating is completed;

[0072] (5) drop the solution obtained in the step (4) onto the prepared substrate, and spin coat at a speed of 4000r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com