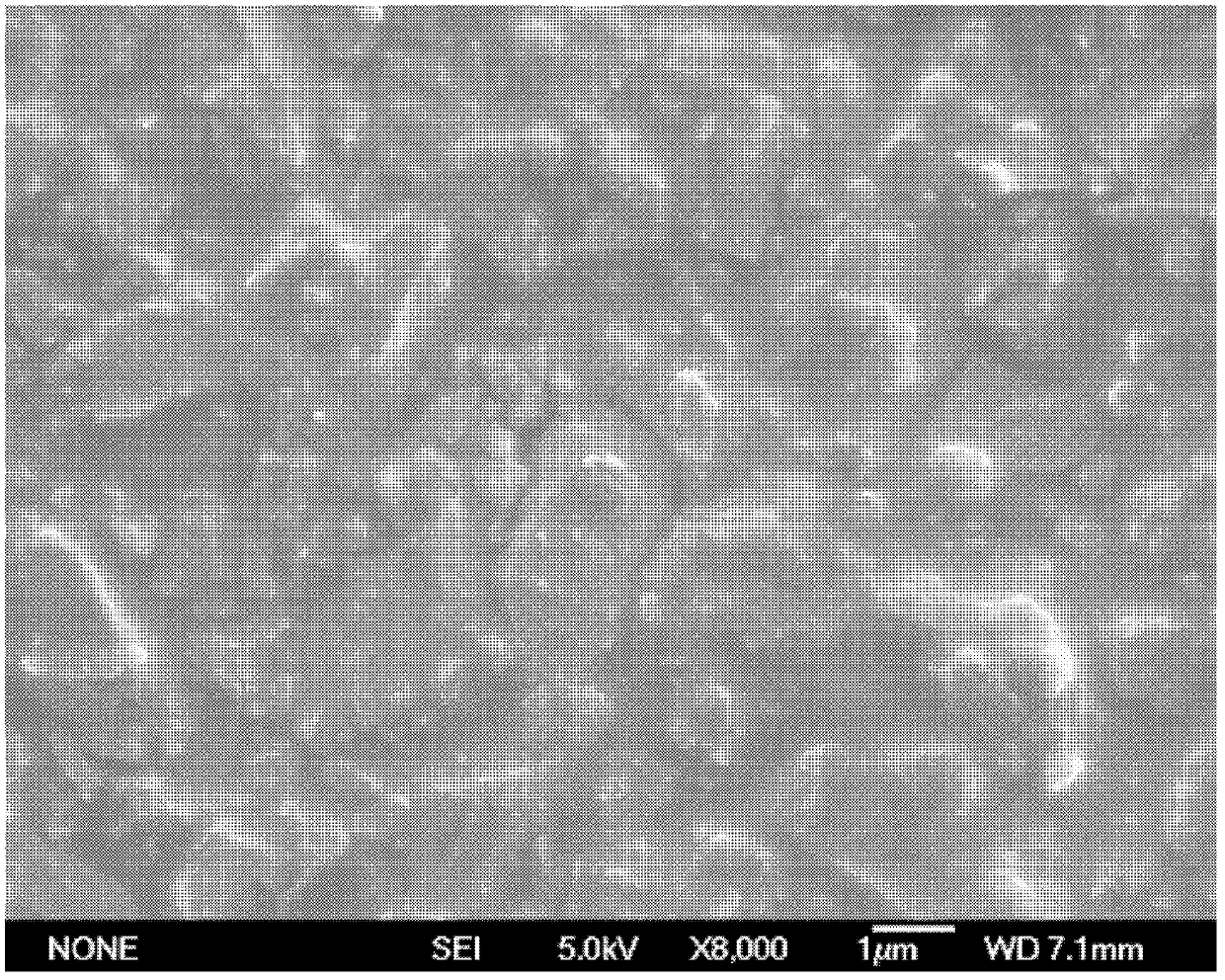

Preparation method of resin binder diamond abrasive product used for accurate grinding

A precision grinding and diamond technology, applied in grinding/polishing equipment, grinding equipment, metal processing equipment, etc., can solve the problems of long delivery time, high price, complicated purchase procedures, etc., and achieve less internal defects, organization Uniform, highly reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Formed grinding wheel features: 5306-30×50×6-RVD M10 / 20B 100

[0055] raw material

diamond

liquid polyimide

Nano

Cu powder

Cr 2 o 3

ZnO

[0056] (10-20μm)

Amine resin

SiO 2

(15μm)

wt%

31

30

2

18

10

9

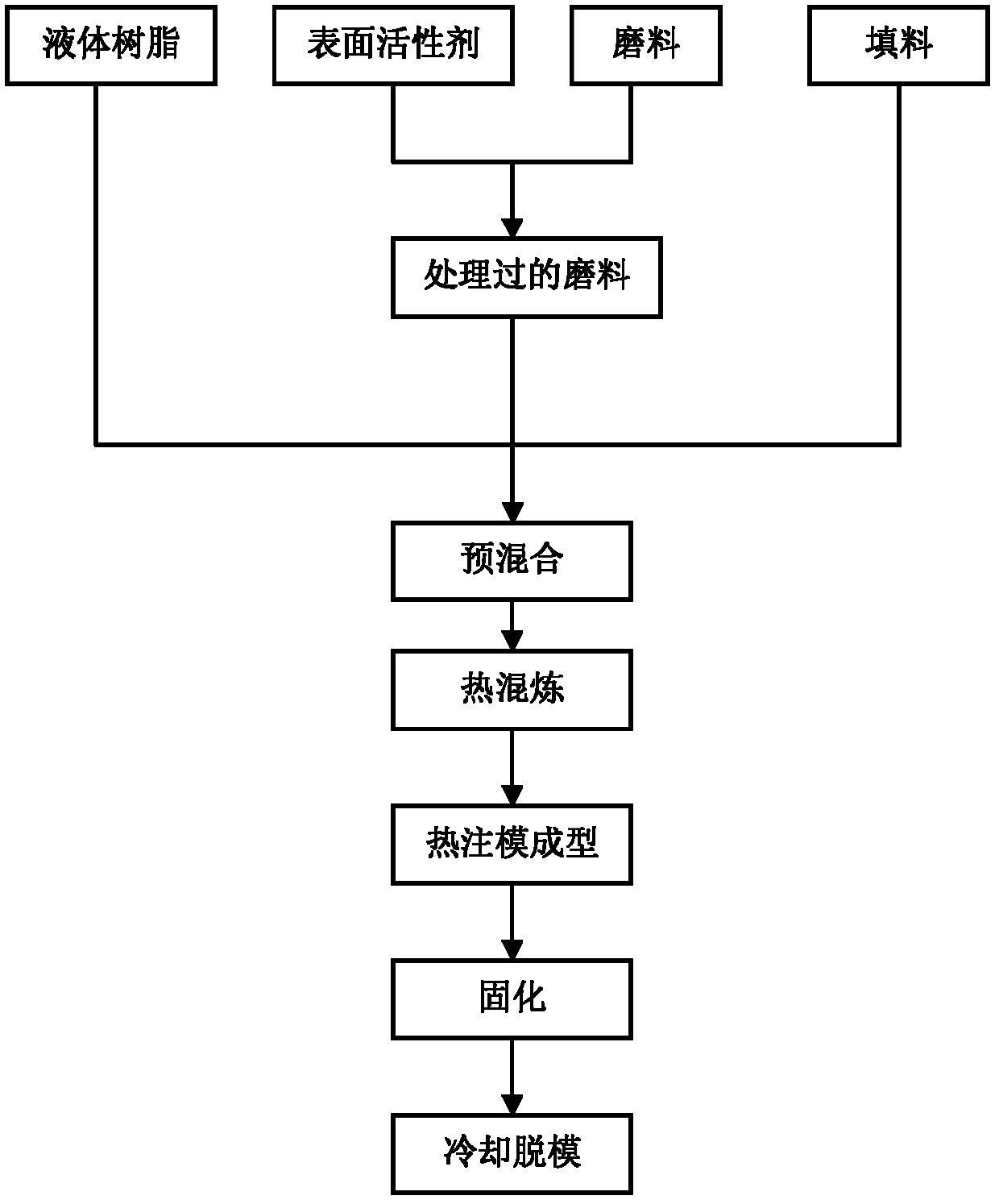

[0057] Carry out surface treatment to diamond abrasive with oleic acid, dosage is 3ml / kg diamond abrasive, carry out weighing and measuring according to the proportion, then add ball mill in the ball mill tank (15r / min) 0.5h, can obtain the diamond abrasive of surface treatment .

[0058] Calculate and weigh the raw materials according to the formula in the above table, and pre-mix them, then add them to a temperature-controlled mixing device, and heat-mix at a temperature of 80±5°C to form a uniform and plastic molding material.

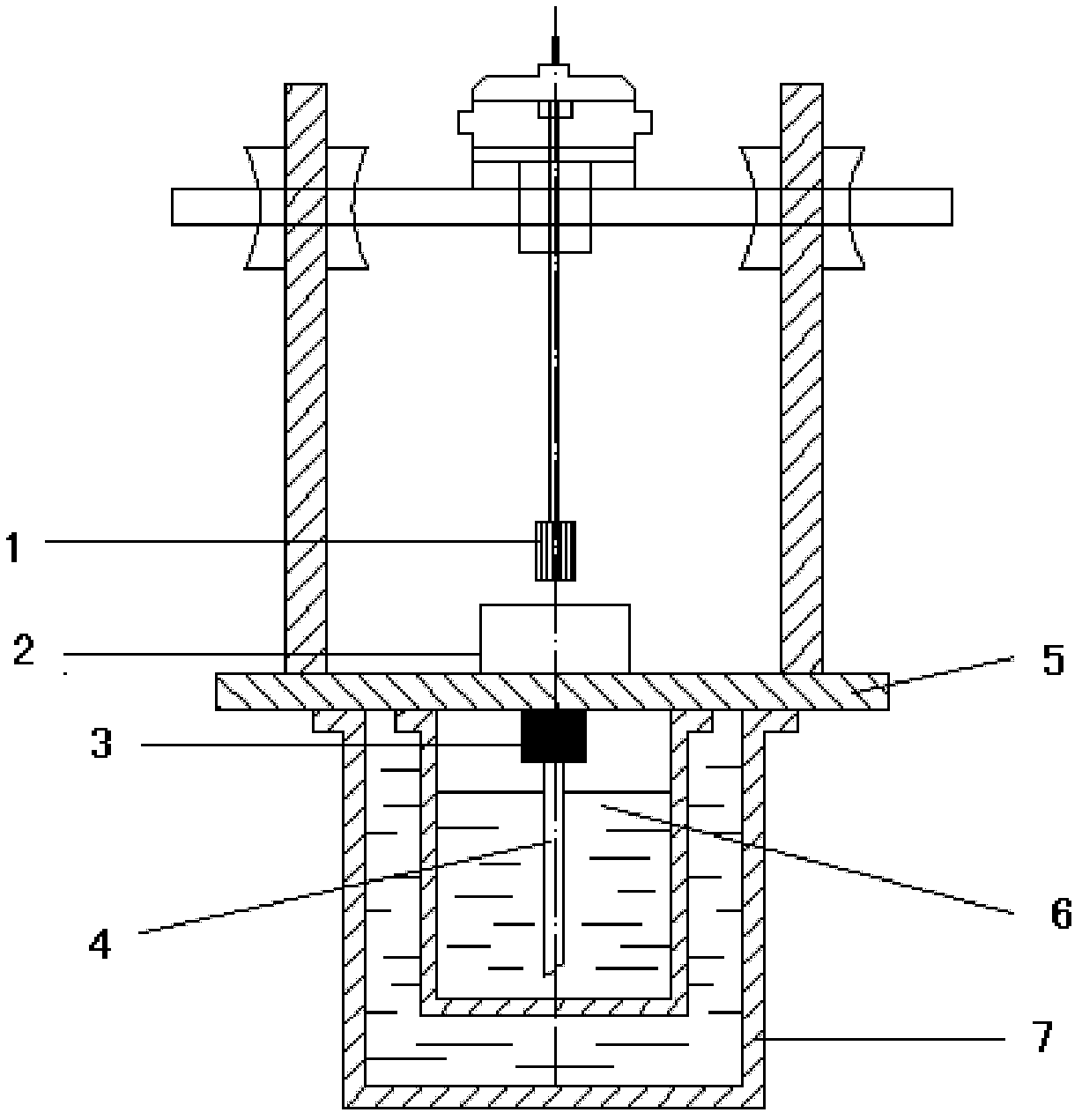

[0059] Put the above molding material into the hot injection molding device, control the temperature of the molding mat...

Embodiment 2

[0062] Formed grinding wheel features: 6-10 x 6.5 x 4-2, 2-RVD M5 / 10B 100

[0063]

[0064] Carry out surface treatment to diamond abrasive with oleic acid, consumption is 4ml / kg diamond abrasive, carry out weighing and measuring according to the proportion, then add ball mill in the ball mill tank (15r / min) 0.5h, can obtain the diamond abrasive of surface treatment .

[0065] Calculate and weigh the raw materials according to the formula in the above table, and pre-mix them, then add them to a temperature-controlled mixing device, and heat-mix at a temperature of 80±5°C to form a uniform and plastic molding material.

[0066] Place the above-mentioned molding material in a hot injection molding device, control the temperature of the material at 80±5°C and the mold temperature at 70±5°C, inject the molding material into the mold under a pressure of 0.5MPa, keep the temperature and pressure for 2 minutes, and finally take the mold Carry out the curing of the grinding wheel,...

Embodiment 3

[0068] Formed grinding wheel features: 6-10 x 6.5 x 4-2, 2-RVD M5 / 10B 100

[0069]

[0070] Use a silane coupling agent to carry out surface treatment on the diamond abrasive, the amount of coupling agent is 2ml / kg abrasive, weigh and measure according to the proportion, add it to a beaker filled with an appropriate amount of toluene, and then carry out ultrasonic dispersion, and mix it after ultrasonic 20min The solution was transferred to a three-necked flask, passed through cooling water, heated to the reflux temperature of toluene for 3 hours, then cooled to room temperature, filtered, and dried at 80°C for 10 hours to obtain the treated diamond abrasive.

[0071] Calculate and weigh the raw materials according to the formula in the above table, and pre-mix them, then add them to a temperature-controlled mixing device, and heat-mix at a temperature of 70±5°C to form a uniform and plastic molding material.

[0072] Place the above-mentioned molding material in a hot inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com