X65MS/X70MS spiral submerged-arc welded pipe with excellent SSCC (Sulfide Stress Corrosion Cracking) stress corrosion resistance as well as manufacturing method thereof

A stress corrosion and submerged arc welded pipe technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of large residual stress and poor uniformity of the welded pipe, achieve low residual stress, less band segregation, and prevent the occurrence of SSCC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

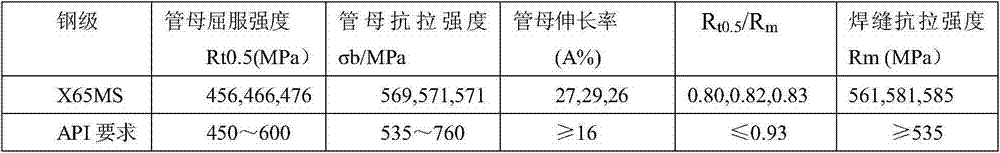

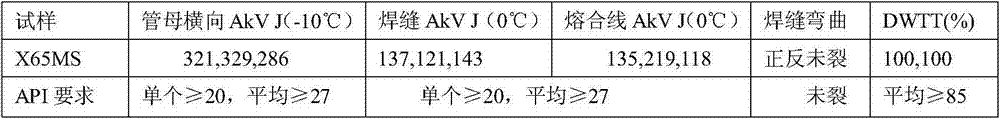

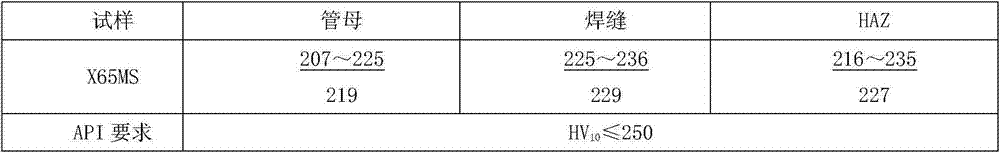

[0026] Example 1: Φ508×9.5mmX65MS steel grade SSCC stress corrosion resistant spiral submerged arc welded pipe and its manufacture

[0027] 1) Raw material

[0028] The X65MS steel plate with a wall thickness of 9.5mm is used, and its chemical composition is analyzed in the following table (wt%):

[0029] Table 1X65MS chemical composition analysis (wt%)

[0030] C

mn

Si

P

S

Al

Mo

B

Nb+V+Ti

Cu+Ni+Cr

0.05

1.20

0.21

0.009

0.001

0.03

0.006

0

0.07

0.10

[0031] 2) After edge milling, the up-groove angle is 60°, and the blunt edge height is 7-7.5mm;

[0032] 3) According to the actual yield strength level of the coil, adopt the external control forming method, precisely measure and control the position and angle of each forming roller, adjust the inclination angle of the 1# roller to 19° and the inclination angle of the 3# roller to 28°, and reasonably adjust the pressure of the 2# roller ...

Embodiment 2

[0058] Example 2: Manufacture of X70MSΦ711×10mm hydrogen sulfide corrosion-resistant spiral submerged arc welded pipe

[0059] 1) Raw materials

[0060] The X70MS steel plate with a wall thickness of 10mm is used, and its chemical composition is analyzed in the following table (wt%):

[0061] Table 8X70MS chemical composition analysis (wt%)

[0062] C

mn

Si

P

S

Al

Mo

B

Nb+V+Ti

Cu+Ni+Cr

0.05

1.17

0.21

0.007

0.0007

0.027

0.006

0.0004

0.12

0.50

[0063] 2) Edge milling: After edge milling, the angle of the upward groove is 110°, and the height of the blunt edge is 8.5mm;

[0064] 3) Forming: According to the actual yield strength level of the coil, adopt the external control forming method, precisely measure and control the position and angle of each forming roller, adjust the inclination angle of the 1# roller to 18° and the inclination angle of the 3# roller to 26°, and adjust the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com