Patents

Literature

31results about How to "Strong and tough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing rotary drill creeper tread material

The present invention is process of preparing material for track block of rotary drilling machine. The material contains C 0.28-0.34 wt%, Cr 0.6-0.8 wt%, Mn 1.0-1.2 wt%, Si 0.5-0.9 wt%, Mo 0-0.4 wt%, RE 0.03-0.05 wt% and P+S less than 0.04 wt% and is smelted in MF inducing electric furnace. The preparation process includes deoxidation with Al in the amount of 0.3-0.6 wt% of molten steel while the molten steel is heated to overheat of 1600-1620 deeg.c, tapping at 1580-1600 deg.c, casting at 1530-1560 degg.c, forming in surface dry water glass sand mold, heating to 840-860 deg.c, maintaining for 50-70 min, lowering in the furnace to 720-750 deg.c, temperature equalization for 0.5 hr, water quenching outside the furnace, tempering at 520-540 deg.c for 50-70 min. The present invention has the advantages of high toughness, low cost, simple production process and long service life.

Owner:UNIV OF SCI & TECH BEIJING

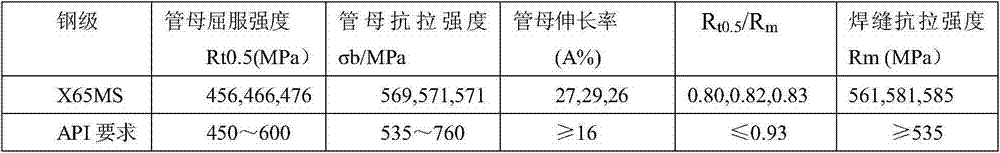

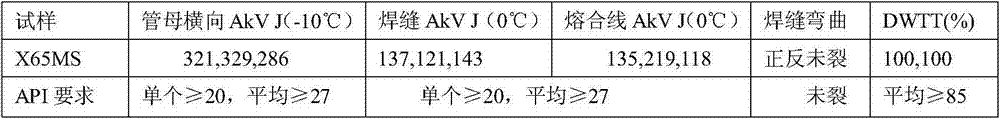

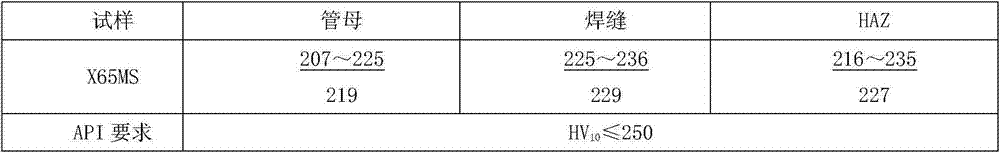

X65MS/X70MS spiral submerged-arc welded pipe with excellent SSCC (Sulfide Stress Corrosion Cracking) stress corrosion resistance as well as manufacturing method thereof

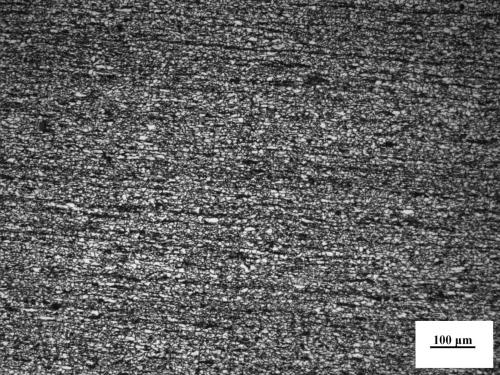

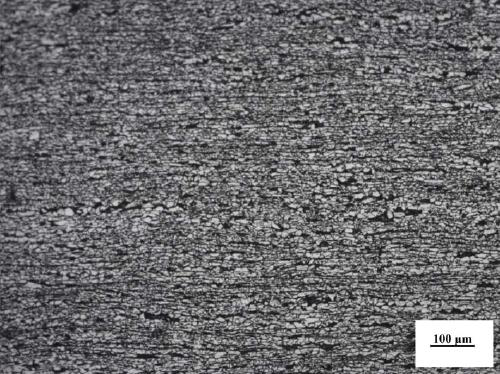

ActiveCN103540834AUniform tissueImprove anti-SSCC performanceFurnace typesHeat treatment furnacesEnergy controlTest sample

The invention discloses an X65MS / X70MS spiral submerged-arc welded pipe with excellent SSCC (Sulfide Stress Corrosion Cracking) stress corrosion resistance as well as a manufacturing method thereof. In a welded pipe manufacturing process, the X65MS / X70MS steel-level spiral submerged-arc welded pipe with high strength, high toughness and excellent SSCC stress corrosion resistance can be obtained by mainly adopting technologies such as low-stress forming, anti-corrosion wire welding and flux welding and heat input line energy control. The X65MS / X70MS steel-level spiral seam submerged-arc welded pipe disclosed by the invention has excellent H2S corrosion resistance; an SSCC test is carried out in liquor A by adopting NACE (National Association of Corrosion Engineer) TM0177 standards, specified yield strength stress level of over 90% sigma s is applied, a stretching surface of a test sample is perfect without appearing any cracks, and therefore, the X65MS / X70MS spiral submerged-arc welded pipe is suitable for a high-pressure large-flow oil field gathering pipeline or being used for conveying an acidic oil-gas medium.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

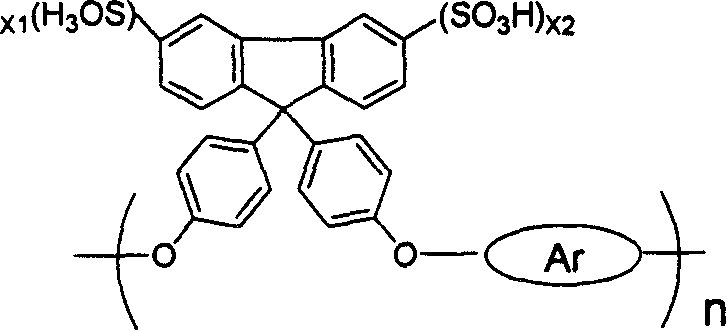

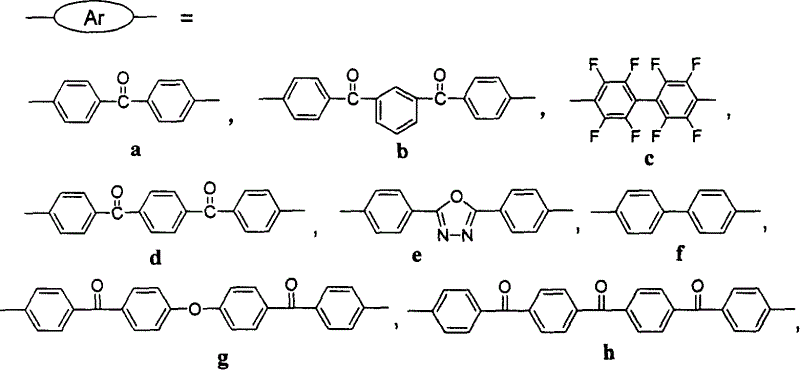

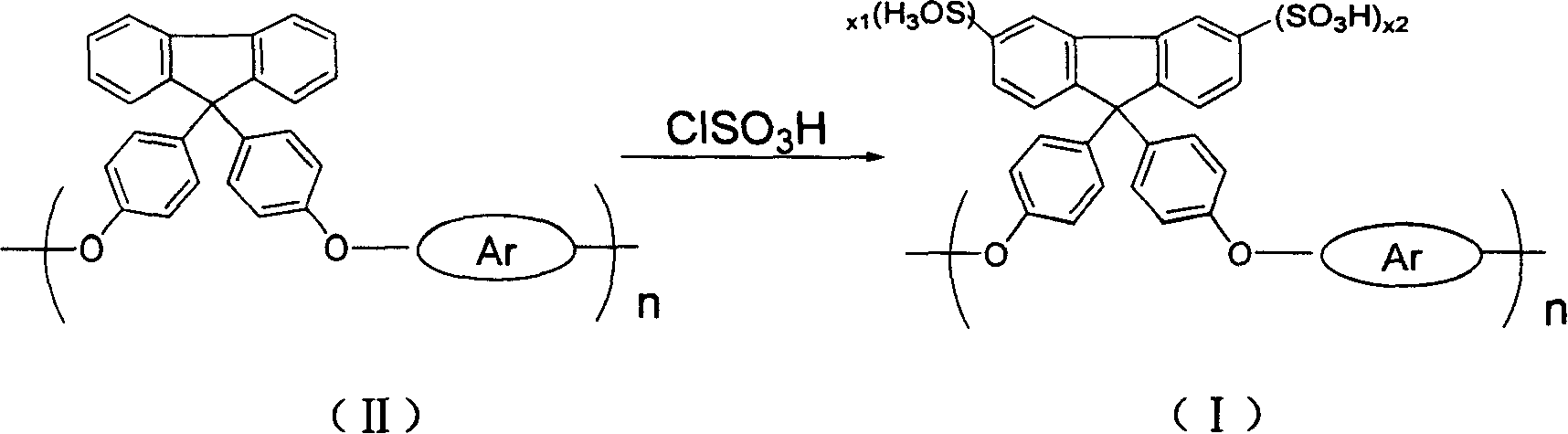

Sulfonated fluorine-containing poly-arylether (arone) and its preparing method and use

InactiveCN1621431ALow costLow priceChemical recyclingFuel cell detailsComposite filmChlorosulfuric acid

The present invention relates to one kind of sulfonated fluorene-containing polyaryl ether (ketone) and its application in preparing proton exchanging film. The sulfonated fluorine-containing polyaryl ether (ketone) may be prepared through polymerization of 9, 9-(4, 4-dihydroxyphenyl) fluorene and chloric or fluorous arone (arene) to form polyaryl ether (ketone); and the subsequent sulfonation with chlorosulfonic acid in the controlled consumption for controlled product sulfonation degree. The sulfonated fluorine-containing polyaryl ether (ketone) may be dissolved in different polar solvents before being cast to form single-component film, or be mixed with other polymer material for preparing composite film, or be mixed with heteropoly acid and other inorganic matter for preparing hetero film; and all these kinds of film have the advantages of low cost, high stability, high water absorption, small equivalent molecular weight, etc. and are expected to find use in fuel cell.

Owner:SUN YAT SEN UNIV

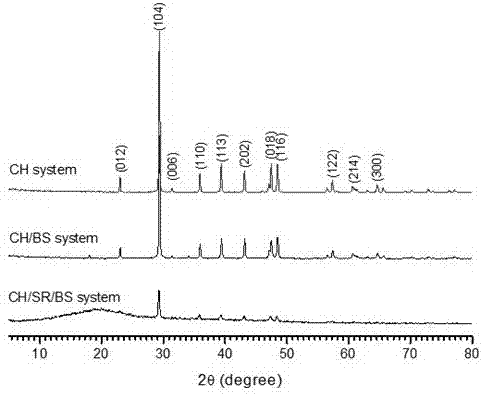

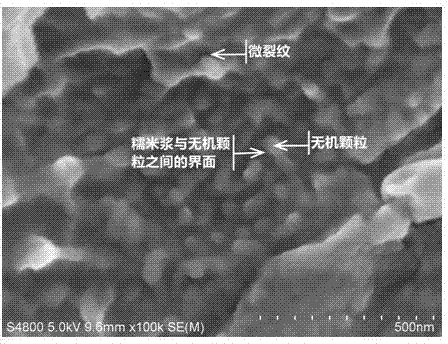

High-performance historic site repair material and preparation method thereof

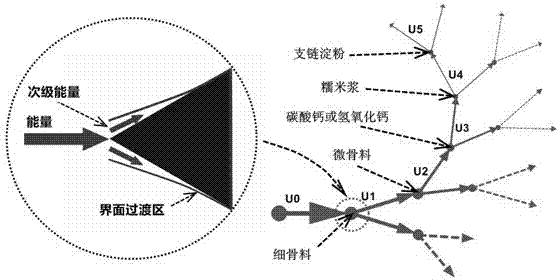

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

Modified water-based acrylate laminating adhesive used for plastic film compositing and preparation method and application thereof

ActiveCN103059783AImprove stabilityStrong and toughNon-macromolecular adhesive additivesSynthetic resin layered productsWater basedKetone

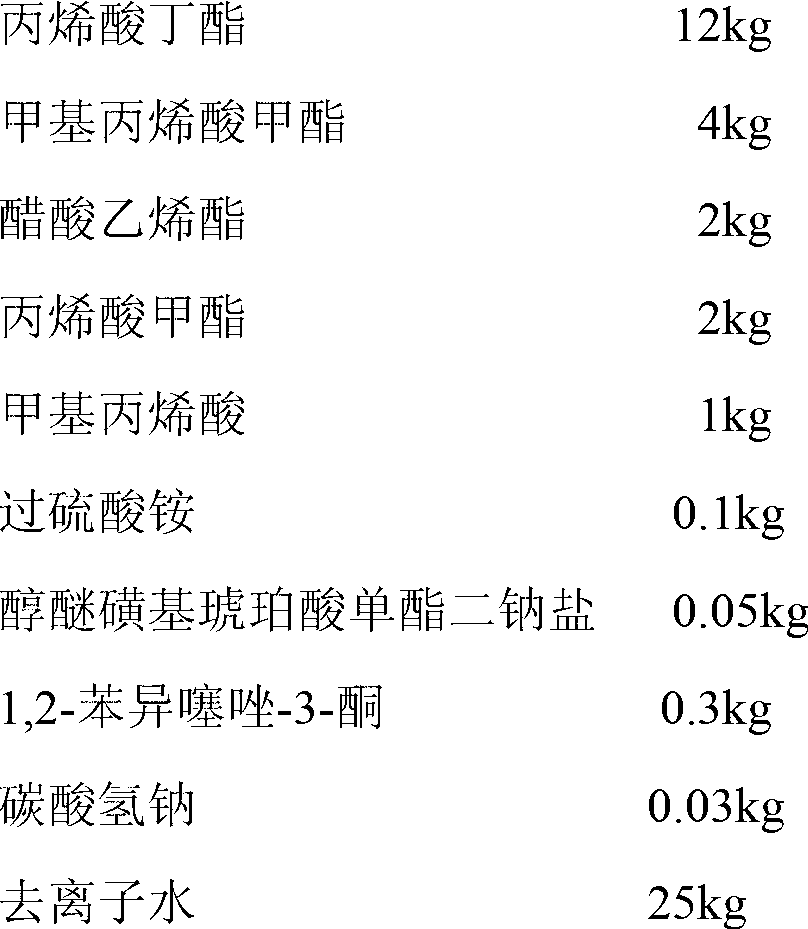

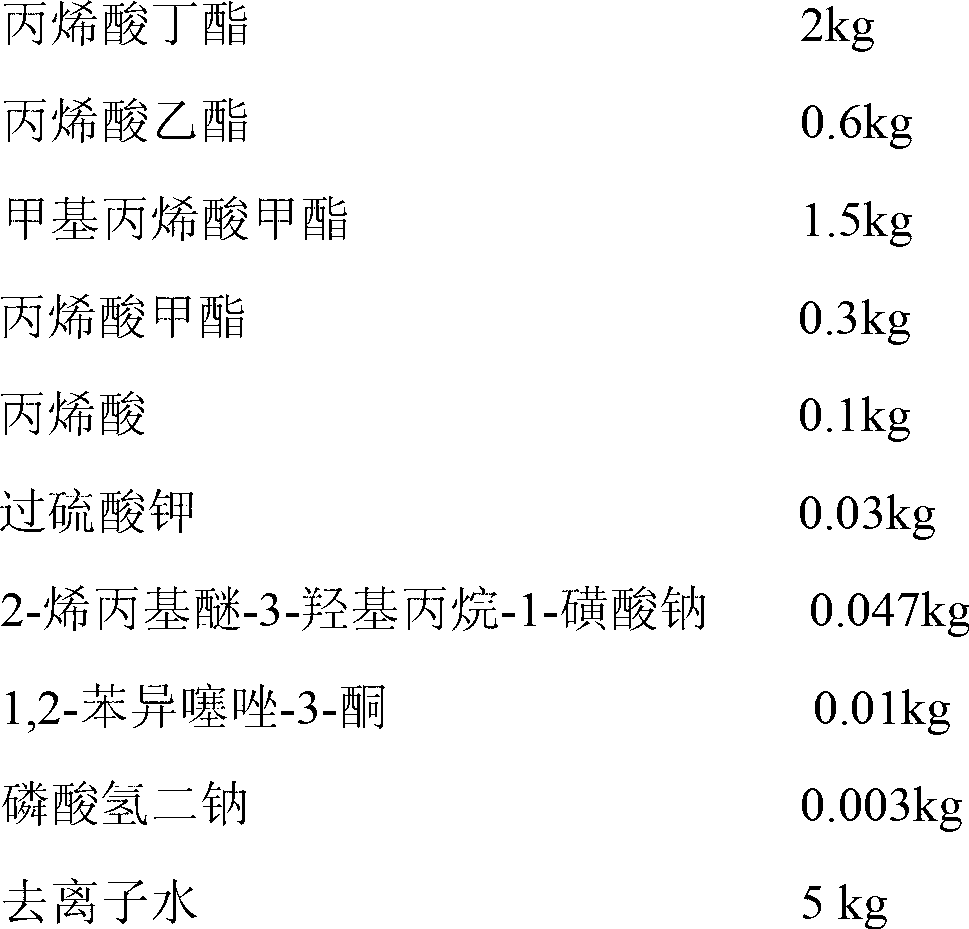

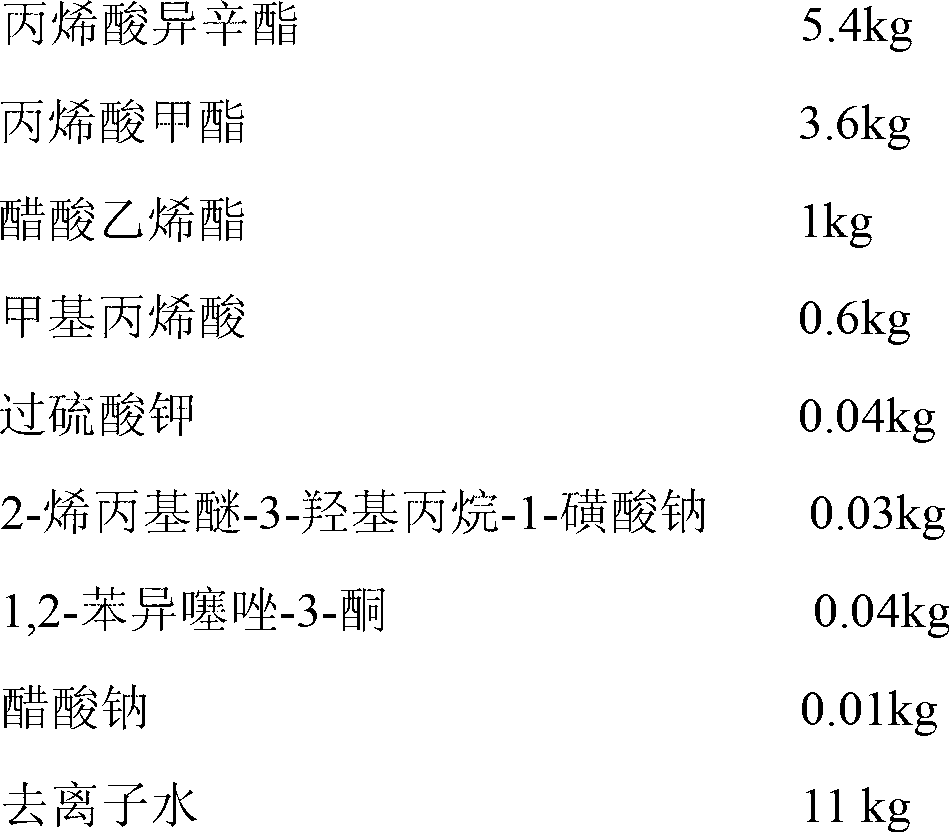

The invention discloses modified water-based acrylate laminating adhesive used for plastic film compositing, and a preparation method and application of the modified water-based acrylate laminating adhesive. The laminating adhesive is prepared from compound emulsion and crosslinking agent, wherein the compound emulsion contains ethylene-acrylic acid emulsion (EAA emulsion) and acrylate emulsion, and the acrylate emulsion is prepared from soft monomers, hard monomers, crosslinking monomers, initiator, emulsifier and antiseptic 1, 2-benzene isothiazole-3-ketone. Due to the fact that the EAA emulsion is strong in the adhesive capacity to film base material and good in compatibility with the acrylate emulsion system, moreover the crosslinking agent polyether imide and the antiseptic 1, 2-benzene isothiazole-3-ketone are added, the obtained modified water-based acrylate laminating adhesive is good in compatibility among the component, capable of enabling the EAA to be cross-linked with long-chain molecules of the acrylate when the modified water-based acrylate laminating adhesive is dried to form a film, good in adhesion to the film base material, high in bonding strength and peel strength, good in stability and coating property and capable of effectively restraining the phenomenon of latex moulding and prolonging the quality guarantee period, and meanwhile has stability of the acrylate emulsion and the obdurability of the EAA emulsion.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Stainless steel seamless tube for sodium-cooled fast reactor and preparation method of stainless steel seamless tube

The invention discloses a stainless steel seamless tube for a sodium-cooled fast reactor. Microalloying component fine adjustment is carried out based on a 316H stainless steel base material, the stainless steel seamless tube comprises the following components in percentage by mass: 0.04-0.05% of C, less than or equal to 0.6% of Si, 1.00-2.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 17.0-18.0% of Cr, 11.5-12.5% of Ni, 2.50-2.70% of Mo, less than or equal to 0.10% of Cu, 0.05-0.07% of N, less than or equal to 0.0015% of B, less than or equal to 30 ppm of O, less than or equal to 5.0 ppm of H and the balance of Fe and impurities, and the ferrite content is controlled to be less than or equal to 1%. The stainless steel seamless tube for the sodium-cooled fast reactor is manufactured through a high-purity smelting process, microalloying component fine adjustment, a stainless steel casting process, a hot perforation treatment process and finished product cold machining. By means of the mode, the stainless steel seamless pipe for the sodium-cooled fast reactor and a preparation method can meet the use standard of nuclear safety high-temperature nano pipelines, and the stainless steel seamless pipe has obdurability, corrosion resistance and durability.

Owner:高虹

Low-cost chromium-containing Q460MC steel plate and production method thereof

The invention discloses a low-cost chromium-containing Q460MC steel plate and a production method thereof. The low-cost chromium-containing Q460MC steel plate comprises the following chemical components in percentages by weight: 0.08%-0.11% of C, 0.10%-0.20% of Si, 1.30%-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.005% of S, 0.015%-0.035% of Als, 0.030%-0.040% of Nb, 0.15%-0.25% of Cr, 0.010%-0.020% of Ti and the balance of Fe and inevitable impurities. The production method comprises the steps of converter smelting, refining, continuous casting, heating, rough rolling, finish rolling and cooling. Through the design of alloy components, no V element is added, the cheap Cr element is used for solution strengthening and hardenability improvement, the TMCP production process is optimized, and finally the steel plate with high strength, high toughness and low cost is obtained.

Owner:HEBEI PUYANG IRON & STEEL

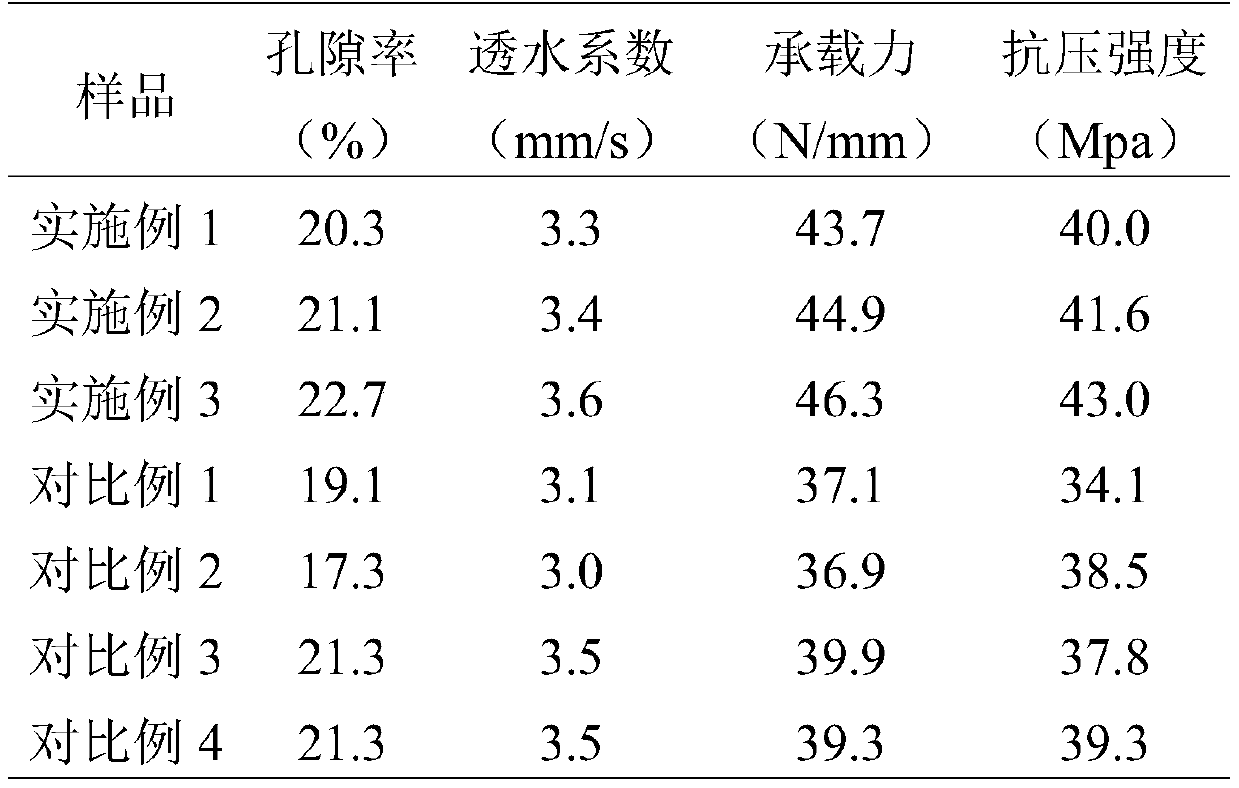

Water-permeable concrete and preparation method thereof

The invention discloses water-permeable concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 10-15 parts of acrylate water-based laminating adhesive, 1500-1600 parts of crushed stone, 100-200 parts of super absorbent resin microspheres, 300-400 parts of cement, 5-7 parts of polyol, 5-10 parts of triisopropanolamine, 10-15 parts of nano calcium carbonate, 1-5 parts of nano silicon particles, 2-4 parts of sodium lignin sulfonate, 4-6 parts of an emulsifier and 130-160 parts of water. The acrylate water-based laminating adhesive isprepared from an ethylene-acrylic emulsion, an acrylate emulsion and a cross-linking agent; the cross-linking agent comprises polyetherimide. The water-permeable concrete can improve the water permeability and the bearing capacity, is not prone to breakage and has high freezing and thawing resistance and durability.

Owner:XIJING UNIV

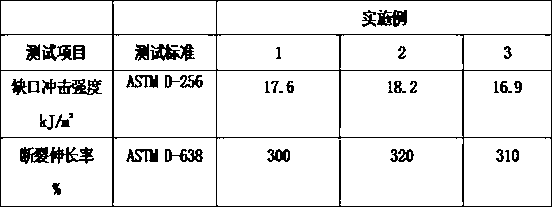

Composite material and lithium ion battery plastic shell made of the same

InactiveCN103102594AStrong and toughWith impact resistanceCell component detailsPolypropyleneHigh-density polyethylene

Relating to the field of battery manufacturing, the invention discloses a composite material and a lithium ion battery plastic shell made of the composite material. The composite material is prepared by mixing the following components by weight: 80%-90% of polypropylene PP; 7%-15% of high density polyethylene HDPE; and 3%-5% of a lubricant. The preparation method of the packaging composite material consists of: (1) mixing and stirring the polypropylene, the high density polyethylene and the lubricant to a uniform state; and (2) placing the uniformly stirred mixture into a screw extruder to perform melt mixing for 2-4min, and controlling the screw temperature at 145DEG C-210DEG C and the screw rotation speed at 200-300rpm. The composite material prepared by the method and an acid and alkali resistant color masterbatch are subjected to blending and baking in proportion, and then subjected to injection molding through an injection mold. The lithium ion battery plastic shell made of the composite material provided in the invention has obdurability and shock resistance.

Owner:DONGGUAN RUNGUANG BATTERY TECH

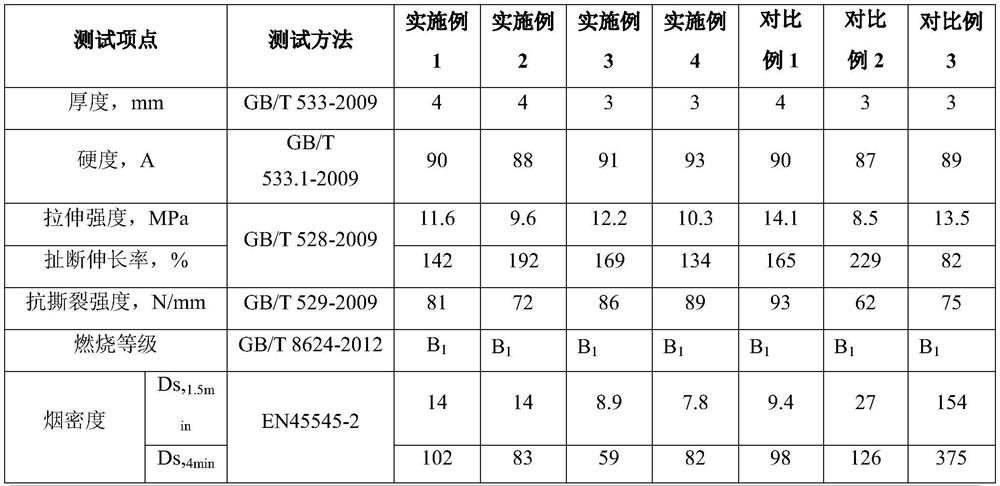

Sound insulation type elastic coiled material floor for rail transit and preparation method thereof

InactiveCN112031330AImprove sound insulationWeight increaseCovering/liningsFlooring insulationsElastomerPolyolefin

The invention discloses a sound insulation type elastic coiled material floor for rail transit and a preparation method of the sound insulation type elastic coiled material floor. The sound insulationtype elastic coiled material floor is formed by hot-pressing compounding of a sound insulation layer and a wear-resistant layer, the sound insulation layer is prepared from the following components including,10-30 parts of polyolefin elastomer, 5-25 parts of styrene elastomer, 60-150 parts of heavy filler, 20-100 parts of a flame retardant and 2-6 parts of auxiliaries, and the wear-resistant layer is prepared from the following components including, 5-30 parts of polyolefin elastomer, 10-30 parts of styrene elastomer, 5-30 parts of wear-resistant reinforced resin, 10-60 parts of a flame retardant, 1-8 parts of a compatilizer, 2-15 parts of a wear-resistant agent and 2-5 parts of auxiliaries. Through compounding of the sound insulation layer and the wear-resistant layer, the sound insulation performance of the coiled material floor is greatly improved, additional use of sound insulation materials is reduced, the comprehensive cost is reduced, the coiled material floor has lower smoke density and smoke toxicity, zero plasticizer addition can be achieved, and the coiled material floor has very good environmental friendliness.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Ice skate blade provided with alloy coating and used for skating shoes

The invention provides an ice skate blade provided with an alloy coating and used for skating shoes. A matrix blade of the ice skate blade is subjected to heat treatment, different hardness degrees required by different parts of the ice skate blade are obtained, so that after being coated with the coating, the ice skate blade body has rigidity and toughness of resisting and transmitting ice push-off power, and a cutting edge can be wear-resistant enough and has surface roughness as small as possible. Besides, alloy coated powder of the skate blade alloy coating adopts a specific alloy element composition proportion, so that the hardness of the alloy coating is remarkably improved, and the ice skate blade has quite high wear resistance, good hardness and oxidation resistance.

Owner:HUAINAN BAIBANG PNEUMATIC TECH CO LTD

Nano bamboo carbon PTT enhanced master batch

The invention discloses a nano bamboo carbon PTT enhanced master batch. The nano bamboo carbon PTT enhanced master batch comprises the following ingredients, by weight, 15%-50% of PTT resins, 10%-30% of glass fibers, 15%-40% of nano bamboo carbon, 10%-25% of ACR, 3%-8% of compatibilizers, 2%-5% of heat resistant agents and 0.5%-3% of dispersants. The beneficial effects are that the enhanced master batch has functions of no pollution, high dispersion, high intensity, and strong adsorption, sterilization, deodorizing, purifying and anti ultraviolet functions, when 5%-15% of the enhanced master batch is added in PTT production, good sterilization, toughening, reinforcing and anti-ultraviolet modification effects are achieved, the heat resistance, processing properties and appearance quality of the material are raised obviously, the production cost is lowered, and the production efficiency is raised.

Owner:QINGDAO XINZHAN PLASTIC

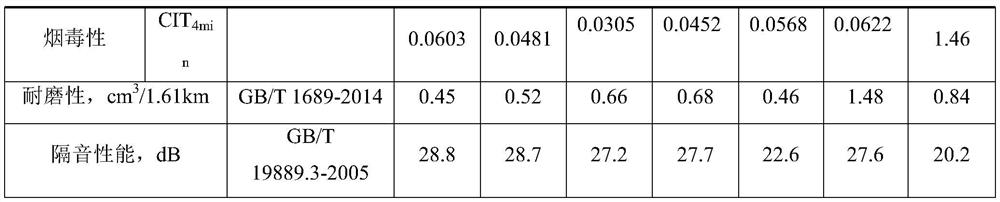

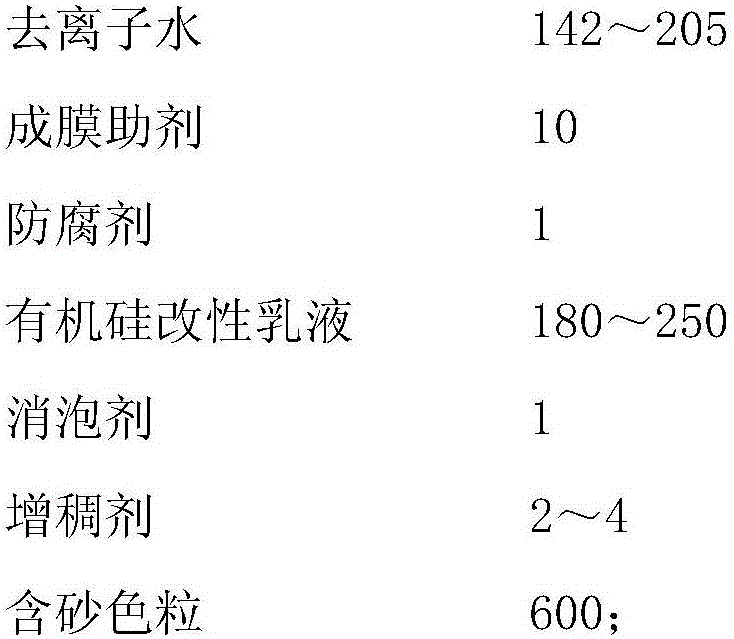

Sand-in-water environment-friendly paint achieving wet-on-wet construction with high build paint and preparation method of sand-in-water environment-friendly paint

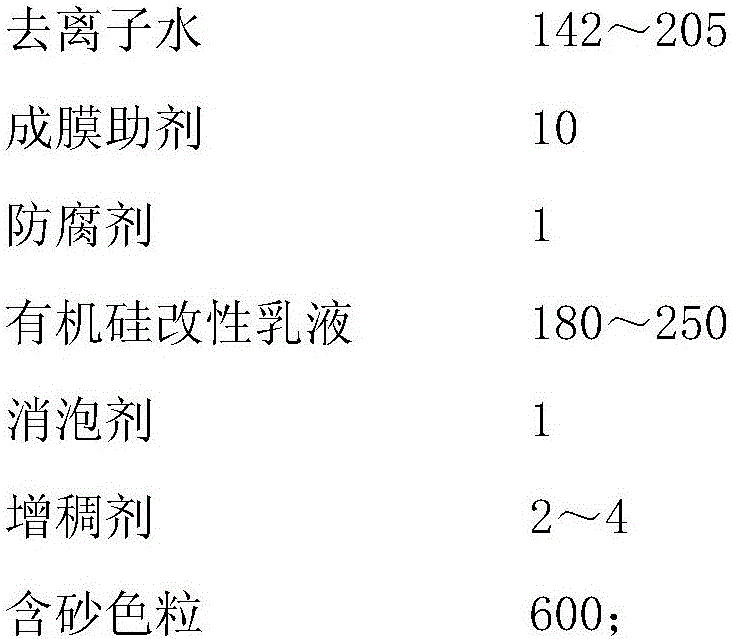

The invention discloses sand-in-water environment-friendly paint achieving wet-on-wet construction with high build paint and a preparation method of the sand-in-water environment-friendly paint. The sand-in-water environment-friendly paint is prepared from deionzed water, a coalescing agent, an anti-corrosive agent, organosilicone-modified emulsion, a defoaming agent, a thickening agent and sand-containing colored particles by weight, wherein the sand-containing colored particles are prepared from basic paint with various colors and a protective adhesive according to the weight ratio of (75-80):60. According to the paint, the prepared sand-containing colored particles not only are higher in texture, but also cannot precipitate to the bottom to influence the appearance and construction due to the fact that the sand-containing colored particles contain natural colored sand; in construction, an imitation burnt stone litchi surface effect can be obtained by directly spraying the sand-in-water environment-friendly paint in a wet state after high build paint construction is completed, one-time forming is achieved, the construction time is greatly shortened, and the material cost is greatly reduced; in addition, the organosilicone-modified emulsion is used in the paint, a film not only has the good leakproofness on a substrate, but also has the excellent weather resistance and stability, and meanwhile due to the fact that the emulsion does not contain APEO, the low-emission green and environment-friendly requirements are met.

Owner:FIRST NEW MATERIAL TECH DEV

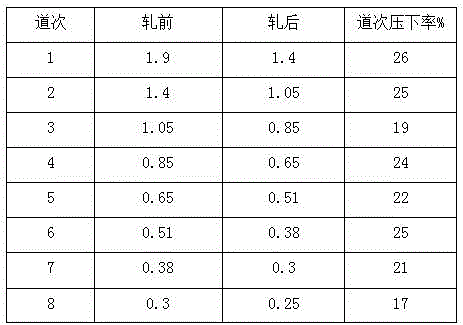

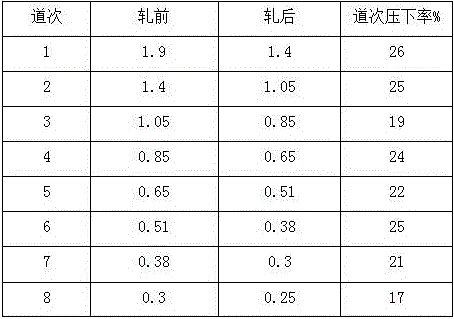

Process for realizing sorbitizing cold rolling of high-strength and high-fatigue spring narrow band steel

InactiveCN106399647AStrong and toughExcellent cold workabilityFurnace typesHeat treatment furnacesQuenchingNarrow band

The invention discloses a process for realizing sorbitizing cold rolling of high-strength and high-fatigue spring narrow band steel. High-carbon steel SK5 with the thickness of 2.5mm is selected; the process comprises the process routes of unreeling and shelling, pickling, temper rolling, reeling, first-stage cold rolling, isothermal quenching, second-stage cold rolling, striping and packaging; process parameters are set as follows: the outlet thickness of a temper rolling mill is set to be 2.3mm; the first-stage cold rolling thickness is 1.9mm; lead bath is adopted in isothermal quenching, the lead bath entering temperature is 790 DEG C, the lead bath temperature is 420 DEG C, the band steel running speed is 2.0m / min, water cooling is carried out after a structure is taken out of the lead bath, and the structure taken out of the lead bath is required to be a sorbite; and a finished product with the thickness of 0.25mm is rolled by three rolling processes in the second-stage cold rolling. A safety belt collecting coil spring produced by using the process disclosed by the invention is subjected to durability test for 90000 times or above, so that the requirement for materials of medium-high-end cars is met.

Owner:NANJING IRON & STEEL CO LTD

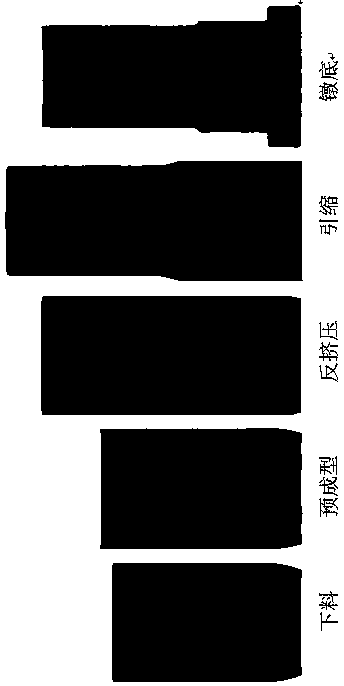

All-fiber shaping method for deep-hole shell copper component

The invention discloses an all-fiber shaping method for a deep-hole shell copper component, which includes the steps of: blanking, homogenized annealing, pre-shaping, reverse-extrusion, cold extrudingthinning and drawing, cold heading and stress relief annealing. In the blanking step, required volume of raw material is calculated according to the structure and shape of the copper component and then a copper rod is cut according to corresponding length; in the homogenized annealing, the green body is thermally treated in a protective atmosphere at maintained temperature of 400-600 DEG C and for temperature maintaining time of 2-2.5 h; in the pre-shaping step, the green body is subjected to upsetting blank production and plastic deformation; the reverse-extrusion is a cold-extrusion process, deformation quantity being about 60%. In the method, through the multi-pass cold-extrusion shaping process, metal fibers and radial structure of metal of the deep-hole shell copper component are notdamaged, so that the method can significantly improve the indices of size precision, surface quality, toughness and the like.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

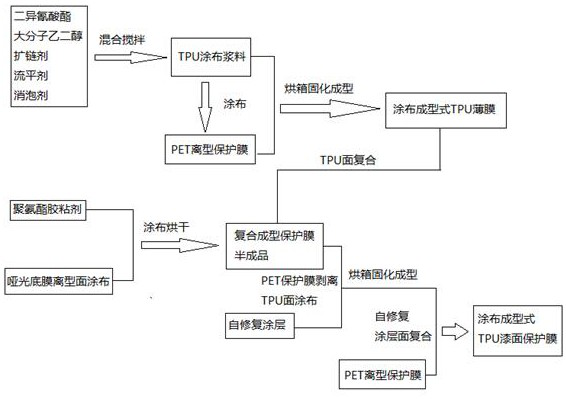

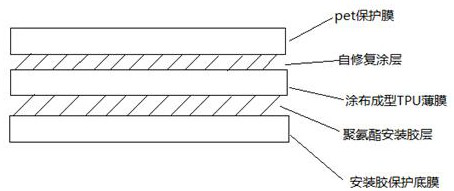

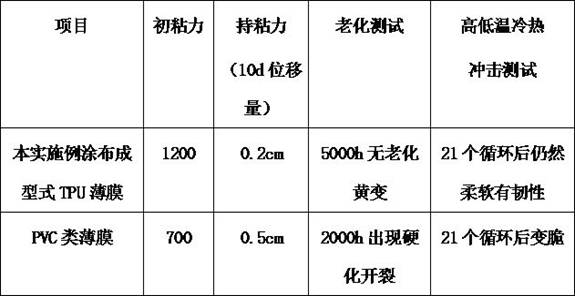

Preparation and application of coating forming type TPU film and coating forming type TPU paint surface protective film

PendingCN114058047AStrong and toughAging resistantFilm/foil adhesivesGlycol synthesisEthylene glycol

The invention discloses preparation and application of a coating forming type TPU film and a coating forming type TPU paint surface protective film. The preparation method comprises the steps of dissolving isocyanate in a solvent, adding macromolecular ethylene glycol to prolong the reaction time, then adding a chain extender, a flatting agent and a defoaming agent, and stirring through a stirrer to prepare a TPU pre-coating material, conveying the TPU pre-coating material to a high-precision coating head, uniformly coating the release surface of a PET release protective film to form a TPU film layer with uniform thickness; and conveying the coated TPU film layer to a drying oven through a conveying device, removing redundant solvent through evaporation, crosslinking and curing the monomers are under the high-temperature condition to form a solid elastic film, and finally rolling and forming the solid elastic film. According to the process, the TPU particle re-forming processing process is omitted, the manufacturing process is greatly simplified and shortened, and the production cost is reduced. The coating forming type TPU paint surface protective film prepared by the invention has the advantages of high stretch rate, high strength and toughness, higher initial adhesion and excellent permanent adhesion.

Owner:海安浩驰科技有限公司

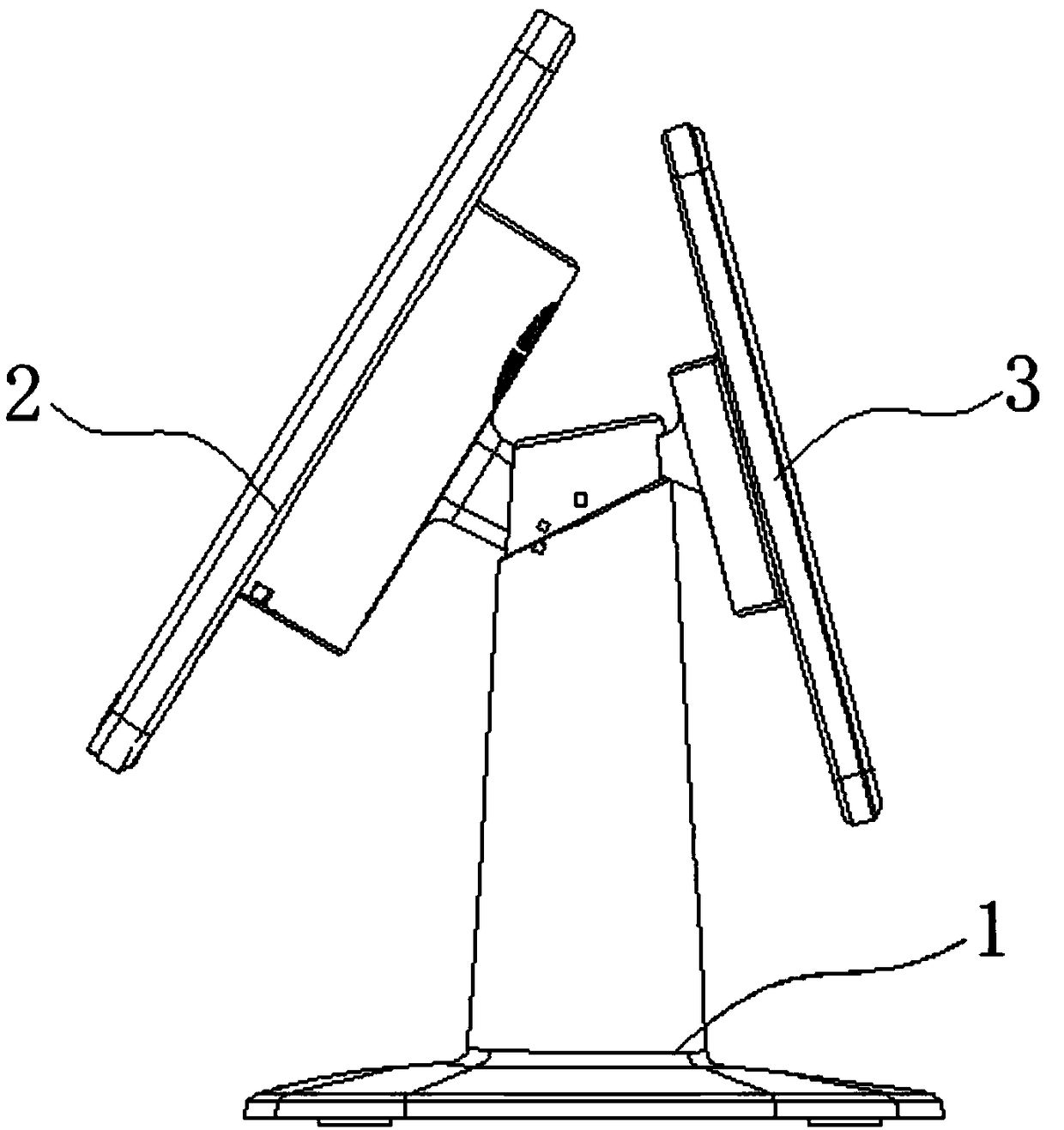

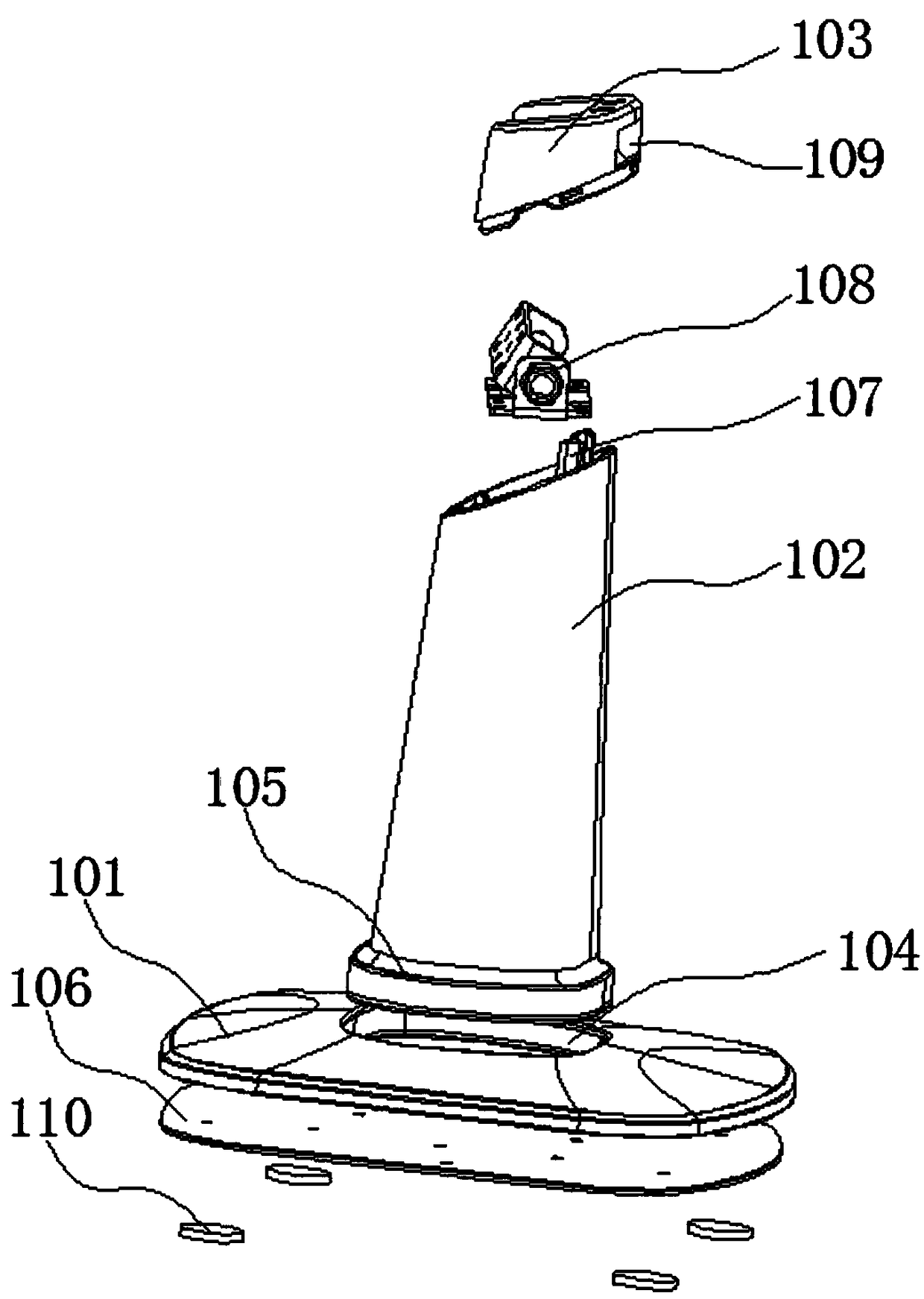

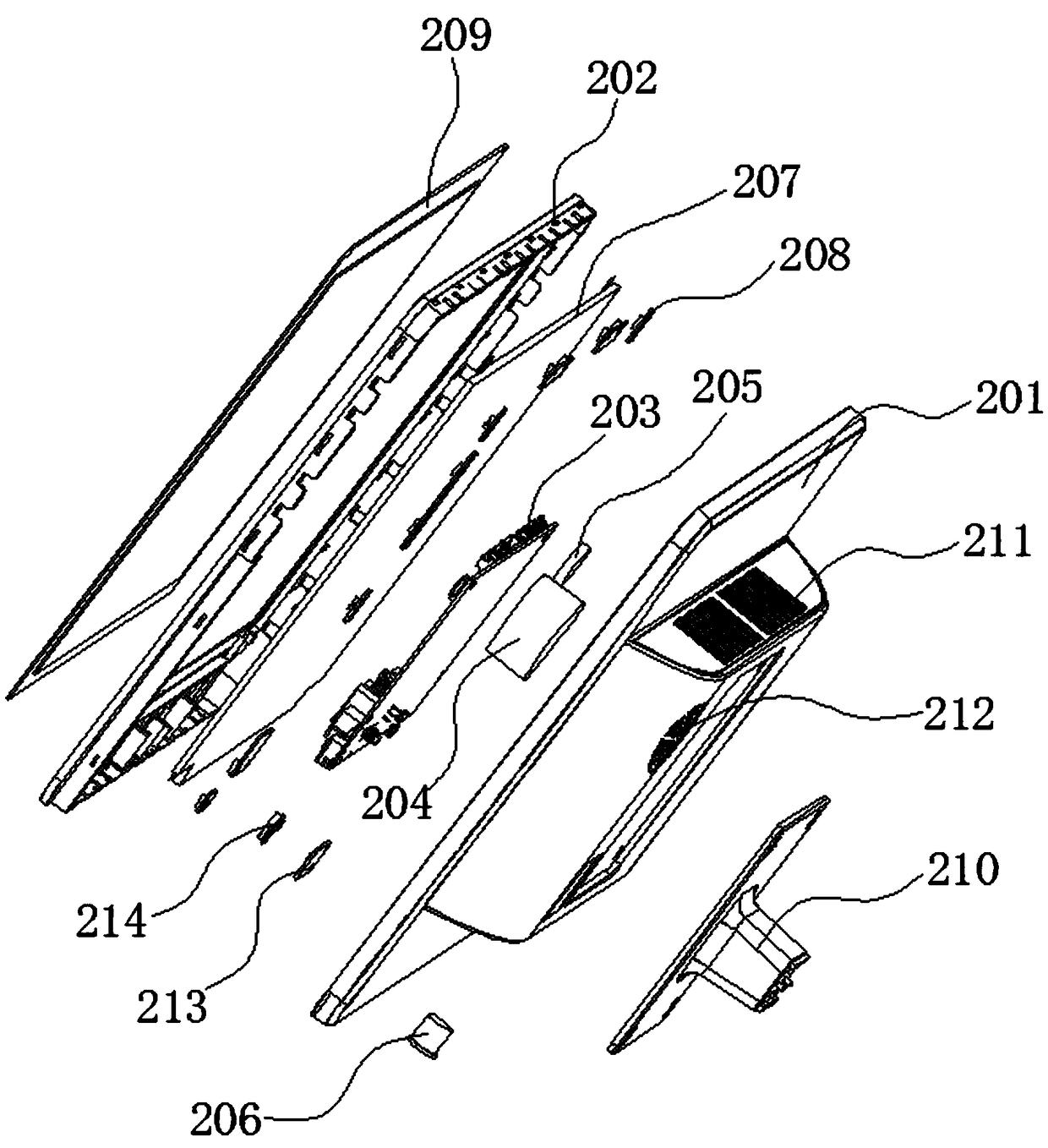

Double-screen cash register

The invention discloses a double-screen cash register, and relates to the technical field of cash registers. The double-screen cash register comprises a base, a main screen and an auxiliary screen, wherein the base comprises a base lower cover, a base middle cover and a base upper cover; the top part of the base middle cover is clamped and fixed with the bottom part of the base upper cover; the middle part of the base lower cover is provided with a groove opening; a clamp block is fixedly arranged at the bottom part of the base middle cover, and is in transition fit with the groove opening; acounterweight block is fixedly arranged at the bottom part of the base lower cover. The double-screen cash register has the advantage that a front casing of the main screen and a back casing of the main screen are fixed together in a clamping way, a front casing of the auxiliary screen and a back casing of the auxiliary screen are fixed together in a clamping way, the groove opening is in transition fit with the clamp block to fix the base middle cover and the base lower cover into a whole, the auxiliary screen is arranged at one side of the base through a clamp strip, a groove channel, an installation groove opening and an installation block, and the main screen is conveniently installed through a hardware rotary shaft and a main screen bracket, so as to solve the problem of low production and assembly efficiency due to inconvenience in installation of the existing cash register.

Owner:宋濂

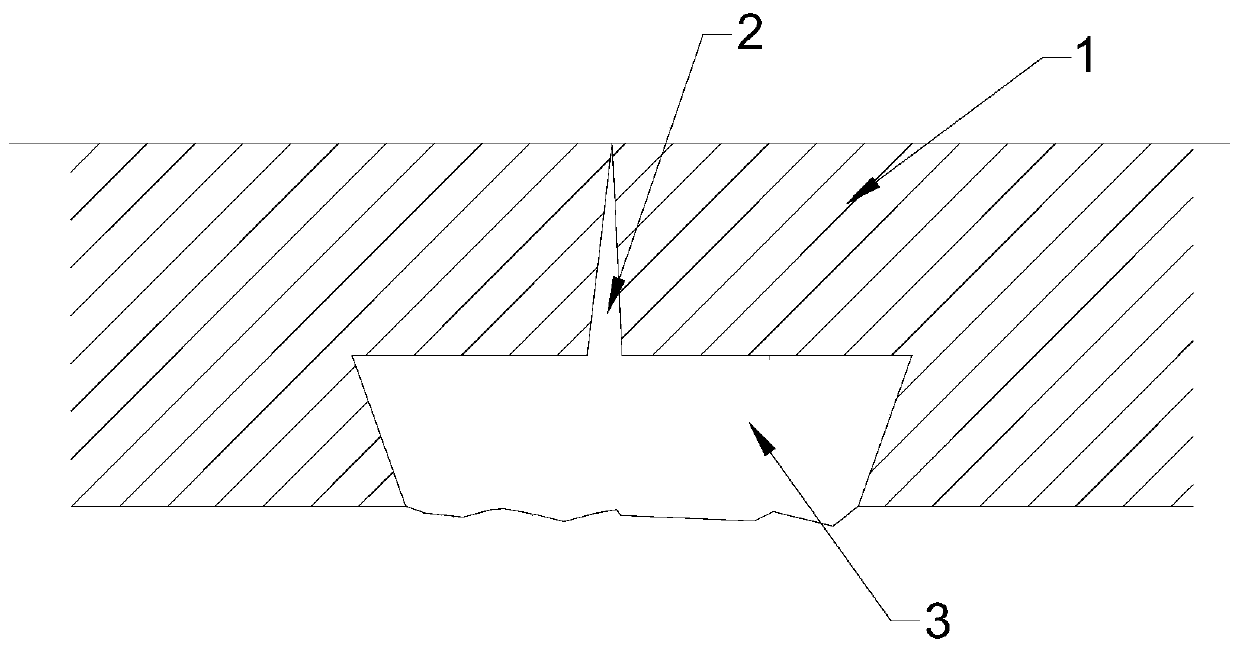

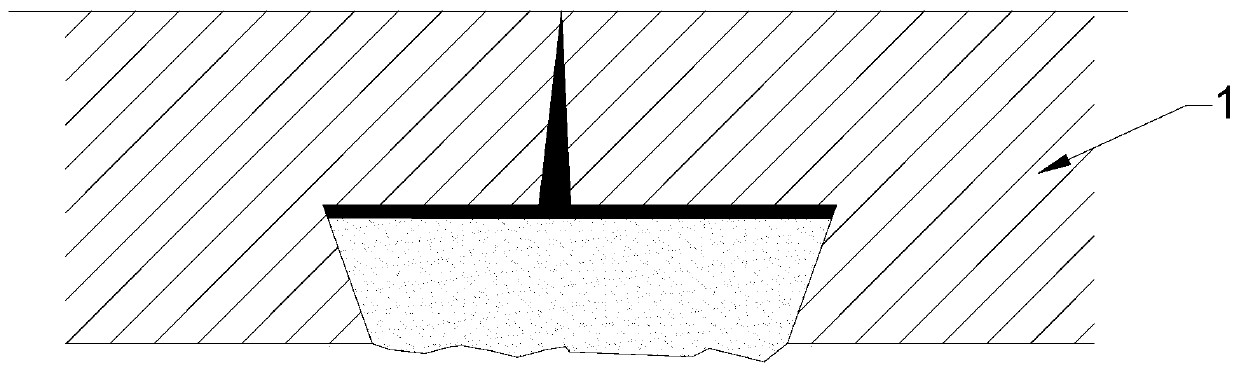

Building exterior wall and structure exterior wall repairing method

The invention provides a building exterior wall and structure exterior wall repairing method which comprises the following steps: (1) cleaning the exterior wall surface, removing stains and mildew spots on the exterior wall surface, and then carrying out drying in the air; (2) cutting a groove on two sides of a crack, cleaning the crack and the groove, and carrying out drying in the air; (3) fullyfilling the crack with a caulk compound, coating the inner surface of the groove with a waterproof agent after the caulk compound is solidified, and carrying out drying in the air; (4) filling the groove with a composite epoxy resin material and carrying out solidification; (5) brushing the exterior wall surface with a mildew inhibitor and carrying out drying in the air; and (6) carrying out coating with the waterproof agent on the mildew inhibitor, and carrying out coating with finishing paint after drying in the air. According to the building exterior wall and structure exterior wall repairing method provided by the invention, the crack can be cut into the groove of which the interior is large and the exterior is small; due to the characteristic that the exterior of the groove is largeand the interior of the groove is small, the separation of the newly-repaired part can be restricted; and the newly-repaired part can be protected against the falling-off phenomenon.

Owner:LIUHEFENG TIANJIN TECH CO LTD

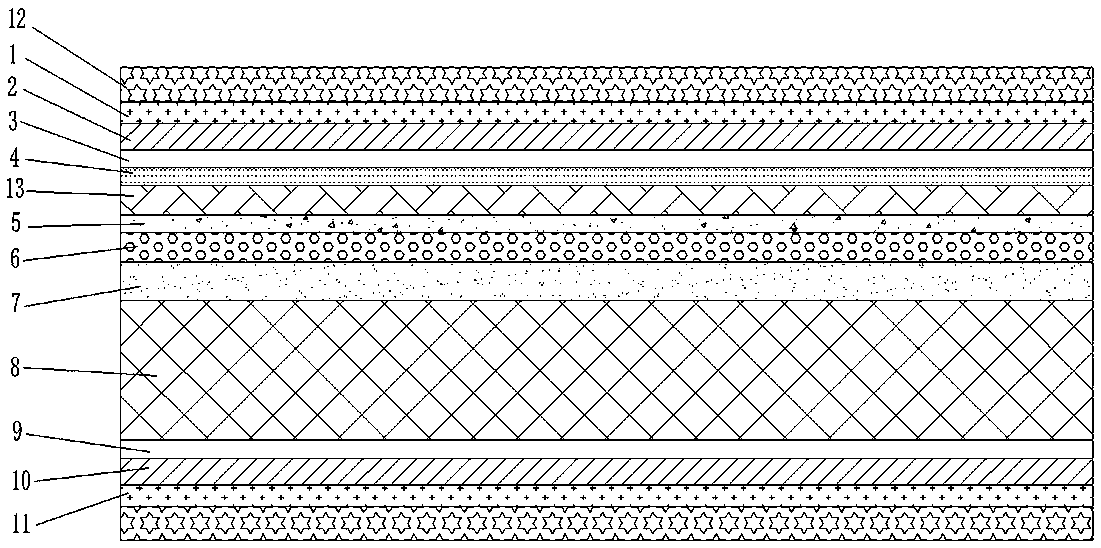

Magnetic mattress

PendingCN107928242ABlock lossIncrease flow rateElectrotherapyStuffed mattressesAromatherapyEngineering

The invention relates to a magnetic mattress, which comprises a mattress body, wherein the mattress body comprises a first bamboo charcoal floss layer, a first bamboo charcoal cotton layer, a first non-woven fabric layer, a far-infrared fibrous layer, a nano fragrance layer, a polyurethane layer, a geomagnetic layer, a foamed pearl cotton layer, a second non-woven fabric layer, a second bamboo charcoal cotton layer and a second bamboo charcoal floss layer in sequence from top to bottom. The magnetic mattress is of a multi-layer structure; the air heat preservation can be increased; the loss ofshell temperature is blocked, and the blood circulation of a human body can be effectively improved.

Owner:兴城舒磁康健康科技有限公司

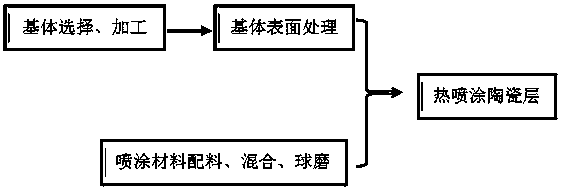

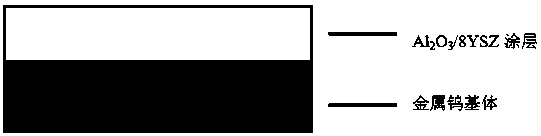

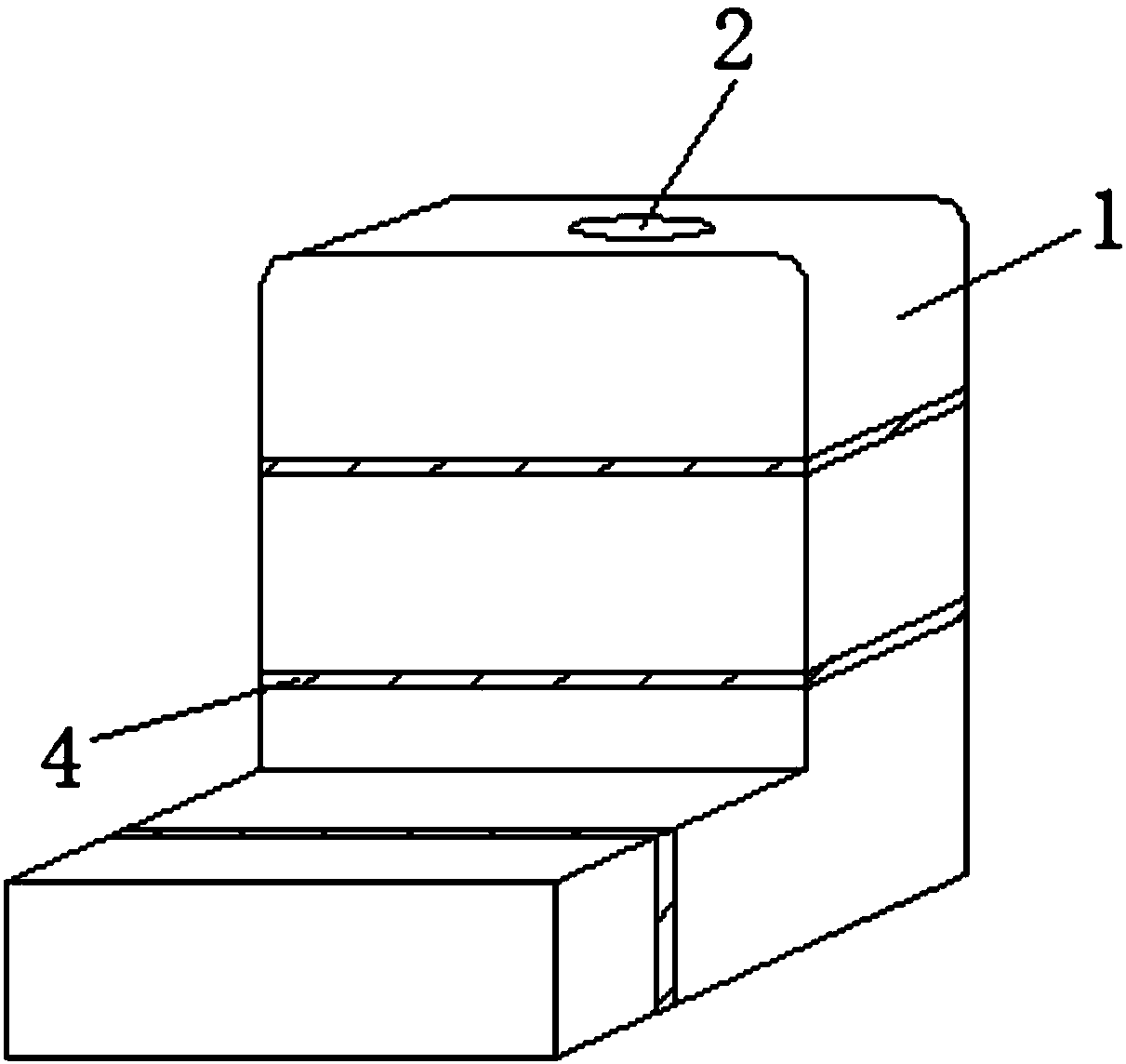

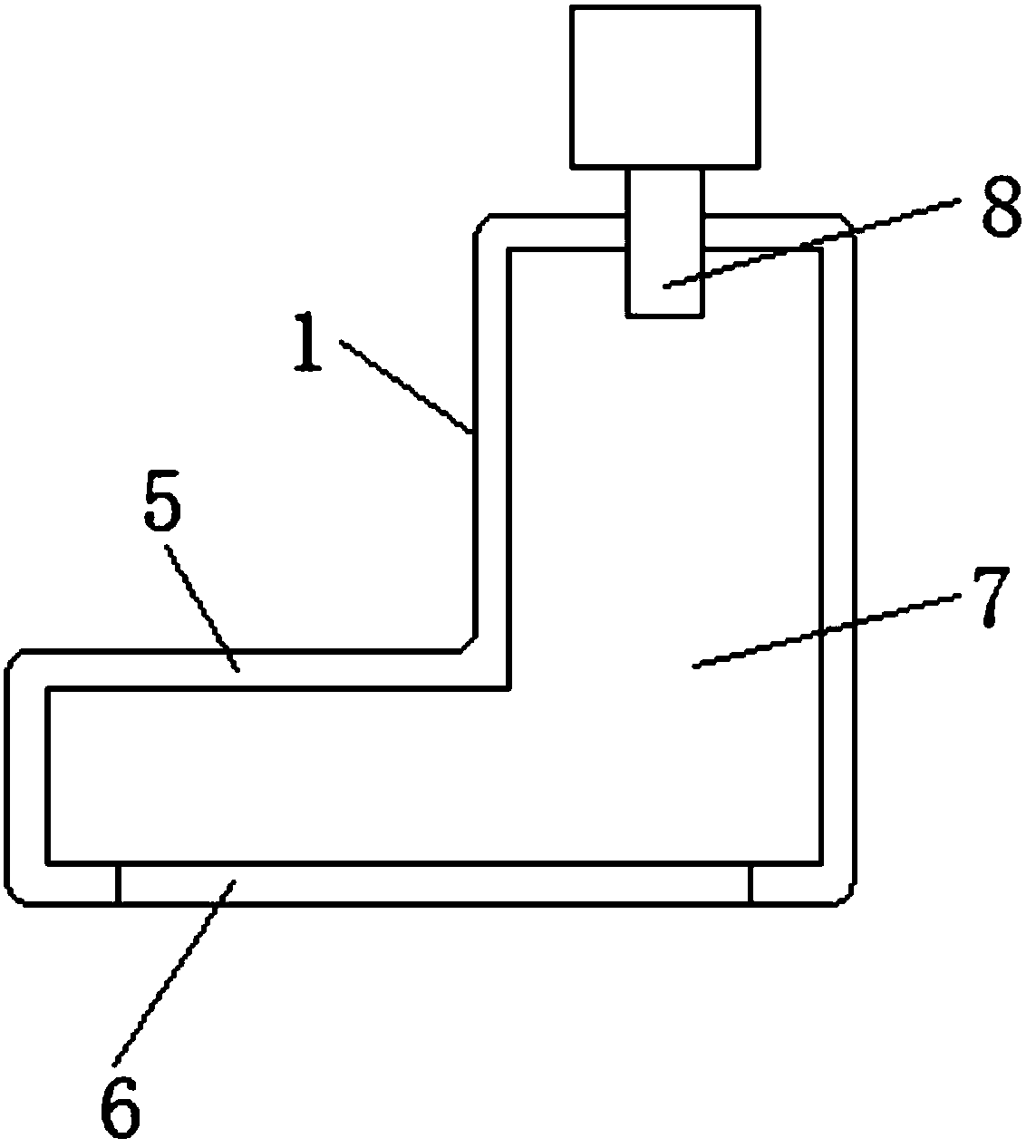

Internal heating evaporation boat with composite ceramic coating and preparation method thereof

ActiveCN107904559AHeat resistantStrong and toughMolten spray coatingVacuum evaporation coatingMolten stateComposite ceramic

The invention discloses an internal heating evaporation boat with a molten-aluminum-corrosion-resistant composite ceramic coating and a preparation method thereof. A plasma spraying method process isadopted on a surface of a high-purity tungsten boat so as to prepare an Al2O3-8YSZ ceramic layer with a composition structure with the thickness being 0.5 to 0.8mm. Aluminum oxide and yttria-stabilized zirconia powder are weighed and mixed according to different mass ratios (10 to 55 percent by weight of Al2O3: 90 to 45 percent by weight of 8YSZ) to obtain a uniform spraying material. A plasma spraying technology is characterized in that a plasma arc is adopted as a heat source, ceramics, alloys, metals and other materials are heated to a melt or half-melt state, and Al2O3-8YSZ composite powder can be fully melted and sprayed to a surface of a workpiece at a high speed so as to form a surface protection coating firm to attach.

Owner:FUZHOU UNIV

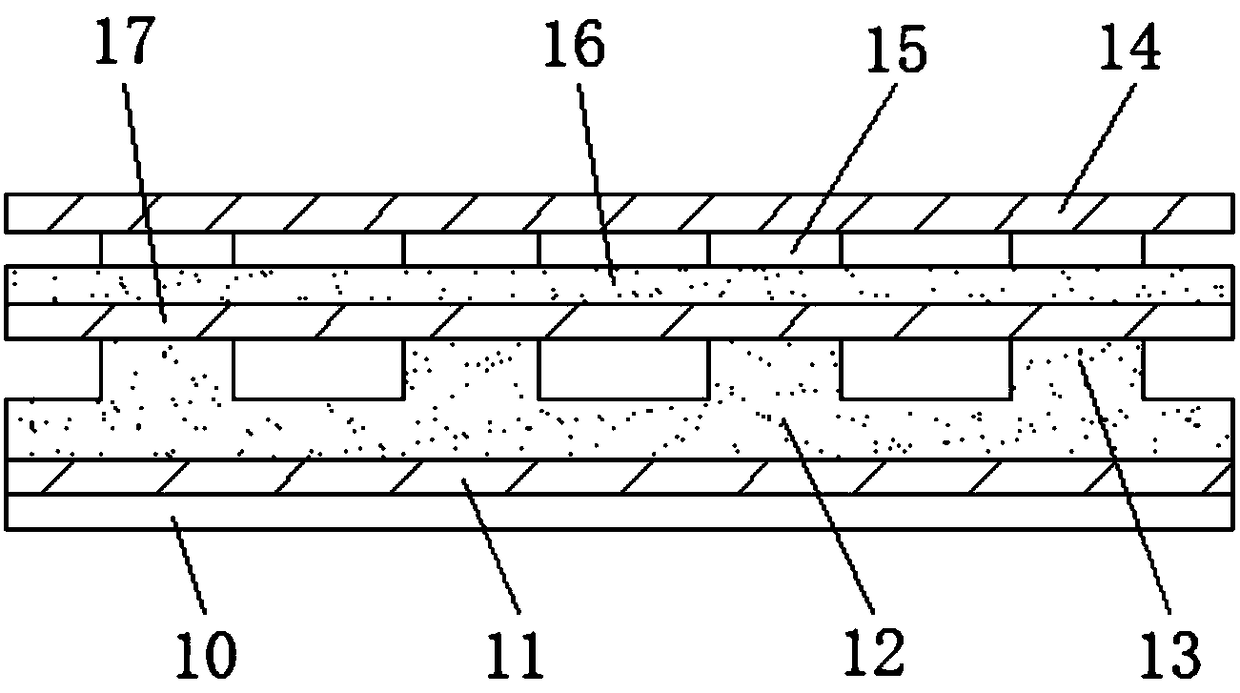

Seat plastic film protective cover

InactiveCN108657041AExtended service lifeEasy to useSeat coveringsSynthetic resin layered productsPolyesterEngineering

The invention discloses a seat plastic film protective cover. The seat plastic film protective cover includes a protective cover body, the protective cover body is internally provided with an inner cavity, and the protective cover body covers the exterior of an automobile seat. A positioning hole for mounting an adjusting rod is formed in the top end of the protective cover body, a cover inlet isformed in the bottom end of the protective cover body, and the cover inlet communicates with the inner cavity. The protective cover body sequentially comprises a TPU film layer, a plastic film, a second non-woven layer, a spongy layer, a first non-woven layer and a polyester fiber layer from outside to inside, the cover inlet is provided with a wrapping strip, the TPU film layer, the plastic film,the second non-woven layer, the spongy layer, the first non-woven layer and the polyester fiber layer which are located at the edge of the cover inlet are sewn and fixed by a needle and thread, and reinforcing bands are arranged on the protective cover body. The seat plastic film protective cover has the advantages of good wear resistance and long service life, and can be widely promoted and used.

Owner:许世能

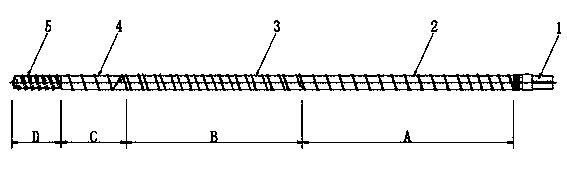

Plastic extrusion screw rod of PC (poly carbonate) thin film

InactiveCN103465460ACorrosion resistantHas rust resistanceFlat articlesEngineeringMechanical engineering

The invention discloses a plastic extrusion screw rod of a PC (poly carbonate) thin film. The whole plastic extrusion screw rod is made of a 48CrMo rolled steel and comprises a screw rod main boy (1), a feeding section (A), a fusion section (B), a compression section (C) and an extrusion section (D), the plastic extrusion screw rod is characterized in that the length of the screw rod main boy (1) is 40-45cm, and the feeding section (A), the fusion section (B), the compression section (C) and the extrusion section (D) are provided with embossing threads. The plastic extrusion screw rod provided by the invention has the advantages that the capacity is greatly improved and can achieve 400-450KG / h, and the maintenance cost of equipment is reduced under the premise that the product quality is met.

Owner:昆山地博光电材料有限公司

Preparation method of high-toughness cast steel material

PendingCN113005359AStrong and toughSuitable for extreme weather conditionsHeat conservationMolten steel

The invention discloses a preparation method of a high-toughness cast steel material. The preparation method comprises the following steps that 1, pig iron and a steel material are smelted to obtain molten steel; 2, the molten steel obtained in the step 1 is casted to obtain a casting; 3, the casting obtained in the step 2 is subjected to heat preservation for 30 minutes - 60 minutes under the condition of 850 DEG C - 860 DEG C; 4, the casting subjected to heat preservation in the step 3 is subjected to heat preservation for 30 minutes - 40 minutes under the condition of 650 DEG C - 680 DEG C, the temperature is increased to 850 DEG C - 860 DEG C, and heat preservation is conducted for 40 minutes - 90 minutes; and 5, after the heat preservation is conducted for 40 minutes - 90 minutes in the step 4, heat preservation is conducted on the casting for 4 hours - 6 hours at the temperature of 600 DEG C - 620 DEG C, and the high-toughness cast steel material is obtained. The cast steel material prepared through the preparation method has impact energy greater than or equal to 30 J and has high toughness, the cast steel material is suitable for extreme climate working conditions, and is good in effect and low in cost.

Owner:张玉琪

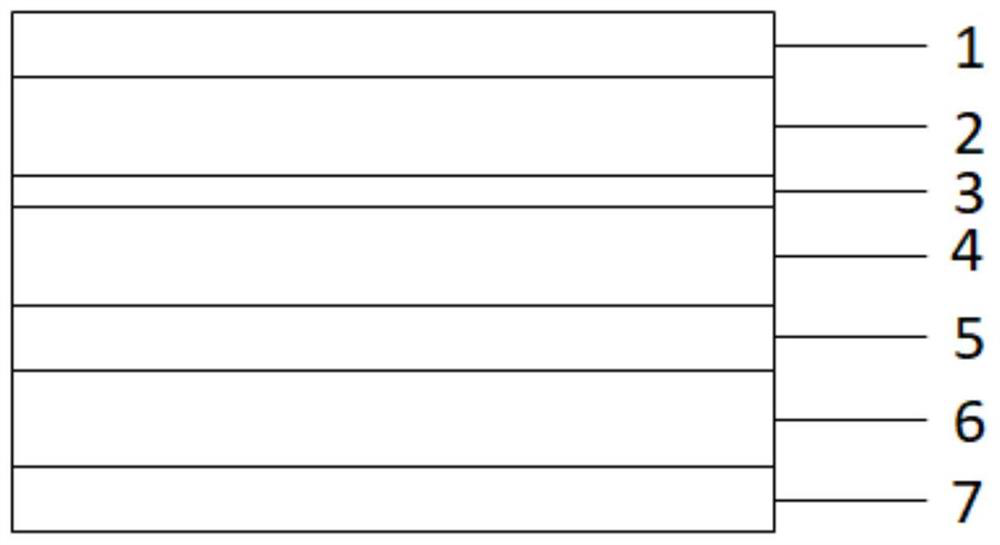

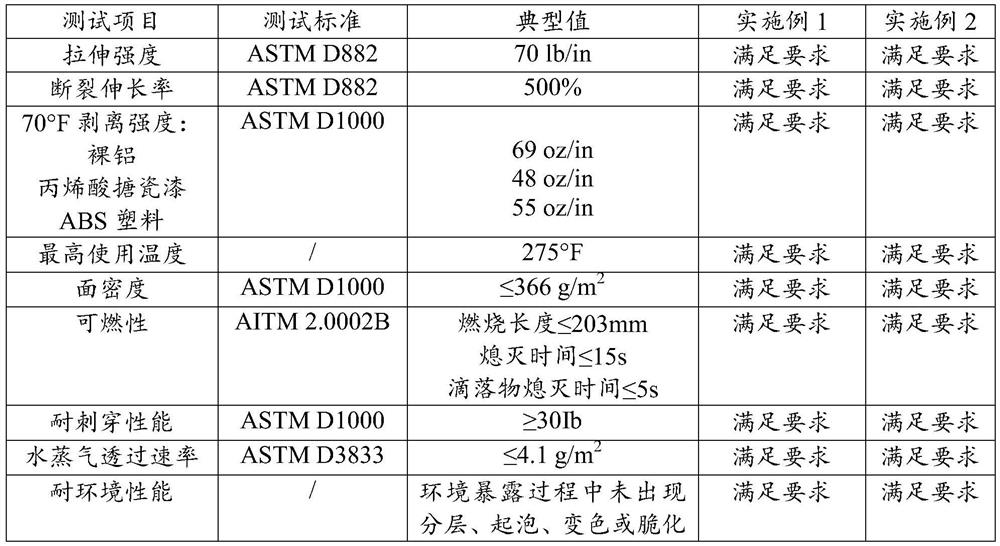

Weaponry field sealing and storage envelope, composite material for weaponry field sealing and storage outer package and preparation method of composite material

PendingCN113829705AStrong and toughAging resistantFlexible coversWrappersCarbon fiber reinforced compositeAluminum foil

The invention discloses a weaponry field sealing and storage envelope, a composite material for a weaponry field sealing outer package and a preparation method of the composite material. The composite material for the weaponry field sealing outer package sequentially comprises an anti-corrosion layer, a first bonding layer, a high-barrier layer, a second bonding layer, a base material layer, a third bonding layer and a heat sealing layer from top to bottom; the anti-corrosion layer is made of an organic silicon resin composite material, the high-barrier layer is made of one of aluminum foil or PVDC, the base material layer is made of a carbon fiber reinforced composite material, and the heat sealing layer is made of a TPU material. The field sealing envelope prepared from the composite material is light in weight and soft, and is not rusted, not deteriorated and not reduced in performance in a specified sealing period under the condition that the field storage environment condition is extremely severe, and the field sealing envelope plays an important role in improving the storage reliability of an airplane, prolonging the service life and improving the guarantee capability of equipment.

Owner:上海自图新材料科技有限公司

High-toughness cast steel material

The invention discloses a high-toughness cast steel material. The high-toughness cast steel material is prepared from the following chemical components in percentage by weight: 0.2-0.6% of C, 0.01 - 0.04%of S, 0.12 - 0.45% of Si, 0.002 - 0.006% of V, 1.0 - 1.5% of Mn, 0.75 - 1.25% of Cr, 0.2 - 0.6% of Mo, 0.01 - 0.05% of P, 0.001 - 0.0028% of Ni, and the balance of iron. The impact energy of the high-toughness cast steel material is greater than or equal to 30 J, and the cast steel material is high in toughness, suitable for extreme climate working conditions, good in effect and low in cost.

Owner:张玉琪

Pole erecting machine

PendingCN114763597AConstant efficiency operationImprove wear resistanceMaterial nanotechnologyMolten spray coatingThermal sprayingNanoceramic

The invention discloses a pole erecting machine which is characterized in that a nano ceramic material is sprayed on the surface of a flow guide body of the pole erecting machine by adopting a plasma thermal spraying mode, and a super polymer nano ceramic protective coating which has strong toughness, corrosion resistance and thermal shock resistance and has the thickness of 2-5 microns is formed on the surface of the flow guide body. And the gap between the flow guide body and the impeller is kept constant for a long time in the using process of the centrifugal compressor. The thickness of the coating is smaller, the coating is closer to an original curve of machining, and it can be guaranteed that the fit clearance between the flow guide body and the impeller is more accurate, so that the leakage amount is reduced, the energy consumption of the centrifugal compressor is reduced, and the overall efficiency is improved.

Owner:东台市富康机械有限公司

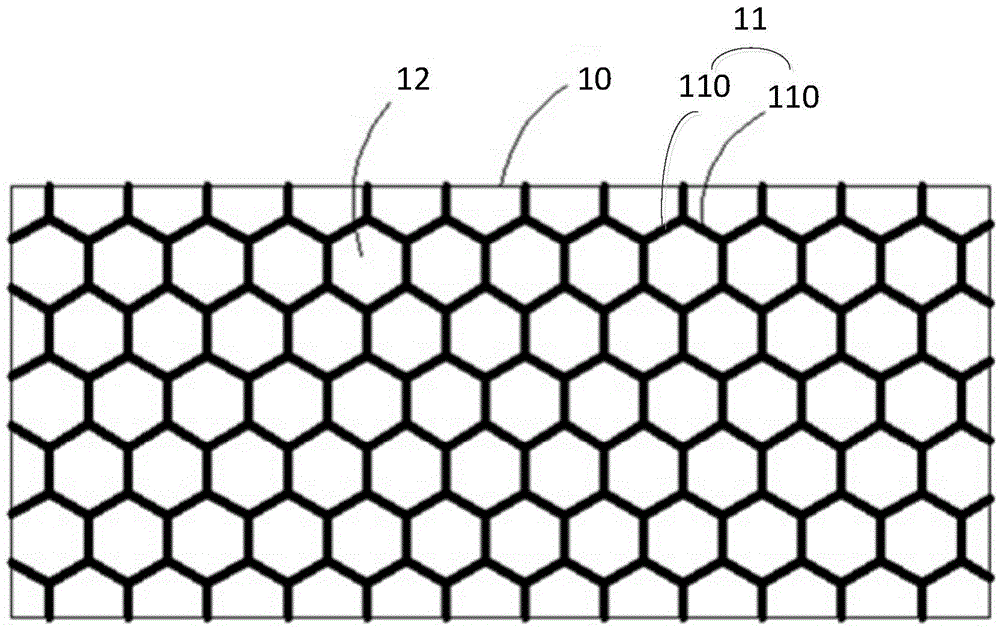

Embossed paper

InactiveCN106606325AImprove stretch elasticityStrong and toughPaper/cardboard layered productsDomestic applicationsEngineeringPulp and paper industry

The invention discloses embossed paper which comprises basic layer paper. The basic layer paper comprises a plurality of embossing units. Each embossing unit is closed embossing defined by linear concave / convex parts, and the linear concave / convex parts of adjacent embossing units are overlapped. By means of the above manner, the embossed paper obtained after embossing treatment has high tenacity and flexibility at the same time, and is high in water absorbing capacity.

Owner:GOLD HONG YE PAPER

Lithium-ion pouch cell and preparation method thereof

InactiveCN107732289AHigh temperature resistantStrong and toughFinal product manufactureElectrolyte accumulators manufactureLithiumSilica gel

The invention belongs to the technical field of lithium-ion cells and particularly relates to a lithium-ion pouch cell and a preparation method thereof. The preparation method comprises packaging a core with a silicone shell in a specific mode; the prepared lithium-ion pouch is water resistant, uncontrollable reaction in the cell can be successfully prevented, and accordingly fire, burn and explosion chances are slimmed; the finally prepared cell has better safety since the inside of the core is fully insulated from the outside. In addition, a packaging method herein is simple, the material cost is low, the process is easy to control, and the production efficiency is high.

Owner:梁百胜

Pattern machining technology for metal product machining

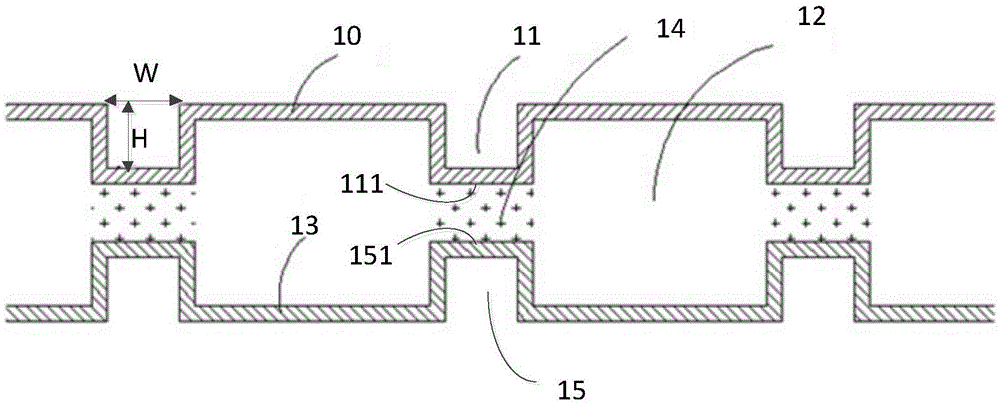

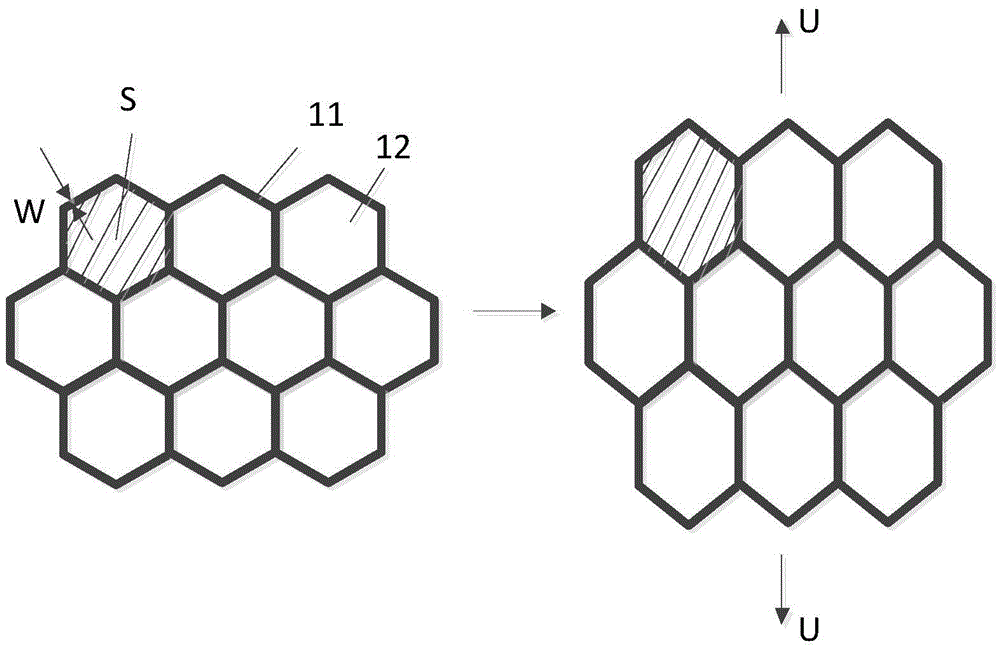

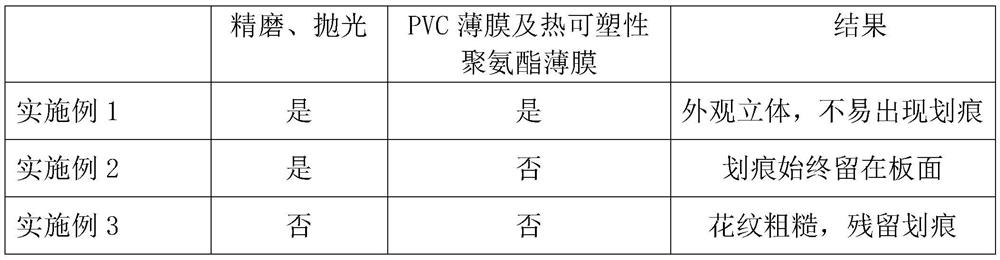

PendingCN113682076AImprove aestheticsPresent a three-dimensional pattern effectLiquid surface applicatorsRevolution surface grinding machinesPolymer scienceThermoplastic polyurethane

The invention discloses a pattern machining technology for metal product machining, and particularly relates to the technical field of pattern machining. A resin layer and a transparent protective film are arranged, a PVC film and a thermoplastic polyurethane film are sequentially connected on the resin layer in a bonded mode, the thermoplastic polyurethane film has certain extension, toughness and aging resistance characteristics, further has a certain waterproof and moisture-permeable effect, patterns on pattern lines are not prone to being abraded or scratched, through ornamentation of background patterns, the patterns are sprayed on a PVC thin film, the PVC thin film is tightly attached to a metal product and the pattern lines, the PVC thin film is completely attached to all concave-convex positions of the pattern lines, by adding the resin layer, the PVC film sprayed with the background patterns has a certain thickness, the patterns sprayed on the PVC film are suspended on the paint surface, and therefore the three-dimensional pattern effect is achieved, and compared with a traditional pattern machining technology, the solution effectively improves the pattern attractiveness of the metal product.

Owner:无锡盛方圆精密刀模有限公司

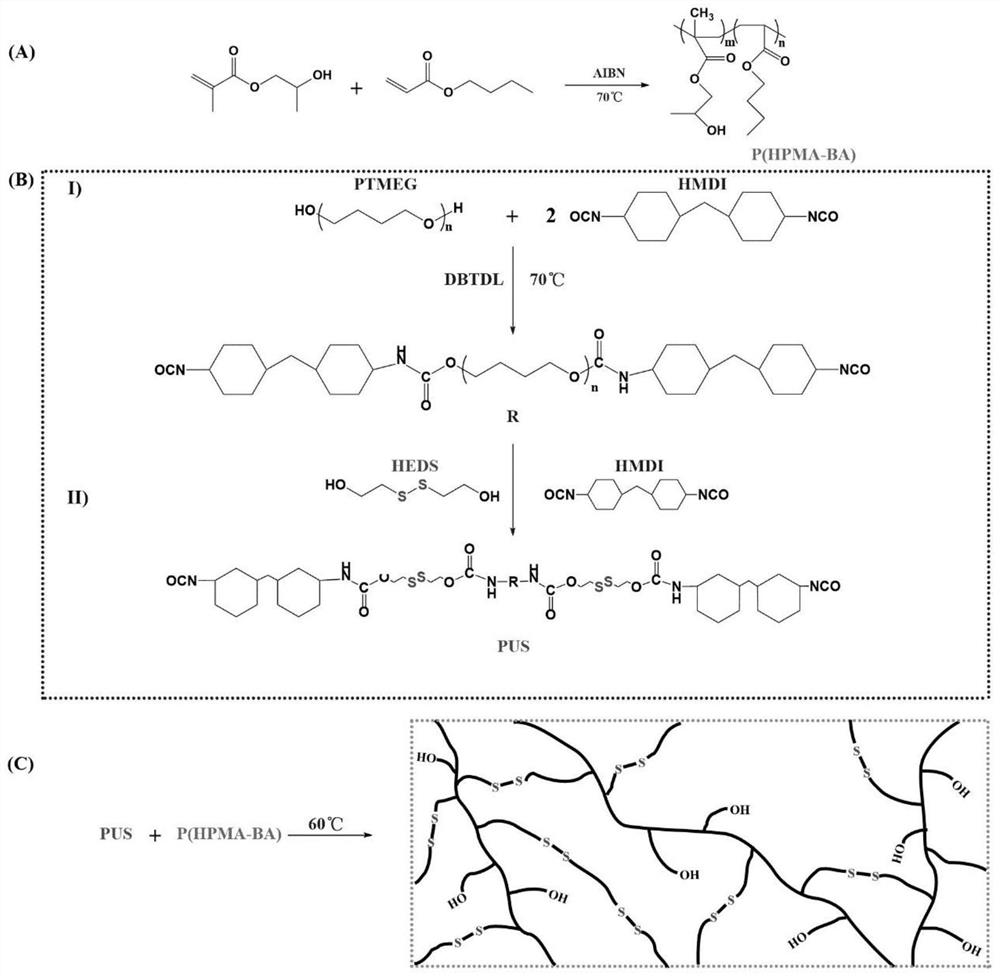

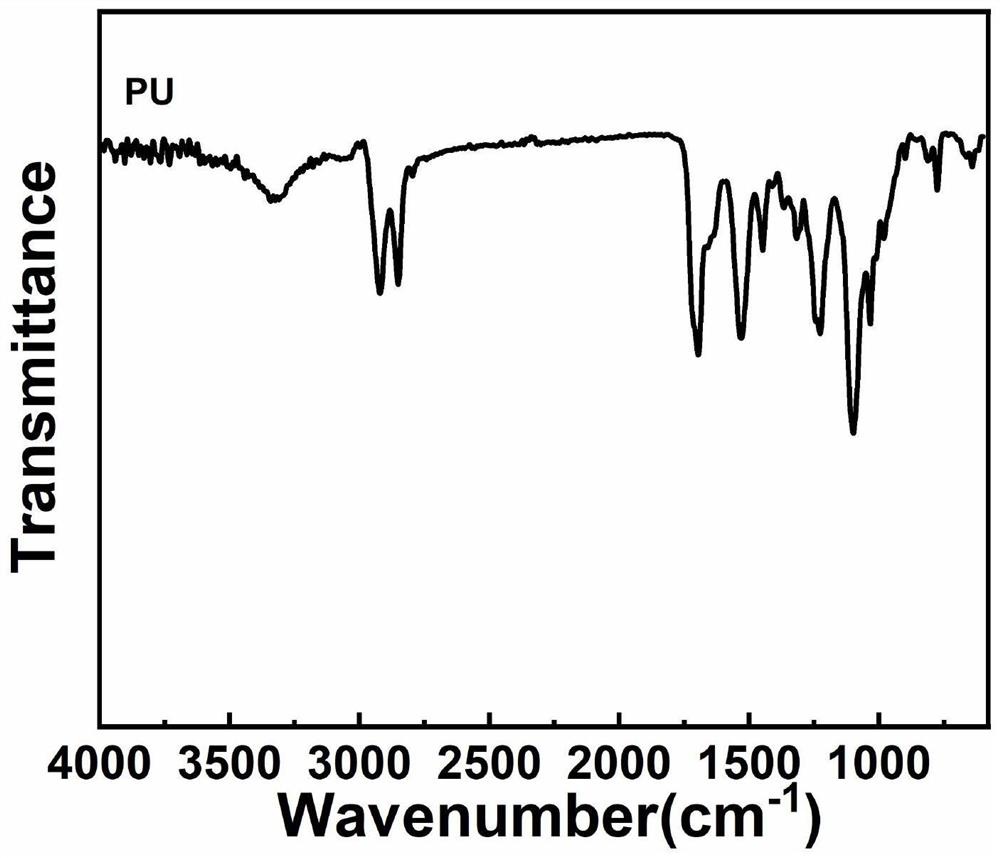

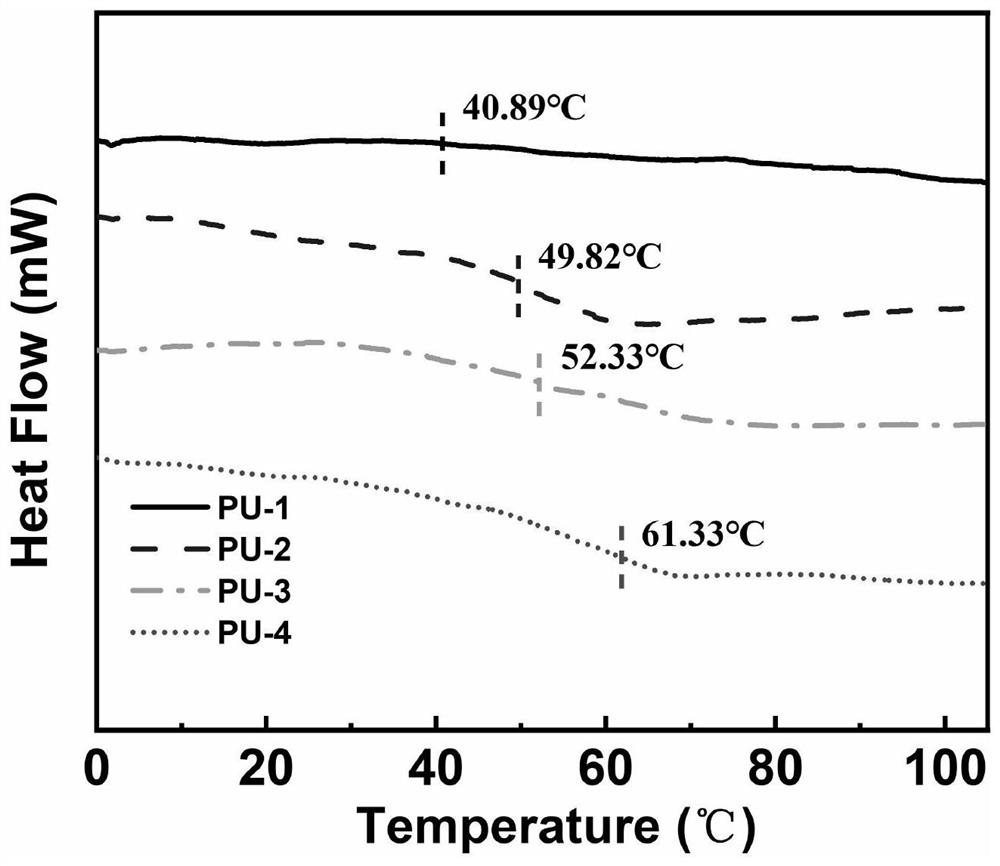

Self-repairing acrylate polyurethane material and synthesis method thereof

The invention provides a self-repairing acrylate polyurethane material and a synthesis method thereof, and belongs to the technical field of high polymer materials. The molecular structure of the obtained self-repairing acrylate polyurethane material comprises a hard segment, a soft segment and a cross-linked structure, wherein the hard segment is a copolymer of dicyclohexylmethane 4, 4'-diisocyanate and 2, 2'-dithiodiethanol, the soft segment is polytetrahydrofuran, and the cross-linked structure is polyacrylate. According to the invention, polyurethane containing 2-hydroxyethyl disulfide as a functional group and hydroxyl-containing acrylate are subjected to cross-linking curing to synthesize the self-repairing acrylate polyurethane with high self-repairing efficiency, strong toughness and transparency. The self-repairing of the material is realized based on the exchange reaction of dynamic disulfide bonds and hydrogen bonds, a cross-linked network is provided by taking polyacrylate as a cross-linking agent, and the obtained material has excellent mechanical properties, higher Young modulus and obdurability, and meanwhile, the material has the properties of good transparency, higher self-repairing efficiency and the like.

Owner:江苏富琪森新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com