Self-repairing acrylate polyurethane material and synthesis method thereof

A polyurethane material and acrylate technology are applied in the field of self-healing acrylate polyurethane materials and their synthesis, achieving the effects of high self-repairing efficiency, high toughness value and high synthesis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

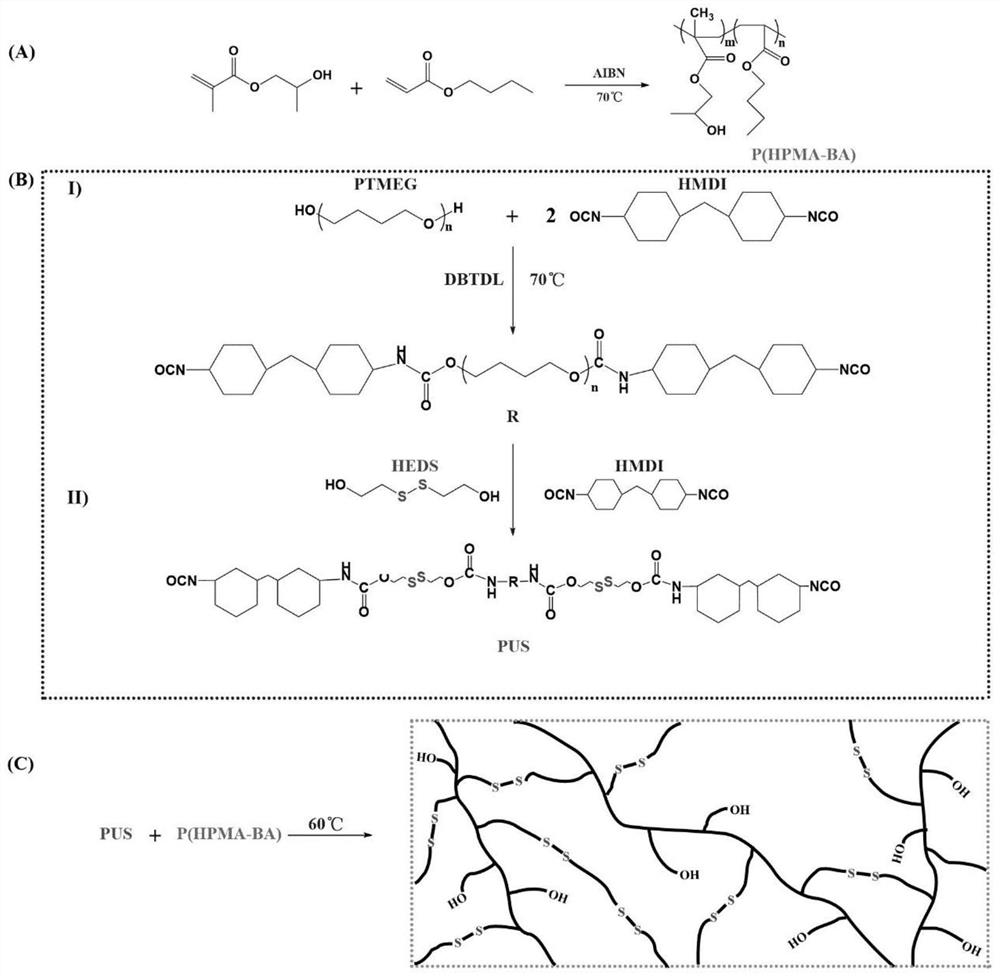

[0046] In the present invention, the preparation method of the polyacrylate comprises the following steps:

[0047] Mix butyl acrylate and hydroxypropyl methacrylate in a solvent, add an initiator and react to obtain it.

[0048] In the present invention, the reaction of butyl acrylate and hydroxypropyl methacrylate is carried out under the protection of an inert gas, and the inert gas is nitrogen.

[0049] In the present invention, the solvent is preferably N,N-dimethylacetamide, and the initiator is preferably N,N-azobisisobutyronitrile.

[0050]In the present invention, the molar volume ratio of butyl acrylate, hydroxypropyl methacrylate and solvent is 0.5-1.2mol: 0.5-1.5mol: 10-12mL, preferably 0.8-1.0mol: 0.8-1.4mol: 11 mL, more preferably 1 mol: 1 mol: 11 mL.

[0051] In the present invention, the content of the initiator is 1-1.5%, preferably 1.2-1.4%, and more preferably 1.3%, of the total mass of the reactants in the system.

[0052] The invention provides a kind o...

Embodiment 1

[0070] (1) Take 2.16g of hydroxypropyl methacrylate with a molecular weight of 144.17g / mol and place it in a reaction kettle, add 11ml of N,N-dimethylacetamide, and add 1.92g of butyl acrylate and 0.1g of azo Diisobutyronitrile, the reaction system was fully reacted at 70°C for 2 hours under the protection of nitrogen, and the product of colorless and transparent liquid was polyacrylate.

[0071] (2) Take 5 g of polytetrahydrofuran with a molecular weight of about 1000 in the reaction kettle, pass nitrogen into the reaction kettle for 10 minutes, place the reaction kettle at 120 ° C for 2 hours in vacuum, completely remove the moisture in the reaction kettle, and put it under the protection of nitrogen , add 2.63g of dicyclohexylmethane 4,4'-diisocyanate and 0.04g of catalyst dibutyltin dilaurate into the reaction system, and react the reaction system at 70°C for 1 hour to obtain an isocyanate-terminated prepolymer.

[0072] (3) Dissolve 0.77g of chain extender 2,2'-dithiodiet...

Embodiment 2

[0075] (1) Take 2.16g of hydroxypropyl methacrylate with a molecular weight of 144.17g / mol and place it in a reaction kettle, add 11ml of N,N-dimethylacetamide, and add 1.92g of butyl acrylate and 0.1g of azo Diisobutyronitrile, the reaction system was fully reacted at 70°C for 2 hours under the protection of nitrogen, and the product of colorless and transparent liquid was polyacrylate.

[0076] (2) Take 5 g of polytetrahydrofuran with a molecular weight of about 1000 in the reaction kettle, pass nitrogen into the reaction kettle for 10 minutes, place the reaction kettle at 120 ° C for 2 hours in vacuum, completely remove the moisture in the reaction kettle, and put it under the protection of nitrogen , add 2.63g of dicyclohexylmethane 4,4'-diisocyanate and 0.04g of catalyst dibutyltin dilaurate into the reaction system, and react the reaction system at 70°C for 1 hour to obtain an isocyanate-terminated prepolymer.

[0077] (3) 1.54g of chain extender 2,2'-dithiodiethanol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com