Self-repairing dielectric elastomer composite material and preparation method thereof

A technology for dielectric elastomers and composite materials is applied in the field of self-healing dielectric elastomer composite materials and their preparation, which can solve problems such as limiting the scope of application, and achieve enhanced dielectric properties, simple and efficient preparation methods, and excellent self-healing properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

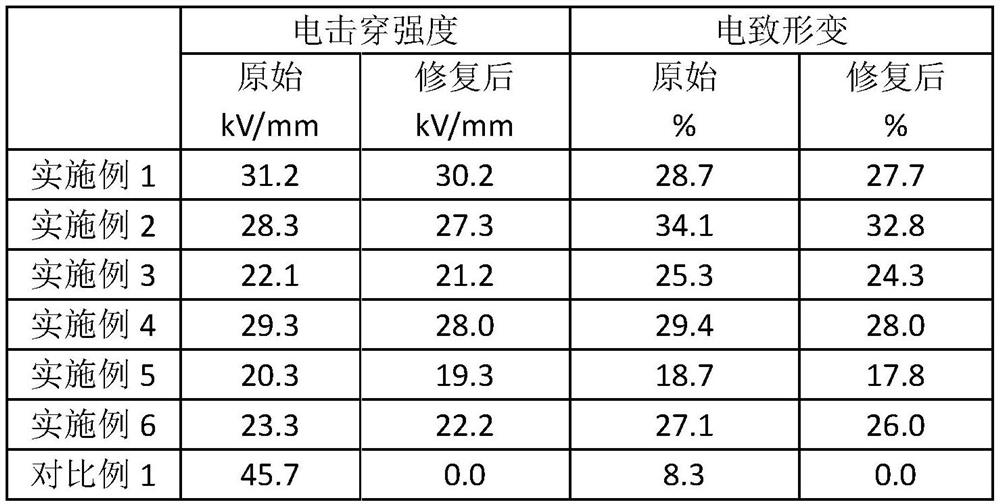

Examples

preparation example Construction

[0030] Specifically, the preparation method of the self-healing dielectric elastomer composite material may include: 5-25 parts by weight of Ti 3 C 2Filler, 20-40 parts of hydroxyl-terminated polydimethylsiloxane and 60-80 parts of polyacrylic acid are dispersed in an organic solvent (the organic solvent is toluene, tetrahydrofuran, chloroform, N,N-dimethylformamide at least one of them), and in 0.7 to 1.3 parts of catalyst (the catalyst is preferably composed of 0.4 to 0.8 parts of N, N"-dicyclohexylcarbodiimide and 0.3 to 0.5 parts of 4-(dimethylamino)pyridine Composition) under the catalysis reaction, thereby prepare above-mentioned self-healing dielectric elastomer composite material.This preparation method specifically can comprise the following steps:

[0031] Step 1. According to every 5-25g of Ti 3 C 2 Filler use 50~250mL of organic solvent ratio, the Ti 3 C 2 The filler is dispersed in the organic solvent to form a first solution.

[0032] Step 2. For every 60-8...

Embodiment 1

[0044] A kind of self-healing dielectric elastomer composite material, its preparation method can comprise the following steps:

[0045] Step a, disperse 2g of lithium fluoride powder in 40mL of hydrochloric acid solution with a concentration of 9mol / L, place on a magnetic stirrer and stir at room temperature for 10min, so that the lithium fluoride powder is uniformly dispersed in the hydrochloric acid solution to obtain etchant; then 1 g of Ti in the MAX phase 3 AlC 2 The powder is added into the etchant for etching within 5 minutes to form a mixed liquid.

[0046] Step b, using deionized water and ethanol to alternately wash the mixed solution described in step a until the pH value is 5 to 6, centrifuge to obtain the supernatant, filter and dry, and repeat multiple groups to obtain a large amount of Ti 3 C 2 filler.

[0047] Step c, the Ti of 5g 3 C 2 The filler was ultrasonically dispersed in 50 mL of tetrahydrofuran to form a first solution.

[0048] Step d, ultraso...

Embodiment 2

[0054] A kind of self-healing dielectric elastomer composite material, its preparation method is basically the same as above-mentioned embodiment 1, and its difference is: Ti in the step c 3 C 2 The amount of filler used was 15 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com