Silicon dioxide microcapsule self-repairing anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and silica, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of low repair rate and complex production process, achieve high load capacity, simple preparation process, and improve flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

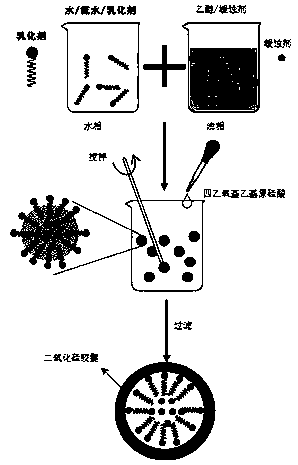

[0039] (1) Add 1.5kg of 2-mercaptobenzothiazole into 22 kg of ether, disperse evenly, and form an oil phase;

[0040] (2) Dissolve 2 kg of ammonia water and 1.5 kg of dodecyltrimethylammonium bromide in 40 kg of water to form a water phase, then add 35 kg of oil phase during stirring and disperse evenly, then add dropwise 3.5 kg of four Ethoxyethyl orthosilicic acid was reacted at room temperature for 1 h to obtain an emulsion;

[0041] (3) Aging the emulsion in a closed container at a temperature of 30°C for 26 hours, then centrifugally washing and drying the obtained precipitated capsules to obtain the silica-coated corrosion inhibitor capsule material;

[0042] (4) Combine 2kg of silica-coated corrosion inhibitor capsule material, 15kg of polyurethane emulsion with a mass concentration of 12%, 10kg of acrylic emulsion with a mass concentration of 15%, 1.2kg of mica powder, and 0.1kg of polyether modified silicone Foaming agent and 0.125kg fumed silica were dispersed at a h...

Embodiment 2

[0044] (1) Add 1.2 kg of benzotriazole and its derivatives into 28 kg of ether, disperse evenly, and form an oil phase;

[0045] (2) Dissolve 1.5 kg of ammonia water and 1.2 kg of sodium dodecylsulfonate in 45 kg of water to form a water phase, then add 40 kg of oil phase during stirring and disperse evenly, then add dropwise 2.5 kg of tetraethoxy Ethyl orthosilicic acid was reacted at room temperature for 0.5h to obtain an emulsion;

[0046] (3) Aging the emulsion in a closed container at a temperature of 28°C for 27 hours, then centrifuging and drying the obtained precipitated capsules to obtain the silica-coated corrosion inhibitor capsule material;

[0047] (4) 3kg of silica-coated corrosion inhibitor capsule material, 12kg of polyurethane emulsion with a mass concentration of 12%, 10kg of acrylic emulsion with a mass concentration of 15%, 1kg of talc powder, and 0.1kg of polyether modified silicone defoaming agent, 0.12 kg of fumed silica was dispersed at a high speed of...

Embodiment 3

[0049] (1) Add 1.8 kg of tetrazole derivatives into 20 kg of ether, disperse evenly, and form an oil phase;

[0050] (2) Dissolve 2.5 kg of ammonia water and 1.8 kg of sorbitan polyoxyethylene ester in 35 kg of water to form a water phase, then add 30 kg of oil phase during stirring and disperse evenly, then add dropwise 4 kg of tetraethoxyethylene Based orthosilicic acid, reacted at room temperature for 1h to obtain an emulsion;

[0051] (3) Aging the emulsion in a closed container at a temperature of 32°C for 25 hours, and then centrifugally washing and drying the obtained precipitated capsules to obtain a silica-coated corrosion inhibitor capsule material;

[0052] (4) Combine 2kg of silica-coated corrosion inhibitor capsule material, 15kg of polyurethane emulsion with a mass concentration of 12%, 10kg of acrylic emulsion with a mass concentration of 15%, 1.5kg of mica powder, and 0.1kg of polyether modified silicone The foaming agent and 0.1 kg of fumed silica were disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com