Patents

Literature

98 results about "ORTHOSILICIC ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orthosilicic Acid Review. Orthosilicic Acid (OSA) is a type of silicic acid that naturally occurs in water, seawater, and certain beverages (like beer). It is often referred to as “soluble silica” because Orthosilicic Acid is a dietary form of silicon (a mineral that is involved in the creation of collagen and bones).

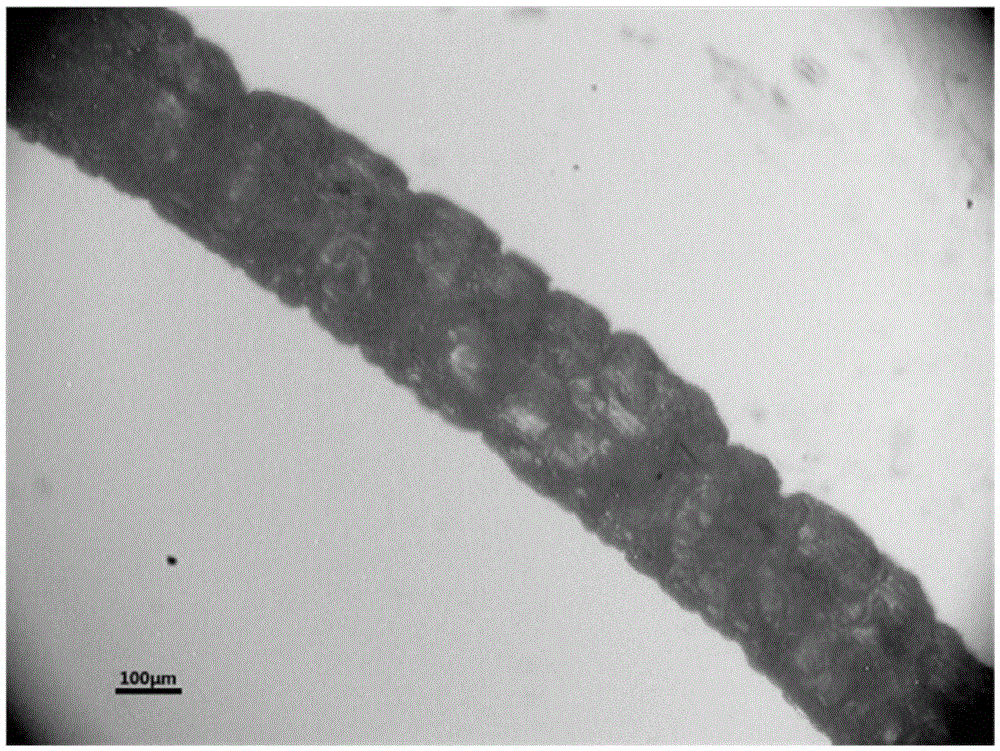

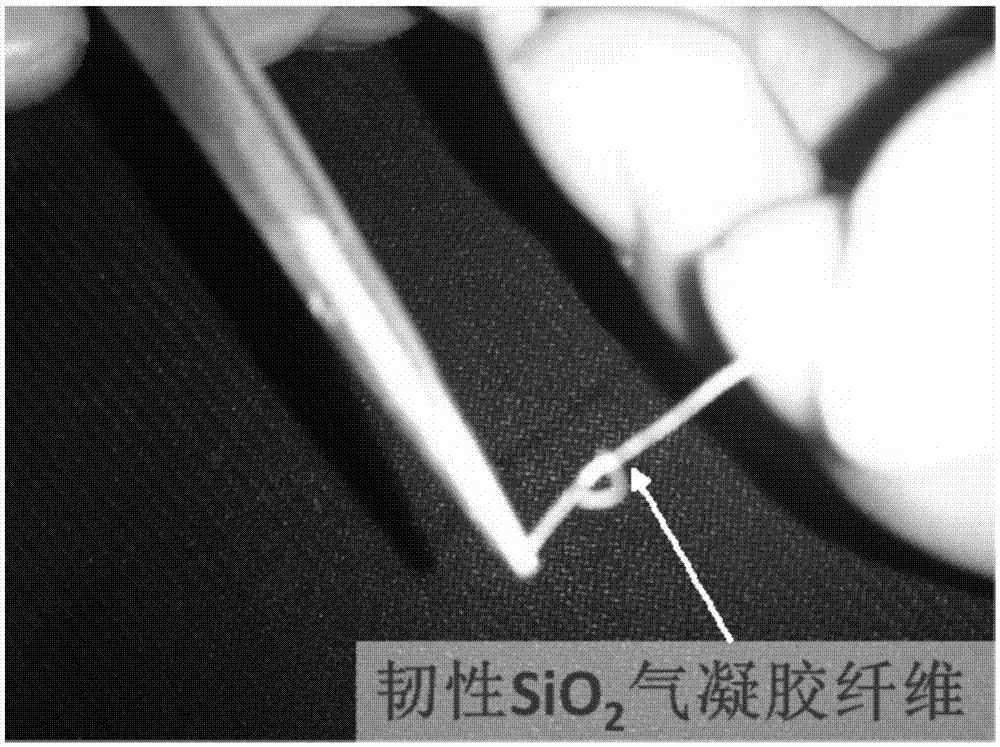

Preparing method for SiO2/cellulose tough aerogel fibers

ActiveCN105463603AAdjust the size of the specific surface areaAchieve preparationArtificial filaments from cellulose solutionsWet spinning methodsRoom temperatureCellulose fiber

The invention relates to a preparing method for SiO2 / cellulose tough aerogel fibers. The preparing method comprises the steps that silicate or silanol sol is prepared into a spinning solution, a cellulose solution is added, then the mixture is injected into an H2SO4 / Na2SO4 solution for a reaction for wet method spinning, and orthosilicic acid / silicate / cellulose fibers are obtained; the fibers are wound and steeped into an H2SO4 / Na2SO4 solution for aging at the room temperature, the fibers are washed with deionized water to be neutral, solvent replacement is carried out, the fibers are dried, and the SiO2 / cellulose tough aerogel fibers are obtained. The method has the advantages that raw materials are cheap and easy to obtain, the reaction process is simple, and spinnability is good. The prepared continuous SiO2 / cellulose tough aerogel fibers contain abundant holes, have a high specific surface area and are resistant to high temperatures and chemical corrosion; meanwhile, the fibers are adjustable in specific surface area and have certain toughness, the application range of the aerogel fibers can be enlarged, and higher practical value is achieved.

Owner:DONGHUA UNIV

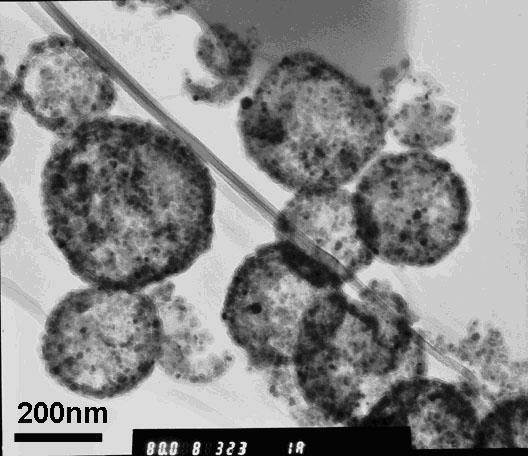

Preparation method of magnetic fluorescence dual-function silicon oxide hollow microspheres

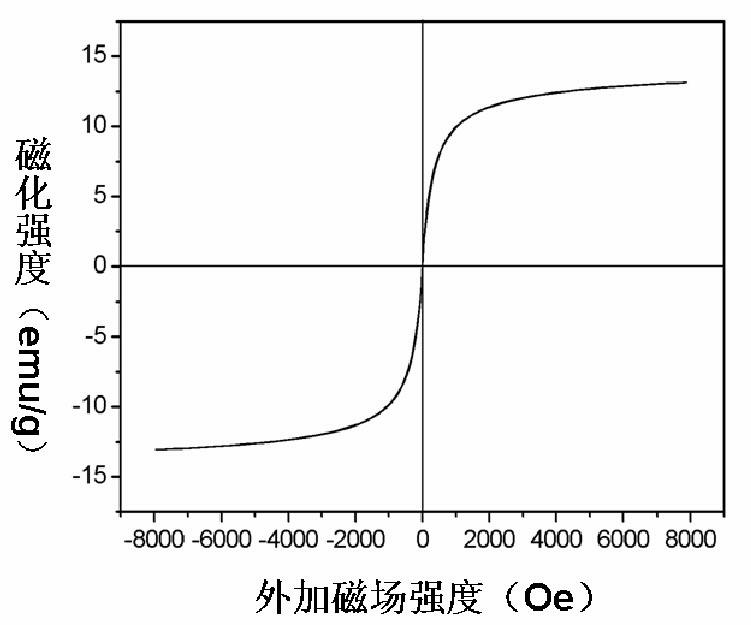

ActiveCN102198385AHas fluorescent propertiesHigh saturation magnetizationInorganic material magnetismLuminescent compositionsAlkaneMicrosphere

The invention relates to a preparation method of magnetic fluorescence dual-function silicon oxide hollow microspheres, comprising the steps of: preparing magnetic nanometer particles by a coprecipitation method; diffusing the magnetic nanometer particles in long-chain alkane after the surfaces of the magnetic nanometer particles are modified by oleic acid; mixing the oil phase composed of alkanedispersion consisting of a styrene monomer, a superhydrophobic agent and magnetic nanometer particles, and the orthosilicic acid alkyl ester with water phase in which a surface active agent is dissolved; pre-emulsifying and finely emulsifying the mixture to obtain a fine emulsion drop system; when the drops are in free radical polymerization, adding an alkali catalyst to control the generation ofsilicon oxide and the phase separation of the organic and inorganic components of the system; in the reaction process, adding proper ammonia water and a silane coupling agent which is marked by fluorescein to obtain the hollow compound microspheres which are different in sizes, inorganic shell thicknesses and magnetic particle solid content and have stable fluorescence signals. The preparation method disclosed by the invention is simple, the raw materials are low in cost and easy to obtain; and the obtained fluorescence dual-functional hollow silicon oxide microspheres are narrow in size distribution, high in magnetic substance content and stable in fluorescence performance.

Owner:SUZHOU WIN BIO TECH CO LTD

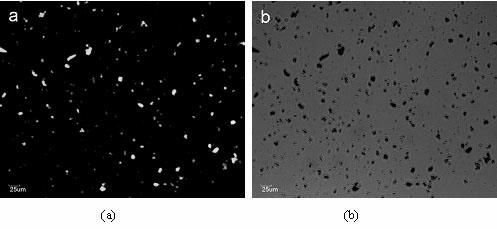

Method for preparing controllable monodisperse spherical large-particle-size nano-silicon dioxide

The invention relates to a method for preparing controllable monodisperse spherical large-particle-size nano-silicon dioxide. According to the method, on the basis of the Stober sol-gel method, tetraethoxysilane hydrolyzes to obtain orthosilicic acid, and dehydration synthesis is carried out through the method for replenishing tetraethoxysilane intermittently to obtain silicon dioxide. The method is simple in technological process, moderate in condition, high in production efficiency and suitable for industrial production, and the post-treatment mode is easy and convenient to perform. By replenishing the reagent intermittently, the large-particle-size nano-silicon dioxide particles can be synthesized in a controllable mode. The nano-silicon dioxide particles obtained through the preparation method have the advantages of being regular in spherical shape, excellent in monodispersity and the like.

Owner:BEIJING UNIV OF CHEM TECH

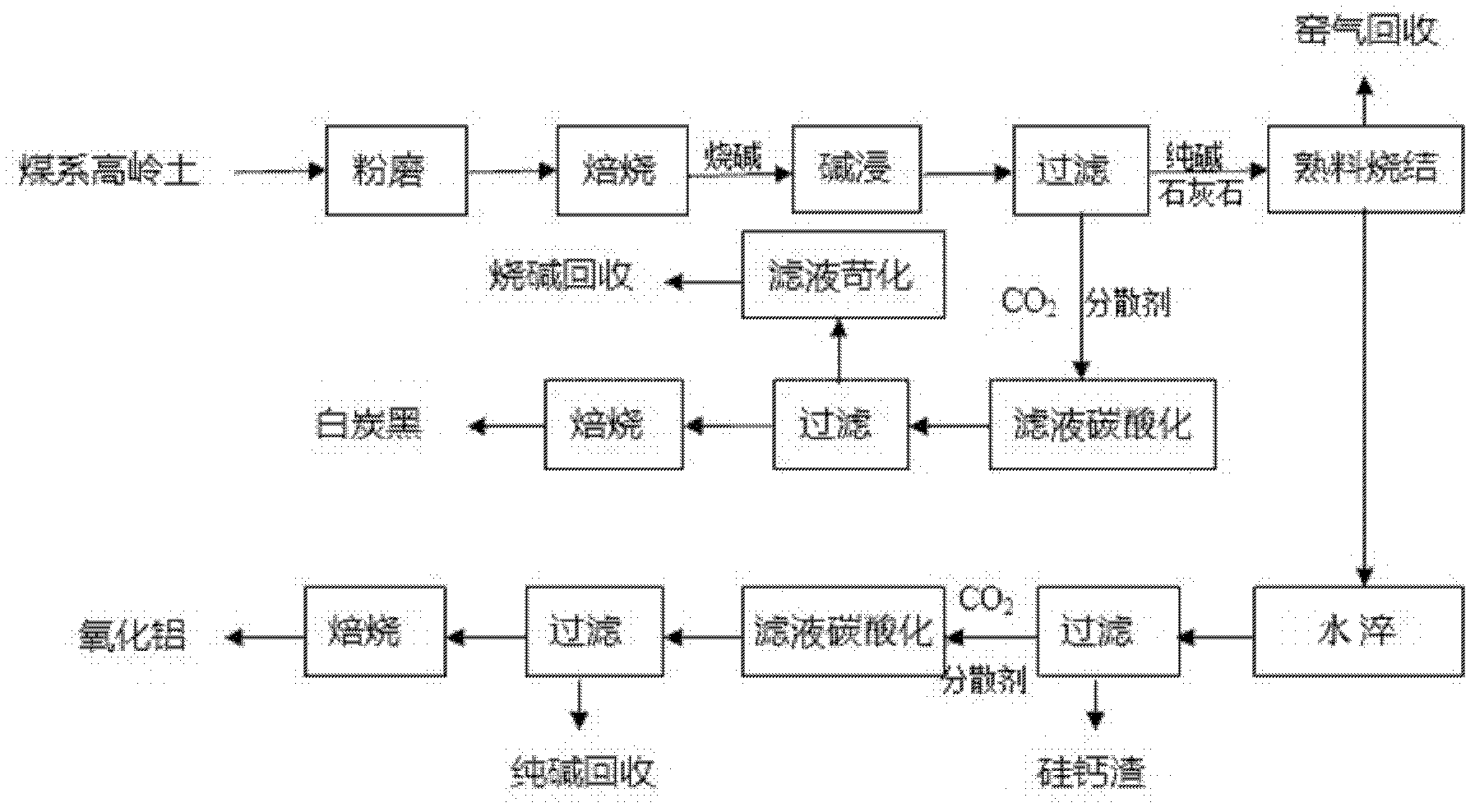

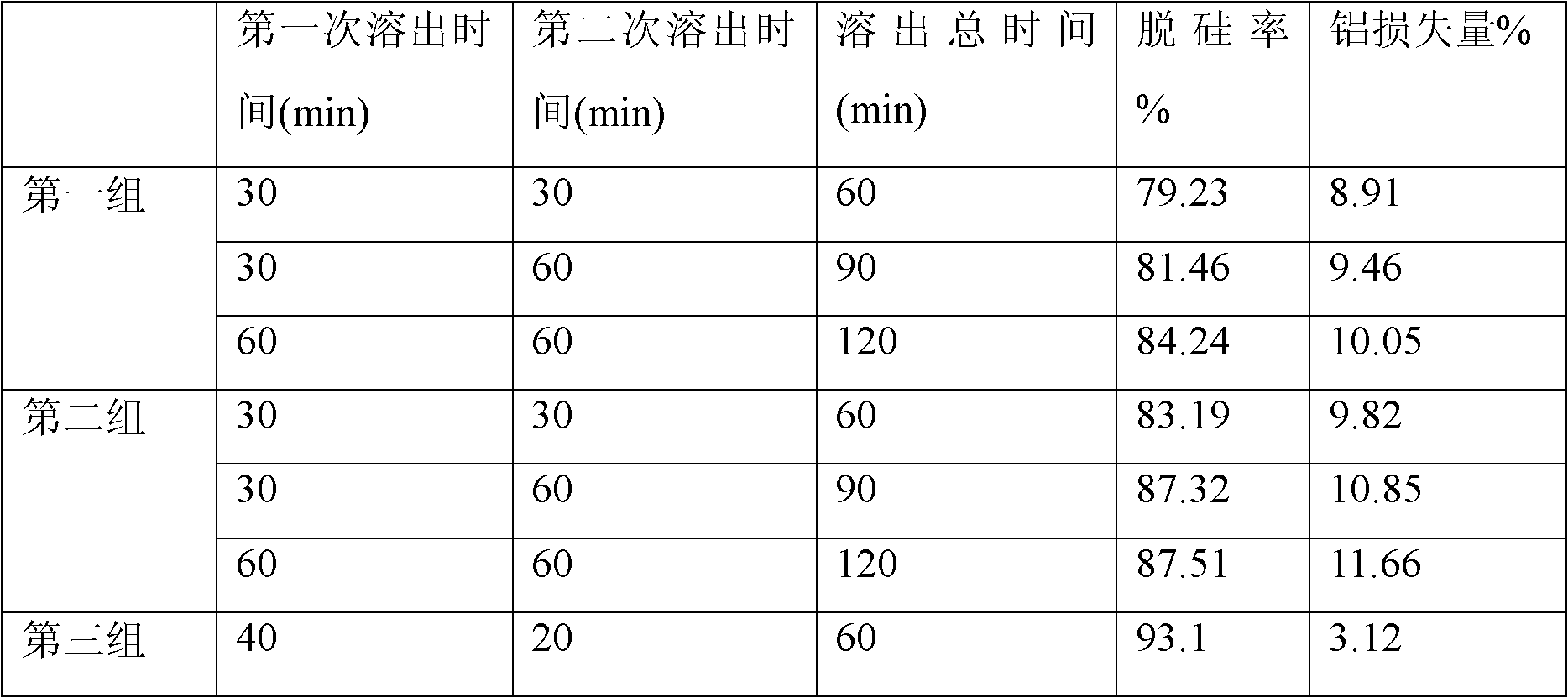

Method for preparing ultrafine alumina and coproducing and white carbon black by utilizing coal series kaolin

InactiveCN103121700ALower requirementReduce energy consumptionSilicaEnergy inputAdditional valuesSodium silicate

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for performing compact silicon aluminum coating on titanium dioxide

InactiveCN107652714AGood weather resistanceLow labor intensity of production processInorganic pigment treatmentWeather resistanceSilicic acid

The invention discloses a method for performing compact silicon aluminum coating on titanium dioxide and belongs to the field of titanium dioxide. The invention aims to provide a novel method for performing compact silicon aluminum coating on the titanium dioxide. The method for performing compact silicon aluminum coating on the titanium dioxide comprises the following steps: A, pulping a titaniumdioxide primary product, controlling the pulping concentration to be 150 to 350 g / L based on TiO2, and adding inorganic alkali to control the pH value of the pulp to be 9.0 to 11.0; B, heating to 60to 90 DEG C, adding orthosilicic acid and inorganic alkali, controlling the pH value of the pulp to be 8.0 to 11.0 and ageing for 1 to 3 hours; adjusting the temperature of the pulp to be 50 to 90 DEGC, adding inorganic acid and sodium metaaluminate, or adding inorganic acid, sodium metaaluminate, aluminum sulfate and inorganic alkali, controlling the pH value of the terminal pulp to be 6.0 to 10.0, ageing for 1 to 3 hours and completing coating. According to the method, the coating effect is uniform and compact, the weather resistance of the titanium dioxide pigment is obviously improved, and a new approach is provided for titanium dioxide surface coating.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

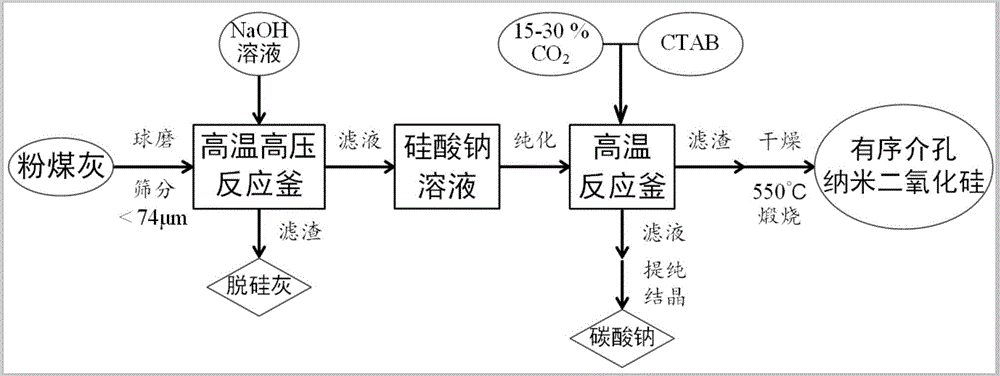

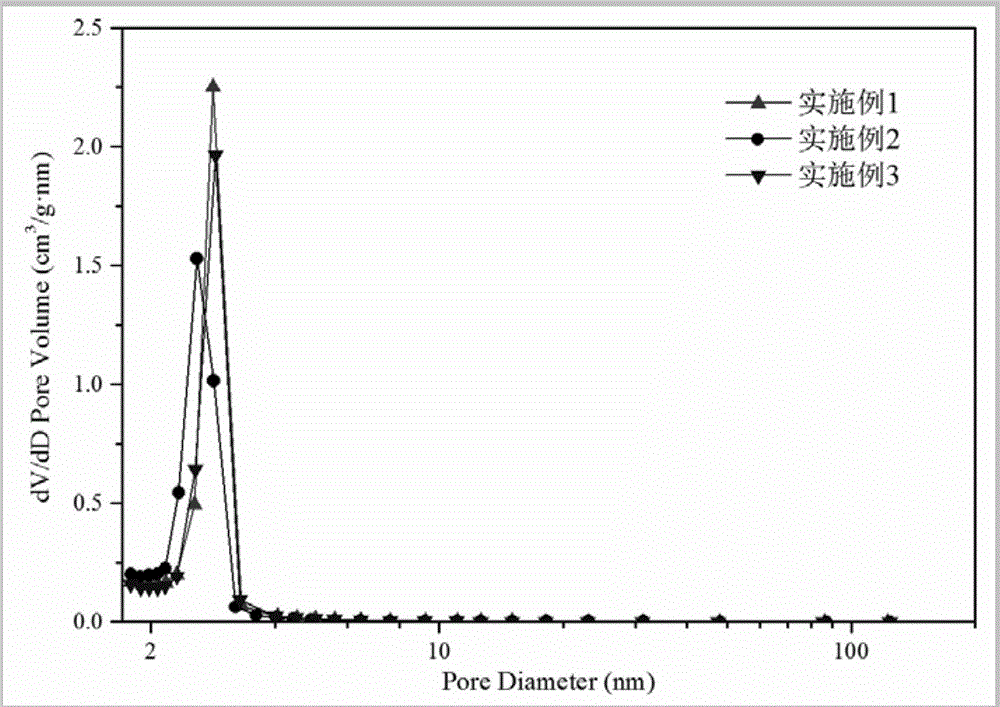

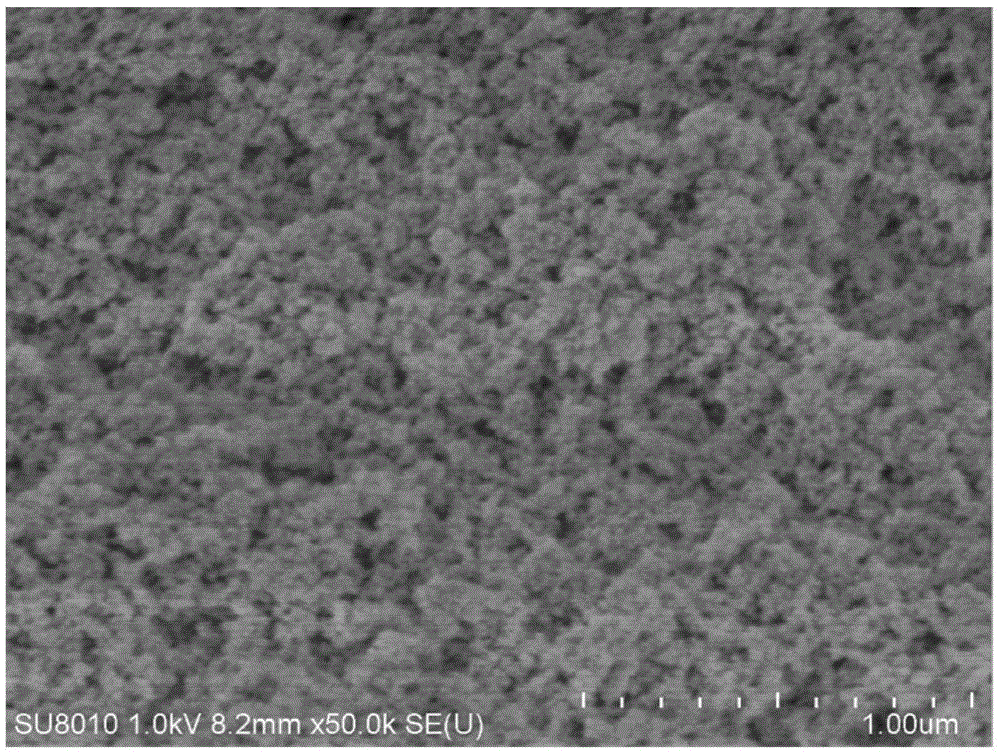

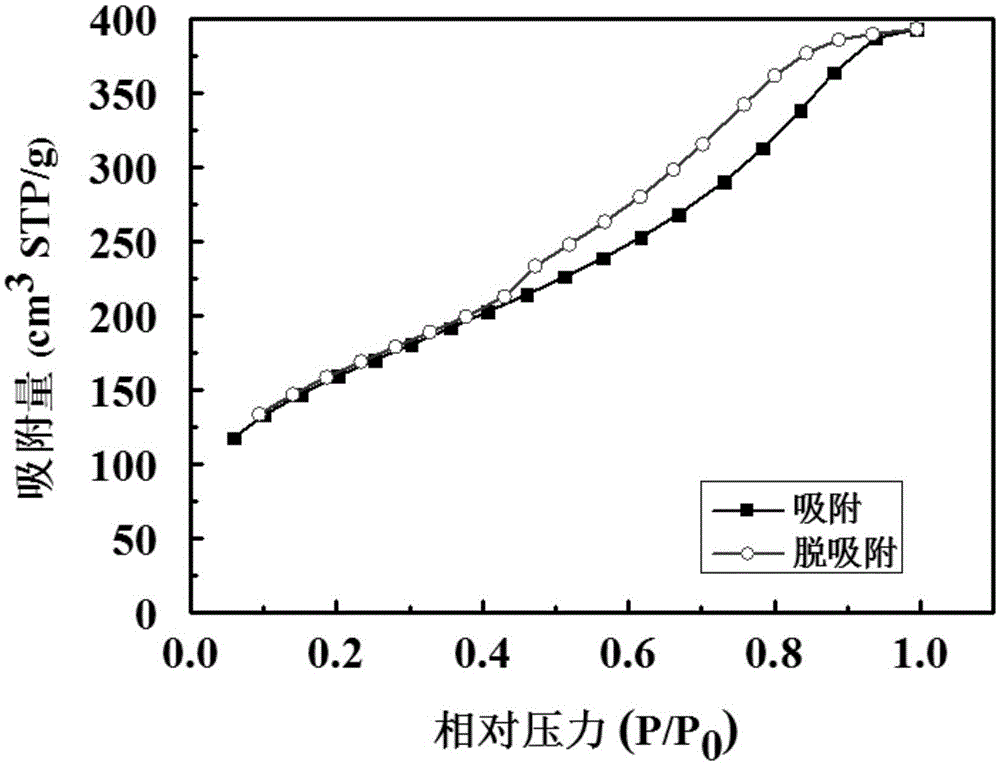

Method for synthesizing ordered mesopore nano-silica through pulverous coal

InactiveCN106517222ARealize resource utilizationIncrease valueSilicaNanotechnologyChemical reactionResource utilization

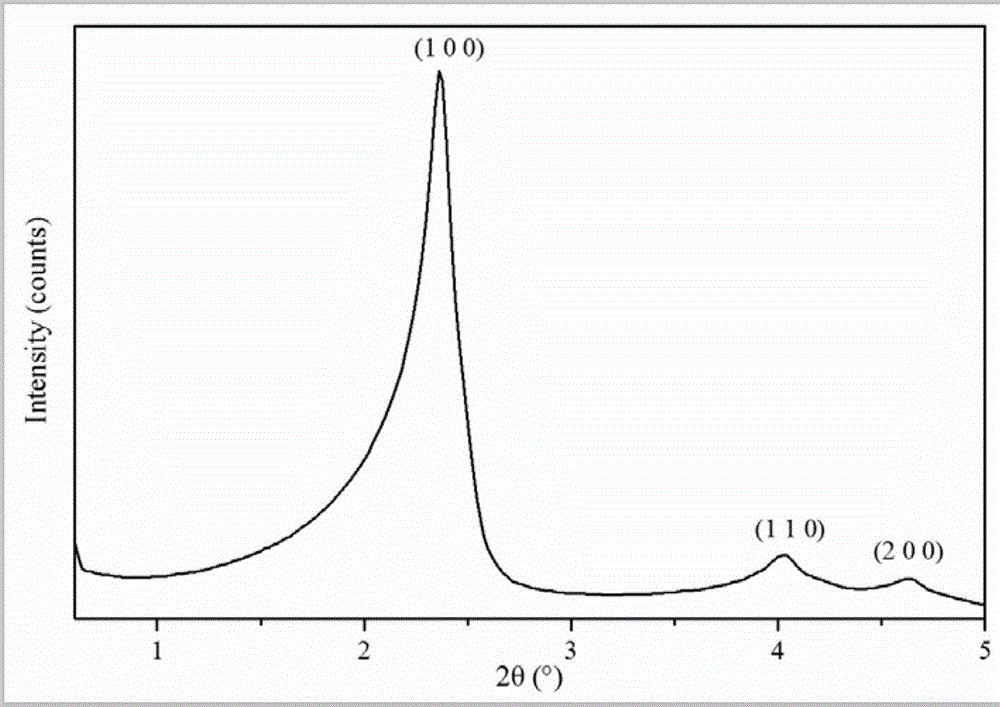

The invention provides a method for synthesizing ordered mesopore nano-silica through pulverous coal. The pulverous coal is broken and ground through a planetary ball mill; the screened pulverous coal and a sodium hydroxide solution are mixed and react at a high temperature under high pressure, and a purified sodium silicate solution is obtained after separation, pH regulation and re-separation; a surfactant and the purified sodium silicate solution are placed in a high-temperature reaction kettle with the temperature being 80 DEG C, CO2 gas with the volume fraction ranging from 15 vol% to 30 vol% is injected in the high-temperature reaction kettle under the magnetic stirring condition, and a sodium carbonate solution and orthosilicic acid sediments are obtained after the mixture reacts for 3 h and is then separated; and orthosilicic acid is dried for 2 h at the temperature being 105 DEG C, calcined for 4 h to 8 h at the temperature being 550 DEG C to 600 DEG C and cooled to obtain an ordered mesopore nano-silica product. By means of the method, the resource utilization of the pulverous coal is achieved, the high-value ordered mesopore nano-silica and sodium carbonate by-products are synthesized, and the method is a sustainable chemical reaction route; and meanwhile, by means of the technology, the production cost is substantially reduced, the production efficiency is substantially improved, the product has a regular hexagonal porous structure, the specific area is larger than 1000 m<2> / g, and the average pore size ranges from 2.5 nm to 3.5 nm.

Owner:TSINGHUA UNIV

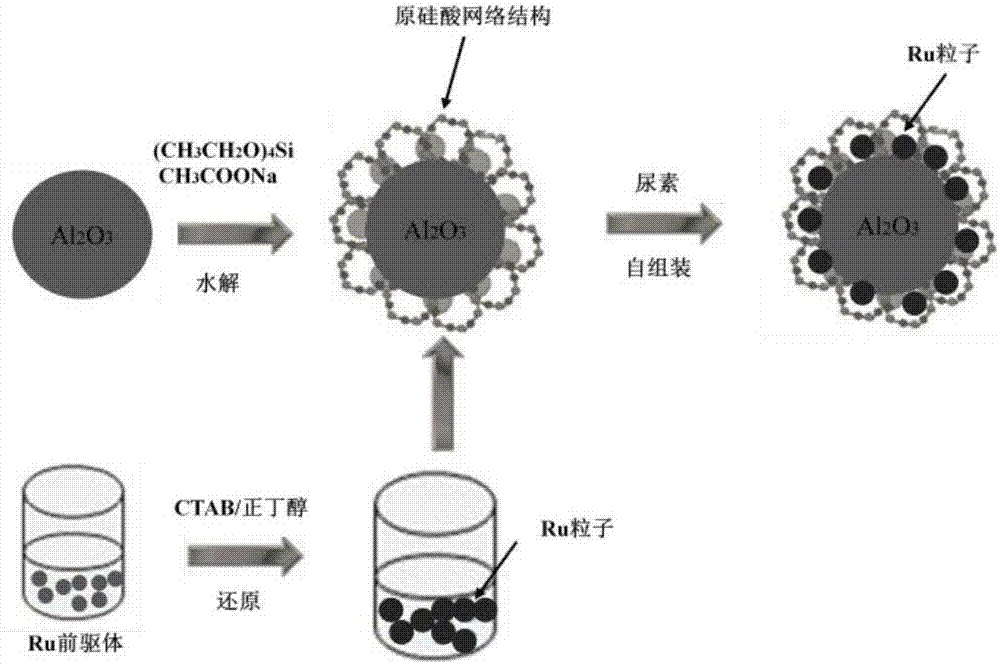

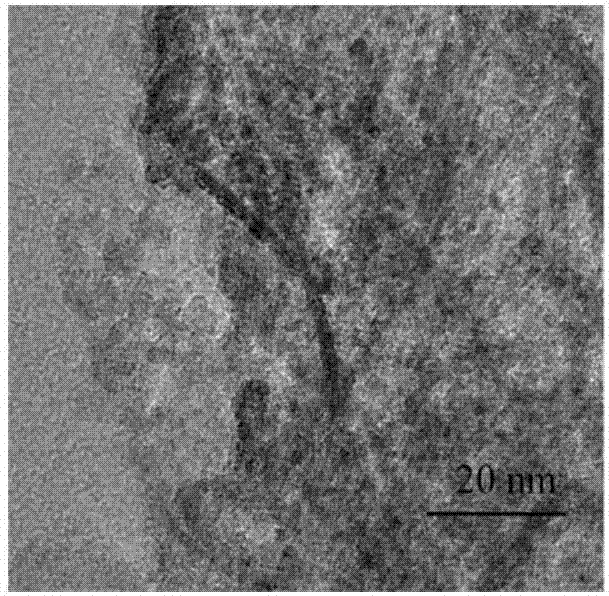

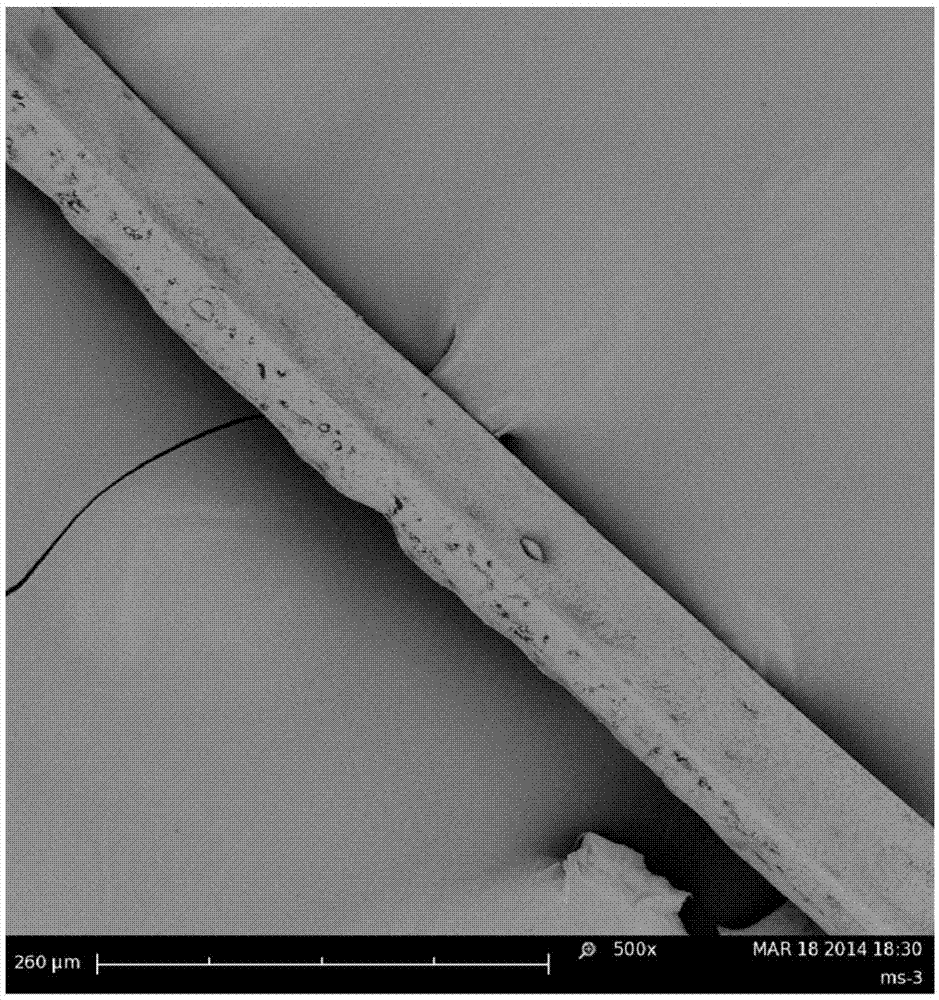

Method for preparing continuous SiO2/nano-metal aerogel fibers with catalysis performance through finally loading nano-metal

ActiveCN105664933AAdjust the size of the specific surface areaHas catalytic propertiesMetal/metal-oxides/metal-hydroxide catalystsFiberSolvent

The invention relates to a method for preparing continuous SiO2 / nano-metal aerogel fibers with a catalysis performance through finally loading a nano-metal. The method comprises the following steps: processing silicate or silanol sol to prepare a spinning stock solution; adding an acidic solution to a coagulation tank to form a coagulation bath; and injecting the spinning stock solution to the coagulation bath, carrying out reaction wet spinning to obtain orthosilicic acid / silicate fibers, reeling the orthosilicic acid / silicate fibers, ageing the reeled orthosilicic acid / silicate fibers, washing the aged orthosilicic acid / silicate fibers with deionized water until neutrality, immersing the neutral orthosilicic acid / silicate fibers in a metal salt solution, taking out the immersed fibers, removing a solvent on the surface of the orthosilicic acid / silicate fibers, immersing the obtained fibers in a reducing agent, washing the obtained fibers with deionized water until the fibers are neutral, displacing the fibers with deionized water or ethanol, and drying the displaced fibers to obtain the continuous SiO2 / nano-metal aerogel fibers. The method has the advantages of cheap and easily available raw materials, simple reaction process and good spinnability, and the aerogel fibers obtained in the invention have the advantages of abundant holes, high specific surface area, high temperature resistance, chemical corrosion resistance, and adjustable specific surface area and nano-metal load capacity.

Owner:DONGHUA UNIV

Delivery System Comprising A Silicon-Containing Material

ActiveUS20120128786A1Improve stabilityImprove bioavailabilityBiocideCosmetic preparationsControl releaseNanoparticle

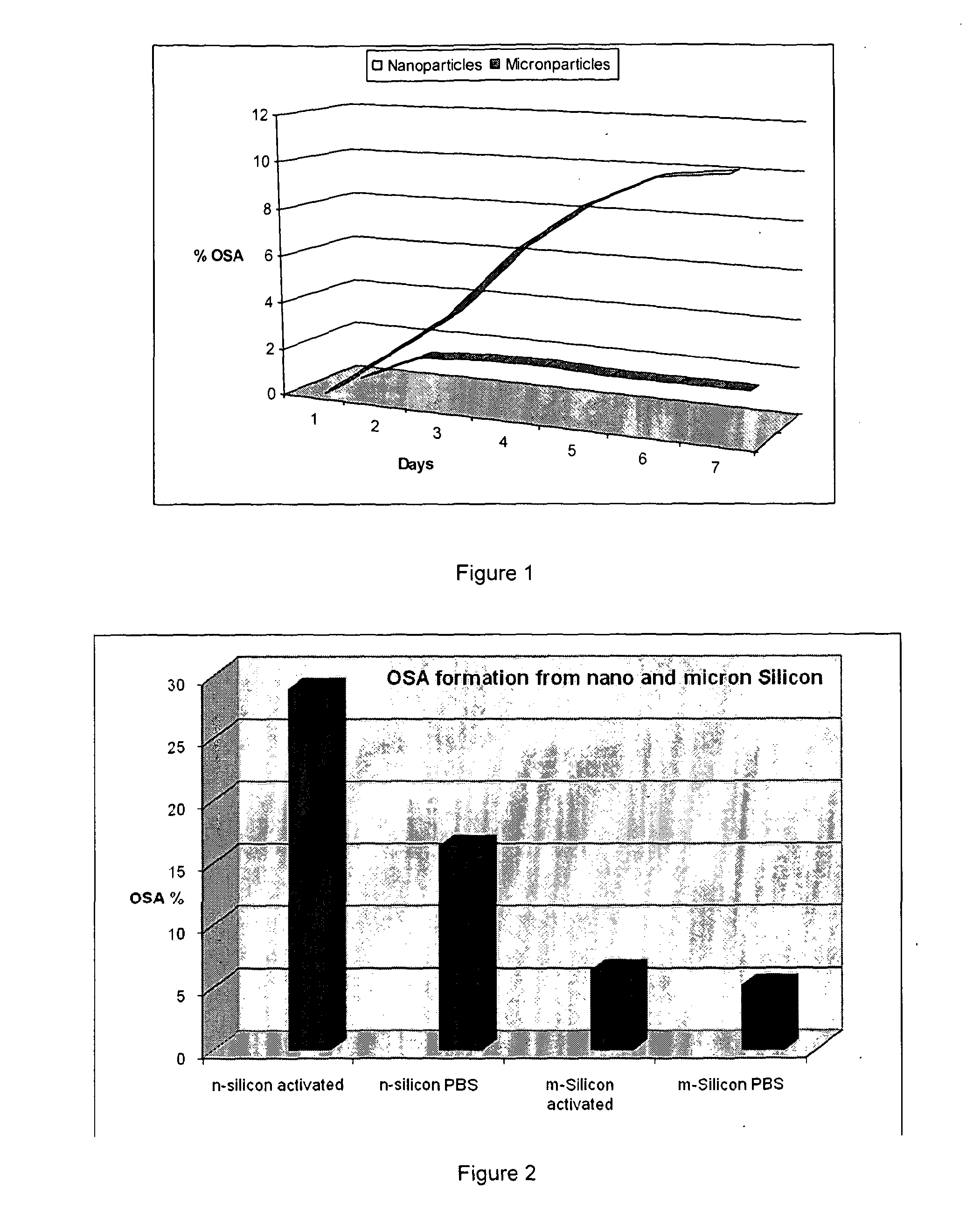

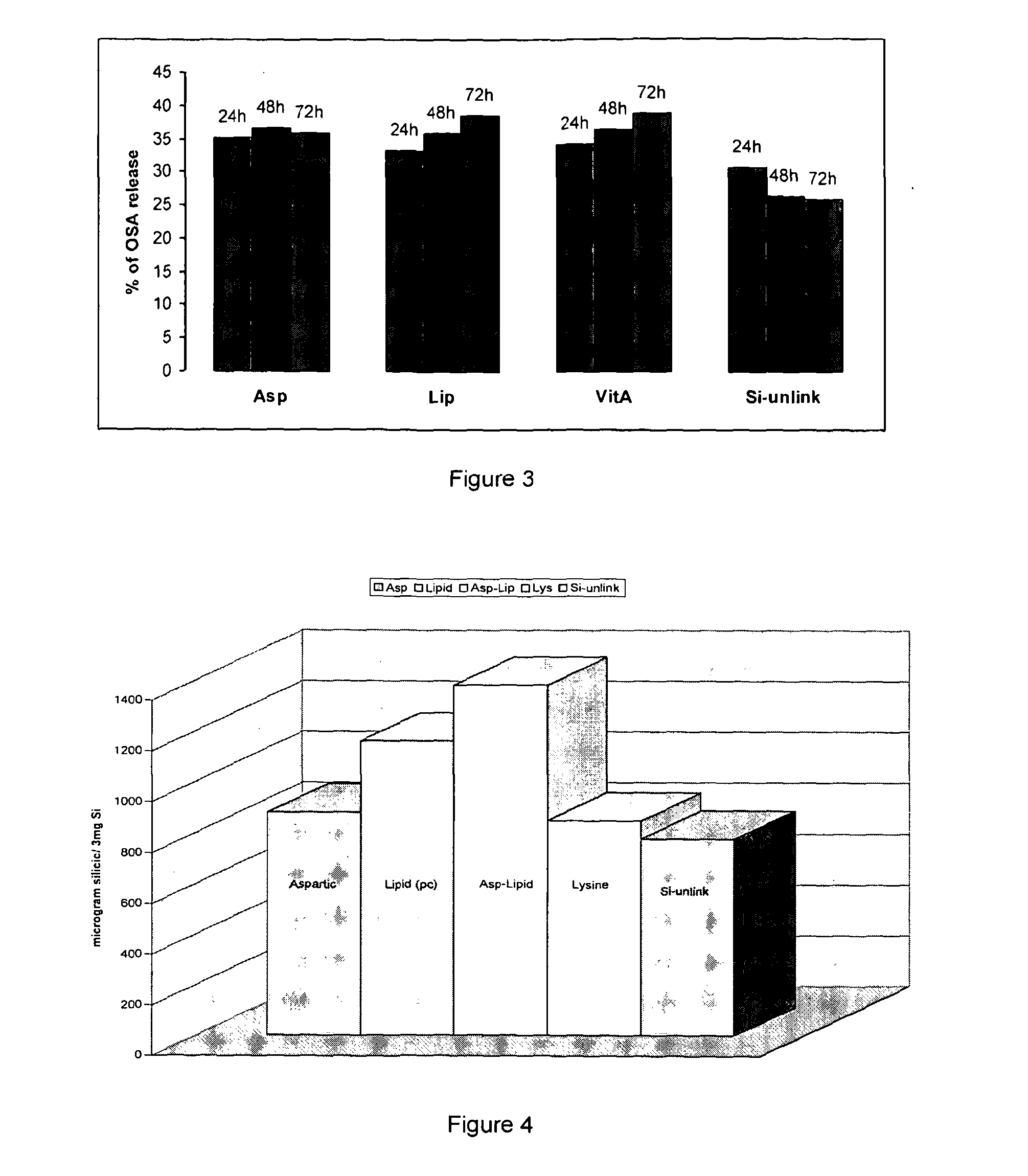

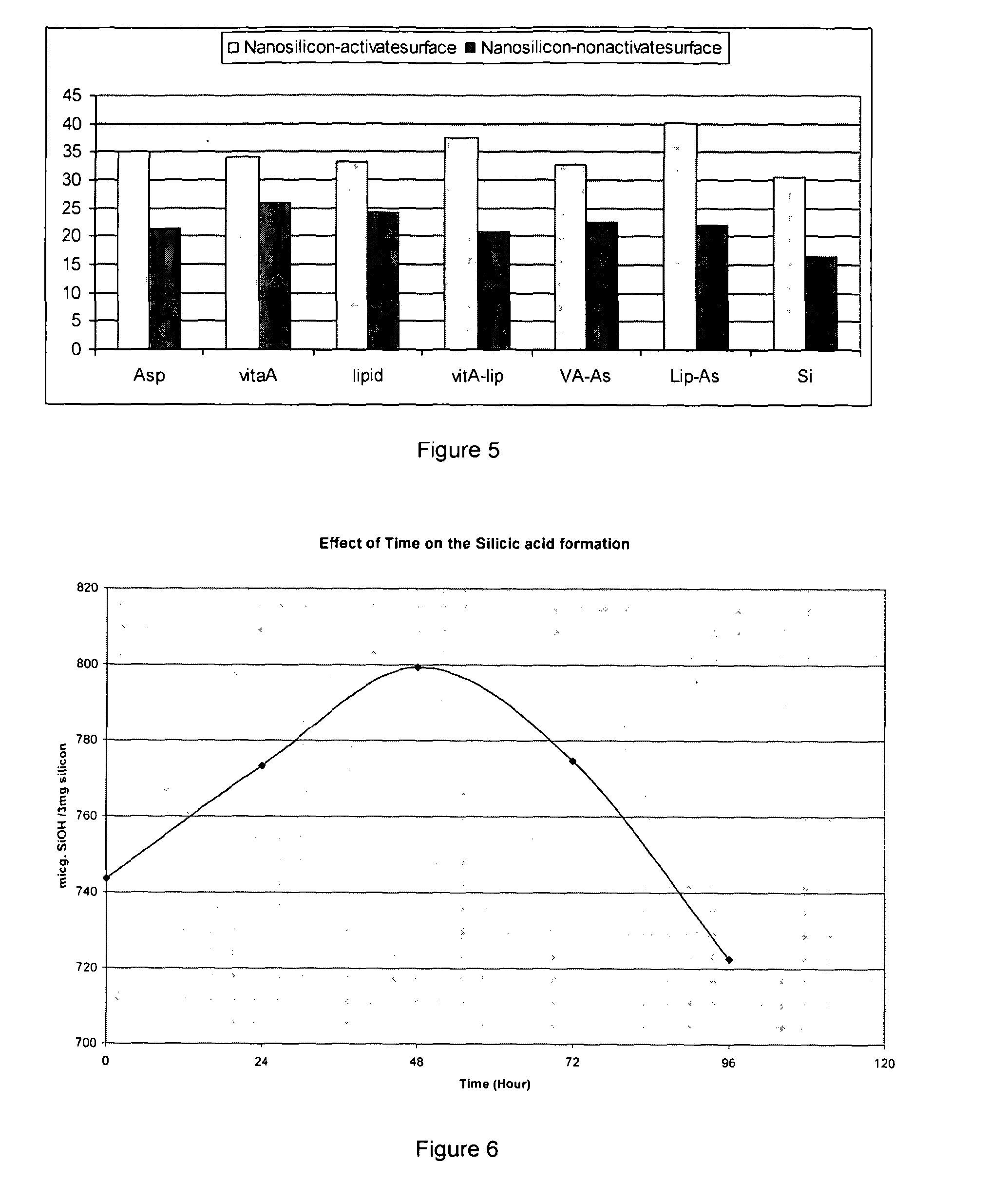

A composition comprising nanoparticles of a hydrolysable silicon-contain material for use as a delivery system for a bioactive ingredient, wherein surface of the silicon-containing material is associated with a stabilizing agent which modifies the rate of hydrolysis of the silicon-contain material and / or inhibits the rate of orthosilicic acid polymerisation and a method of promoting the controlled release of orthosilicic acid on degradation of a composition comprising nanoparticles of a hydrolysable silicon-contain material, the method involving the treatment of the surface of the silicon-containing material with a stabilizing agent to modify the rate of hydrolysis of the silicon-containing material and / or inhibit the rate of orthosilicic acid polymerisation.

Owner:SISAF

Titanium dioxide silicon-aluminum coating method

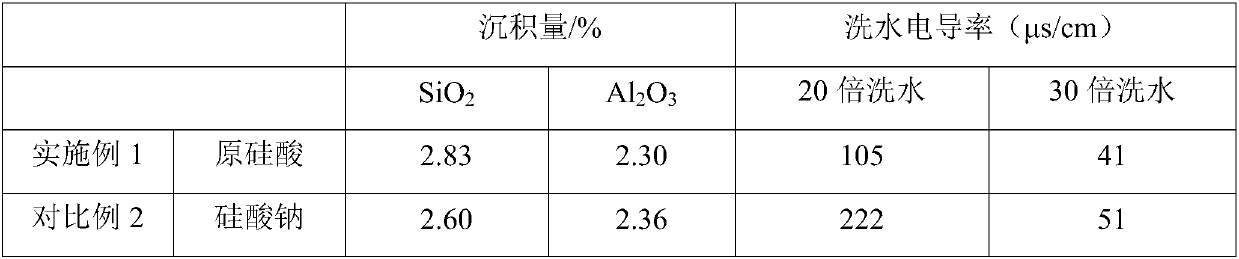

The invention belongs to the technical field of titanium dioxide production and specifically relates to a titanium dioxide silicon-aluminum coating method. Aiming at the problems that utilizing silicon oxide to coat titanium dioxide has insufficient brightness, difficulty in washing and a large water washing amount, the invention provides the titanium dioxide silicon-aluminum coating method. The titanium dioxide silicon-aluminum coating method comprises the following steps: a, preparing the titanium dioxide into slurry, adding orthosilicic acid and sodium hydroxide, controlling a pH of the slurry as 6.5 to 8.0, stirring, depositing a layer of silicon dioxide on the surfaces of titanium dioxide particles and stirring and curing for 0.5h to 2h; b, adjusting temperature of the slurry as 60 to90 DEG C and a pH value of the slurry as 5.0 to 10.5, adding sodium metaaluminate and inorganic acid, maintaining the pH value as 5.0 to 10.5, stirring and curing for 0.5h to 1h, coating a layer of aluminum oxide film to obtain silicon-aluminum coated titanium dioxide. The coated titanium dioxide prepared by the method disclosed by the invention has the advantages of higher brightness, more easiness in washing and low production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation for orthosilicic acid

InactiveCN101279737AReduce manufacturing costSimple preparation processProductsReagentsSilicic acidHazardous substance

The invention relates to a method for preparing orthosilicic acid, the chemical formula of orthosilicic acid is H4SiO4. The method is characterized by the following steps: A, SiO2 and water are mixed according to the weight ratio of 10-20:100 and strongly stirred and NaOH or KOH solution is dropped until the pH value reaches 8-9 below the temperature of 15 DEG C; B, under strong stirring, the mixture is oil-bath heated until the temperature comes to 50-55 DEG C and reacts for 2-3 hours to obtain even solution; C, the solution is cooled to room temperature and under strong stirring, CO2 gas is fed into the even solution until the pH value is less than or equal to 4; D, choline chloride is added, wherein the weight ratio of choline chloride and the solution obtained from the step C is 20-45:100, then stirred for 10-20 minutes to obtain stable orthosilicic acid solution, wherein, the silicon content of the stable orthosilicic acid solution is 2-2.5 percent. The method of the invention has low cost to prepare orthosilicic acid, environmentally friendly preparation technique and no hazardous and noxious substances discharging during the preparation process; the orthosilicic acid solution obtained has the advantages of multifunction and long preservation time.

Owner:嘉兴市红日化工有限公司

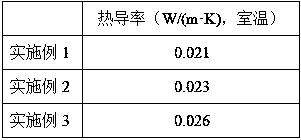

Preparation method of aerogel felt heat insulation material

The invention belongs to the field of heat insulation materials and discloses a preparation method of an aerogel felt heat insulation material. Orthosilicic acid ester, ethanol and water are uniformlymixed, NH4F solution and ammonia water are sequentially added and uniformly stirred to obtain silica sol A; a resin, an initiator, a coupling agent and hollow glass beads are uniformly stirred and mixed in a sealable container to obtain a slurry B; a fiber felt is first impregnated in the silica sol A, then impregnated in the freshly prepared slurry B after being taken out, and the operation is repeated for 3 to 4 times so that the silica sol A is always in a stirring state when the fiber felt is impregnated in the slurry B, and then the fiber felt is taken out and placed in a vacuum condition for sealing and standing; the obtained fiber felt is subjected to aging and modifying, solvent replacing is performed by absolute ethanol, drying and heat treatment are performed to obtain the aerogel felt heat insulation material. On the premise of not affecting the heat insulation effect of the felt body, the invention overcomes the situation that the powder of the traditional silica aerogel felt falls off.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Coating paint for ink-jetting CTP (cytidine triphosphate) plate, printing plate base and preparation method thereof

ActiveCN102220055AHydrophilicImprove adsorption capacityPlate printingCoatingsPolyvinyl acetateCarvacryl acetate

The invention discloses a coating paint for an ink-jetting CTP (cytidine triphosphate) plate, a printing plate base and a preparation method thereof. The coating paint for ink-jetting a CTP plate is prepared by mixing orthosilicic acid tetraalkyl ester, polyvinyl acetate and inorganic oxide particles, and the weight of the orthosilicic acid tetraalkyl ester is 0.2-50 times that of the polyvinyl acetate. The paint containing the polyvinyl acetate, the orthosilicic acid tetraalkyl ester and the inorganic oxide particles is coated on the surface of the printing plate base, crosslinking reaction is completely carried out on the paint in the drying process to form a dense net structure with a great amount of micropores, so that the dried coating has hydrophily, high adsorption performance and high abrasion performance, so as to prepare the ink-jetting CTP plate with high imaging precision, high printability and high pressrun. The offset plate is imaged by printing of an ink-jet printer, and the imaged plate can be printed on the machine through proper baking.

Owner:陈凯

Low-capacity and high-dispersibility type desulfurization adsorbent for benzol refining and preparation method thereof

ActiveCN107008223AExtended service lifeImprove adsorption capacityOther chemical processesAdsorption purification/separationSorbentSilicic acid

The invention discloses low-capacity and high-dispersibility type desulfurization adsorbent for benzol refining and preparation method thereof. The adsorbent mainly comprises active component metal Ru, aluminum oxide and orthosilicic acid polymer, wherein the metal RU is mainly dispersed on the outer surface of the aluminum oxide carrier modified by the orthosilicic acid polymer. The preparation method is outstandingly characterized in that the preparation method, using coprecipitation and impregnation, of traditional desulfurization adsorbent for benzol refining is broken through, the metal Ru is firmly assembled to the surface of the aluminum oxide carrier through the orthosilicic acid polymer, and the Ru is stably dispersed on the surface of the absorbent in a high-dispersibility manner. Compared with the prior art, the ruthenium-based absorbent is high in sulfur capacity, low in Ru content, high in stability, long in service life and promising in industrial application prospect.

Owner:贵研工业催化剂(云南)有限公司

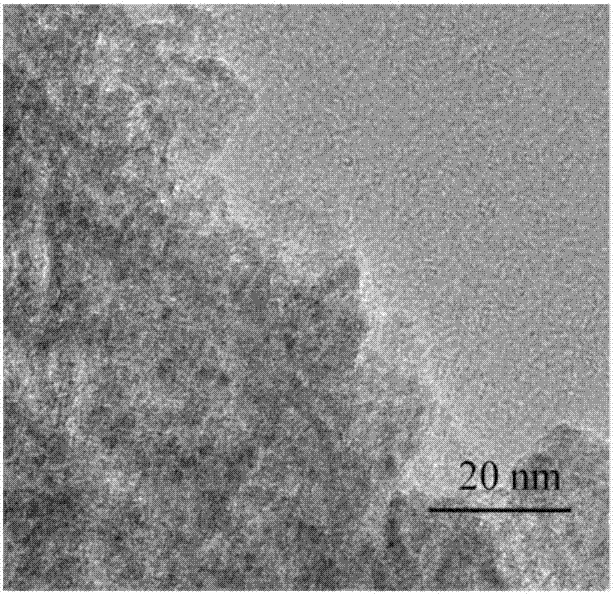

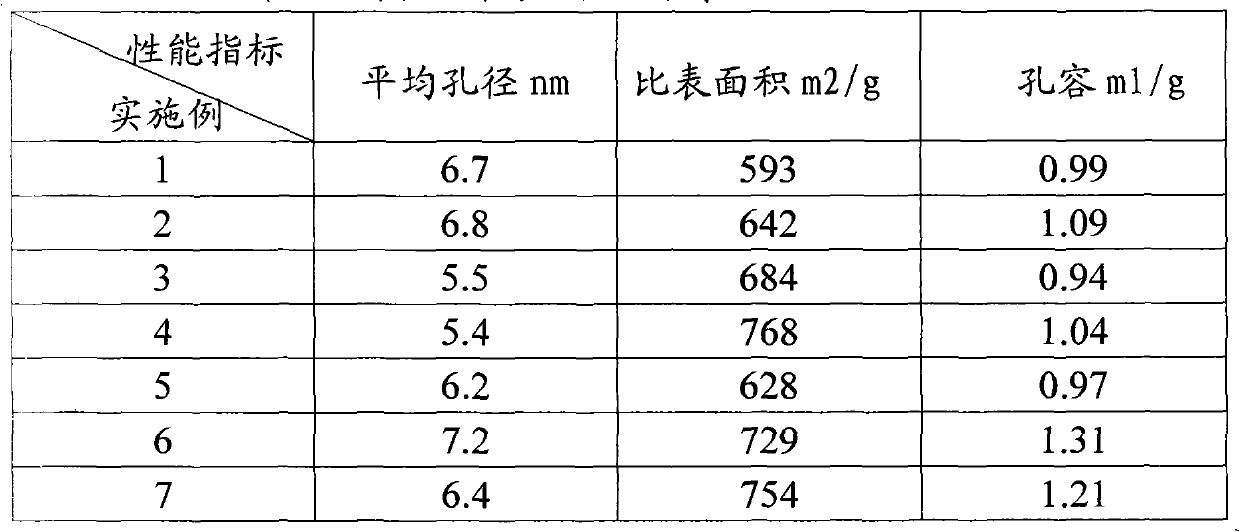

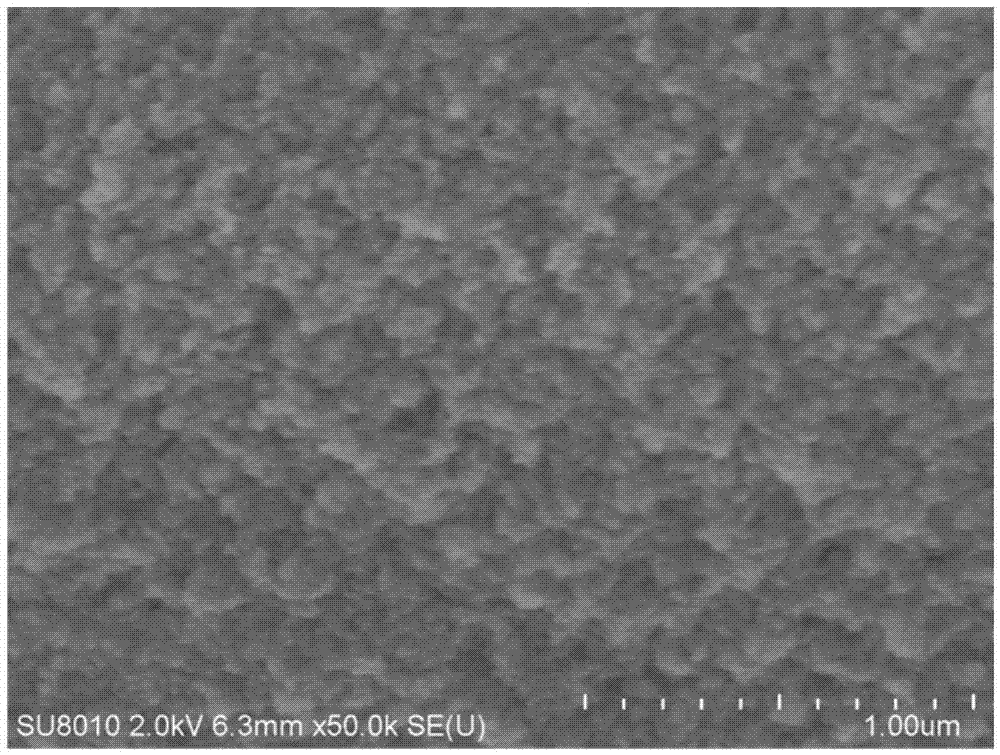

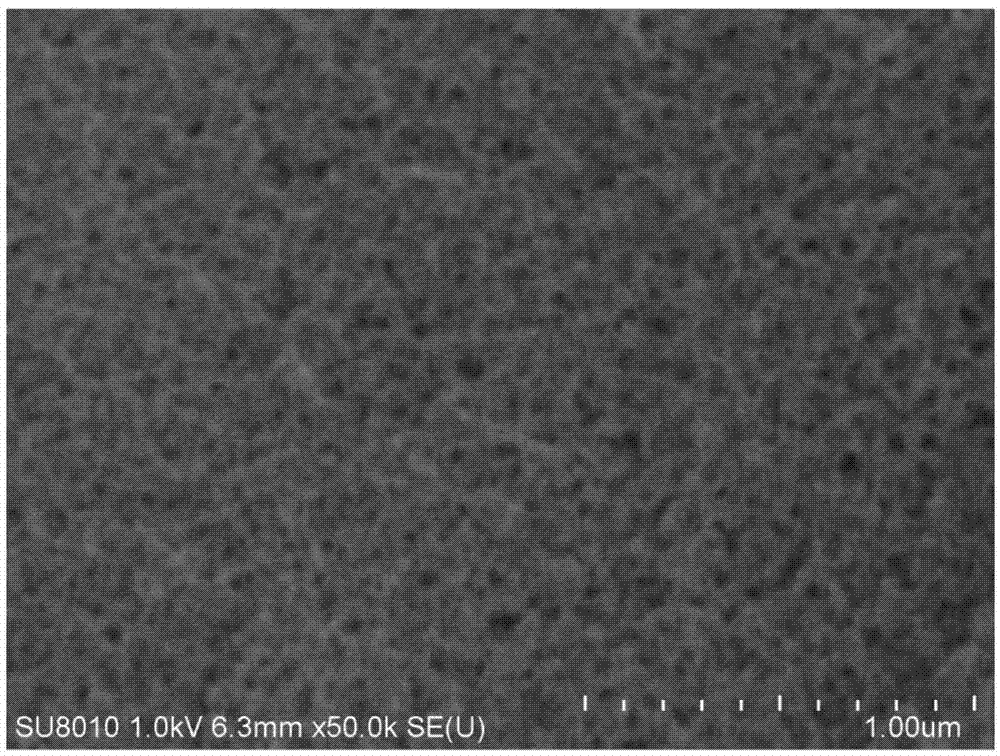

Preparation method of continuous SiO2 aerogel fibers

ActiveCN105671687AAdjust the size of the specific surface areaInnovativeInorganic material artificial filamentsWet spinning methodsFiberFiltration

The invention relates to a preparation method of continuous SiO2 aerogel fibers. The method comprises the following steps: processing silicate or silanol sol to prepare a spinning stock solution; adding an acidic solution to a coagulation tank to form a coagulation bath; and injecting the spinning stock solution to the coagulation bath, carrying out reaction wet spinning to obtain orthosilicic acid / silicate fibers, reeling the orthosilicic acid / silicate fibers, immersing the reeled fibers in an ageing solution, ageing the immersed fibers at normal temperature for 2-10d, washing the aged fibers with deionized water until the aged fibers are neutral, carrying out solvent displacement, and drying the obtained fibers to obtain the continuous SiO2 aerogel fibers. The method has the characteristics of cheap and easily available raw materials, simple reaction process and good spinnability, and solves the problem of difficult production of fibers through spinning SiO2 aerogel. The inorganic SiO2 aerogel fibers prepared in the invention have the characteristics of abundant holes, high specific surface area, high temperature resistance, chemical corrosion resistance and adjustable specific surface area, and can be applied in the fields of catalyst carriers and adsorbing filtration.

Owner:DONGHUA UNIV

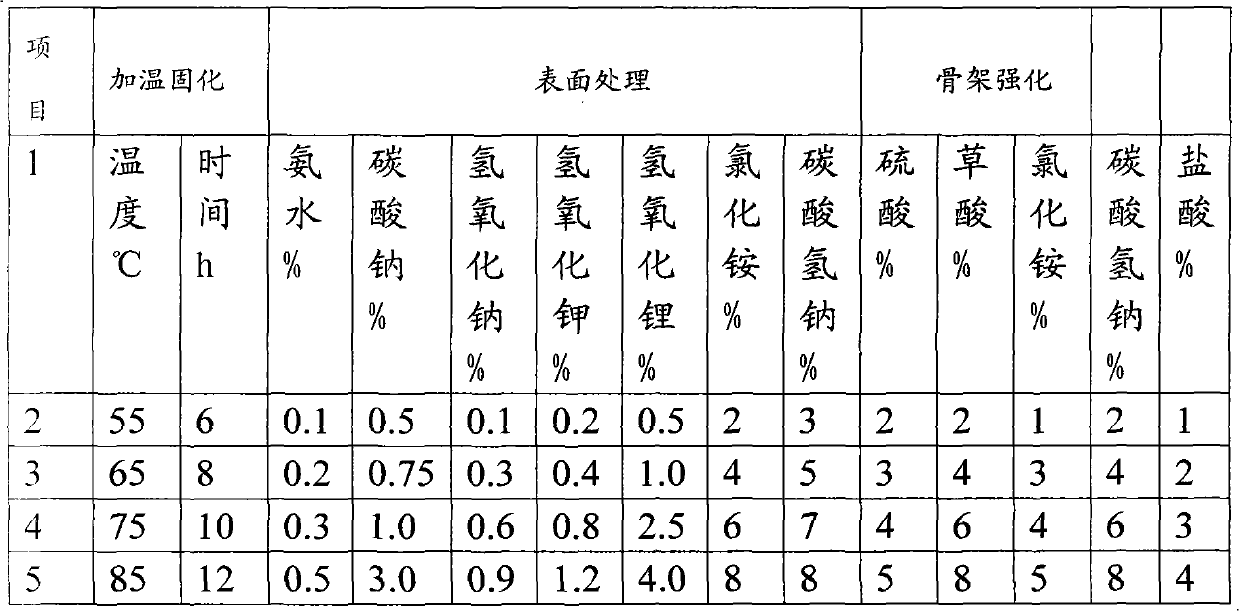

Novel B type large-pore volume silica gel and manufacture method thereof

The invention provides a novel B type large-pore volume silica gel and a manufacture method of the novel B type large-pore volume silica gel. The manufacture method comprises the following steps of A, generating orthosilicic acid in a vortex type mixing reactor through sodium silicate solution and diluted mineral acid according to the conventional silica gel technology, and then standing and curing, and granulating twice; B, heating and curing, transferring the silica gel in an environment at 40 to 90 DEG C for being retained for 8 to 24 hours; C, surfacing the washed silica gel through inorganic salt and inorganic base, wherein for modifying the internal silanol on the internal surface of the silica gel hole, the alkaline can be sodium hydroxide, potassium hydroxide and lithium hydrate; and the inorganic salt can be ammonium chloride, sodium chloride, sodium carbonate, sodium bicarbonate and ammonium bicarbonate; and D, reinforcing the framework through the technology of dipping mineral acid and inorganic salt and thermally processing. According to the manufacture method, the silica gel is transferred into 0.01 to 10% of inorganic salt solution for being heated in water bath, and then is parched in a thermal environment at 100 to 200 DEG C, thus obtaining the silica gel provided by the invention. The manufacture method provided by the invention is simple, and easy to achieve mass production.

Owner:山东辛化硅胶有限公司

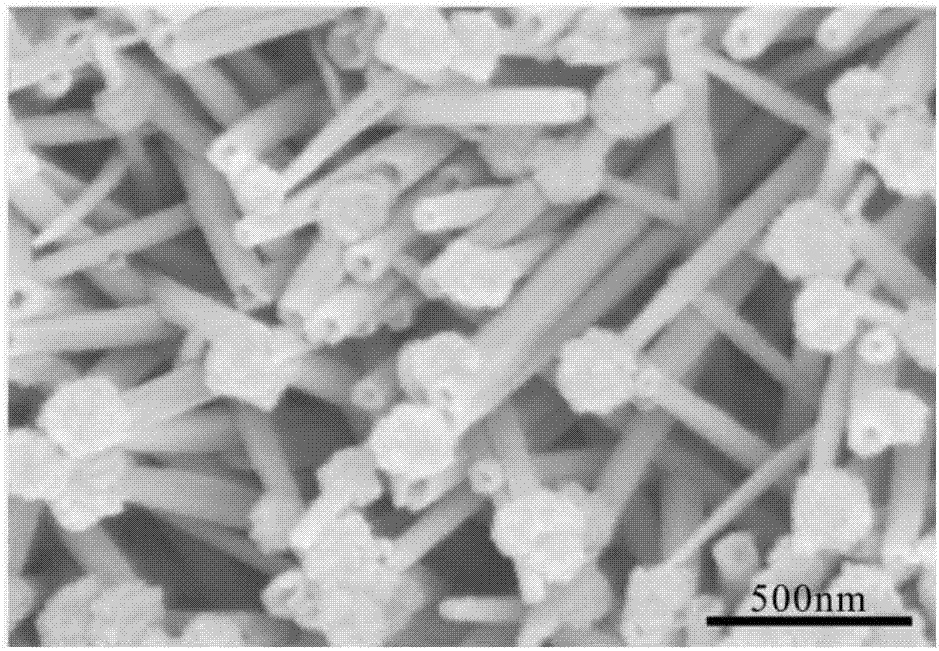

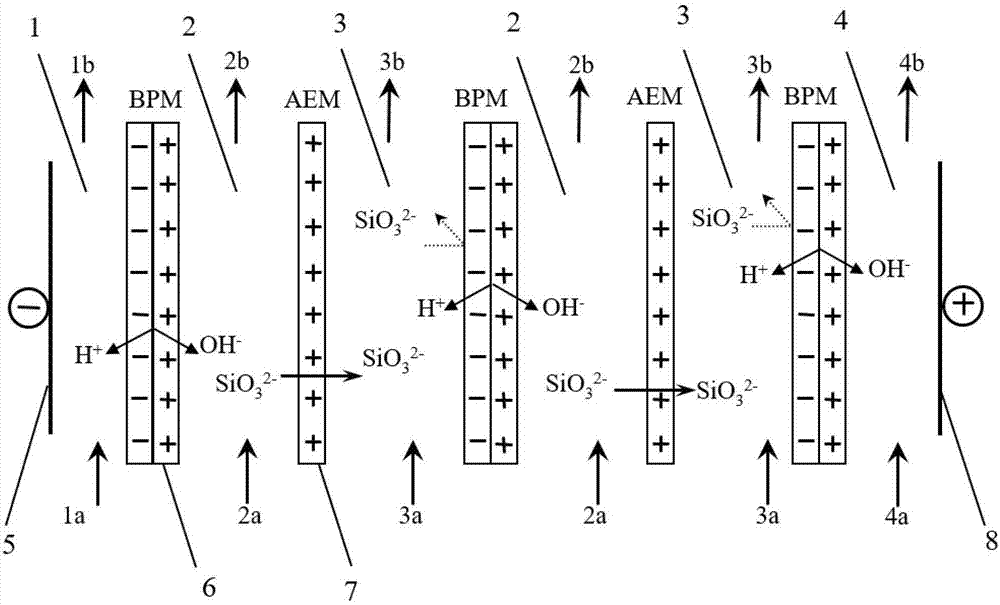

Method for preparation of pharmaceutical adjuvant silica by bipolar membrane electrodialysis

The invention discloses a method for preparation of pharmaceutical adjuvant silica by bipolar membrane electrodialysis. The method includes the steps of: 1. membrane preparation, which specifically comprises the steps of: A), growing oriented ZIF nanotubes on a metal sheet surface to obtain an intermediate, wherein the oriented ZIF nanotubes include cobalt ions; B), soaking the intermediate in a high polymer solution to obtain an oriented ZIF based anion-exchange membrane, wherein the high polymer in the high polymer solution contains benzyl chloride or benzyl bromide groups; 2. placing the oriented ZIF based anion-exchange membrane in a bipolar membrane electrodialysis device to prepare an orthosilicic acid multimer by bipolar membrane electrodialysis; and 3. heating the orthosilicic acid multimer prepared by the step 2 to obtain silica. The method provided by the invention employs bipolar membrane electrodialysis to prepare the pharmaceutical adjuvant silica, and provides a new preparation process for preparation of the pharmaceutical adjuvant silica.

Owner:HUAINAN UNITED UNIVERSITY

Composite glass clarifying agent

The invention discloses a composite glass clarifying agent, which belongs to the field of the glass production. The composite glass clarifying agent is prepared from the raw materials such as acrylamide and sodium dimethyl diacrylamide sulfonate and can be slowly expanded after being heated, and can form a wrapping and supporting effect for a netted structure formed by silicate and SiO2 in a glasssystem, polymer microspheres comprise partial gas in the preparation process, in the application process, the partial gas overflows rapidly, so that the dispersity is good, and a better bubble inhibition and removal effect can be achieved; and polyether is introduced into the organic silicon, no only can the hydrophilic group but also the oleophylic group be provided, by introducing the paraffinand microcrystalline paraffin, a long-chain aliphatic compound can be introduced, the silicon tetrahydride can be rapidly hydrolyzed into orthosilicic acid and hydrogen under an alkaline condition, generation of other bubbles can be prevented, the secondary bubbles can be further prevented, and a better bubble eliminating effect can be achieved. By adopting the composite glass clarifying agent, the problem that the conventional glass clarifying agent is poor in bubble removal efficiency.

Owner:CHANGZHOU UNIV

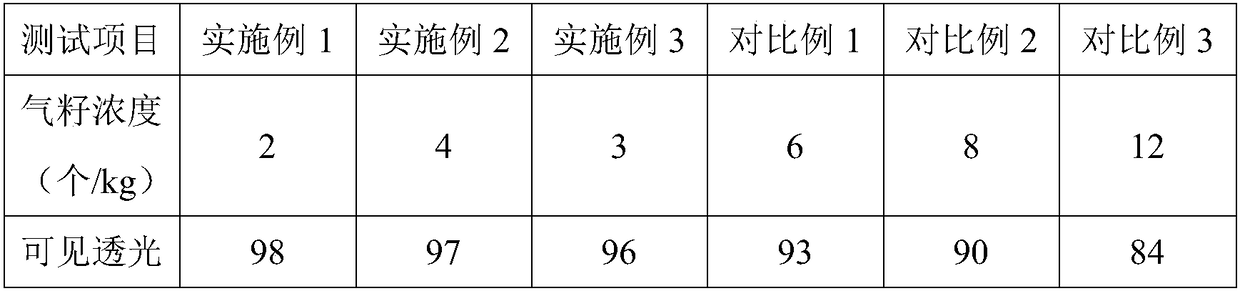

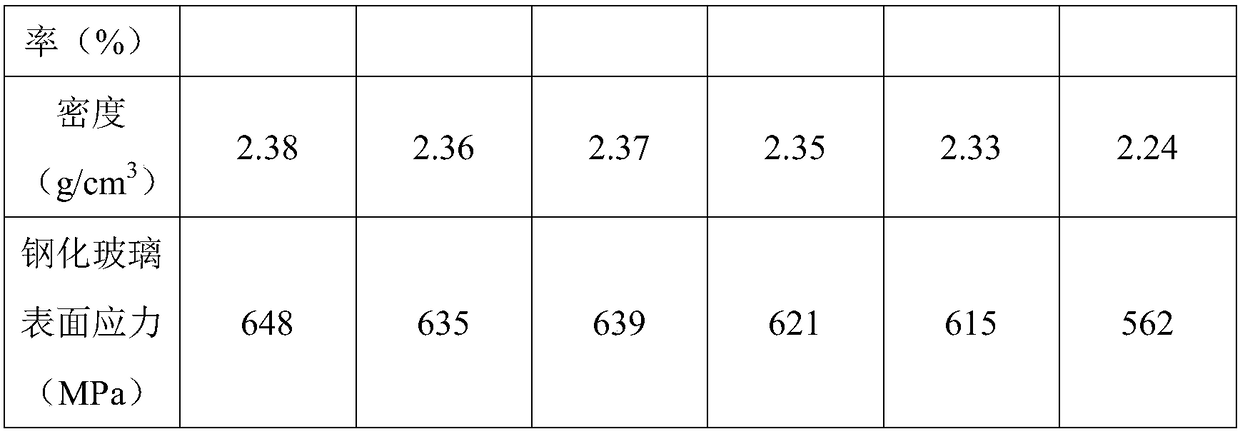

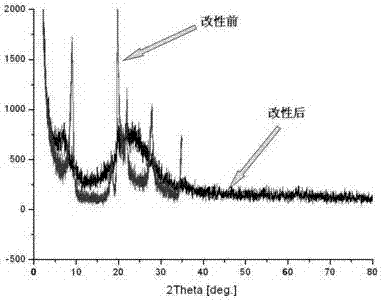

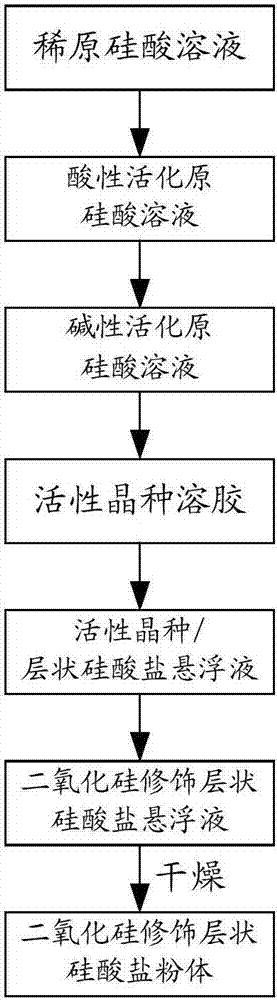

Method for layered silicate modified silica sol

ActiveCN107487774AReduce manufacturing costSimple processAluminium silicatesOrganic solventWorking environment

The invention provides a method for a layered silicate modified silica sol, wherein a dilute orthosilicic acid solution, an acidic activated orthosilicic acid solution, an alkaline orthosilicic acid solution, an active crystal seed sol, a first-stage growth silica sol and a first-stage growth silica sol / layered silicate suspension are prepared so as to finally obtain the layered silicate modified silica sol. According to the present invention, the cheap water glass is used as the raw material, and all the processes are carried out in the water phase without the organic solvents, such that the production cost is substantially reduced, the working environment is safe and health, and the method has advantages of simple process, low cost, and environment protection.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

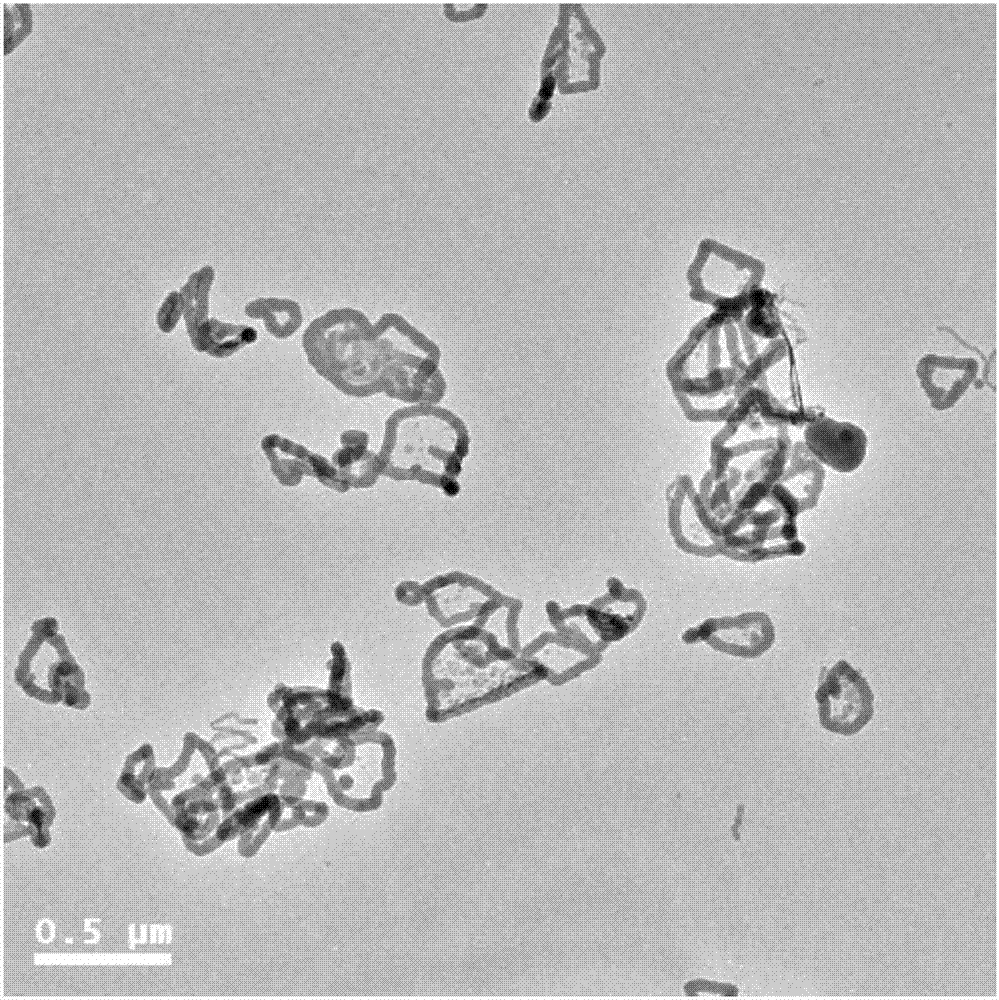

Method for modifying layered silicate powder by using silicon dioxide

ActiveCN107488366AAvoid the problem of poor heat resistance and affect the application temperatureHigh purityInorganic pigment treatmentIn situ polymerizationSilicon dioxide

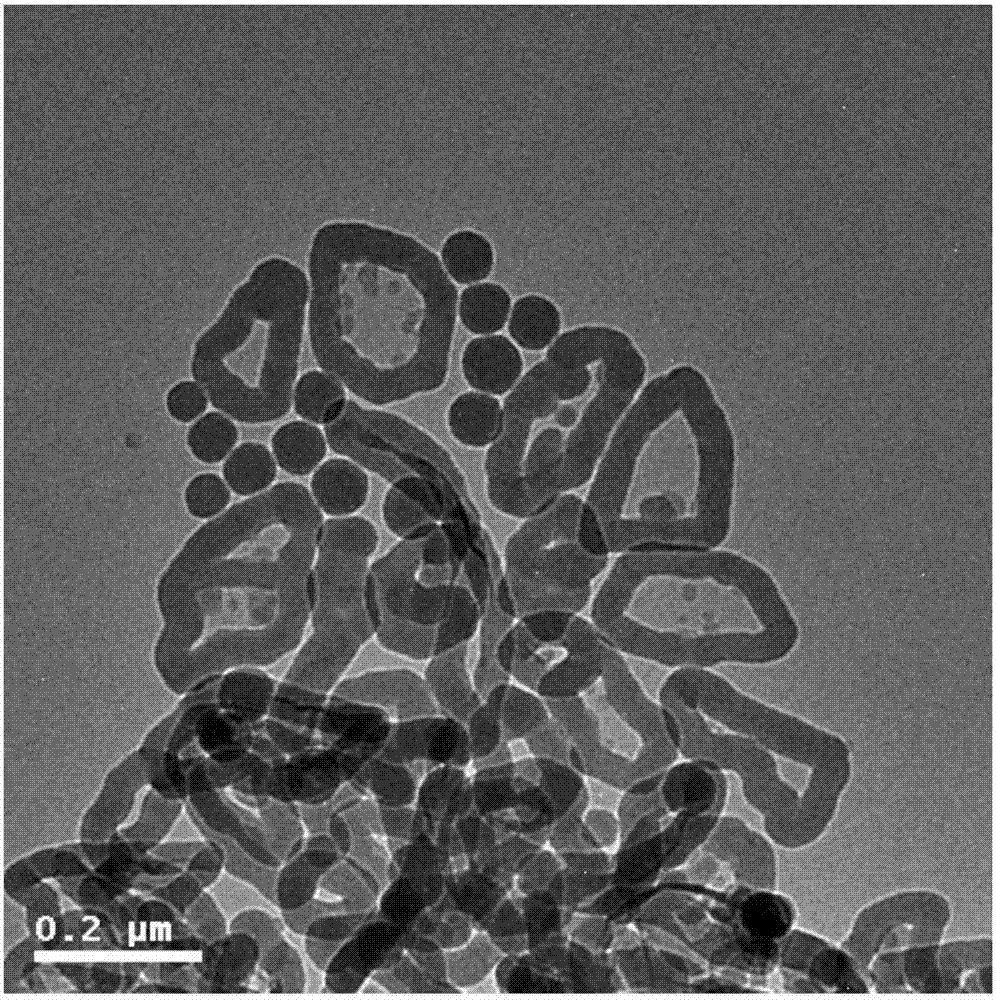

The invention provides a method for modifying layered silicate powder by using silicon dioxide. The method comprises: preparing a dilute orthosilicic acid solution, an acidic activated orthosilicic acid solution, an alkaline orthosilicic acid solution, an active crystal seed sol, an active crystal seed / layered silicate suspension and an in-situ growing silica modified layered silicate, and drying the silica modified layered silicate suspension so as to finally obtain the silica modified layered silicate powder. According to the present invention, the silica particles can be simultaneously prepared on the surface and the edge of the layered silicate, such that the layered structure of the layered silicate can be peeled off, and the problem that the application temperature is affected by the poor heat resistance of the polymer intercalation molecules due to the in-situ intercalation or in-situ polymerization with long chain quaternary ammonium salts and other intercalators can be avoided.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method of high-strength water-proofing clay sculpture material

InactiveCN107602049AIncrease stickinessImprove hydrophobicity and water resistanceClay mineralsSlurry

The invention relates to the technical field of sculpture material preparation and particularly relates to a preparation method of a high-strength water-proofing clay sculpture material. In the method, orthosilicic acid precipitate is mixed with quick lime to obtain a paste mixture, and flax straw and the paste mixture are soaked and fermented for a long time, so that the flax straw is mildewed, wherein grass tendon, which is high in toughness and strength, remain and is precipitated with the lime; the materials are heated and boiled so that the orthosilicic acid precipitate is heated and decomposed to generate nano SiO2 which is packed in the slurry, wherein the high-strength nano SiO2 can further increase the mechanical strength of cured and shaped slurry so as to finally obtain self-made tendon slurry which has very high viscosity and high strength; then clay mineral kaolin is blended with flour and castor oil to perform fermentation, so that castor oil is degraded to generate estergroups under effect of microorganisms, finally the ester groups are introduced to the surface of kaolin for improving the hydrophobicity and water resistance of clay to fially produce the high-strength water-proofing clay sculpture material, which has broad application prospect.

Owner:常州富思通管道有限公司

Method for improving germanium leaching rate of germanium-rich zinc suboxide smoke dust

ActiveCN110607453AImprove leaching rateResolve separabilitySilicaProcess efficiency improvementSlagSlurry

The invention relates to a method for improving the germanium leaching rate of germanium-rich zinc suboxide smoke dust, and belongs to the technical field of non-ferrous metal wet smelting. The methodmainly comprises five steps of slurrying, first-stage leaching, second-stage leaching, third-stage leaching and filtering, wherein the pH value of the slurry is adjusted and controlled, and zinc, silicate and germanium are selectively leached in sequence, so that the silicate is leached before the germanium, generated orthosilicic acid is precipitated into slag in the form of hydrated silicon protein, and the influence of synchronous dissolution and coprecipitation of the silicate and the germanium on the germanium yield is effectively eliminated; and the germanium and zinc are recovered fromthe filtrate after the leaching ore slurry is subjected to liquid-solid separation. The method solves the technical problem of low germanium leaching rate caused by coprecipitation of silicon and germanium during leaching, and the germanium leaching rate is improved by 15-22%.

Owner:YUNNAN HONGCHI RESOURCE INTEGRATION UTILIZATION CO LTD

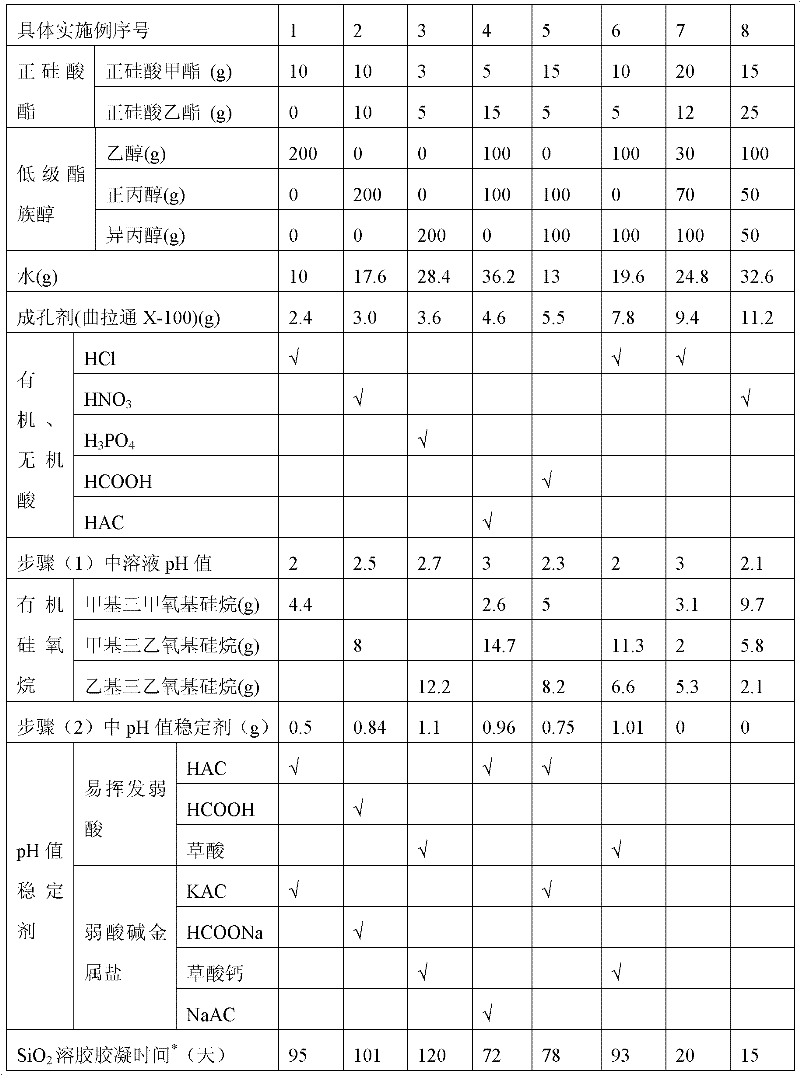

Method for preparing sol for stabilizing properties of anti-reflection film of solar glass

The invention relates to the preparation of sol and aims to provide a method for preparing sol for stabilizing the properties of an anti-reflection film of solar glass. The method comprises the following steps of: adding orthosilicic acid ester into a lower aliphatic alcohol solvent with stirring, and mixing uniformly; adding water, adding a pore-forming agent, namely triton X-100, mixing, adding organic acid or inorganic acid to regulate the pH value of a solution to be 2 to 3, and reacting for 4h at the temperature of 60 DEG C; adding alkyl siloxane, mixing uniformly, and continuing to react for 2h at the temperature of 60 DEG C to obtain SiO2 polymer sol for the anti-reflection film; and adding a pH value stabilizer with the pH value of between 6.8 and 7.8, and mixing uniformly to obtain a product. By the method, the subsequent reaction speed of the system is greatly reduced, and the stability of the system is improved and the preservation time of the system is prolonged. Meanwhile, during the use of film sol, volatile weak acid in a buffer solution is volatilized and weak acid salt of the volatile weak acid is remained through the curing and heating of a film in the post-heat treatment process; and the film system becomes alkaline and is easier to cure at this time.

Owner:温州市康尔微晶器皿有限公司

Preparation method of hydrophobic carbon fiber paper

InactiveCN110055808AImprove stabilityHigh porosityNon-fibrous pulp additionCarbon fibresFiberModified carbon

The invention discloses a preparation method of a hydrophobic carbon fiber paper and belongs to the technical field of paper products. The method comprises taking sodium silicate as a raw material toproduce orthosilicic acid precipitates under acid conditions; blending and mixing nanosilicon dioxide and nickel to uniformly deposit the catalyst of nickel onto the surface of the nanosilicon dioxide; inletting methane gas to binding aliphatic ester onto the surface of carbon nanofibers to endow modified carbon nanofibers with hydrophobicity; mixing dodecane diamine and ethanol solution for high-temperature reaction with graphene to enhance interfacial interaction between polyurethane foam and modified graphene. Therefore, the contact angle between the prepared hydrophobic carbon fiber paperand water can be increased, hydrophobic properties of graphene-grafted polyurethane foam can be improved, the hydrophobicity of the prepared hydrophobic carbon fiber paper can be further enhanced, andaccording to the principles of polarity similarity and compatibility, binding between the hydrophobic carbon fiber paper and the water can be tighter. The hydrophobic carbon fiber paper has a broad application prospect.

Owner:龙仕君

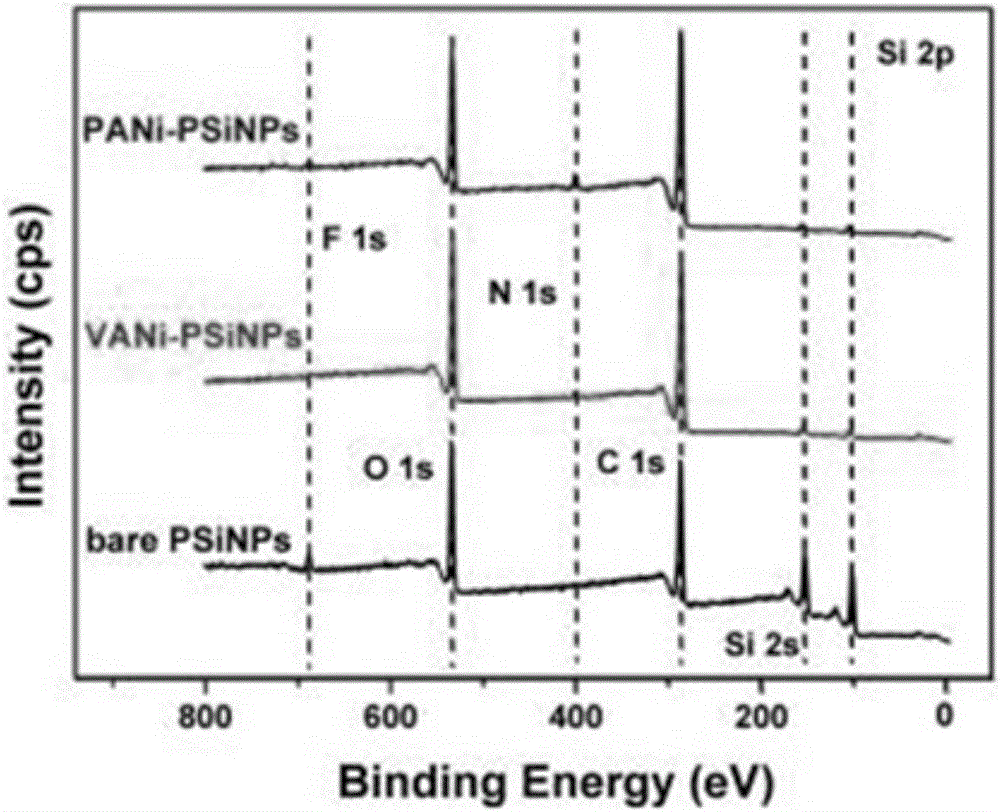

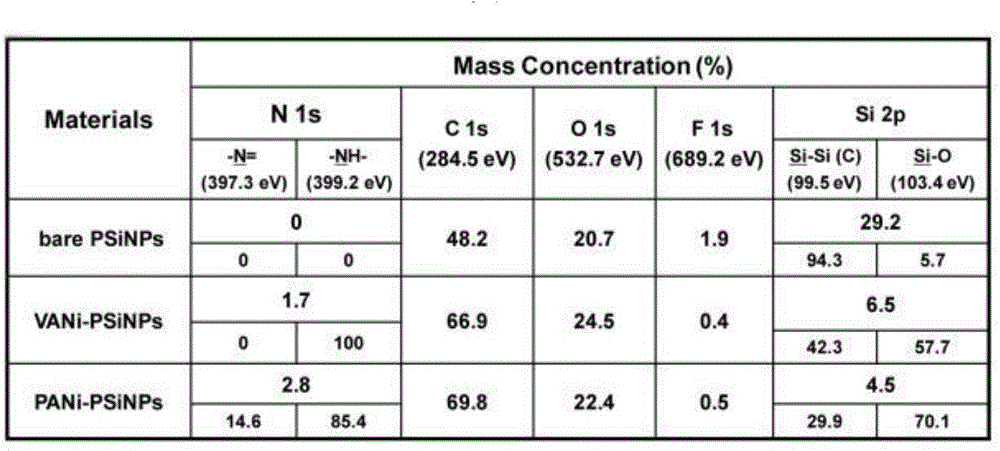

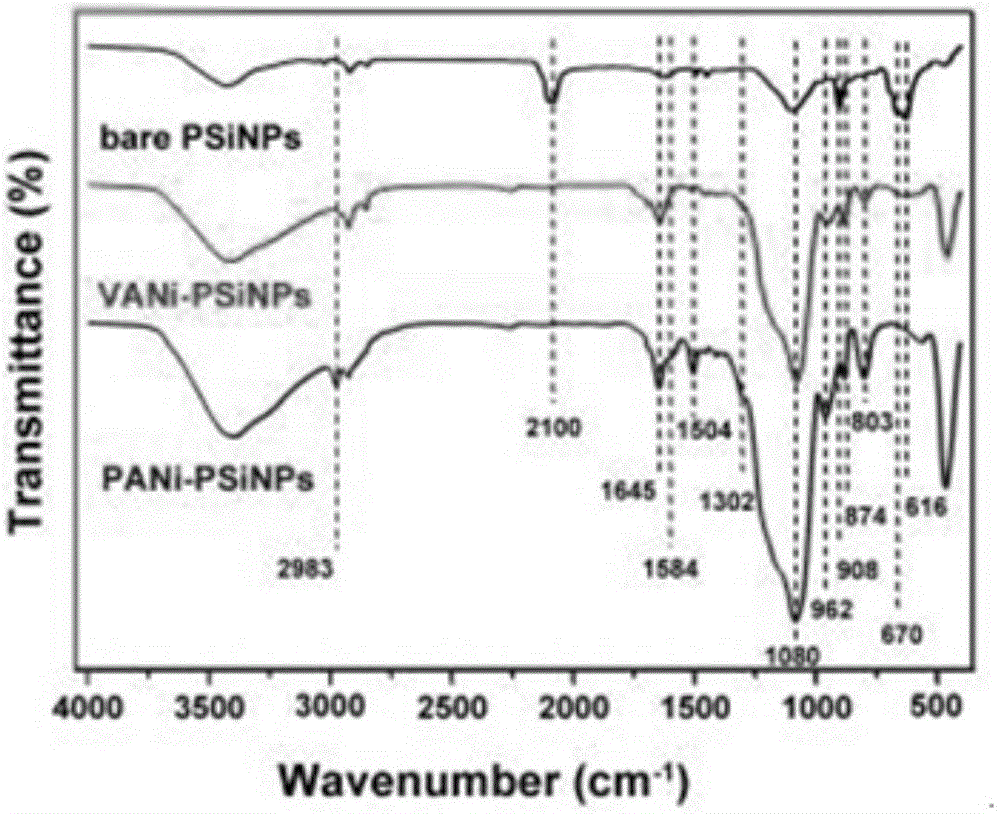

Degradable polyaniline/porous silicon nanocomposite as well as preparation method and application thereof

ActiveCN106478946AAperture adjustableIncrease surface areaOrganic active ingredientsEnergy modified materialsSolubilityBiocompatibility Testing

The invention discloses a degradable polyaniline / porous silicon nanocomposite as well as a preparation method and application thereof. Compared with other inorganic nano materials, the porous silicon nano material prepared in the invention has adjustable aperture, large surface area and easily-functionalized surface and can be used for loading different organic molecules, biomacromolecules, nano materials and the like. Moreover, with perfect biocompatibility and biodegradability, the porous silicon nano material has great potential in clinical application since the porous silicon nano particles can be degraded in vivo into orthosilicic acid which is discharged out through urine. Therefore, a degradable polyaniline / porous silicon nanocomposite is synthesized; and the material has obvious and stable photo-thermal ability, perfect water solubility and excellent biocompatibility and degradability, and can effectively load doxorubicin and realize a remarkable chemotherapy-thermotherapy combination synergistic treatment effect in vivo or in vitro.

Owner:NANJING FORESTRY UNIV

Preparation method of ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone)

ActiveCN105442098AImprove toughnessToughness hasInorganic material artificial filamentsWet spinning methodsFiberPolymer science

The invention relates to a preparation method of a ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone). The preparation method comprises the following steps: a spinning solution is prepared from silicate or silanol sol; an acid solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution is added to the coagulating bath for reaction wet spinning, an orthosilicic acid / silicate fiber is obtained and is subjected to winding, aging and washing to be neutral, and solvent exchange and drying performed; the dried fiber is soaked in a PVP aqueous solution, taken out and dried, and a product is obtained. The preparation method has the characteristics of cheap and available raw materials, simple reaction process and good spinnability; the prepared inorganic SiO2 aerogel fiber has rich pores, high specific surface area, high-temperature resistance and chemical corrosion resistance, meanwhile, the specific surface area of the fiber is adjustable, the fiber has certain toughness, the application range of the aerogel fiber can be expanded, and the aerogel fiber has higher practical value.

Owner:DONGHUA UNIV

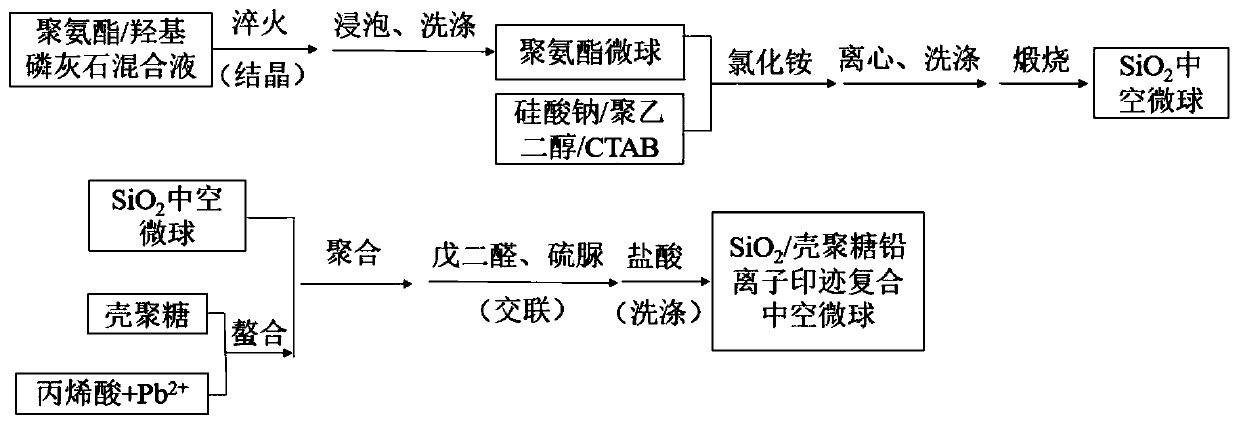

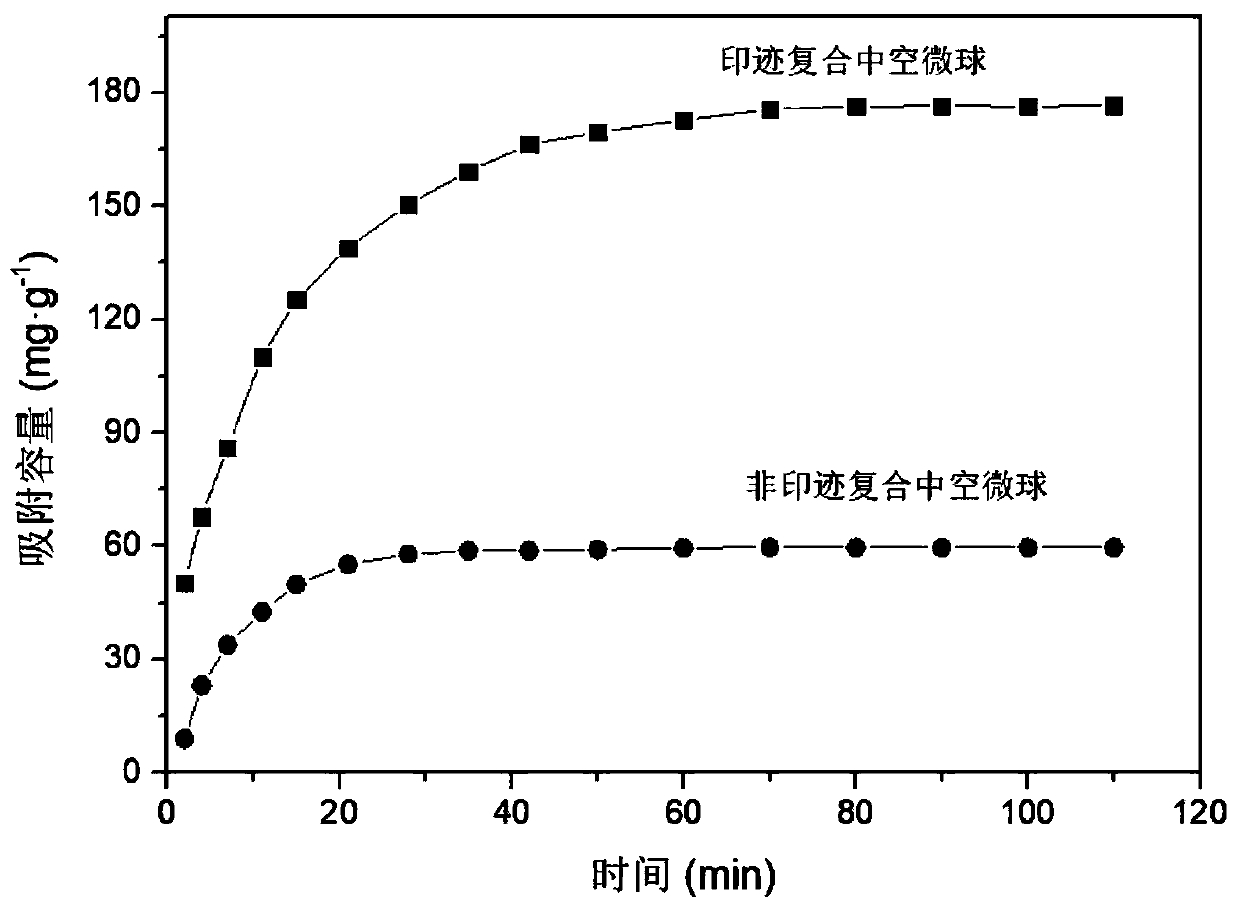

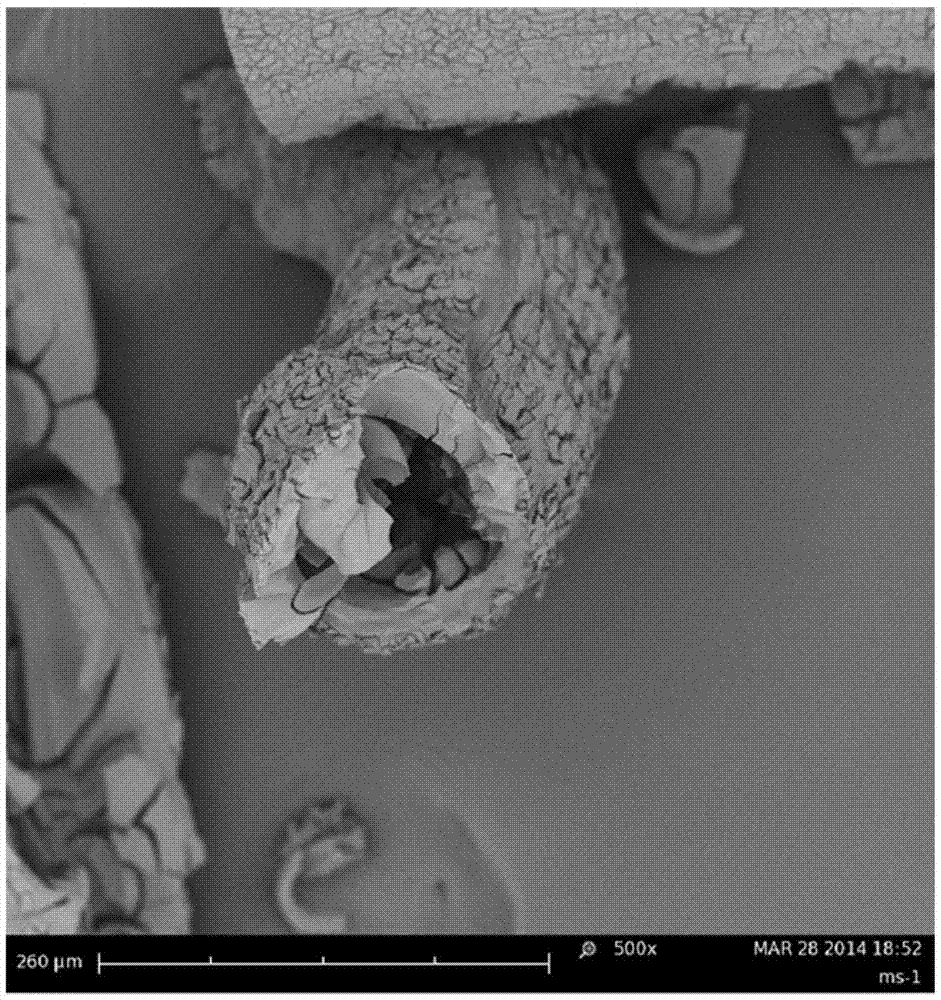

Preparation method of SiO2/chitosan-based lead ion imprinted hollow microspheres

ActiveCN110523397AHigh porosityLarge specific surface areaOther chemical processesWater contaminantsPorositySilicic acid

The invention discloses a preparation method of SiO2 / chitosan-based lead ion imprinted hollow microspheres. The method comprises the following steps: preparing polyurethane microspheres by using a thermally induced phase separation process; uniformly mixing ethanol, distilled water, sodium silicate, polyethylene glycol and a surfactant, and adding the polyurethane microspheres to form a mixed liquid; preparing SiO2 hollow microspheres by utilizing the mixed liquid; and dissolving chitosan into an acrylic acid aqueous solution, adding lead nitrate, performing uniform mixing, adding the SiO2 hollow microspheres and ammonium persulfate, and performing a series of reactions to obtain the SiO2 / chitosan-based lead ion imprinted hollow microspheres. The method provided by the invention has the following beneficial effects: the polymer microspheres are used as a template, orthosilicic acid is supported on the surface of the template, finally calcination is performed to obtain the SiO2 hollow microspheres, and the prepared SiO2 hollow microspheres have high porosity and a large specific surface area, and can be used as a carrier of loading of a catalyst, an adsorbent and a drug.

Owner:晋江瑞碧科技有限公司 +1

Method for preparing continuous hollow SiO2 porous fibers through coaxial spinning

ActiveCN105442093AAdjust the size of the specific surface areaLarge specific surface areaInorganic material artificial filamentsFiltrationSolvent

The invention relates to a method for preparing continuous hollow SiO2 porous fibers through coaxial spinning. The method comprises steps as follows: a spinning stock solution is prepared from silicate or silanol sol; one acid solution is added to a coagulating tank to be used as a coagulating bath, and the other identical acid solution is used as a coaxial spinning core spinning solution; the spinning stock solution and the coaxial spinning core spinning solution are injected into the coagulating bath through coaxial spinning needles at the same flow rate, reaction wet spinning is performed, hollow orthosilicic acid / silicate fibers are obtained, wound, aged and washed to be neutral with deionized water, solvent displacement is performed, and the continuous hollow SiO2 porous fibers are obtained through drying. The method has the characteristics that equipment is simple, raw materials are cheap and easy to obtain, the reaction process is simple and the spinnability is good. The hollow inorganic SiO2 porous fibers obtained with the method have rich pores and ultra-large specific surface area, are resistant to the high temperature and chemical corrosion, and have more advantages than common porous fibers in fields of catalysis, adsorption, filtration and the like.

Owner:DONGHUA UNIV

Preparation method of high toughness metal ceramic

ActiveCN107723494AGood toughening effectGood compatibilityPolycrystalline material growthAfter-treatment detailsPotassium borohydrideCarboxylic acid

The invention relates to the technical field of metal ceramic preparation, and in particular to a preparation method of high toughness metal ceramic. According to the preparation method of the high toughness metal ceramic, a rice husk pore is enlarged through soda boiling firstly; then a sodium silicate solution is immerged into rice husks; hydrochloric acid and sodium silicate react to generate gelatinous orthosilicic acid, and then the rice husks are carbonized and sintered to obtain porous silicon carbide whiskers with the high specific surface area; then the silicon carbide whiskers, lemonsmashing materials rich in organic carboxylic acid and grape skin rich in saccharomycetes are mixed and fermented; organic carboxylic acid is degraded and free carboxyl groups are generated under theeffect of microorganism; the free carboxyl groups are introduced to the surface of porous silicon carbide whiskers under the self-crosslinking effect of microorganism; nickel ions are chelated and absorbed by using the chelating property of carboxyl; at last, under the effect of high temperature sintering, the carboxyl is disintegrated and the nickel ions are exposed again; the nickel ions are reduced to nickel simple substance. By using the characteristic that the nickel simple substance has unlimited compatibility with metal molybdenum and metal titanium, the compatibility of the silicon carbide whiskers and a metal base body is improved; and the toughening effect of the silicon carbide is improved.

Owner:江苏英特耐机械制造有限公司

Choline-silicic acid complex with osmolytes and divalent trace elements

ActiveUS20120015047A1Improve bioavailabilityRaise the pHBiocideHeavy metal active ingredientsOligomerSilicic acid

The invention relates to a biological preparation comprising orthosilicic and silicic acid, a primary (“constant / first”) osmolyte choline and a weak alkalinizing agent without free hydroxyl groups and to a method for preparing the preparation, comprising: i) hydrolyzing a silicon comprising choline solution thereby forming a choline stabilized orthosilicic acid and oligomers solution; ii) alkalizing the choline orthosilicic acid and oligomers solution by adding a weak alkalizing agent without hydroxyl groups; and iii) optionally adding a divalent trace element and / or secondary osmolyte, to biological preparation obtainable and its uses.

Owner:BIO MINERALS

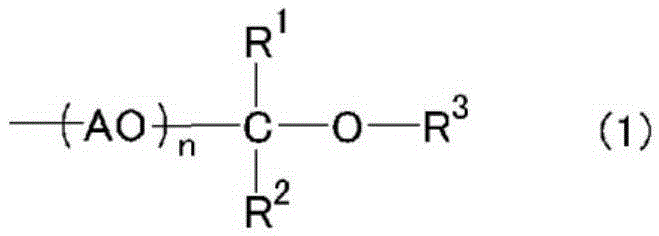

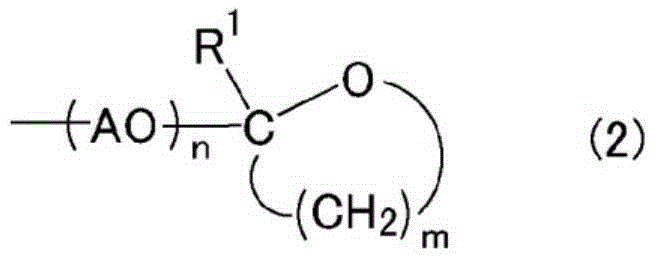

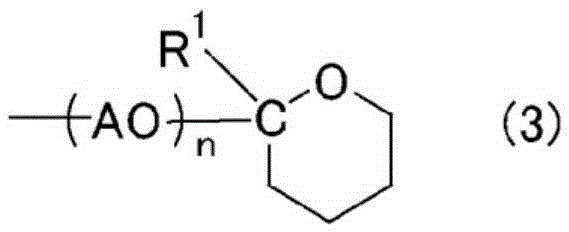

Solid cleaning agent composition

InactiveCN105339480AFine foamReduce foamingInorganic/elemental detergent compounding agentsSurface-active detergent compositionsHydrogen atomEther

This cleaning agent composition is characterized by containing the following (A) and (B) components: (A) a nonionic surfactant having a structure represented by general formula (1) on an end thereof; and (B) one or more types of alkali agent selected from a group consisting of an alkali metal hydroxide, an alkali metal salt of a metasilicic acid, an alkali metal salt of a sesquisilicic acid, an alkali metal salt of an orthosilicic acid, an alkali metal salt of an orthophosphoric acid, an alkali metal salt of a pyrophosphoric acid, an alkali metal salt of a tetraphosphoric acid, an alkali metal salt of a pentaphosphoric acid, an alkali metal salt of a hexaphosphoric acid, and an alkali metal salt of a carboxylic acid. (In the formula, R1 represents a hydrogen atom or an alkyl group, R2 and R3 represent hydrocarbon groups which may contain an ether bond and may form a ring, AO represents an oxyalkylene group which may be identical or different, and n represents the average number of added moles of the oxyalkylene group, and is a number between 1 and 400, inclusive.)

Owner:NIITAKA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com