Preparation method of aerogel felt heat insulation material

A technology of heat insulation and airgel felt, which is applied in the field of heat insulation materials, can solve problems such as felt body falling off, health threats to construction personnel, and inconvenience in construction, etc., to achieve reduced powder drop, orderly and complete pore structure distribution, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

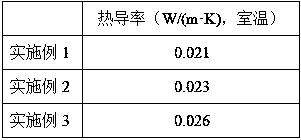

Examples

Embodiment 1

[0028] A kind of preparation method of airgel blanket thermal insulation material, the steps are as follows:

[0029] (1) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2 mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol A;

[0030] (2) In parts by weight, stir and mix 20 parts of resin, 0.04 parts of initiator, 3 parts of coupling agent, and 100 parts of hollow glass microspheres in a sealable container to obtain slurry B;

[0031] (3) First immerse the glass fiber felt in the silica sol A obtained in step (1) for 6 hours, and then immerse it in the freshly prepared slurry B for 3 hours after taking it out;

[0032] (4), repeat the operation step (3) 4 times and the silica sol A is always in a stirring state when the glass fiber mat is impregnated in the slurry B, then take out the glass fiber mat and place it under vacuum condition for 2 h ;

[0033] (5) Aging the glass fiber mat obtained in step (4) under heating cond...

Embodiment 2

[0037] A kind of preparation method of airgel blanket thermal insulation material, the steps are as follows:

[0038] (1) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2 mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol A;

[0039] (2) In parts by weight, stir and mix 18 parts of resin, 0.05 parts of initiator, 4 parts of coupling agent, and 100 parts of hollow glass microspheres in a sealable container to obtain slurry B;

[0040] (3) First immerse the glass fiber felt in the silica sol A obtained in step (1) for 5 hours, and then immerse it in the freshly prepared slurry B for 3 hours after taking it out;

[0041] (4), repeat the operation step (3) three times and the silica sol A is always in a stirring state when the glass fiber mat is impregnated in the slurry B, then take out the glass fiber mat and place it under vacuum condition for 2 h ;

[0042] (5) Aging the glass fiber mat obtained in step (4) under heating ...

Embodiment 3

[0046] A kind of preparation method of airgel blanket thermal insulation material, the steps are as follows:

[0047] (1) Mix ethyl orthosilicate, absolute ethanol and water evenly, then add 2 mol / L NH 4 Stir F solution and 0.2moL / L ammonia water evenly to obtain silica sol A;

[0048] (2) In parts by weight, stir and mix 15 parts of resin, 0.02 parts of initiator, 2 parts of coupling agent, and 100 parts of hollow glass microspheres in a sealable container to obtain slurry B;

[0049] (3) First immerse the glass fiber felt in the silica sol A obtained in step (1) for 6 h, then take it out and then immerse it in the freshly prepared slurry B for 2 h;

[0050] (4), repeat the operation step (3) three times and the silica sol A is always in a stirring state when the glass fiber mat is impregnated in the slurry B, then take out the glass fiber mat and place it under vacuum condition to seal and stand for 3 h ;

[0051] (5) Aging the glass fiber mat obtained in step (4) under h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com