Patents

Literature

31results about How to "Avoid powder shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

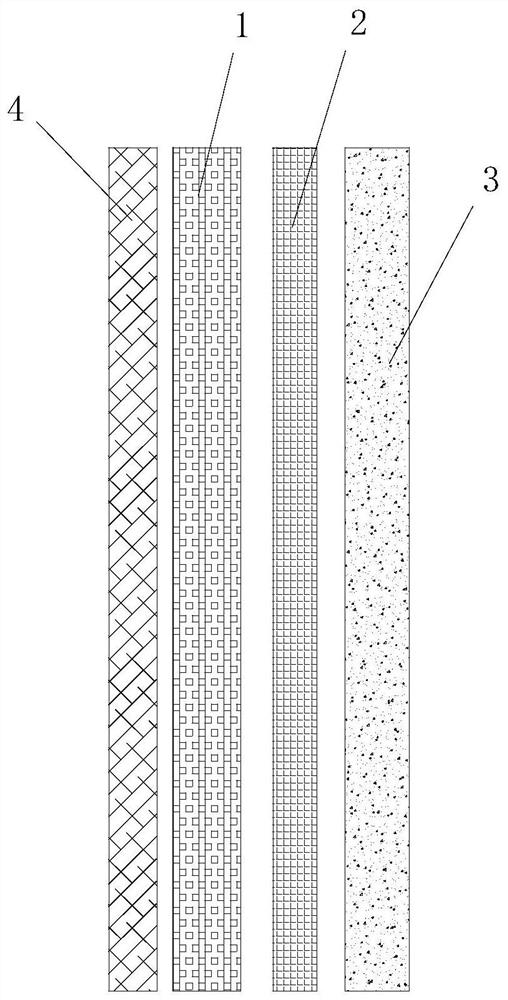

Composite film with high-temperature resistance layer, preparation method thereof and battery

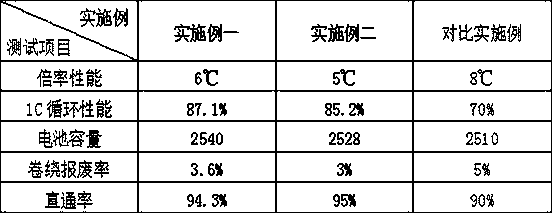

ActiveCN103078075AHigh peel strengthAvoid powder sheddingCell component detailsComposite filmTemperature resistance

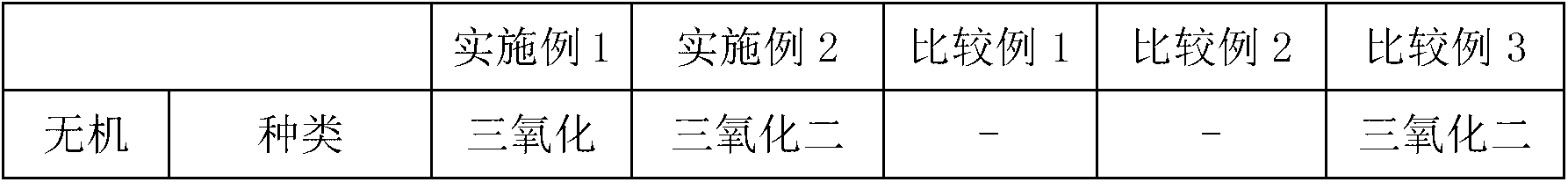

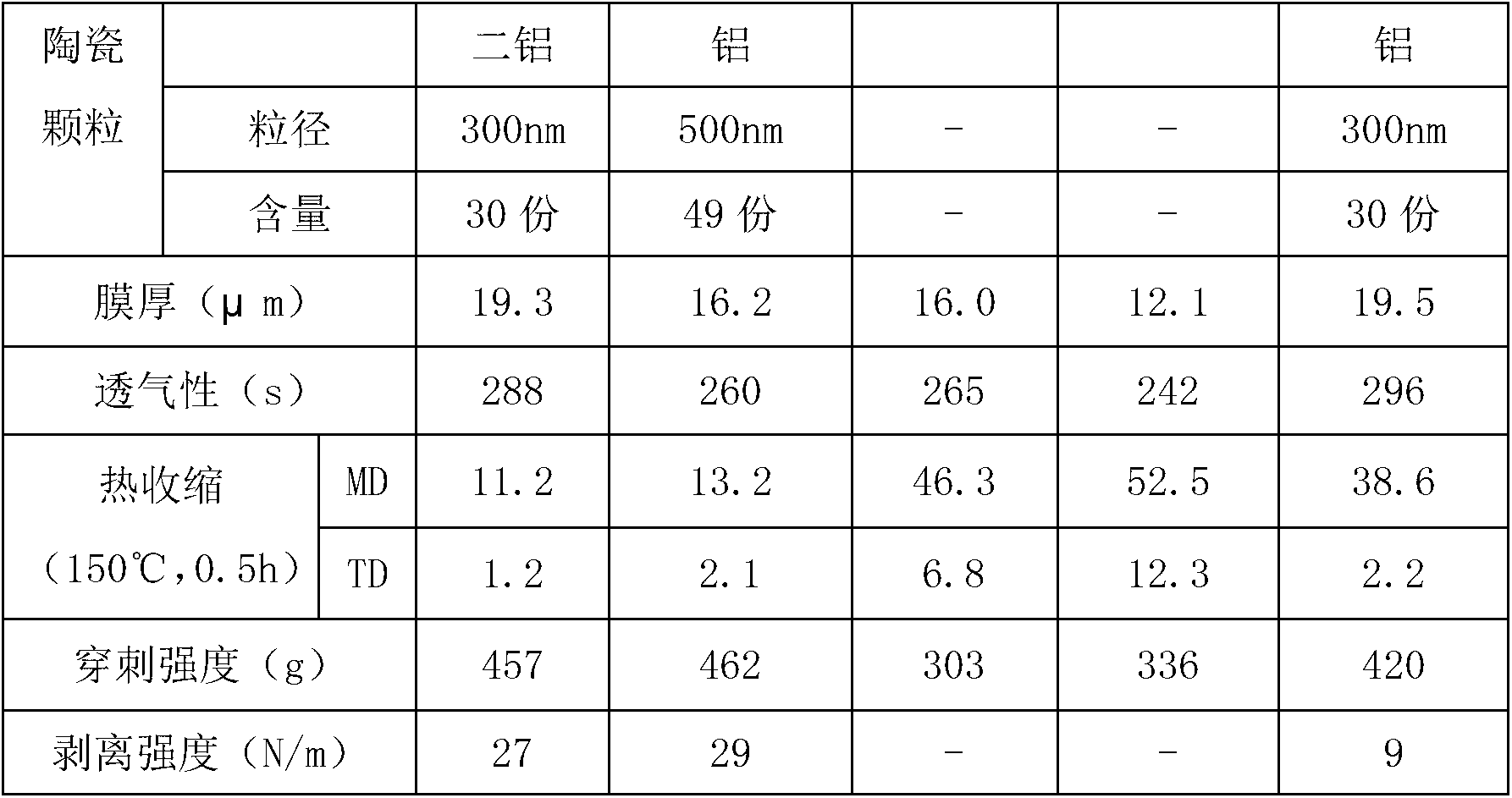

The application relates to the field of lithium batteries, and particularly discloses a composite film with a high-temperature resistance layer, a preparation method thereof and a battery. The composite film disclosed by the application comprises a base film and the high-temperature resistance layer, wherein the base film is a porous thermoplastic resin film; the high-temperature resistance layer is an inorganic ceramic layer containing ceramic particles; the inorganic ceramic layer is fixed on at least one surface of the porous thermoplastic resin film by polymerization; and the peel strength of the porous thermoplastic resin film and the inorganic ceramic layer is larger than or equal to 25 N / m under the condition of 180 DEG C. The invention further discloses the preparation method and the application of the composite film and the battery adopting the composite film. According to the application, the peel strength of inorganic ceramic layer and the porous thermoplastic resin film is greatly improved so as to effectively avoid a powder falling phenomenon of the inorganic ceramic particles in the composite film. Meanwhile, the composite film has excellent high temperature resistance performance, and can reduce battery short circuit phenomena caused by heat shrinkage of the composite film in the application.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Preparation method of aerogel felt heat insulation material

The invention belongs to the field of heat insulation materials and discloses a preparation method of an aerogel felt heat insulation material. Orthosilicic acid ester, ethanol and water are uniformlymixed, NH4F solution and ammonia water are sequentially added and uniformly stirred to obtain silica sol A; a resin, an initiator, a coupling agent and hollow glass beads are uniformly stirred and mixed in a sealable container to obtain a slurry B; a fiber felt is first impregnated in the silica sol A, then impregnated in the freshly prepared slurry B after being taken out, and the operation is repeated for 3 to 4 times so that the silica sol A is always in a stirring state when the fiber felt is impregnated in the slurry B, and then the fiber felt is taken out and placed in a vacuum condition for sealing and standing; the obtained fiber felt is subjected to aging and modifying, solvent replacing is performed by absolute ethanol, drying and heat treatment are performed to obtain the aerogel felt heat insulation material. On the premise of not affecting the heat insulation effect of the felt body, the invention overcomes the situation that the powder of the traditional silica aerogel felt falls off.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Preparation method of anti-powder-falling composite silicon dioxide aerogel felt

ActiveCN110978737AImprove compression performanceImprove thermal insulation performanceLamination ancillary operationsLaminationThermal insulationPhotoinitiator

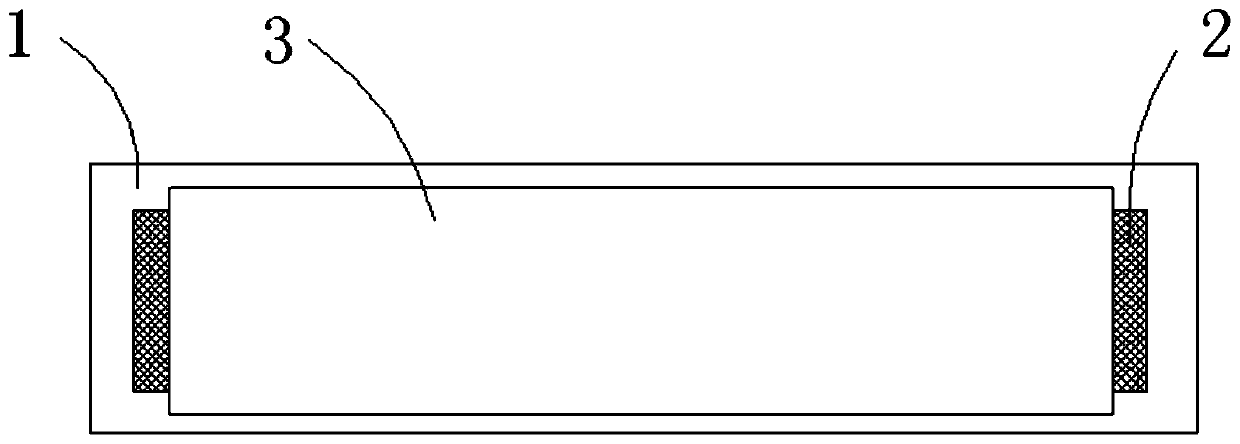

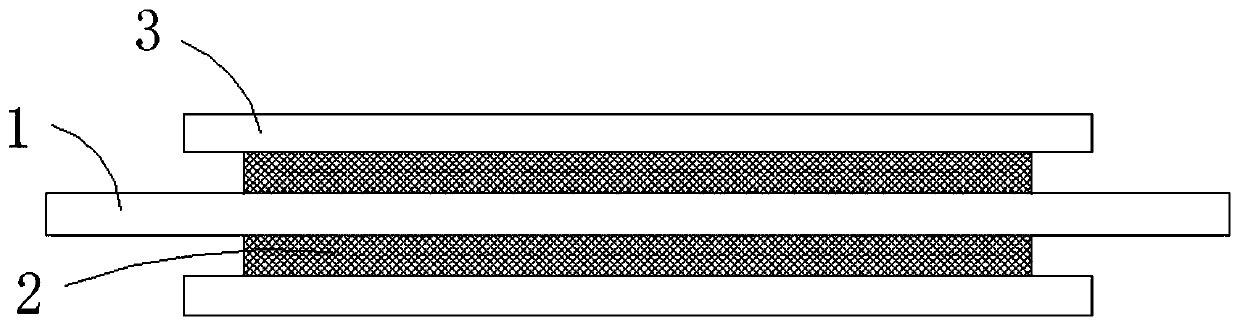

The invention belongs to the field of thermal insulation materials, and discloses a preparation method of an anti-powder-falling composite silicon dioxide aerogel felt. The preparation method comprises the following steps: S1, preparing a silicon dioxide aerogel felt; S2, dispersing hot melt adhesive powder and short fibers into water, uniformly stirring and mixing to obtain a slurry, uniformly coating one surface of the silicon dioxide aerogel felt with the slurry, then superposing another silicon dioxide aerogel felt on the silicon dioxide aerogel felt, repeatedly superposing multiple timesaccording to a silicon dioxide aerogel felt-slurry-silicon dioxide aerogel felt mode, and carrying out hot press molding to obtain a composite silicon dioxide aerogel felt; and S3, uniformly mixing aphotocuring resin and a photoinitiator to obtain a photocuring agent, uniformly spraying the front surface and the back surface of the composite silicon dioxide aerogel felt with the photocuring agentby using a spraying method, and carrying out ultraviolet curing to obtain the composite anti-powder-falling silicon dioxide aerogel felt. According to the invention, under the premise of no influenceon the heat insulation effect of the aerogel felt, the mechanical property of the aerogel felt is enhanced, and the defect of powder falling of the traditional silicon dioxide aerogel felt is overcome.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

High-adhesion aqueous polymer coat diaphragm and preparation method and application thereof

ActiveCN109065803ANo plugging occursImprove breathabilitySecondary cellsCell component detailsCoated membranePolyolefin

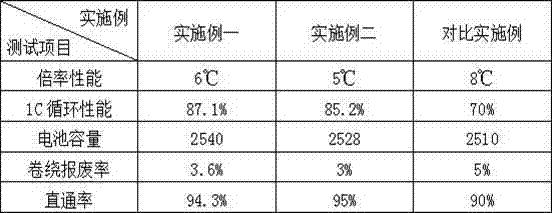

A method for prepare a high-adhesiveness water-borne polymer coated membrane comprise uniformly mixing polymer powder, dispersant, adhesive, thickener, surfactant and deionize water to obtain polymercoated slurry, mixing that polymer powder, dispersant, adhesive, thickener, surfactant and deionized water to obtain polymer coated slurry, and mixing the polymer powder, dispersant, adhesive, thickener and deionized water. The obtained polymer coating slurry is coated on a polyolefin film and dried to obtain a coated diaphragm crude product; The obtained coated diaphragm crude product is immersedin a modified liquid, and the modified coated diaphragm is obtained by rolling the coated diaphragm in the modified liquid; The obtained modified coating diaphragm is dried to obtain a highly adhesive aqueous polymer coating diaphragm. The high-adhesion waterborne polymer coated diaphragm prepared by the invention remarkably improves the adhesion of the coated diaphragm, avoids the powder dropping phenomenon, is favorable for subsequent processes such as slitting and core winding, and simultaneously remarkably improves the comprehensive performance of the lithium ion battery diaphragm.

Owner:湖南烁普新材料有限公司

Preparation method of lithium ion battery positive plate and lithium battery manufactured thereby

ActiveCN104779368AReduce the problem of easy breakageGood flexibilitySecondary cellsElectrode screen printingScreen printingPhysical chemistry

The invention discloses a preparation method of a lithium ion battery positive plate. The method comprises the following steps: 1, adding dry powder containing polyoxyethylene PEO into a solvent to prepare a glue solution; 2, adding the glue solution into a mixture of a positive active material and a conductive agent and stirring to prepare positive paste; and 3, coating the positive paste by means of silk-screen printing coating and drying. According to the preparation method of the lithium ion battery positive plate and the lithium ion battery positive plate manufactured by using the preparation method, PEO softening positive paste is added to prevent the crisping of the positive plate; by using a silk-screen printing coating way, the phenomenon that powder falls down during slicing is avoided, and the performance of the lithium ion battery is greatly improved.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Internally heated getter pump

ActiveCN109681406AImprove heating efficiencyImprove stabilityPumpsPositive-displacement liquid enginesThin metalThin shells

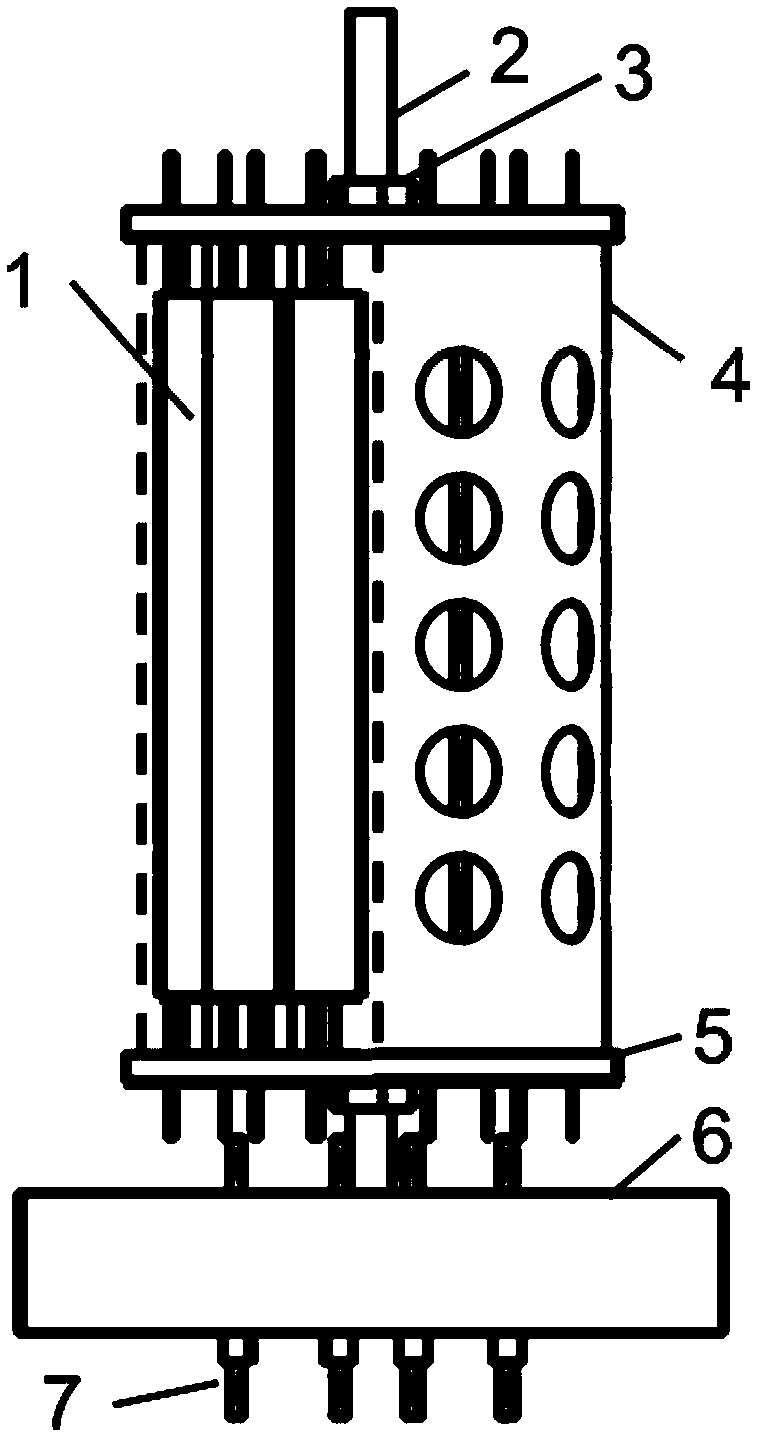

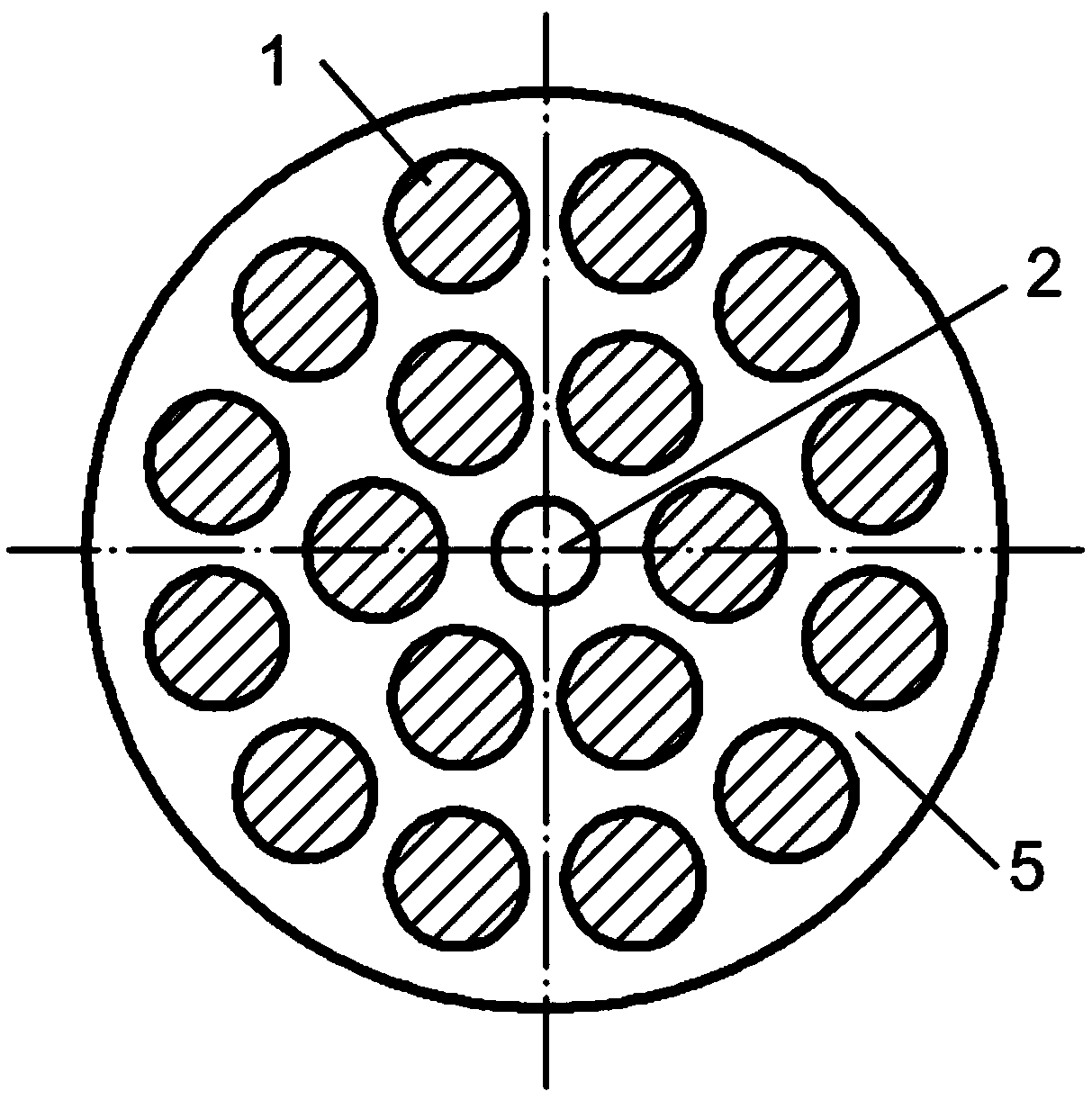

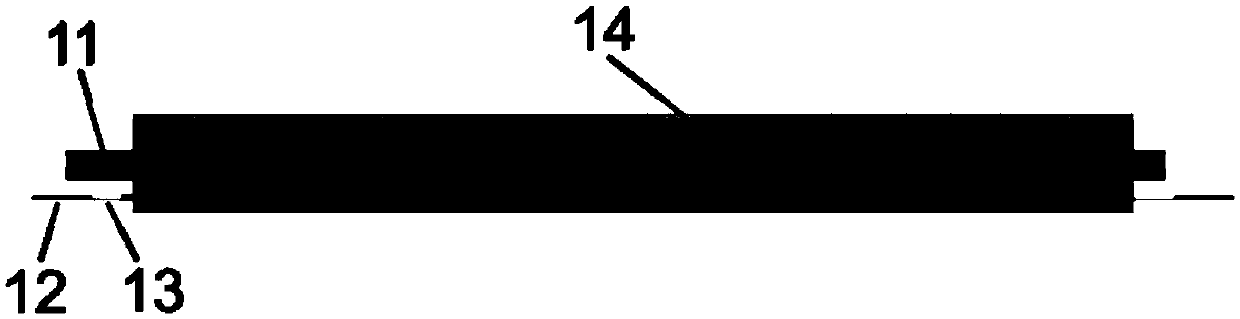

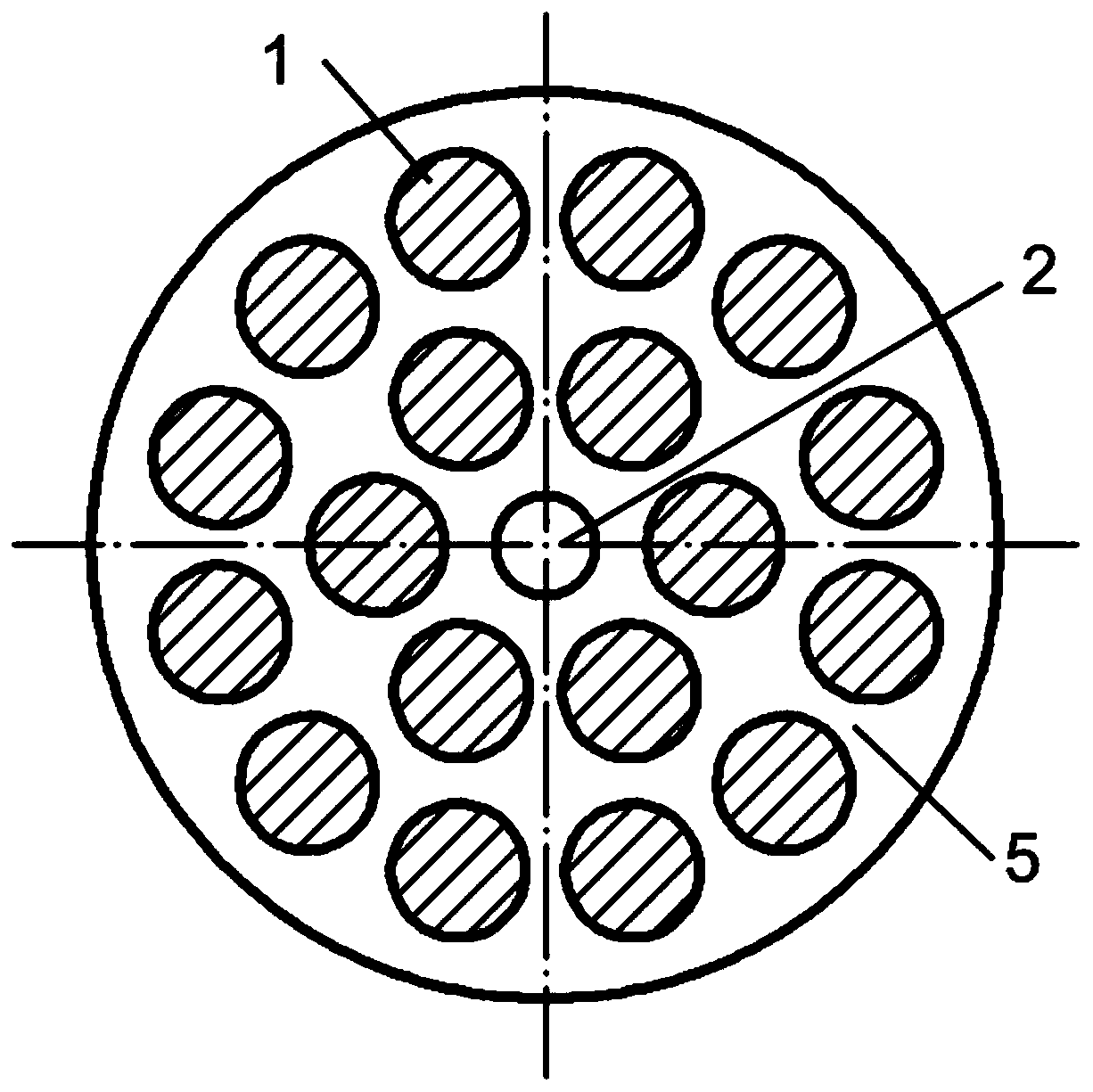

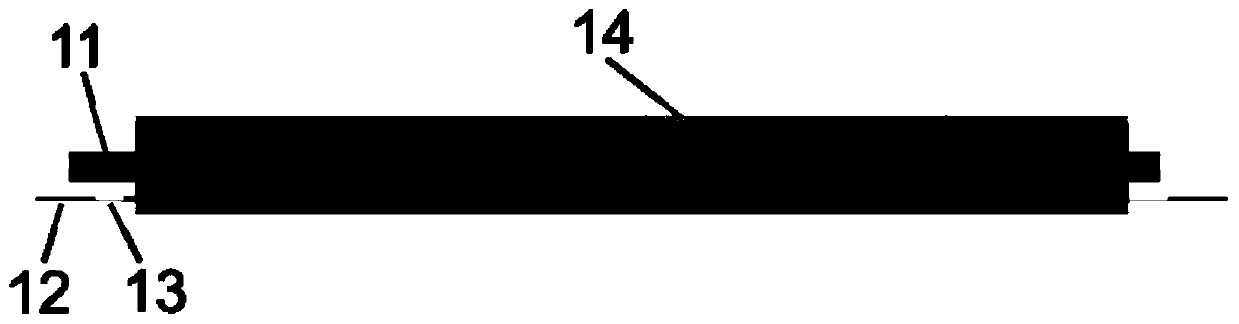

The invention relates to an internally heated getter pump. The pump comprises a plurality of air suction elements 1, a supporting body, positioning plates 5 and a base 6. The supporting body comprisesa central supporting bar 2 and a cylindrical hollowed-out thin shell 4. The central supporting bar 2 is connected with the cylindrical hollowed-out thin shell 4 through one positioning plate 5. The positioning plates 5 and the cylindrical hollowed-out thin shell 4 are fixed to the base 6 through the central supporting bar 2. A pump body is provided with the multiple air suction elements 1 which are uniformly fixed to the positioning plates 5 through thin metal bars 11 correspondingly. The base 6 is a high vacuum CF flange and is connected with the pump body central supporting bar 2 in a threaded form and connected with heating systems and thermocouples in the pump body and an external power supply by embedding four vacuum electrodes 7 in the base through kovar alloy. The internally heatedgetter pump provided by the invention adopts the internal heating column shaped air suction elements and is high in heating efficiency, uniform in exciting and high in air suction speed.

Owner:GRIMAT ENG INST CO LTD

Process for preventing lithium ion battery pole piece from powder shedding during processing

PendingCN110311089AImprove liquid absorption capacityImprove wettabilityElectrode manufacturing processesCeramic coatingPole piece

The invention discloses a process for preventing a lithium ion battery pole piece from powder shedding during processing. The process is characterized in that a layer of glue or ceramic coating is applied on a surface of the lithium ion battery pole piece, the glue layer or the ceramic coating completely covers a coating area of the lithium ion battery pole piece, wherein the glue layer is formedby dissolving CMC in the deionized water or dissolving PVDF in NMP to prepare glue solution coated on the coating of the lithium ion battery pole piece and drying the coated lithium ion battery pole piece, and the ceramic coating is prepared by mixing and stirring the ceramic powder and the PVDF glue solution, coating the mixture on the coating of the lithium ion battery pole piece and drying thecoated lithium ion battery pole piece. The process is advantaged in that the powder material can be prevented from shedding from the pole piece, adhesion between the pole piece and a diaphragm is improved, hot pressing and shaping capability of the battery is further improved, moreover, the liquid absorption capability of the pole piece is improved, and thereby the wetting effect of the electrolyte for the pole piece is improved.

Owner:YINLONG ENERGY CO LTD

Renovated iron drum production process

InactiveCN110549070AEfficient removalReduce wearOrganic detergent compounding agentsHollow article cleaningPolyethylene glycolHigh pressure

The invention discloses a renovated iron drum production process. Cleaning solvent adopted in high-pressure cleaning comprises 40-60 weight parts of propanediol butyl ether, 16-20 weight parts of xylene, 10-30 weight parts of surface active agent, 6-8 weight parts of polyethylene glycol, 0.5-3 weight parts of coconut oil fatty acid diethanolamide, 3-5 weight parts of corrosion inhibitor, 0.5-1 weight part of modified polyether defoaming agent and 2-4 weight parts of stabilizing agent; then, water is used for washing the internals and the externals of drums; during cleaning, the cleaning solvent is removed by adopting a pressure difference; the shot blasting treatment is performed on the internal and the externals of the iron drums; shots of a shot blasting machine are stainless steel shotsor iron shots with diameters of 1.5-3 mm; a dust removing system is arranged on the shot blasting machine; and the powder spraying, the paint spraying and the drying are performed at 170-180 DEG C. The renovated iron drum production process controls each process link in a refined mode, is not easy to generate leakage at the bottoms of the renovated drums and uniform and beautiful in powder spraying to the surfaces, and only reaches the defective rate of about 2%.

Owner:南通天地和环保科技有限公司

Preparation method of solid state lithium ion batteries

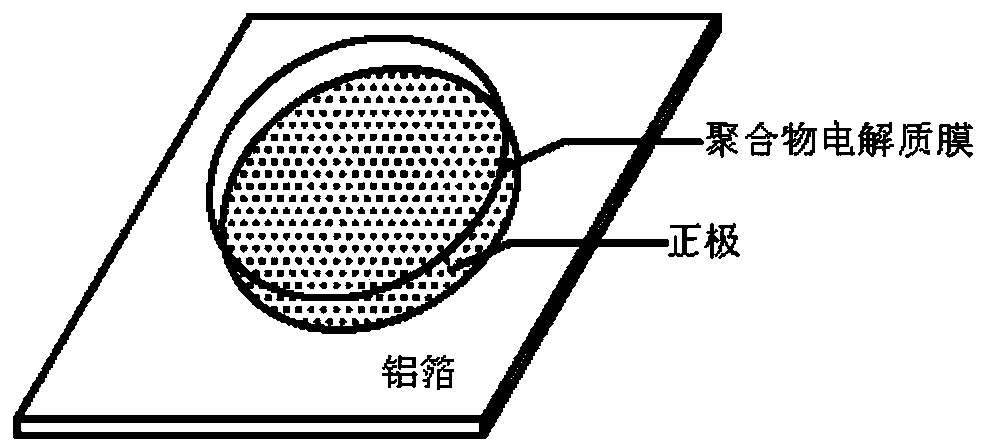

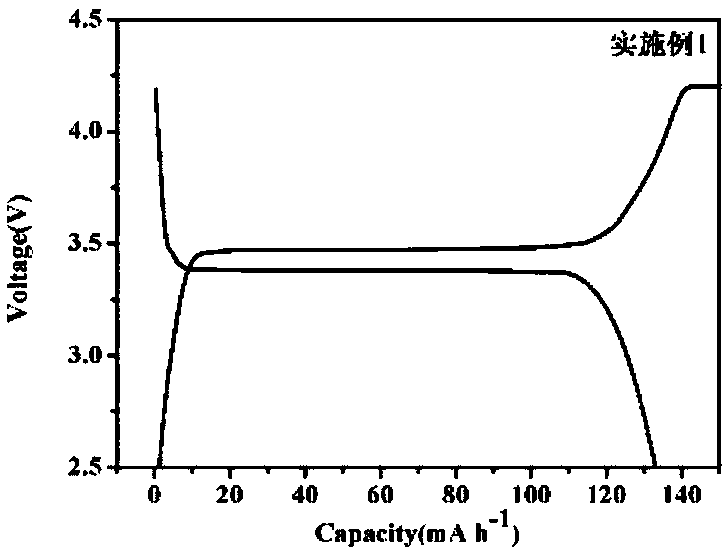

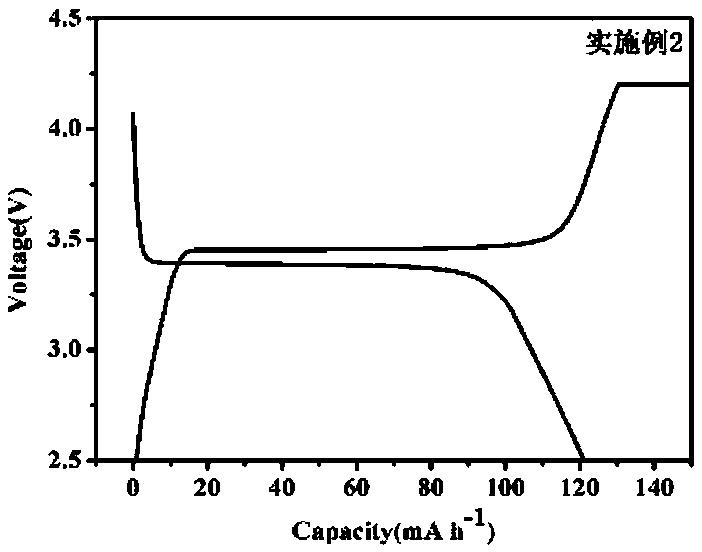

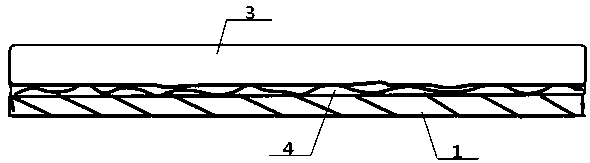

InactiveCN108933231AUniform thicknessControllable shapeFinal product manufactureElectrode collector coatingNew energySlurry

The invention belongs to the technical field of material new energy, and more specifically relates to a preparation method of solid state lithium ion batteries. The preparation method comprises following steps: a cathode active substance, a conductive agent, and a binder are added into a solvent so as to prepare a cathode slurry, screen printing technology is adopted to prepare a positive plate, and drying treatment is carried out; at a protective atmosphere, polyoxyethylene, a lithium salt, a nanometer inorganic oxide, and ethyl cellulose are added into a solvent so as to obtain a polymer slurry, screen printing technology is adopted to prepare a polymer electrolyte film on the positive plate, and drying treatment is carried out; the positive plate, the polymer electrolyte film, and a negative lithium plate are subjected to sealing assembling in a punching machine so as to obtain a button solid state lithium ion battery. The shape of the prepared solid state lithium ion battery is controllable; the polymer electrolyte film and the electrode materials are combined preferably; interface performance is ensured; battery performance is better; the preparation method is simple in operation; and cost is reduced.

Owner:ZIBO TORCH ENERGY

Formula and production method of high-tensile-strength plastering gypsum

InactiveCN112723907AHigh tensile strengthImprove insulation performanceCeramicwareNanoceramicUltimate tensile strength

The invention provides a formula and a production method of high-tensile-strength plastering gypsum, and relates to the technical field of building materials. The high-tensile-strength plastering gypsum is prepared from the following raw materials in parts by weight: 50 to 60 parts of gypsum powder, 30 to 35 parts of purified water, 2 to 3 parts of tackifier, 10 to 13 parts of coarse whiting, 10 to 13 parts of slurry asbestos wool, 3 to 6 parts of vitrified microbeads, 10 to 20 parts of clay powder, 20 to 25 parts of lightweight aggregate, 30 to 35 parts of polypropionic acid resin, 5 to 15 parts of nano ceramic hollow microbeads and 2 to 6 parts of polyacrylamide. By adding the slurry forming asbestos wool and the vitrified micro bubbles into the plastering gypsum, the tensile strength and the heat insulation performance of the plastering gypsum can be improved, the flowability and the self-resistance strength of mortar are improved through the vitrified micro bubbles, the cohesiveness among all the materials is improved through the tackifier and the clay powder, and polyacrylamide is higher in cohesiveness and better in durability; therefore, the plastering gypsum is worthy of vigorous popularization.

Owner:贵州中亚高科涂料有限公司

High-performance low-basis-weight dictionary paper and preparation method thereof

ActiveCN111608014AHigh opacityImprove tightnessDefoamers additionNatural cellulose pulp/paperDeinkingPlant fibre

The invention discloses high-performance low-basis-weight dictionary paper and a preparation method thereof. The paper comprises a plant fiber layer and coatings arranged on two sides of the plant fiber layer; the basis weight of the paper is 22-30g / m <2>; and slurry for preparing the plant fiber layer comprises, by mass, 45%-65% of bleached natural-color softwood pulp and 35%-55% of bleached hardwood pulp. The paint for preparing the coatings is prepared from the following raw materials in parts by weight: 200 to 300 parts of modified filler, 40 to 60 parts of retention aid, 1 to 2 parts of water-retaining agent, 1 to 3 parts of lubricating agent, 0.05 to 0.1 part of defoaming agent, 5 to 10 parts of sodium hydroxide and 500 to 1000 parts of water. A modified filler is used in the coatings on the two sides of the plant fiber layer, substances introduced into the surface of the modified filler can react with fibers, so that the filler is firmly connected with the fiber layer, and the retention rate of the filler is increased; and the phenomena of page penetration and deinking can be prevented by adsorbing color generation substances in printing ink.

Owner:XIANHE CO LTD

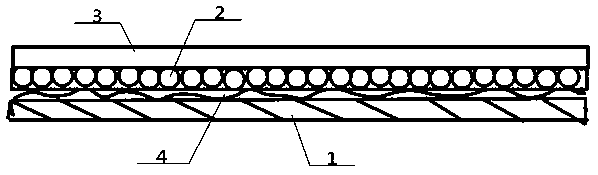

Water swelling type water-blocking belt for optical cables and cables and preparation method thereof

PendingCN109308955AProtective coreDoes not block immersionSynthetic resin layered productsLaminationWater blockMetal

The invention discloses a water swelling type water-blocking belt. The water-blocking belt includes a matrix layer, a water-absorbing layer and a protective layer; the inner wall of the matrix layer is in contact with the external of an optical cable or a cable; the bottom of the water-absorbing layer is connected to the outer wall of the matrix layer; the protective layer externally wraps the part, other than the junction part of the water-absorbing layer and the matrix layer, on the water-absorbing layer; the bottom of the protective layer covers the junction part of the water-absorbing layer and the matrix layer; the water-absorbing layer contains a superabsorbent expansion material; the protective layer is a thin film which can be dissolved after absorbing water; a bonding layer can bearranged between the matrix layer and the water-absorbing layer; and the matrix layer is preferred to be metal. The water-blocking belt is strong in water absorbing and blocking performance, less inlayer, simple and light in structure, high in water swelling multiple, high in water-absorbing efficiency and good in water blocking performance; influences on the using of the optical cables or the cables cannot be caused; and the water-blocking belt has advantages of shielding signals and preventing rats from biting.

Owner:WUHAN TEXTILE UNIV

Preparation method of high-retention paper-making filler

ActiveCN108560299AImprove physicsImprove adsorption capacityMicroorganism/enzyme additionPaper/cardboardFiberChemical adsorption

The invention relates to the technical field of paper-making filler, in particular to a preparation method of a high-retention paper-making filler. Self-made superfine fiber powder serves as a template to absorb hydrotalcite to obtain hydrotalcite powder, lemon, eucalyptus leaves and range peel essential oil are mildewed, mixed fermentation modification is conducted by means of fermentation liquidand highly dispersed hydrotalcite, and the high-retention paper-making filler is obtained finally; due to the fact that fiber surface space steric hindrance exists, the growth of hydrotalcite powderis limited, mildewing is conducted by means of biomass, the hydrotalcite powder and hydrotalcite are subjected to blend fermentation, the physical and chemical adsorption of the hydrotalcite is greatly improved, the retension performance of the hydrotalcite paper-making filler on paper fiber is increased, and meanwhile the bonding stability between the filler and paper is enhanced; part of organicmatter is degraded by microorganisms, a large number of active groups are generated, the active groups and hydroxy in the paper fiber can generate chemical bonding force, the bonding strength betweenthe paper-making filler and the paper is improved, and the method has a wide application prospect.

Owner:广东华能环保材料有限公司

A kind of preparation method of airgel blanket thermal insulation material

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

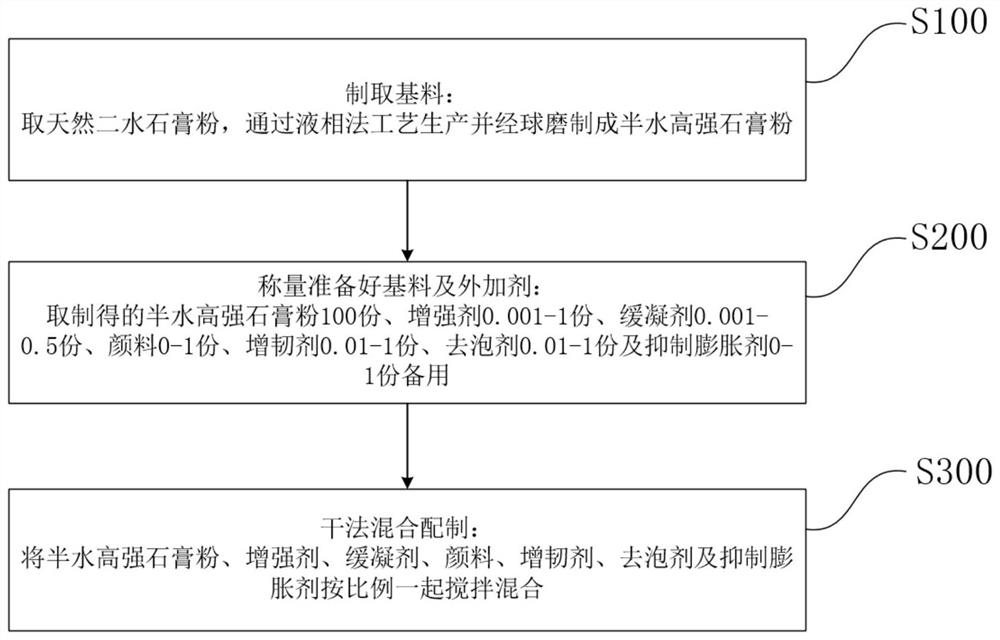

Method for improving powder falling of dental gypsum

The invention discloses a method for improving powder falling of dental gypsum. The method comprises the following steps: S100, preparing a base material: taking natural dihydrate gypsum powder, producing through a liquid phase method process, and carrying out ball milling to prepare semi-hydrated high-strength gypsum powder; S200, weighing and preparing a base material and an additive: taking 100 parts of the prepared semi-hydrated high-strength gypsum powder, 0.001-1 part of a reinforcing agent, 0.001-0.5 part of a retarder, 0-1 part of a pigment, 0.01-1 part of a toughening agent, 0.01-1 part of a defoaming agent and 0-1 part of an expansion inhibiting agent for later use; and S300, performing dry-process mixing preparation: stirring and mixing the semi-hydrated high-strength gypsum powder, the reinforcing agent, the retarder, the pigment, the flexibilizer, the defoaming agent and the swelling inhibitor in proportion. The method has the beneficial effects that under the synergistic effect of all the components, the surface strength of the dental gypsum is improved, and powder falling during demolding of the dental gypsum and a film printing material is avoided. The toughness of the dental gypsum is also improved, and the defects that the gypsum is crisp and is not easy to repair when a dental gypsum model is repaired are overcome. The dental gypsum is low in price, excellent in performance and good in clinical application effect.

Owner:SHENZHEN QINGQINGYUAN TECH

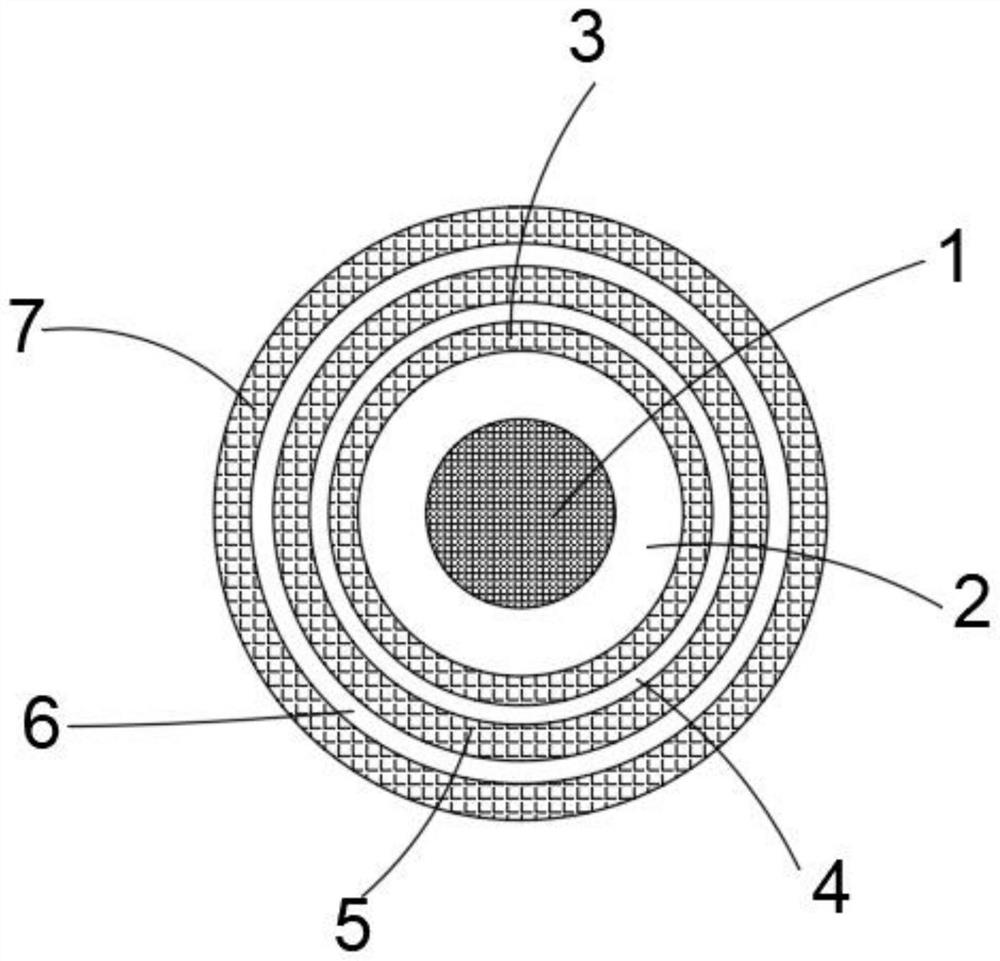

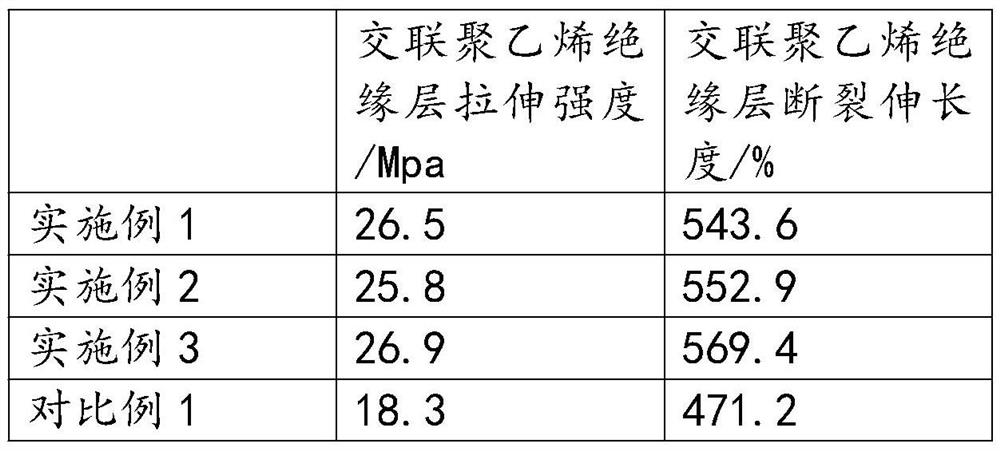

A XLPE insulated DC cable for urban light rail subway

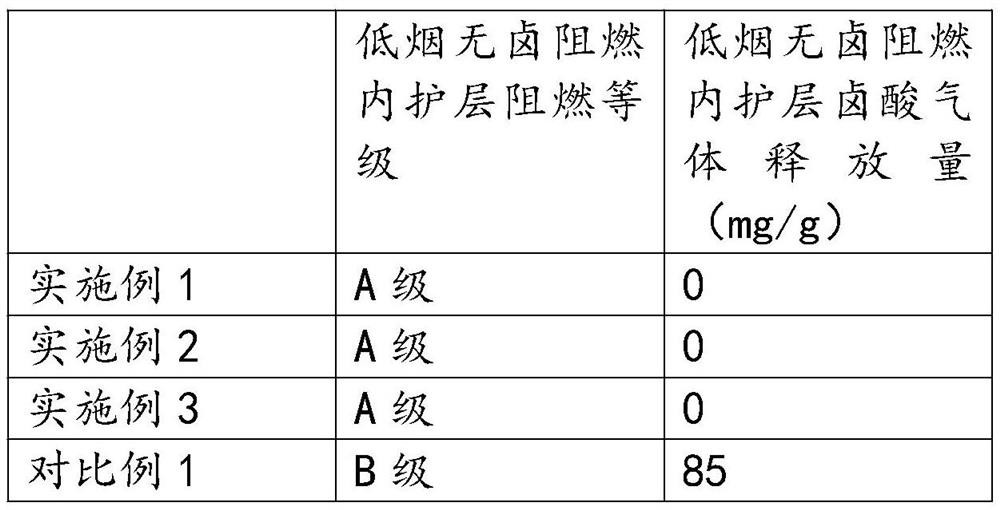

ActiveCN112768115BHigh hardnessImprove toughnessPlastic/resin/waxes insulatorsInsulated cablesCopper conductorLow smoke zero halogen

The invention discloses a cross-linked polyethylene insulated direct current cable for urban light rail subway, comprising a copper conductor, a cross-linked polyethylene insulating layer, an intumescent water-blocking tape, an aluminum-plastic bonded comprehensive protective layer, a low-smoke halogen-free flame retardant inner a protective layer, an anti-mouse ant layer and an outer sheath; the cross-linked polyethylene insulating layer covers the copper conductor, the intumescent water-blocking tape covers the cross-linked polyethylene insulating layer, the aluminum The plastic-bonded comprehensive protective layer is extruded and wrapped around the intumescent water-blocking tape, and the low-smoke halogen-free flame-retardant inner protective layer is wrapped with an aluminum-plastic bonded comprehensive protective layer. The low-smoke halogen-free flame retardant inner protective layer is wrapped around layer by layer, and the outer sheath is extruded and wrapped around the anti-mouse and ant layer; the compound antioxidant can prevent or slow down the degradation of the cross-linked polyethylene insulating layer. The self-oxidation reaction rate can delay the aging and degradation of the cross-linked polyethylene insulating layer, effectively improve the service life of the product, and at the same time improve the mechanical and electrical properties of the product.

Owner:GUIZHOU XINSHUGUANG CABLE CO LTD

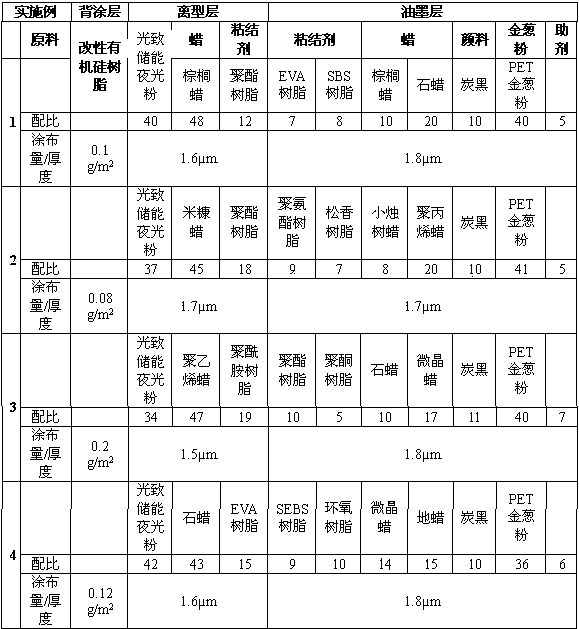

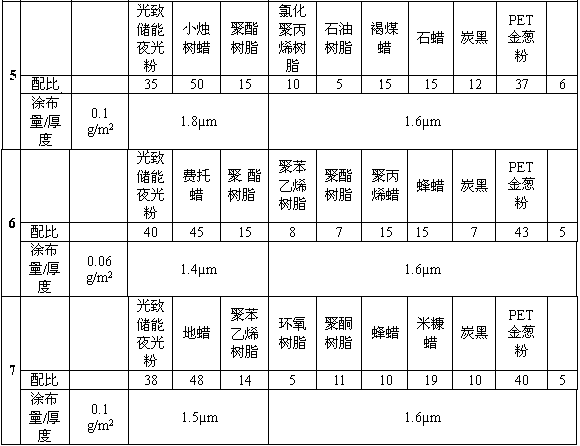

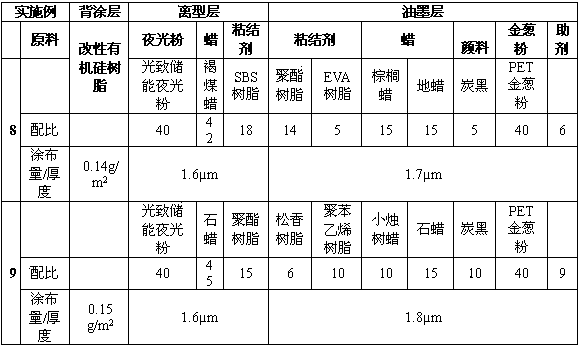

Glitter luminous thermal transfer carbon ribbon and preparation method thereof

The invention relates to a glitter powder noctilucent heat transfer printing ribbon. The glitter powder noctilucent heat transfer printing ribbon is composed of a base membrane, a heat-resisting back coating applied to one face of the base membrane, a releasing layer and an ink layer, wherein the releasing layer and the ink layer are applied to the other face of the base membrane. The thickness of the releasing layer ranges from 1.4 micrometers to 1.8 micrometers. The releasing layer is prepared from, by mass percent, 10-20% of a binder, 35-55% of wax and 30-45% of noctilucent powder. The thickness of the ink layer is controlled within 1.6-2.0 micrometers. The ink layer is prepared from, by mass percent, 10-20% of a binder, 20-35% of wax, 5-15% of pigment, 35-45% of glitter powder and 3-8% of an auxiliary. The glitter powder noctilucent heat transfer printing ribbon has the beneficial effects of being convenient to use, clean, free of contamination, economical and applicable, and meanwhile, on the aspect of performance, the glitter powder noctiluent heat transfer printing ribbon has the excellent characters of being high in transfer printing definition, high in recognition for naked eyes on visible light reflection, visible at night, high in scraping resistance, low in noise, high in blackness, free of powder falling of the coatings, and has relatively good application and popularization value.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

A kind of high-performance low-quantity dictionary paper and preparation method thereof

ActiveCN111608014BHigh opacityImprove tightnessNatural cellulose pulp/paperDefoamers additionDeinkingPlant fibre

Owner:XIANHE CO LTD

Technique for preparing suction plate of hydrogen atom frequency marker

InactiveCN102810440BAvoid powder sheddingAvoid smelting processElectric discharge tubesElectric discharge lampsHydrogen atomEngineering

The invention discloses a technique for preparing a suction plate of a hydrogen atom frequency marker. The suction plate is obtained by cutting a slot on a titanium rod, removing oil and cleaning, threading, cleaning, vacuum degassing, pressing and molding. The suction plate has the advantages that a large suction surface area is kept so as to ensure a high pumping rate, and the picking phenomenon of the existing non-evaporable suction plate for pressing powder in a using process is also avoided, meanwhile, the suction plate is a pure metal non-evaporable suction plate; the material source is simple, and various metal melting processes of an alloy suction plate are avoided; in addition, the process is simple and the manufacture is easy.

Owner:中国航天科工集团第二研究院二〇三所

Composite film with high-temperature resistance layer, preparation method thereof and battery

ActiveCN103078075BHigh peel strengthAvoid powder sheddingCell component detailsComposite filmTemperature resistance

The application relates to the field of lithium batteries, and particularly discloses a composite film with a high-temperature resistance layer, a preparation method thereof and a battery. The composite film disclosed by the application comprises a base film and the high-temperature resistance layer, wherein the base film is a porous thermoplastic resin film; the high-temperature resistance layer is an inorganic ceramic layer containing ceramic particles; the inorganic ceramic layer is fixed on at least one surface of the porous thermoplastic resin film by polymerization; and the peel strength of the porous thermoplastic resin film and the inorganic ceramic layer is larger than or equal to 25 N / m under the condition of 180 DEG C. The invention further discloses the preparation method and the application of the composite film and the battery adopting the composite film. According to the application, the peel strength of inorganic ceramic layer and the porous thermoplastic resin film is greatly improved so as to effectively avoid a powder falling phenomenon of the inorganic ceramic particles in the composite film. Meanwhile, the composite film has excellent high temperature resistance performance, and can reduce battery short circuit phenomena caused by heat shrinkage of the composite film in the application.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

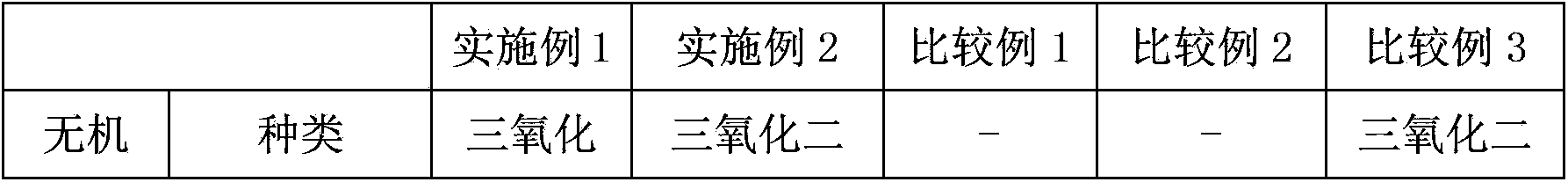

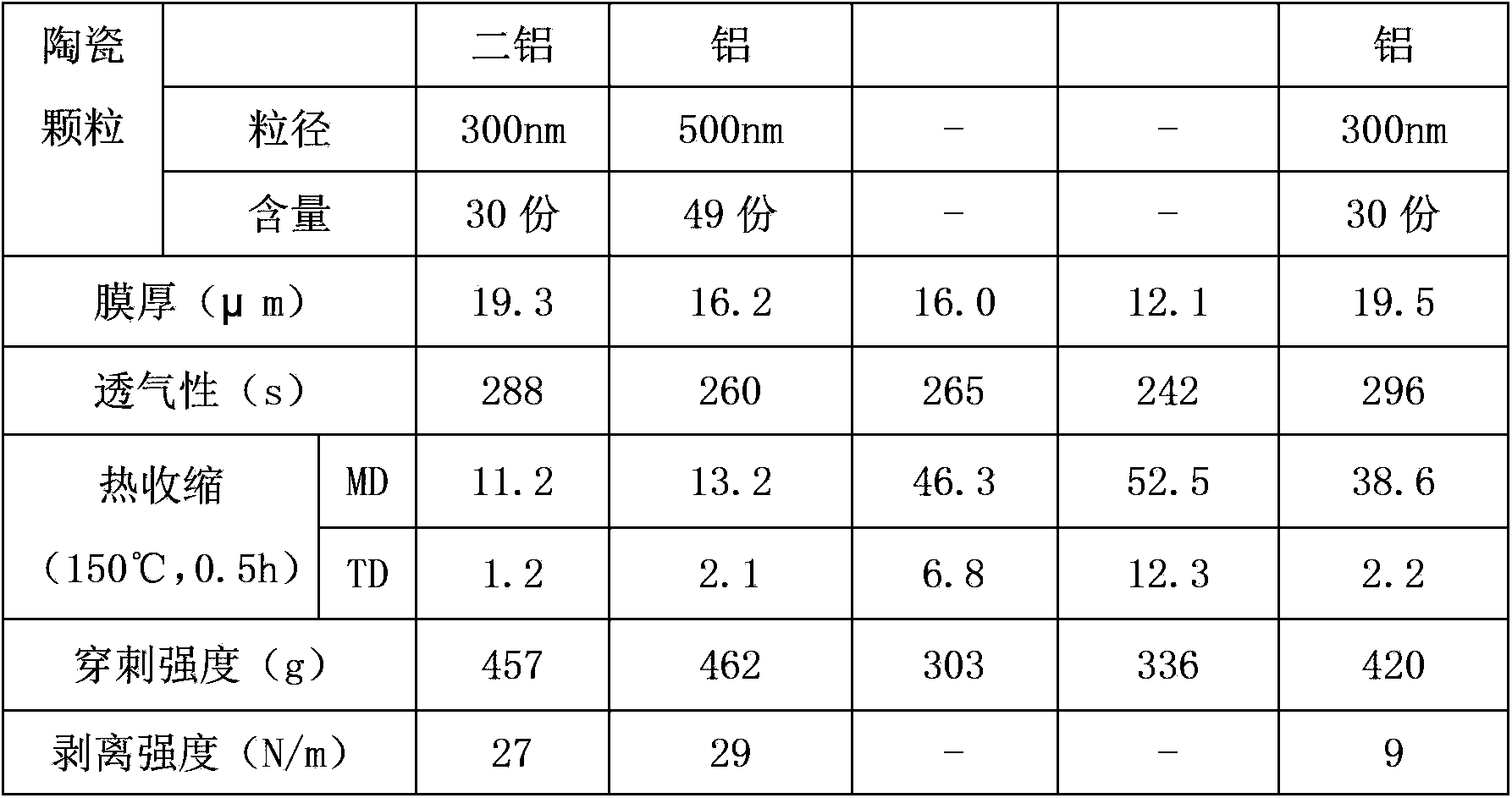

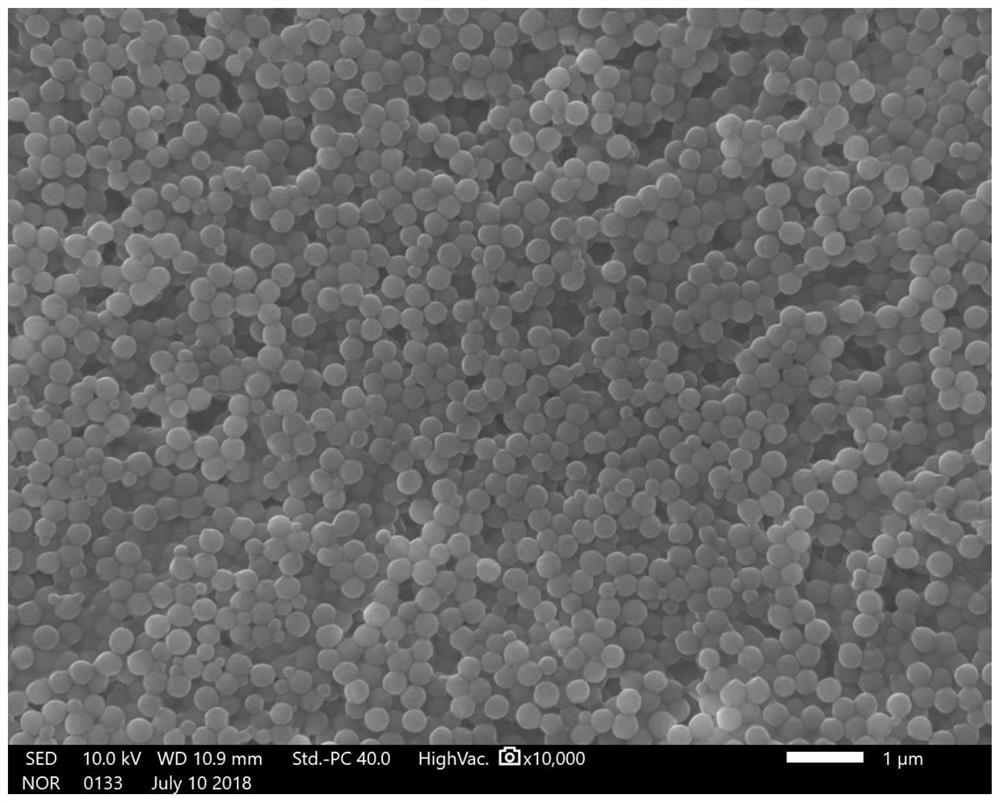

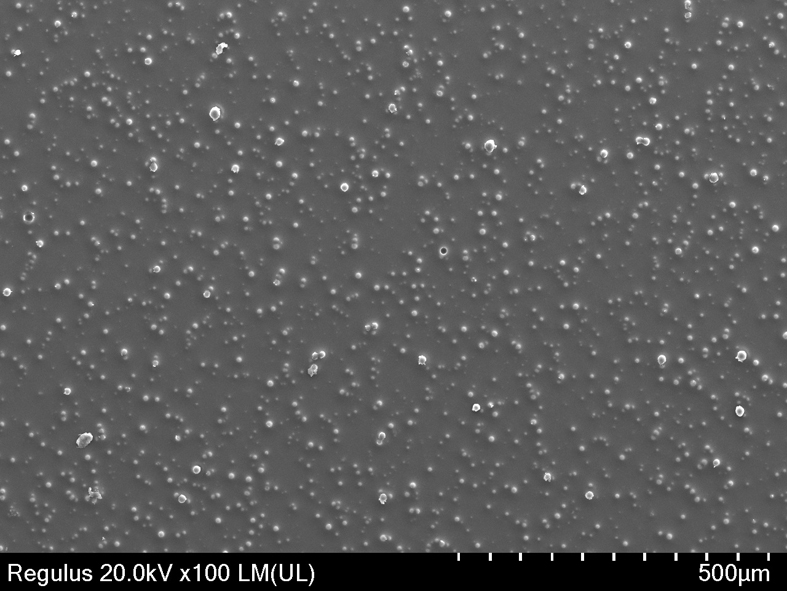

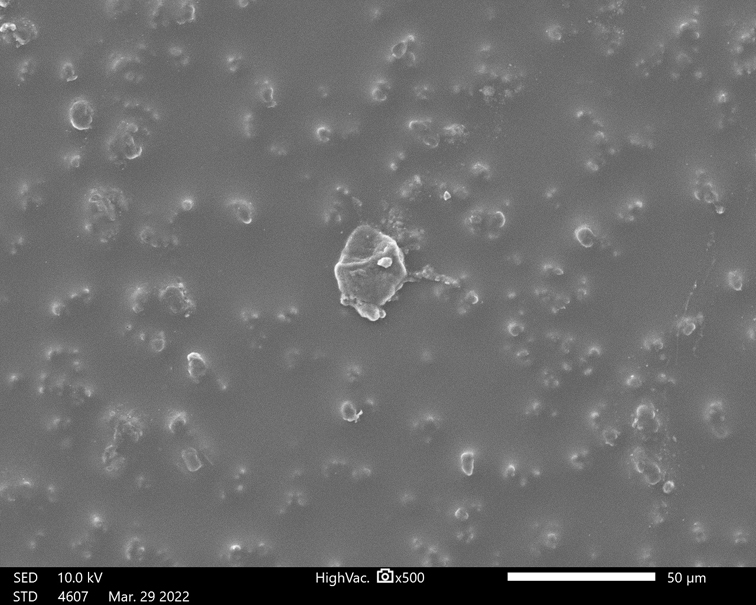

A kind of ceramic composite lithium-ion battery diaphragm and preparation method thereof

ActiveCN107910476BHigh strengthImprove puncture abilityMaterial nanotechnologyCell component detailsCeramic compositeElectrical battery

The invention provides a preparation method of a ceramic composite lithium-ion battery separator, the preparation method at least includes: 1) mixing ceramic powder with a dispersant, adding it to a solvent, performing ball milling, and then adding a certain mass of polymer, light Curing the resin and the photoinitiator, and mechanically stirring to obtain an electrospinning solution; 2) providing a matrix film, and using the electrospinning solution to perform an electrospinning process to deposit nano ceramic fiber layers on both sides of the matrix film , to obtain a composite film after drying treatment; 3) using ultraviolet light to cure the composite film, and obtaining a ceramic composite lithium-ion battery diaphragm after drying treatment. The ceramic composite diaphragm prepared by the method of the present invention has the advantages of high electrolyte retention rate, high strength, high membrane rupture temperature, uniform pore size distribution, and difficult peeling of the matrix membrane and nano-ceramic fiber layer, which is conducive to improving the cycle stability of lithium-ion batteries. And high rate charge and discharge performance, suitable for power lithium-ion batteries.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

A kind of preparation method of anti-powder dropping composite silica airgel felt

ActiveCN110978737BGood compressibilityImprove insulation effectLamination ancillary operationsLaminationFiberThermal insulation

The invention belongs to the field of thermal insulation materials and discloses a method for preparing a powder-drop-proof composite silica airgel felt. S1, preparing silica airgel felt; S2, dispersing hot melt adhesive powder and short fibers in water, stirring and mixing evenly to obtain slurry; evenly brushing the slurry on one side of the silica airgel felt, and then Overlay another silica airgel felt on it, repeat the stacking multiple times in the manner of silica airgel-slurry-silica airgel felt, and heat press to obtain a composite silica airgel felt ; S3, uniformly mix the photocurable resin and the photoinitiator to obtain a photocuring agent; spray the photocuring agent evenly on the front and back sides of the composite silica airgel felt by spraying, and UV-cure to obtain the composite Anti-shedding silica airgel felt. The invention enhances the mechanical properties of the airgel felt without affecting the heat insulation effect of the airgel felt, and overcomes the problem of powder falling off of the traditional silicon dioxide airgel felt.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

An internally heated getter pump

ActiveCN109681406BImprove heating efficiencyImprove stabilityPumpsPositive-displacement liquid enginesThin metalThermocouple device

The invention relates to an internally heated getter pump. The pump comprises a plurality of air suction elements 1, a supporting body, positioning plates 5 and a base 6. The supporting body comprisesa central supporting bar 2 and a cylindrical hollowed-out thin shell 4. The central supporting bar 2 is connected with the cylindrical hollowed-out thin shell 4 through one positioning plate 5. The positioning plates 5 and the cylindrical hollowed-out thin shell 4 are fixed to the base 6 through the central supporting bar 2. A pump body is provided with the multiple air suction elements 1 which are uniformly fixed to the positioning plates 5 through thin metal bars 11 correspondingly. The base 6 is a high vacuum CF flange and is connected with the pump body central supporting bar 2 in a threaded form and connected with heating systems and thermocouples in the pump body and an external power supply by embedding four vacuum electrodes 7 in the base through kovar alloy. The internally heatedgetter pump provided by the invention adopts the internal heating column shaped air suction elements and is high in heating efficiency, uniform in exciting and high in air suction speed.

Owner:GRIMAT ENG INST CO LTD

Technique for preparing suction plate of hydrogen atom frequency marker

InactiveCN102810440AAvoid powder sheddingAvoid smelting processElectric discharge tubesElectric discharge lampsHydrogen atomEngineering

The invention discloses a technique for preparing a suction plate of a hydrogen atom frequency marker. The suction plate is obtained by cutting a slot on a titanium rod, removing oil and cleaning, threading, cleaning, vacuum degassing, pressing and molding. The suction plate has the advantages that a large suction surface area is kept so as to ensure a high pumping rate, and the picking phenomenon of the existing non-evaporable suction plate for pressing powder in a using process is also avoided, meanwhile, the suction plate is a pure metal non-evaporable suction plate; the material source is simple, and various metal melting processes of an alloy suction plate are avoided; in addition, the process is simple and the manufacture is easy.

Owner:中国航天科工集团第二研究院二〇三所

High-adhesive water-based polymer-coated separator and its preparation method and application

ActiveCN109065803BImprove adhesionNo plugging occursCell seperators/membranes/diaphragms/spacersSecondary cellsPolymer sciencePolyolefin

The invention provides a high-adhesive water-based polymer coated diaphragm and its preparation method and application. The preparation method steps are: polymer powder, dispersant, adhesive, thickener, surfactant and deionized Mix with water evenly to obtain a polymer coating slurry; coat the obtained polymer coating slurry on a polyolefin film, and dry to obtain a crude coated separator; soak the crude coated separator in the modifying solution , and rolling in the modifying solution to obtain a modified coating diaphragm; drying the obtained modified coating diaphragm to obtain a high-adhesive water-based polymer coating diaphragm. The high-adhesive water-based polymer coated separator prepared by the present invention significantly improves the adhesiveness of the coated separator, avoids the phenomenon of powder dropping, is beneficial to subsequent processes such as slitting and cell winding, and significantly improves the performance of the lithium-ion battery separator. Comprehensive performance.

Owner:湖南烁普新材料有限公司

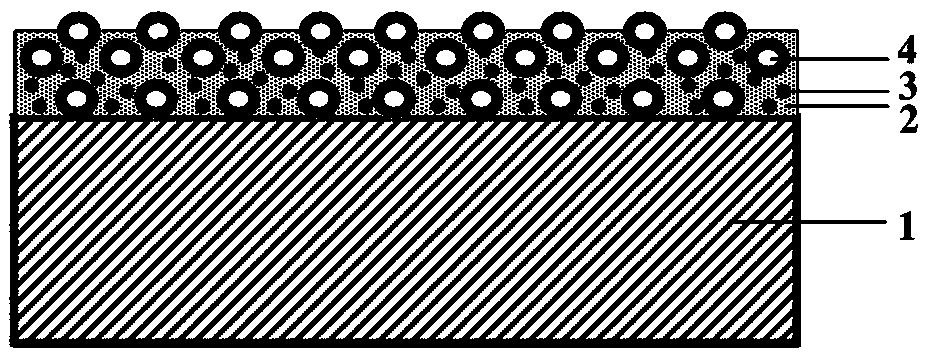

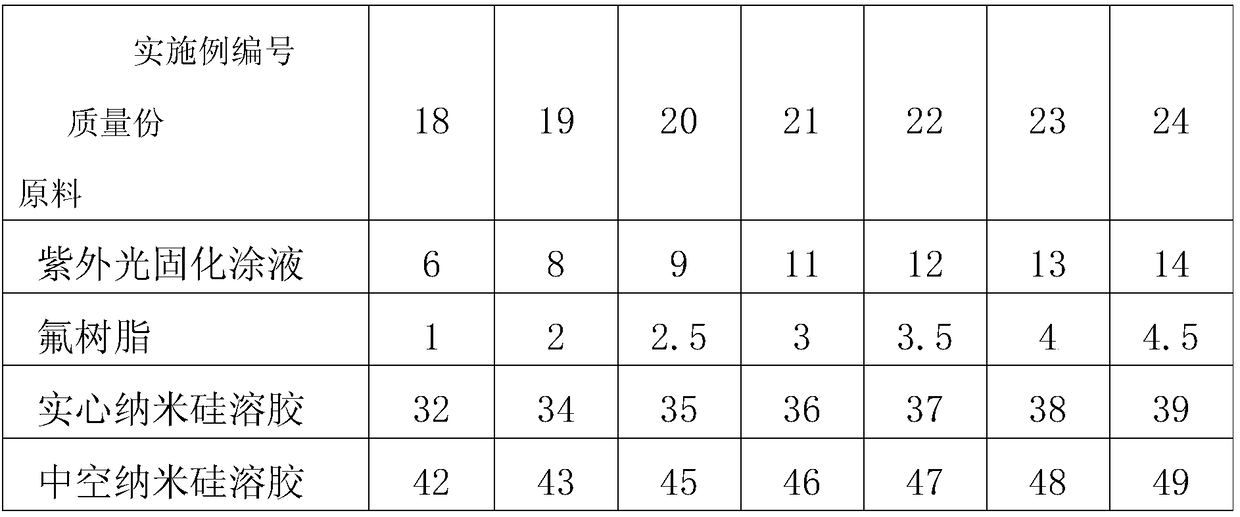

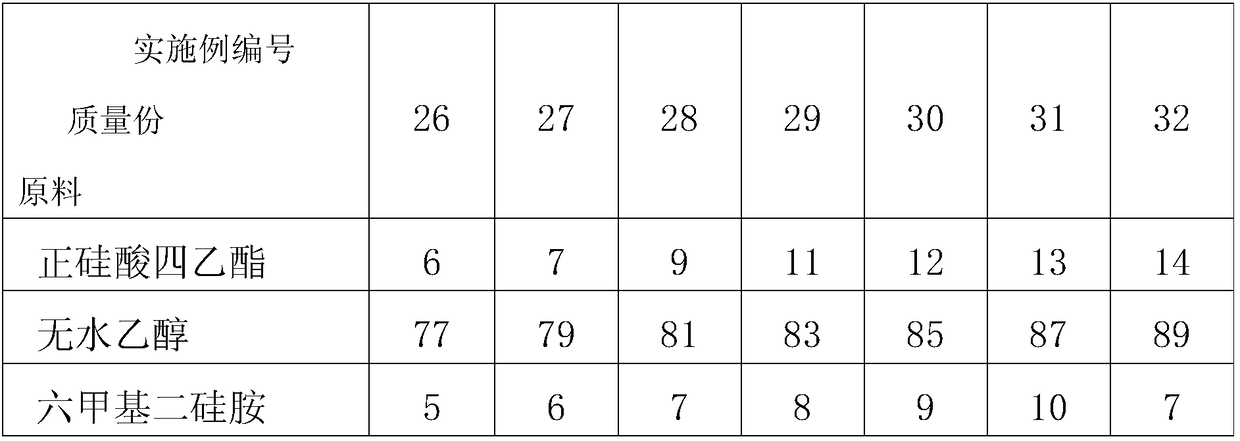

A preparation method of anti-reflection and anti-fingerprint coating film suitable for plastic substrates

ActiveCN106009021BGood anti-reflection functionImprove bindingMaterial nanotechnologyCoatingsSpray coatingUltraviolet lights

The invention discloses a preparation method of an anti-reflection and anti-fingerprint coating film suitable for a plastic substrate. The preparation method is characterized in that 5-15 parts by mass of an ultraviolet curing coating solution, 1-5 parts by mass of fluororesin, 30-40 parts by mass of solid nano-silicon sol and 40-50 parts by mass of hollow nano-silicon sol are mixed uniformly, and a coating liquid is prepared; the coating liquid is applied to the surface of the plastic substrate in a shower coating, spray coating or dip coating manner; the plastic substrate coated with the coating liquid is dried at the temperature of 75-90 DEG C for 1-15 min and irradiated under ultraviolet light, and a coating product is prepared. With the adoption of the preparation method, the film layer of the coating product and the substrate are firmly combined, the reflection rate in the visible light area is not higher than 5%, the water drop contact angle is not lower than 110 degrees, and the coating film can be widely applied to fields such as display panels of electronic products, solar photovoltaic assemblies, product display cabinets, advertising boxes and the like and has wide market prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of preparation method of lithium-ion battery positive plate and prepared lithium-ion battery

ActiveCN104779368BReduce the problem of easy breakageGood flexibilitySecondary cellsElectrode screen printingScreen printingElectrical battery

Owner:DONGGUAN CHUANGMING BATTERY TECH

Layered coating type scratch-resistant coating reflecting film and preparation method thereof

ActiveCN114779378AAvoid wrappingImprove scratch resistanceMirrorsPhotovoltaic energy generationAdhesive cementCoated surface

The invention discloses a layered coating type scratch-resistant coating reflecting film and a preparation method thereof. The scratch-resistant coating reflecting film comprises a reflecting base film, a mixed adhesive layer arranged on the reflecting base film and an elastic particle layer positioned on the surface of the mixed adhesive layer, the mixed adhesive layer coating liquid comprises the following components in percentage by mass: 10-15% of a polyacrylate adhesive, 20-30% of an organic silicon resin adhesive, 0.5-1% of a curing agent, 1-1.5% of a silane coupling agent and the balance of a solvent; the elastic particle layer coating liquid comprises the following components: 20-30% of elastic particles, 15-20% of a polyacrylate adhesive, 1-2% of a curing agent and the balance of a solvent. According to the invention, the mixed adhesive and the elastic particles are coated on the surface of the reflective base film in a layered manner, and the coated elastic particles can be half exposed on the surface of the coating through the viscosity difference of the two layers of coating liquid, so that the scraping resistance of the reflective film is improved, and the elastic particles are prevented from falling off at the same time.

Owner:NINGBO CHANGYANG TECH

Ribbon for edge press printer and manufacturing method thereof

ActiveCN108583032BHigh resolutionGood transferability and colorInk ribbonsPrinting inkMaterials science

The invention provides an edge rolling type thermal transfer ribbon for a printer and a manufacturing method thereof. The edge rolling type thermal transfer ribbon comprises a base film, a release layer, a thermal transfer printing ink layer and a heat resisting layer, wherein the thermal transfer printing ink comprises 10-30% by weight of resin, 0.5-4% by weight of additive, 10-20% by weight of pigment, and 50-70% by weight of solvent; the temperature of the solvent is increased, and thus the solvent is heated and the resin is dissolved to prepare resin liquid; the resin liquid is fully mixedwith the pigment and the additive and then is milled into the printing ink through a horizontal sand mill; a release coating coats the base film, and 3.2-4.0g of release coating coats the base film per square; the printing ink coats the surface of the release layer, and 1.8-2.5g printing ink coats the surface per square; and the heat resisting coating coats the other layer of the base film, and 0.1-1.0g of heat resisting coating coats the other layer per square. With the adoption of the thermal transfer ribbon, an image printed through the printer has the advantages of being high in resolution, resistant to friction, and resistant to ageing; the printing speed is up to 24inch / S, so that the requirement of ultrahigh-speed printing is met.

Owner:南京爱宝文仪有限公司

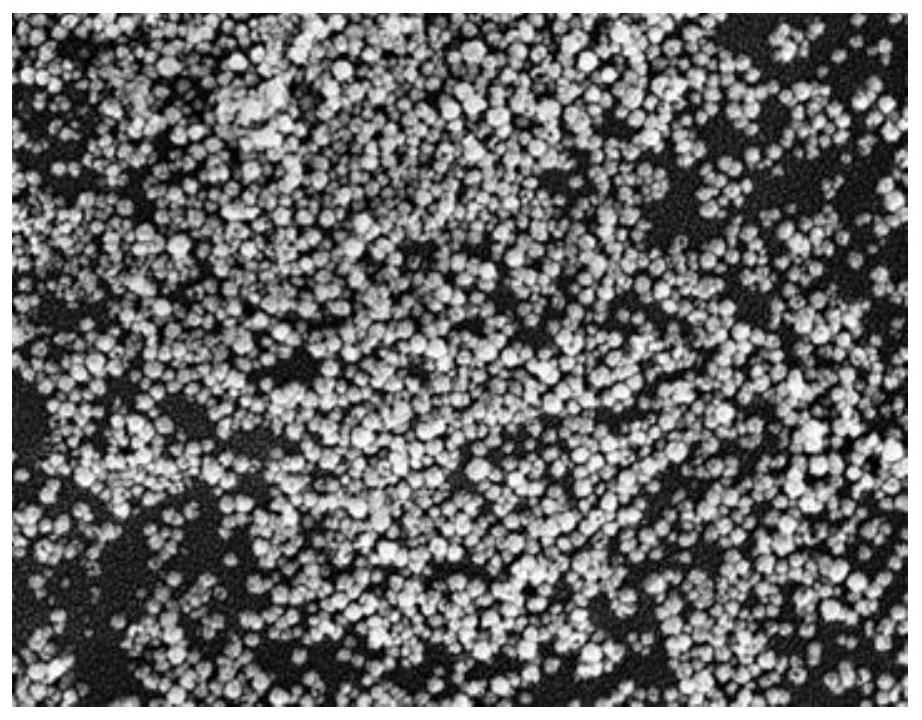

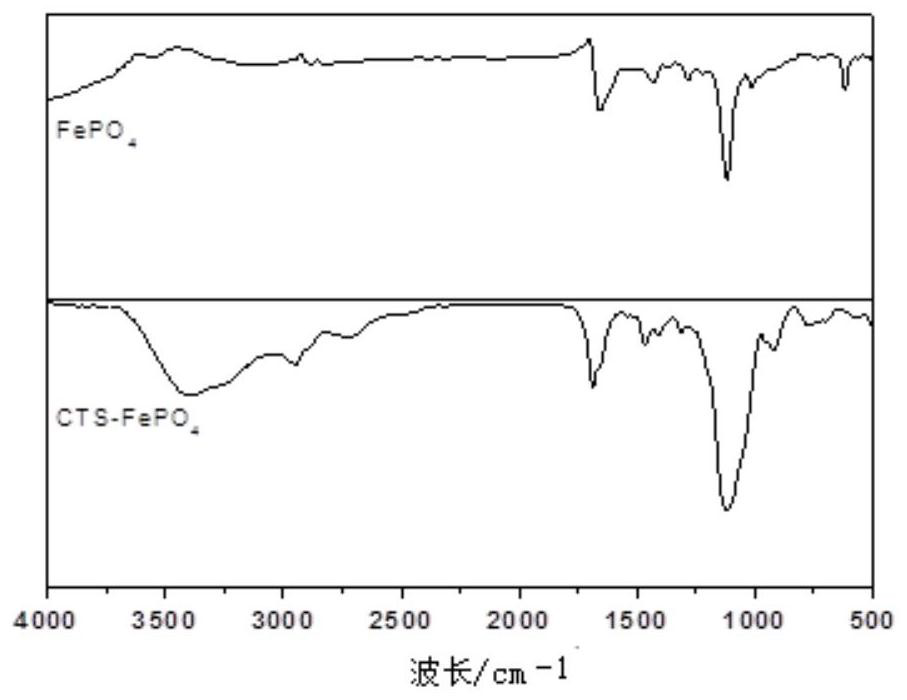

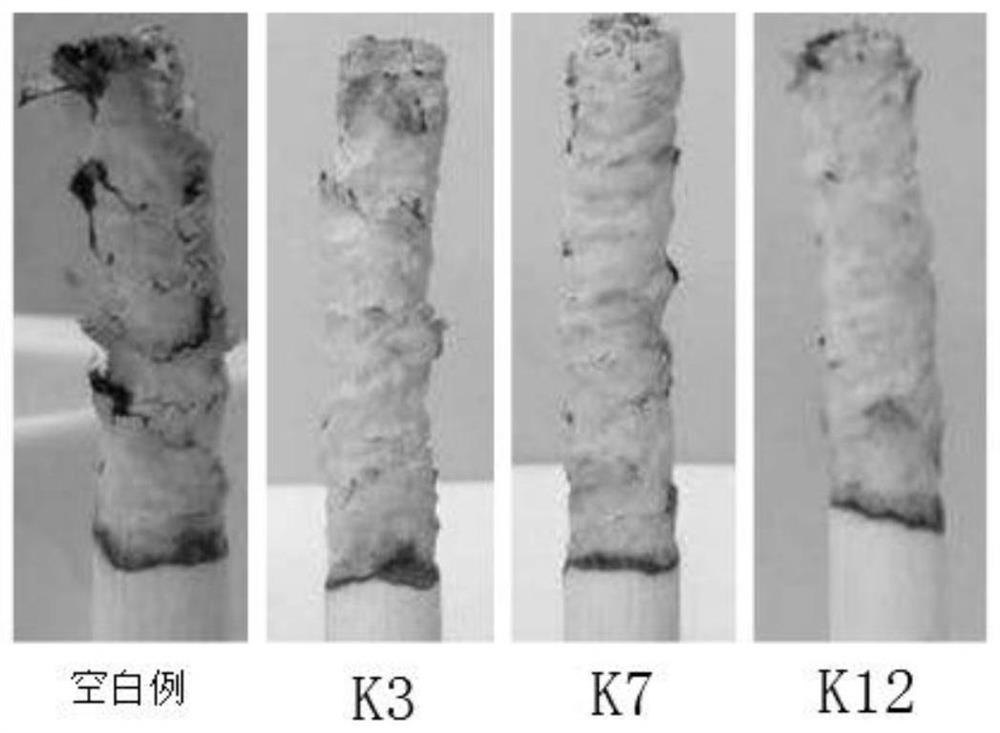

Ash coating additive, preparation method and ash coating cigarette paper

ActiveCN112411251AGood dispersionGuaranteed uniformityNon-macromolecular organic additionPaper/cardboardNanoparticleIron phosphate

The invention relates to an ash wrapping aid, a preparation method and ash wrapping cigarette paper, wherein the ash wrapping aid is chitosan-modified iron phosphate nanoparticles, and a sizing agentprepared from the chitosan-modified iron phosphate nanoparticles is coated on the surface of the cigarette paper in an offline coating manner, and the improved ash wrapping cigarette paper is obtainedafter drying. According to the technical scheme, chitosan is used for carrying out surface modification on nano iron phosphate, the dispersity of nano particles can be improved, the uniformity of material dispersion in the coating process is guaranteed, meanwhile, the iron phosphate particles are attached to the surface of cigarette paper, and the powder stripping phenomenon is avoided. Accordingto the technical scheme, the CTS-FePO4 nanoparticles are used as the ash coating auxiliary agent for the first time, so that the preparation process is mild, environment-friendly and easy to operate;the ash coating performance of the paper can be remarkably improved after the CTSFePO4 nanoparticles are coated on the cigarette paper.

Owner:CHINA TOBACCO HENAN IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com