A preparation method of anti-reflection and anti-fingerprint coating film suitable for plastic substrates

A plastic substrate and anti-reflection technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, coatings, etc., can solve complex processes, poor film adhesion, and unsuitability for plastic substrates, etc. problem, to achieve a firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

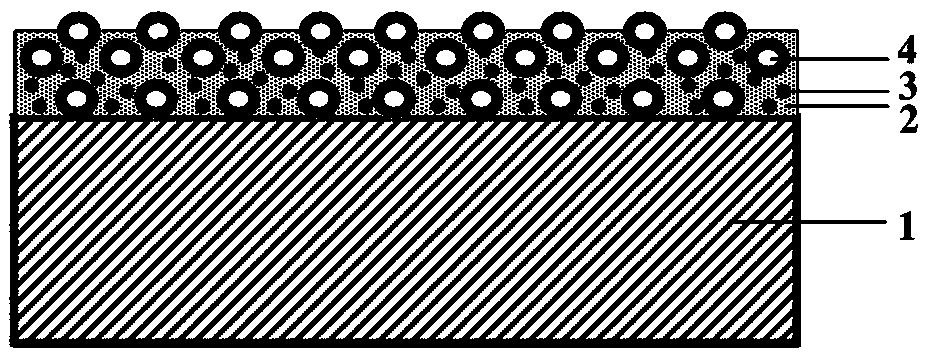

Image

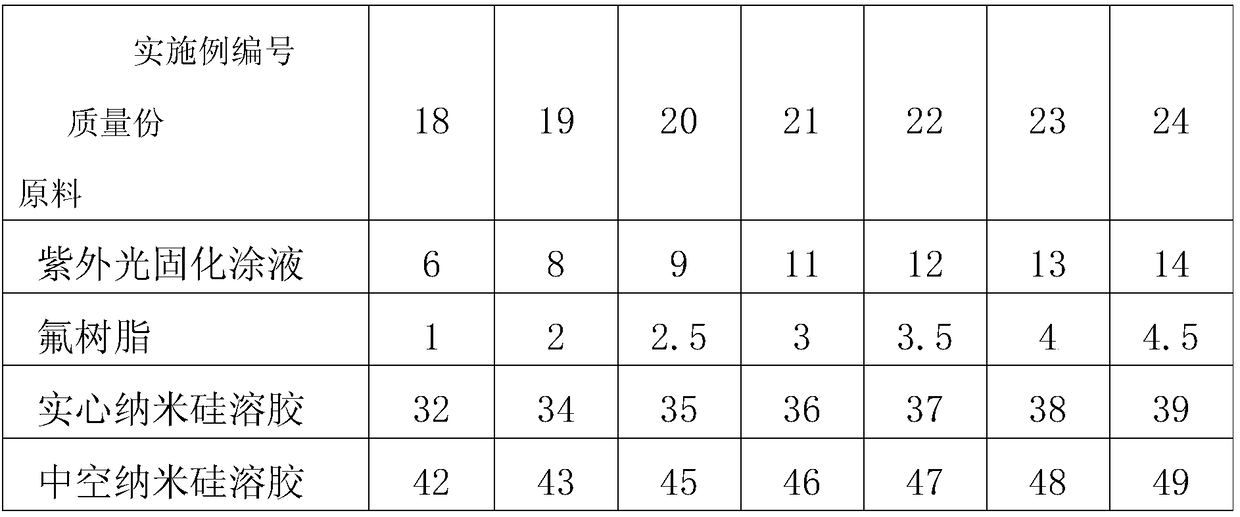

Examples

Embodiment 1

[0039] A method for preparing an anti-reflection and anti-fingerprint coating film suitable for plastic substrates, the steps are:

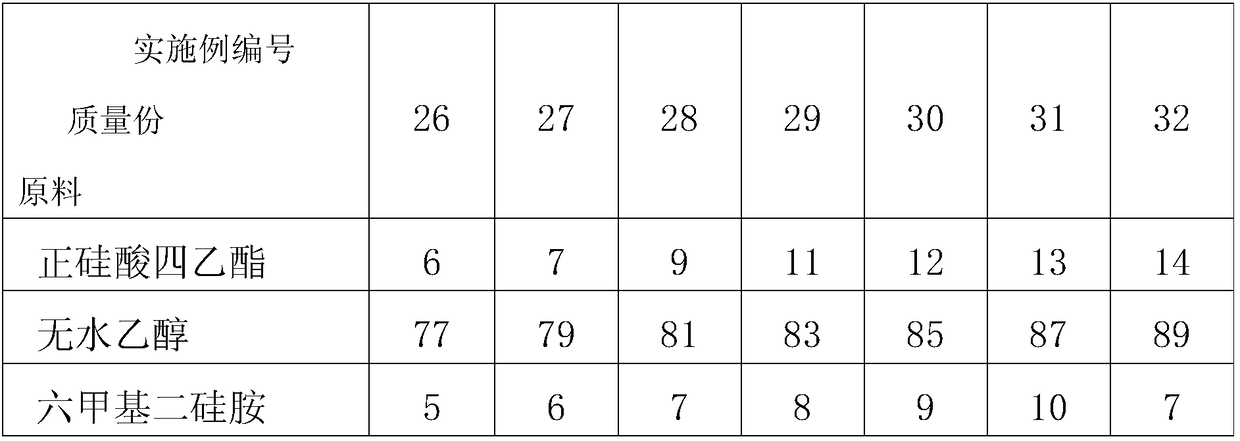

[0040] Mix 10 parts by mass of tetraethyl orthosilicate and 80 parts by mass of absolute ethanol evenly, then adjust the pH of the system to 8 with ammonia water (mass concentration 28%) under stirring, and after standing for 8 hours, add 10 parts by mass of tetraethyl orthosilicate Methyl disilazide, after standing for 24 hours, the solid nano-silica sol with a particle size of 20-40nm was obtained;

[0041] Dissolve 0.6 parts by mass of PAA (Mw=800~1000) in 3.2 parts by mass of ammonia water (mass concentration 28%), then pour it into 90 parts by mass of absolute ethanol, and stir for 4 times at 0.3 parts by mass each time Add tetraethyl orthosilicate at an interval of 1 hour, add 5 parts by mass of HMDS 2 hours after the fourth addition of ethyl acetate, and continue stirring for 6 hours to obtain a hollow nano-silica sol with a particle size ...

Embodiment 2

[0045] A method for preparing an anti-reflection and anti-fingerprint coating film suitable for plastic substrates, the steps are:

[0046] Mix 10 parts by mass of tetraethyl orthosilicate and 80 parts by mass of absolute ethanol evenly, then adjust the pH of the system to 8 with ammonia water (mass concentration 28%) under stirring, and after standing for 8 hours, add 10 parts by mass of HMDS , and then placed for 24 hours to obtain a solid nano-silica sol with a particle size of 20-40 nm.

[0047] Dissolve 0.6 parts by mass of PAA (Mw=800~1000) in 3.2 parts by mass of ammonia water (mass concentration 28%), then pour it into 90 parts by mass of absolute ethanol, and stir for 4 times at 0.3 parts by mass each time Ethyl orthosilicate was added at an interval of 1 hour, 5 parts by mass of HMDS was added 2 hours after the fourth addition of ethyl acetate, and stirring was continued for 6 hours to obtain a hollow nano-silica sol with a particle size of 80-150 nm.

[0048] The a...

Embodiment 3

[0051] A method for preparing an anti-reflection and anti-fingerprint coating film suitable for plastic substrates, the steps are:

[0052] Mix 10 parts by mass of tetraethyl orthosilicate and 80 parts by mass of absolute ethanol evenly, then adjust the pH of the system to 8 with ammonia water (mass concentration 28%) under stirring, and after standing for 8 hours, add 10 parts by mass of HMDS , and then placed for 24 hours to obtain a solid nano-silica sol with a particle size of 20-40 nm.

[0053] Dissolve 0.6 parts by mass of PAA (Mw=800~1000) in 3.2 parts by mass of ammonia water (mass concentration 28%), then pour it into 90 parts by mass of absolute ethanol, and stir for 4 times at 0.3 parts by mass each time Ethyl orthosilicate was added at an interval of 1 hour, 5 parts by mass of HMDS was added 2 hours after the fourth addition of ethyl acetate, and stirring was continued for 6 hours to obtain a hollow nano-silica sol with a particle size of 80-150 nm.

[0054] The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com