Patents

Literature

100results about How to "Good anti-fingerprint effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-soiling aging-resisting stainless steel paint and preparation method thereof

ActiveCN101215438AImprove aging resistanceImproves UV resistanceLiquid surface applicatorsAntifouling/underwater paintsEpoxyWater based

The invention relates to anti-pollution anti-aging rustless steel coating material and a process for preparation, and coating material comprises acroleic acid resin, film forming matter, filling material, dissolvent and auxiliary agent which are mixed, the film forming matter comprises fluoro containing resin, water-based polyurethane and epoxide resin, the filling material comprises nanometer silicon oxide. The process comprises dissolving acroleic acid resin in dissolvent, further adding film forming matter, filling material, and auxiliary agent, balling to evenly mix. The rustless steel coating material of the invention adopts nanometer silicon oxide and fluoro containing resin to modify acroleic acid coating material, utilizes the ultraviolet screening performance of nanometer silicon oxide, the particle diameter of nanometer-grade particle and low surface tension of fluoro containing resin to lead the anti-aging capability and anti-ultraviolet performance of acroleic acid resin which is prepared to be greatly enhanced, the invention has longer life span than the existing normal acroleic acid resin coating material, which has better fingerprint resisting effect, and the quality and the level are greatly improved, the scope of application is further enlarged.

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD +1

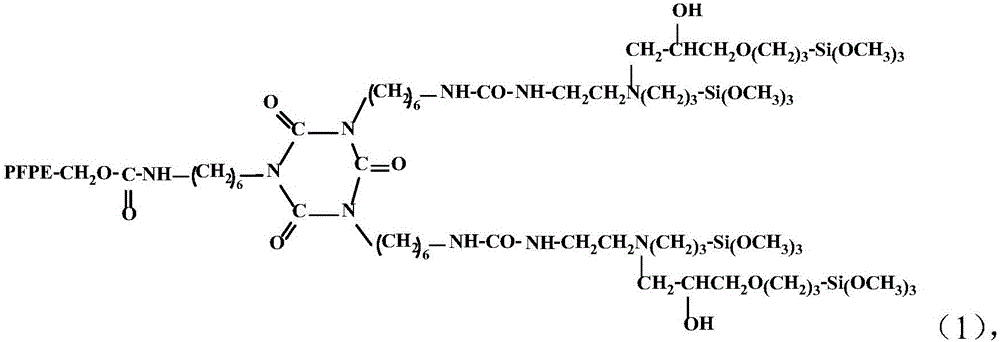

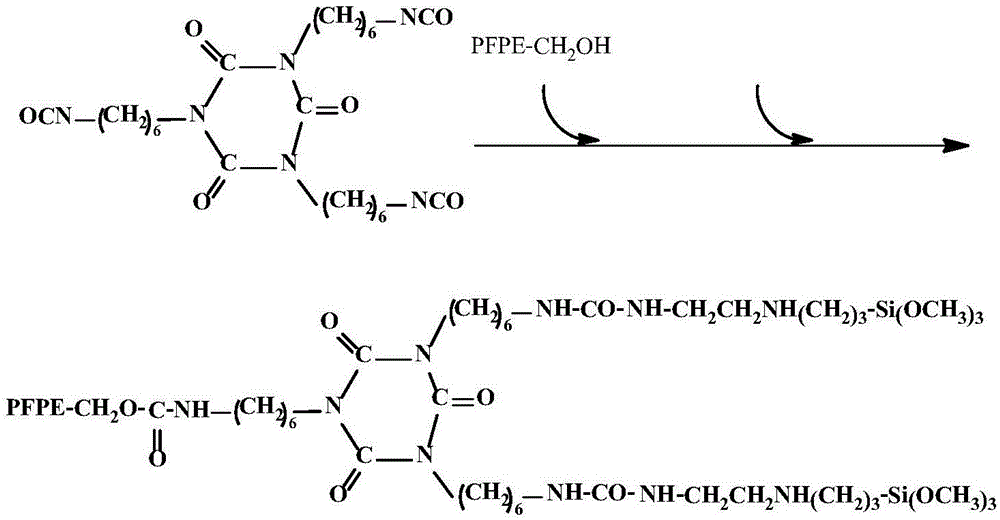

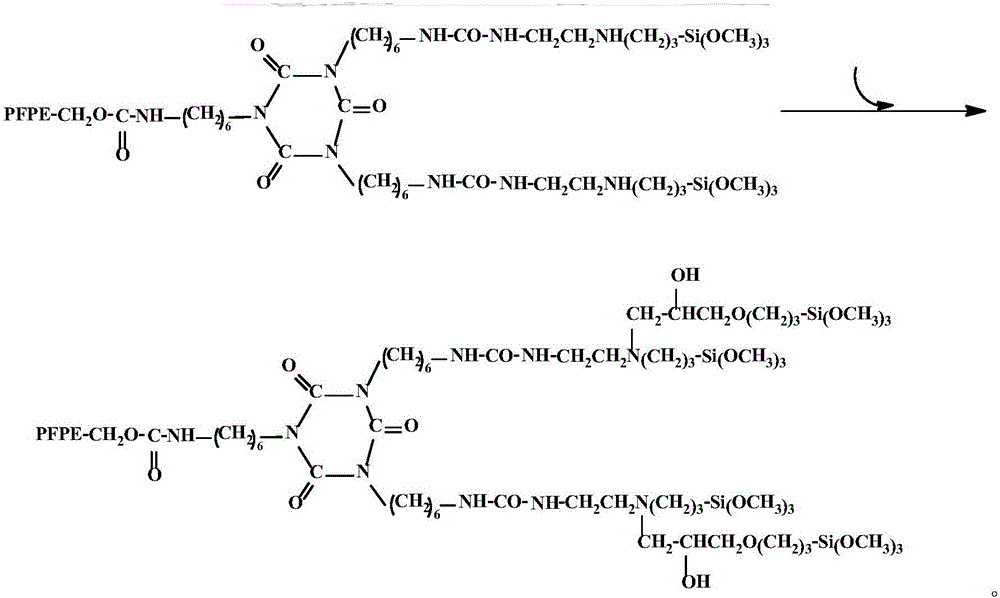

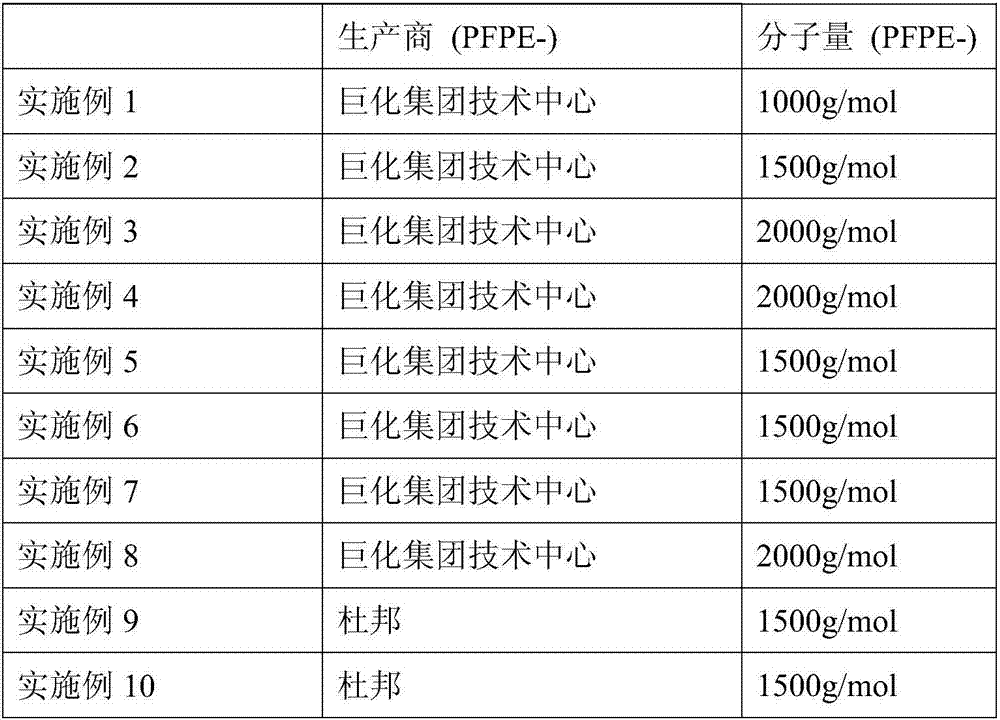

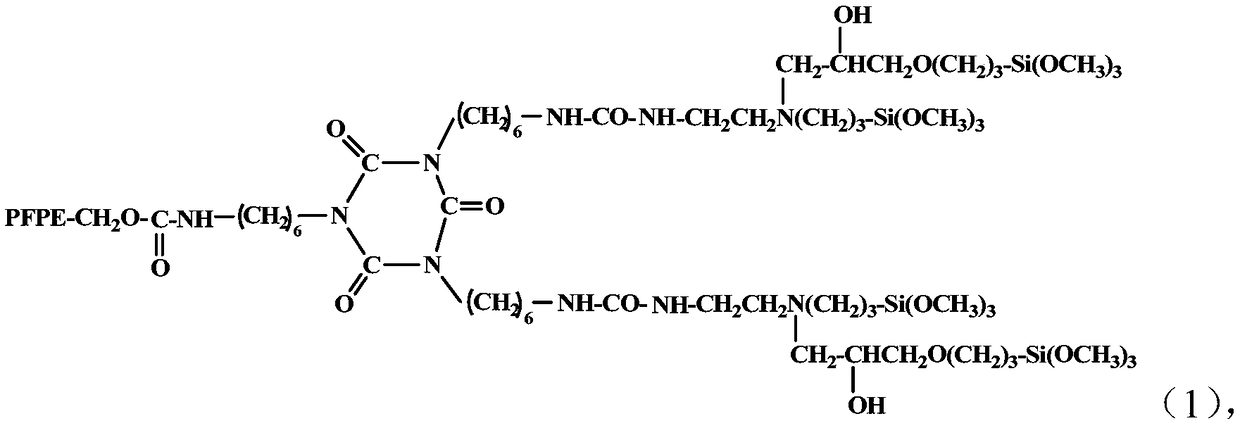

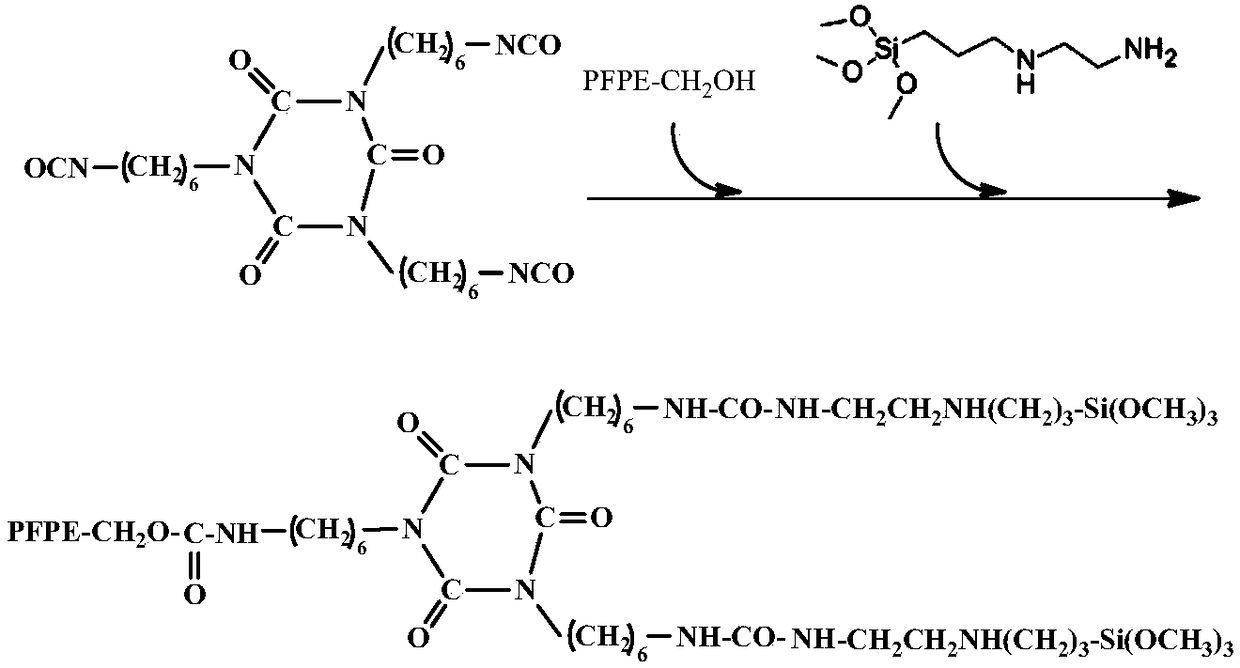

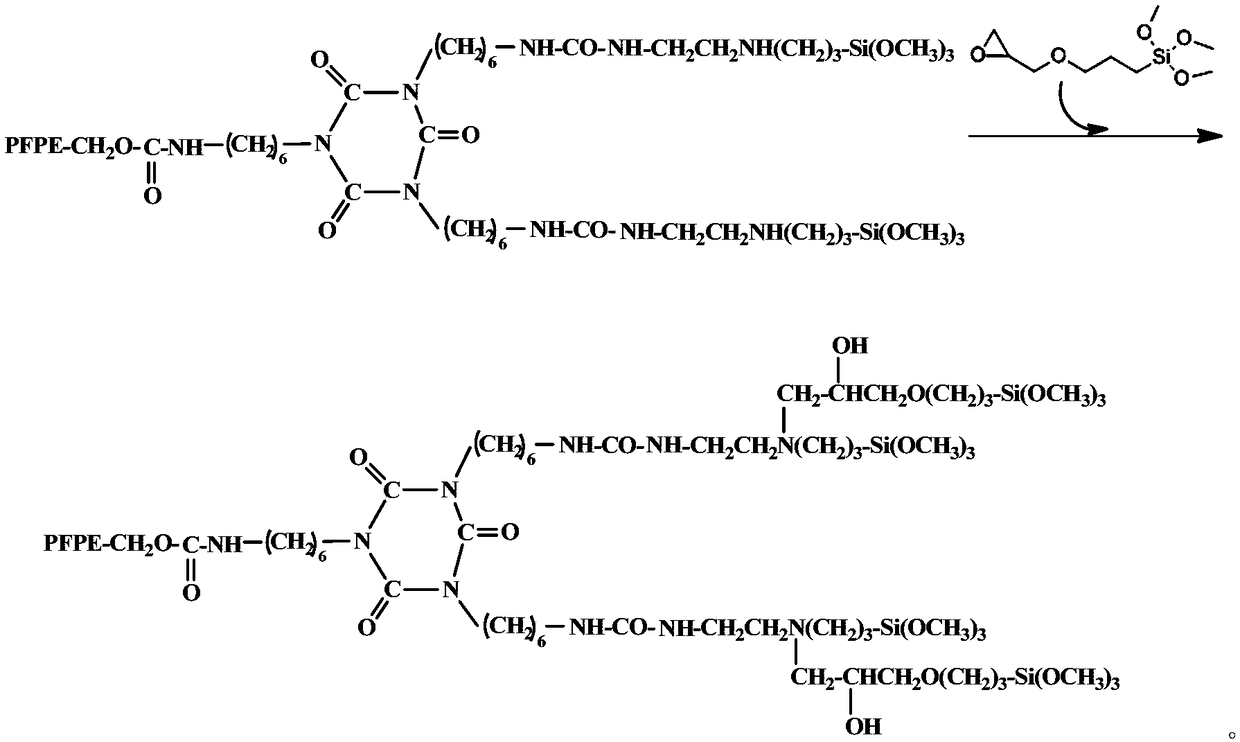

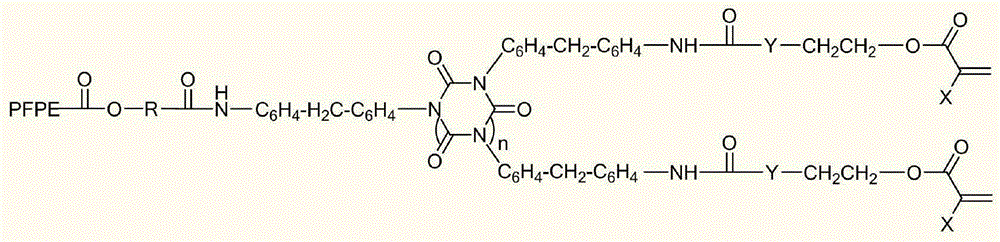

Novel perfluoropolyether alkoxy silane compound and synthesis method thereof

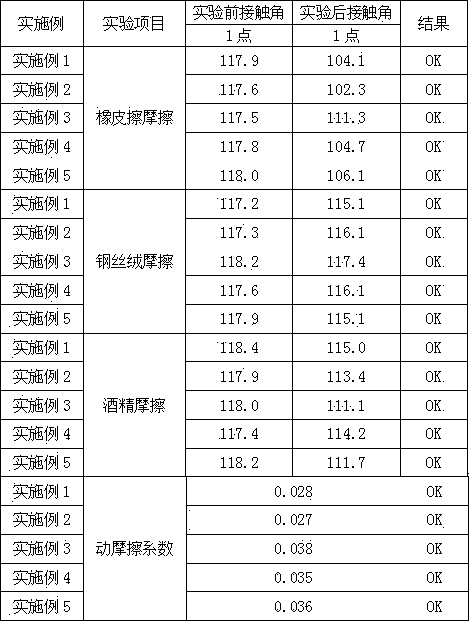

ActiveCN106432686AGood antifoulingGood anti-fingerprint effectAntifouling/underwater paintsPaints with biocidesSilane compoundsPerfluoropolyether

The invention discloses a novel perfluoropolyether alkoxy silane compound and a synthesis method thereof. The structure of the compound is shown as formula (1). The synthesis method includes: reacting hydroxyl terminated perfluoropolyether (PFPE), 3-(2-aminoethyl)aminopropyltrimethoxysilane, 3-(2, 3-epoxypropoxy)propyltrimethoxysilane (KH560), and an HDI trimer in a molar ratio of 1:2:2:1, during reaction, employing a certain amount of a solvent to dilute the mixed hydroxyl terminated perfluoropolyether and 3-(2-aminoethyl)aminopropyltrimethoxysilane, then adding the HDI trimer dropwise, carrying out reaction for 6h at certain temperature, then adding KH560 dropwise, and carrying out reaction for 6h again at certain temperature then reducing pressure and removing the solvent, thus obtaining the perfluoropolyether alkoxy silane compound. The compound can be coated on glass, plastic, film, and other substrate surfaces, and after crosslinking and curing, a layer of solid film can be formed, and the substrate is endowed with excellent anti-fingerprint and antifouling performance and abrasion resistance.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

Ultraviolet light curing fingerprint resistant paint

InactiveCN101250340AExcellent anti-fingerprintGood wear resistancePolyurea/polyurethane coatingsFingerprintPolymer chemistry

The invention discloses ultraviolet light curing anti-fingerprint paint, which comprises components with percentage by weight of 5-25 wt% high function aliphatic polyurethane acrylic ester, 10-30 wt% acrylic ester modified by fluorine, 5-20 w% large molecular resin, 10-25 wt% trifunctionanal function aliphatic polyurethane acrylic ester, 5-15 wt% double function acrylic ester, 1-5 wt% photo initiator, 15-40 wt% diluent and 0.01-1 wt% auxiliary agent, wherein high function aliphatic polyurethane acrylic provides hardness and high abrasion resistance, acrylic ester modified by fluorine is formed by grafting fluorine monomer with acrylic ester. The anti-fingerprint paint can permanently reduce the surface tension of painting film, and eliminates the generation of fingerprints.

Owner:HUIZHOU CHANGRUNFA PAINT

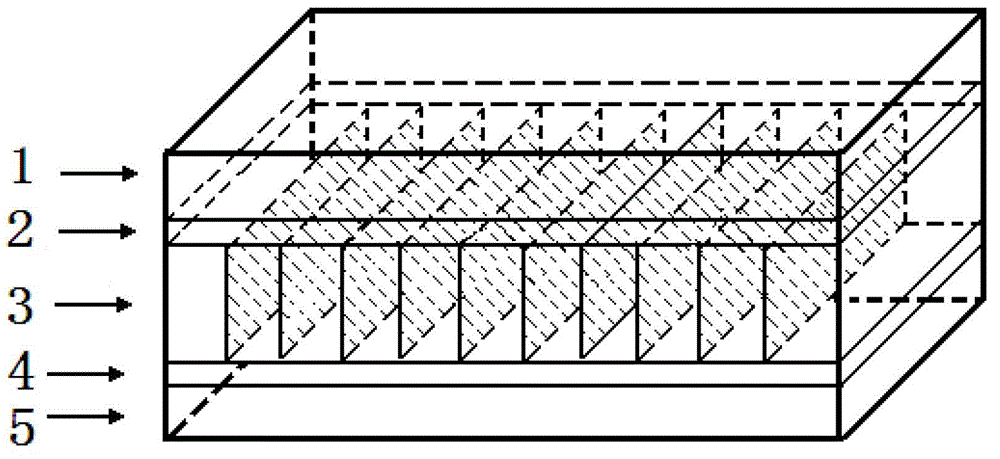

Nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film

ActiveCN102717549AExcellent scratch resistanceInnovative materials and treatmentsSynthetic resin layered productsFingerprintIn situ polymerization

The invention discloses a nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film, which comprises an organic silica gel layer, a peep-proof polarization film, a bonding agent layer, a PET (Polyester) film layer and an anti-glare fingerprint-resistant nano coating from inside to outside. The anti-glare fingerprint-resistant nano coating takes silicon-fluorine polymers as a substrate, and is prepared by forming a layer of silicon dioxide or calcium carbonate with nano microbumps on the surface of a PET film in a in-situ polymerization manner; the peep-proof polarization film comprises a plurality of strip-shaped photoresists that are arranged in parallel, the cross section of each strip-shaped photoresist is square, and a non-transparent interlayer is arranged on the strip-shaped photoresist; and the interval of the photoresist is half of the thickness of the photoresist. The surface hardness of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film is greater than 4H, and the fingerprint-resistant performance of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film obviously surpasses the commercial conventional merchandises; the peep-proof polarization film adopts photoresist solidification and non-transparent matter filling technologies, and has greater innovations in material and processing method; in addition, a PC (polycarbonate) film is replaced by the PET film with the effects of tough texture, good stiffness, high transparency and low price, so that the quality is ensured, and the cost is lowered at the same time.

Owner:SHANGHAI BENPU TECH DEV

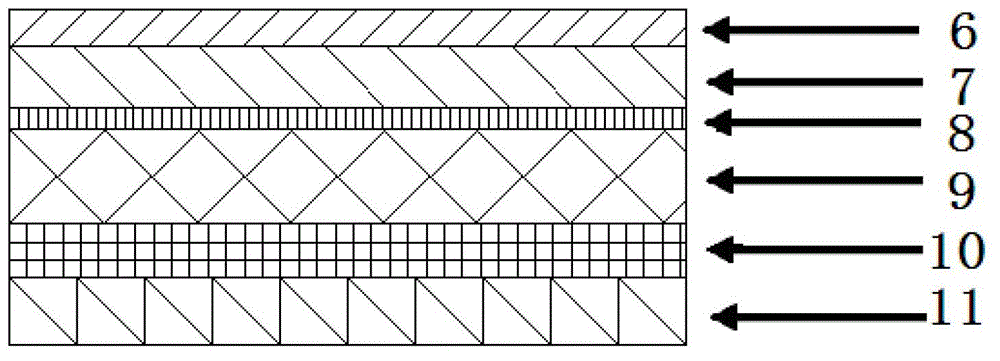

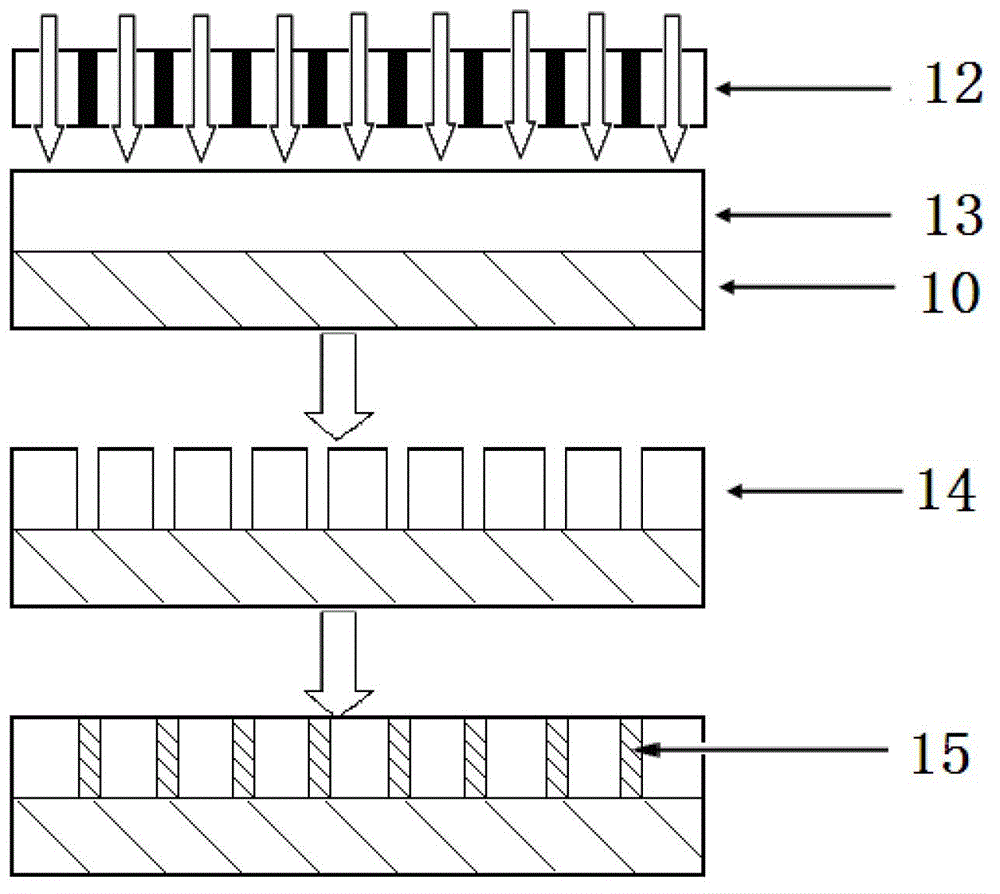

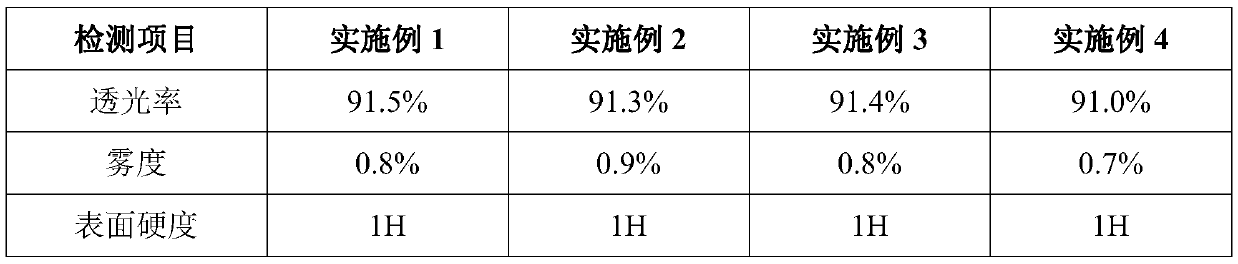

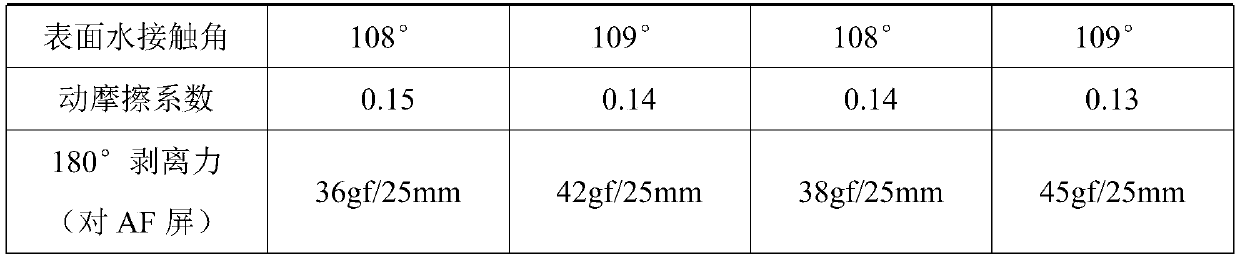

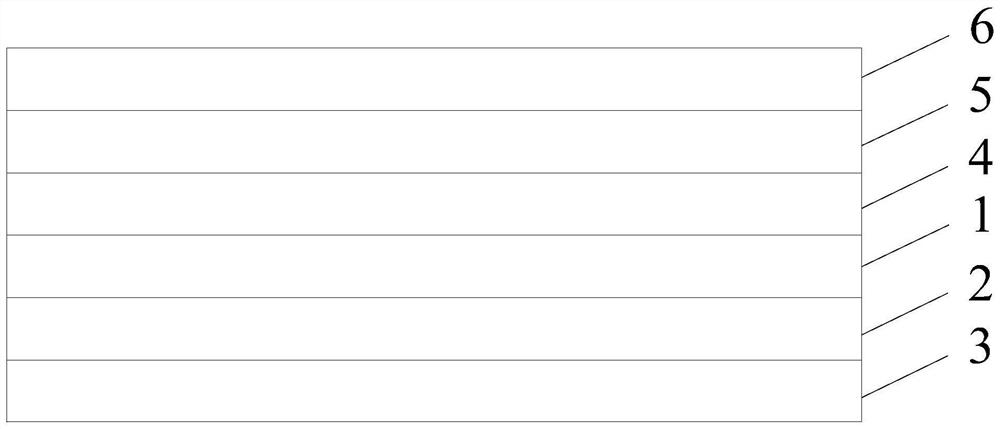

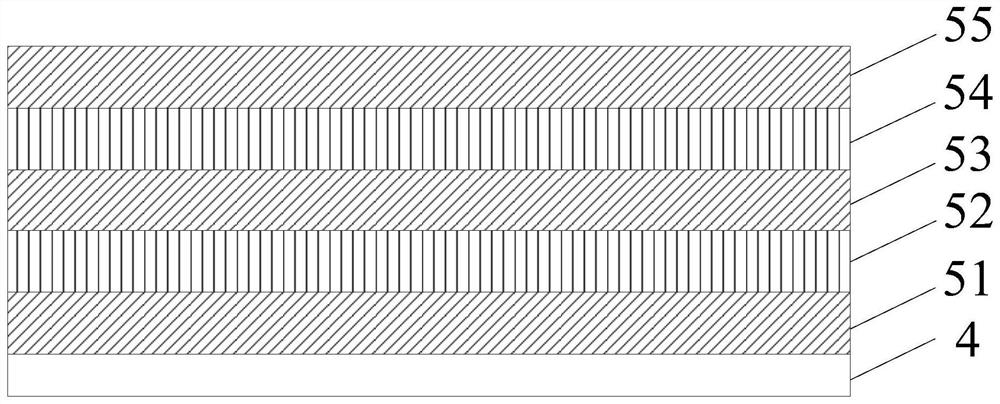

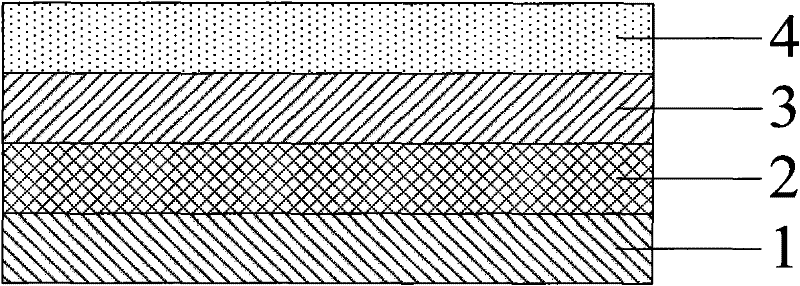

Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

PendingCN111484810AGood optical performanceImprove smoothnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterColloidal silica

The invention discloses an anti-fingerprint TPU protective film for a 3D curved screen. The protective film comprises a low-viscosity protective film, an anti-fingerprint UV hardening coating, an optical hard TPU resin film layer, an optical-grade high-viscosity silica gel pressure-sensitive adhesive layer and a fluorine element release film which are attached from top to bottom; the anti-fingerprint UV hardening coating is formed by coating an anti-fingerprint UV hardening coating; the optical hard TPU resin film layer is formed by coating optical hard TPU glue, the optical-grade high-viscosity silica gel pressure-sensitive adhesive layer is formed by coating an optical-grade high-viscosity silica gel pressure-sensitive adhesive; the anti-fingerprint UV hardening coating is prepared fromthe following components: UV prepolymer resin, an acrylate reactive diluent, a photoinitiator, a slipping aid and a first solvent, the optical-grade hard TPU glue is formed by polymerizing polyisocyanate, polyester polyol and a chain extender in a second solvent under the action of a first catalyst; the optical-grade high-viscosity silica gel pressure-sensitive adhesive is composed of silica gel resin, a cross-linking agent, an anchoring agent and a second catalyst. The anti-fingerprint TPU protective film for a 3D curved screen has the properties of fingerprint resistance, scratch resistance,difficulty in bursting and good fitting property of the curved screen.

Owner:GUANGDONG BANGGU FILM COATING INNOVATION ACAD CO LTD

Curved screen protection film and preparation method thereof

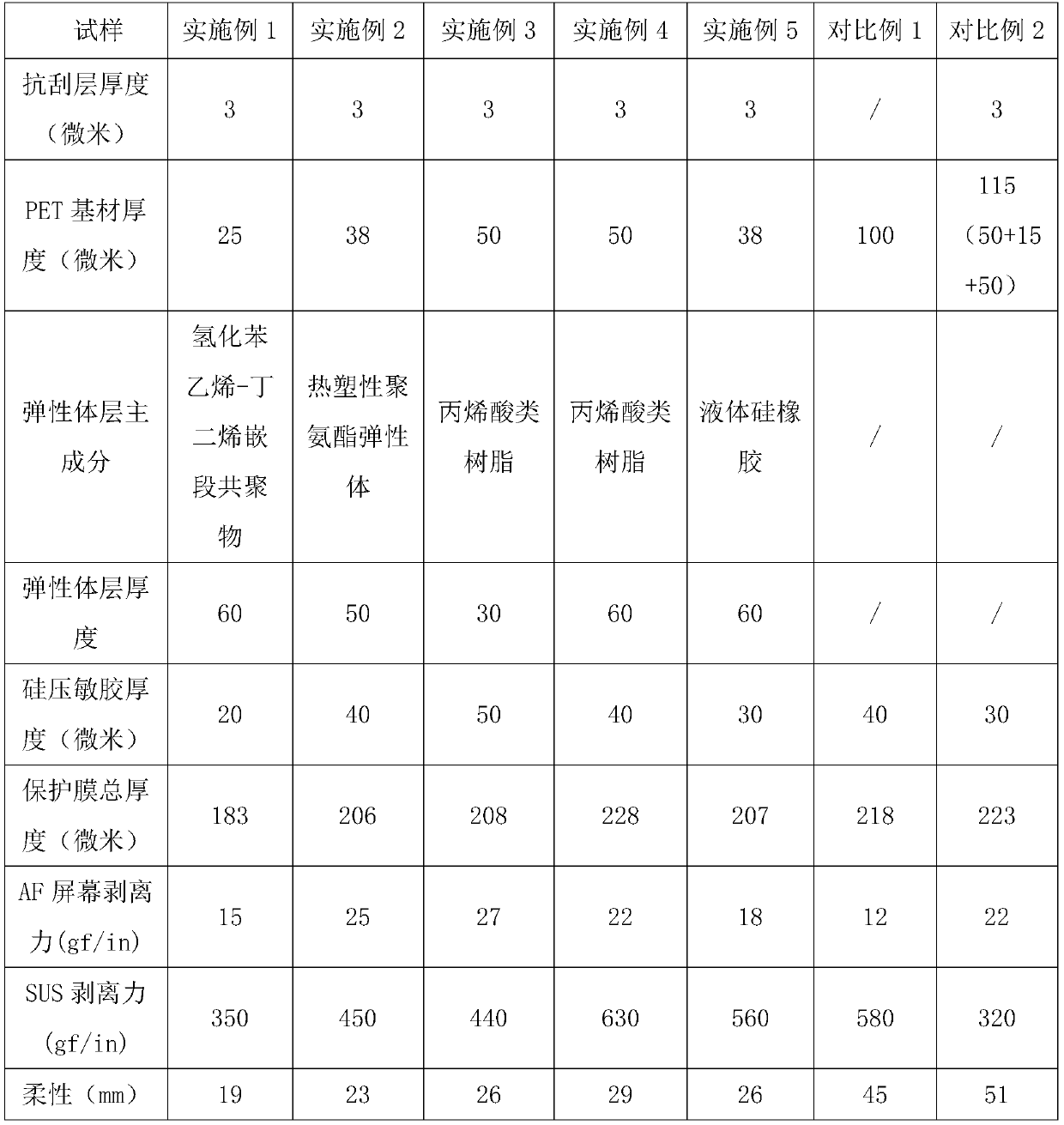

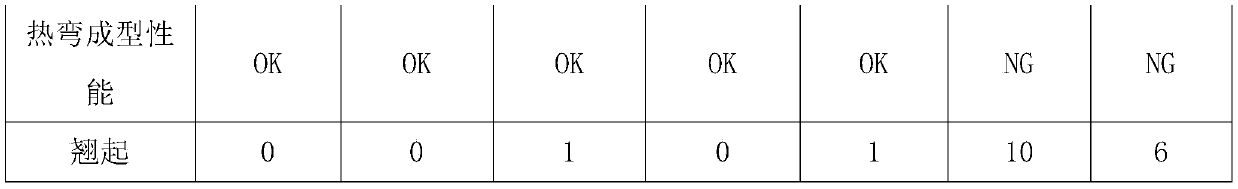

ActiveCN110105896AImprove bendabilityImprove impact performanceFilm/foil adhesive primer layersPolyurea/polyurethane coatingsElastomerTectorial membrane

The invention relates to the technical field of curved screen protection films, in particular to a screen protection film for protecting curved liquid crystal screens and a manufacturing method of thescreen protection film. The curved screen protection film structurally comprises an anti-scratching layer, a PET base material, an elastomer layer, a silica gel layer and a fluorine release film which are sequentially arranged. According to the protection film, the arranged elastomer layer is beneficial to improving the bending property and drop resistance of the protection film, and under cooperation with the silica gel layer arranged on a protection film body, improvement of the fixing and fitting property of the protection film is facilitated, so that the problem of edge warping is effectively solved, and the protection film is suitable for the design of large angles and radians of the edge positions of mobile phone screens. Through the reasonable arrangement of the structure and thickness of each layer, the protection film has the basic performance of a PET screen protection film, and meanwhile, the flexibility, drop resistance and edge warping resistance of the protection film are further improved.

Owner:佛山固泰明科技有限公司

Water-based ultraviolet-curing anti-fingerprint coating and preparation method thereof

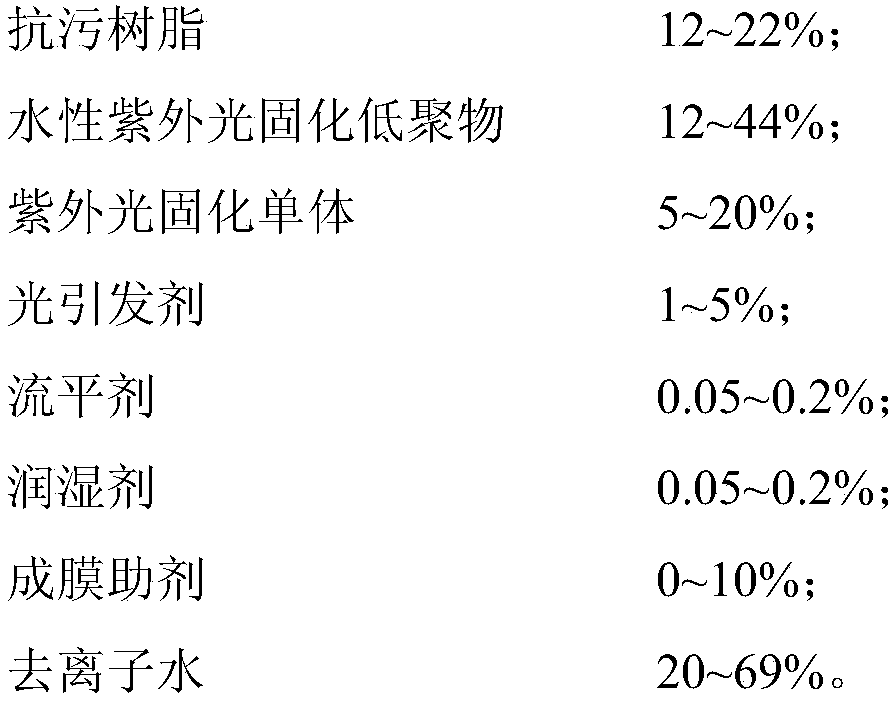

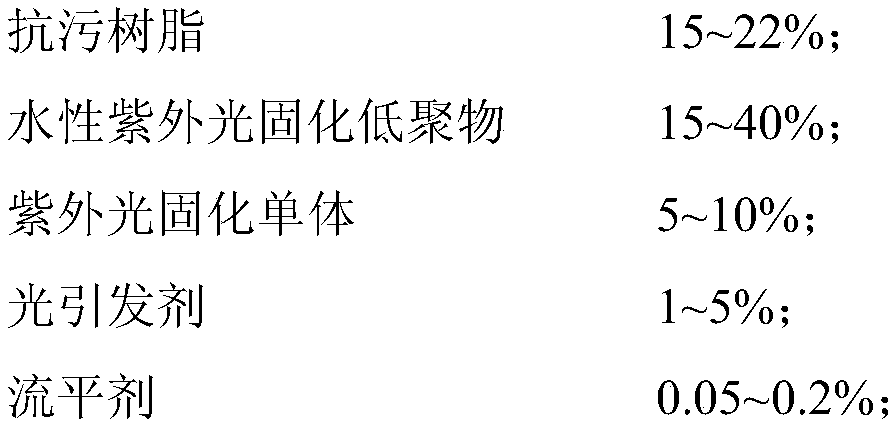

ActiveCN108300274ASmall smellLow VOC contentAntifouling/underwater paintsPaints with biocidesWater basedStaining

The invention discloses a water-based ultraviolet-curing anti-fingerprint coating and a preparation method thereof, and belongs to the technical field of coating processing. The coating comprises, bymass, 12-22% of anti-staining resin, 12-44% of an aqueous ultraviolet-curing oligomer, 5-20% of an ultraviolet-curing monomer, 1-5% of a photoinitiator, 0.05-0.2% of a leveling agent, 0.05-0.2% of a wetting agent, 0-10% of a film forming additive and 20-69% of deionized water. The water-based ultraviolet-curing anti-fingerprint coating prepared through the certain preparation method by adopting the fluorine-containing or silicon-containing anti-staining resin and the aqueous ultraviolet oligomer as a main body adopts water as a dispersion medium, has the characteristics of low odor, non-flammability, low VOC content, washability and the like, reserves the advantages of short curing time, high production efficiency and low energy consumption of UV coatings, and meets the requirements of green and environmental laws and regulations; and a coating layer obtained by using the coating has the advantages of excellent anti-fingerprint effect and strong durability.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

Antireflector and display device

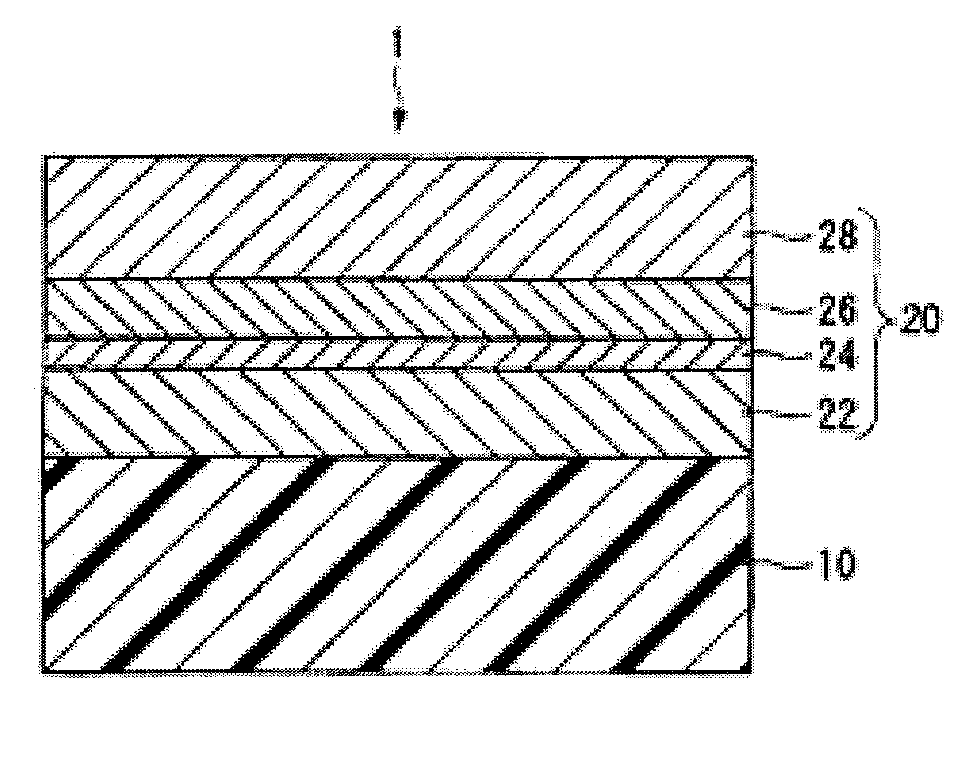

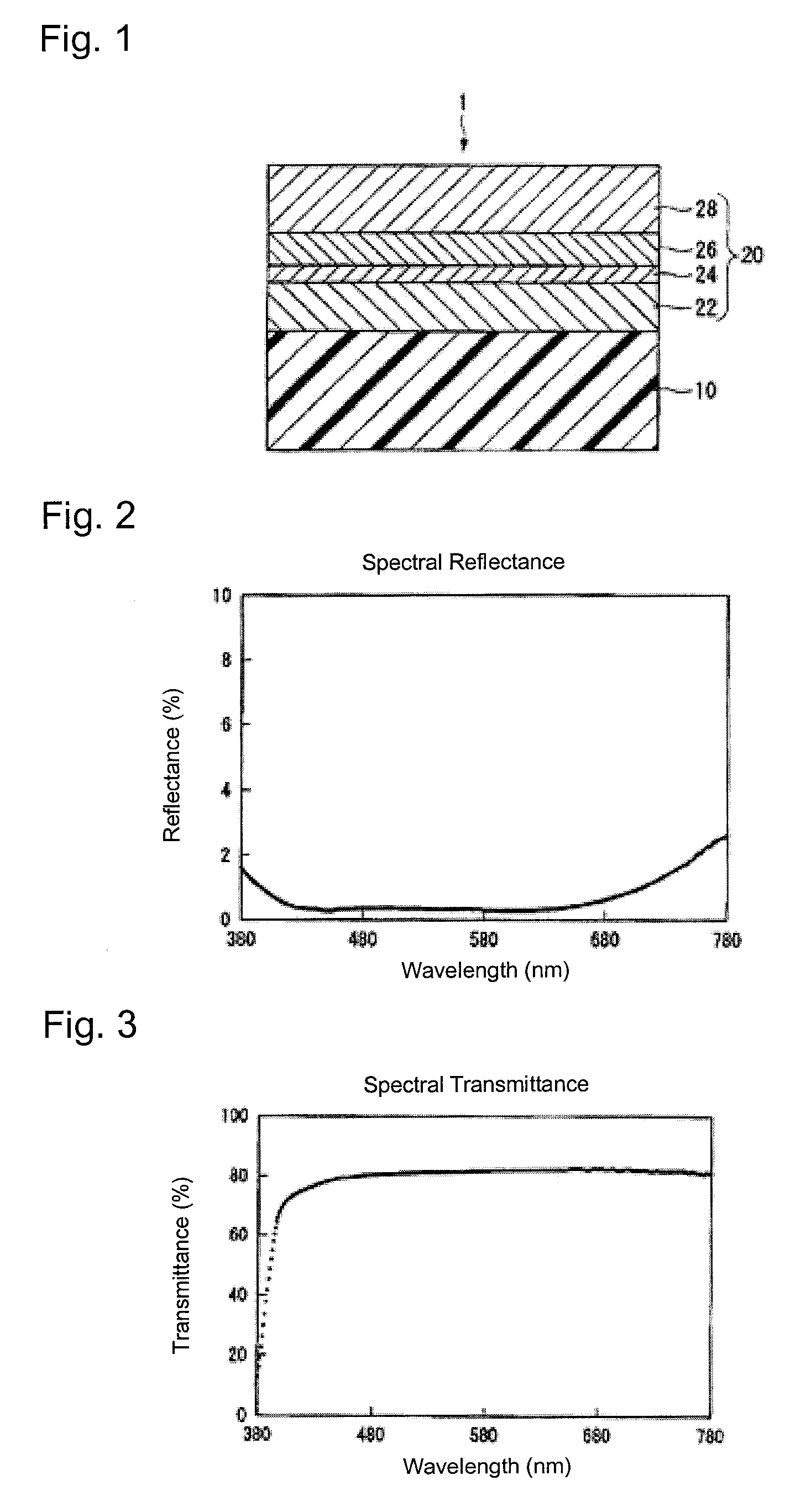

InactiveUS20100014163A1Layer structure is simpleHigh visible light transmittanceLayered productsCoatingsIndiumRefractive index

There are provided an antireflector having a simple layer structure, a high visible light transmittance, a low visible light reflectance and an excellent anti-fingerprint property, and a display device having an excellent viewability.An antireflector 1 including a substrate 10 and an antireflection film 20; the antireflection film 20 having a first high refractive index layer 22, a metal layer 24, a second high refractive index layer 26 and a low refractive index layer 28 disposed therein sequentially from a substrate side facing the substrate 1; the first high refractive index layer containing at least one member selected from the group consisting of tin, gallium and cerium in the form of an oxide, and indium in the form of an oxide; the metal layer containing silver and palladium and having a palladium content of from 3 to 20 mass % relative to the total amount of the metal layer (100 mass %); the second high refractive index layer containing at least one member selected from the group consisting of tin, gallium and cerium in the form of an oxide and indium in the form of an oxide. A display device including the antireflector 1 disposed on an observer' side of a display panel.

Owner:ASAHI GLASS CO LTD

Hard coating anti-fingerprint additive and preparation method thereof

ActiveCN107141867AImprove waterproof performanceGood oil proofAntifouling/underwater paintsPaints with biocidesReaction temperatureCyclic compound

The invention discloses a hard coating anti-fingerprint additive and a preparation method thereof. The hard coating anti-fingerprint additive contains the following components: perfluoropolyether, fluorine-containing polysiloxane, an acrylate monomer and an organic silicon cyclic compound. The preparation method comprises the following steps: a) adding the fluorine-containing polysiloxane and a solvent A into a three-mouth flask, fully stirring the solution to be uniform, and heating to a reaction temperature; b) adding the perfluoropolyether and the solvent A into the three-mouth flask while stirring so as to obtain a perfluoropolyether and organic fluorosilicone polymer; c) adding the acrylate monomer, a catalyst and the solvent A into the three-mouth flask while stirring, reacting for 4-20 hours, continuing to drip the organic silicon cyclic compound, and reacting for 4-10 hours; and d) cooling to room temperature after the reaction is ended, diluting to the solid content of 20% by using a solvent B. The antifouling additive disclosed by the invention stably exists at the room temperature, has excellent compatibility with coatings, and can provide excellent water resistance, oil resistance, fouling resistance, fingerprint resistance, smoothness, heat resistance and friction resistance for the hard coating after beingsubjected to UV (Ultraviolet)-curable film forming.

Owner:QUZHOU FLUORIDE & SILICON RES INST

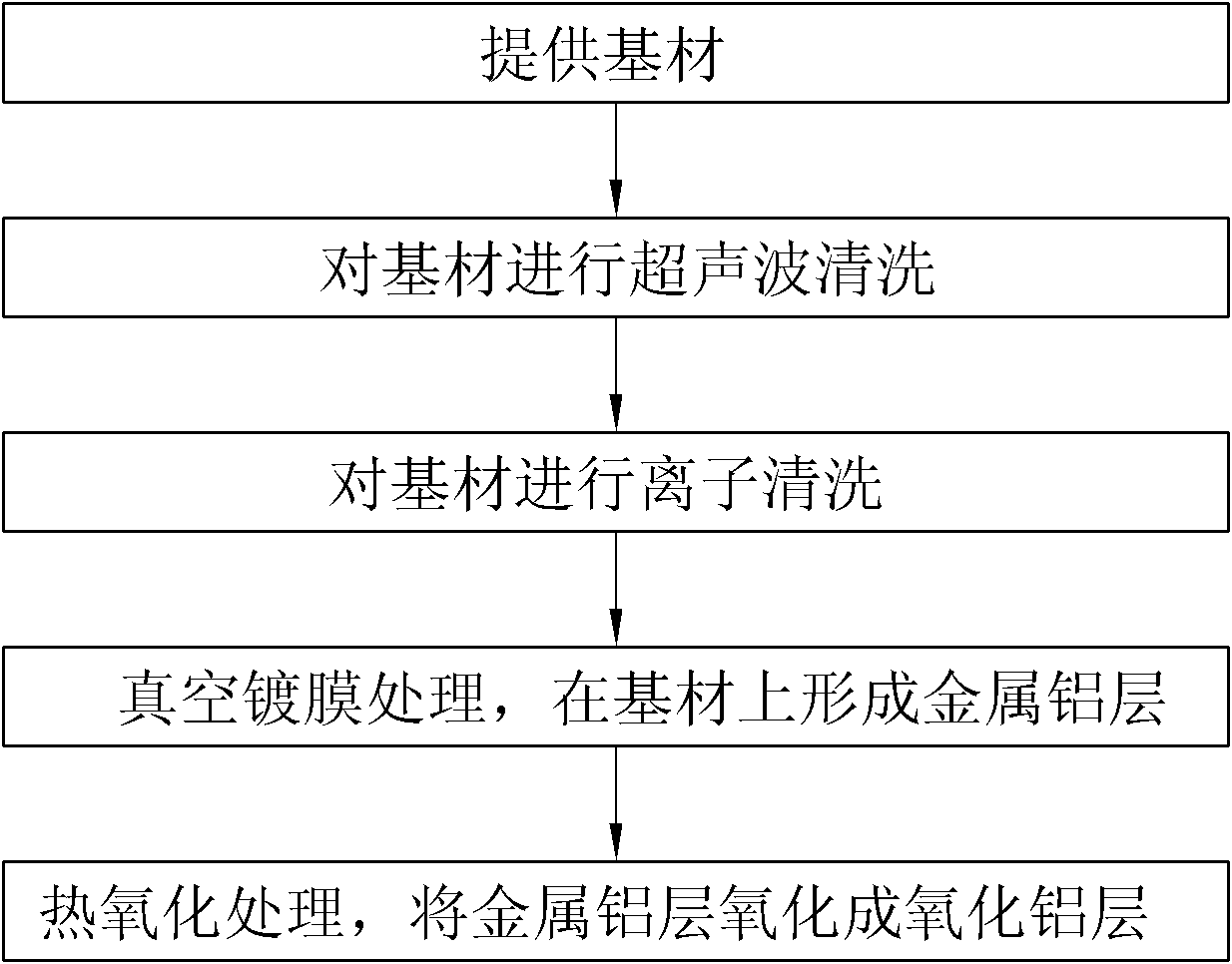

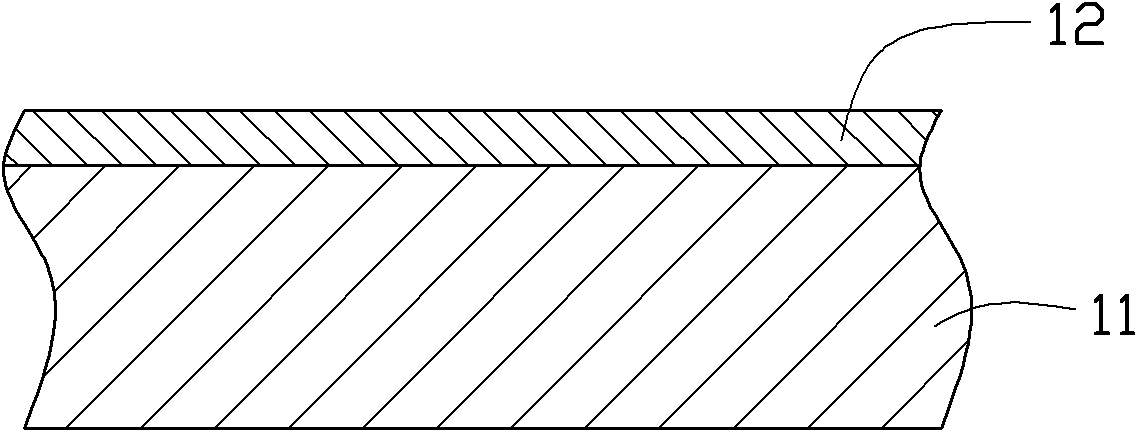

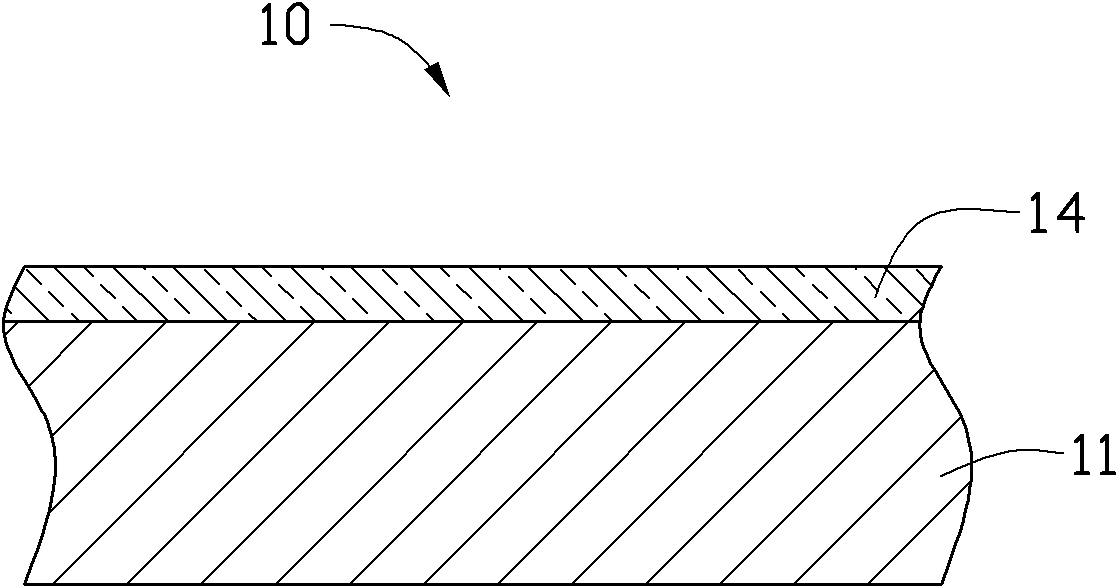

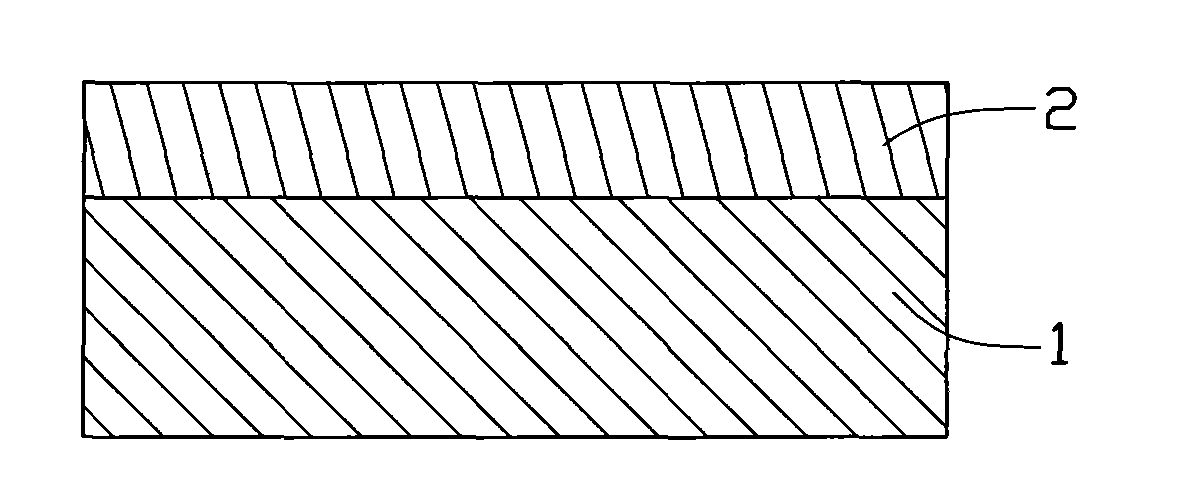

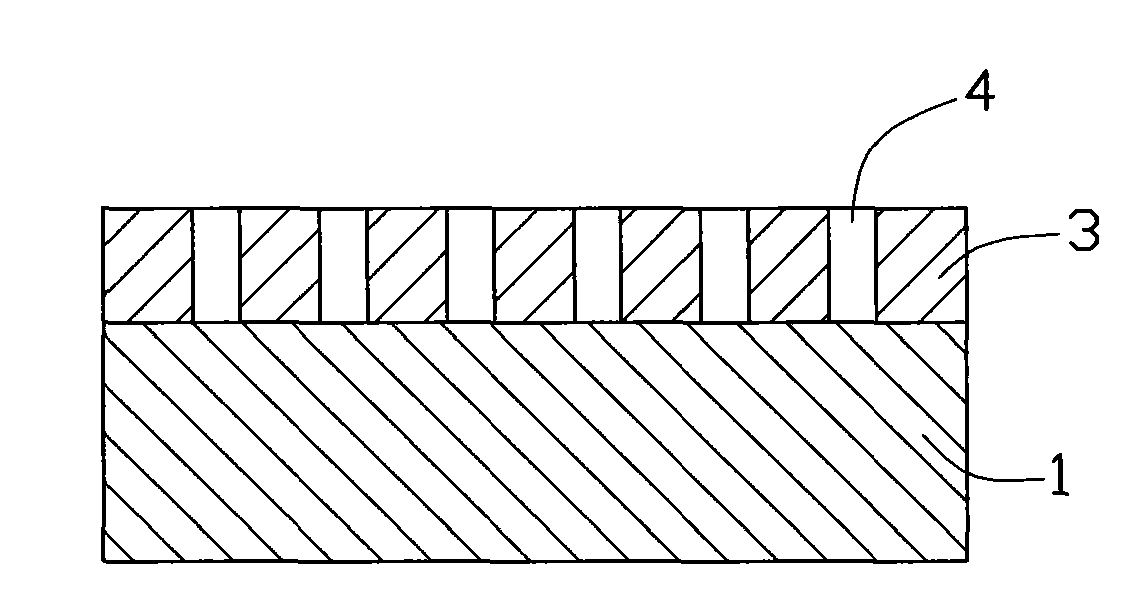

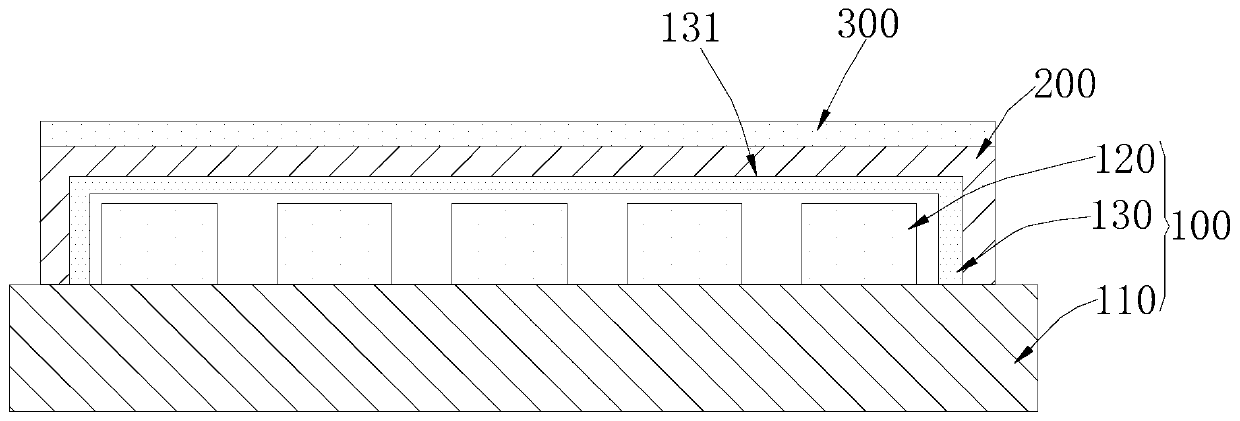

Metal surface anti-fingerprint treatment method and metal product prepared by the metal surface anti-fingerprint treatment method

InactiveCN102400102AHarmless to healthGood anti-fingerprint effectVacuum evaporation coatingSputtering coatingMetallic substrateVacuum coating

The invention provides a metal surface anti-fingerprint treatment method. The metal surface anti-fingerprint treatment method comprises the following steps of preparing a metal base material, depositing an aluminum layer on the metal base material through a vacuum coating method, and carrying out thermal oxidation treatment on the aluminum layer to enable the aluminum layer to be oxidized into an alumina layer, wherein multiple nanometer mastoids are distributed on the alumina layer. The invention also provides a metal product prepared by the metal surface anti-fingerprint treatment method. The metal product comprises a metal base material and an alumina (Al2O3) layer formed on the metal base material, wherein multiple nanometer mastoids are distributed on the surface of the alumina (Al2O3) layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

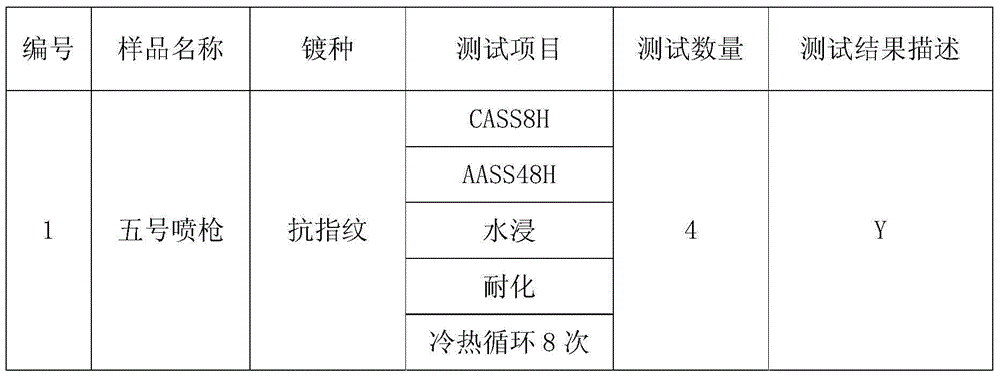

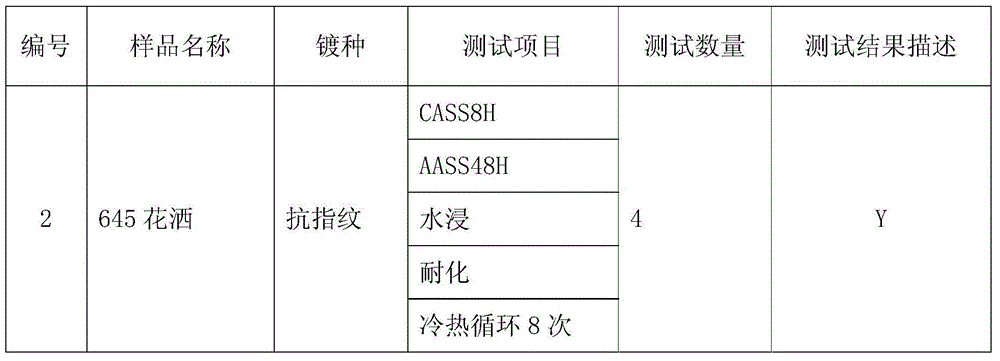

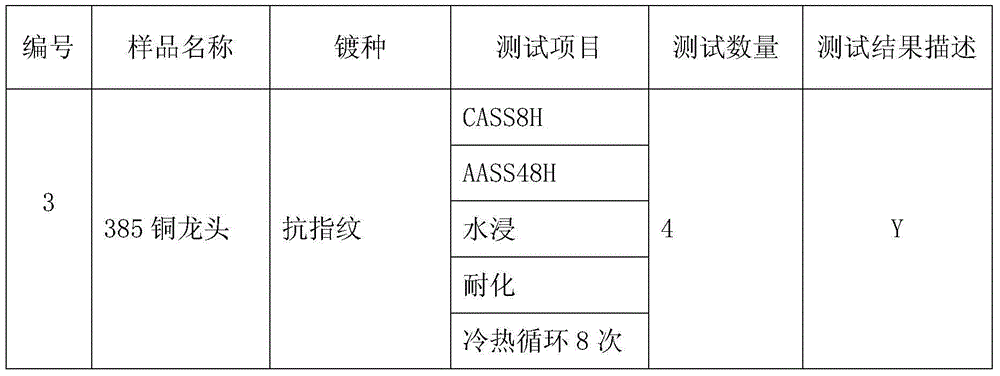

Method for forming anti-fingerprint membrane on sanitary product

ActiveCN104694929ANo emissionsGood anti-fingerprint effectVacuum evaporation coatingSputtering coatingEnvironmental resistanceIntermediate frequency

A method for forming an anti-fingerprint membrane on a sanitary product relates to surface treatment of sanitary products. The method for forming the anti-fingerprint membrane on the sanitary product is environmentally friendly and high in corrosion resistance and wearing resistance and achieves anti-fingerprint properties. The method comprises applying oil on the surface of an electronickelled base material with drawn grains, applying a corrosion-resistant alloy membrane layer through vacuum plating, applying a color layer through vacuum plating, applying a transparent silicon oxide membrane through intermediate-frequency magnetron sputtering and applying a fluorine polymer transparent nano anti-fingerprint membrane layer through vacuum evaporation to complete preparation of the anti-fingerprint membrane on the surface of the sanitary product. The anti-fingerprint membrane is environmentally friendly and meanwhile is high corrosion resistance, excellent in wear-resisting performance and capable of high-quality requirements in existing sanitary industry.

Owner:XIAMEN RUNNER IND CORP

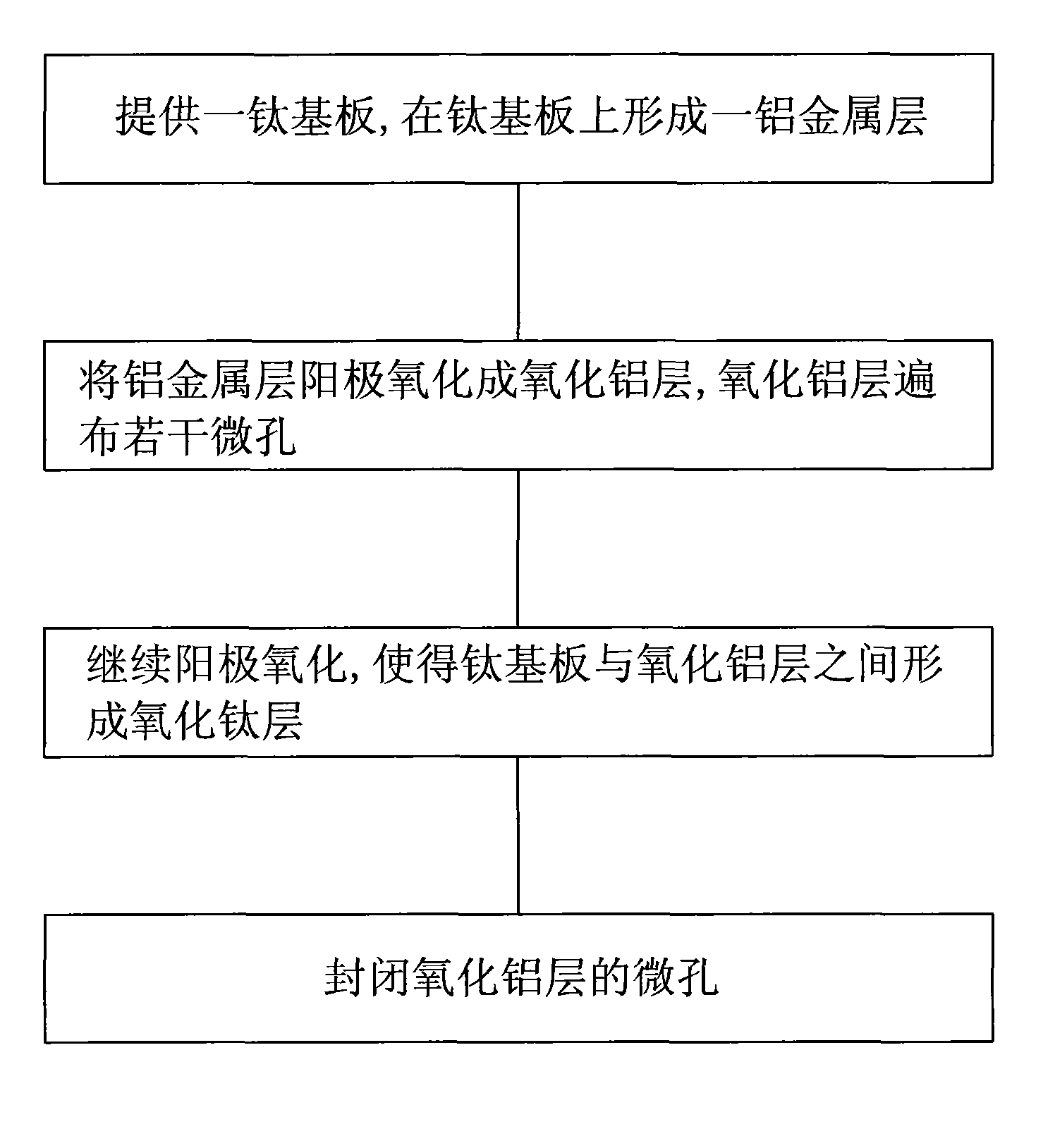

Titanium-base composite material and manufacturing method thereof

InactiveCN101603190ANot easy to retainGood anti-fingerprint effectAnodisationThin material handlingTitanium matrix compositesTitanium

The invention relates to a titanium-base composite material comprising a titanium-base plate, wherein a titanium oxide layer is covered on the titanium-base plate, and an aluminum oxide layer is covered on the titanium oxide layer. Compared with the prior art, the aluminum oxide layer is covered on the titanium-base plate of the titanium-base composite material and is a dense layer, impurities are difficult to retain on the surface of the aluminum oxide layer, and the aluminum oxide layer has better fingerprint performance resistance. The invention also discloses a manufacturing method of the titanium-base composite material.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

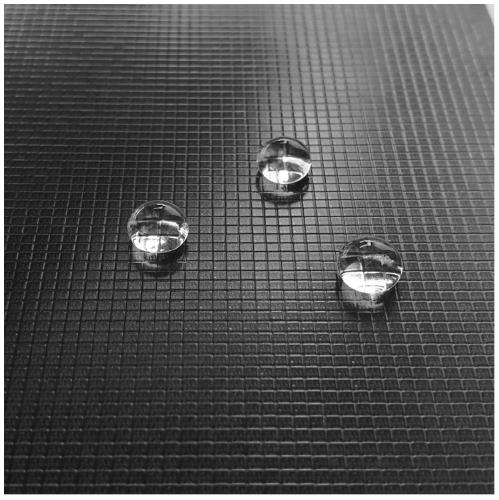

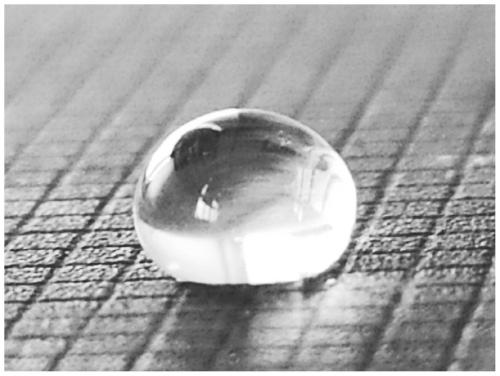

Hydrophobic film-coating liquid and production process of anti-pollution anti-fingerprint film-coated layer prepared therefrom

InactiveCN103865390AImprove adhesionImprove hydrophobicityPretreated surfacesCoatingsPerfluoropolyetherSpray coating

The invention relates to a hydrophobic film-coating liquid and a production process of an anti-pollution anti-fingerprint film-coated layer prepared therefrom. The hydrophobic film-coating liquid comprises 100 parts by mass of a fluorosiloxane, 0.1-0.5 part by mass of perfluoropolyether, 1-20 parts by mass of distilled water or deionized water, 10-50 parts by mass of an alcohol and 0.1-2 parts by mass of an inorganic acid. The production process of the film-coated layer comprises the following steps: a, firstly, cleaning a base material, and carrying out hydroxylation treatment on the surface of the cleaned base material; b, pouring the hydrophobic film-coating liquid into a spray coating device, putting the base material after the hydroxylation into the spray coating device, and carrying out a spray coating operation; c, putting the base material after spray coating into a baking oven, and baking with the baking temperature of 150 DEG C and the baking time of 30 minutes; and d, finally, taking out the baked base material, cooling for 10 minutes, and thus obtaining the base material having the anti-pollution anti-fingerprint film-coated layer. The film-coated layer has good anti-pollution anti-fingerprint performance and has good super-hydrophobic performance and wear-resisting performance.

Owner:KIWILL TECH SHENZHEN

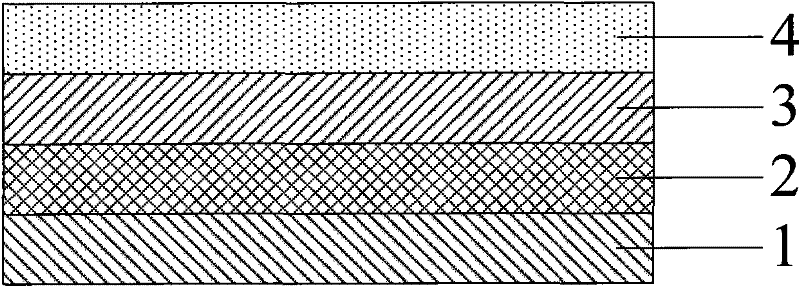

Anti-dazzle, anti-reflection and anti-fingerprint film

InactiveCN112694847AImprove anti-reflection effectImprove explosion-proof performanceFilm/foil adhesivesFilm baseThin membrane

The invention discloses an anti-dazzle, anti-reflection and anti-fingerprint film. The anti-dazzle, anti-reflection and anti-fingerprint film comprises a film base layer, an adhesive layer, a release film, an anti-dazzle layer, an anti-reflection layer and an anti-fingerprint layer, wherein the adhesive layer and the release film are sequentially arranged on one side of the film base layer from inside to outside; the anti-dazzle layer, the anti-reflection layer and the anti-fingerprint layer are sequentially arranged on the other side of the substrate from inside to outside; the anti-dazzle layer is prepared on the film base layer through combination of cured resin and UV transfer printing; the anti-reflection layer is formed by sequentially and alternately laminating a first preset number of high-refractive-index film layers and a second preset number of low-refractive-index film layers on the anti-dazzle layer; and the anti-fingerprint layer is coated on the anti-reflection layer. The anti-dazzle layer formed in a UV transfer printing mode is stable, the anti-reflection layer obtained by alternately stacking the high-refractive-index film layers and the low-refractive-index film layers is good in anti-reflection effect, the fingerprint prevention effect is good, the hardness is high, the abrasion resistance is good, the anti-dazzle layer is attached to the base material through an attaching process, the explosion resistance of the glass can be enhanced, and the film is environmentally friendly, low in cost and high in production yield.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

Anti-glare coating composition having improved Anti-fingerprint function and Anti-glare film prepared therefrom

ActiveUS20140133033A1Good anti-fingerprint effectMaintain good propertiesSynthetic resin layered productsPolyether coatingsInorganic particleInorganic particles

The present invention relates to an anti-glare coating composition for preparation of anti-glare films having good anti-fingerprint properties as well as improved contrast ratio and image definition. More specifically, the coating composition comprises organic or inorganic particles, a photocurable resin, a photoinitiator, and a compound including an olefin oxide repeating unit.

Owner:LG CHEM LTD

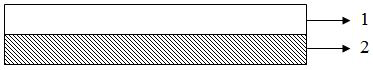

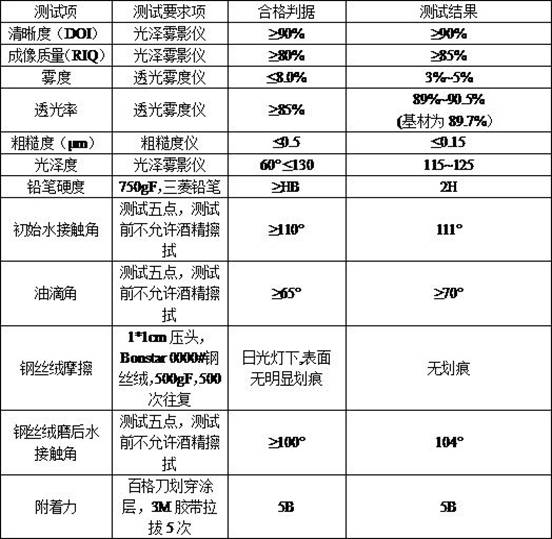

Anti-fingerprint and anti-glare coating, protective film containing same and preparation method of protective film

ActiveCN112094588AExcellent anti-fingerprint and anti-glare functionImprove clarityFireproof paintsAntifouling/underwater paintsFunctional monomerImaging quality

The invention discloses an anti-fingerprint and anti-glare coating, a protective film containing the same and a preparation method of the protective film. The protective film comprises the anti-fingerprint and anti-glare coating and a base material layer which are sequentially stacked from top to bottom. The anti-fingerprint and anti-glare coating comprises the following components in percentage by weight: 10-15% of urethane acrylate, 5-8% of fluorine-containing acrylate, 3-5% of six-functional monomer, 2-3% of low-functionality monomer, 1-2% of fluorine-containing functional monomer, 0.5-0.8%of inorganic filler, 0.5-2% of POSS monomer, 2-3% of assistant, 0.5-1% of photoinitiator and 65-75% of composite solvent, totaling 100%. The coating disclosed by the invention has the characteristicsof low haze, high light transmittance, high definition, good imaging quality, high visual visibility and the like, and can be used for a long time in a relatively complex and harsh environment.

Owner:NINGBO FUNA NEW MATERIALS TECH CO LTD

True metal wiredrawing composite board

InactiveCN102173135ALow costSimple preparation processGlass/slag layered productsMetal layered productsPolyvinyl chlorideOperating environment

The invention provides a true metal wiredrawing composite board which is characterized in that a substrate is made of toughened glass, a temperature-resisting double faced adhesive tape is adhered to the toughened glass, a composite membrane layer is covered on the temperature-resisting double faced adhesive tape, and the composite membrane layer is composed of polyethylene terephthalate (PET), an aluminium foil wiredrawing layer and polrvinyl chlorides (PVC). The true metal wiredrawing composite board provided by the invention has the advantages that the PET / aluminium foil wiredrawing layer / PVC composite membrane layer is compounded on the surface of the toughened glass through the temperature-resisting double faced adhesive tape, thus the effects of adornment, protection and beautification are achieved, and meanwhile, the manufacturing process is simple, and the operation is convenient; due to the beautiful colors, the obtained product is delicate, and appropriate for durability products; the board is good in abrasion resistance and stain resistance; and the step of painting is omitted, thus the operating environment is ensured to be neat and clean, the expenditures can be cut down, and the productivity can be improved. The true metal wiredrawing composite board can be applied to refrigerator panels through replacing stainless steel wiredrawing boards, thereby remarkably reducing the cost of materials.

Owner:SUZHOU HESHENG NEW MATERIALS

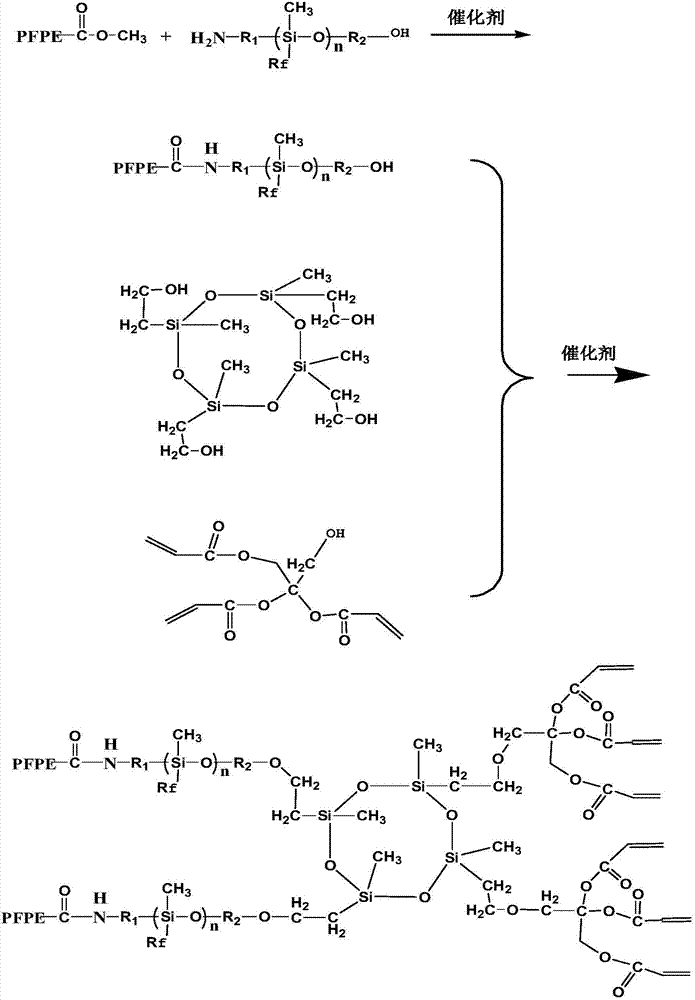

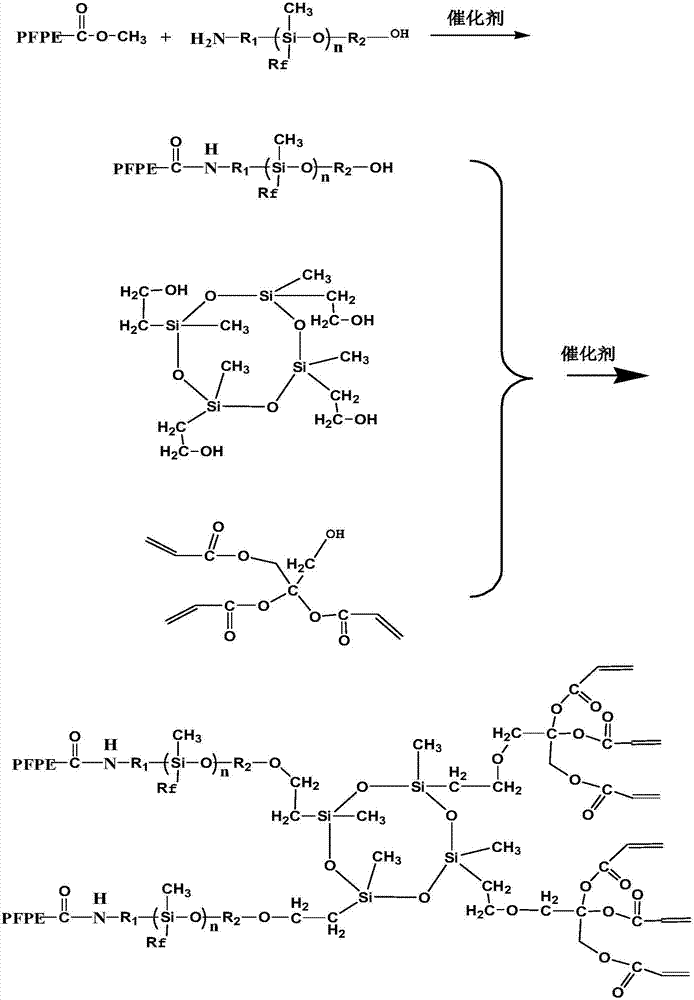

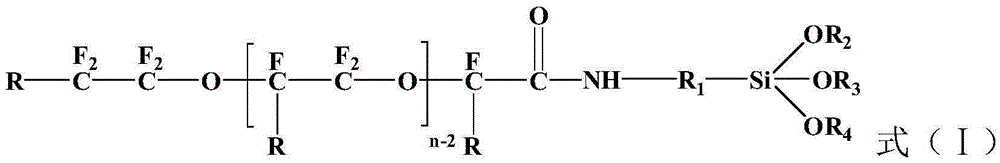

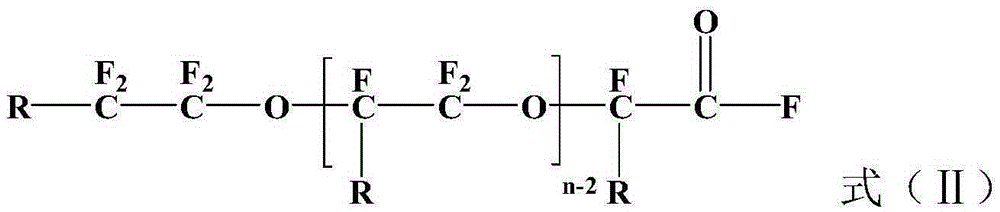

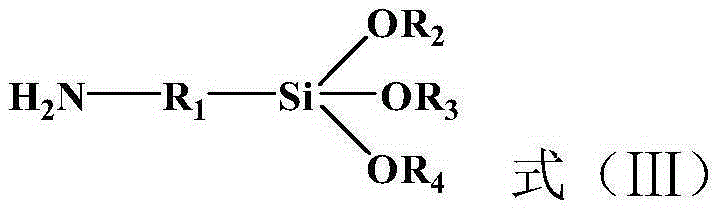

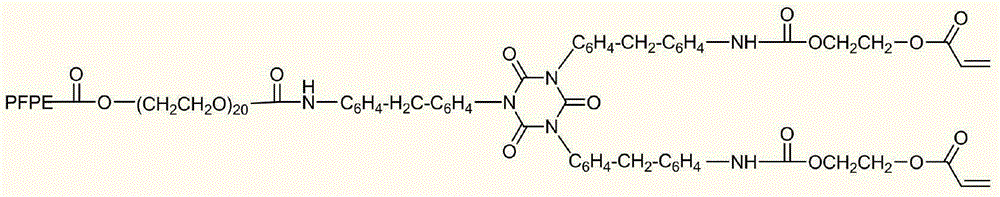

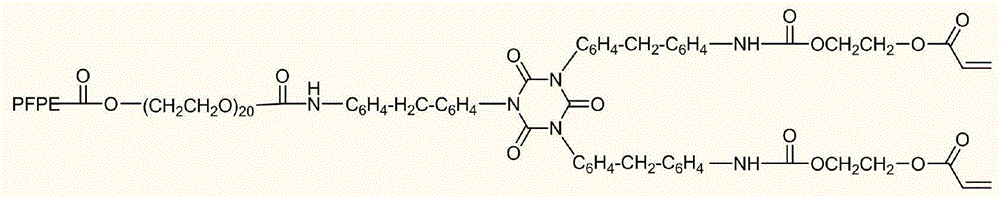

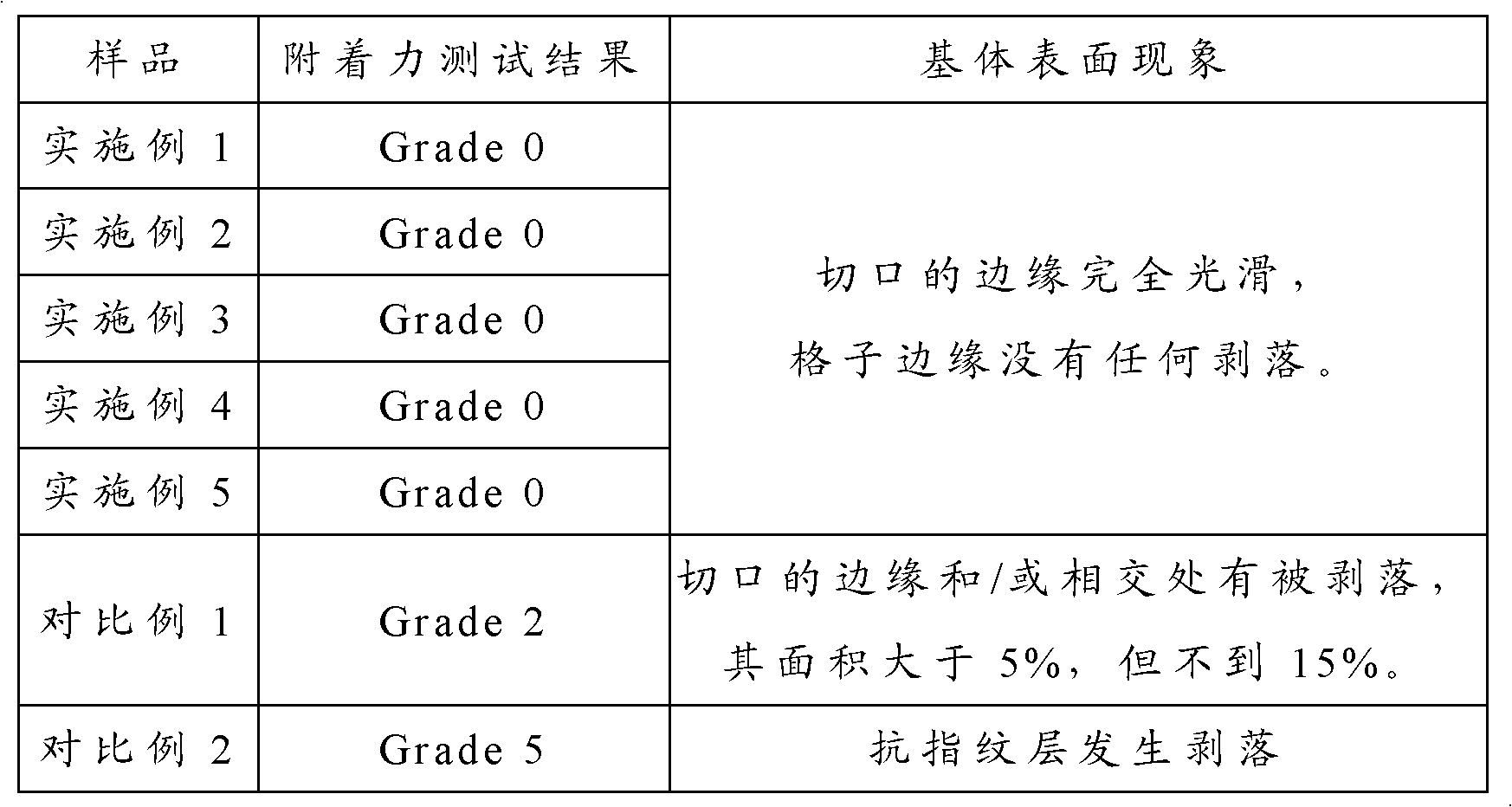

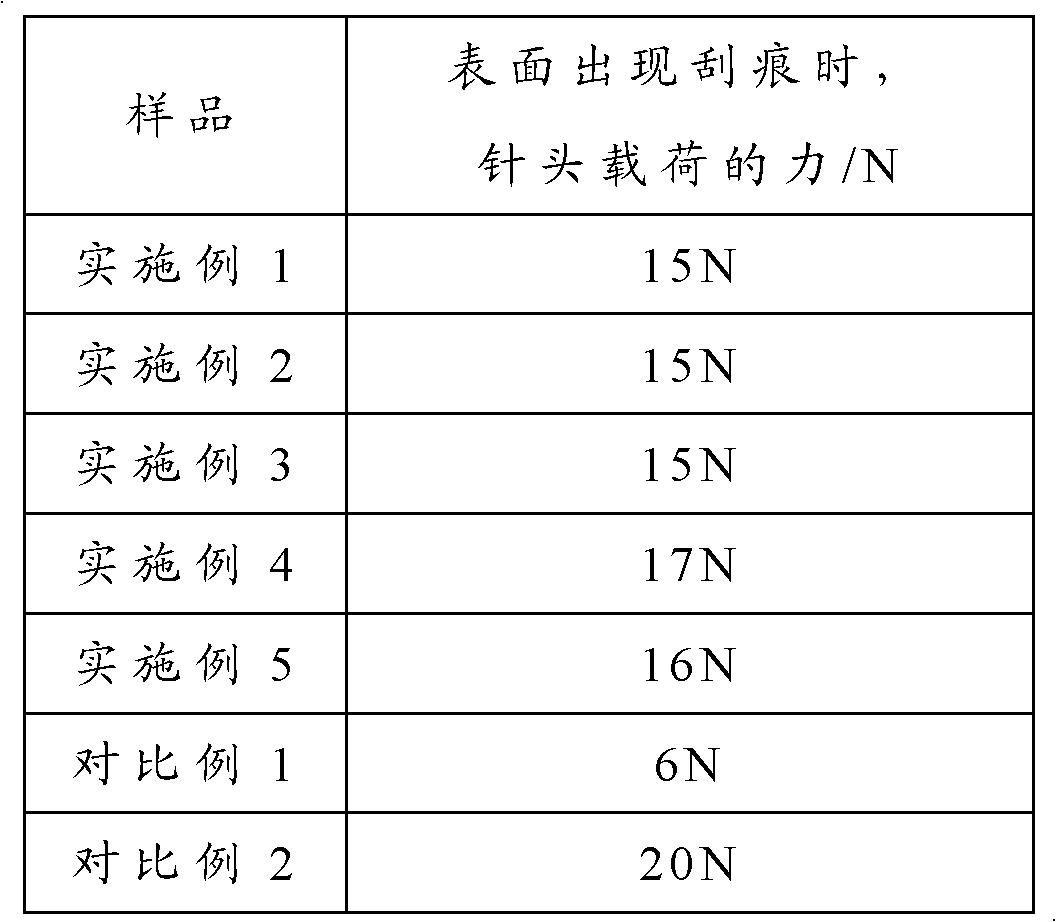

Silane modified fluorine-containing polymer as well as preparation method and fingerprint-proof paint thereof

The invention relates to the field of fingerprint-proof paint, and discloses a silane modified fluorine-containing polymer. The structural formula of the fluorine-containing polymer is shown in formula (I), wherein, R is -CF3 or -F, R1 is alkylidene or phenylene of C1-C16, R2, R3 and R4 are independently alkyl of C1-C16 or -H, and value of n allows number-average molecular weight of the fluorine-containing polymer to be 500-10000. The invention also discloses a preparation method of the silane modified fluorine-containing polymer, and the silane modified fluorine-containing polymer prepared by the method. The invention also discloses fingerprint-proof paint, and the fingerprint-proof paint contains the silane modified fluorine-containing polymer.

Owner:BYD CO LTD

Anti-fingerprint antibacterial film, and preparation method of hardening liquid

InactiveCN108299663AGood antibacterial functionSimple structureAntifouling/underwater paintsPaints with biocidesTitaniumHardness

The invention discloses an anti-fingerprint antibacterial film. The antibacterial film comprises a substrate layer and a hardened layer, the hardened layer comprises a nitrogen-doped titanium salt, the antibacterial film has a good antibacterial function and makes the film with an excellent anti-fingerprint effect, and the hardened coating layer contains a nitrogen-modified titanium dioxide photocatalyst with an antibacterial function. The antibacterial film has the advantages of simple structure, good wear resistance, good transparency, high hardness, strong adhesion, effectiveness in fingerprint proofing, antibacterial function, prevention of fingerprints from remaining on a screen, and great reduction of damages of bacteria to bodies. The invention also discloses a preparation method ofa hardening liquid used for the hardened layer.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Method for making abrasion-resistant anti-fingerprint glass

InactiveCN104291669AImprove wear resistanceImprove bindingCoatingsGlass tempering apparatusPlasma sprayedPhotochemistry

The invention relates to a method for making abrasion-resistant anti-fingerprint glass. The method sequentially comprises the following steps of: carrying out primary cleaning on a glass substrate, then strengthening at the temperature of 150-200 DEG C for 20-24 hours, and then carrying out secondary cleaning; then descaling by using a plasma spray gun; finally carrying out anti-fingerprint treatment by using an AF-102 anti-fingerprint coating agent to obtain a product. The glass made through the method disclosed by the invention has the advantages of good abrasion-resistant property and good anti-fingerprint property.

Owner:昆山濡鑫光电科技有限公司

Preparation method of perfluoropolyether siloxane compound and anti-fingerprint agent

InactiveCN113583231AEasy and efficient to prepareWide variety of sourcesPolyether coatingsChemical industryPolymer science

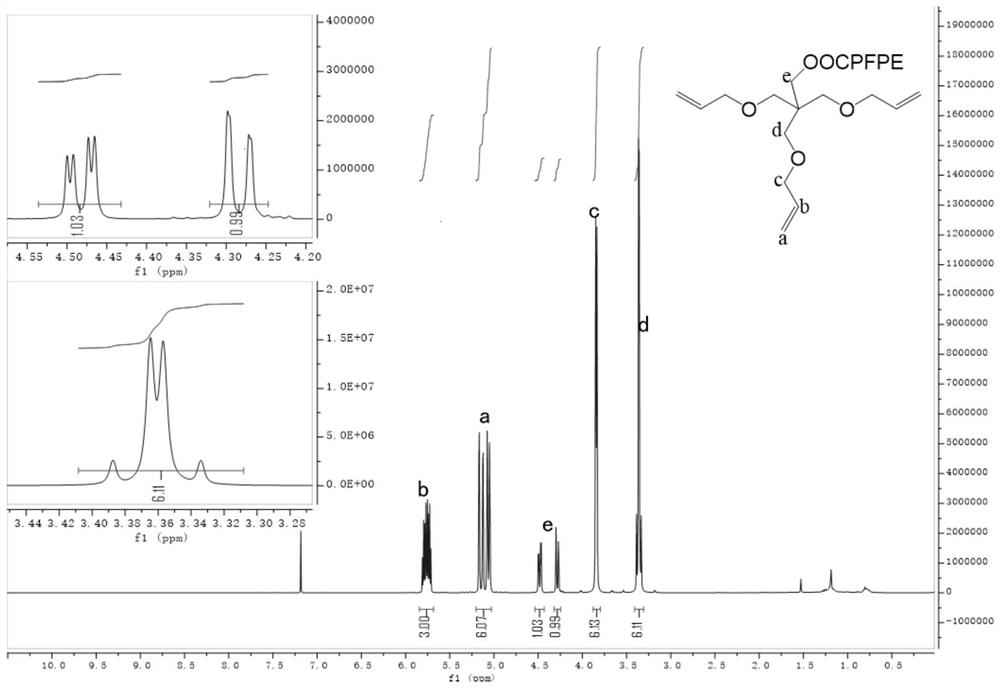

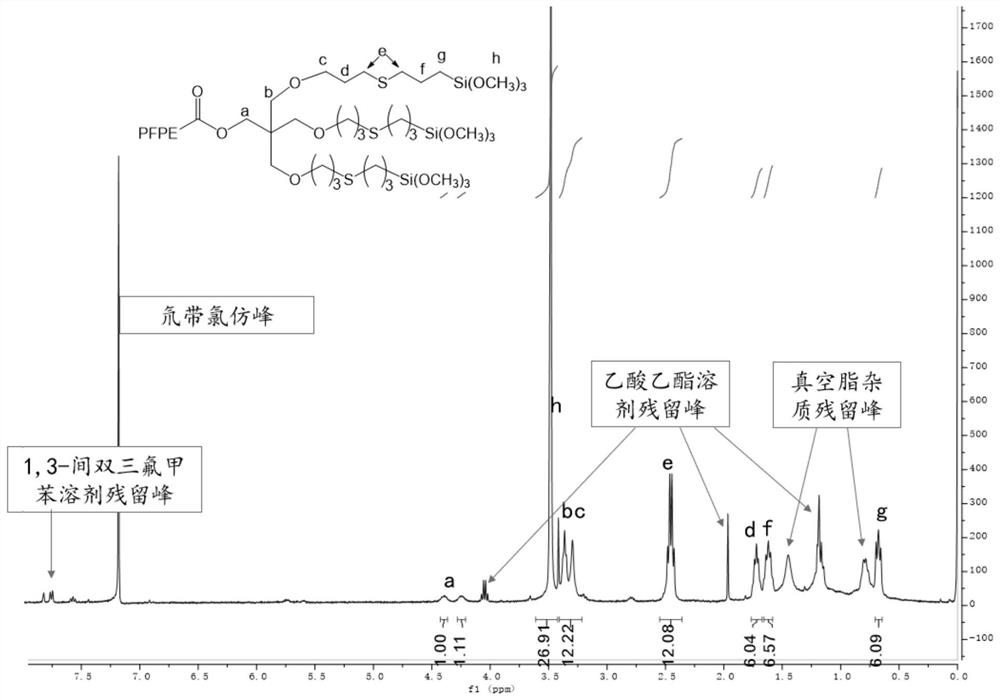

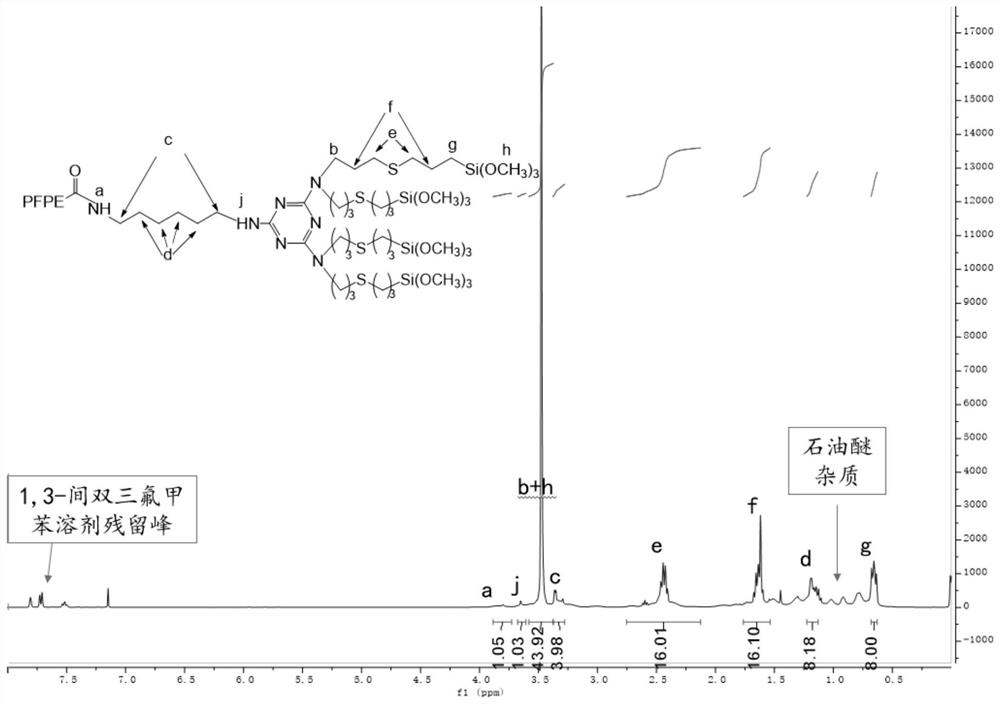

The invention provides a preparation method of a perfluoropolyether siloxane compound and an anti-fingerprint agent, and belongs to the technical field of fine fluorine chemical industry. The preparation method comprises the steps of firstly, under the protection of inert gas, perfluoropolyether acyl fluoride reacts with alcohol or amine containing carbon-carbon double bonds under the catalytic action of a basic catalyst A to obtain a perfluoropolyether intermediate M containing the carbon-carbon double bonds; and then enabling the perfluoropolyether intermediate M and a sulfydryl-containing silane coupling agent to be subjected to a sulfydryl-olefin click reaction under the catalytic action of a catalyst B, and obtaining the perfluoropolyether siloxane compound. According to the invention, a series of perfluoropolyether siloxane compounds containing 1-4 siloxane groups can be efficiently prepared through reaction of acyl fluoride and alcohol or amine compounds containing different numbers of double bonds, the prepared siloxane compounds are controllable in structure and high in purity, and when the siloxane compound is applied to an anti-fingerprint agent to be coated on the surface of a workpiece, a hydrophobic and oleophobic coating with excellent wear resistance can be obtained.

Owner:DONGHUA UNIV

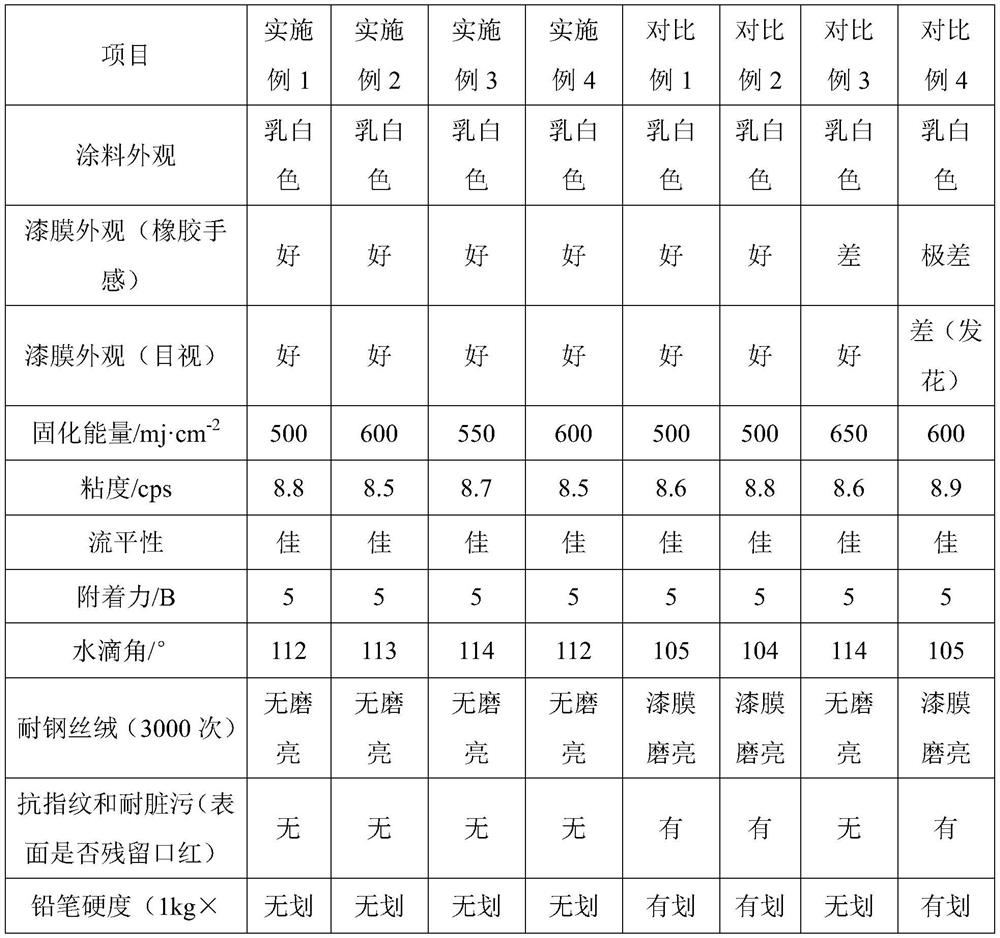

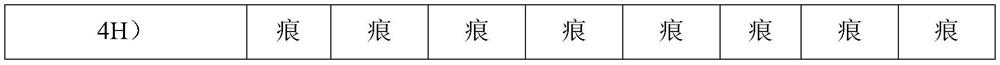

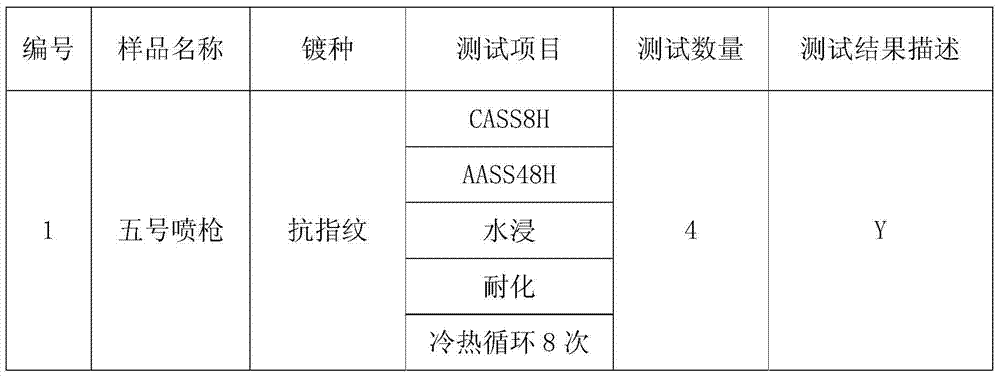

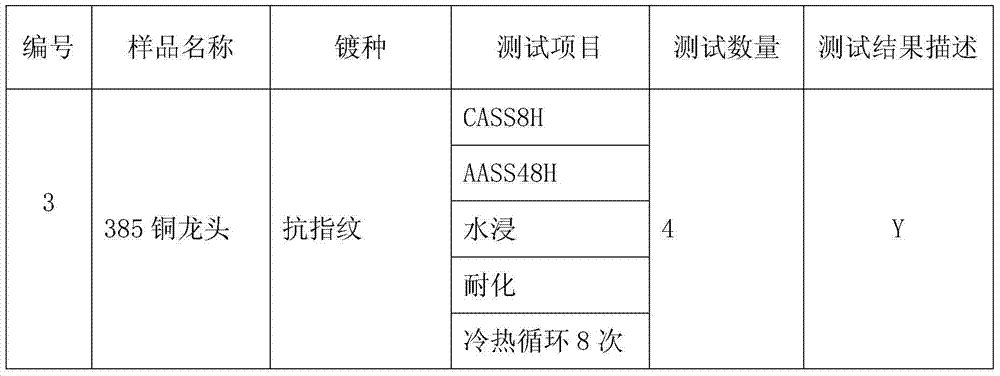

Anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and preparation method thereof

PendingCN113683952AGood rubber skin feelGood slipperinessPolyurea/polyurethane coatingsPhotoinitiatorPolymer chemistry

The invention discloses an anti-dazzle anti-fingerprint wear-resistant hardening liquid with rubber hand feeling, and a preparation method thereof. The hardening liquid comprises, by weight, 40-50 parts of organic fluorine-silicon special modified polyurethane acrylic resin, 10-15 parts of special modified UV matte polyurethane acrylic resin, 5-10 parts of an acrylic monomer, 1-5 parts of a photoinitiator, 1-2 parts of fluorine-containing acrylic compound resin, 1-3 parts of a rubber skin feeling auxiliary agent, 4-5 parts of matting powder, 3-4 parts of wear-resistant powder, 1-2 parts of an anti-settling agent, 1-2 parts of a wetting dispersant and 20-30 parts of a solvent. The hardening liquid obtained by the invention is high in hardness, good in hand feeling, good in wear resistance and excellent in anti-fingerprint effect, can meet the higher requirements of the market on anti-glare hardening liquid, can be used for spraying and also can be used for shower coating, and compared with spraying, the shower coating can greatly reduce the production cost, avoid environmental pollution and relieve harm to human bodies.

Owner:湖南宏泰新材料有限公司

A method for preparing anti-fingerprint film on the surface of bathroom products

ActiveCN104694929BNo emissionsGood anti-fingerprint effectVacuum evaporation coatingSputtering coatingCorrosion resistant alloySputtering

The invention discloses a method for preparing an anti-fingerprint film on the surface of sanitary products, which relates to the surface treatment of sanitary products. Provides a method for preparing an anti-fingerprint film on the surface of sanitary products, which is environmentally friendly, highly corrosion-resistant, highly wear-resistant, and has anti-fingerprint performance. Degrease the surface of the substrate with wire drawing lines after electroplating nickel, and then vacuum-plate corrosion-resistant alloy film layer, vacuum-plate color layer, intermediate-frequency magnetron sputtering transparent silicon oxide film, and vacuum-evaporate fluoropolymer in sequence. Transparent nano-anti-fingerprint film layer, that is, to complete the preparation of anti-fingerprint film on the surface of bathroom products. It is environmentally friendly, and at the same time, the film layer has high corrosion resistance and excellent wear resistance, which can meet the high-end quality requirements of the current sanitary industry.

Owner:XIAMEN RUNNER IND CORP

Surface treatment technology with ceramic and fingerprint simulating effects and application

ActiveCN110124967AGood flexibilityExcellent anti-fingerprintPretreated surfacesCoatingsFingerprintSurface finishing

The invention discloses a surface treatment technology with ceramic and fingerprint simulating effects and application. The surface treatment technology comprises the following steps that firstly, dirt removal cleaning is conducted on the surfaces of formed base materials, and drying treatment is conducted; secondly, UV primer is sprayed to a cleaned spraying piece, and drying treatment is conducted; thirdly, finishing coat is sprayed to the surface of the spraying piece, and drying treatment is conducted; fourthly, the spraying piece to which the finishing coat is sprayed is placed in an optical plating furnace, and optical color film plating is conducted on the spraying piece through optical vacuum plating; and fifthly, the spraying piece to which an optical color film is sprayed is placed in the other optical plating furnace, and plating of an AF clad layer material is conducted on the spraying piece through optical vacuum plating. Through spraying of the UV primer and the finishingcoat, sequential plating of the optical color film and the AF clad layer material is conducted, the product surface achieves the ceramic simulating effect, and flexibility and gloss texture are good;and meanwhile, good fingerprint preventing, pollution preventing and waterproof effects can be achieved, and surface abrasion resistance and hardness are improved.

Owner:GREATECH MOLD & PLASTIC

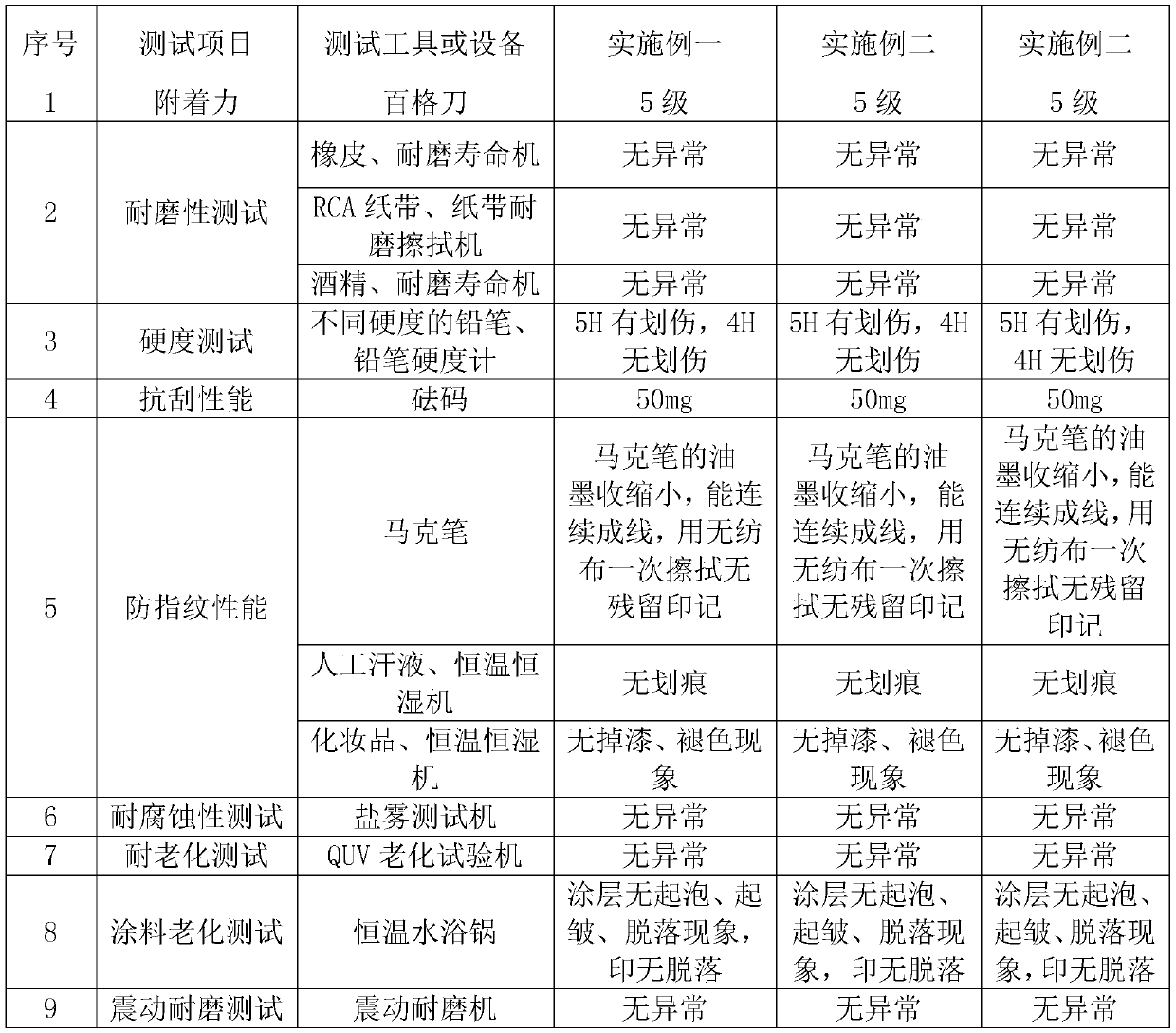

A kind of perfluoropolyether alkoxysilane compound and its synthesis method

ActiveCN106432686BGood antifoulingGood anti-fingerprint effectAntifouling/underwater paintsPaints with biocidesSilane compoundsSynthesis methods

The invention discloses a novel perfluoropolyether alkoxysilane compound and a synthesis method thereof. The compound structure is shown in formula (1), and the synthesis method is as follows: hydroxyl-terminated perfluoropolyether (PFPE), 3-(2 ‑Aminoethyl)aminopropyltrimethoxysilane, 3‑(2,3‑glycidoxy)propyltrimethoxysilane (KH560), HDI trimer in a molar ratio of 1:2:2:1 In the reaction process, a certain amount of solvent is used to dilute and mix the hydroxyl-terminated perfluoropolyether, 3-(2-aminoethyl) aminopropyltrimethoxysilane, and then dropwise add the HDI trimer. After reacting for 6 hours at a certain temperature , then add KH560 dropwise, react at a certain temperature for another 6 hours, and then remove the solvent under reduced pressure to obtain the perfluoropolyether alkoxysilane compound of the present invention. The compound can be coated on the surface of glass, plastic, film and other substrates, and after cross-linking and curing, it forms a solid film, endows the substrate with excellent anti-fingerprint and anti-fouling properties, and has excellent wear resistance.

Owner:QUZHOU FLUORIDE & SILICON RES INST +1

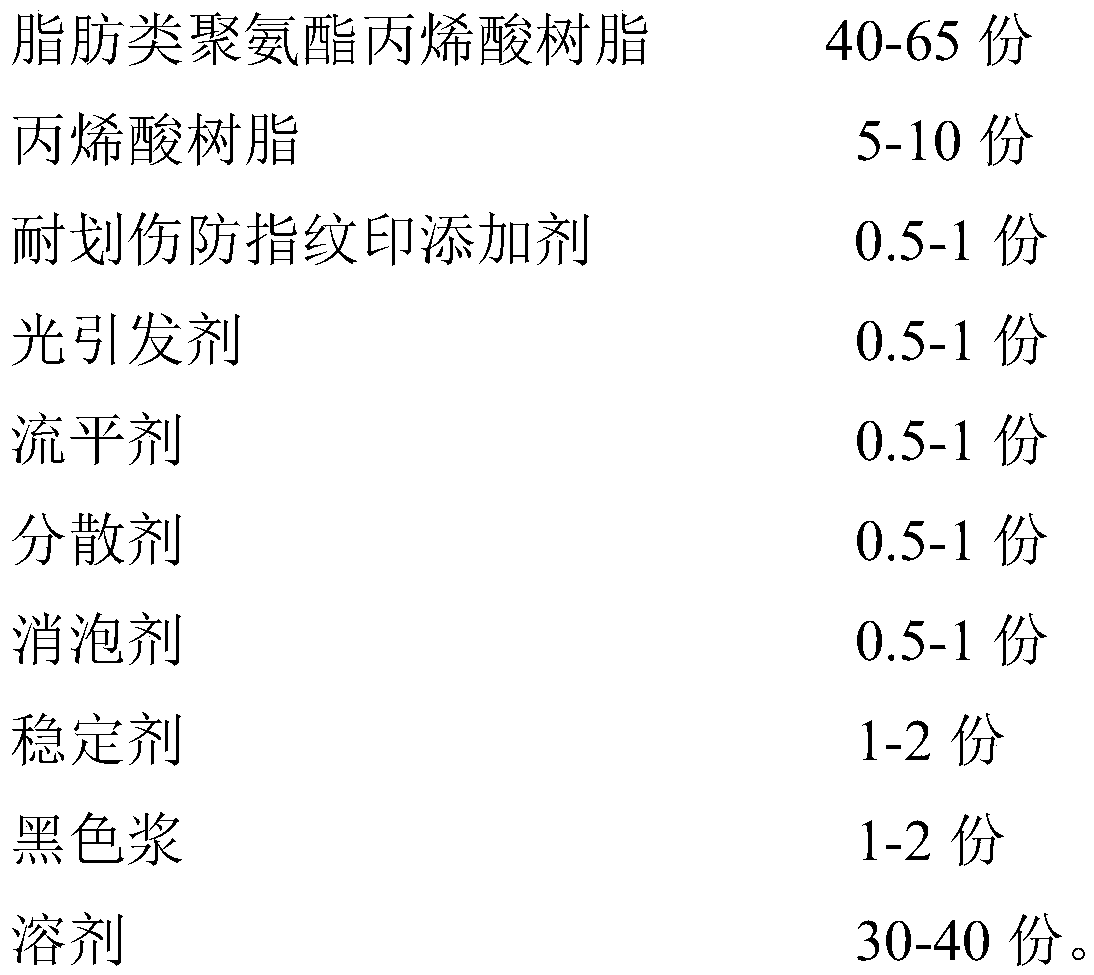

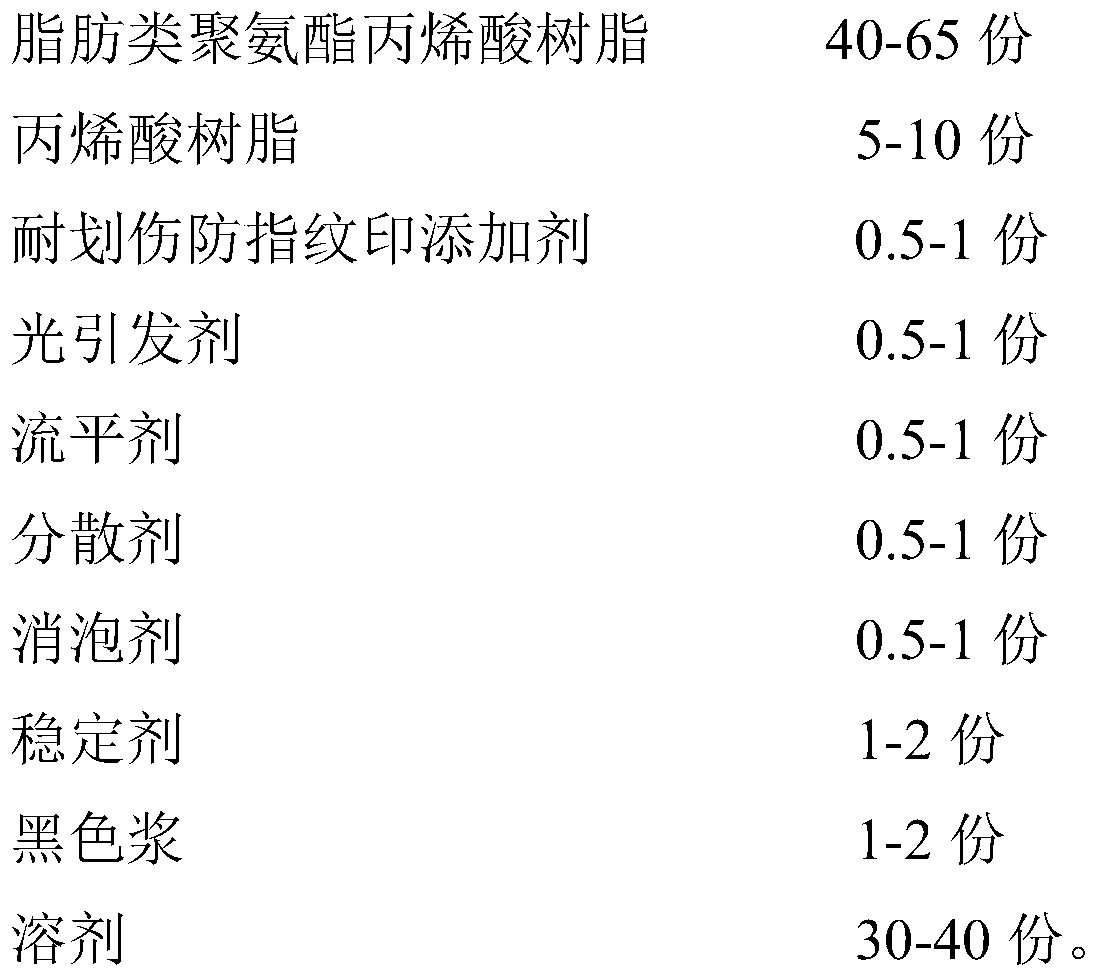

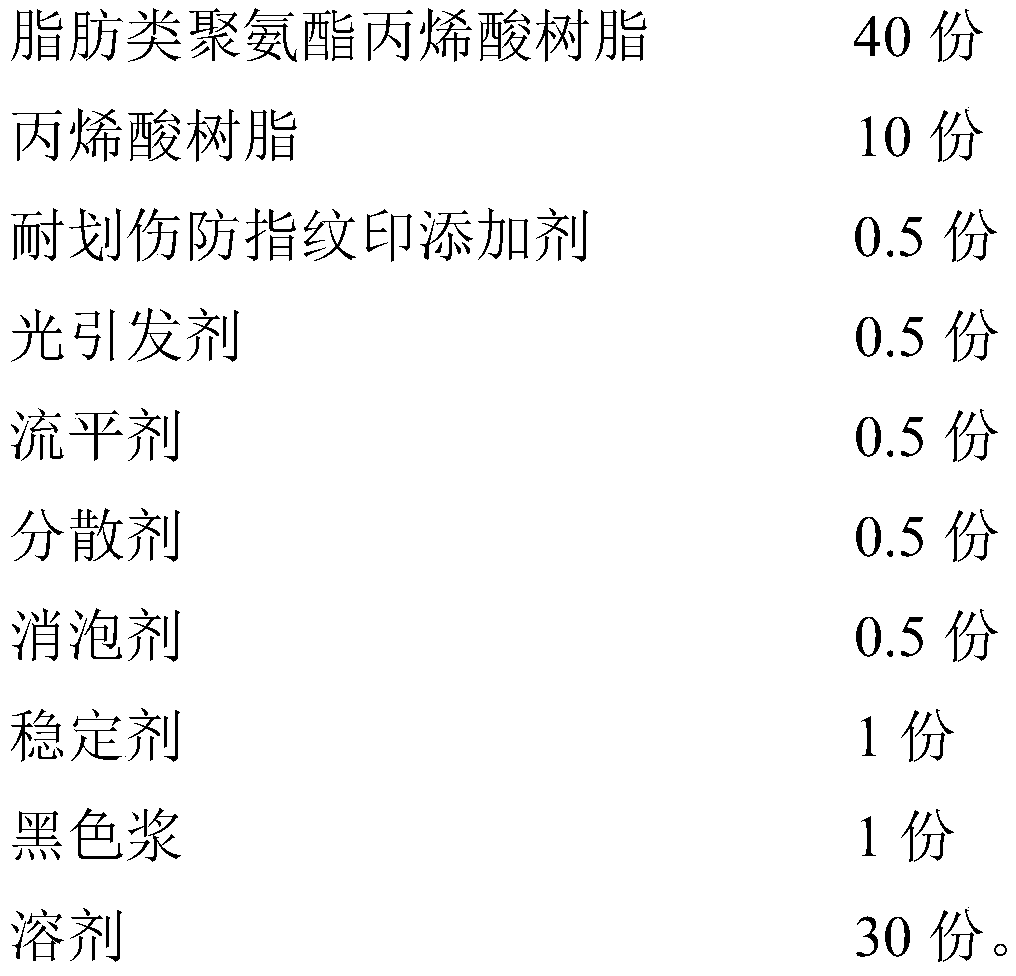

Scratch-resistant and fingerprint-proof highlight piano black paint and preparation method thereof, and application of scratch-resistant and fingerprint-proof highlight piano black paint

ActiveCN110885626AImprove scratch resistance and anti-fingerprint effectGood compatibilityPolyurea/polyurethane coatingsPhotoinitiatorAntifoam agent

The invention discloses scratch-resistant and fingerprint-proof highlight piano black paint and a preparation method thereof, and application of scratch-resistant and fingerprint-proof highlight pianoblack paint. The scratch-resistant fingerprint-proof highlight piano black paint is composed of the following components in parts by weight: 40-65 parts of aliphatic polyurethane acrylic resin, 5-10parts of acrylic resin, 0.5-1 parts of a scratch-resistant and anti-fingerprint additive, 0.5-1 parts of a photoinitiator, 0.5-1 parts of a leveling agent, 0.5-1 parts of a dispersing agent, 0.5-1 parts of an antifoaming agent, 1-2 parts of a stabilizer, 1-2 parts of black paste and 30-40 parts of a solvent. A scratch-resistant and fingerprint-proof additive adopted by the invention can be subjected to directional cross-linking reaction with acrylic resin during UV photocuring, so that fluorine-containing molecular chains are gathered on the surface of a paint coating, and the scratch-resistant and fingerprint-proof effects are improved while the high glossiness of the paint coating is ensured.

Owner:DONGFENG MOTOR CORP HUBEI

UV photo-curing composition additive and preparation method thereof

ActiveCN105385216AImprove waterproof performanceGood oil proofAntifouling/underwater paintsPaints with biocidesHydrogenMonomer

The invention discloses a UV photo-curing composition additive and a preparation method thereof. Raw materials for the additive include perfluorinated polyether containing polyether polyol groups, a monomer containing activated hydrogen groups and self-crosslinking functional groups and a non-fluorinated crosslinking agent, and the additive is prepared through reaction under a certain conditions. The additive is excellent in preservation stability before curing and can provide excellent waterproof, oil-proof, anti-fouling, anti-fingerprint and friction-resisting performance for a coating after curing. The UV photo-curing composition additive is mainly used for the coating having the waterproof, oil-proof, anti-fouling, anti-fingerprint and friction-resisting performance.

Owner:宝士龙新材料科技(龙岩)有限公司

Anti-fingerprint stainless steel composite plate and preparation method thereof

InactiveCN107880673AHigh strengthAchieve bondingMonocarboxylic acid ester polymer adhesivesMacromolecular adhesive additivesEpoxyComposite plate

The invention discloses an anti-fingerprint stainless steel composite plate. The composite plate includes a substrate; the substrate is coated with a stainless steel layer through a polymer binder, and the outer surface of the stainless steel layer is coated with varnish; the stainless steel layer is prepared from, by weight, 70-80 parts of iron, 15-20 parts of chromium, 5-10 parts of nickel, 5-10parts of silicon, 1-3 parts of tungsten, 1-3 parts of molybdenum, 1-3 parts of neodymium, 1-3 parts of tin and 1-3 parts of zirconium; an anti-fingerprint agent in the varnish is prepared from, by weight, 50-60 parts of perfluoropolyether, 20-30 parts of waterborne polyurethane, 10-15 parts of epoxy resin, 5-8 parts of diatomite, 5-8 parts of zeolite and 2-5 parts of titanium dioxide. According to the anti-fingerprint stainless steel composite plate and the preparation method thereof, by adding chromium, nickel, silicon, tungsten, molybdenum, neodymium, tin and zirconium, the strength of thestainless steel layer is improved, and a modifier in the varnish is developed independently and has good anti-fingerprint capacity.

Owner:宁波市恩迪卫浴有限公司

Anti-fingerprint agent, and method and product applying the same to conduct surface treatment

ActiveCN103160174AGood anti-fingerprint effectGood chemical resistanceCoatingsThin material handlingAlcoholSilicic acid

An anti-fingerprint agent is mainly composed of polytetrafluoroethylene and silane solutions. The volume ratio of the polytetrafluoroethylene and the silane solutions is 0.5-0.8. The silane solutions are mainly composed of methyl triethoxysilane, ethyl orthosilicate, absolute ethyl alcohol, deionized water and dilute sulphuric acid. The invention further provides a method and a product applying the anti-fingerprint angent to conduct surface treatment.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

LED display screen and preparation method thereof

ActiveCN109903689AImprove hydrophobicityImprove bindingCoatingsIdentification meansNano siliconLED display

The invention discloses an LED display screen and a preparation method thereof. The LED display screen is provided with a lamp surface, wherein a hydrophilic resin protective layer and a transparent modified polysilazane resin layer are sequentially arranged on the lamp surface; the hydrophilic resin protective layer is positioned between the lamp surface and the transparent modified polysilazaneresin layer; and the transparent modified polysilazane resin layer comprises the following components: polysilazane resin, a silane coupling agent and vapor phase hydrophobic nano silicon oxide particles. According to the LED display screen, the transparent modified polysilazane resin layer is arranged on the hydrophilic resin protective layer, so that a better fingerprint prevention effect can beachieved. Due to the adoption of the polysilazane resin, the bonding force between the vapor phase hydrophobic nano silicon oxide particles and the hydrophilic resin protective layer can be improved,and thus the bonding force between a nano coating of the transparent modified polysilazane resin layer and an adhesive surface of the hydrophilic resin layer is stronger, a more stable fingerprint prevention effect can be realized, and the hydrophobic effect is better.

Owner:UNILUMIN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com