Preparation method of perfluoropolyether siloxane compound and anti-fingerprint agent

A technology of perfluoropolyether siloxane and perfluoropolyether, applied in polyether coatings, coatings, etc., can solve problems such as poor wear resistance and low silicon content, and achieve improved antifouling and wear resistance, The effect of low production cost, excellent anti-fingerprint effect and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

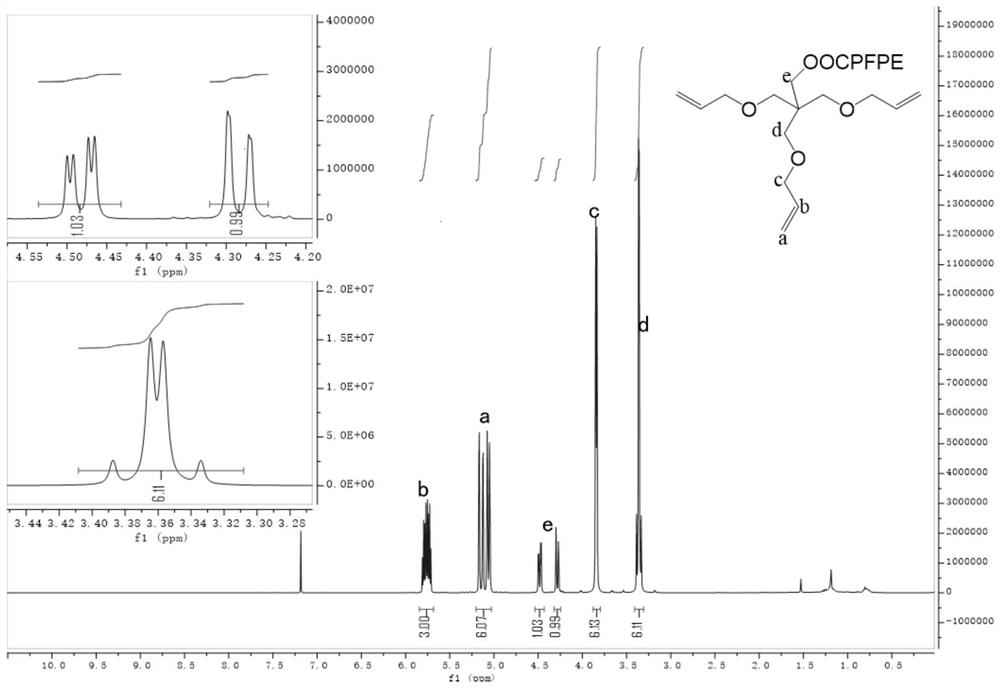

[0038] (1) Preparation of a single double bond-terminated perfluoropolyether intermediate M1-1

[0039]Under the protection of nitrogen, add 6.15g ethylene glycol monoallyl ether (60mmol) and 6.1g triethylamine (60mmol) to a 250ml three-necked flask. Perfluorocyclic ether solution [91.5g perfluoropolyetheramide fluoride (molecular weight 1829.5g / mol, 50mmol) dissolved in 100ml perfluorocyclic ether], control the dropping temperature not to exceed 40°C, after the dropping, react for 3h , filtered, the filtrate was washed twice with 50ml methanol, and concentrated to obtain intermediate M1-1.

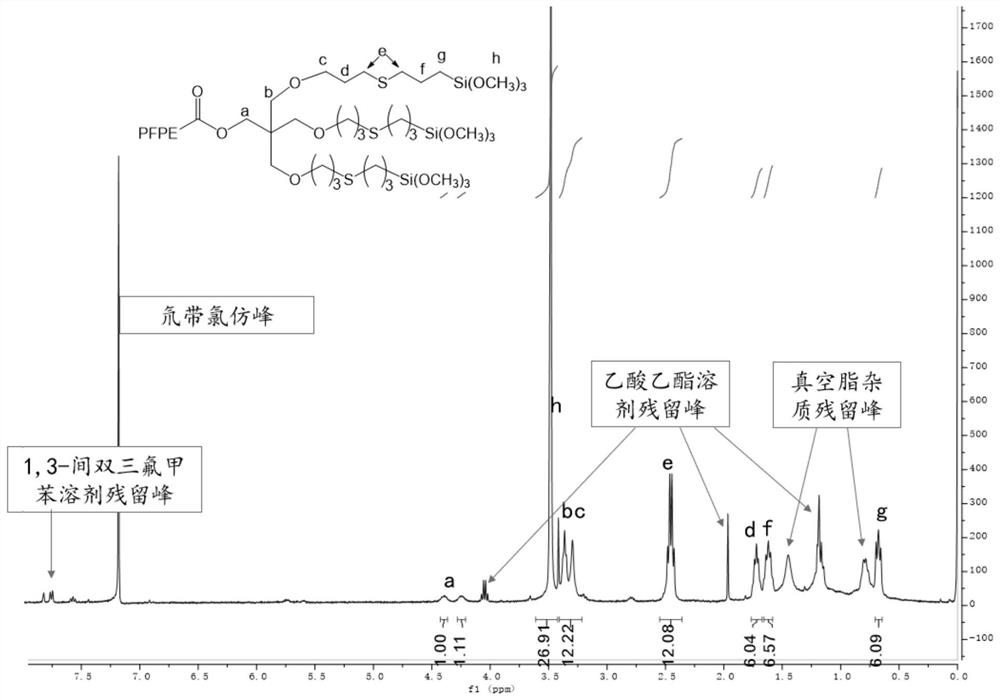

[0040] (2) Preparation of monosubstituted perfluoropolyether siloxane TM1-1

[0041] Under the protection of nitrogen, add to the reaction flask, 9.56g M1-1 intermediate (5mmol), 1.05g mercaptopropyltrimethoxysilane (5.3mmol), 0.08g azobisisobutylcyanide (0.5mmol), 20ml 1,3-Bis(trifluoromethyl)benzene, mixed evenly, reacted at 70°C for 6h, after the reaction was complete, concentrated t...

Embodiment 2

[0043] (1) Preparation of a single double bond-terminated perfluoropolyether intermediate M1-2

[0044] Under the protection of nitrogen, add 3.08g ethylene glycol monoallyl ether (30mmol) and 3.05g triethylamine (30mmol) to a 250ml three-necked flask. Perfluorocyclic ether solution [112g perfluoropolyetheramide fluoride (molecular weight: 4500g / mol, 25mmol) dissolved in 120ml perfluorocyclic ether]. , the filtrate was washed twice with 60ml of methanol and concentrated to obtain intermediate M1-2.

[0045] (2) Preparation of monosubstituted perfluoropolyether siloxane TM1-2

[0046] Under the protection of nitrogen, add in the reaction bottle, 22.9g M1-2 intermediate (5mmol), 1.2g mercaptopropyltrimethoxysilane (6mmol), 0.08g azobisisobutylcyanide (0.5mmol), 50ml of 1 , 3-bis(trifluoromethyl)benzene, after mixing evenly, react at 70°C for 8h, after the reaction is complete, concentrate and remove volatile components to obtain monosubstituted perfluoropolyether siloxane TM1-...

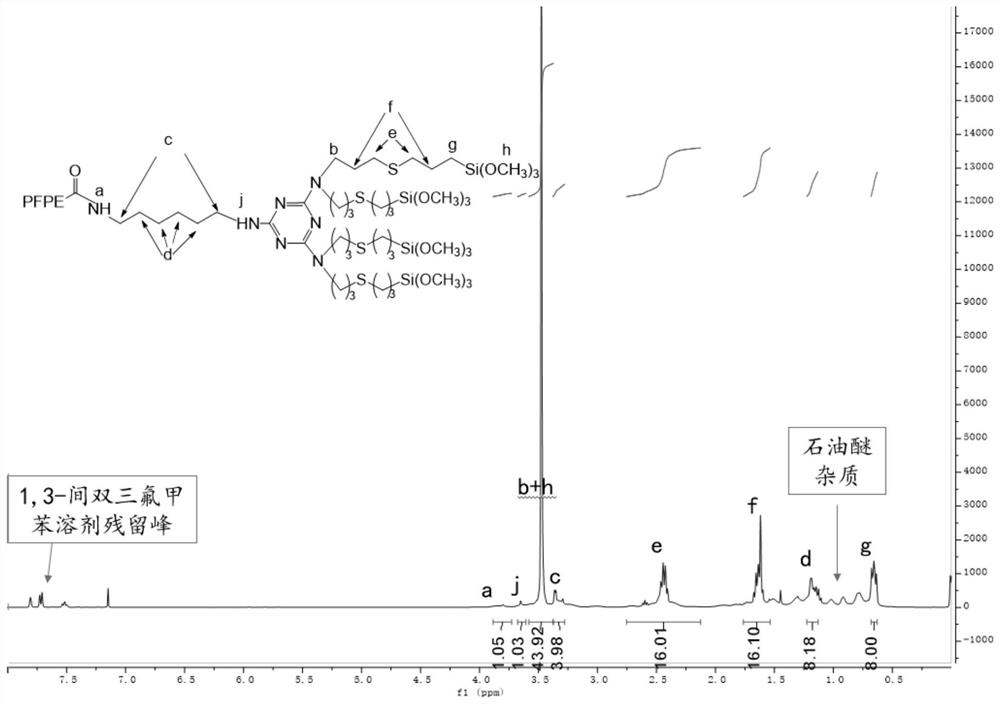

Embodiment 3

[0048] (1) Preparation of a single double bond-terminated perfluoropolyether intermediate M1-3

[0049] Under nitrogen protection, add 3.08g ethylene glycol monoallyl ether (30mmol) and 3.05g triethylamine (30mmol) to a 500ml three-necked flask, stir well, and drop perfluoropolyether fluoride therein at room temperature Perfluorocyclic ether solution [194g perfluoropolyetheramide fluoride (molecular weight: 7760g / mol, 25mmol) dissolved in 250ml perfluorocyclic ether]. , the filtrate was washed twice with 150ml methanol and concentrated to obtain intermediate M1-3.

[0050] (2) Preparation of monosubstituted perfluoropolyether siloxane TM1-3

[0051] Under the protection of nitrogen, add in the reaction flask, 39.2g M1-3 intermediate (5mmol), 1.2g mercaptopropyltrimethoxysilane (6mmol), 0.08g azobisisobutylcyanide (0.5mmol), 100ml of 1 , 3-bis(trifluoromethyl)benzene, after mixing evenly, react at 70°C for 8h, after the reaction is complete, concentrate and remove volatile co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com