LED display screen and preparation method thereof

A technology of LED display screen and polysilazane, which is applied in the field of display screen, can solve the problems of inability to achieve anti-fingerprint effect, poor hydrophobic effect of nano-coating, poor bonding force between nano-coating and hydrophilic resin layer glue surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

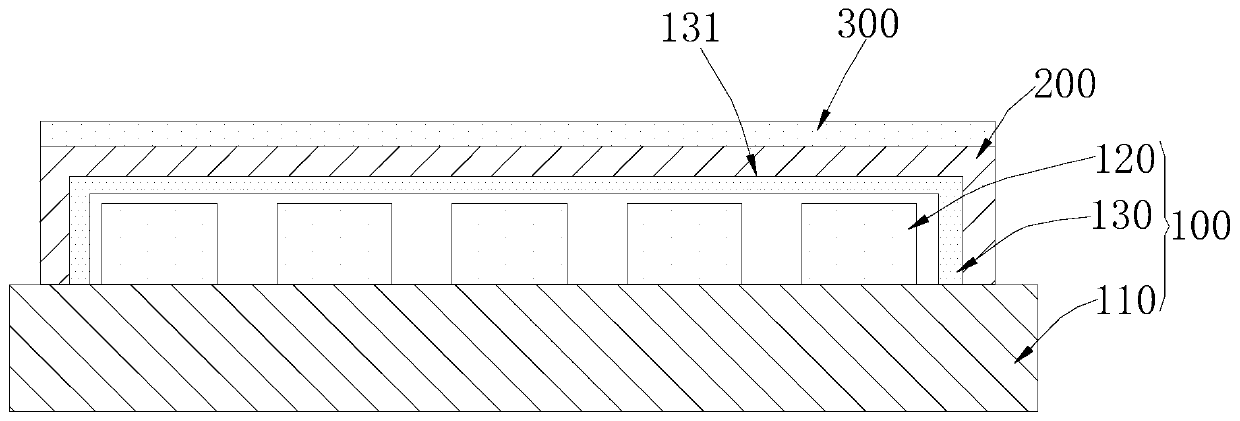

[0049] The present invention also provides a method for preparing an LED display screen. The LED display screen has a lamp surface. The preparation method of the LED display screen includes the following steps: forming a protective layer of a hydrophilic resin on the lamp surface; A transparent modified polysilazane resin layer is formed on the side of the resin protective layer away from the lamp surface, wherein the material of the transparent modified polysilazane resin layer includes the following components: polysilazane resin, silane Linking agent and gas-phase hydrophobic nano-silica particles. For example, the preparation method of the LED display screen is the preparation method of the LED display screen described in any one of the above embodiments.

[0050] In order to further illustrate the preparation method of the above-mentioned LED display screen, another example is that the LED display screen has a lamp surface, and the preparation method of the LED display sc...

specific Embodiment 1

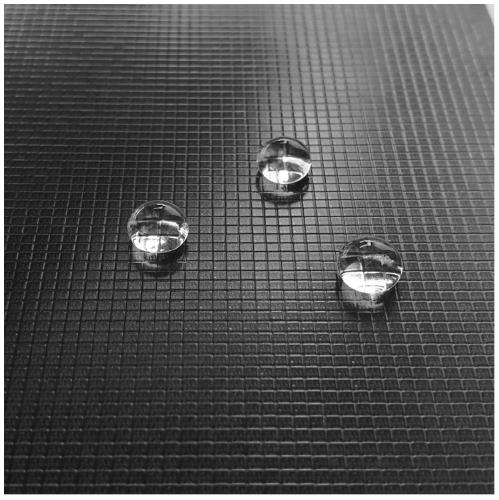

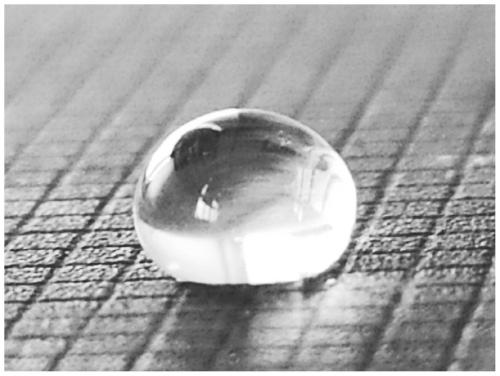

[0093] An LED display screen, the LED display screen has a lamp surface, a hydrophilic resin protective layer and a transparent modified polysilazane resin layer are sequentially arranged on the lamp surface, and the hydrophilic resin protective layer is located on the Between the lamp surface and the transparent modified polysilazane resin layer; wherein, the material of the transparent modified polysilazane resin layer includes the following components: polysilazane resin, silane coupling agent and gas phase hydrophobic Nano silica particles. Wherein, the preparation method of LED display screen comprises the following steps:

[0094] 1. Form a protective layer of hydrophilic resin on the lamp surface. In this embodiment, the material of the hydrophilic resin protective layer is epoxy resin. Specifically, forming a hydrophilic resin protective layer includes the following steps:

[0095] (1) Prepare 60g of epoxy resin glue with the A and B components of epoxy resin accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com