Patents

Literature

40results about How to "Good stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-strength cured filter paper

ActiveCN102953295AImprove air permeabilityGood stiffnessPaper coatingFiltration separationBursting strengthPapermaking

The invention relates to a method for preparing high-strength cured filter paper. The method comprises the following steps: (1) taking the following components in percentage by weight: 30-35% of softwood pulp, 45-55% of mercerization wood pulp and 15-20% of bleached hardwood pulp; and repulping and grinding to obtain mixed paper pulp size; (2) papermaking and molding to obtain body paper, and drying the body paper; (3) curing agent preparation: selecting phenolic resin and formaldehyde as a curing agent; and preparing the curing agent according to the proportion of 1-1.5% of paper pulp size; (4) coating the synthesized curing agent on the surface of the body paper; heating to precure the raw materials of the curing agent step by step, wherein the coating amount of the curing agent is 40-55g / m<2>; and (5) cured filter paper drying: drying the body paper coated with the curing agent through a drying tunnel or a drying oven, wherein the drying temperature is 120-135 DEG C, and the drying time is 15-30 seconds. The high-strength cured filter paper prepared by the method provided by the invention has higher air permeability, and simultaneously has better stiffness and waterproof effect; the bursting strength of the high-strength cured filter paper after being cured is improved; and the service life is prolonged.

Owner:杭州特种纸业有限公司

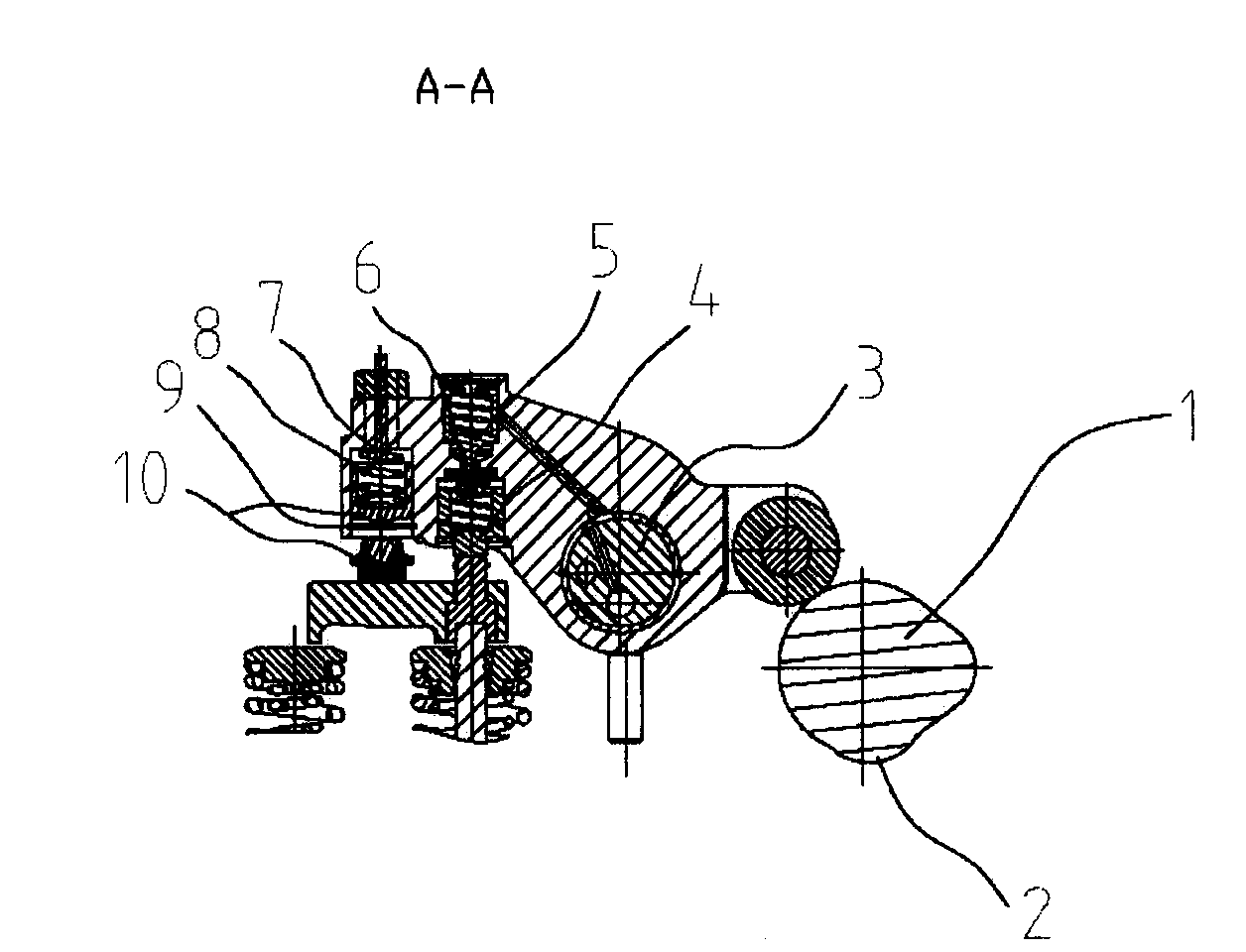

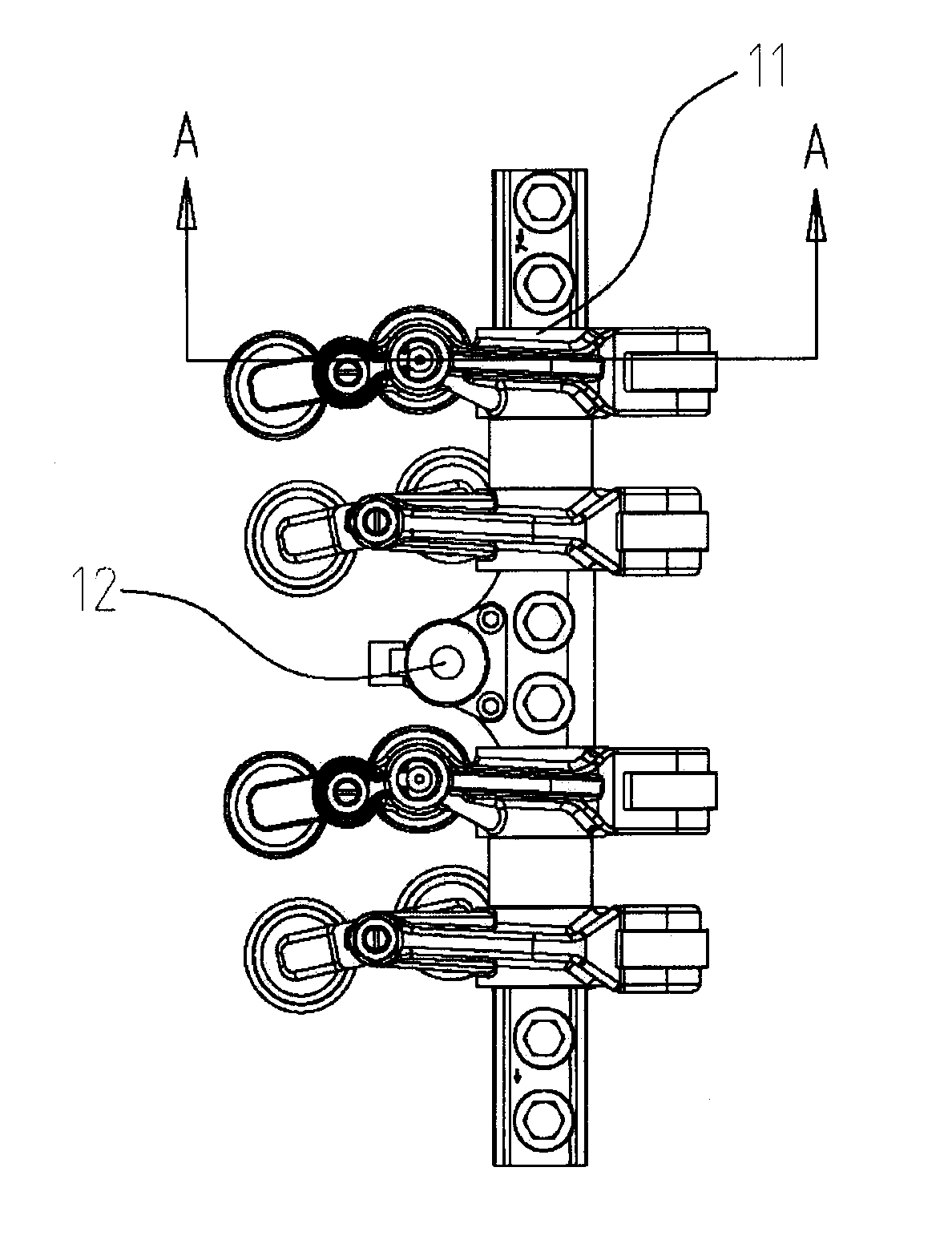

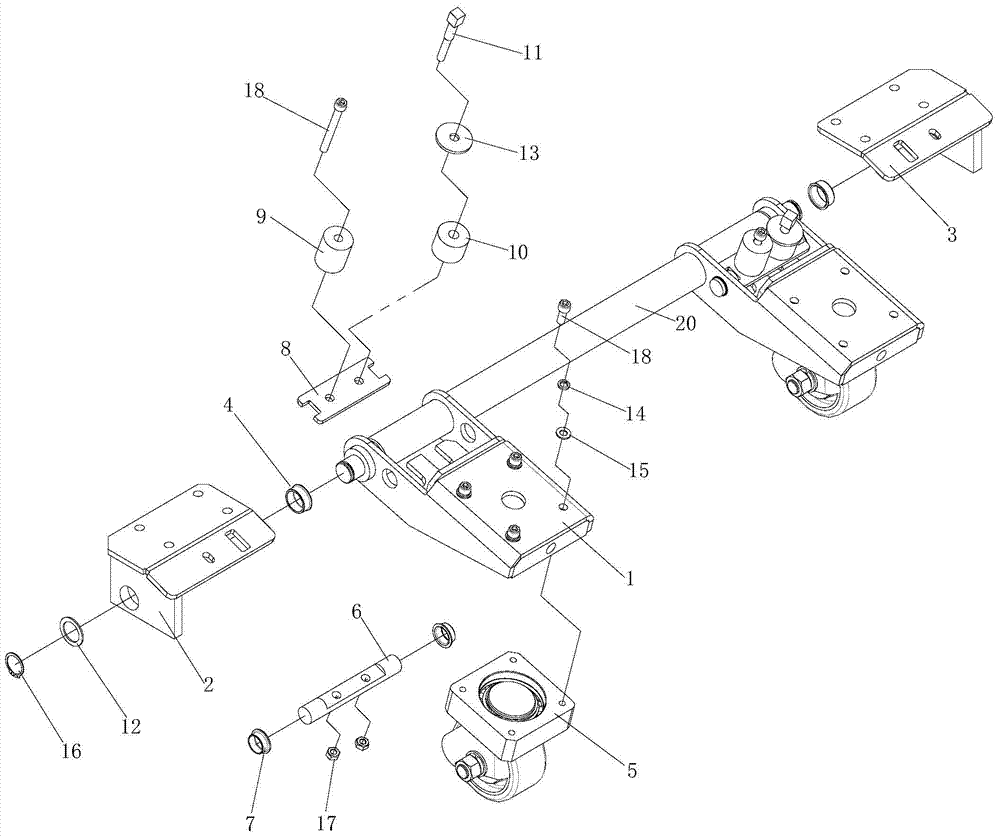

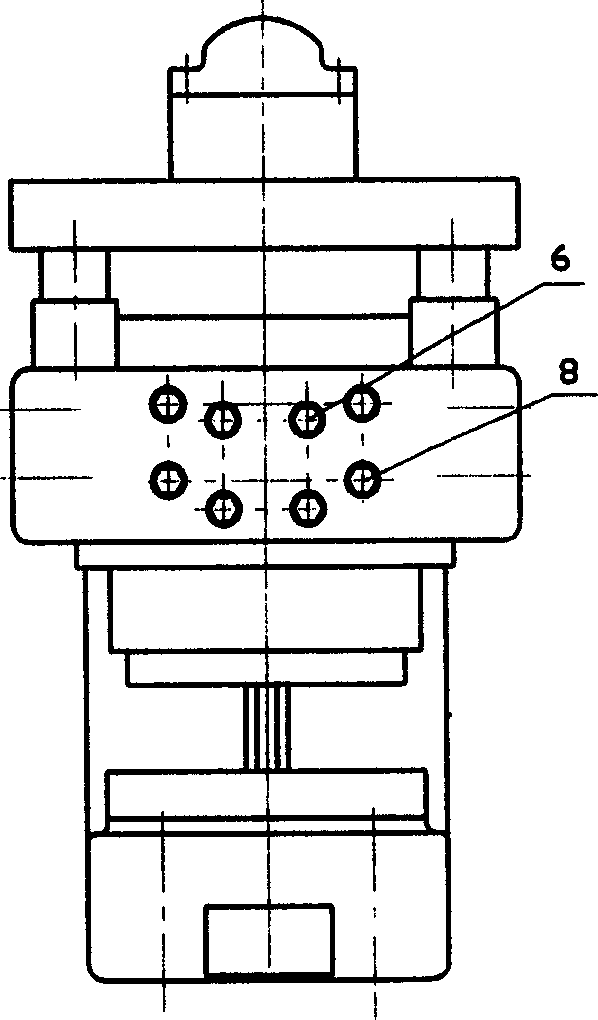

Engine braking device

InactiveCN101672206ASimple structureGood stiffnessValve arrangementsOutput powerRocker armBase plane

The invention relates to an engine braking device, which is characterized in that an exhaust cam of an engine is provided with a brake cam; two devices are integrated in an exhaust rocker; one of thetwo devices is a compensation gap device which mainly comprises an adjusting bolt-exhaust valve rocker, an exhaust valve elephant-foot assembly, a snap ring and a return spring, a cavity is formed below an adjusting bolt hole-exhaust valve rocker at the front end of the exhaust valve rocker, the exhaust valve elephant-foot assembly is fixed in the cavity through the snap ring, and a certain gap isreserved on a base plane of the cavity provided with the return spring, the adjusting bolt-exhaust valve rocker and the elephant-foot assembly; and the other one of the two devices is an engine brakeswitch device consisting of a brake plunger, a one-way valve assembly and a control valve, the upper part and the lower part of the middle part of the exhaust valve rocker are provided with a cavityrespectively, the control valve is arranged in the upper cavity, the brake plunger is arranged in the lower cavity, and the upper cavity is connected with the lower cavity through the one-way valve. The engine braking device has the characteristics of simple structure, good rigidity, low cost and the like, and simultaneously both the realizability and the self working performance of the braking device have unique predominance.

Owner:CHINA FIRST AUTOMOBILE

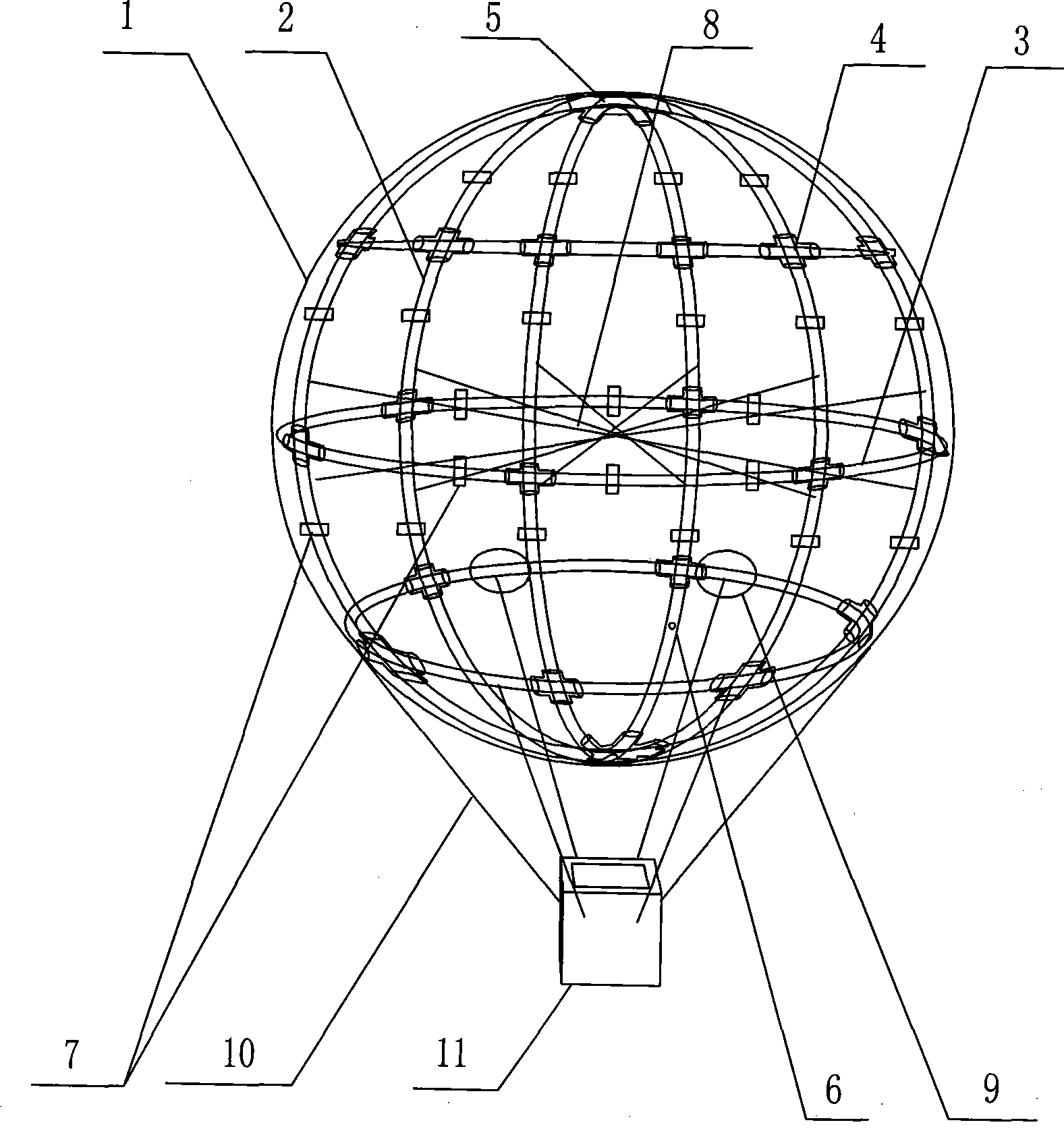

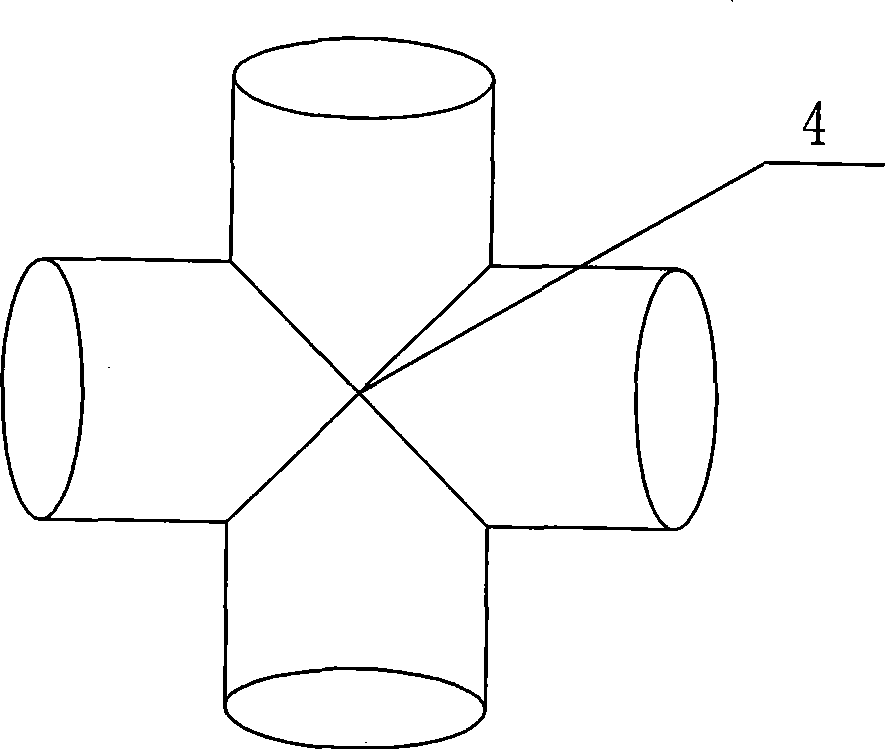

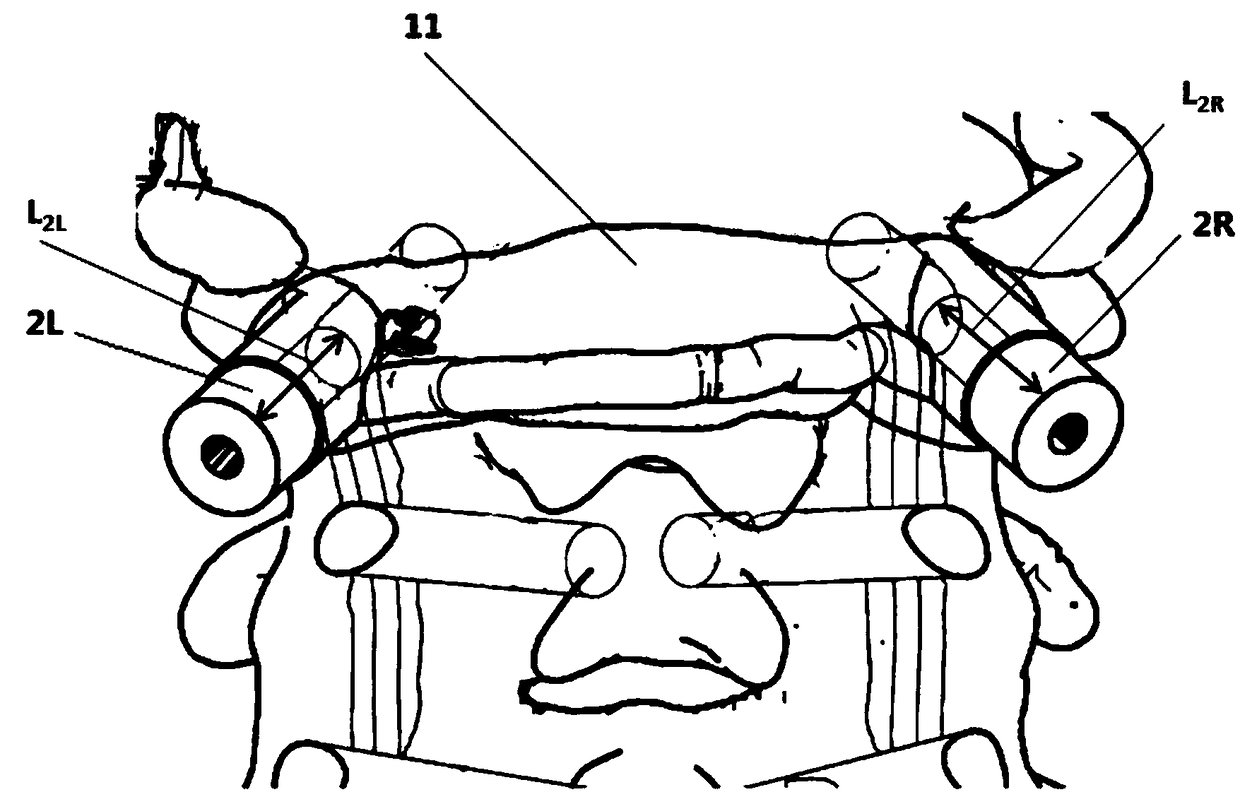

Shape preserving high-altitude balloon

A form-preserving high-altitude balloon relates to a high-altitude balloon and aims at solving the defects of the existing high-altitude balloon that the rigid under the low internal-pressure is low; and the form alters along the changing of wind and then the form-preserving capability is poor so that the located floating of the high-altitude balloon cannot be realized. An air intake (6) is arranged on a first charging framework (2) of the form-preserving high-altitude balloon and the upper borders and the lower borders of a plurality of first charging frameworks (2) are communicated respectively through a communicator (5); the first charging framework is communicated with the border of a second charging framework (3) through a four-way (4); a skin (1) is fixed on to a network surface formed by the first charging framework (2) and the second charging framework (3); and one end of a suspension cable (10) is fixedly connected with the skin (1) and the other end of the suspension cable (10) is fixedly connected with an effective load (11). The form-preserving high-altitude balloon is provided with the better rigid and can resist the distortion caused by wind; and the form-preserving capability is better and the located floating of the high-altitude balloon can be realized. The form-preserving high-altitude balloon reduces the requirement on the skin materials so as to reduce the cost and the balloon can bear the heavier effective load.

Owner:HARBIN INST OF TECH

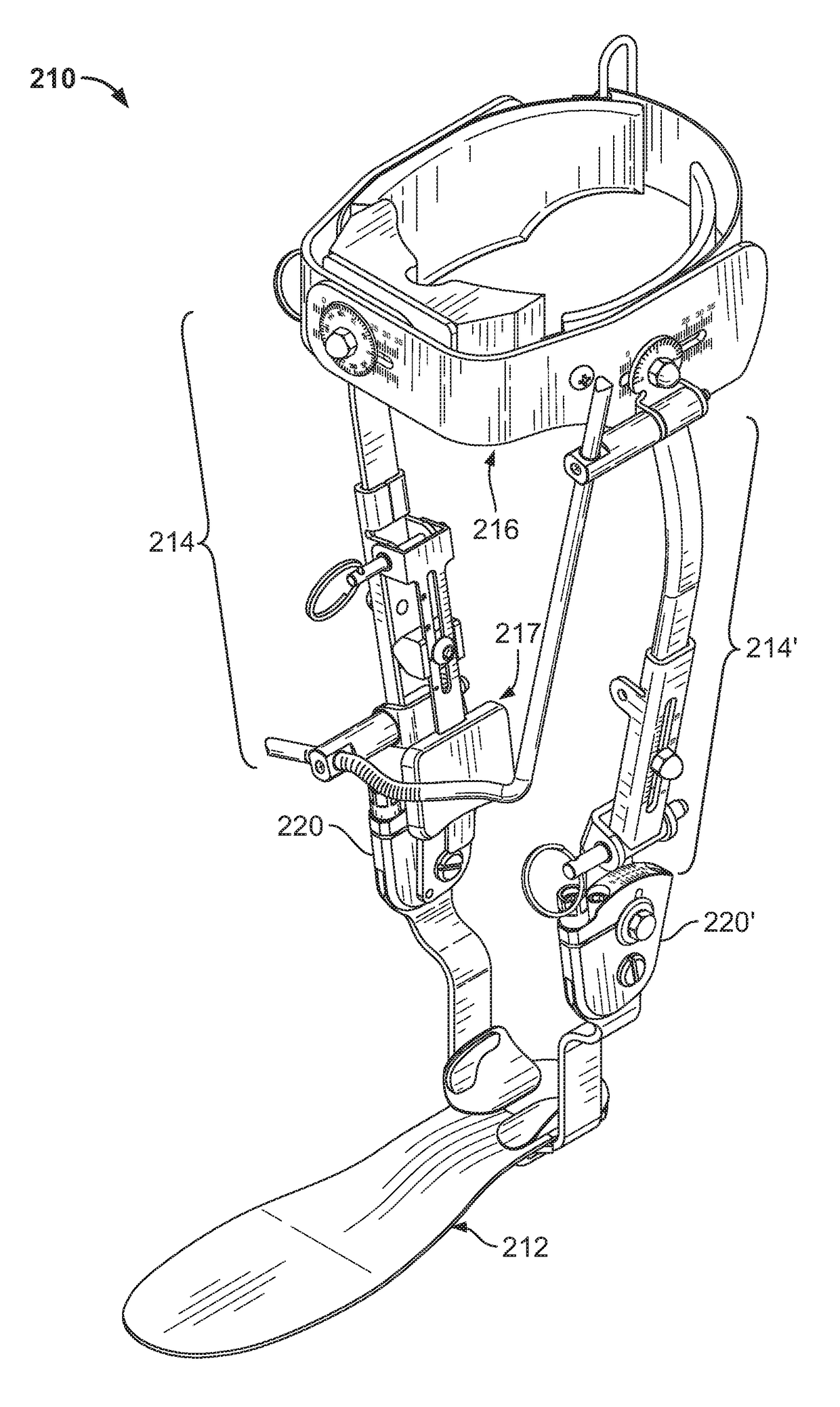

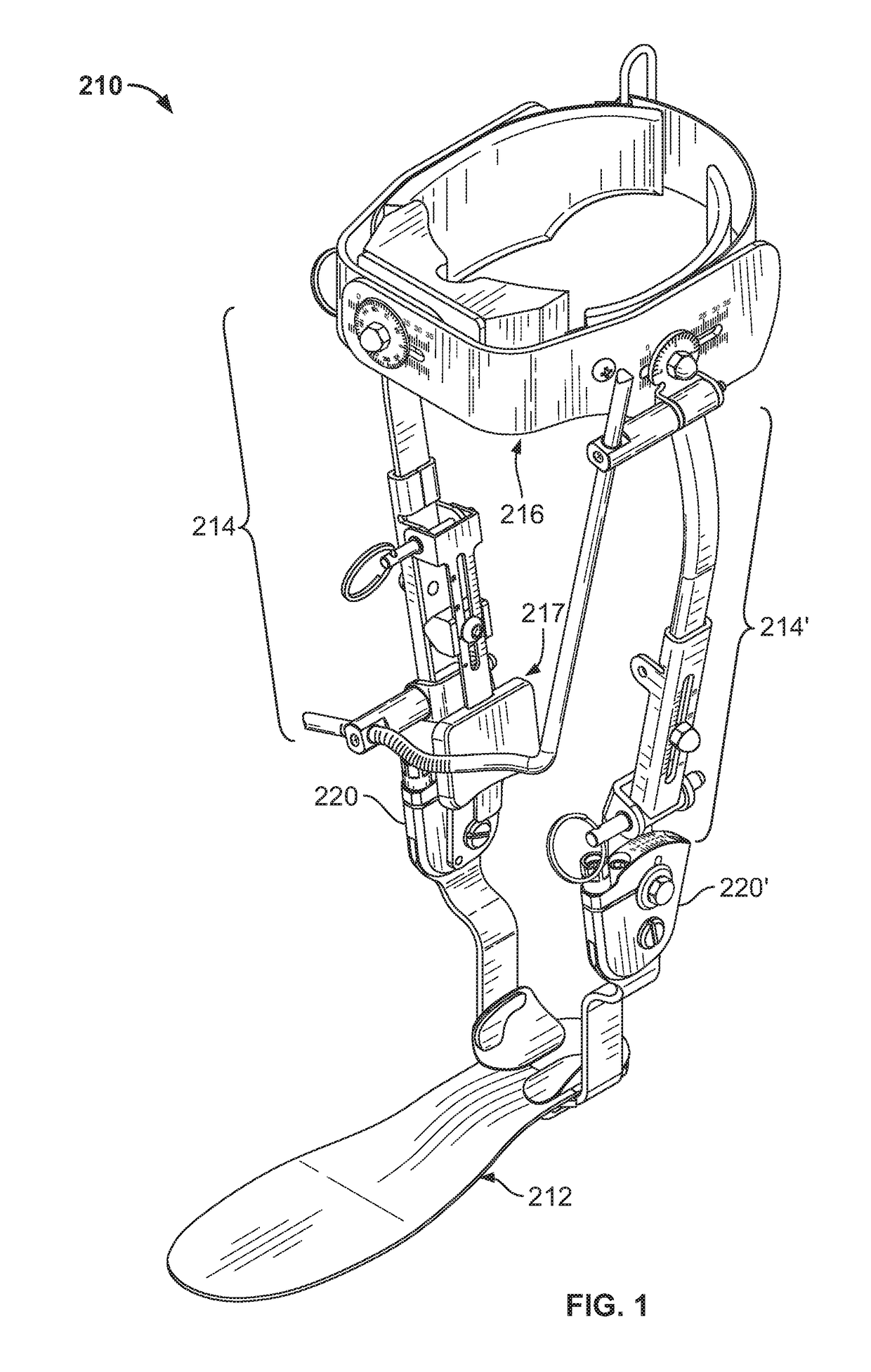

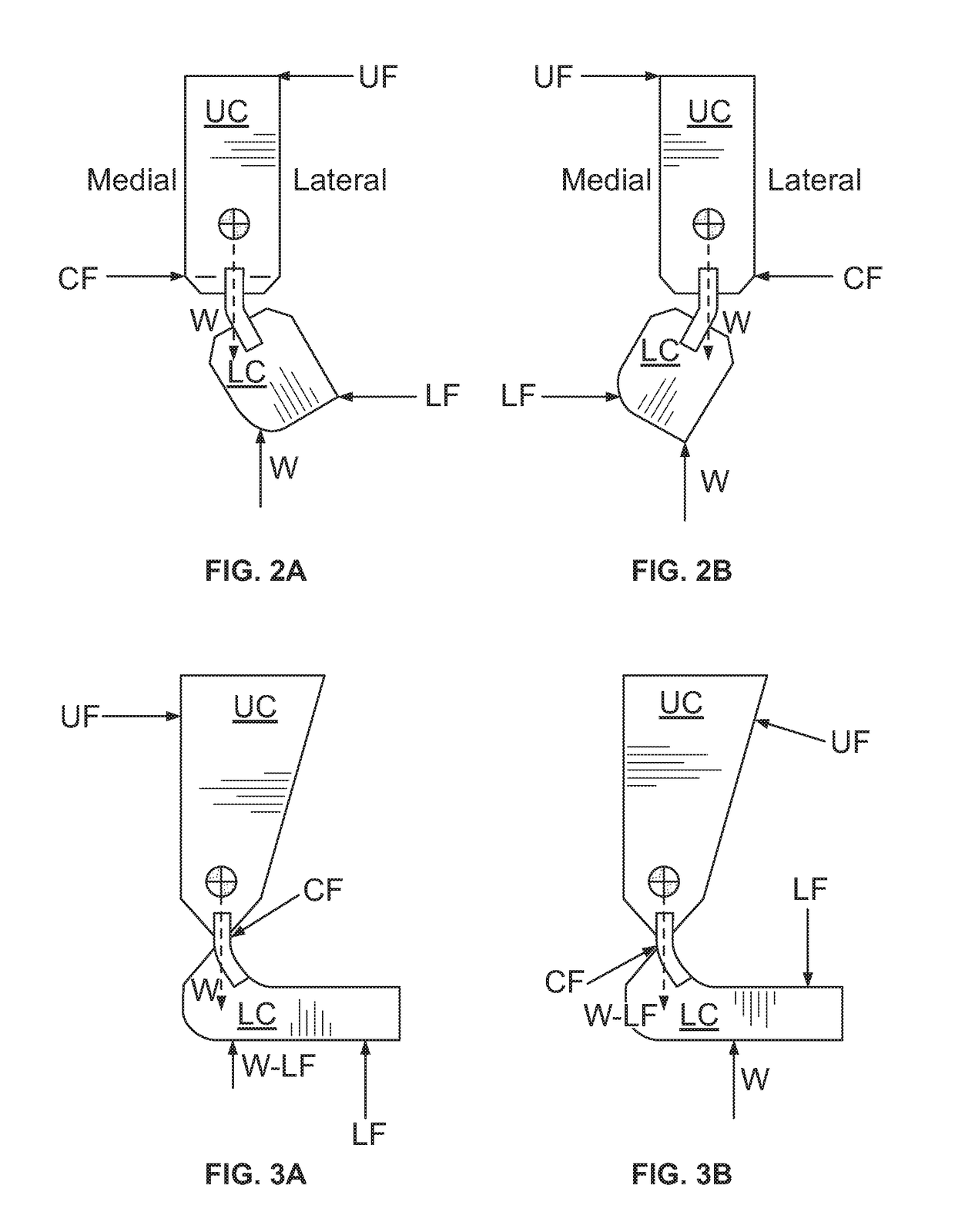

Configurable orthosis and method of definitive orthotic design, fabrication and validation

ActiveUS20180318122A1Good stiffnessGood resistanceAdditive manufacturing apparatusNon-surgical orthopedic devicesSacroiliac jointAnkle/foot orthosis

Configurable orthoses having a high degree of independent adjustability of various parameters are provided. In the example of a rehabilitation-evaluation ankle-foot orthosis (REAFO), these parameters may include calf band anteroposterior, height, width, sagittal tilt, coronal tilt, and mediolateral displacement adjustments; mediolateral displacement adjustments of a supramalleolar support; heel width / stirrup separation adjustment; and sagittal active joint resistance and neutral angle adjustments. Calf band mediolateral displacement adjustment may be provided by a lockable four-bar pivoting frame linkage of the REAFO. In one aspect, the configurable orthosis is used in conjunction with a plastically deformable precursor member to facilitate the design and manufacture of a definitive orthosis customized for a particular patient. In another aspect, the orthosis communicatively transmits limb shape data to either a positive shape receiver apparatus or a CAD / CAM apparatus, to facilitate design and manufacture of a definitive orthosis.

Owner:BECKER ORTHOPEDIC APPLIANCE CO

Telescopic manipulator

The invention relates to a telescopic manipulator. The telescopic manipulator is characterized by at least comprising a driving arm component, a driven arm component and a wall penetration pipe component; the driving arm component and the driven arm component are hinged to a driving end and a driven end of the wall penetration pipe component respectively; the driving arm component at least comprises counterweight pipe components, a steel wire rope locking mechanism, a driving arm fixed pulley component, an operating clamp, a wrist component, a driving arm inner pipe component, an electrical control box, an upper pipe seat component, a driving arm movable pulley component, an upper top plate component, a connection seat component, a counterweight seat component, a Y-direction motor component, an X-direction motor component and a Y-direction locking mechanism. The driving arm component is in a structure that an extension pipe moves up and down between two column pipes, and two balance weights in Z-direction action move up and down in the two column pipes along with stretch and retraction of a driving telescoping pipe. The telescopic manipulator has the advantages of high rigidity and attractiveness in appearance; by arraignment of the X-direction and Y-direction motor components, an operation range of a driven arm can be expanded while convenience in mounting and demounting is achieved.

Owner:XIAN XAE AERO SPACE GROUND EQUIP

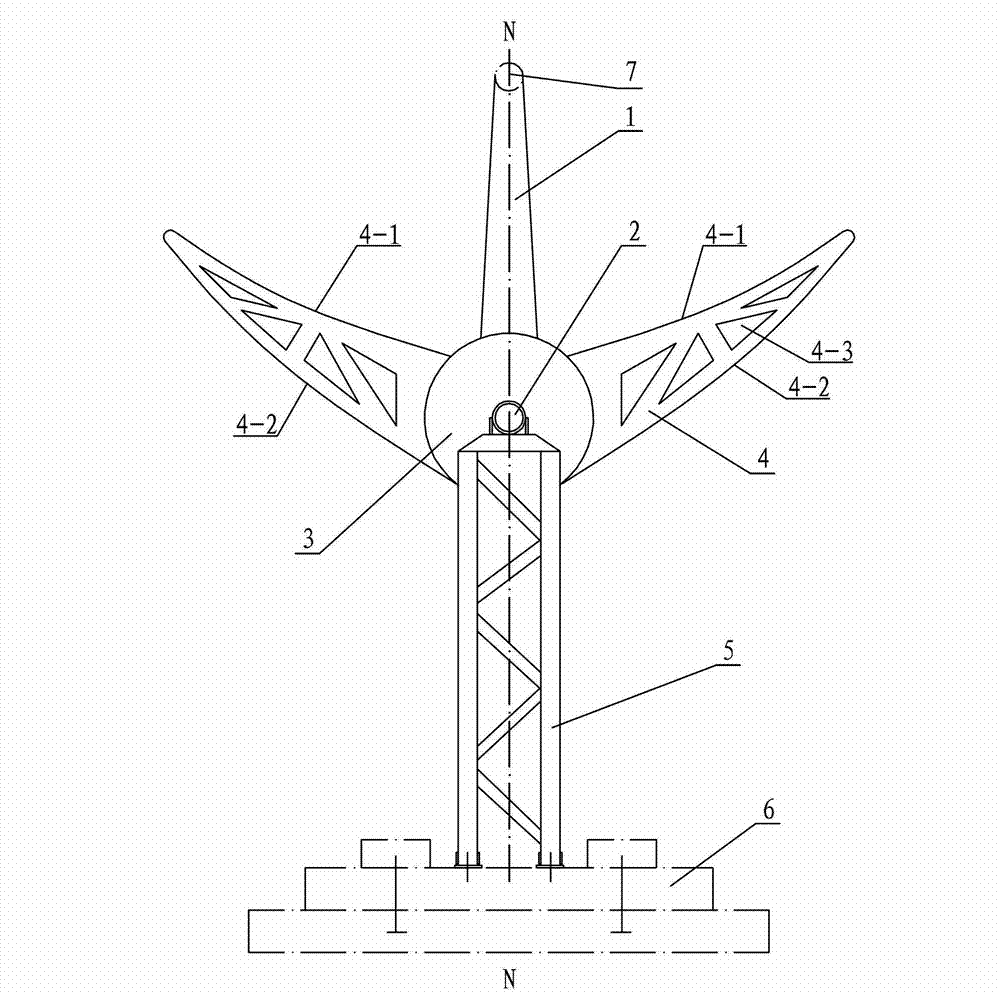

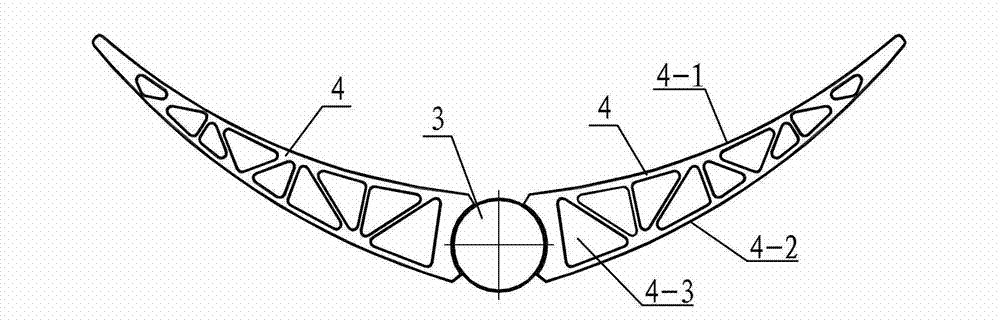

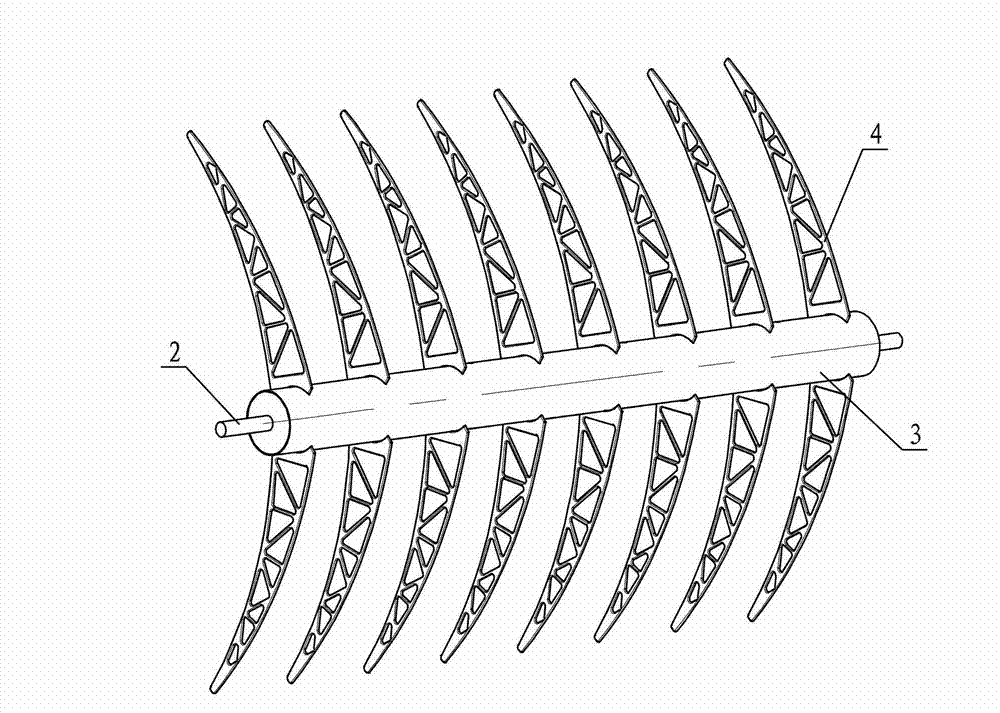

Stamped support for solar heat-collecting power generation system

InactiveCN102853573AGood stiffnessImprove bearing strengthSolar heat devicesSolar thermal energy generationMultiple componentEngineering

The invention discloses a stamped support for a solar heat-collecting power generation system, and relates to a support. The stamped support aims to solve the problem that an existing support for supporting reflectors is an assembly with multiple components connected with one another by bolts, and is insufficient in bearing strength when used under severe conditions with strong wind and the like, and bolt connection positions of the existing support are easy to loose. The stamped support is characterized in that two fixed shafts are symmetrically welded at two axial positions of two ends of a rotating tube, a supporting tower bridge is assembled at the lower end of each fixed shaft, the fixed shafts are arranged in rolling bearings on the supporting tower bridges, the upper end surface of each stamped cantilever is an inwards concave arc-shaped surface, the lower end surface of each stamped cantilever is an outwards concave arc-shaped surface, one end of each stamped cantilever is narrower than the other end of the stamped cantilever, the at least sixteen stamped cantilevers are divided into eight groups, each group comprises two stamped cantilevers, the eight groups of cantilevers are uniformly arranged along the length direction of the rotating tube, the two stamped cantilevers in each group are symmetrically arranged on two sides of the rotating tube, the wide ends of the stamped cantilevers are fixedly connected with the rotating tube, and a plurality of heat-collecting tubes are uniformly disposed along the length direction of the rotating tube. The stamped support is used for solar heat-collecting power generation systems.

Owner:HARBIN TURBINE

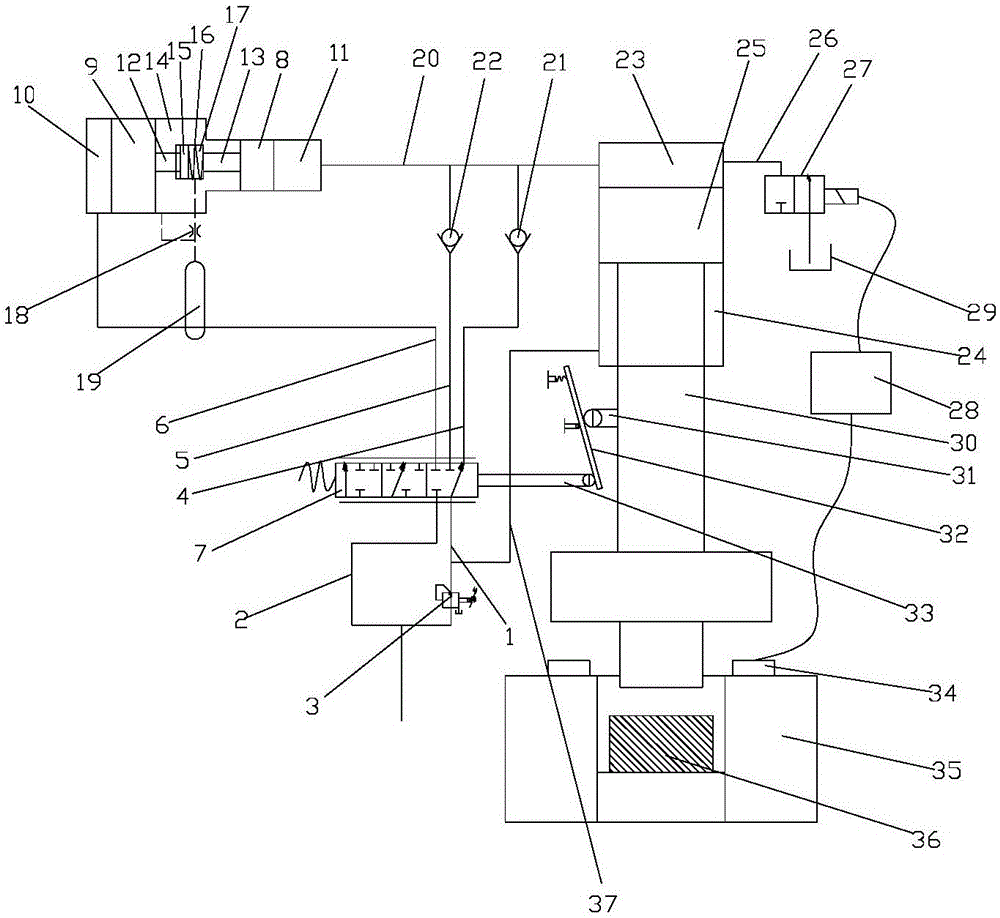

Electrohydraulically-controlled pressing machine reversing through mechanical signal

The invention discloses an electrohydraulically-controlled pressing machine reversing through a mechanical signal. The electrohydraulically-controlled pressing machine comprises an execution mechanism and a hydraulic control mechanism, wherein the execution mechanism comprises an execution cylinder body, an execution piston and a stamping rod; the hydraulic control mechanism comprises a first oil inlet pipeline and a second oil inlet pipeline, a pressure reducing valve, a three-position five-way reversing valve, a pressurization mechanism, a linkage mechanism and a hydraulic buffering control mechanism. A pressure continuously rises when the stamping rod enters the third stroke section to enable a workpiece to generate elasticoplastic deformation due to the cooperation of the pressurization mechanism and the hydraulic buffering control mechanism of the hydraulic control mechanism, so that the requirement of the workpiece on the gradual increasing of the pressure during the elasticoplastic deformation are met; and the hydraulic control mechanism in the invention enables the stamping rod to meet the change of the pressure in three stroke sections, so that the stamped workpieces are high in rigidity and low in rejection rate. The three-position five-way reversing valve and the stamping rod realize linkage through the linkage mechanism.

Owner:宣城托新精密科技有限公司

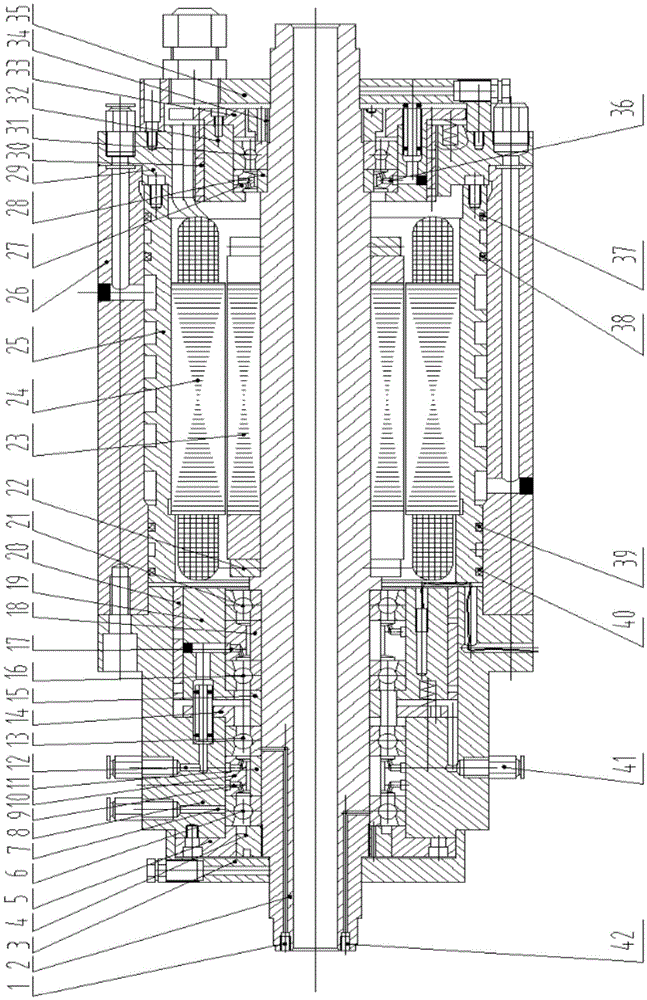

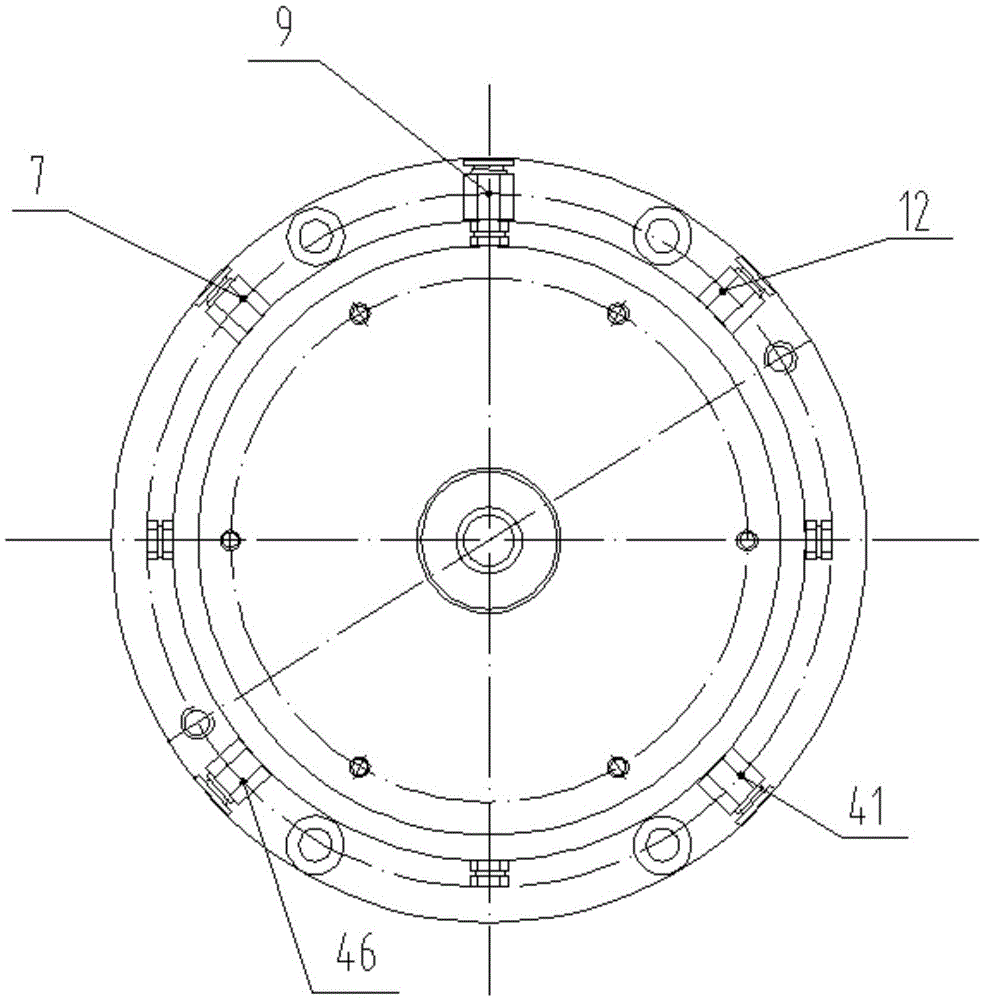

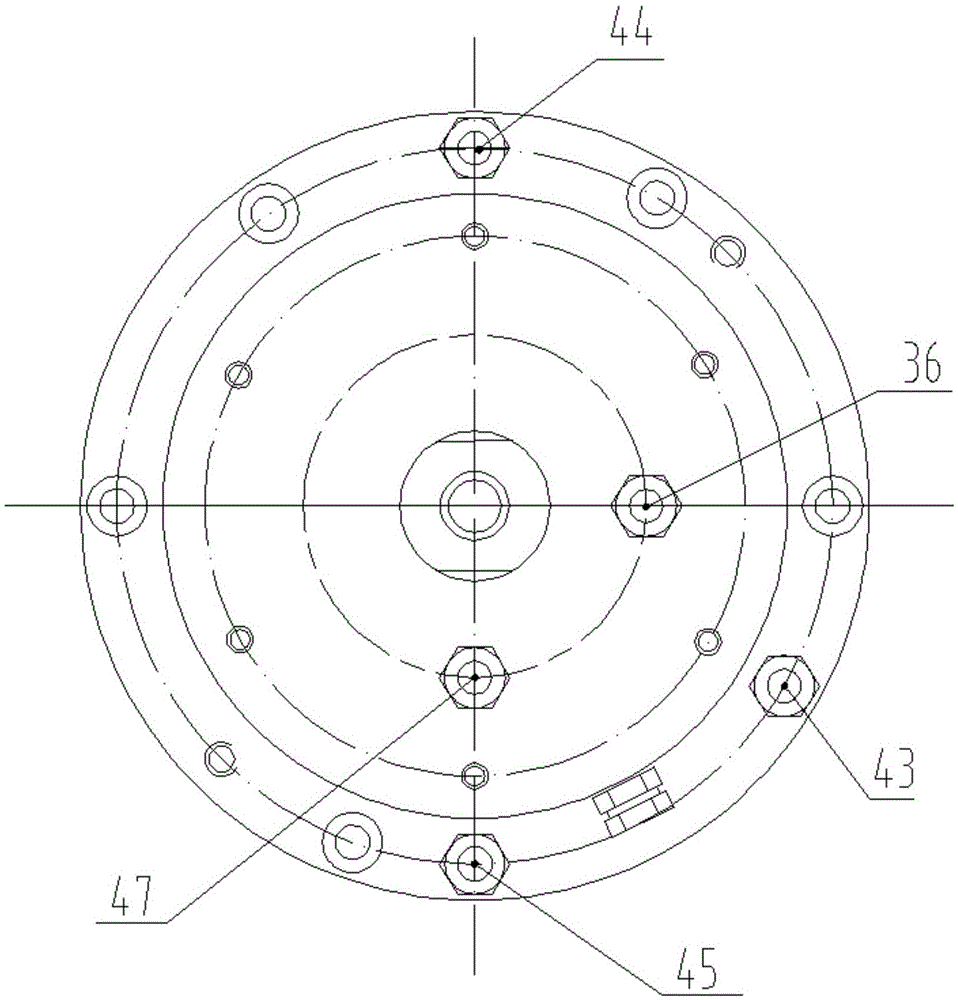

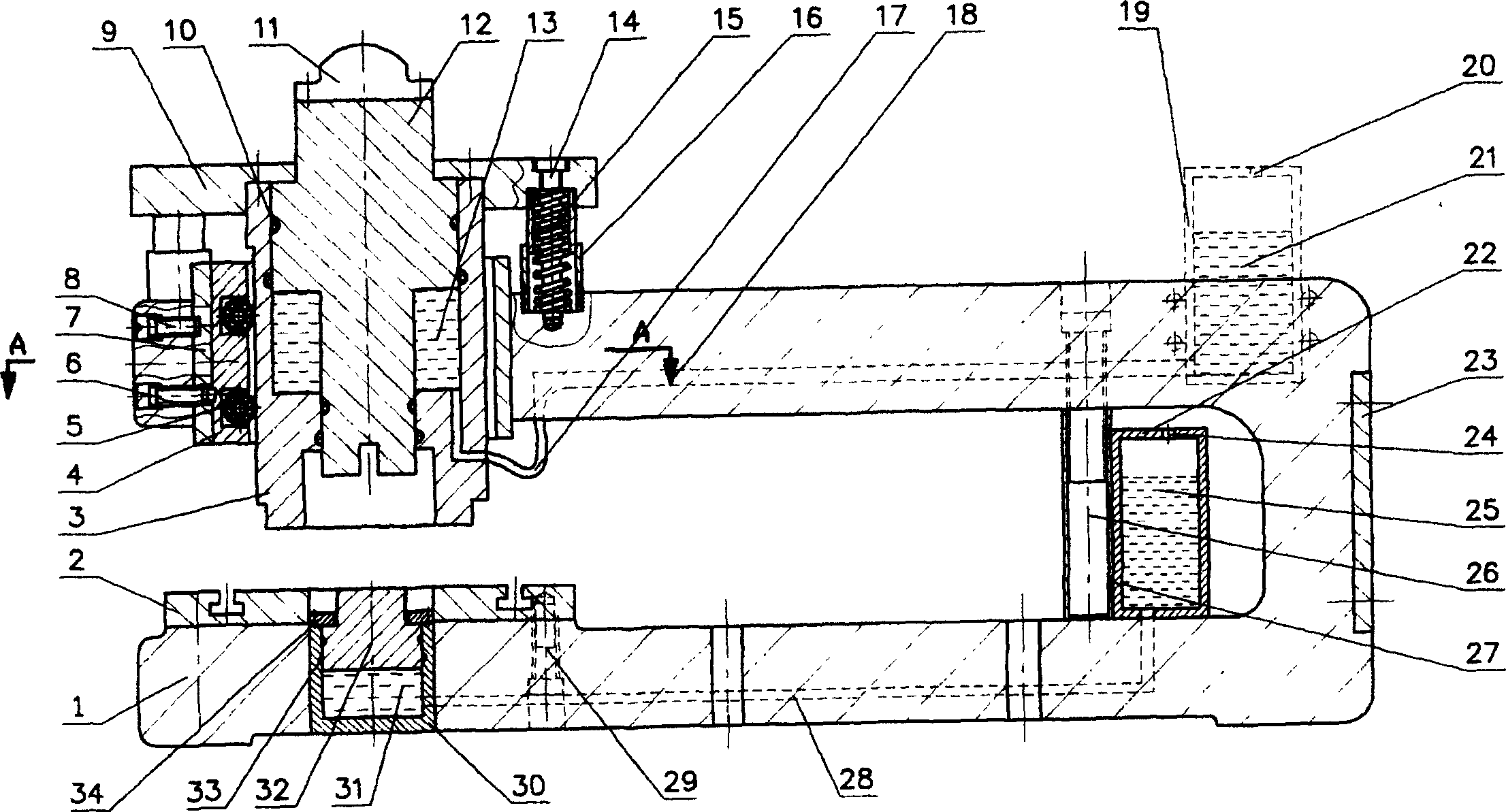

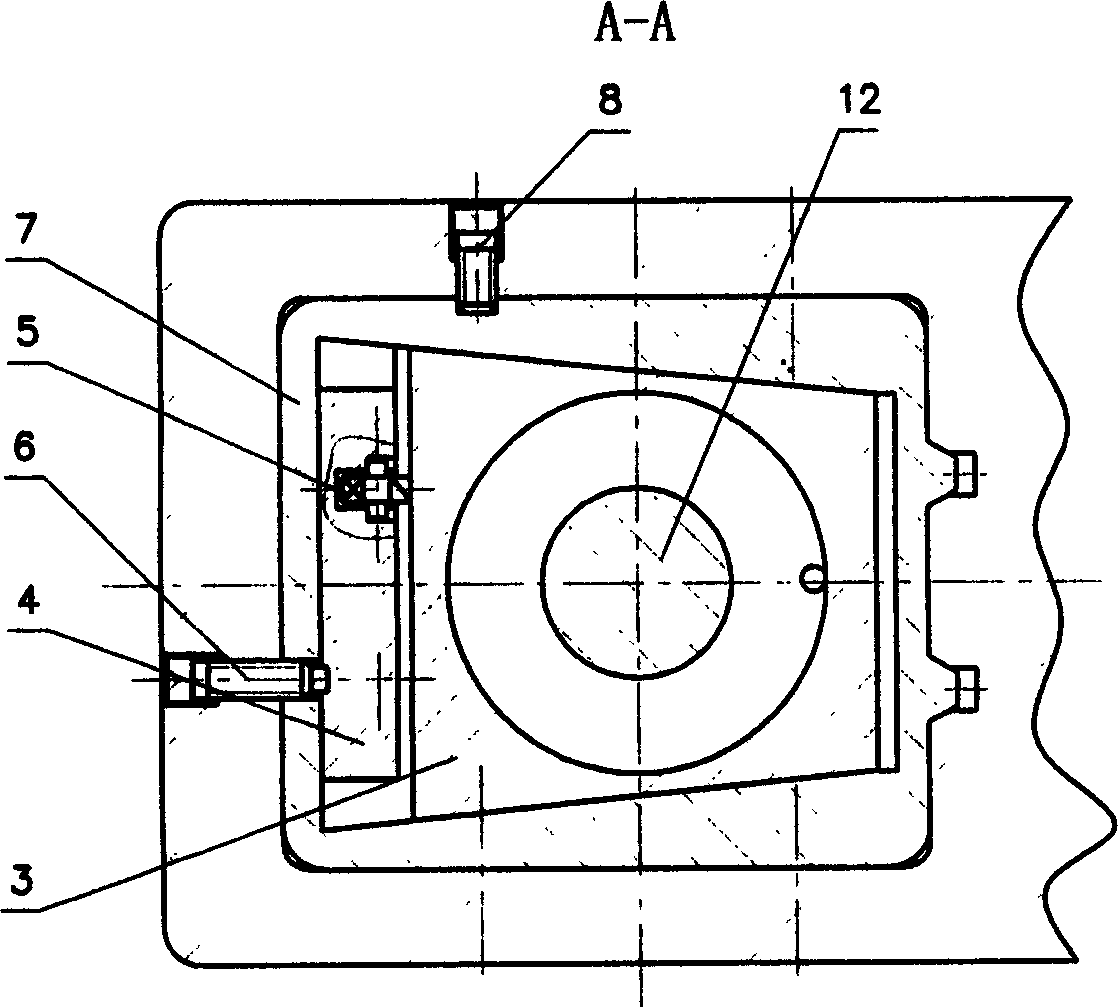

High-speed electric main shaft device where ultra-precise angular contact ball and cylindrical roller bearings are used

InactiveCN105458306AGood stiffnessPrecise and quantitative lubrication is convenientLarge fixed membersMaintainance and safety accessoriesLubricationEngineering

The invention discloses a high-speed electric main shaft experimental device supported by an angular contact ball and cylindrical roller bearings. A single column of cylindrical roller bearings with conical holes are arranged at the rear end of a rotating shaft. A first front supporting bearing, a second front supporting bearing, a third front supporting bearing and a fourth front supporting bearing are arranged at the front end of the rotating shaft. The first front supporting bearing and the second front supporting bearing are connected in series to form a group. The third front supporting bearing and the fourth front supporting bearing are connected in series to form a group. The two groups are arranged in a back-to-back manner. A gap between the two groups is supplemented by a shaft shoulder sleeve, and the two groups are separated through a front spring baffle. The first front supporting bearing and the second front supporting bearing are testing bearings. The third front supporting bearing and the fourth front supporting bearing are auxiliary supporting bearings. The actual work environment needed for monitoring and researching a rolling bearing in the high-speed electric main shaft device is achieved, the structure supporting rigidity is good, precise and quantitative lubrication is achieved, the testing bearings can be conveniently replaced, and precision stability of an electric main shaft is guaranteed during long-time running.

Owner:XI AN JIAOTONG UNIV

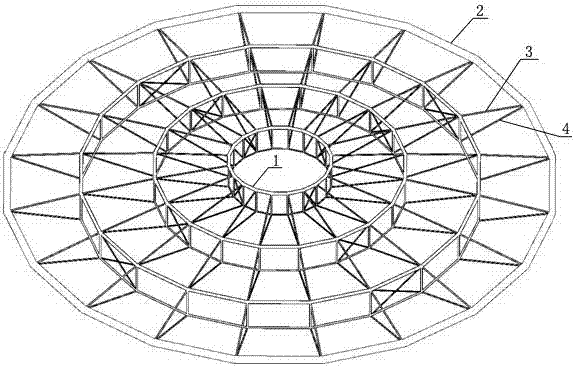

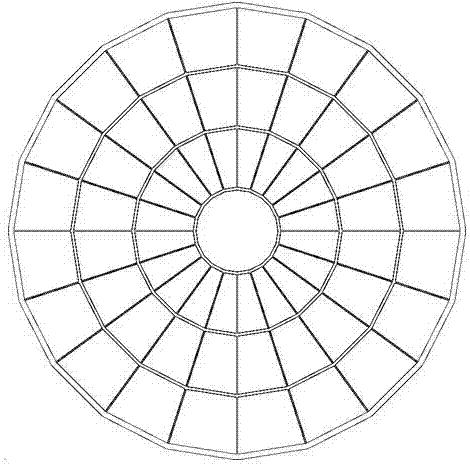

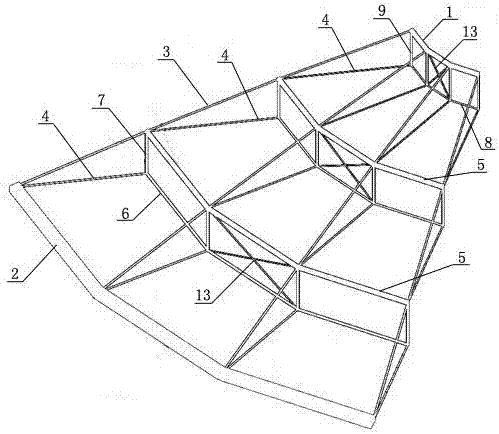

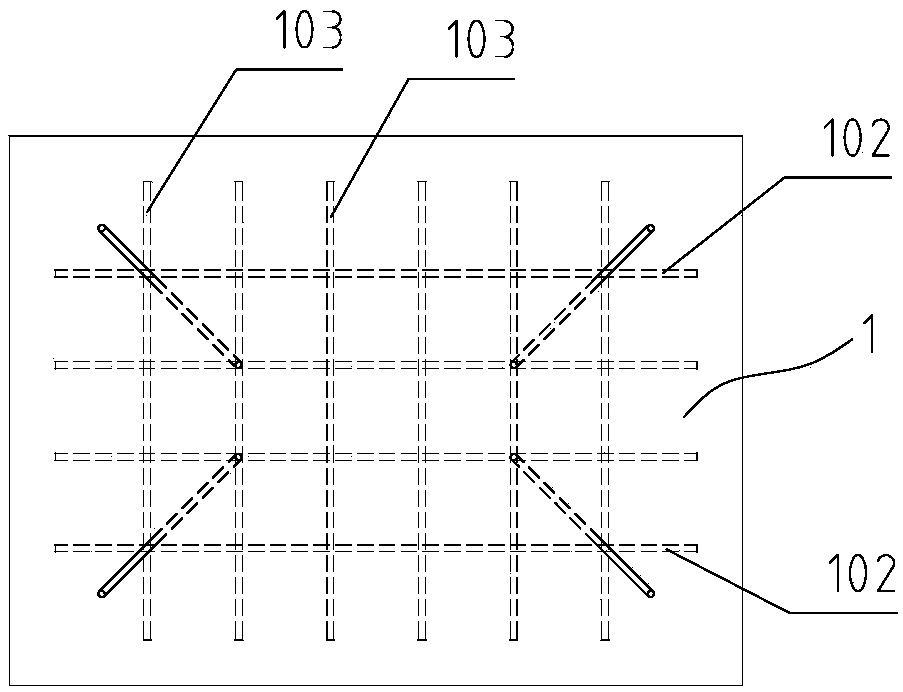

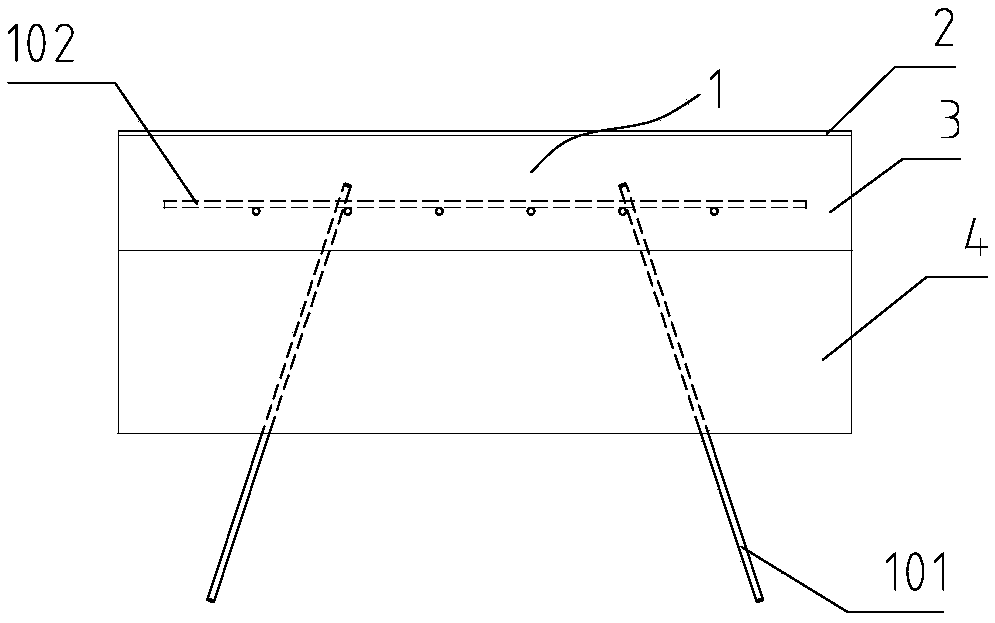

Rigid roof cable-dome structure with circumferential-direction support

PendingCN107268792AHigh material utilizationGood stiffnessBuilding roofsArched structuresSupport point

The invention discloses a rigid roof cable-dome structure with a circumferential-direction support. The rigid roof cable-dome structure comprises an internal pull ring and an external ring, at least one round of circumferential-direction assembly is arranged between the internal pull ring and the external ring, and the circumferential-direction assembly separates the part between the internal pull ring and the external ring into at least two stages of structures; a plurality of ridge cables arranged in a radial shape in the radial direction are arranged between the internal pull ring and the external ring, one ends of the ridge cables are connected with the internal pull ring, the other ends of the ridge cables are connected with supporting points of the external ring, and the middle of each ridge cable is connected with the upper end portion of the corresponding circumferential-direction assembly; and oblique cables are arranged between the circumferential-direction assembly and the external ring as well as between the circumferential-direction assembly and the internal pull ring correspondingly, if multiple rounds of circumferential-direction assemblies are arranged, oblique cables are arranged between the every two adjacent circumferential-direction assemblies, and the oblique cables are arranged in a radial shape in the radial direction. According to the rigid roof cable-dome structure with the circumferential-direction support, force transferring is direct, the high-strength character of an inhaul cable is brought into full play, the rigid roof cable-dome structure has the advantages of being good in rigidity, good in stability, simple in structure, rapid in construction and the like, meanwhile a rigid roof technology adopted by the rigid roof cable-dome structure is mature, and the cost is relatively low.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

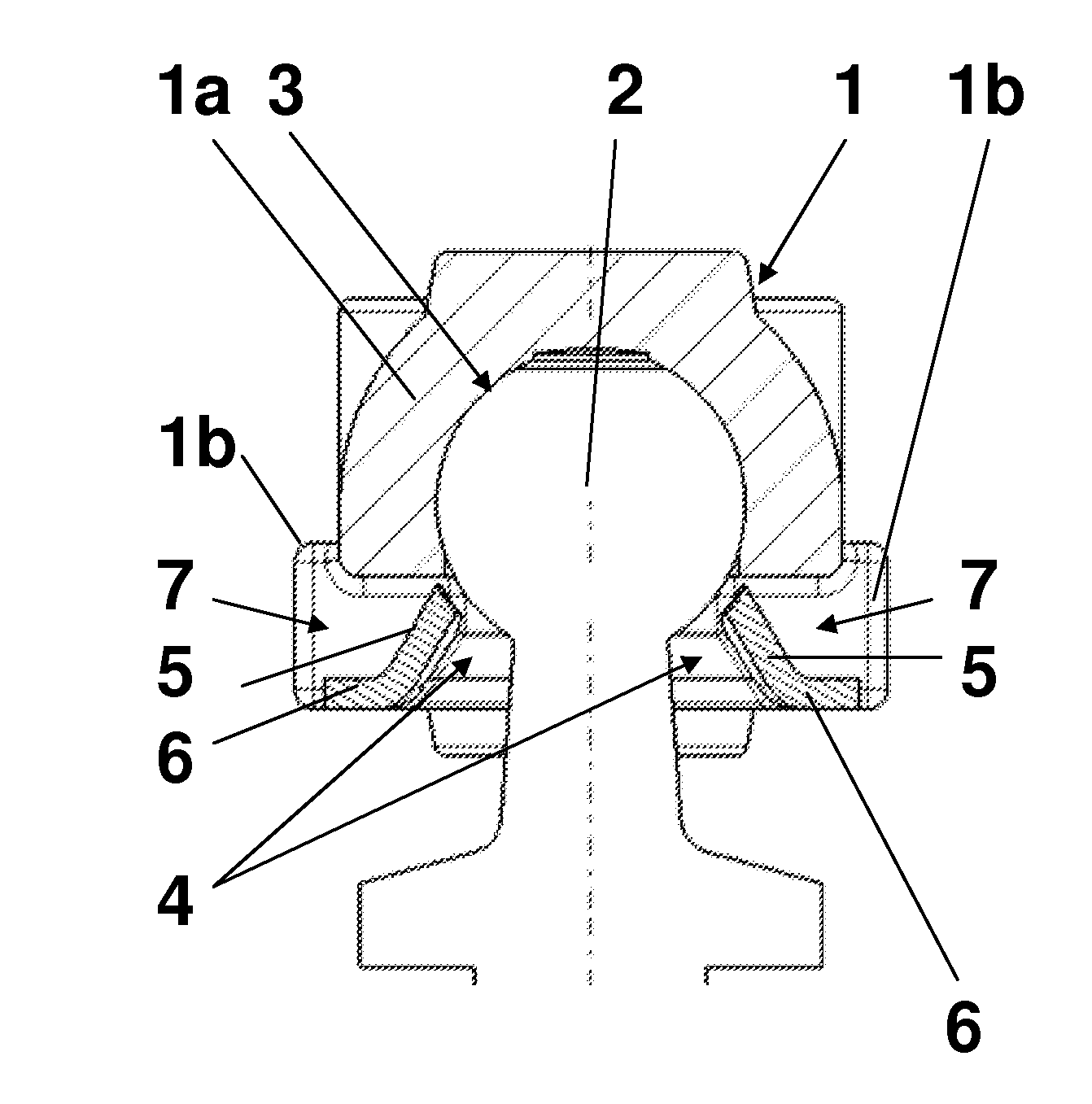

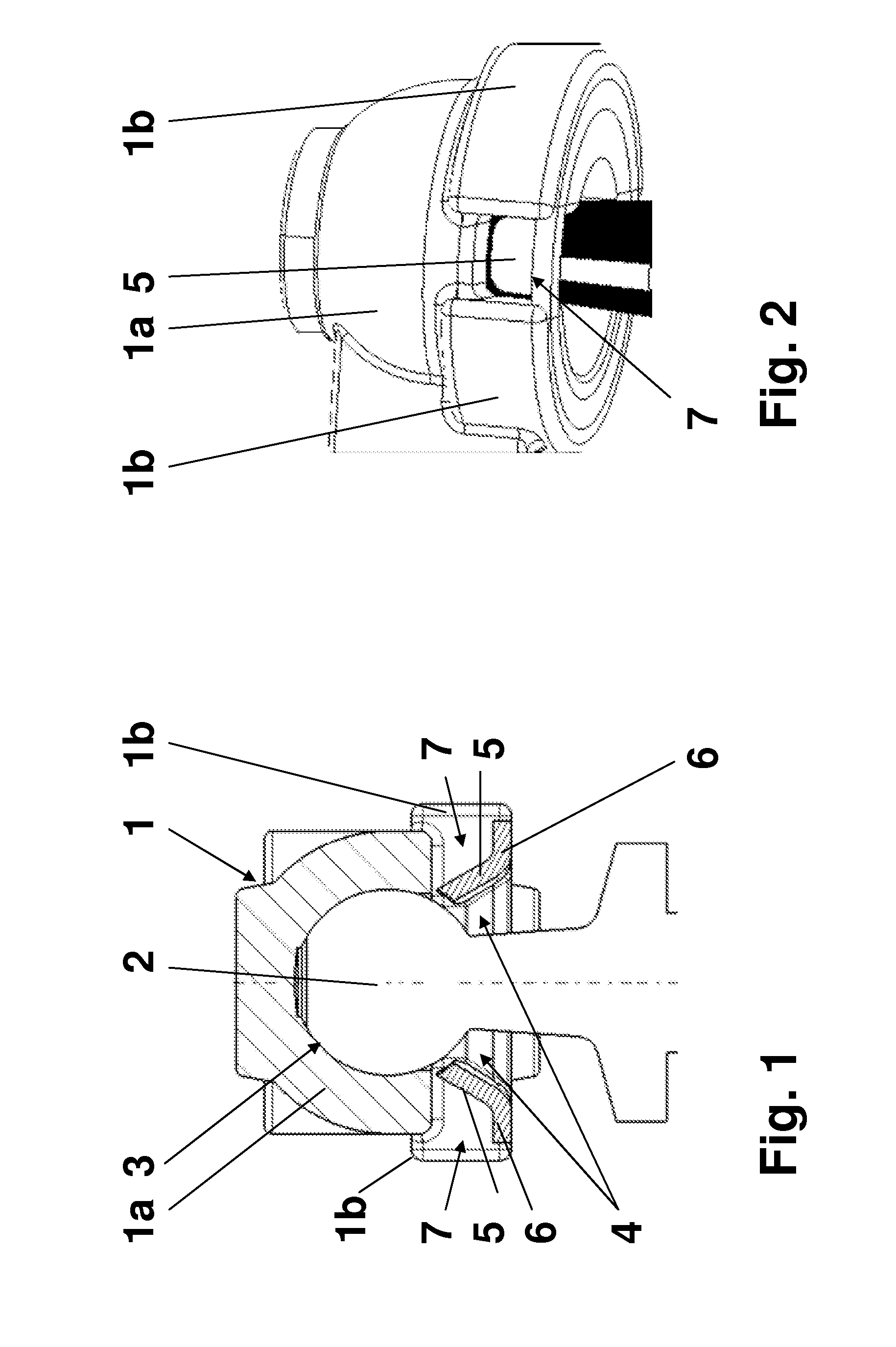

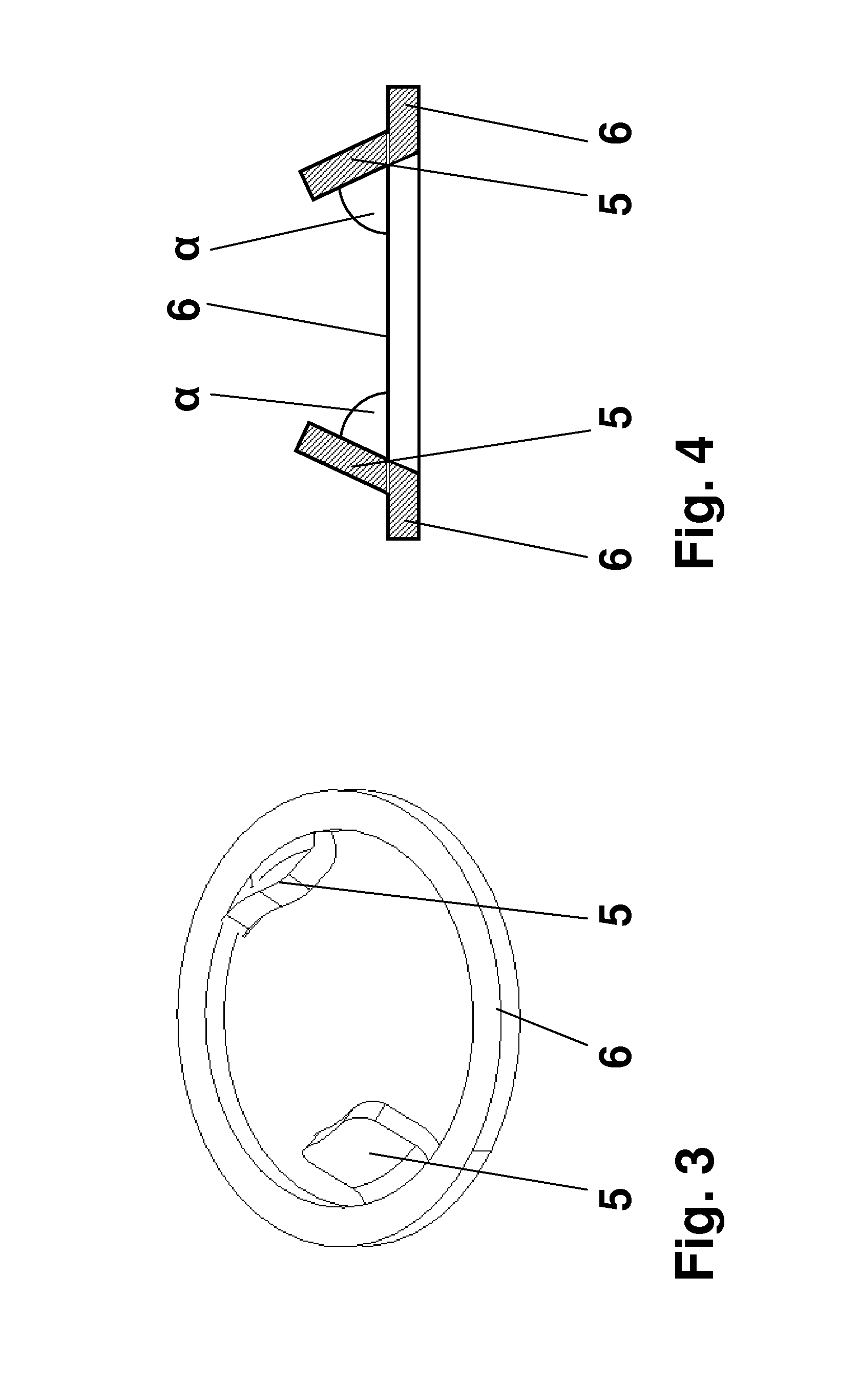

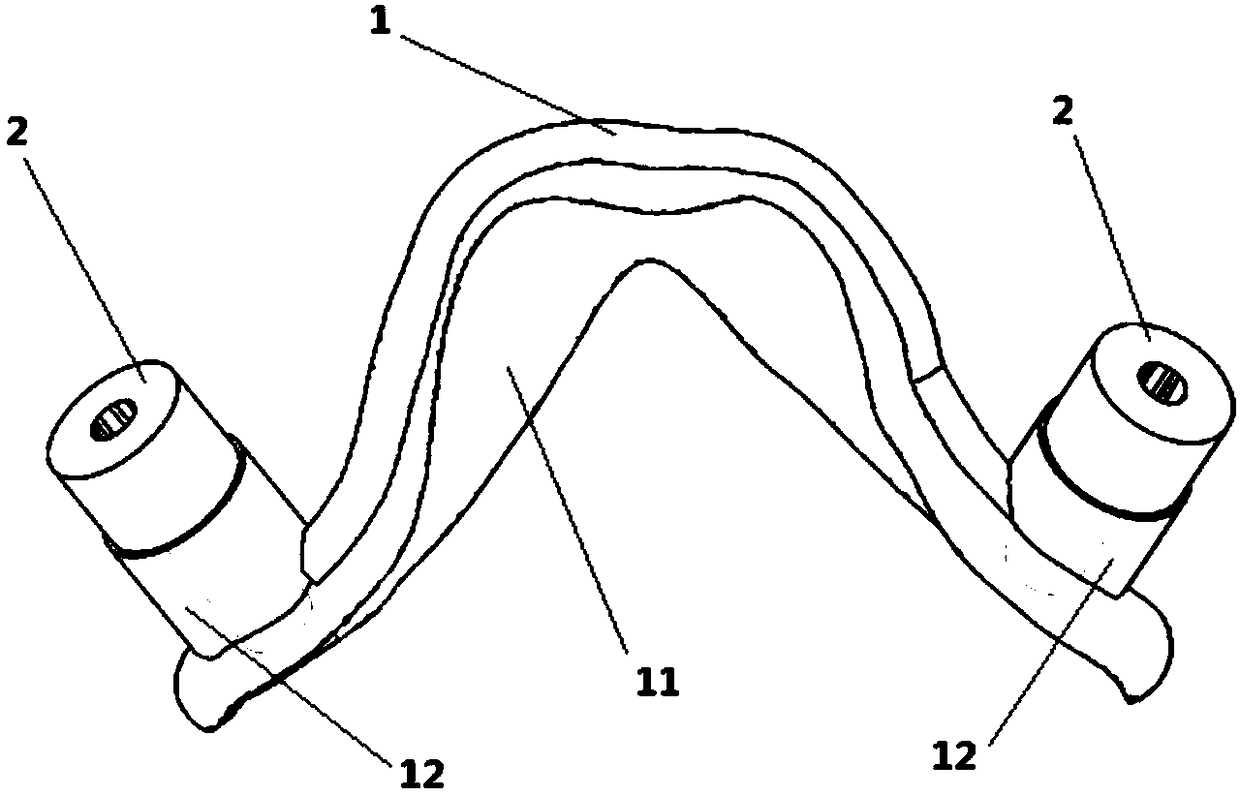

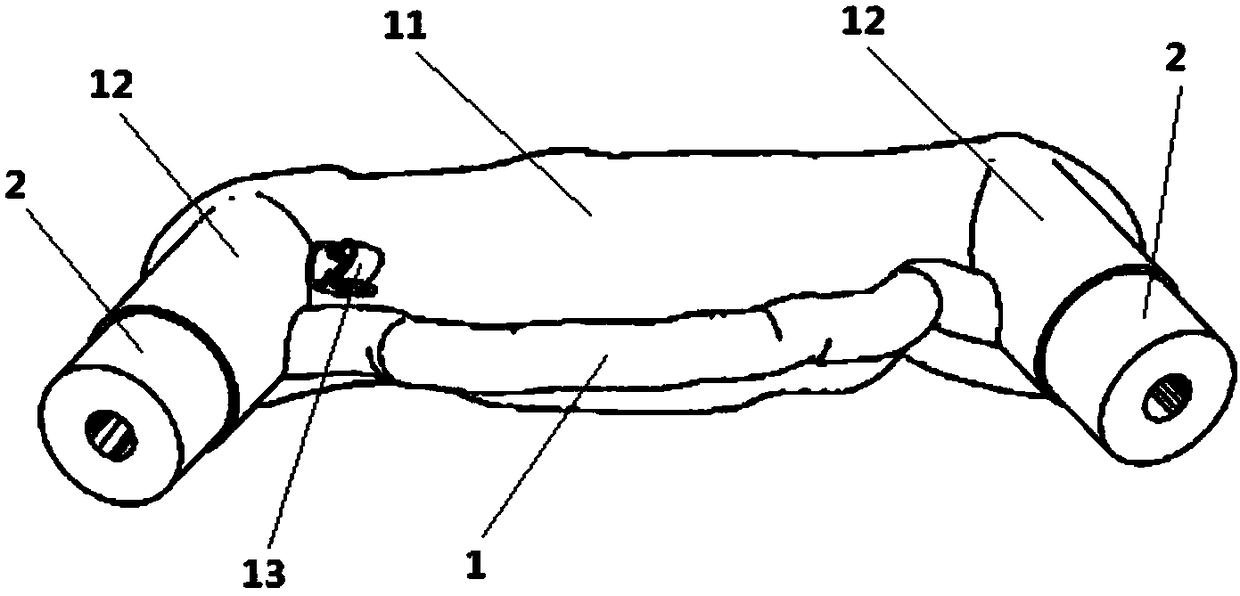

Ball Joint Connection

InactiveUS20160138646A1Facilitate assemblyGood stiffnessShaftsCouplings for rigid shaftsSacroiliac jointEngineering

Owner:HELLA KGAA HUECK & CO

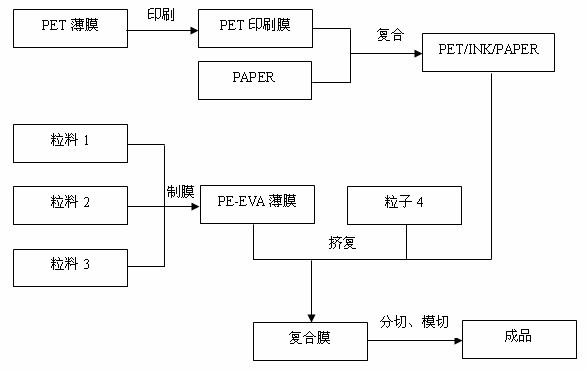

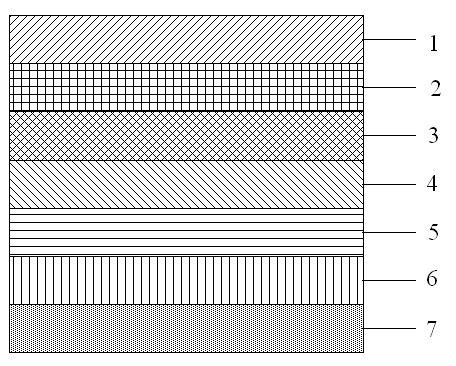

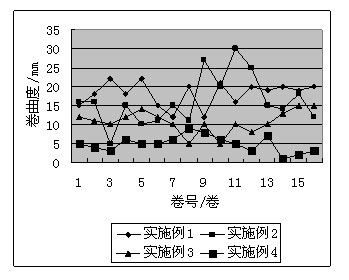

Microwave heatable bowl cover film with good planeness and preparation method thereof

InactiveCN102514331AGood heat sealing performanceGood stiffnessFlexible coversWrappersPolyurethane adhesivePolyethylene terephthalate glycol

The invention relates to a microwave heatable bowl cover film with good planeness and a preparation method thereof. The bowl cover film comprises, from top to bottom, an external layer, an intermediate layer and a heat sealing layer; the external layer is a PET (polyethylene terephthalate) film surface layer; the intermediate layer is a double gummed paper layer; the heat sealing layer which is a composite polyethylene-vinyl acetate film is obtained by coextruding a composite layer, a core layer and a sealing layer from top to bottom, materials of the composite layer and the core layer are formed by mixing low density polyethylene and linear low density polyethylene according to a weight ratio of 3:2, and the material of the sealing layer is ethylene-vinyl acetate; the PET film surface layer and the double gummed paper layer are composited together by a polyurethane adhesive layer; and the double gummed paper layer and the composite polyethylene-vinyl acetate film are composited together by a casting polyethylene layer. The bowl cover film prepared in the invention, which has a good planeness, can be heated by microwaves.

Owner:JIANGYIN BAOBO PACKING

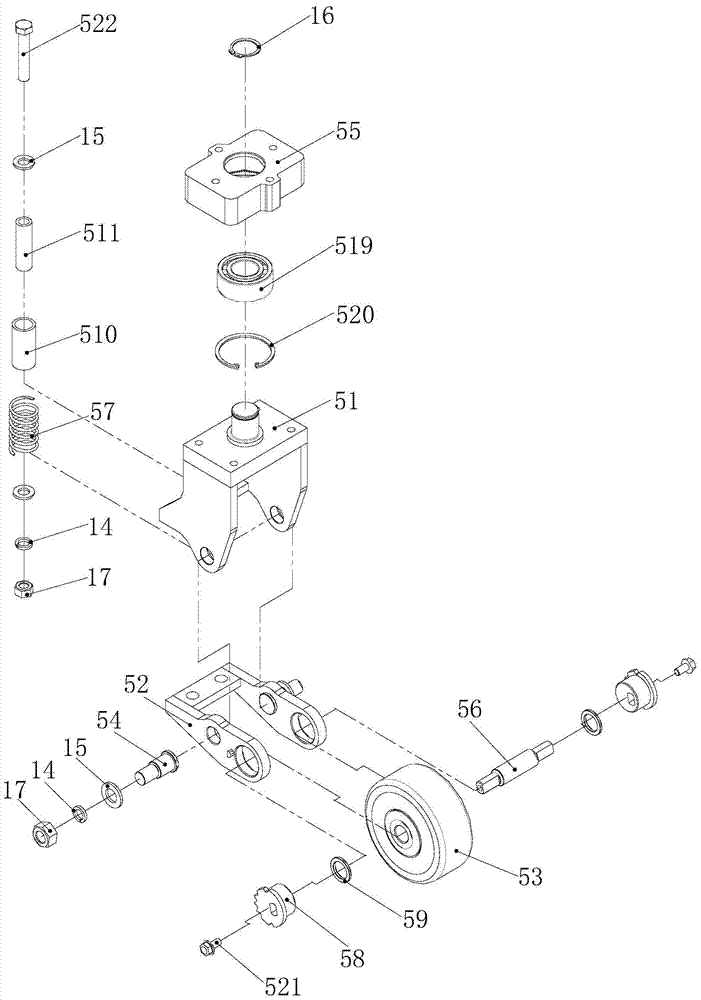

Integral type grading bearing mechanism

The invention discloses an integral type grading bearing mechanism, which comprises a connecting rod, brackets, a left support seat plate, a right support seat plate and a wheel assembly, wherein the two ends of the connecting rod are respectively provided with the corresponding bracket, a connecting shaft is arranged on the brackets, a spring seat is arranged on the connecting shaft, a primary damping spring and a first secondary damping spring are arranged on the spring seat, and the wheel assembly is arranged at the bottom part of the corresponding bracket. The integral type grading bearing mechanism has the advantages that the sufficient adhesion on a driving system of a warehouse type forklift under the empty load condition is guaranteed, so the slippage of the forklift is avoided; under the full load condition, auxiliary wheels are guaranteed to share much gravity, so the damage to a gearbox due to the overload of the driving system is avoided.

Owner:安徽安歌机器人有限公司

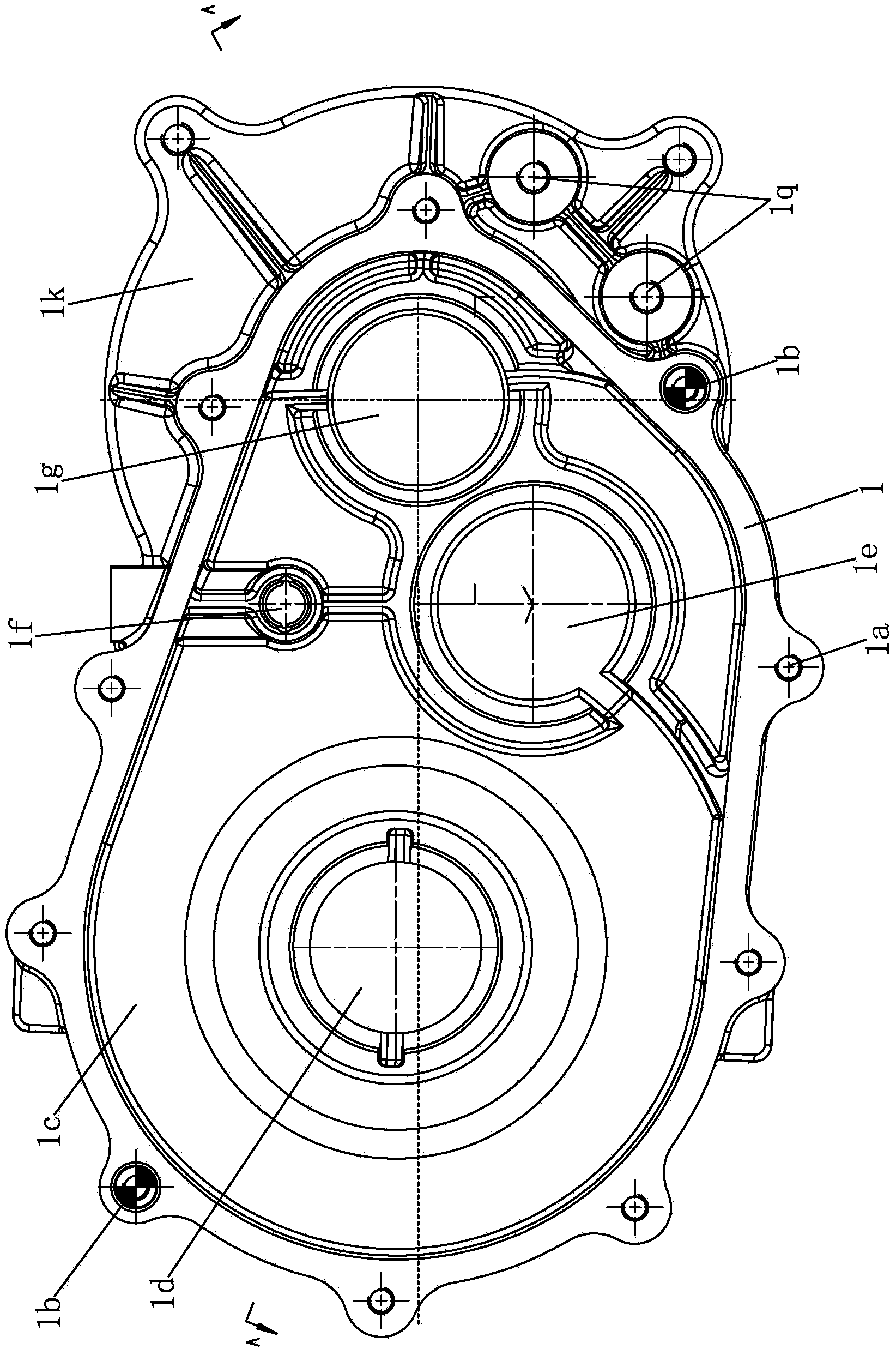

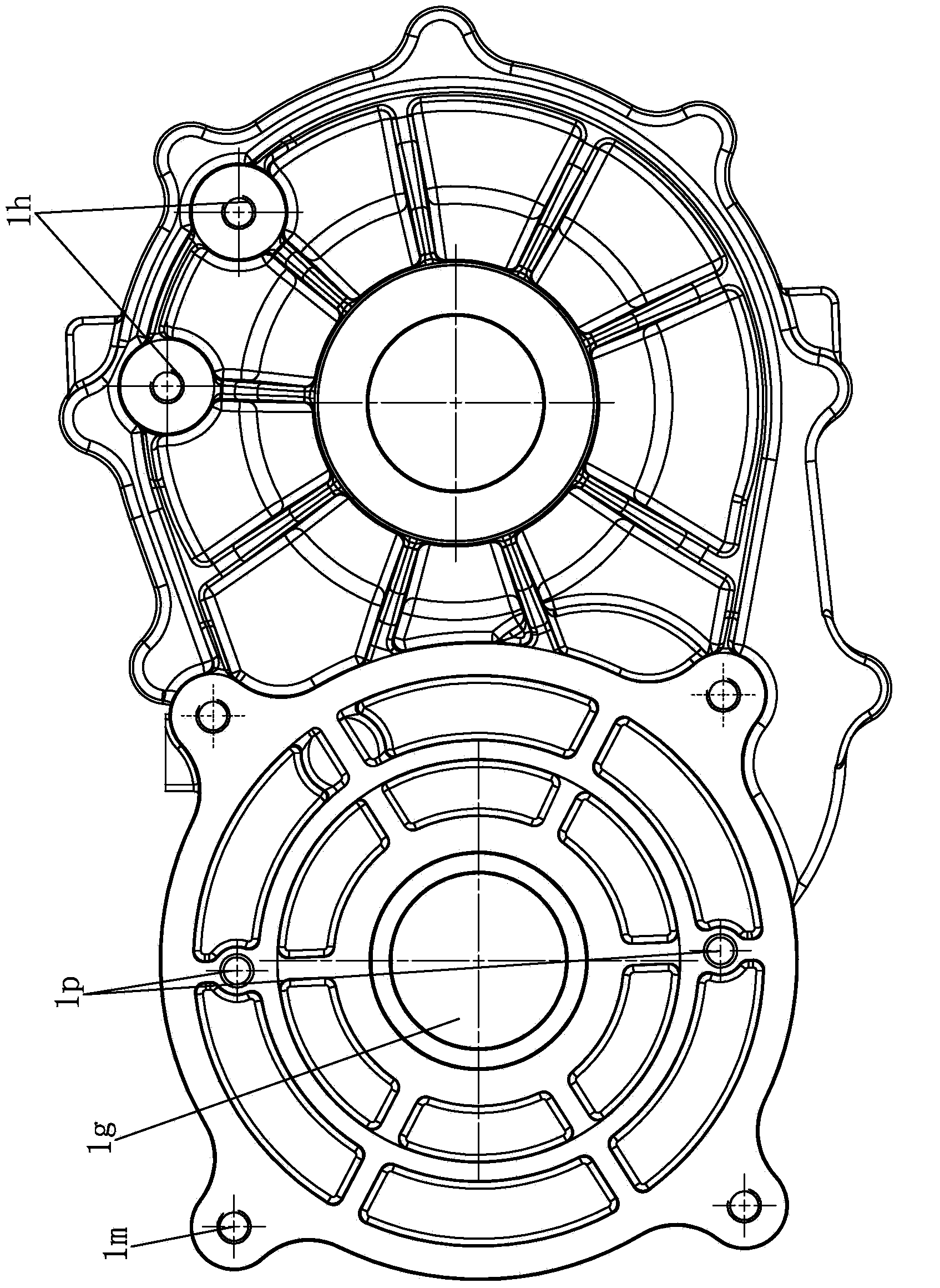

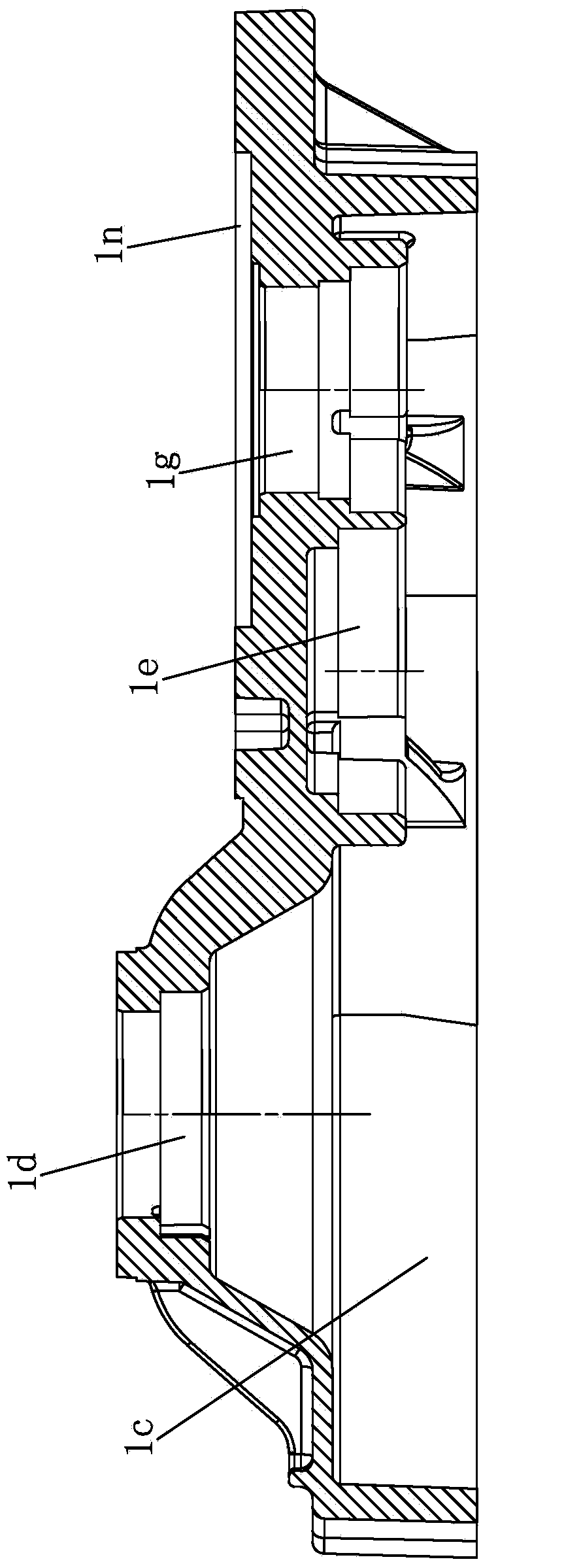

Right box of bi-gear gearbox assembly of electric vehicle

The invention discloses a right box of a bi-gear gearbox assembly of an electric vehicle. The front side of the right box body is a box body combined surface, the box body combined surface is provided with eight bolt mounting holes and two positioning pin holes circumferentially, the inner side of the box body combined surface is a form cavity, and the left portion of the bottom of the form cavity is provided with output bevel gear mounting holes. The bottom of the middle lower portion of the form cavity is provided with a bearing mounting sinking platform, and the bottom of the right upper portion of the form cavity is provided with an input shaft mounting hole. The left upper portion of the rear side of the right box body is provided with two first suspension mounting holes, the rear side of the right portion of the right box body is a motor mounting portion, and a motor mounting surface of the rear side of the motor mounting portion is provided with four threaded holes. The inner side of the motor mounting surface of the motor mounting portion is a motor mounting cavity, and the front side of the motor mounting portion is provided with two first suspension mounting holes. The right box is compact in structure, high in strength and convenient to be arranged on the gearbox assembly, and can be used as a mounting base for positioning pins, output bevel gears, bearings, an input shaft, a motor and suspensions.

Owner:重庆亿捷汽车配件制造有限公司

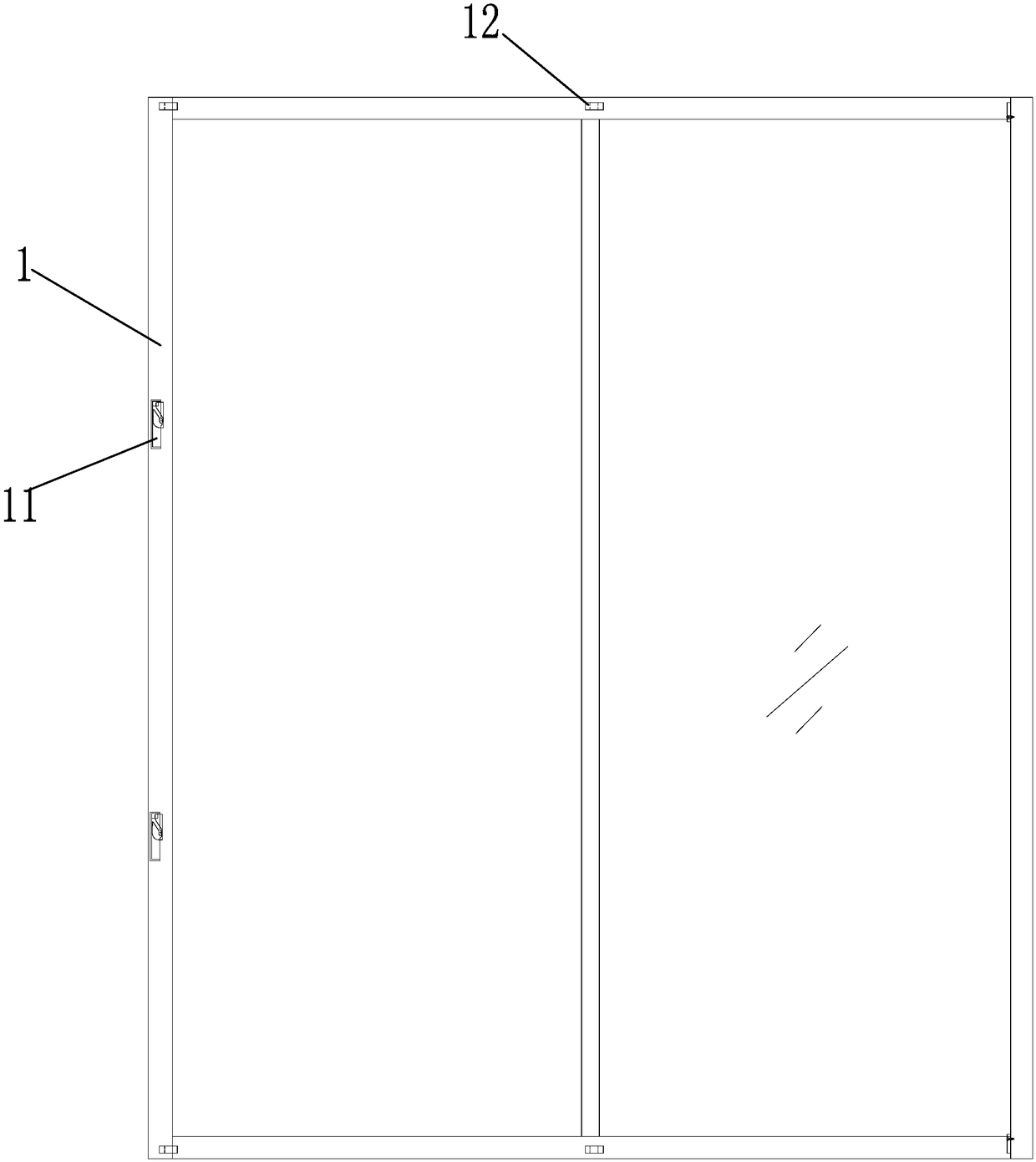

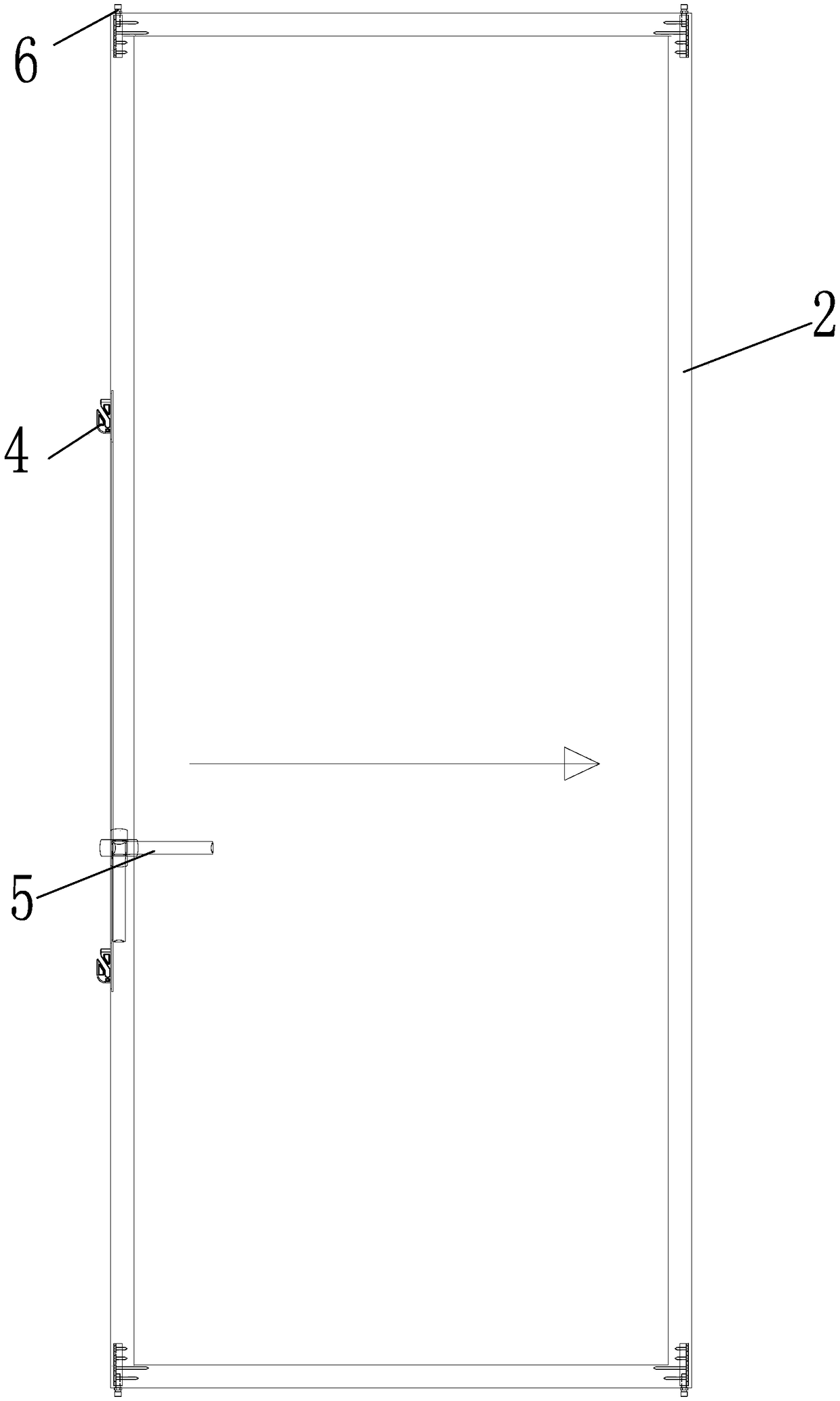

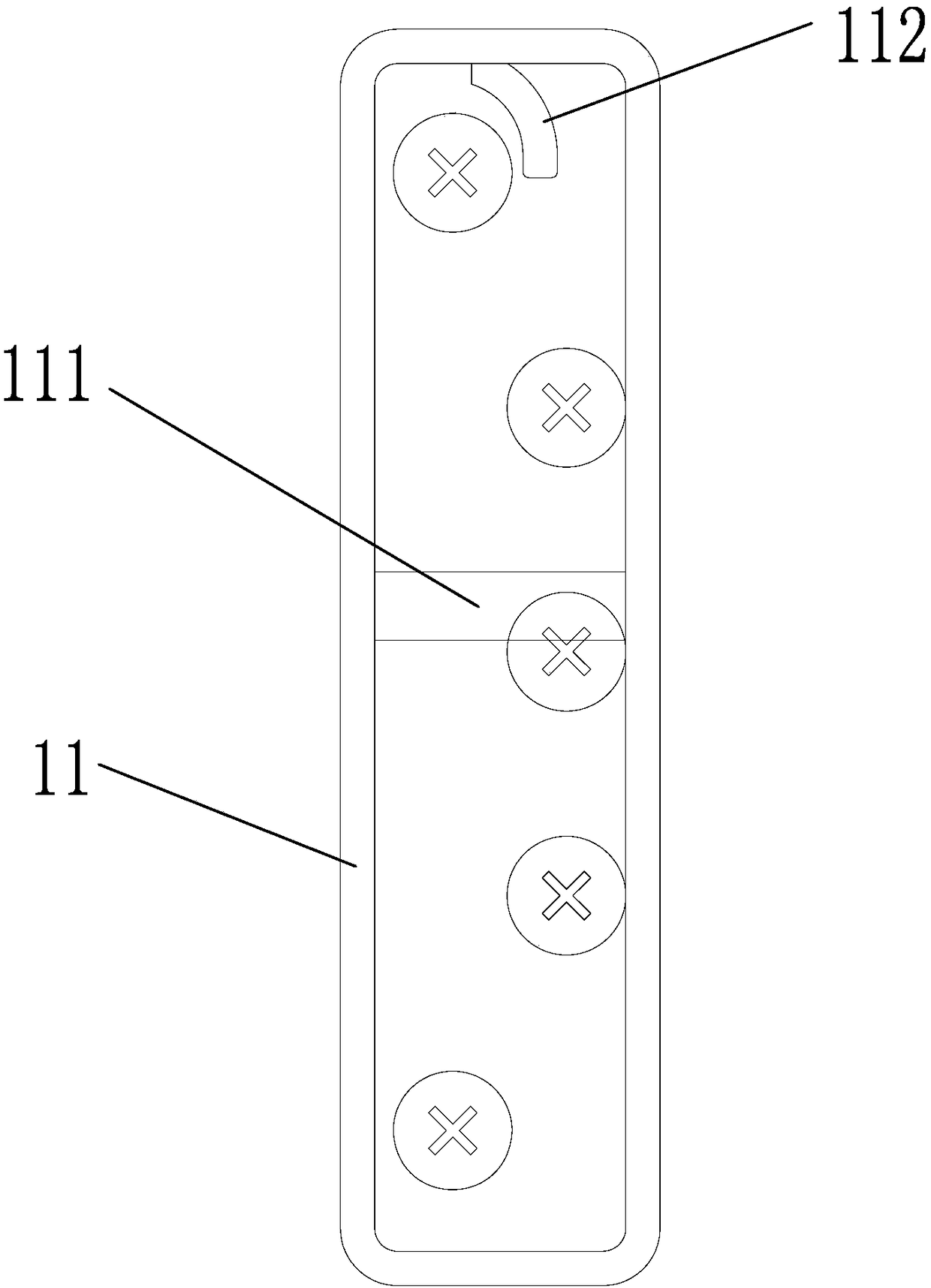

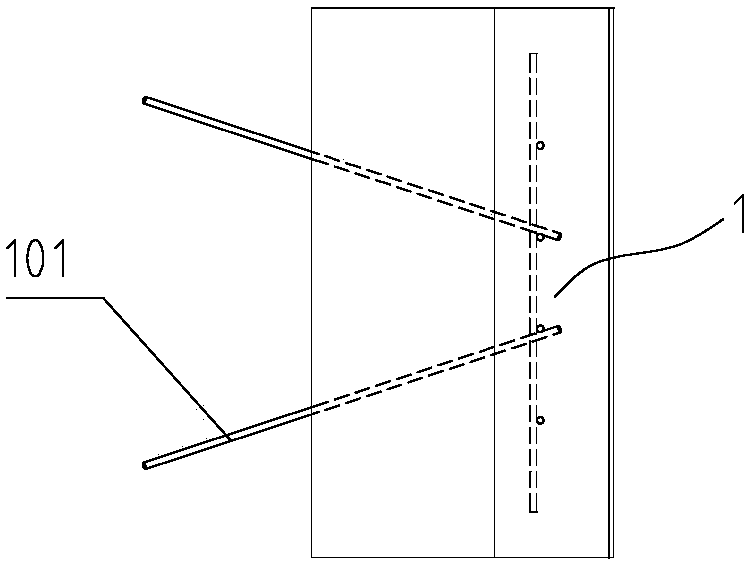

Aluminum alloy translation sealing sliding door and window hardware structure

InactiveCN108119016AGood stiffnessImprove reliabilityWing fastenersWindow/door framesEngineeringHardware structure

A aluminum alloy translation sealing sliding door and window hardware structure comprises a frame material and a leaf material. A hook lock seat is arranged inside one side of the frame material, anda horizontal pin shaft is arranged in the hook lock seat; the top and bottom of the frame material are internally provided with a guide bolt seat, the guide bolt seat is provided with an arc-shaped first guide groove, one side of the leaf material towards the hook lock seat is provided with a first clamping groove, a driving rod is buckled in the first clamping groove, a hook lock is fixedly disposed on the outer side of the driving rod, and the hook lock is provided with an arc-shaped second guide groove. The outer side of the leaf material is provided with a rotatable handle, the inner end of the handle is connected with the driving rod through a rotating part, one side of the leaf material towards the guide bolt seat is provided with a second clamping groove with the cross section in aT shape, a guide bolt is buckled in the second clamping groove, and the guide bolt is fixedly connected with the inner wall of the second clamping groove through a fixing screw. The guide bolt is provided with a lock bolt extending out of the leaf material, and the lock bolt can slide into the inner end of the first guide groove from the open end of the first guide groove. The aluminum alloy translation sealing sliding door and window hardware structure is stable in structure and attractive.

Owner:BEIJING GANGYUAN CURTAIN WALL CO LTD

Steel wire net frame composite outer wall heat insulating plate

PendingCN108277897AGood stiffnessStrong shear resistanceWallsHeat proofingElectrical and Electronics engineeringExternal wall insulation

Owner:山东隆济时节能科技股份有限公司

Preparation method of compound glassfiber filter felt

InactiveCN106362493AHigh strengthUniform thicknessDispersed particle filtrationFiltration separationWater bathsActivated sludge

The invention discloses a preparation method of a compound glassfiber filter felt, and belongs to the technical field of filter felt materials. The preparation method comprises the following steps: firstly taking acrylonitrile, acrylamide and the like to carry out a water bath reaction, carrying out reconcentration on a petroleum ether extraction organic layer, adding dimethylformamide to carry out spinning, carrying out oxidation and carbonization to obtain standby carbon fiber, taking a liquid supernatant after activated sludge and smashed lotus leaf powder are fermented, then adding nanosilicon dioxide, gamma-aminopropyltriethoxysilane and the like for stirring to obtain wetting fluid, then carrying out needling on a carbon fiber layer and base cloth to prepare the filter felt, then soaking in the wetting fluid, drying and cooling to obtain the compound glassfiber filter felt. According to the preparation method, the carbon fiber is obtained by carbonizing polyacrylonitrile fiber, so that the intrinsic characteristics of a traditional carbon material are maintained, and the high performances such as high strength and high temperature resistance are also improved, and the filter felt prepared through staggered spinning with the glassfiber is more compact in surface; and living examples indicate that the obtained filter felt can work under high temperature for a long period of time, and is high in temperature resistance, high in tensile strength and good in stripping quality for dust.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Screw placing guide plate for spine and manufacturing method of screw placing guide plate

PendingCN108652731AImprove nail placement accuracyAvoid deformationOsteosynthesis devicesSurgical riskEngineering

The invention discloses a screw placing guide plate for the spine and a manufacturing method of the screw placing guide plate. The screw placing guide plate for the spine comprises an attaching plateand screw placing sleeves, wherein the attaching plate comprises an attaching clamping part and guide parts; the attaching clamping part is in attaching clamping with the outer surface of the spine ina screw placing area for the spine of a patient; the guide parts are cylinder-shaped guide holes arranged in the left and right sides of the attaching plate, and then the position and angle of a screw placing channel for placing a screw into the spine of the patient are determined. The screw placing sleeves are fixedly connected with the guide holes in two sides of the attaching plate, the axialdirection is consistent with the axial direction of the guide holes, the bottom ends of the screw placing sleeves are arranged inside the guide holes, and the top ends of the screw placing sleeves arehigher than the guide holes by certain height. In the screw placing surgery, an opening cone is used for drilling inside the spine of the patient along the axial direction of the screw placing sleeves, then the screw placing channel is established, the screw is placed in the spine of the patient along the screw placing channel, and then the screw placing surgery is completed. With the screw placing guide plate for the spine, the screw placing is accurate in position and is safe, the surgical risk can be effectively reduced, the surgical time can be shortened, and the guide plate is convenientfor popularization and application, and has the obvious application value.

Owner:深圳市美创医核医疗科技股份有限公司 +1

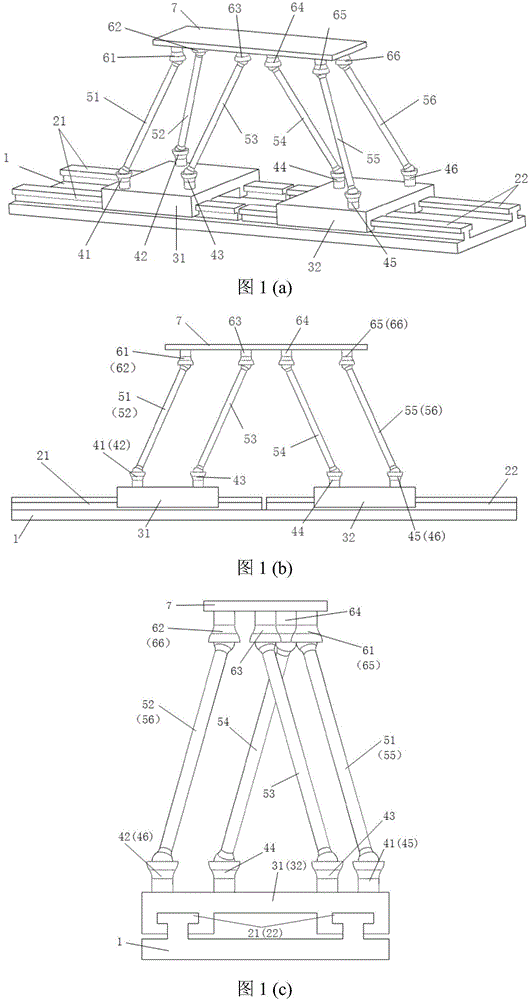

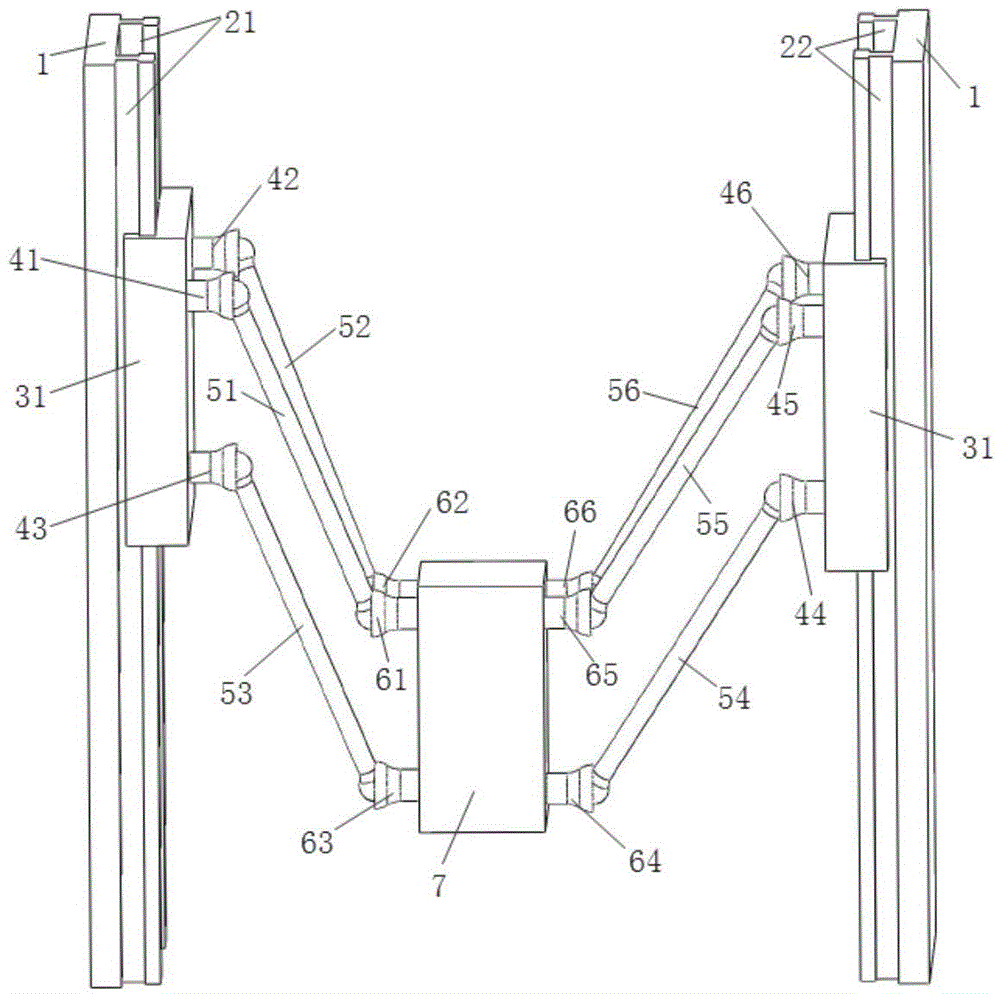

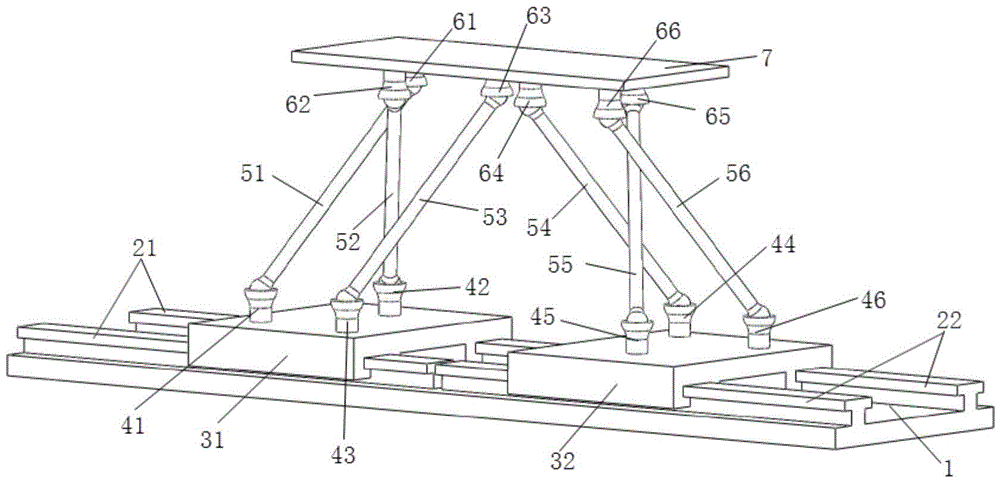

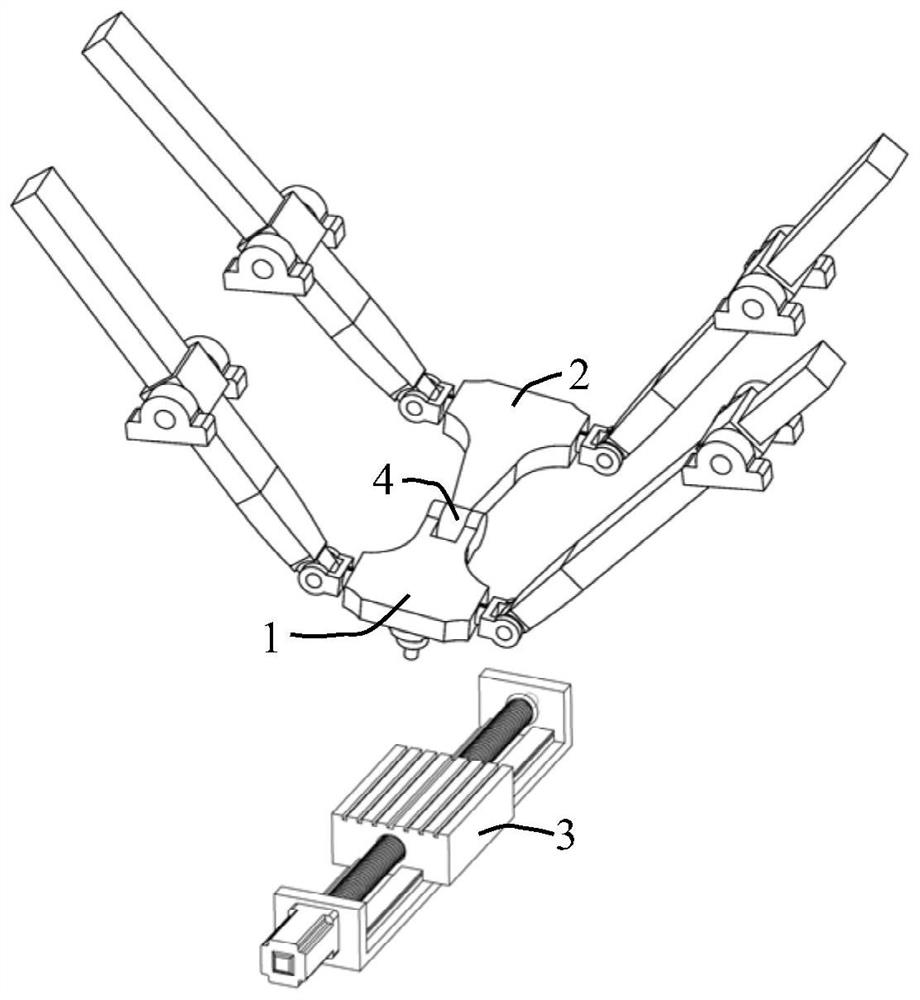

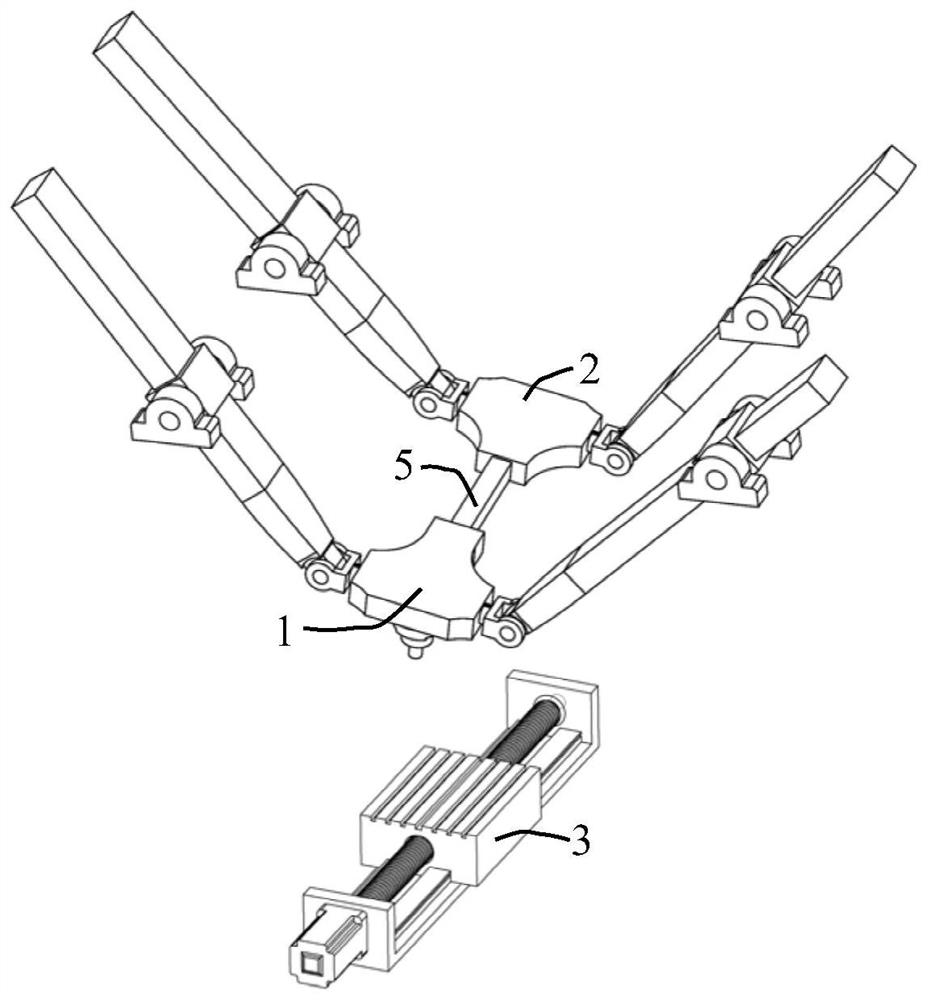

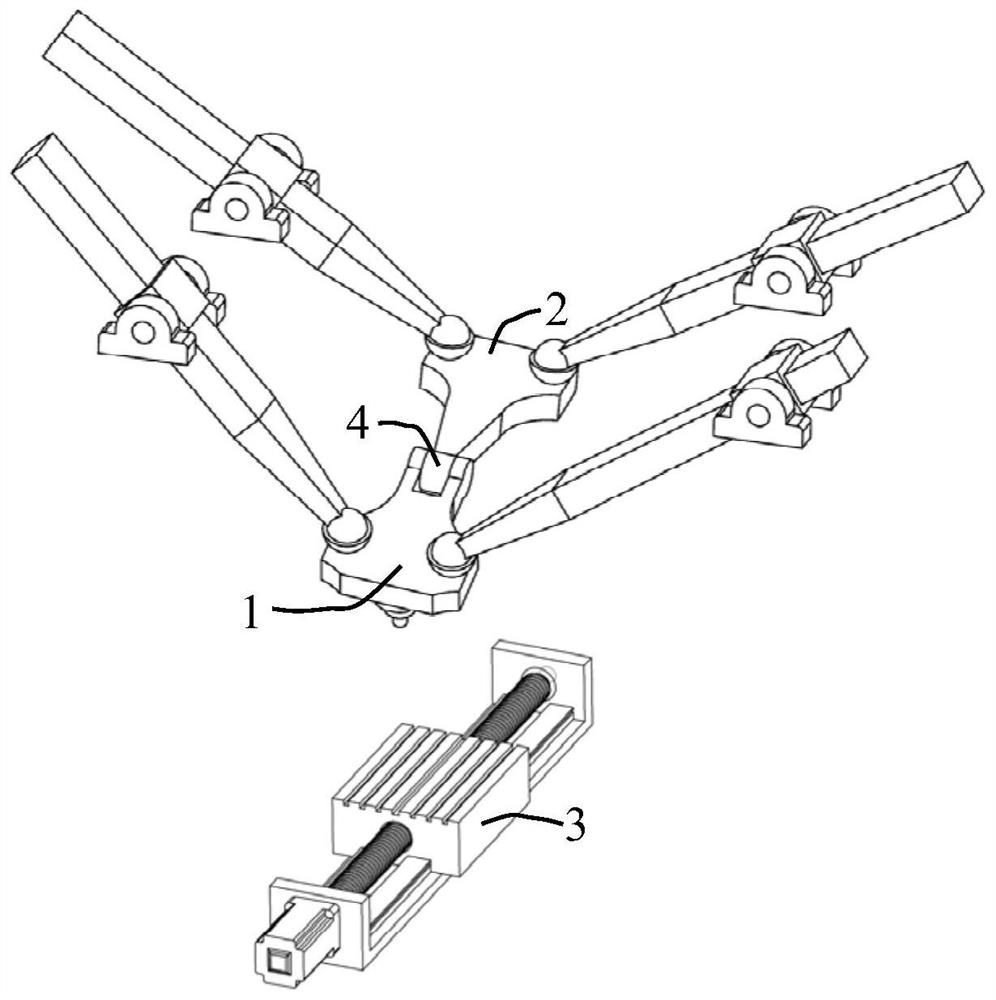

Two-degree-of-freedom plane translational parallel mechanism with passive hinges to be spherical hinges

ActiveCN103600344AGood stiffnessFull play of mechanical propertiesProgramme-controlled manipulatorLarge fixed membersHinge angleTwo degrees of freedom

Owner:NANJING UNIV OF SCI & TECH

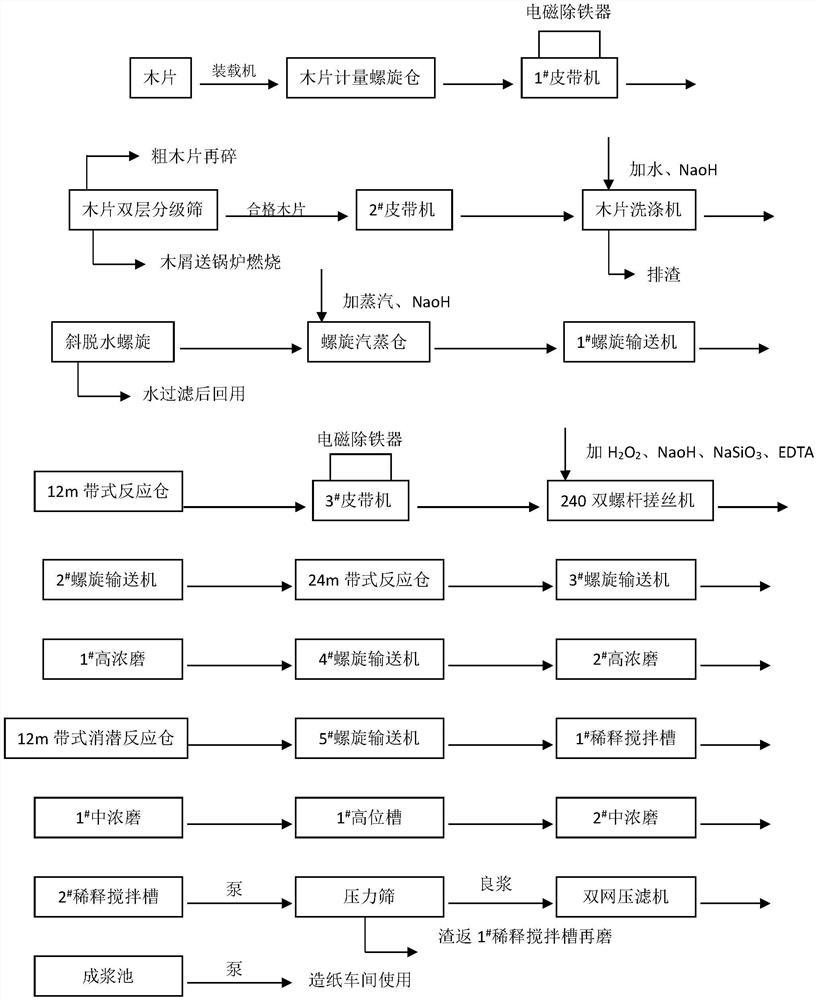

Production process of high-yield poplar chemi-mechanical pulp

PendingCN112878096AImprove surface strengthImprove stiffnessChemical/chemomechanical pulpPulp beating/refining methodsWoodchipsPaper sheet

The invention relates to the field of papermaking pulping, and in particular, relates to a production process of high-yield poplar chemi-mechanical pulp, wherein the production process comprises the steps: S10, metering wood chips; S20, electromagnetically removing iron; S30, screening; S40, washing; S40, carrying out dehydration; S60, carrying out steam softening; S70, carrying out a reaction in a softening reaction bin; S80, electromagnetically removing iron; S90, carrying out thread rolling; S110, carrying out a reaction in a bleaching reaction bin; S120, connecting two stages of high-concentration grinders in series for coarse grinding; S130, carrying out a reaction in a latency reaction bin; and S140, connecting two stages of medium-consistency grinders in series. The method is simple and clear in process flow, low in investment, quick in effect, good in flexibility and high in applicability; the produced pulp is used for preparing medium-grade and high-grade electrostatic copy paper, two-side offset paper, patterned paper, water color paper, water-absorbing base paper, cup paper, light paper and the like, has good paper surface strength, bulk and air permeability superior to those of full-chemical reed pulp paper, and is flat, smooth, good in stiffness and good in printing property; therefore, the poplar chemi-mechanical pulp production process is an effective way for improving product structures, improving product grades and increasing economic benefits in small and medium-sized enterprises.

Owner:江西中竹生物质科技有限公司

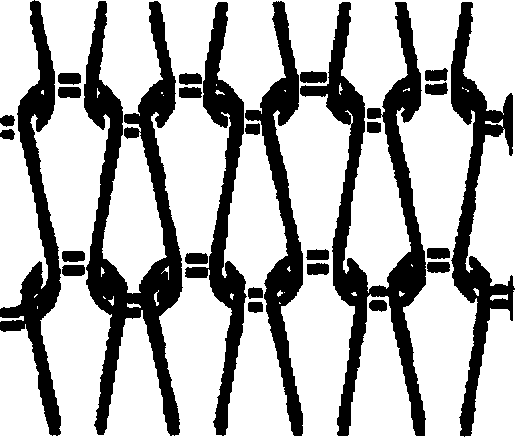

Production process of 200-220g/m<2> spun silk knitted garment fabric

ActiveCN104164740AAvoid the disadvantages of soft and closeGuaranteed strongSucessive textile treatmentsWeft knittingProcess specificationEngineering

The invention discloses a production process of 200-220g / m<2> spun silk knitted garment fabric. The production process comprises the following steps that 120N / 2 barreled spun silk plied yarn and single-face plain weave are adopted in the process specification design, and the gram weight, transverse density and longitudinal density of fabric for printing are 200 G / M<2> to 220 G / M<2>, 62 meshes / 5 cm and 82 meshes / 5 cm respectively; in the spinning barreling procedure, the twist of cabling is 700 T / m to 800 T / m, and the weight of an tension sheet in the spooling process is 18 g to 22 g; in the knitting procedure, 18G single-face circular machine knitting is adopted, a silk yarn lubricating device containing 22# knitting emulsified oil is arranged at the position of a yarn guide hole of a creel, looping is carried out in a double-yarn feeding and double-yarn knitting mode, the yarn feeding tension is 4 CN to 5 CN, the yarn conveying length of a yarn conveying disc is 16.5 cm / 50 stitches, the number of knitting ways is 42, and the coiling speed of raw gray fabric volumes is 20 mm / turn; the refining procedure has the steps of primary refining, oxygen bleaching, cleaning, whitening and normal-temperature cleaning in sequence. After the production process is adopted, the fabric is even in knitting looping, small in knot, few in flaw, high in cloth cover flatness and good in moisture absorption, and the obtained braided fabric is beneficial for even printing and coloring, and can be adopted as the fabric of outerwear and underwear.

Owner:DALI SILK ZHEJIANG

Fine punching mold frame

The precise punching die frame has U-shaped main body; upper punching pin, upper cover, pre-stressed spiral spring, hold-down die sleeve and raised die handle mounted onto the upper arm of the main body; and work bench mounted onto the lower arm of the main body. It features that the hold-down die sleeve is mounted onto the upper arm via roller bearing and fixed lining in movable fit; and the upper hydraulic cavity formed with the raised die handle as plunger and the hold-down die sleeve as cylinder is connected to the upper high pressure sealed container.

Owner:JILIN UNIV

Preparation method of all-cotton high-count high-needle gage one-side weft plain knitted fabric

InactiveCN108547040AGood dimensional stabilityGood stiffnessShrinkingMercerising of indefinite length fabricsSizingYarn

The invention relates to a preparation method of an all-cotton high-count high-needle gage one-side weft plain knitted fabric. The method comprises the steps that a 60 / 1 tight spun yarn serves as a raw material, a one-side high-speed multi-track knitting machine serves as a weaving machine, preshrinking treatment is firstly carried out after weaving, then mercerization, dyeing and sizing are carried out to obtain the all-cotton high-count high-needle gage one-side weft plain knitted fabric. The preparation method of the all-cotton high-count high-needle gage one-side weft plain knitted fabrichas the advantages that the weaving machine is reasonably selected, the dyeing technology is reasonable, the mercerization technology and sizing technology are ingenious, the prepared fabric is light,thin and soft, bias-filling does not exist at all, the size stability is good, the stiffness, smoothness and rebound resilience are excellent, and the all-cotton high-count high-needle gage one-sideweft plain knitted fabric is a good choice for manufacturing slap-up women's wear.

Owner:NINGBO BETTER TEXTILE&GARMENTS

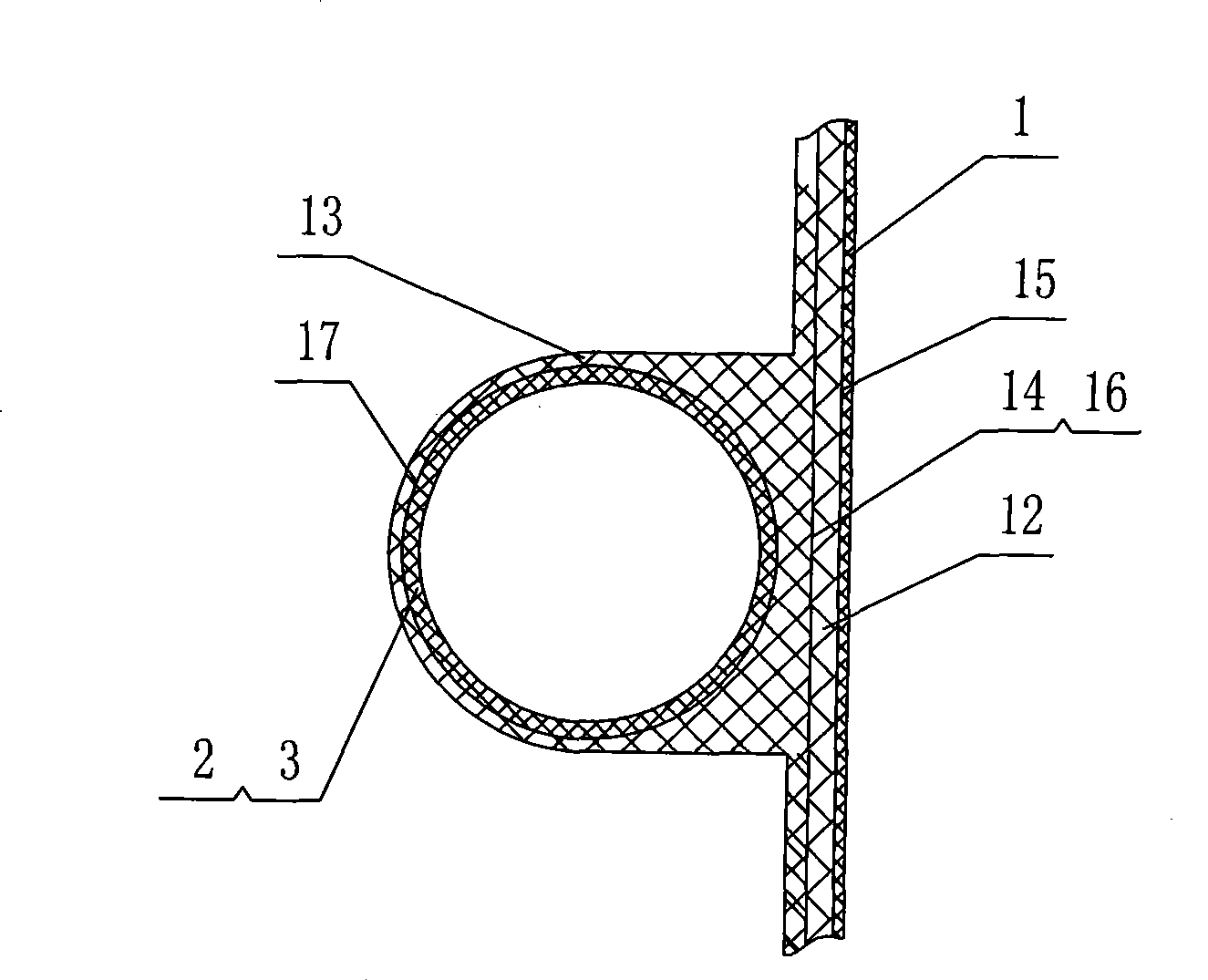

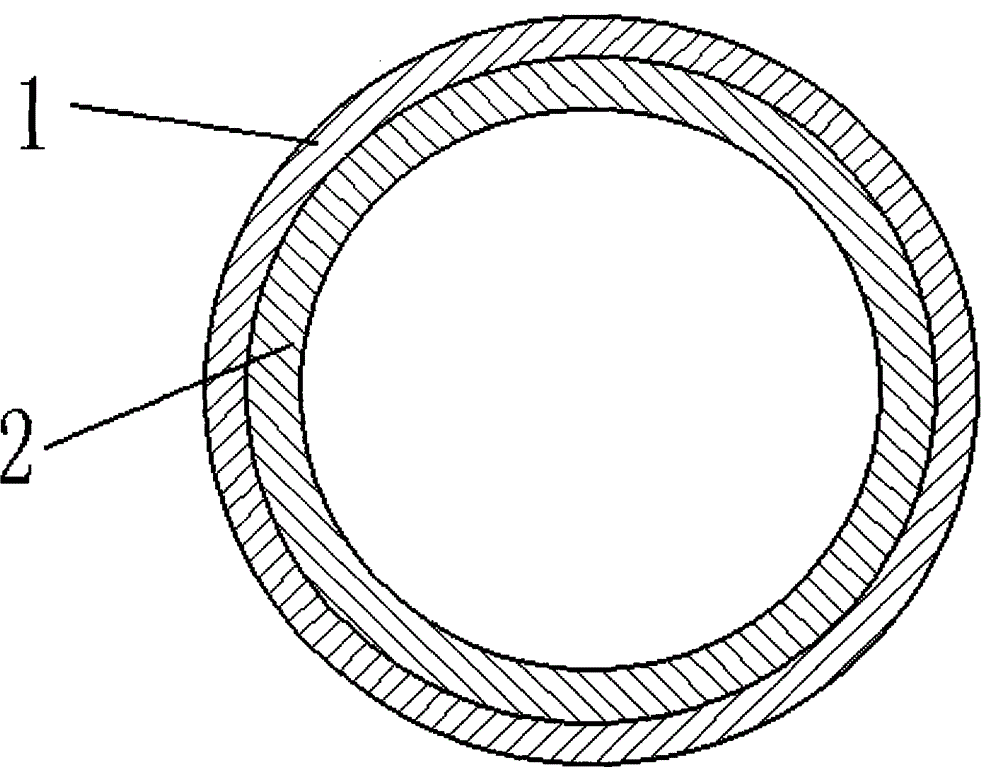

Anti-collision polytetrafluoroethylene composite tube

InactiveCN104875429ASolve the anti-collision gap is too largeGood stiffnessSynthetic resin layered productsCarbon fiber compositeMaterials science

The invention discloses an anti-collision polytetrafluoroethylene composite tube. An anti-collision layer is a composite material protecting layer, a composite material is prepared by compounding resin and carbon fiber or aramid fiber; the anti-collision layer and a polytetrafluoroethylene composite tube are cured to form an integral structure through resin. According to the anti-collision polytetrafluoroethylene composite tube provided by the invention, the composite material is spread on the surface of the polytetrafluoroethylene tube, so that the problem of poor abrasion resistance of the surface of a polytetrafluoroethylene plate can be greatly solved; the polytetrafluoroethylene tube is well protected by utilizing high rigidity of the carbon fiber composite material or the aramid composite material, so that the polytetrafluoroethylene composite tube has anti-collision characteristic. The anti-collision polytetrafluoroethylene composite tube provided by the invention has good abrasion resistance and anti-collision property, adopts a simple production process, is low in cost and has good applicability.

Owner:王兆华

Anti-settlement electric power protecting pipe with ultra toughness and low temperature resistance characteristics

The invention provides an anti-settlement electric power protecting pipe with ultra toughness and low temperature resistance characteristics, and the product is prepared by the following components by weight ratio: 100 parts of three-type PVC resin, 3-5 parts of stabilizing agents, 2-4 parts of antishock type acrylic acid ester, 3-5 parts of chlorinated polyethylene, 8-15 parts of modified rubber, 1-2 parts of lubricants, 3-5 parts of processing auxiliary agents and 0-5 parts of masterbatch. The 100 parts of three type PVC resin are used as a main material, antishock type acrylic acid ester and modified rubber and a plurality of antishock modified material are cooperative for toughness modification, and pipeline products produced by the die has the following characteristics: 1. good toughness with fracture percentage elongation which is more than 350; 2. good rigidity, which is obviously higher than common polyolefin tubings; 3. high recovery rate which is above 70%; 4. strong acid and alkali resistance capability, which has little soda acid influence to underground environment with environmental protection and without pollution because the components do not have inorganic filling materials; 5. the inner and outer surface are slide with small friction resistance; 6. the aging resistance performance is good.

Owner:ZHEJIANG FEILONG PIPE

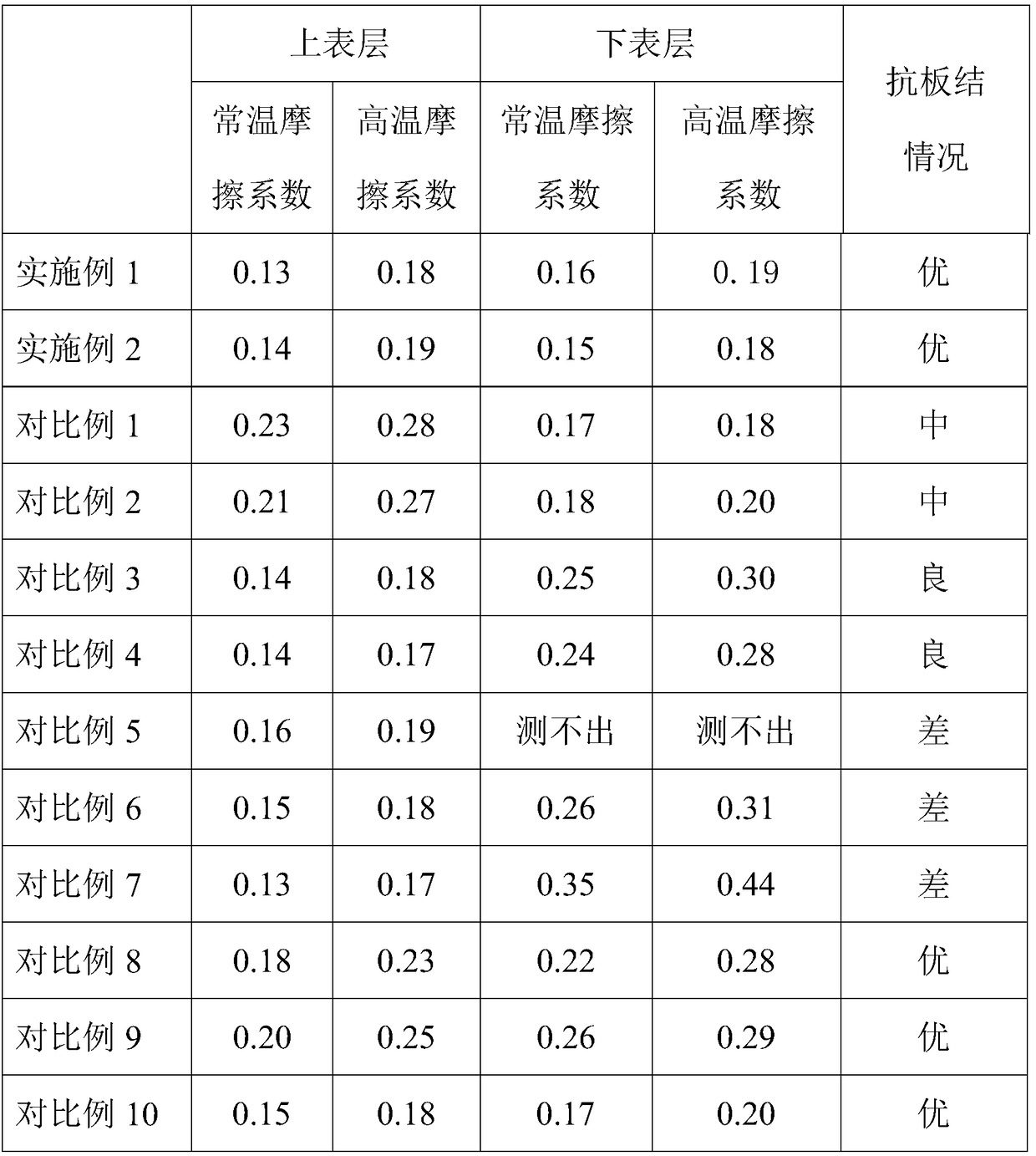

Three-layer co-extrusion packaging film and preparation method thereof

ActiveCN111483195AGood stiffnessSmooth film surfaceFlexible coversWrappersManufacturing engineeringMechanical engineering

The invention relates to the field of container bag packaging, in particular to a three-layer co-extrusion packaging film and a preparation method thereof. The three-layer co-extrusion packaging filmcomprises an inner layer, a middle layer and an outer layer which are sequentially arranged from inside to outside. The three-layer co-extrusion packaging film has the advantages of being good in stiffness, smooth in film surface, easy to open, resistant to high-temperature materials and the like, the high-temperature-resistant temperature can reach 115 DEG C, the requirements of enterprises withspecial downstream packaging requirements can be met, and compared with a traditional flexible freight bag lining bag, the three-layer co-extrusion packaging film can be used for meeting the high-temperature material filling requirement and cannot cause the condition that materials are not easy to discharge due to inner bag adhesion.

Owner:GUANGZHOU XINWEN PLASTIC

Preparation method of intelligent sanitary product

InactiveCN111134965AGood stiffnessEasy compoundMedical applicatorsSanitary towelsProcess engineeringReproductive system

The invention relates to the field of sanitary products, provides a preparation method of an intelligent sanitary product, and solves the problem that sanitary products in the prior art cannot remindhealth of a female reproductive system in daily life. The preparation method comprises the following preparation steps: 1) carrying out on-line uncoiling transmission on an air permeable base film; 2)laminating a water-absorbing material layer on the permeable base film on line; 3) laminating a color-changing chip on the water-absorbing material layer on line; and 4) laminating a pure cotton surface layer on the surface of the article laminated with the color-changing chip on line.

Owner:FUJIAN HENGAN HLDG CO LTD +1

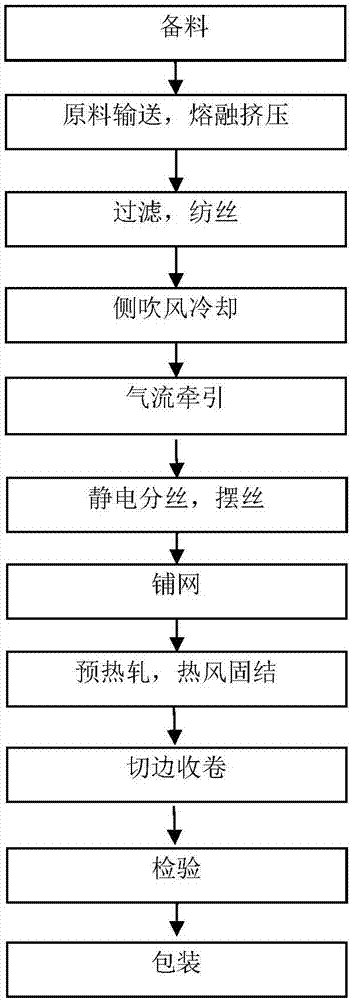

Production method of polypropylene spunbonded hot wind consolidation geotextile

InactiveCN107988714AGood breathability and water permeabilityGood stiffnessArtificial thread manufacturing machinesGeotextilesGeotextilePolypropylene

Disclosed is a production method of polypropylene spunbonded hot wind consolidation geotextile. The production method comprises the following steps of 1, preparing material; 2, conveying, melting andextruding raw material; 3, filtering and spinning; 4, crow air blowing cooling; 5, air drafting; 6, carrying out electrostatic devillicate and pendulum wire; 7, lapping; 8, pre-hot-rolling, and performing hot wind consolidation; 9, trimming and rolling; 10, inspecting and packing; 11, packing. The production method of the polypropylene spunbonded hot wind consolidation geotextile overcomes some disadvantages of needle-punched nonwoven fabric. Moreover, a polypropylene raw material is used, and the geotextile has the advantages of being good in air permeability, water permeability and rigidity,foldable, smooth in surface, good in compactness, free of any chemical bonding agents, more acid and alkali resistant, corrosion resistant, mothproof, antioxidative and the like, which makes the geotextile a quite ideal geotextile material.

Owner:大连华阳百科科技有限公司

Five-degree-of-freedom robot capable of being used for hardware grinding

PendingCN111941204ASimple structureGood stiffnessEdge grinding machinesGrinding carriagesMechanical engineeringRoboty

The invention relates to the technical field of robots, and aims to provide a five-degree-of-freedom robot capable of being used for hardware grinding. The robot has the advantages of being good in rigidity, high in precision, good in dynamic characteristic and the like. According to the technical scheme, the five-degree-of-freedom robot capable of being used for hardware grinding comprises a movable workbench and a rack; and the five-degree-of-freedom robot is characterized by further comprising a combined platform and four first branches, wherein the combined platform is formed by connectinga first tail end platform and a second tail end platform and provided with a grinding head, and the four first branches are connected between the rack and the combined platform in parallel; each first branch comprises a rack revolute pair, a first sliding pair and a first hooke joint or a ball pair which are sequentially connected between the rack and the combined platform, and the first slidingpair is formed by matching a first sliding block with a guide rod; and in the four first branches, two of the four first branches are connected between the rack and the first tail end platform, and the other two first branches are connected between the rack and the second tail end platform.

Owner:ZHEJIANG SCI-TECH UNIV

High operation lightweight 18micrometer BOPP cigarette packaging film and preparation method thereof

ActiveCN108943946AImprove compaction resistanceGood stiffnessSynthetic resin layered productsFlat articlesMicrometerSurface layer

The invention discloses a high operation lightweight 18micrometer BOPP cigarette packaging film and a preparation method thereof. The core layer of the packaging film selects a rigid increasing masterbatch with a benzene ring structure and a diester combined antistatic masterbatch, the upper surface layer selects a high viscosity silicone bead super-smooth masterbatch and an inorganic silica anti-adhesion masterbatch, the lower surface layer selects the high viscosity silicone bead super-smooth masterbatch and a composite anti-adhesion masterbatch, etc. The series of formula design enables theoperability and stability of the 18micrometer cigarette film comparable to those of 21micrometer cigarette films. On the basis of the high operability and high hardening resistance of the newly invented film, the thickness of the product is finally designed as 18 micrometers, thus changing the general tacit way of making up for quality with thickness in the industry, realizing the lightweight requirement put forward by cigarette factories many years ago, and achieving the original intentions of environmental protection and saving in the cigarette film industry.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

Skiing motion simulation device

InactiveCN112843652AIncreased Strength and RigidityGood stiffnessSport apparatusLinear driveClassical mechanics

The invention relates to a skiing motion simulation device which comprises a fixed platform, a movable platform and three motion branches, the fixed platform and the movable platform are both of frame structures, the movable platform comprises a motion frame, synchronous belt modules and snowboards, the synchronous belt modules are symmetrically arranged on the motion frame, the snowboards are arranged on the synchronous belt modules, the three motion branches are all arranged between the fixed platform and the movable platform, each motion branch comprises a linear driving device, a spherical hinge and a rotating shaft, the first end of the linear driving device is connected with a fixed platform spherical pair through the spherical hinge, and the middle part of the linear driving device is connected with a movable platform rotating pair through the rotating shaft. The device can simulate the motion state during skiing, enables an experiencer to achieve skiing actions on the snowboards, combines somatosensory, actions and vision with auxiliary devices such as a vision module and an air blower, can be used for entertainment, professional skiing training and the like, and has positive significance for skiing training.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com