Production process of high-yield poplar chemi-mechanical pulp

A production process and high-yield technology, which is applied in the field of papermaking and pulping, can solve the problems of large production capacity, shortage of raw materials, and incompatibility, and achieves the effect of strong applicability, smooth and smooth paper, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

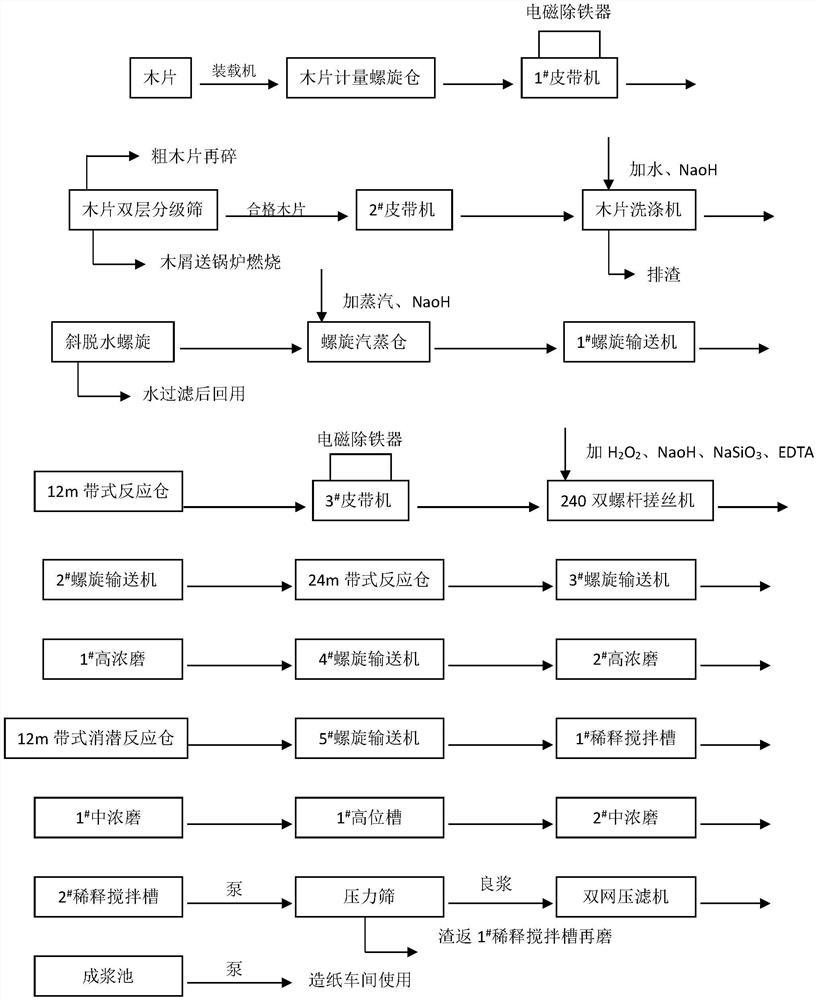

[0038] Such as figure 1 Shown, the specific structure of the present invention is: a kind of high-yield poplar chemical mechanical pulp production process, including S10, wood chips metering; S20, electromagnetic iron removal; S30, sub-sieving; S40, washing; S40, dehydration; S60, steam Softening; S70, softening reaction chamber reaction; S80, electromagnetic iron removal; S90, silk rubbing; S110, bleaching reaction chamber reaction; Medium-level thickening mill; S150, pressure sieve pulp removal and S160, double screen filter press, S10, wood chip metering: mainly stored in the wood chip metering spira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com