Patents

Literature

70results about How to "Process flow is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial pilot test performance testing device and industrial pilot test performance testing method for SCR (selective catalytic reduction) denitration catalyst

PendingCN105628857AVerify activityVerification selectivityChemical analysis using catalysisAir preheaterFlue gas

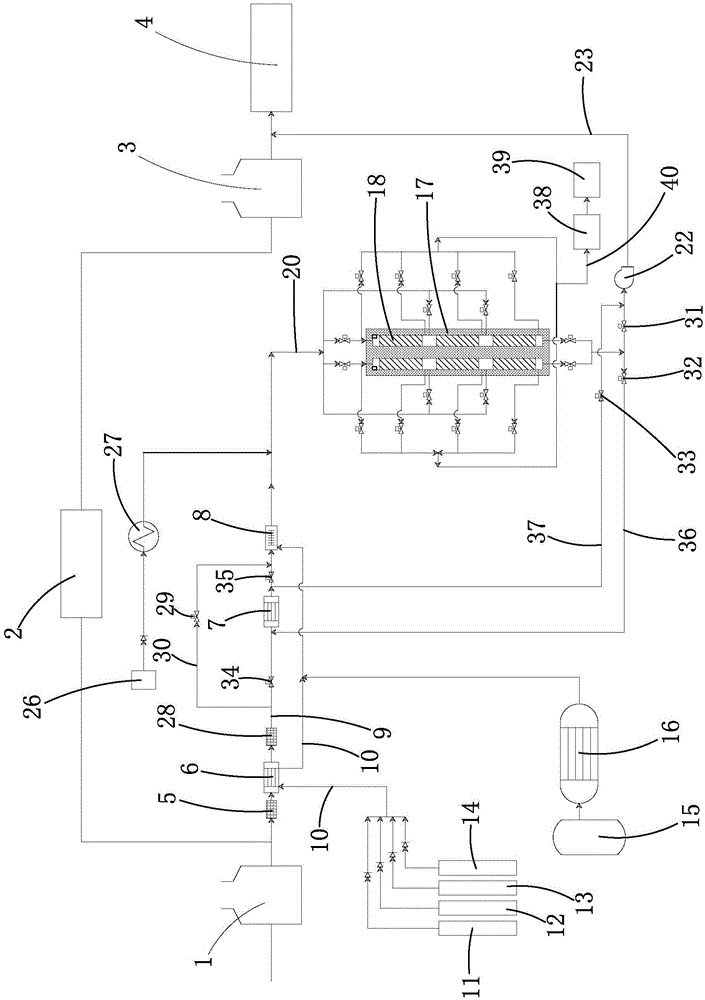

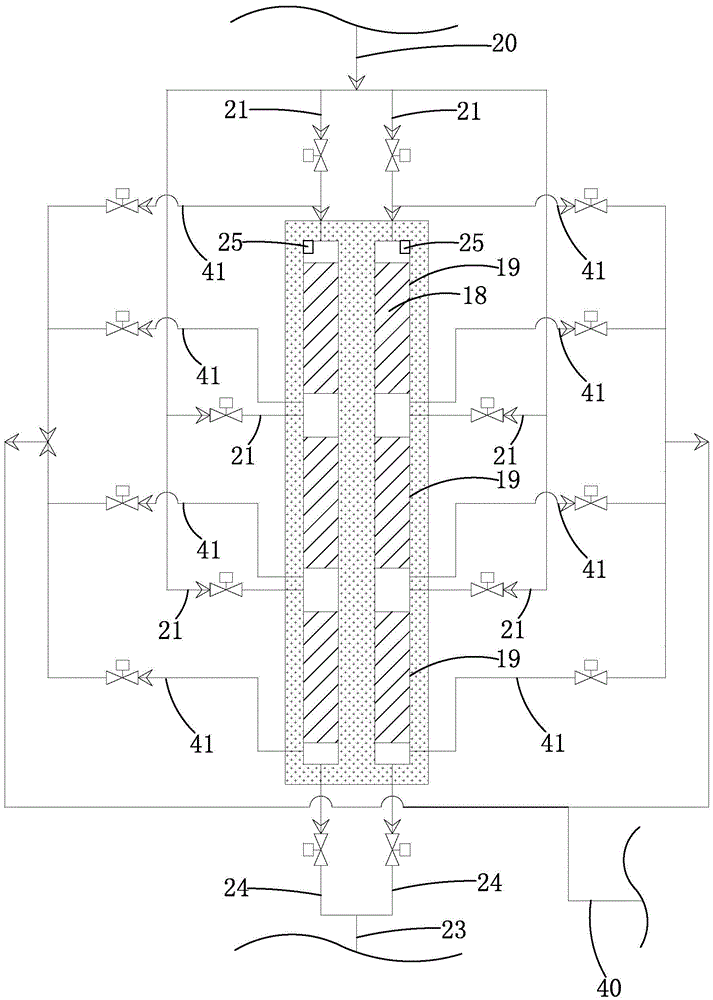

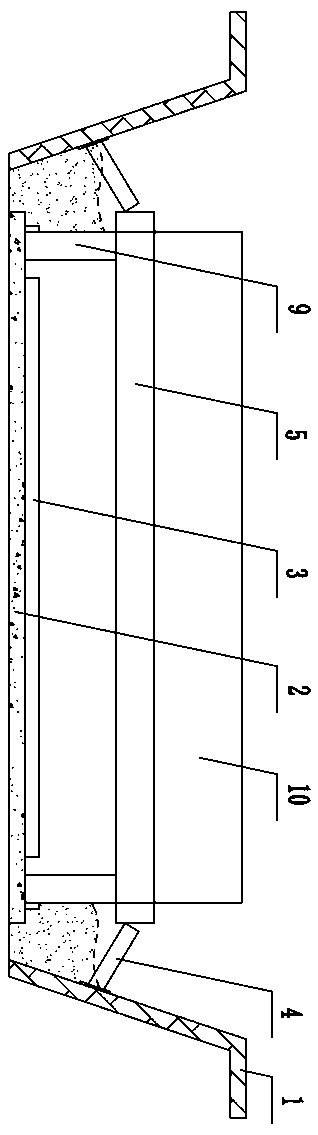

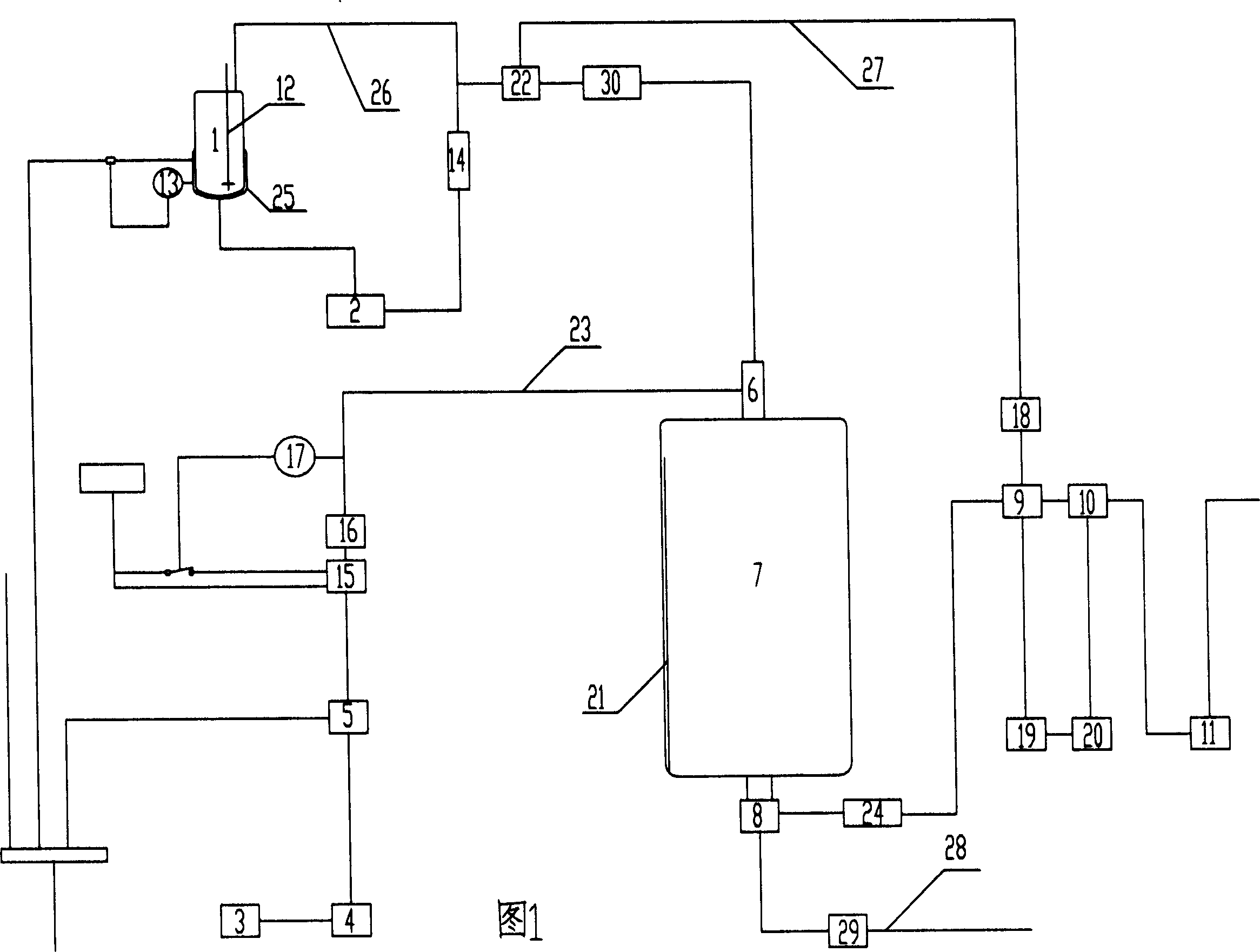

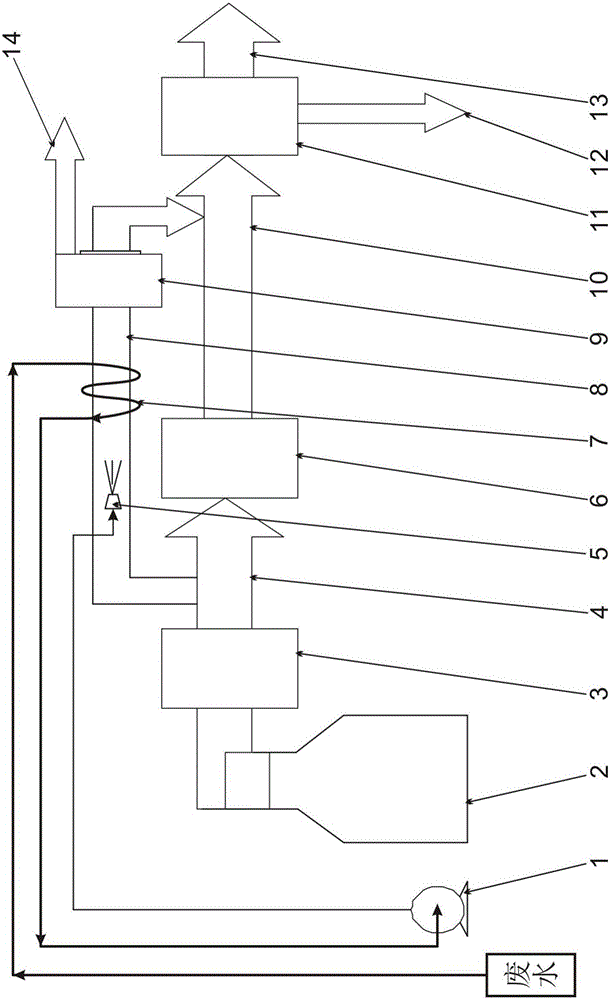

The invention relates to an industrial pilot test performance testing device and an industrial pilot test performance testing method for an SCR (selective catalytic reduction) denitration catalyst, aiming to solve the problem that an existing denitration catalyst testing device is incapable of simulating influences of load change on a catalyst during actual running. The industrial pilot test performance testing device comprises a testing device body comprising a gas distribution portion, a reaction portion and a measurement portion, wherein the gas distribution portion is communicated with a gas outlet of a coal economizer, and the reaction portion is communicated with a gas outlet of an air preheater. The testing device body achieves gas distribution and reaction of boiler tail gas through the gas distribution portion and the reaction portion, and the measurement portion is used for collecting and analyzing sample gas. The testing device body is arranged in a boiler tail gas system during actual industrial production, and the boiler tail gas serving as test gas of the testing device body enables flue gas for testing to have physicochemical and process properties of actual flue gas to produce influencing substances, so that reaction between the catalyst in the reaction portion with the flue gas for testing is guaranteed, and accurate and reliable test data are provided for research on running of the existing catalyst under the conditions of different temperatures and flue gas components.

Owner:ZHEJIANG ZHENENG TECHN RES INST

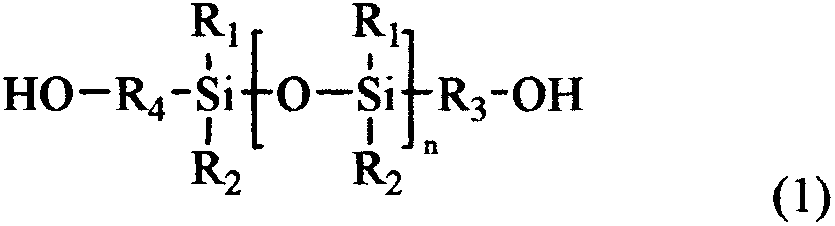

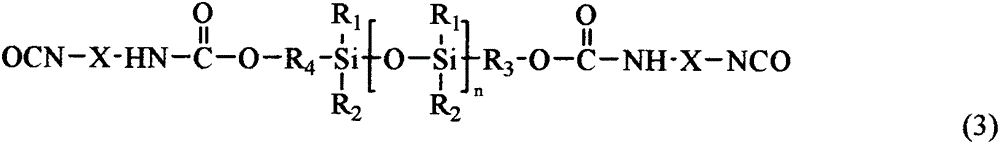

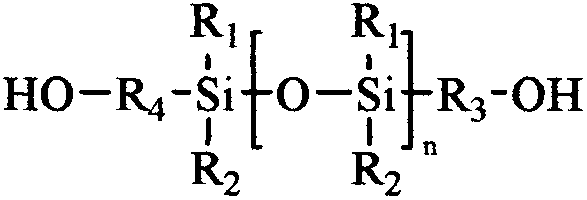

Polysiloxane-polyurethane gel material and preparation method thereof

ActiveCN102942667AImprove buffering effectLow compression setSimple Organic CompoundsChemical reaction

The invention relates to a polysiloxane-polyurethane gel material and a preparation method thereof. The material is the polysiloxane-polyurethane gel material capable of being used as a vibration and noise reduction buffering agent of an underwater acoustic device. The material has good environmental friendliness and good buffering capacity, has no migration or exudation of plasticizer when being used for a long time, and has small compressive deformation. The material has no plasticizer, and enhances buffering capacity by introducing short-chain polysiloxane. Besides, organic compound participates in the chemical reaction of the gel formation, to form a crosslinked macro-molecule gel. No migration or exudation of plasticizer when the material is used for a long time. The material has good environmental friendliness.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

All-cotton warp elastic fabric and weaving method thereof

ActiveCN102140720AProcess flow is clearEasy to operateHeating/cooling textile fabricsWoven fabricsYarnPulp and paper industry

The invention discloses an all-cotton warp elastic fabric and a weaving method thereof. The weaving method comprises the following steps of: 1. winding warp yarn: twisting wrap yarn to reach super high twist; 2. shaping the warp yarn: steaming the warp yarn in a yarn steaming device with high-temperature steam; 3. warping: warping the warp yarn with single tooth single yarn; 4. weaving: leaving a space for the warp yarn to rotate left and right on a woven grey fabric by using high-twist yarn in two twisting directions; and 5. post treating: when the grey fabric fully contracts, drying the grey fabric with an ironing machine under a condition of no tension to obtain the all-cotton warp elastic fabric. By using the weaving method provided by the invention, a real all-cotton warp elastic fabric can be woven, and the method is clear in process and easy to operate.

Owner:CHANGZHOU DL MEDICAL & HEALTH EQUIP

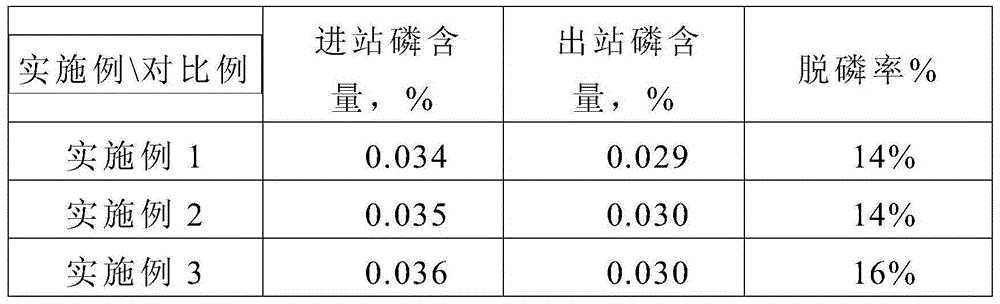

LF furnace shallow dephosphorization refining method

The invention discloses an LF furnace shallow dephosphorization refining method. The method comprises the following steps that firstly, after molten steel enters an LF furnace, a steel ladle bottom blowing pipe and an external oxygen source are connected, bottom oxygen blowing is carried out, and bottom argon blowing is carried out in the whole refining process; secondly, current delivery and slagging are carried out; thirdly, after slag is molten thoroughly, power is cut off, the bottom argon blowing flow is increased to 800-850 NL / min, stirring is carried out, and dephosphorization is carried out; and fourthly, after dephosphorization is finished, lime is added so as to prevent rephosphorization. Dephosphorization is finished in the LF furnace, molten steel furnace returning is avoided, and the steel making production cost is reduced. Converter terminal point slag returning is mainly adopted to finish dephosphorization, secondary utilization of resources is effectively achieved, and good social benefits and economic benefits are achieved. The molten steel dephosphorization task can be finished only by adopting fluorite, ore, fluorite powder and other conventional materials as the auxiliary dephosphorization materials, the medicament input is little, and cost is saved; and the technology process is simple and clear, operability is high, and control is easy.

Owner:武钢集团有限公司

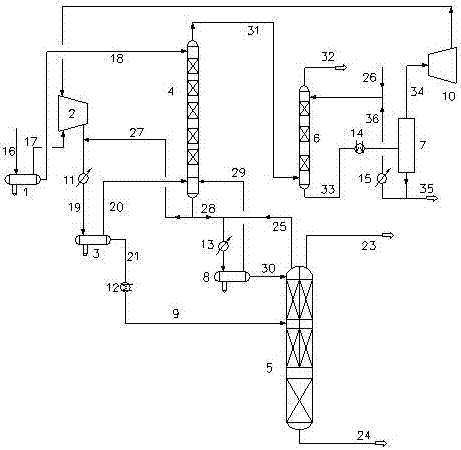

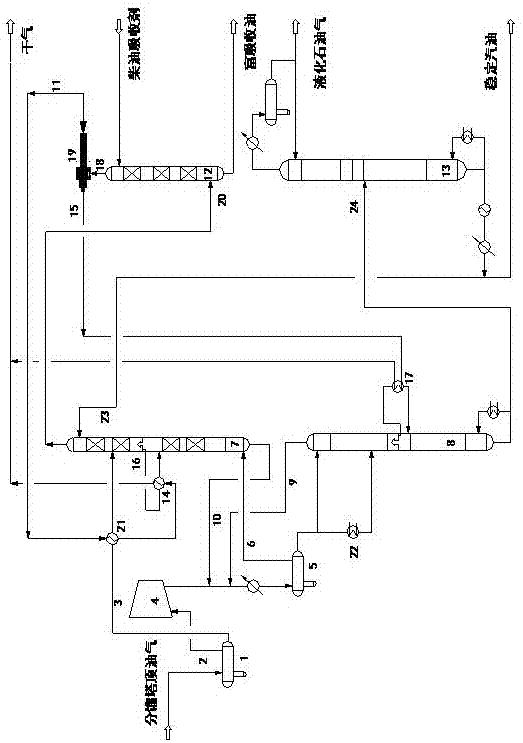

Absorption-stabilization technology and system for refining

ActiveCN107298988AReduce the amount of gas phaseReduce loadGaseous mixture working upGas compressorDesorption

The invention provides an absorption-stabilization technology and system for refining. The absorption-stabilization system comprises a gas-liquid balance tank, a rich gas compressor, a rich gas balance tank, an absorption tower, a desorption-stabilization dividing wall tower, a re-absorption tower, a regeneration tank, a desorption gas balance tank and a vacuum pump. The invention further provides the absorption-stabilization technology utilizing the absorption-stabilization system. By adopting the absorption-stabilization technology and system, provided by the invention, the concentration of liquefied gas in dry gas is greatly reduced; and meanwhile, the yield of catalytic gasoline and the liquefied gas can be improved and the energy consumption of the system is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

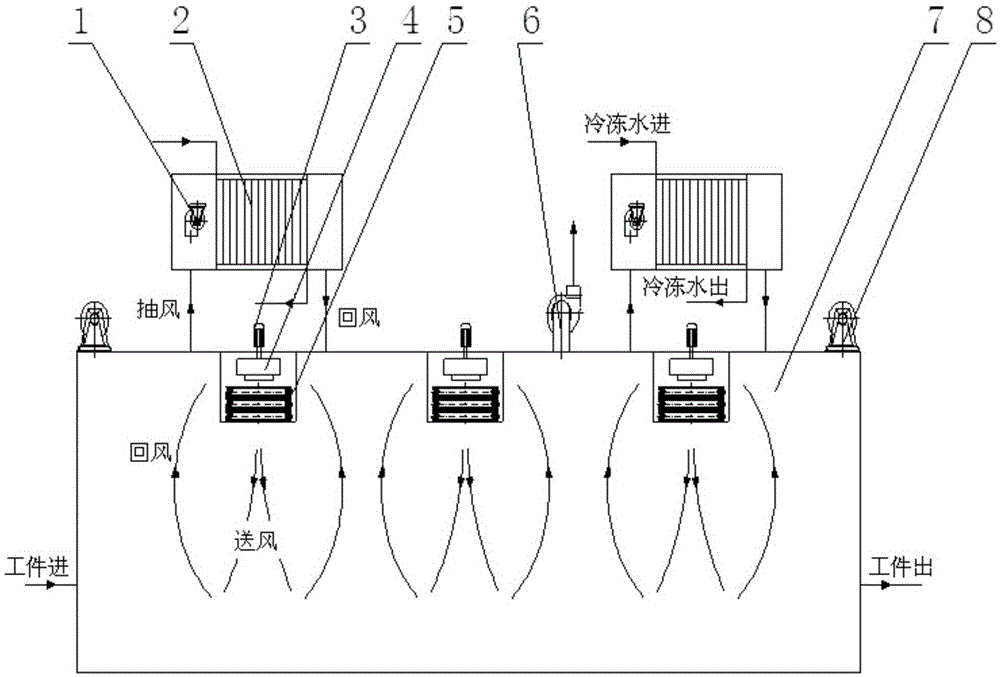

Water-based paint drying system and drying method

InactiveCN105268612AReduce the temperatureReduce spillagePretreated surfacesCoatingsWater basedSolid wood

The invention discloses a water-based paint drying system and a water-based paint drying method suitable for solid wood furniture. A hot air cyclic heating device is arranged in a drying room and a dehumidifying device is arranged outside the drying room, so that control on a heating temperature and humidity in the drying room is realized; a plurality of groups of hot air cyclic heating devices are uniformly distributed on the top in the drying room; a circulating fan is utilized, so that the drying room has cyclic convection air therein, and therefore, a drying speed is increased, more importantly, solid wood furniture is effectively prevented from defects such as pin holes, cracks, color difference, and the like, furniture drying quality is guaranteed, and economic benefits are improved.

Owner:CMCU ENG

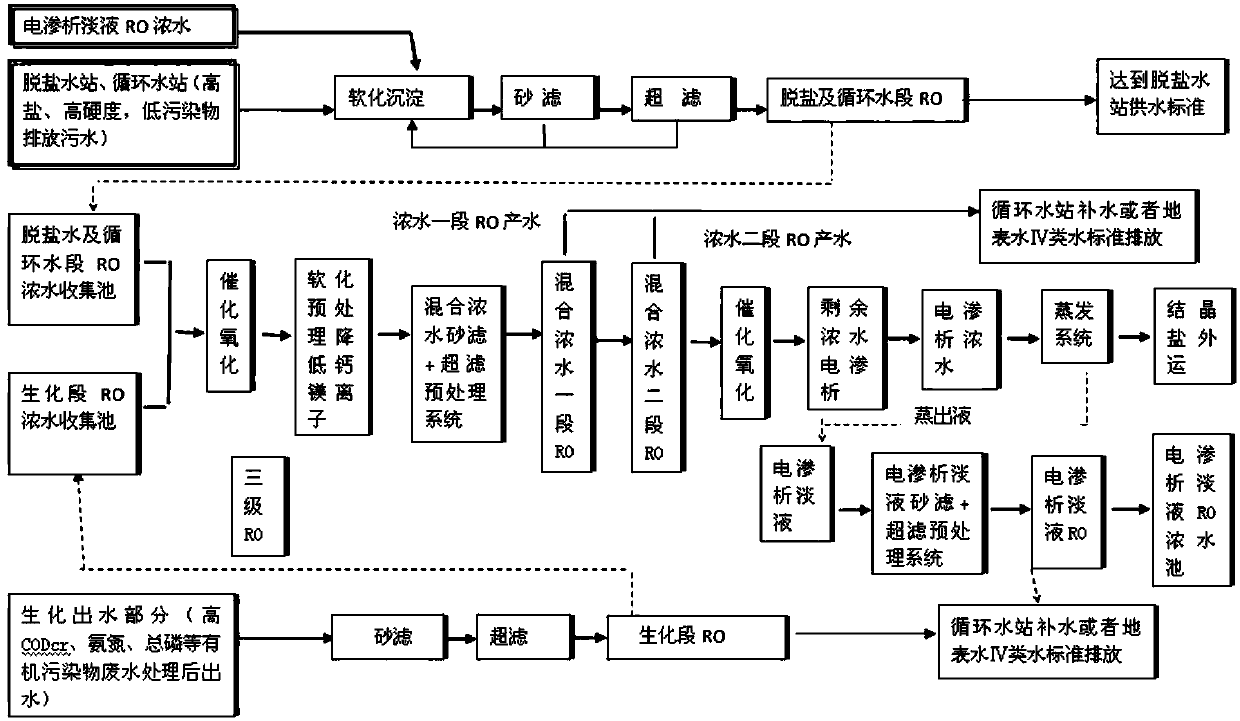

Wastewater treatment zero-emission technology for chemical enterprise and park

PendingCN107857438ALower water costsProcess flow is clearTreatment involving filtrationWater softeningChemical industryUltrafiltration

The invention discloses a wastewater treatment zero-emission technology for chemical enterprise and park. According to the technology disclosed by the invention, the desalted water and the circulatingwater are treated by a treatment technology of 'softening precipitation, sand filtration, ultrafiltration and reverse osmosis'; the domestic and production wastewater is subjected to physiochemical and biochemical treatment while the effluent is treated by a treatment technology of 'sand filtration, ultrafiltration and reverse osmosis'; after that, the concentrated water after the two treatment is treated by a treatment technology of 'catalytic oxidation, membrane treatment, electrodialysis and the like'; the treated water is partially recycled by the enterprise while the rest part is discharged up to standard. According to the technology disclosed by the invention, the wastewater of different natures is treated separately according to the nature; by organically combining a chemical watertreatment technology, a membrane water treatment technology and an evaporation technology, the process flow is clear, the operation is simple and convenient, the recycling rate of the system is high,and the problems of difficult treatment of mixed wastewater and high water consumption of the enterprise are solved in the chemical enterprise and park. The technology disclosed by the invention hashigh recycling rate and realizes zero-emission treatment on water.

Owner:ZHEJIANG BEROOT ENVIRONMENTAL PROTECTION TECH CO LTD

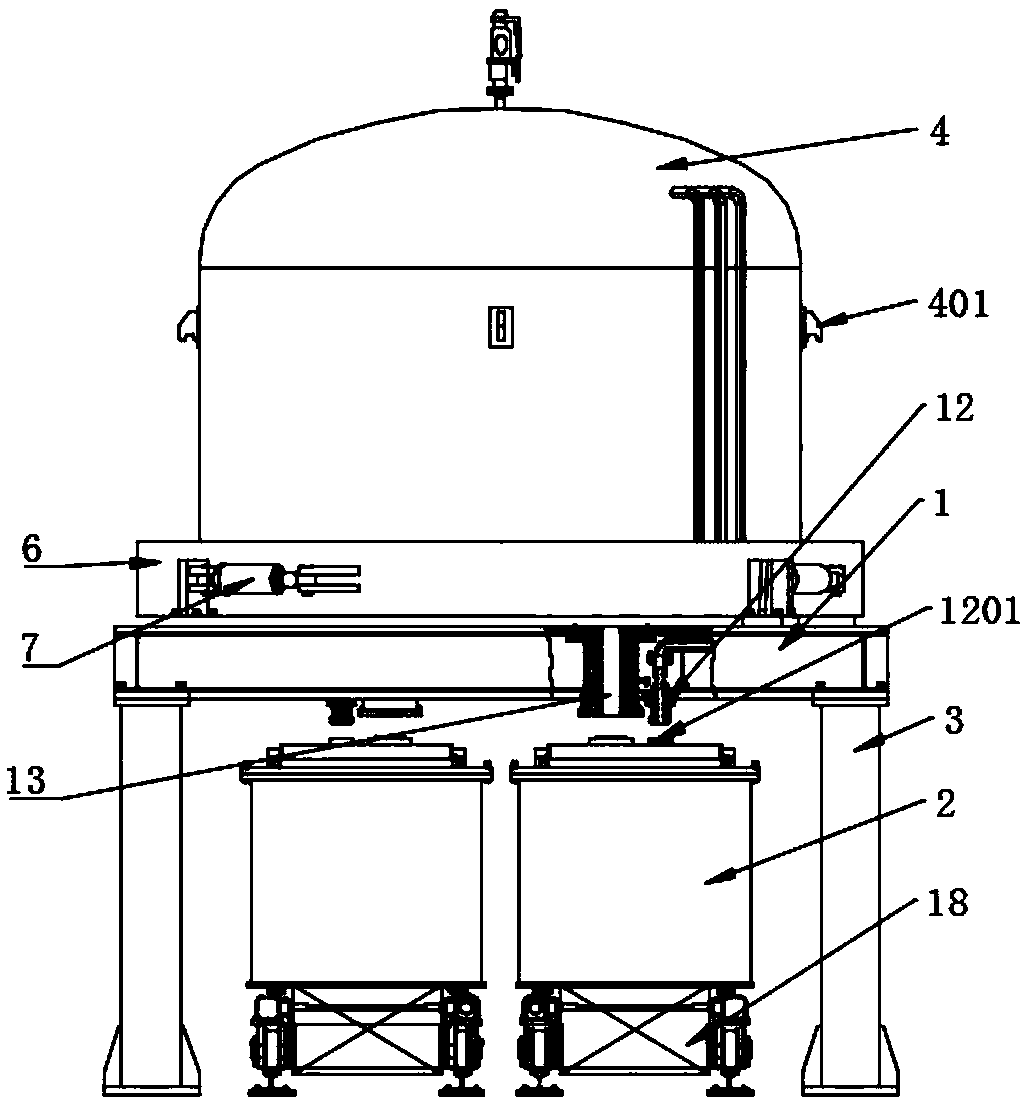

Melt liquid raising device for multi-station parallel-connection pressurizing cast device

InactiveCN108788093AGuaranteed processing temperatureGuaranteed safe operating temperatureButt jointEngineering

The invention discloses a melt liquid raising device for a multi-station parallel-connection pressurizing cast device. The melt liquid raising device is characterized by comprising a liquid raising pipe upper section, a liquid raising pipe lower section and a heat preserving cover arranged on the liquid raising pipe upper section in a wrapping manner. The liquid raising pipe upper section is connected with a liquid filling opening. The liquid raising pipe lower section extends in a melt partially. The liquid raising upper section and the liquid raising pipe lower section are in butt joint through a motion mechanism. The melt liquid raising device is easy to install and convenient to operate, the use process is safe and reliable, the technological process is distinct and high in stability,volume production is achieved in multi-station parallel-connection pressurizing cast of large aluminum alloy frameworks, plates and cabin components, application and popularization value is high, andthe industrial potential is great.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Precast slab formwork nesting connection structure and construction method

PendingCN111535347AReasonable structural designSimplify the installation processFoundation engineeringSteel tubeCushion

The invention relates to a precast slab formwork nesting connection structure. The structure comprises a foundation pit, a cushion layer arranged at the bottom of the foundation pit and a cap foundation arranged on the cushion layer, wherein U-shaped clamping grooves are formed in the peripheral sides of the cap foundation and in the upper plane of the cushion layer; precast slabs I and precast slabs II are arranged correspondingly in the U-shaped clamping grooves in the two sides of the cap foundation in the length and width directions, the adjacent precast slabs I and precast slabs II are mutually nested to form a slab formwork, and square timbers are arranged transversely on the periphery of the slab formwork to clamp the precast slabs I and the precast slabs II; steel pipes are arranged between the square timbers and the side walls of the foundation pit for support. The precast slabs are in nested connection by staggered joints to form the slab formwork, internal hoop force is formed by nested connection of the slab formwork under the action of pressure of backfill soil outside the defined shape of the slab formwork, so that a stable stress system is formed, the construction process is simple and convenient, and a good supporting structure for a cap formwork can be formed.

Owner:SHANGHAI BAOYE GRP CORP

Spraying and drying process and apparatus for Chinese medicine concentrate

A process for concentrating and spray drying of liquid Chinese medicine includes such steps as homogenizing, spray drying and cyclone separating. Its system is composed of liquid supplying tank, pump, pipeline, hot air pipeline with air filter, air heater and accurate air filter, sterilizer, spray drying tower, and the cyclone separation unit consisting of a cyclone separator and dual-cyclone separation tower.

Owner:云南昆船电子设备有限公司

Method for preparing high-purity hydration-resisting calcium oxide crucible

InactiveCN105906356APromotes sintering densificationImproves hydration resistanceCompression moldingCalcium hydroxide

The invention discloses a method for preparing a high-purity hydration-resisting calcium oxide crucible, wherein the method includes the steps: (1) adding yttrium oxide in a high-purity calcium hydroxide powder, carrying out ball milling, and then drying; (2) pressing the dried material into blocks, and then calcining to obtain a sintered material; (3) crushing and screening the sintered material; (4) mixing the screened material, then adding an anhydrous binder, mixing evenly, and then placing the mixture into a crucible mold; (5) vibrating to compact the material in the crucible mold, then carrying out cold isostatic pressing, and carrying out compression molding of the material, to obtain a calcium oxide crucible blank; and (6) sintering the calcium oxide crucible blank, to obtain the calcium oxide crucible. The prepared calcium oxide crucible has good thermal shock resistance and relatively high service life, better solves the problems that a conventional calcium oxide crucible is easy to hydrate when the purity is high and has impurities easily introduced to pollute melted metals and alloys when the purity is low, and is widely applied in pure steel and ultra-pure metal smelting.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

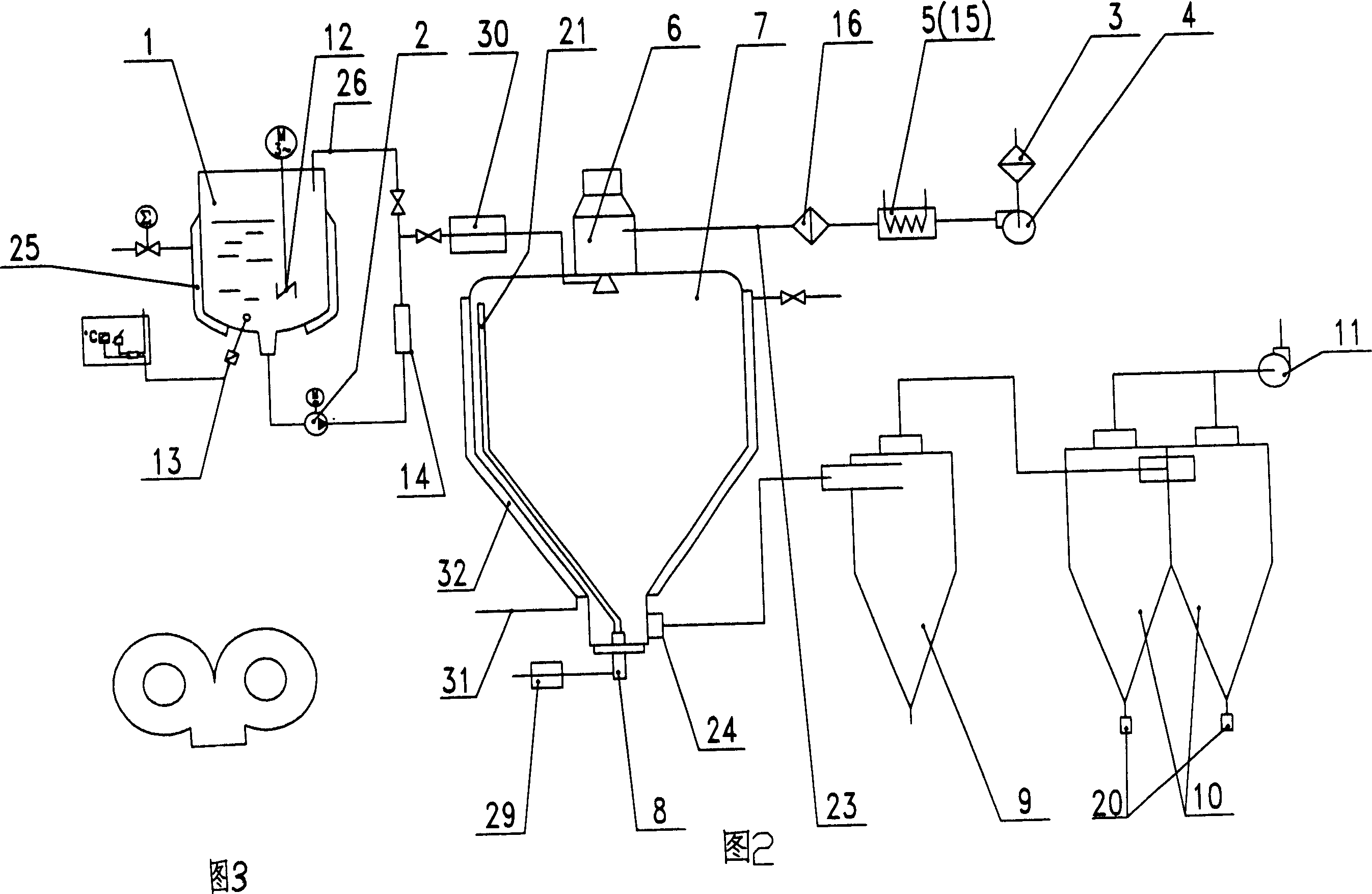

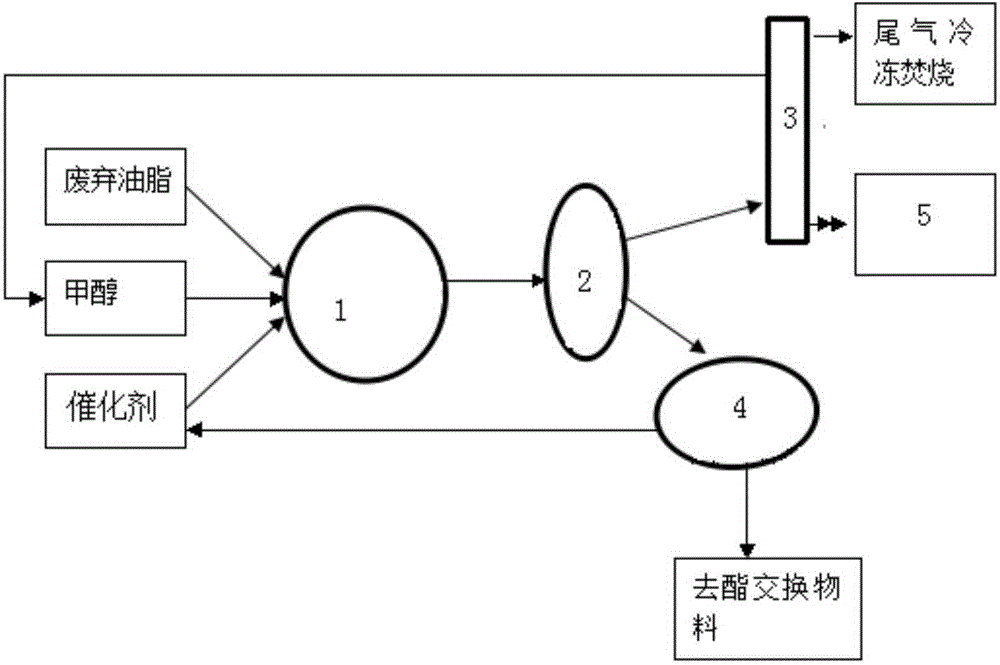

Continuous esterification technique for producing biodiesel from waste grease

InactiveCN104673502ARealize the continuous production of esterificationProcess flow is clearFatty acid esterificationFatty acids production/refiningOil and greaseBiodiesel

The invention discloses a continuous esterification technique for producing biodiesel from waste grease, which comprises the following steps: 1. continuously injecting waste grease, a catalyst and methanol into an esterification reactor by a measuring pump to perform continuous esterification reaction, and discharging; 2. sending into a water -containing methanol separator, and separating into excessive methanol, water and a reaction product; sending the excessive methanol and water into a methanol rectification tower; and sending the material into a continuous catalyst separator, and separating into the catalyst and an ester exchange material with ester exchange reaction. The technique has clear process, enables the acid number to be only 2 mgKOH / g or so, is easy for treatment, and implements continuous esterification production of biodiesel from waste grease.

Owner:JIANGSU WEST ENVIRONMENT PROTECTION TECH

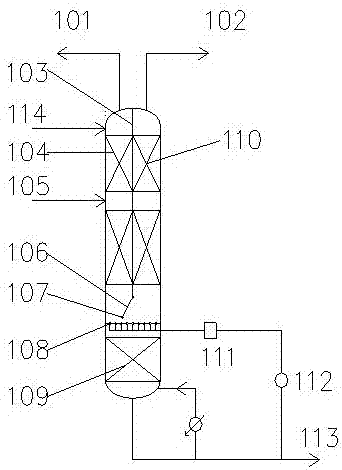

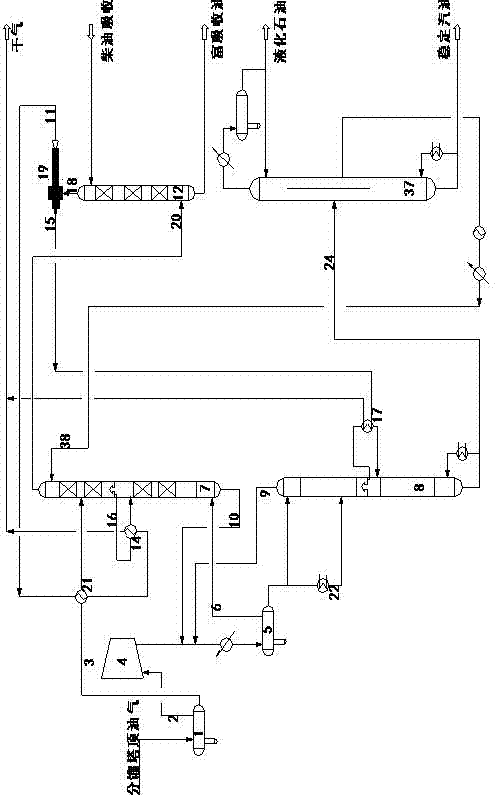

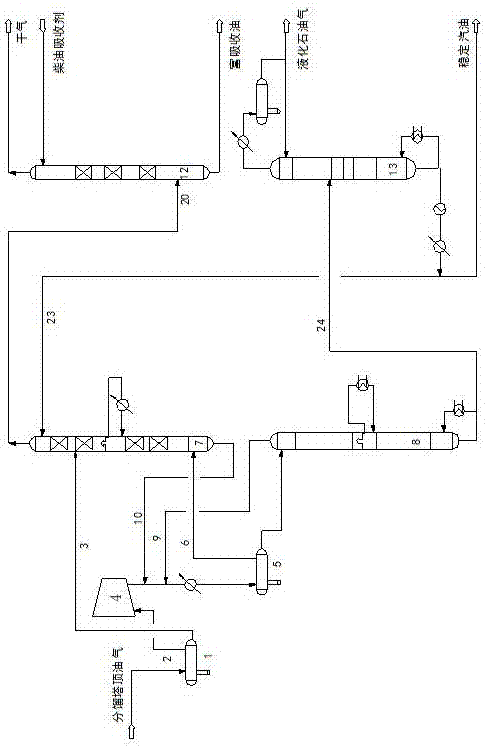

Absorption-stabilization technique capable of enhancing absorption by using complementary energy

ActiveCN107338068AGuaranteed uptimeReduce loadLiquid hydrocarbon mixture recoveryHydrocarbon oils treatment productsAbsorption ratioHeat flow

The invention discloses an absorption-stabilization technique capable of enhancing absorption by using complementary energy. A stabilized gasoline absorption packing section and a gasoline absorption packing section are arranged in a coking absorption tower from top to bottom; and crude gasoline and stabilized gasoline sectionally enter packing bed layers of the gasoline absorption section and stabilized gasoline absorption section. Preferably, the tower top of a reabsorbing tower is provided with a shell-and-tube vortex tube buncher, thereby converting the pressure energy of dry gas on the tower top into a cold flow and a heat flow. A dividing wall column is used for sharp separation to obtain the component with better absorbing capacity, thereby enhancing the absorption effect. The method disclosed by the invention can maximally display the absorbing capacity of stabilized gasoline for C3 and C4, enhance the absorption effect of the absorption tower and greatly lower the circulating volume of the stabilized gasoline complementary absorbent, thereby lowering the energy consumption of the system. The vortex tube buncher can recover the pressure energy formed by the dry gas pressure difference and convert the pressure energy into cold energy and heat energy, and can also optimize the absorption-stabilization technique, thereby implementing the dual effects of lowering the process energy consumption and enhancing the absorptivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

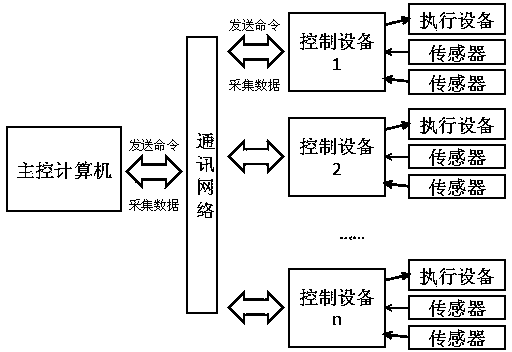

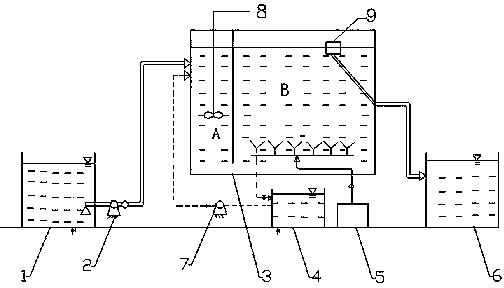

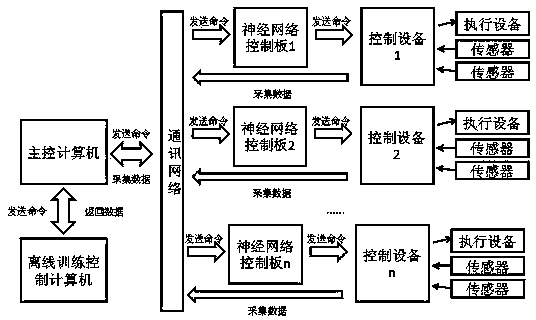

Optimized CAST domestic sewage sludge reduction control system and working method

The invention relates to an optimized CAST domestic sewage sludge reduction control system and a working method. Through arrangement of a main control computer and a control device, high automation of the CAST system is realized, and the purpose of sludge reduction in the domestic sewage processing process can be realized through adjusting technological parameters. The control system of the invention can not only handle parameter arrangement when the sludge concentration rises but also handle parameter arrangement when sludge in a reaction pool is reduced, and the sludge amount and the sludge concentration in the reaction pool can be in a balanced and stable level.

Owner:杨安康 +2

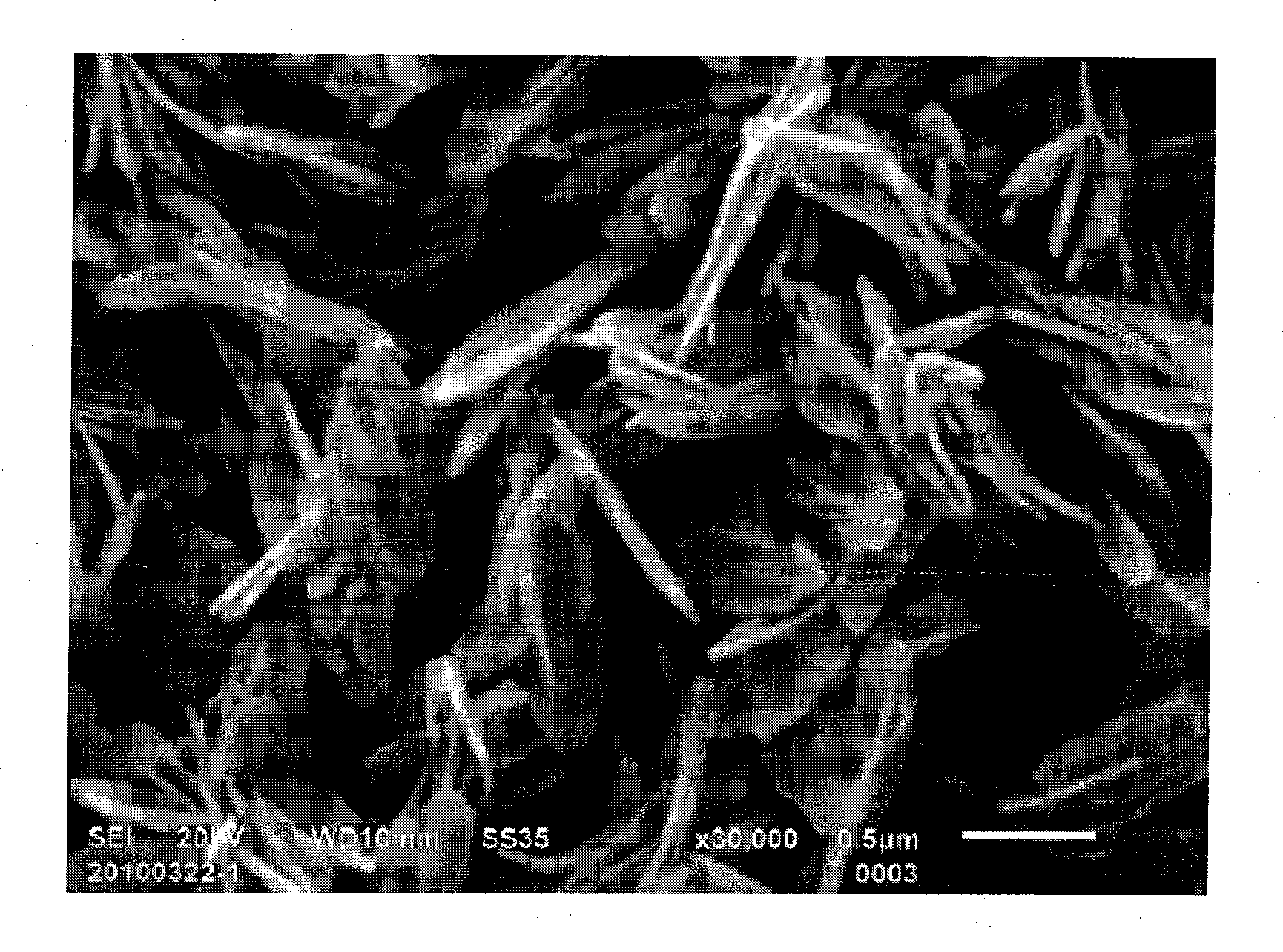

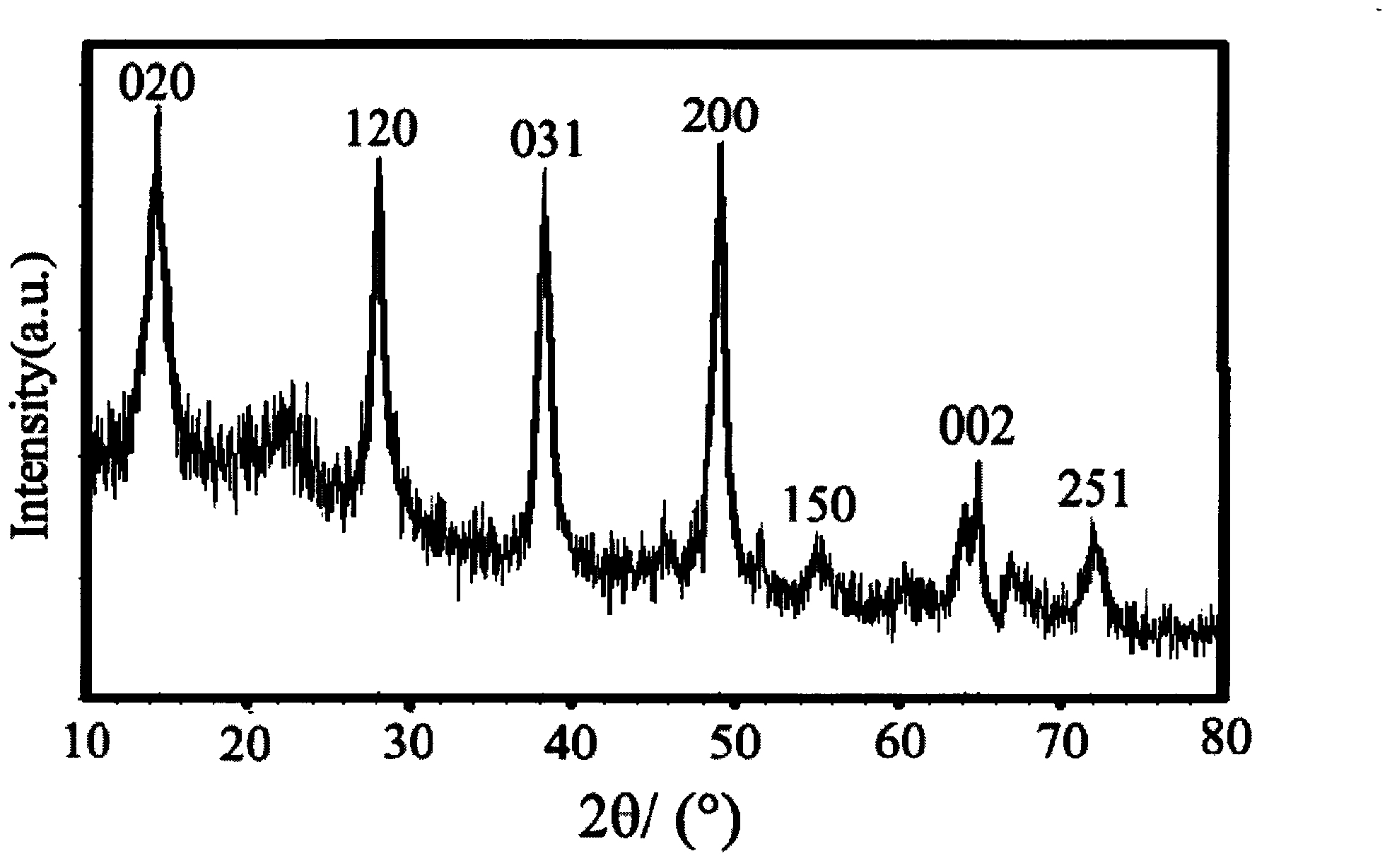

Method for preparing boehmite micropowder having three-dimensional flaky aggregate morphology

InactiveCN104229840AOvercome the hydrothermal reactionProcess flow is clearAluminium oxides/hydroxidesPolystyreneCopolymer

The invention relates to a method for preparing boehmite micropowder having three-dimensional flaky aggregate morphology. The prior art comprises that aluminum nitrate and urea undergo a hydrothermal reaction to produce boehmite micropowder so that only boehmite powder having two-dimensional flaky morphology is obtained. The method for preparing boehmite micropowder having three-dimensional flaky aggregate morphology comprises that the boehmite micropowder having three-dimensional flaky aggregate morphology is prepared from aluminum nitrate and urea as raw materials and an amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate as a structural guider. The method for preparing the boehmite micropowder having three-dimensional flaky aggregate morphology realizes one-step reaction in a liquid phase, has a clear process, utilizes cheap and easily available raw materials and has a simple after-treatment process. The boehmite micropowder has regular three-dimensional flaky aggregate morphology, has good dispersion uniformity, and solves the problem that the traditional aluminum nitrate-urea hydro-thermal reaction only produces the boehmite powder having two-dimensional flaky morphology.

Owner:TAISHAN MEDICAL UNIV

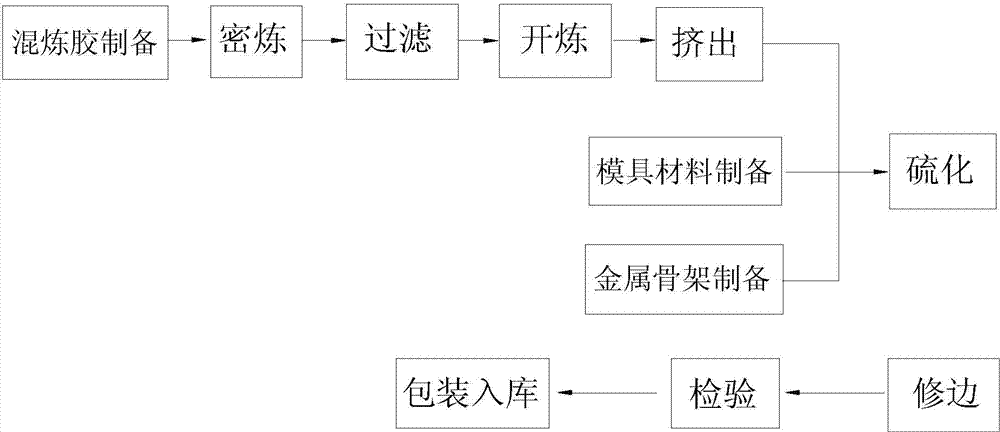

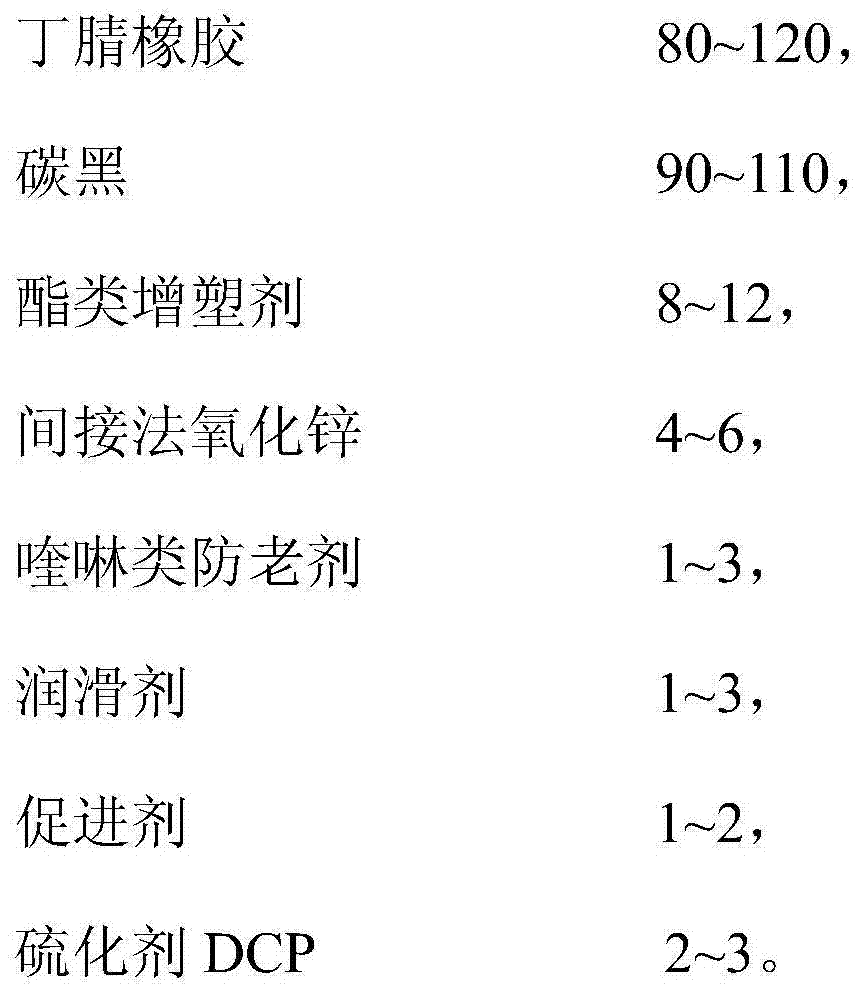

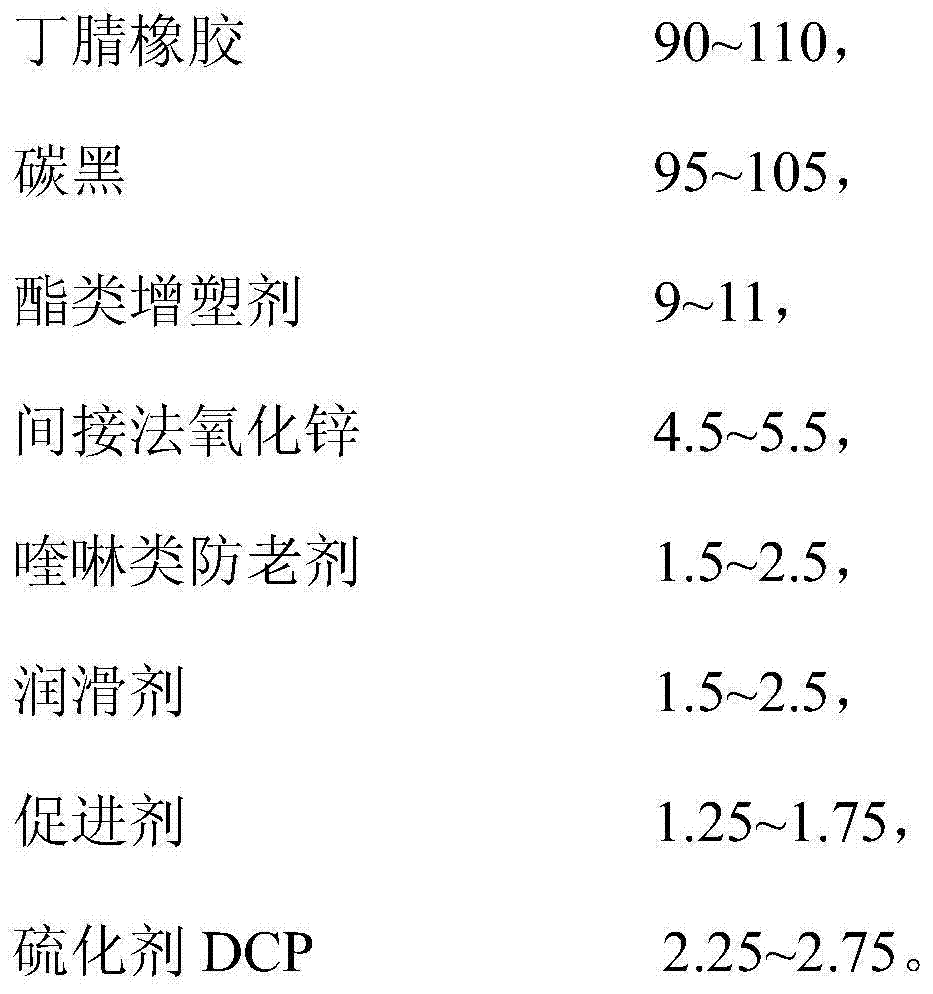

Shock ring rubber assembly for EPS electronic power steering engine and preparation method thereof

The invention discloses a shock ring rubber assembly for an EPS electronic power steering engine and a preparation method thereof. The shock ring rubber assembly for EPS electronic power steering engine includes the following components by weight: 80-120 parts of nitrile rubber, 90-110 parts of carbon black, 8-12 parts of an ester plasticizer, 4-6 parts of indirect method zinc oxide, 1-3 parts of a quinoline rubber antioxidant, 1-3 parts of a lubricant, 1-2 parts of a promoter and 2-3 parts of a vulcanizing agent DCP. Compared with the prior art, the invention improves the wear resistance and metal bonding performance of the shock ring rubber assembly of the EPS electronic power steering engine, and solves the technical problems of rubber wearing and adverse bonding under high temperature and high load, and provides a safe and reliable security for long time operation of the EPS electronic power steering engine.

Owner:ANHUI ZHONGDING SEALING PARTS

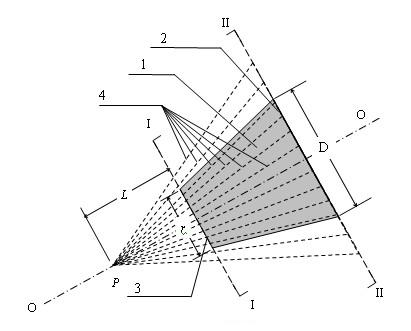

Impermeable choking and grouting method for rock plug truncated cone shell in deepwater

The invention relates to an impermeable choking and grouting method for a rock plug truncated cone shell in deepwater, belonging to the method for grouting a rock plug body in deepwater rock plug blasting engineering. The drilling position, drilling interval, drilling direction and drilling depth for grouting can be determined by a group of coaxial truncated cone surface and the cut concentric circle, so that at the periphery of the rock plug and in the rock bodies on the upper opening and the lower opening, compound serum taking cement as base material is filled in cracks and holes of jointsof the rock body, and after the compound serum is cured, the continuously impermeable body with the shape similar to that of the truncated cone shell can be formed in the grouted rock body. In the invention, the purpose is clear and definite, the pertinence is strong, the grouting effect is obvious, the process is clear, and the implementation is simple.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

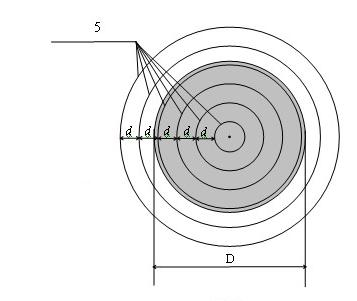

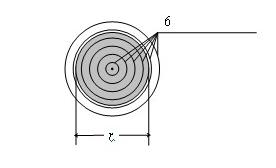

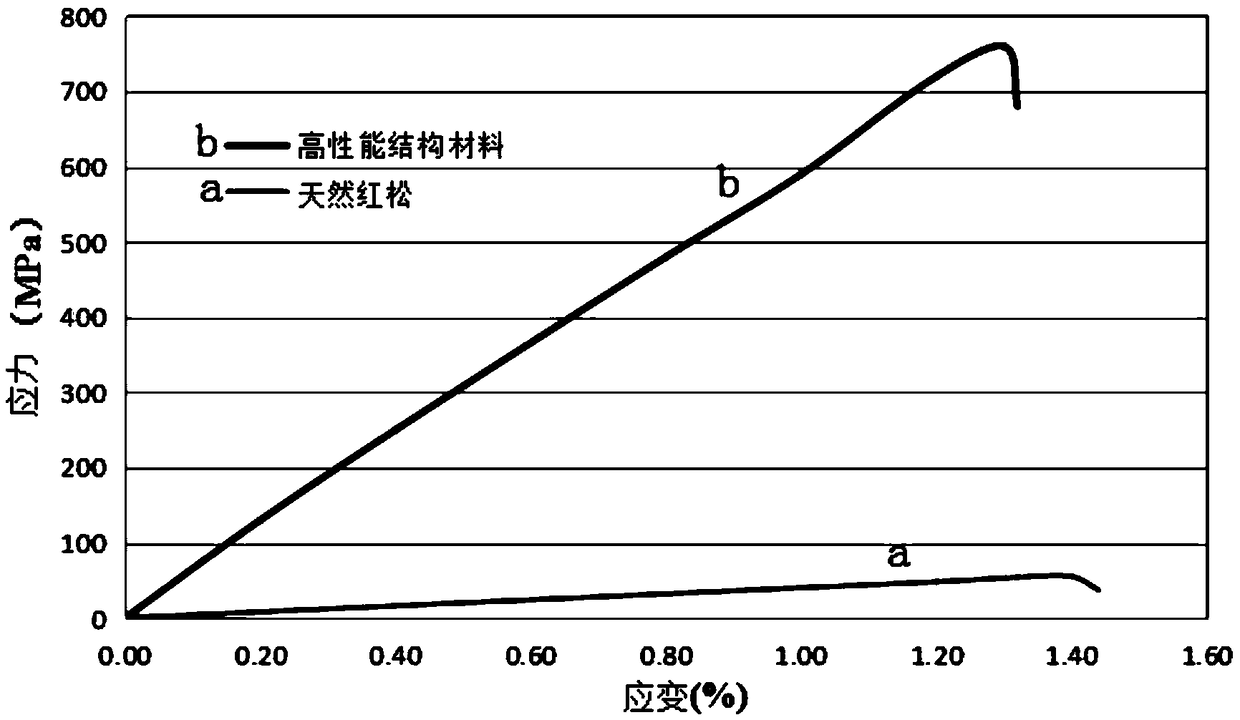

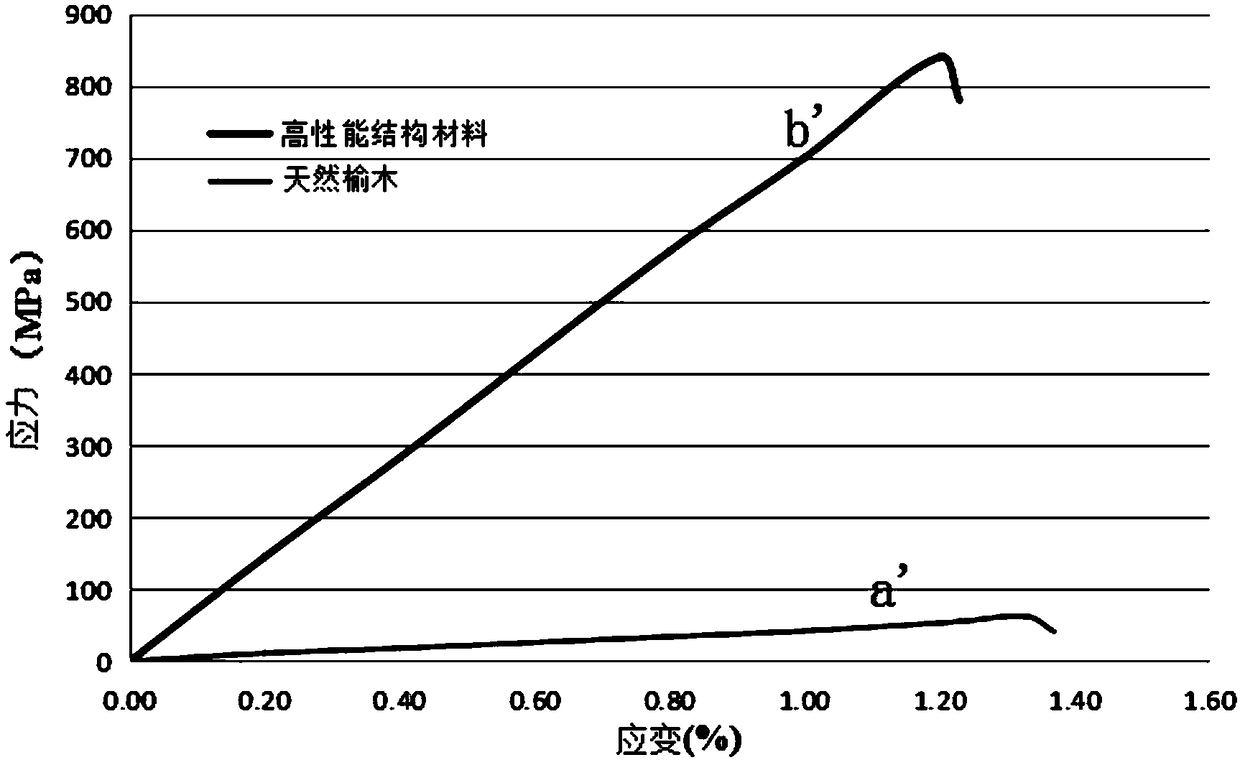

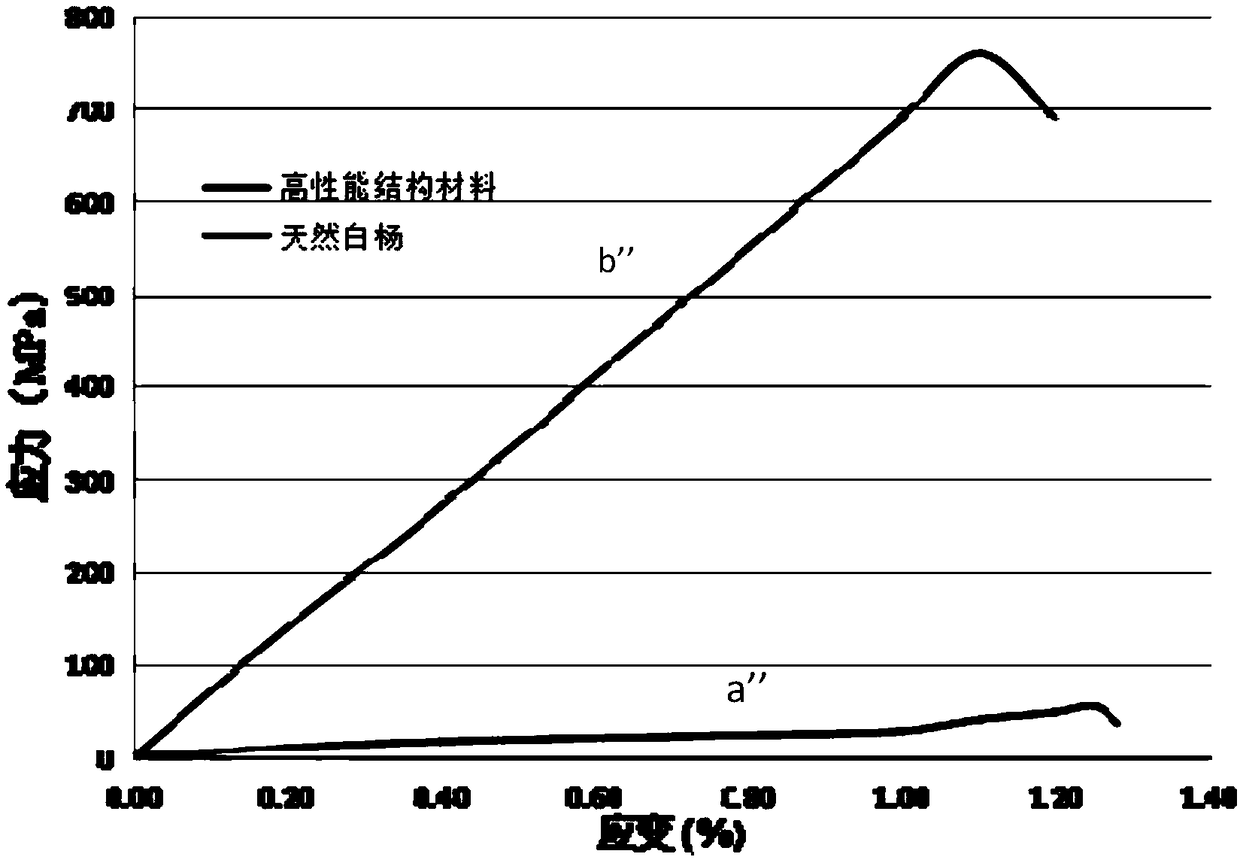

High-performance structural material and preparation method thereof

ActiveCN109129798AGood mechanical propertiesImprove performanceWood working apparatusCelluloseBiological activation

The invention relates to a high-performance structural material and a preparation method thereof. The preparation method comprises the steps that purifying treatment is conducted on cellulose in natural timber, purified timber is obtained, the purified timber is boiled and then washed, the washed timber is obtained and then subjected to activation treatment, the activated timber is subjected to hot pressing treatment, and then the high-performance structural material is obtained. According to the method, a large quantity of hydrogen bonds are constructed among cellulose molecules and constructed among a cellulose single molecule layer, a supermolecule layer and a fibrillar structure layer by taking the cellulose of the natural timber as a structural framework according to the molecular structural features of the cellulose and the self-assembly and crystallinity characteristics of the cellulose through chemical and physical means, a stable and compact three-dimensional structure systemis formed through the hydrogen bonds and Van der Waals force, and therefore the prepared high-performance structural material shows the excellent mechanical properties from the macroscopic angle and is outstanding in comprehensive performance and wide in market prospect.

Owner:北京英华高科技环保有限公司

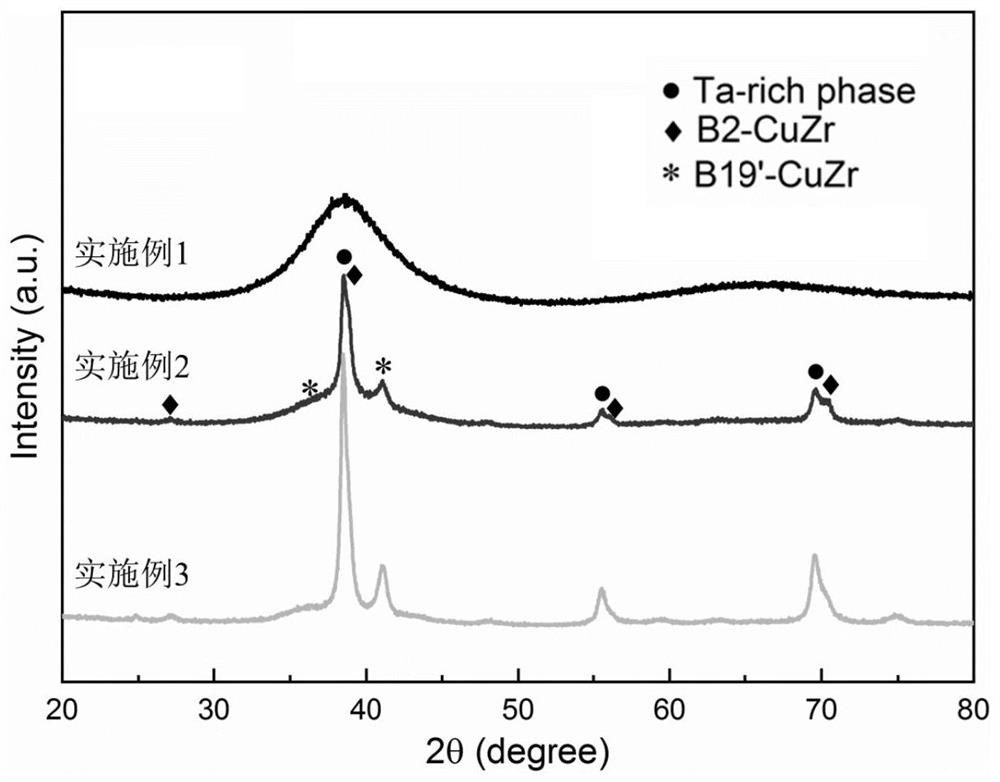

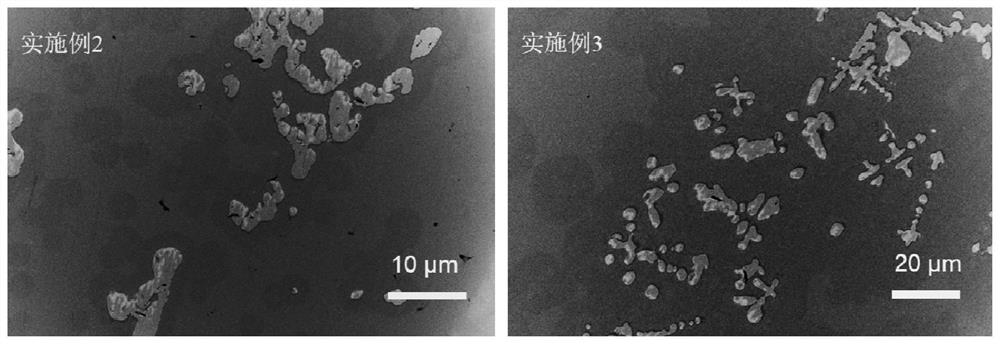

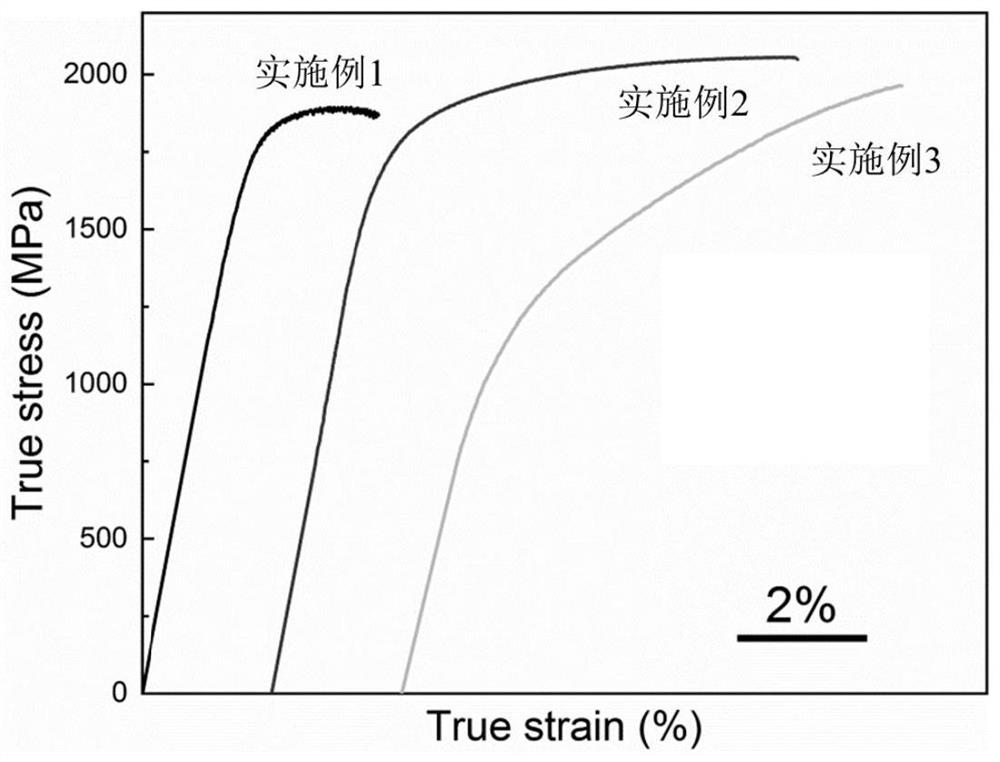

Mixed phase reinforced zirconium-based amorphous composite material and preparation method thereof

The invention belongs to the technical field of amorphous alloy composite materials, and particularly discloses a mixed phase reinforced zirconium-based amorphous composite material and a preparation method thereof. The composition expression of the composite material is (ZrCuAl<c>)<d>Ta<e>, a = b is larger than or equal to 0.46 and smaller than or equal to 0.475, c is larger than or equal to 0.05 and smaller than or equal to 0.08, and a + b + c is equal to 1; d and e are atomic percent, d is larger than or equal to 92 and smaller than 100, e is larger than 0 and smaller than or equal to 8, and d + e is equal to 100; and a matrix of the composite material is zirconium-based amorphous alloy, a reinforcing phase is a mixed phase of a core-shell structure, a Ta-rich phase is the core of the mixed phase, and a B2-CuZr phase and a B19 '-CuZr phase are the shell of the mixed phase. According to the mixed phase reinforced zirconium-based amorphous composite material and the preparation method thereof, the size of the B2-CuZr phase in the zirconium-based amorphous composite material is successfully refined, uniform distribution of the B2-CuZr phase is achieved, meanwhile, a core-shell mixed complex composite structure is introduced, the room-temperature comprehensive mechanical property of the zirconium-based amorphous composite material is further improved, and the application prospect of zirconium-based amorphous materials is expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

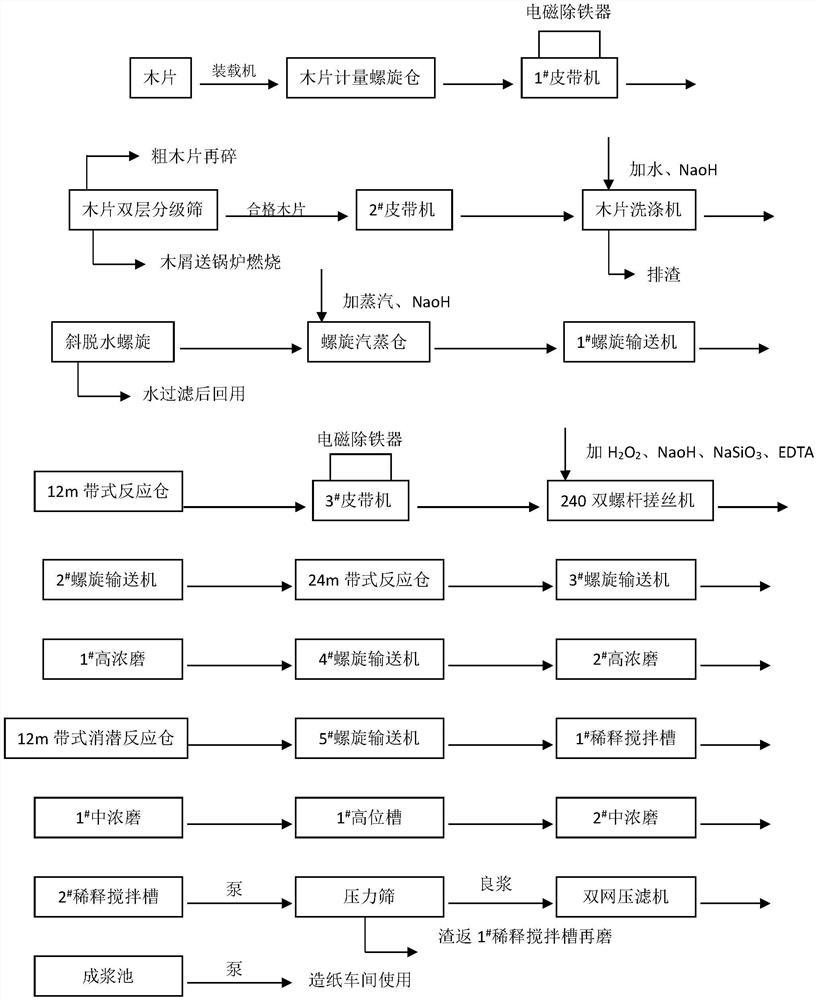

Production process of high-yield poplar chemi-mechanical pulp

PendingCN112878096AImprove surface strengthImprove stiffnessChemical/chemomechanical pulpPulp beating/refining methodsWoodchipsPaper sheet

The invention relates to the field of papermaking pulping, and in particular, relates to a production process of high-yield poplar chemi-mechanical pulp, wherein the production process comprises the steps: S10, metering wood chips; S20, electromagnetically removing iron; S30, screening; S40, washing; S40, carrying out dehydration; S60, carrying out steam softening; S70, carrying out a reaction in a softening reaction bin; S80, electromagnetically removing iron; S90, carrying out thread rolling; S110, carrying out a reaction in a bleaching reaction bin; S120, connecting two stages of high-concentration grinders in series for coarse grinding; S130, carrying out a reaction in a latency reaction bin; and S140, connecting two stages of medium-consistency grinders in series. The method is simple and clear in process flow, low in investment, quick in effect, good in flexibility and high in applicability; the produced pulp is used for preparing medium-grade and high-grade electrostatic copy paper, two-side offset paper, patterned paper, water color paper, water-absorbing base paper, cup paper, light paper and the like, has good paper surface strength, bulk and air permeability superior to those of full-chemical reed pulp paper, and is flat, smooth, good in stiffness and good in printing property; therefore, the poplar chemi-mechanical pulp production process is an effective way for improving product structures, improving product grades and increasing economic benefits in small and medium-sized enterprises.

Owner:江西中竹生物质科技有限公司

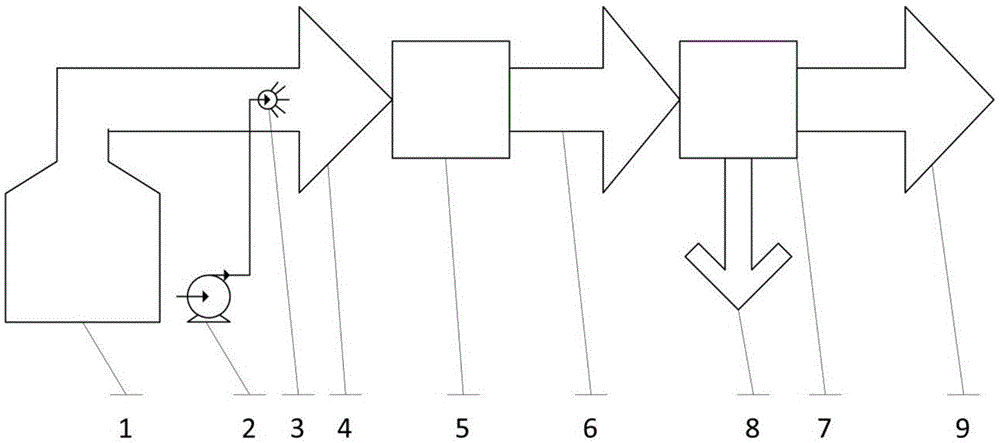

Zero-release device and process for wastewater of coal-fired boiler

PendingCN106315720ARealize harmless treatmentAchieving zero emissionsSpecific water treatment objectivesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a zero-release device and process for wastewater of a coal-fired boiler. The device comprises a coal-fired boiler, a dust remover and an air pre-heater, wherein the coal-fired boiler, a conveying flue, the air pre-heater, a dust removal flue and the dust remover are sequentially communicated with one another; and an atomizing nozzle is arranged in the conveying flue, and a water pump is arranged outside the conveying flue. The process comprises the following steps: wastewater is pumped by virtue of the water pump, is pressurized, is conveyed to the atomizing nozzle and is sprayed into the conveying flue by virtue of the atomizing nozzle; pollutants in the atomized wastewater are crystallized into solids after moisture is evaporated; and the solid pollutants are captured by the dust remover and are discharged into an ash conveying pipeline, and water vapor is discharged into a subsequent flue by virtue of the dust remover. According to the device and the process, the moisture in the wastewater is completely evaporated into water vapor by virtue of existing equipment and the heat of flue gas, and the pollutants in the wastewater are crystallized into solids after the moisture is evaporated, so that the moisture and the pollutants in the wastewater are completely separated so as to be respectively processed, and the thorough innocent treatment of the wastewater of the boiler is realized.

Owner:YICHUAN TECH CHENGDU CO LTD

Construction method of onsite supply operation for micro surfacing

InactiveCN102561144ARealize continuous paving operationReduce distractionsIn situ pavingsRoads maintainenceBatch machineSewage

The invention discloses a construction method of onsite supply operation for micro surfacing. The method is characterized by comprising the following steps: firstly, using a batching machine to load mineral aggregate into bulk bags in specific proportion in accordance with the performance requirement, and tieing the ropes of the bulk bags; secondly, using one crane truck to stack the mineral aggregate in bulk bags along the line, and using another crane truck to lift the mineral aggregate in bulk bags onto seal equipment for unloading; thirdly, using an integrated liquid supply vehicle with a liquefied asphalt tank and a water tank to transfer the modified emulsified asphalt and the water respectively into the seal equipment through waste water and a water pump or onsite supply; fourthly, using a jubilee truck to carry the cement to the construction site, carrying out onsite cement supply to the seal equipment with manpower; fifthly, performing paving in accordance with the normal construction procedure, after the paving is finished, supplying the material, and then performing the paving again; carrying out the operation repeatedly until the paving is finished. By adopting the construction method, the construction efficiency can be remarkably improved, the construction quality is ensured, materials and fuels are saved; in addition, the operation is convenient, and the construction is environmental protection.

Owner:广东能达公路养护股份有限公司

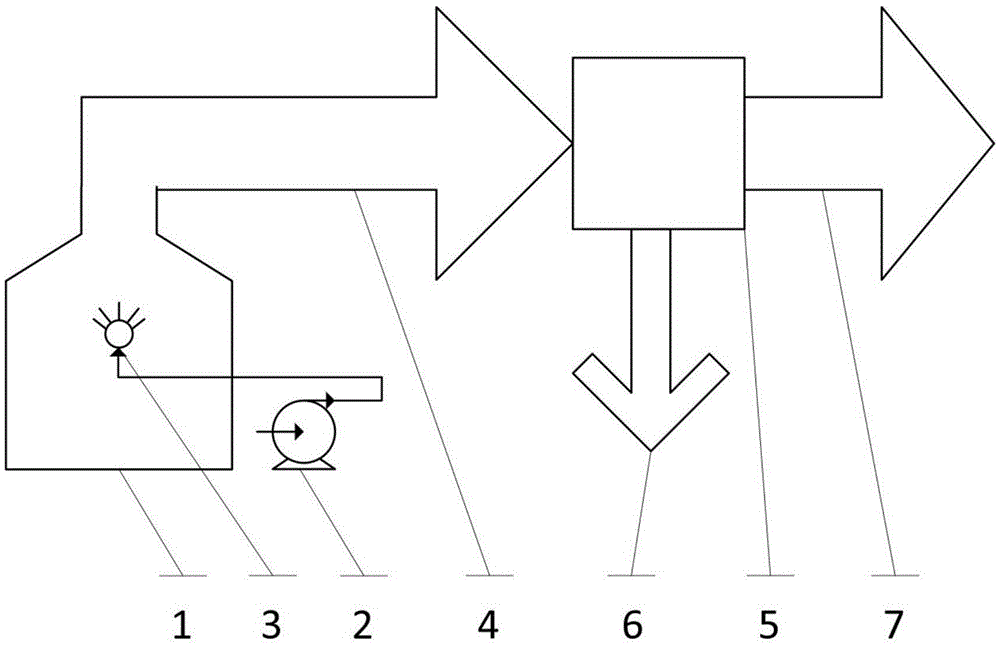

In-furnace wastewater evaporation device and process for coal-fired boiler

PendingCN106315723ARealize harmless treatmentAchieving zero emissionsWater/sewage treatmentWater vaporFlue gas

The invention discloses an in-furnace wastewater evaporation device and process for a coal-fired boiler. The device comprises a coal-fired boiler and a dust remover, wherein an ash conveying pipeline and an subsequent flue are arranged on the dust remover, and the coal-fired boiler and a dust remover are communicated with each other through a dust removal flue; and an atomizing nozzle is arranged in the coal-fired boiler, a water pump is arranged outside the coal-fired boiler, and the atomizing nozzle and the water pump are communicated through a pipeline. The process comprises the following steps: wastewater is pumped by virtue of the water pump, is pressurized, is introduced to the atomizing nozzle and is sprayed into the coal-fired boiler by virtue of the atomizing nozzle; pollutants in the atomized wastewater are crystallized into solids after moisture is evaporated; and the solid pollutants are captured by the dust remover and are discharged into the ash conveying pipeline, and water vapor is discharged into the subsequent flue by virtue of the dust remover. According to the device and the process, the moisture in the wastewater is completely evaporated into water vapor by virtue of existing equipment and the heat of flue gas, and the pollutants in the wastewater are crystallized into solids after the moisture is evaporated, so that the moisture and the pollutants in the wastewater are completely separated so as to be respectively processed, and the thorough innocent treatment of the wastewater of the boiler is realized.

Owner:YICHUAN TECH CHENGDU CO LTD

All-cotton warp elastic fabric and weaving method thereof

ActiveCN102140720BProcess flow is clearEasy to operateHeating/cooling textile fabricsWoven fabricsYarnPulp and paper industry

The invention discloses an all-cotton warp elastic fabric and a weaving method thereof. The weaving method comprises the following steps of: 1. winding warp yarn: twisting wrap yarn to reach super high twist; 2. shaping the warp yarn: steaming the warp yarn in a yarn steaming device with high-temperature steam; 3. warping: warping the warp yarn with single tooth single yarn; 4. weaving: leaving aspace for the warp yarn to rotate left and right on a woven grey fabric by using high-twist yarn in two twisting directions; and 5. post treating: when the grey fabric fully contracts, drying the grey fabric with an ironing machine under a condition of no tension to obtain the all-cotton warp elastic fabric. By using the weaving method provided by the invention, a real all-cotton warp elastic fabric can be woven, and the method is clear in process and easy to operate.

Owner:CHANGZHOU DL MEDICAL & HEALTH EQUIP

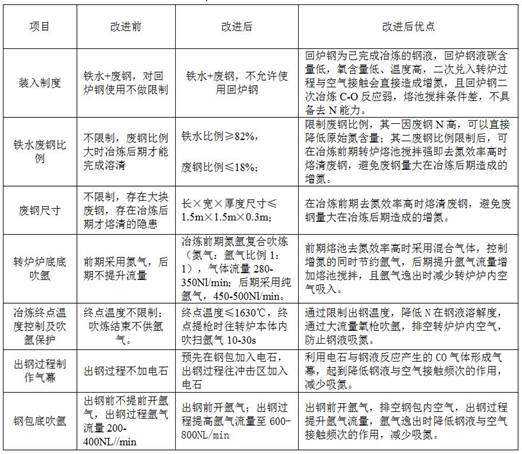

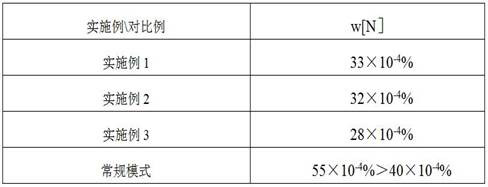

Smelting method for reducing nitrogen increase of molten steel in converter process

PendingCN114635006AReduce total nitrogenReduce contact frequencyManufacturing convertersMolten steelCalcium carbide

The invention relates to a smelting method for reducing nitrogen increase in molten steel in a converter process. The smelting method comprises the following steps: limiting the nitrogen content and size of a waste steel raw material, changing bottom argon blowing in the early stage of a converter into nitrogen-argon combined blowing, increasing the gas flow, adopting bottom pure argon blowing in the middle and later stages of smelting, and increasing the bottom blowing gas flow; the smelting final temperature is smaller than or equal to 1630 DEG C, an oxygen lance is switched into argon, and argon is blown into the converter for 10-30 s; in the tapping process, 1.0 Kg / t to 1.2 Kg / t of calcium carbide is added to the bottom of a steel ladle in advance before tapping, 0.5 Kg / t to 1.0 Kg / t of calcium carbide is thrown in a steel flow impact area in the tapping process, CO generated by calcium carbide deoxidation is used for forming an air curtain, molten steel is isolated from air, and nitrogen absorption of the molten steel is reduced; the content of [O] in the molten steel in the tapping process is controlled to be (200-400) * 10 <-4 >%; bottom argon blowing of the steel ladle is started 20 seconds before tapping, air in the steel ladle is emptied, argon is stopped immediately after tapping is finished from 20 seconds before tapping to the end of tapping, and the steel ladle is covered for heat preservation to prevent molten steel from being exposed to increase nitrogen; the method is simple and clear in technological process, high in operability and easy to control.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

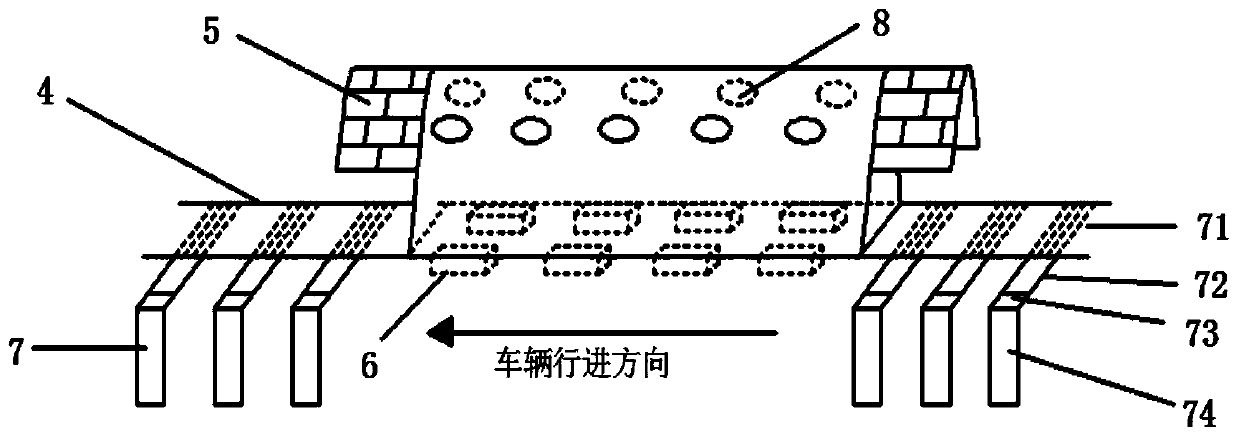

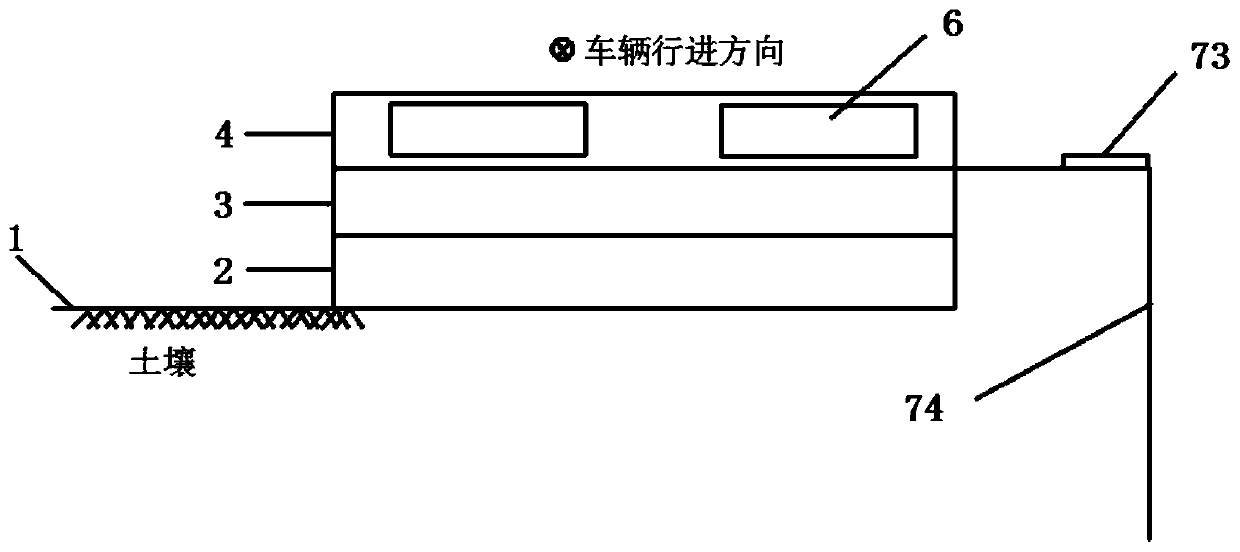

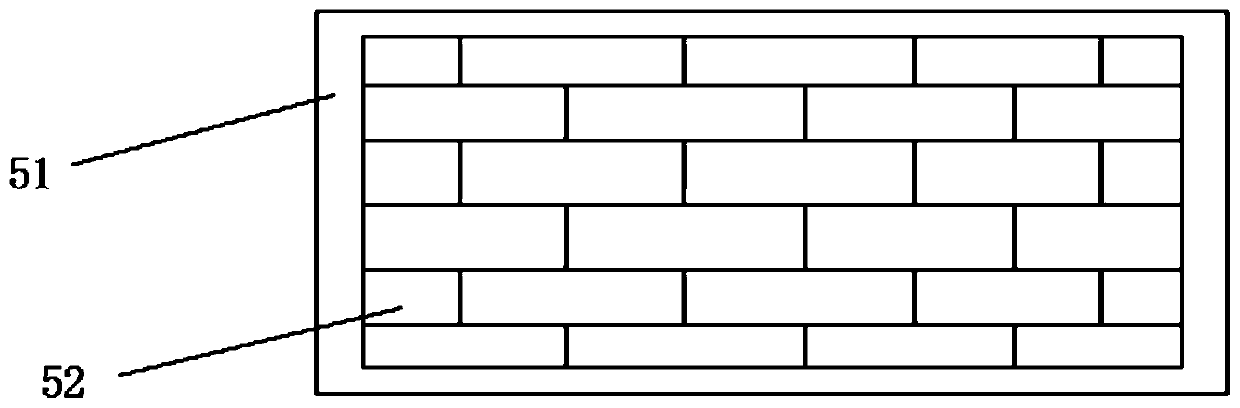

Highway tunnel structure based on intelligent power generation and construction method of highway tunnel structure

PendingCN110319408AEnsure driving safetyImprove the situationBatteries circuit arrangementsMechanical apparatusComing outOperational costs

The invention provides a highway tunnel structure based on intelligent power generation and a construction method of the highway tunnel structure. The photovoltaic power generation devices are arranged at the two ends of a tunnel, and extend outside of the tunnel, a solar power generation plate is used for generating power, the photovoltaic power generation devices and an electrical storage deviceare connected, the electrical storage device stores the power generated by the photovoltaic power generation device, tunnel lighting devices and the electrical storage device are connected, energy inthe tunnel and the surrounding environment is effectively used for being converted electric energy, sufficient electric quantities are provided for the tunnel, the operating cost of the highway tunnel is lowered, energy sources are saved, environmental pollution is reduced, and surrounding environmental conditions are improved. At the same time, the photovoltaic power generation devices extend outside of the tunnel form the two ends of the tunnel, a barrier is formed, the cushioning effect can be given to vision of a driver who want to enter the tunnel from the outside or come out of the tunnel, perception of the driver for the black-hole effect and the white-hole effect is effectively reduced, and tunnel driving safety is ensured.

Owner:CHANGAN UNIV

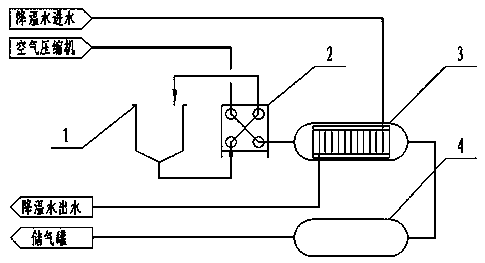

Method and device for recycling heat energy of compressed air of aerobe fermentation system

InactiveCN103954031AProcess flow is clearEasy to transformDispersed particle separationWater heatersThermal energyEngineering

The invention relates to a method and a device for recycling heat energy of compressed air of an aerobe fermentation system. The device comprises a heat exchange water tank, a plate type heat exchanger, a cooling water heat exchanger, a water remover, an air compressor and an air storage tank, wherein an air outlet of the air compressor is connected with an air inlet of an air runner of the plate type heat exchanger; an air outlet of the air runner of the plate type heat exchanger is connected with an air inlet of a cooling water heat exchanger shell side; an air outlet of the cooling water heat exchanger shell side is connected with an air inlet of the water remover; an air outlet of the water remover is connected with an air inlet of the air storage tank; the lower part of the heat exchange water tank is connected with a water inlet of a liquid runner of the plate type heat exchanger; a water outlet of the fluid runner of the plate type heat exchanger is connected with the upper part of the heat exchange water tank; cooling water is fed into a water inlet of the cooling water heat exchanger shell side and is drained through a water outlet of a tube side. The technology of the method is clear in process, the modifying is easy, the water utilization amount of the cooling water heat exchanger is reduced, and full use of the heat energy in heat exchange water is facilitated.

Owner:LIANG SHAN LING HUA BIOTECH CO LTD

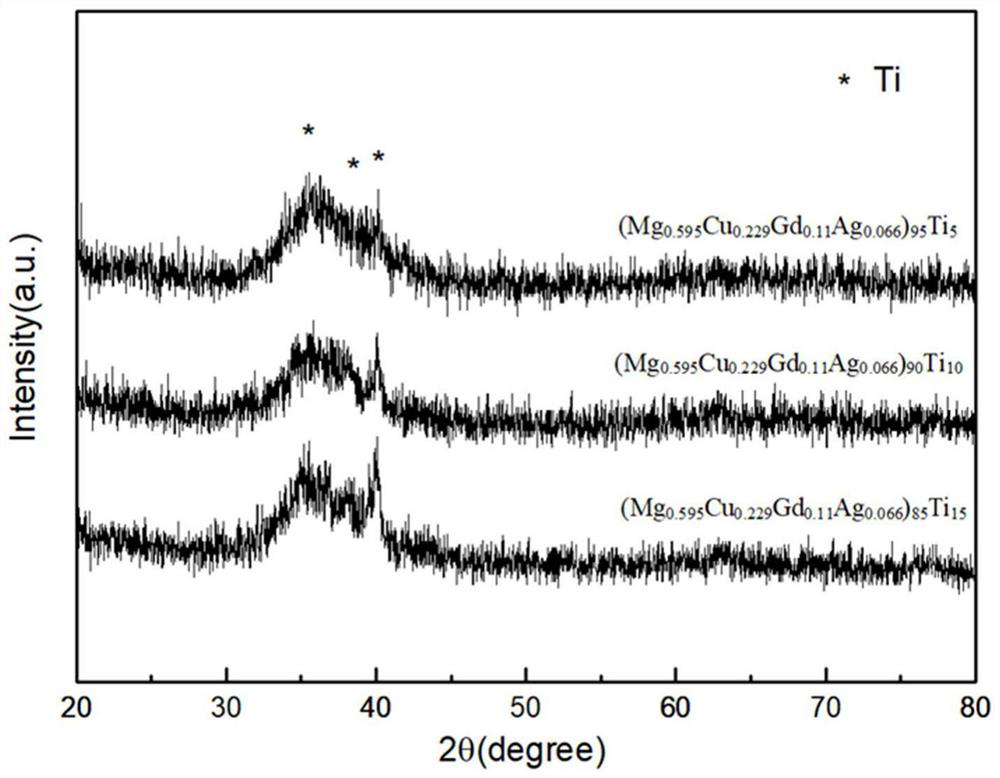

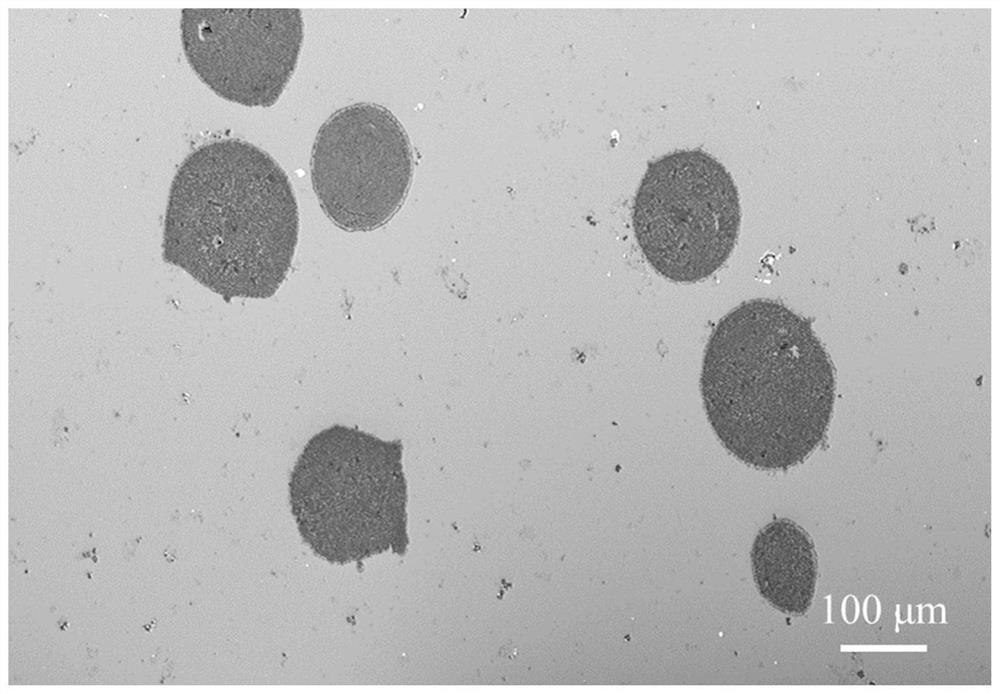

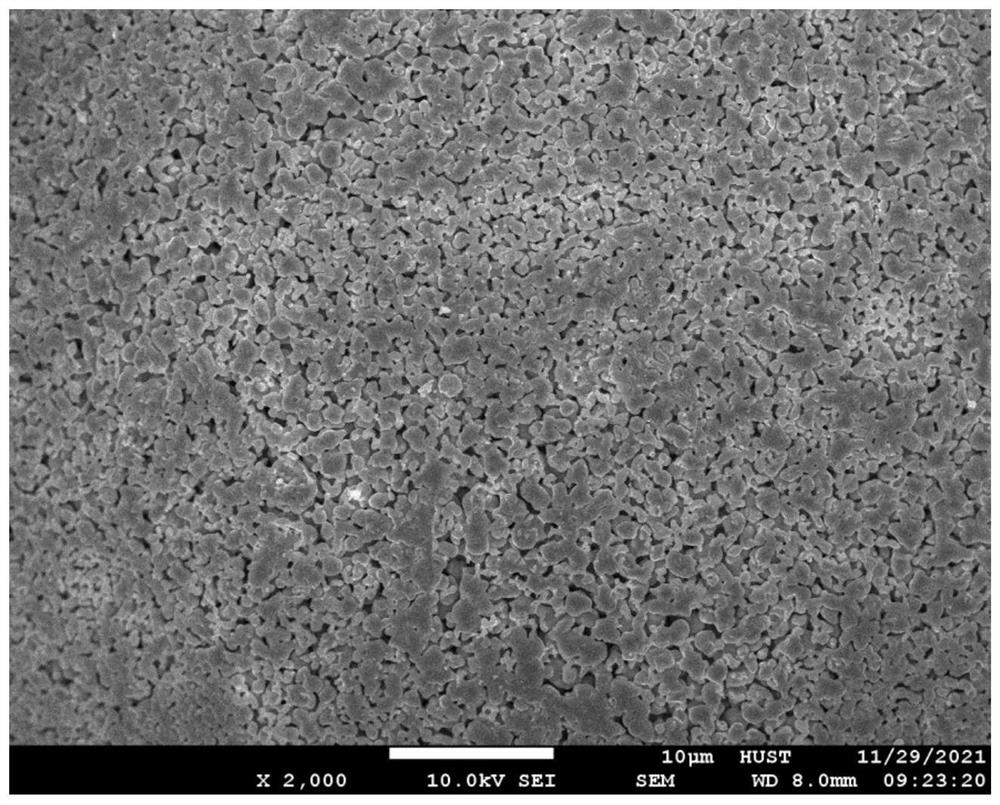

Endogenous porous titanium reinforced magnesium-based amorphous composite material and preparation method thereof

The invention belongs to the technical field of amorphous alloy composite materials, and particularly discloses an endogenous porous titanium reinforced magnesium-based amorphous composite material and a preparation method thereof.The composition expression of the composite material is (Mg0. 595Cu0. 229Gd0. 11Ag0. 066) 100-xTix, x is larger than or equal to 5 and smaller than or equal to 15, and the proportion in the expression is the atomic ratio; a matrix in the composite material is magnesium-based amorphous alloy, and the magnesium-based amorphous alloy comprises Mg, Cu, Gd and Ag elements; a reinforcing phase in the composite material is endogenous porous Ti particles, the porous Ti particles are uniformly dispersed in the matrix, pores of the porous Ti particles are fully filled with the matrix, and the pore size of the porous Ti particles is submicron or nanometer. The size of the second phase of the composite material can reach the submicron level and is close to the size of a magnesium-based amorphous alloy plastic processing area, and a better strengthening and toughening effect can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Coal-fired boiler bypass flue wastewater evaporation device and technology

ActiveCN105668672ARealize harmless treatmentAchieving zero emissionsWater/sewage treatment apparatusAir preheaterWater vapor

The invention discloses a coal-fired boiler bypass flue wastewater evaporation device and technology.The device comprises a coal-fired boiler, an air preheater, a dust remover and a wastewater pump station.The dust remover is provided with an ash conveying pipeline and a follow-up flue.The air preheater is communicated with the dust remover through a dust removal flue, the coal-fired boiler is communicated with the air preheater through a denitration device, the denitration device is communicated with the air preheater through a preheating flue, the preheating flue is communicated with the dust removal flue through a bypass flue, an atomizing nozzle is arranged in the bypass flue, the bypass flue is provided with an additional dust remover, the additional dust remover is provided with an additional ash conveying pipeline, and a heat exchanger communicated with the wastewater pump station is arranged on the bypass flue or the preheating flue.The technology comprises preheating, atomizing, evaporating separation and capturing of solid pollutant.According to the coal-fired boiler bypass flue wastewater evaporation device and technology, existing equipment and flue gas heat are sufficiently utilized, moisture in wastewater is evaporated to be steam, pollutant in the wastewater is crystallized to be in a solid state, moisture and pollutant in the wastewater are completely separated, and therefore wastewater of the boiler is thoroughly and harmlessly treated.

Owner:YICHUAN TECH CHENGDU CO LTD

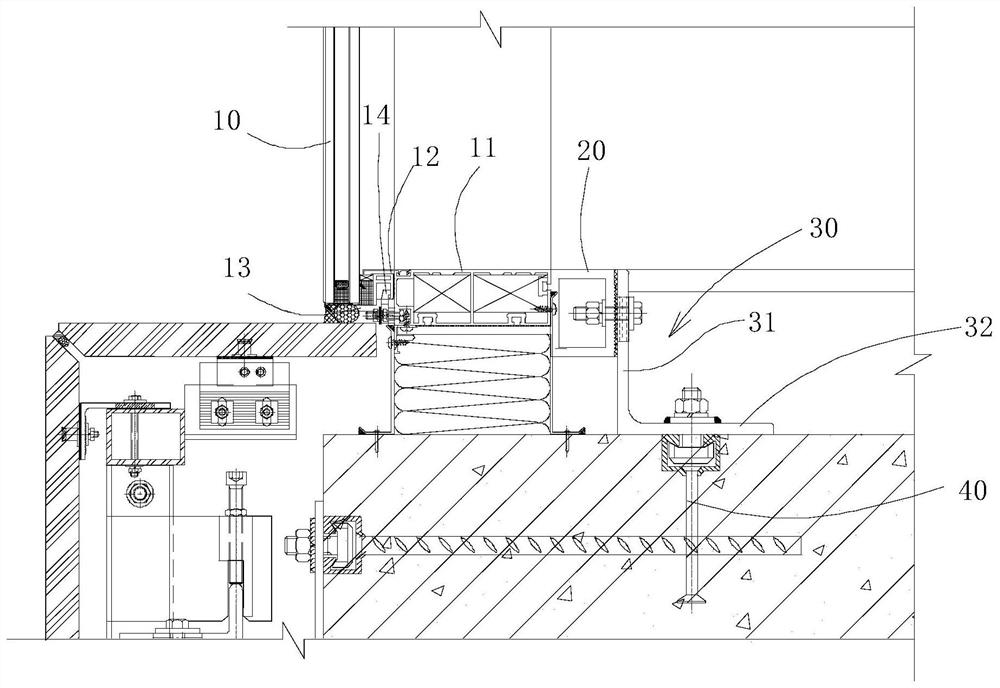

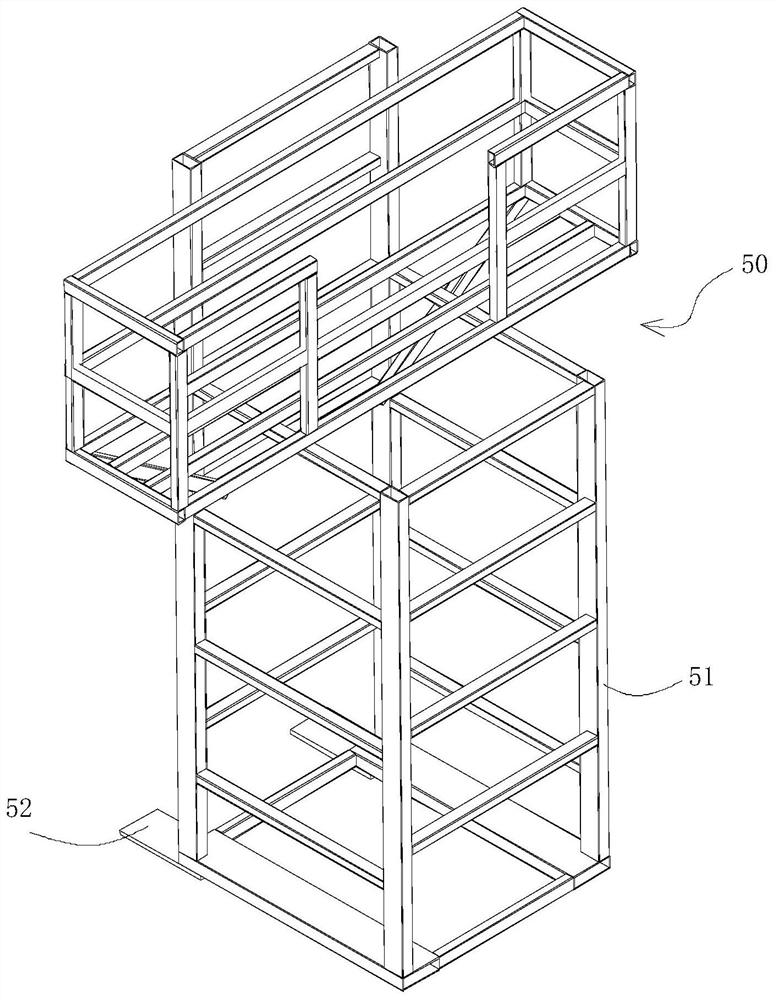

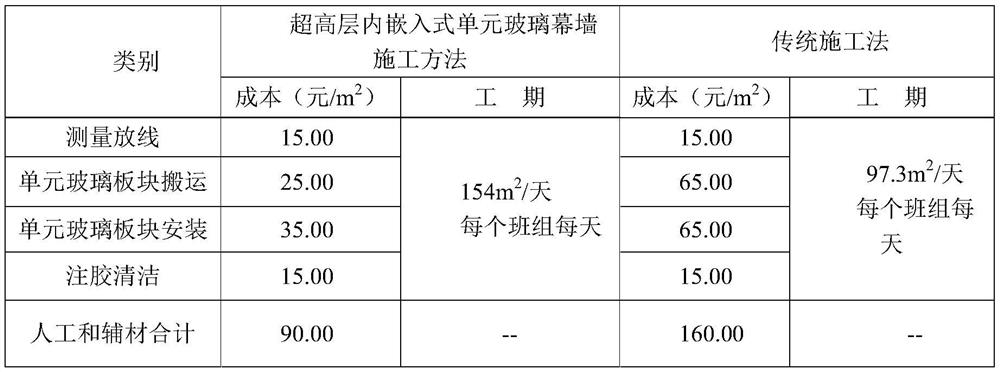

Construction method and structure of embedded unit glass curtain wall in super high-rise

ActiveCN109594697BHigh precisionAvoid the impact of technical level differencesWallsBuilding material handlingArchitectural engineeringSteel frame

The invention provides a construction method and structure of super high-rise embedded unit glass curtain walls. The method comprises the following steps: construction preparation; measuring and setting-out; mounting of slot embedded parts; hoisting of unit glass plates; horizontal transportation of the unit glass plates: the unit glass plates are horizontally transported to vertical turning position points by a forklift and a horizontal transporting steel frame; vertical transportation of the unit glass plates: the unit glass plates are placed vertically from horizontal placement by a vertical turning device, and the forklift drives a vertical transporting steel frame to transport the unit glass plates to proper positions; mounting of the unit glass plates: aluminum supports are mounted on side surfaces of beams of the unit glass plates and connected with steel supports, and the steel supports are mounted in semi-circularen embedded parts. By mechanical transportation and mounting andclamping groove type connection and bolt connection, field mounting efficiency is improved, labor intensity of workers is reduced, construction safety is effectively improved, the construction progress is greatly accelerated, the construction cost is reduced, and engineering construction quality is improved.

Owner:SHENZHEN BAUING CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com