In-furnace wastewater evaporation device and process for coal-fired boiler

A technology for coal-fired boilers and boiler furnaces, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as wastewater cannot be treated, and achieve zero discharge and clear process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

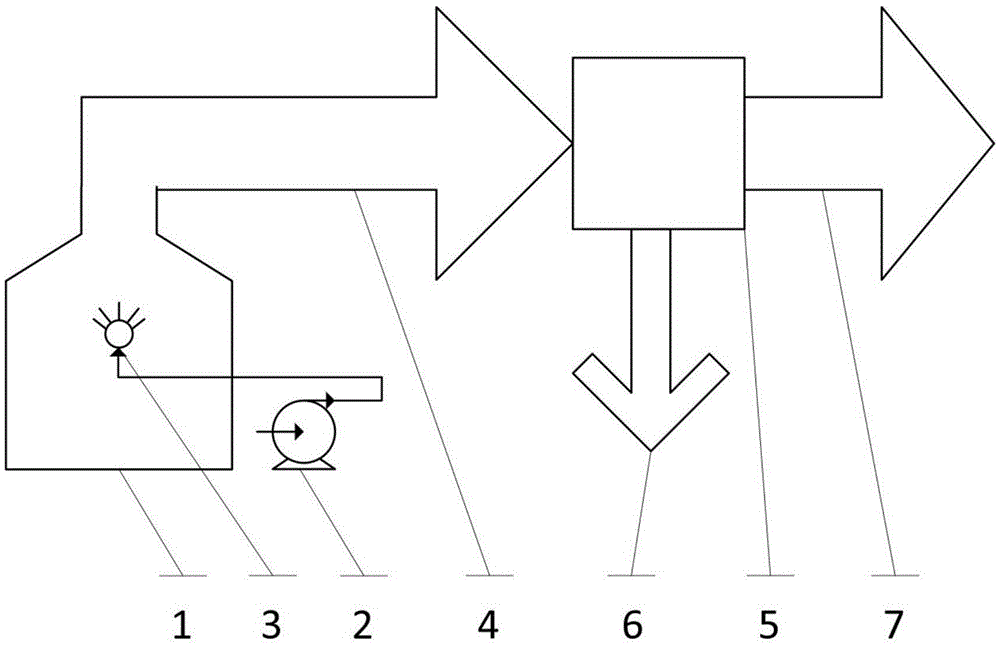

[0016] refer to figure 1 , the present embodiment provides a coal-fired boiler waste water evaporating device, including a coal-fired boiler 1 for coal combustion and a dust collector 5 for removing dust particles in the flue gas. The ash conveying pipeline 6 and the follow-up flue 7 for transporting the filtered flue gas, the coal-fired boiler 1 and the dust collector 5 are connected through the dust removal flue 4; the coal-fired boiler 1 is equipped with an atomizing nozzle 3, and the coal-fired boiler 1 is provided with a water pump 2 for extracting waste water, and the atomizing nozzle 3 and the water pump 2 are connected through pipelines.

[0017] A process for evaporating waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com