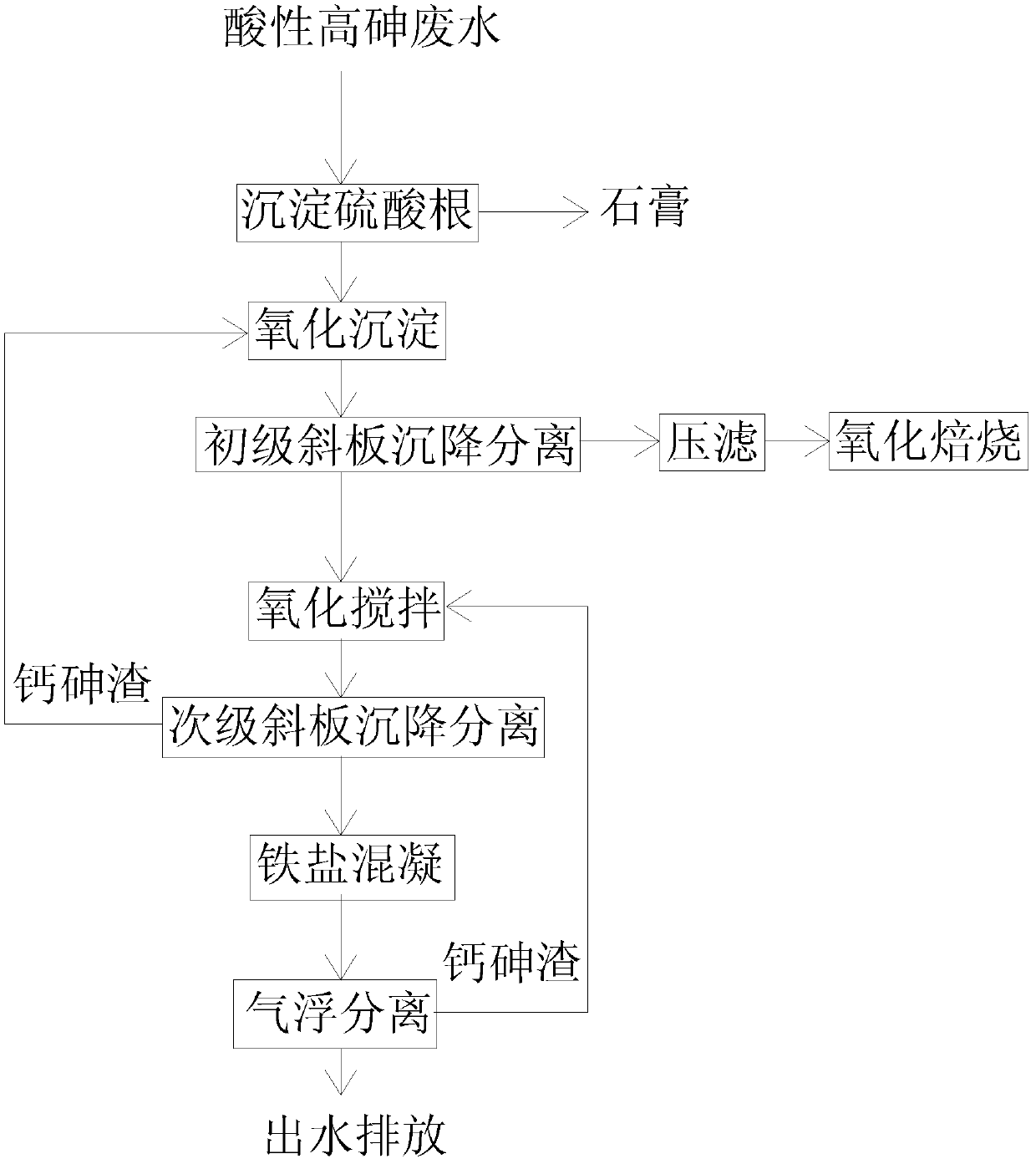

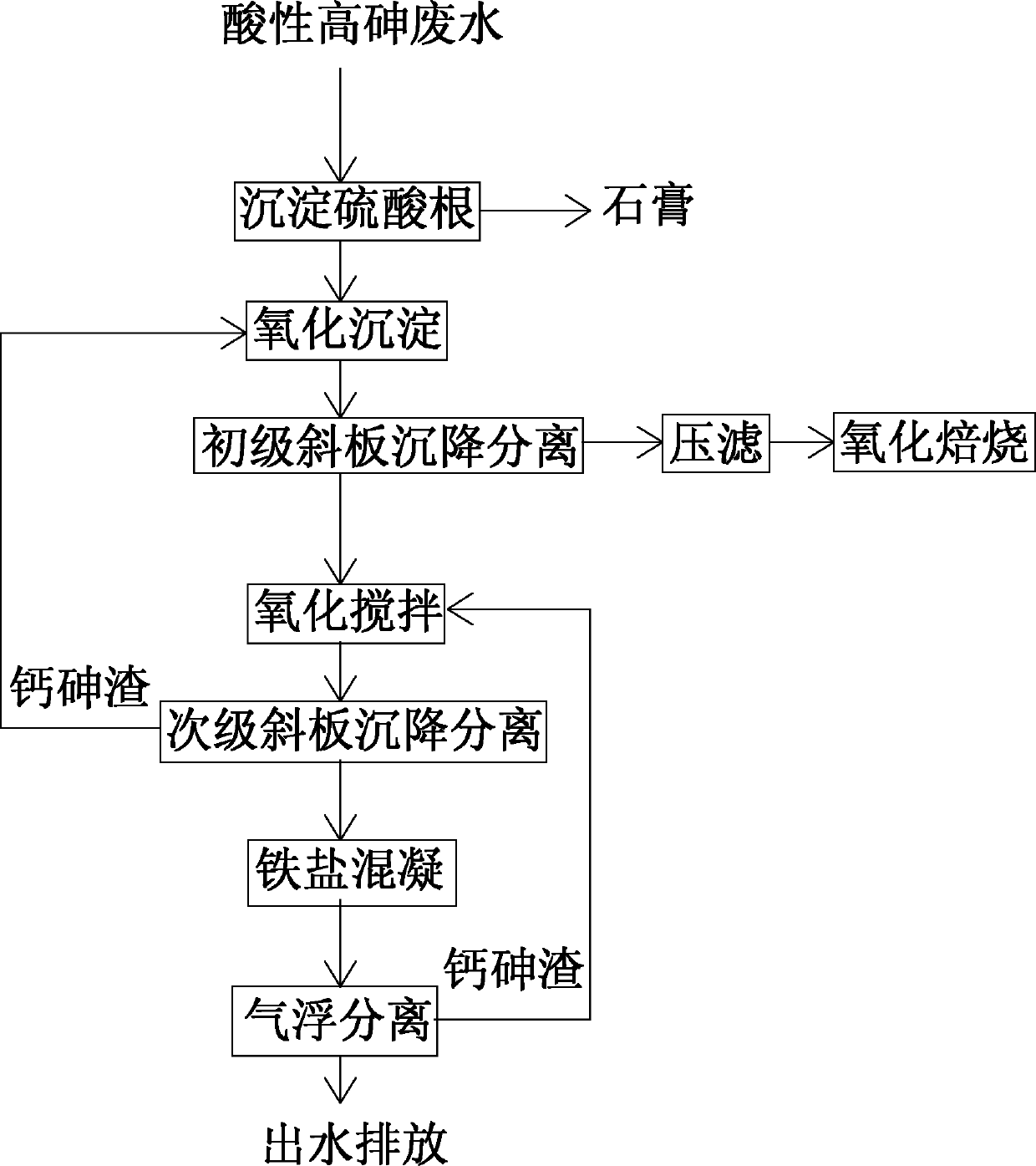

Coupling process method for high-concentration arsenic acidic wastewater

A treatment method and technology for wastewater, applied in the field of water treatment, can solve problems such as high operating cost and atmospheric pollution, and achieve the effects of low operating cost, high arsenic removal rate, and harmless treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A treatment method for arsenic-containing wastewater discharged from the sulfuric acid workshop of a copper smelter, the treatment capacity of arsenic-containing wastewater is 10 m3 / h, the acid concentration is 6%, and the arsenic (As) content in the waste water reaches 4.8g / L. The steps to adopt this processing method are as follows:

[0033] (1) Precipitation of sulfate radicals: add milk of lime to the arsenic-containing wastewater to adjust the pH value, adjust the pH to 1, separate solid-liquid to obtain gypsum and arsenic-containing wastewater, and take out the gypsum after pressure filtration;

[0034] (2), oxidation precipitation: add milk of lime to the liquid separated in the previous step and add calcium hypochlorite at the same time, the molar ratio of calcium hypochlorite to the arsenic content in the treated wastewater is 1, control the reaction pH to be about 10, stir After the reaction is completed, the waste water enters the next step;

[0035] (3) P...

Embodiment 2

[0042] An application for the treatment of arsenic-containing wastewater discharged from the sulfuric acid workshop of a copper smelter. The treatment capacity of arsenic-containing wastewater is 10m3 / h, the acid concentration is 6%, and the arsenic (As) content in the wastewater reaches 4.8g / L. The steps for processing in this method are as follows:

[0043] (1) Precipitation of sulfate radicals: add milk of lime to the arsenic-containing wastewater to adjust its pH value, adjust the pH to 2, separate the solid and liquid to obtain gypsum and arsenic-containing wastewater, and take out the gypsum after pressure filtration;

[0044] (2) Oxidation precipitation: Add lime milk and sodium chlorate to the arsenic-containing wastewater adjusted in the previous step. The molar ratio of sodium chlorate to the arsenic content in the treated wastewater is 5, and the pH of the reaction is controlled to be about 12. , stirring until the waste water after the reaction is completed enters...

Embodiment 3

[0052] A specific embodiment for the treatment of arsenic-containing wastewater discharged from the sulfuric acid workshop of a copper smelter. The treatment capacity of arsenic-containing wastewater is 10m3 / h, the acid concentration is 6%, and the arsenic (As) content of the wastewater reaches 3.5g / L. The steps for processing in this method are as follows:

[0053] (1) Precipitation of sulfate radicals: add milk of lime to the arsenic-containing wastewater to adjust the pH value, adjust the pH to about 1.5, separate solid-liquid to obtain gypsum and arsenic-containing wastewater, and take out the gypsum after pressure filtration;

[0054] (2) Oxidation precipitation: Add lime milk and Fenton's reagent to the arsenic-containing wastewater adjusted in the previous step. The molar ratio of Fenton's reagent to the arsenic content in the treated wastewater is 2, and the pH of the reaction is controlled to be about 11. , stirring until the waste water after the reaction is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com