High-performance structural material and preparation method thereof

A structural material and high-performance technology, applied in the manufacture of tools, wood processing appliances, etc., can solve the problems of reducing the mechanical properties of wood, and achieve the effect of excellent mechanical properties, outstanding comprehensive performance, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

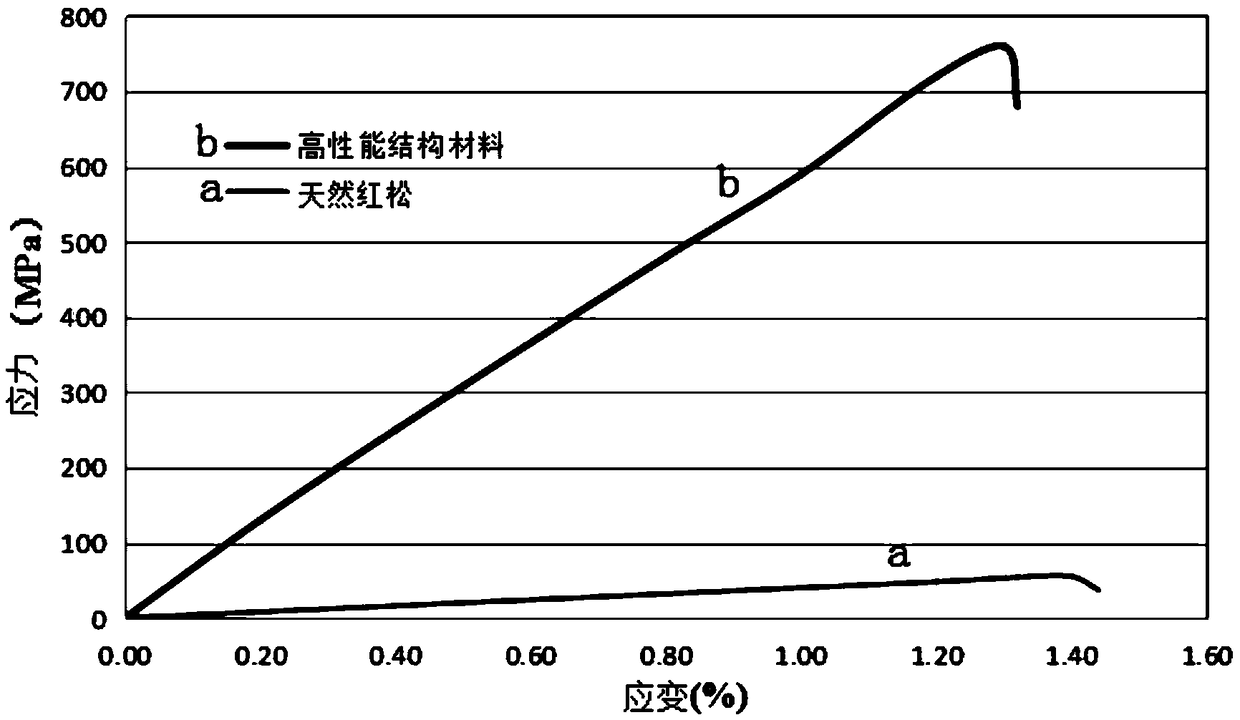

Embodiment 1

[0043] This example provides a method for preparing high-performance structural materials from Korean pine (place of origin: Daxinganling, tree age: 5 years). Table 1 shows the raw material composition analysis table of Korean pine.

[0044] Table 1-The raw material composition analysis table of Korean pine

[0045] composition name

α-cellulose

Benzyl Alcohol Extract

Silicon content

Ash

content(%)

45

17

24

4.8

0.3

1.6

[0046] The fiber size measurement table of Korean pine is shown in Table 2.

[0047] Table 2 - Fiber Size Measurement Chart for Korean Pine

[0048]

[0049] The specific steps for preparing high-performance structural materials with Korean pine as raw materials are as follows:

[0050] (1) The cellulose in Korean pine (20cm×5cm×5cm) is firstly purified by alkali treatment, and then subjected to secondary purification to obtain purified lignin content<15% and hemicellulose ...

Embodiment 2

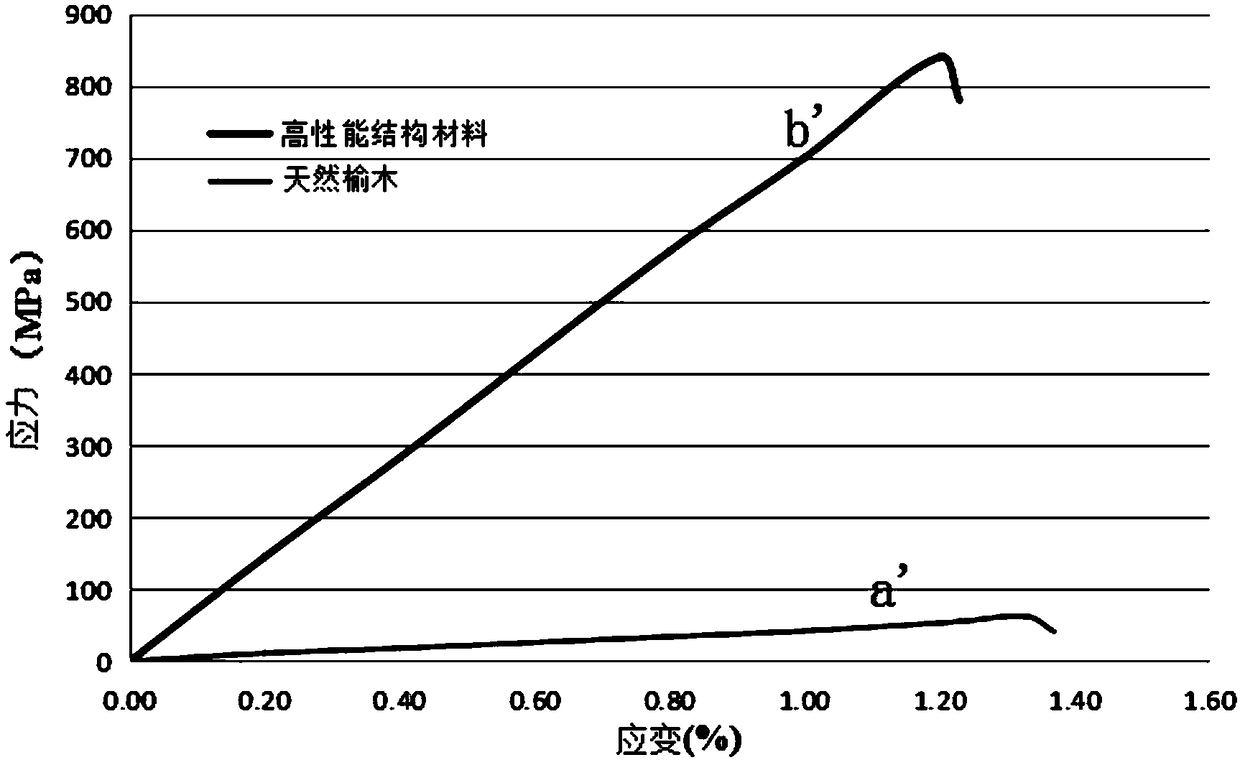

[0057] This example provides a method for preparing a high-performance structural material using elm (place of origin: North China, tree age: 7 years) as a raw material. Table 3 shows the raw material composition analysis table of elm.

[0058] Table 3-The raw material composition analysis table of elm

[0059] composition name

α-cellulose

lignin

Benzyl Alcohol Extract

Silicon content

Ash

content(%)

49

12

29

3.7

0.5

1.2

[0060] The fiber size measurement table of elm is shown in Table 4.

[0061] Table 4 - Fiber Size Measurement Chart for Elm Wood

[0062]

[0063] The specific steps for preparing high-performance structural materials from elm wood are as follows:

[0064] (1) The cellulose in elm wood (20cm × 5cm × 5cm) is firstly purified by solvent method, and then subjected to secondary purification to obtain purified lignin content < 15% and hemicellulose content < 8%. wood; the specific o...

Embodiment 3

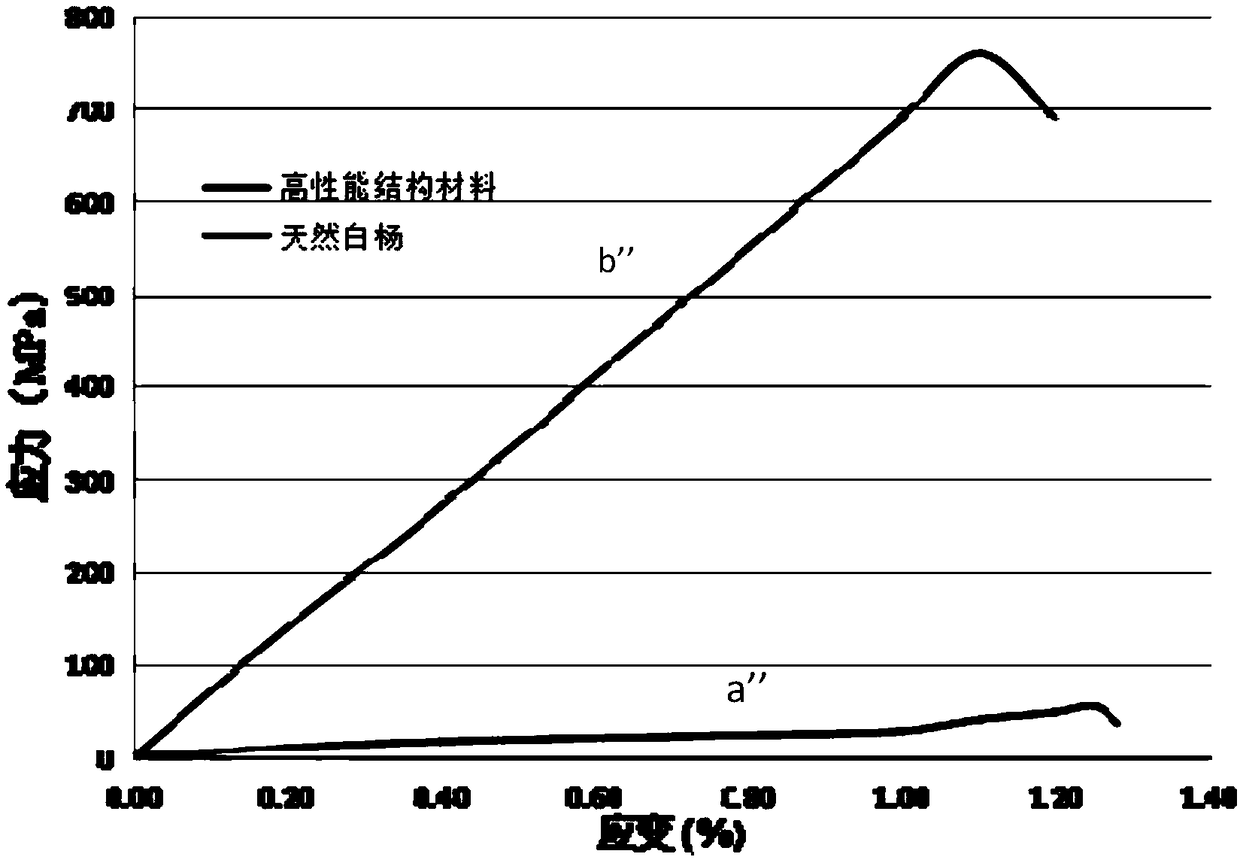

[0071] This example provides a method for preparing high-performance structural materials from natural poplar (place of origin: North China, tree age: 5 years). Table 5 shows the raw material composition analysis table of poplar.

[0072] Table 5-The raw material composition analysis table of poplar

[0073] composition name

α-cellulose

lignin

Benzyl Alcohol Extract

Silicon content

Ash

content(%)

51

15

24

2.7

0.3

0.7

[0074] The fiber size measurement table of poplar is shown in Table 6.

[0075] Table 6 - Fiber Size Measurement Chart for Poplar

[0076]

[0077] The specific steps for preparing high-performance structural materials from poplar are as follows:

[0078] (1) Carry out a purification process to the cellulose in poplar (20cm * 5cm * 5cm) by high temperature hydrothermal method, obtain the wood after the purification of lignin content<15%, hemicellulose content<8%; Carry out describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com