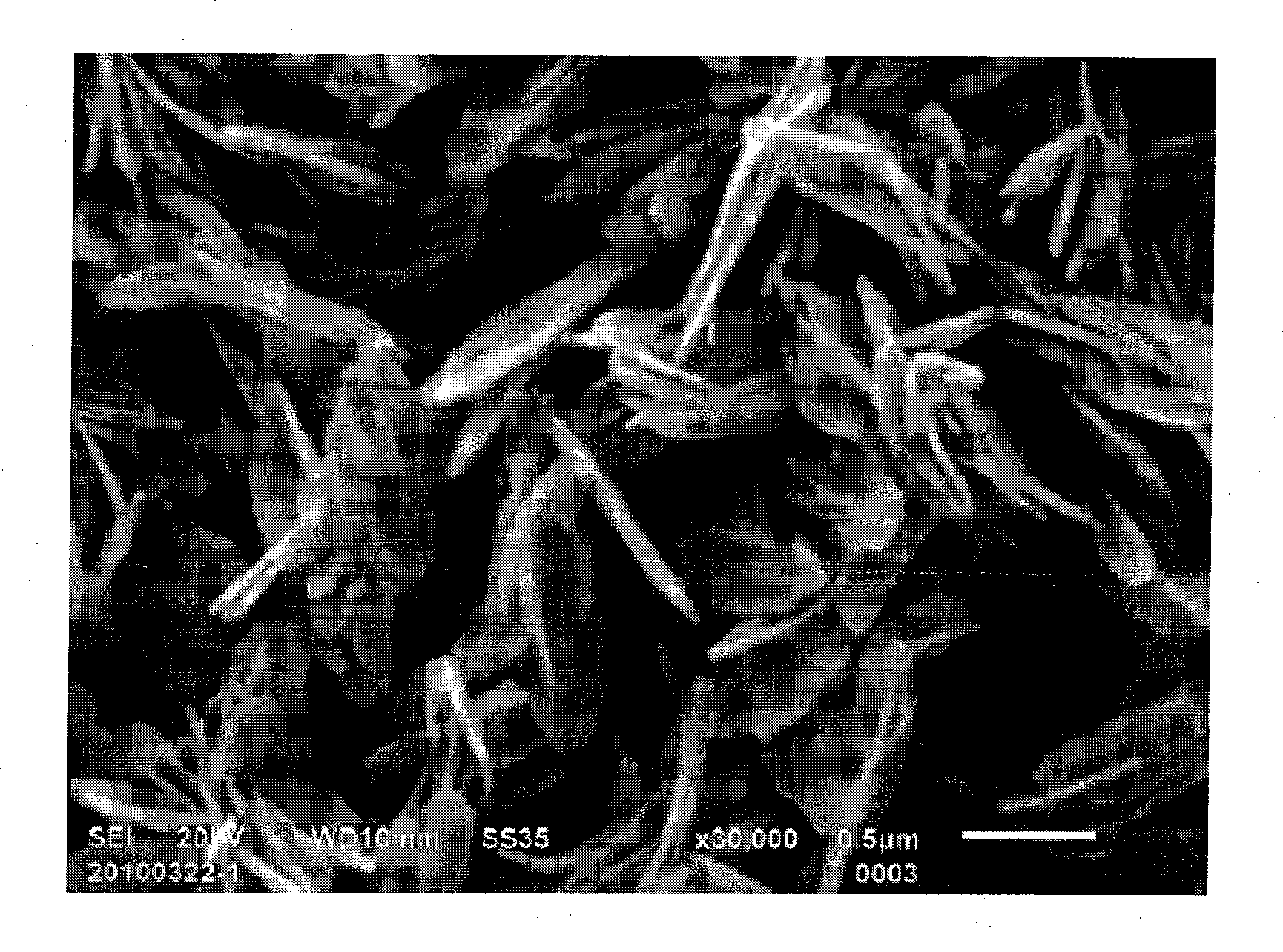

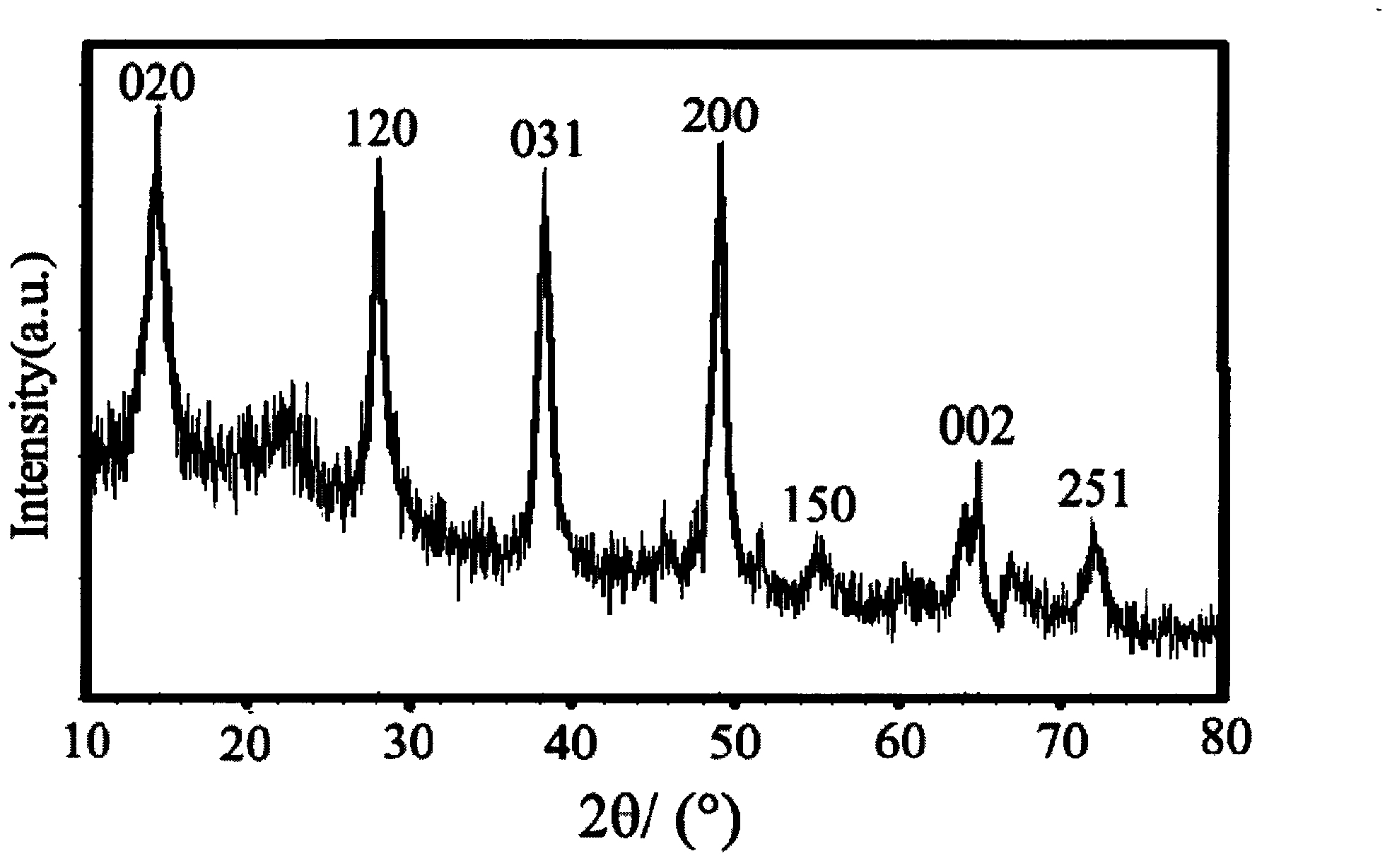

Method for preparing boehmite micropowder having three-dimensional flaky aggregate morphology

A technology of ultra-fine powder and aggregate, applied in the direction of alumina/aluminum hydroxide, etc., to achieve the effect of easy availability of raw materials, uniform dispersion and clear process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Embodiment 1: The method for preparing the boehmite ultrafine powder I with three-dimensional plate-like aggregate morphology includes the following steps,

[0018] 1) A certain amount of analytically pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred on a magnetic stirrer until dissolved to obtain Al 3+ Solution A with the concentration of the substance being 0.1mol / L;

[0019] 2) Add precipitation Al in the solution A that step 1) makes 3+ 125% analytically pure urea of the required theoretical demand, and stirred for 0.5h to prepare solution B;

[0020] 3) A certain amount of amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate is dissolved in tetrahydrofuran to obtain amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate The amount concentration of the substance is 1.25×10 -3 mol / L solution C;

[0021] 4) Add 1 mL of solution C prepared in step 3) to solution B prepared in step 2) to obtain suspension D;

...

Embodiment approach 2

[0025] Embodiment 2: The method for preparing boehmite ultrafine powder II with three-dimensional plate-like aggregate morphology includes the following steps,

[0026] 1) A certain amount of analytically pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred on a magnetic stirrer until dissolved to obtain Al 3+ The concentration of the substance is 0.2mol / L solution A;

[0027] 2) Add precipitation Al in the solution A that step 1) makes 3+ 150% analytically pure urea of the required theoretical demand, and stirred for 0.5h to prepare solution B;

[0028] 3) A certain amount of amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate is dissolved in tetrahydrofuran to obtain the amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate The amount concentration of the substance is 1.25×10 -3 mol / L solution B;

[0029] 4) Add 2 mL of solution C prepared in step 3) to solution B prepared in step 2) to obtain suspension D;

[0030]...

Embodiment approach 3

[0032] Embodiment 3: The method for preparing boehmite ultrafine powder III with three-dimensional sheet-like aggregate morphology includes the following steps,

[0033] 1) A certain amount of analytically pure Al(NO 3 ) 3 9H 2 O was added to deionized water and stirred on a magnetic stirrer until dissolved to obtain Al 3+Solution A with the concentration of the substance being 0.3mol / L;

[0034] 2) Add precipitation Al in the solution A that step 1) makes 3+ 125% analytically pure urea of the required theoretical demand, and stirred for 0.5h to prepare solution B;

[0035] 3) A certain amount of amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate is dissolved in tetrahydrofuran to obtain amphiphilic block copolymer polystyrene-block-polyhydroxyethyl acrylate The amount concentration of the substance is 1.25×10 -3 mol / L solution C;

[0036] 4) Add 2 mL of solution C prepared in step 3) to solution B prepared in step 2) to obtain suspension D;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com