Method and device for recycling heat energy of compressed air of aerobe fermentation system

An aerobic microorganism, compressed air technology, applied in separation methods, chemical instruments and methods, water heaters, etc., can solve the problems of consumption, waste, large cooling water, etc., achieve clear process flow, simple transformation, and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

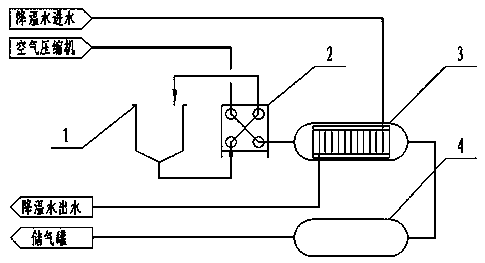

[0040] Example 2 The method and device for recovering compressed air heat energy in an aerobic microbial fermentation system, the structure can still refer to the attached figure 1 , but different from Example 1, the volume of the exchange water tank 1 is 140m 3 ; The heat transfer area of the plate heat exchanger 2 is 350m 2 , the heat exchange area of cooling water heat exchanger 3 is 200m 2 ; The treatment flow rate of the water eliminator 4 is 1500L / min; the displacement of the air compressor is 120m 3 / min; the volume of the gas storage tank is 800m 3 .

[0041] 20000m 3 / h, 150~160oC, 0.3Mpa compressed air, enters the welded plate heat exchanger 2, lowers the temperature to about 95oC, and further heat exchange and cooling through the cooling water heat exchanger 3, after being dewatered by the water eliminator 4, enters gas tank. The heat exchange water at about 20oC in the heat exchange tank 1 enters the welded plate heat exchanger 2, and the temperature is ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com