Highway tunnel structure based on intelligent power generation and construction method of highway tunnel structure

A technology for road tunnels and construction methods, applied in the direction of circuit devices, circuit layouts, battery circuit devices, etc., can solve the problems of high lighting costs and high energy consumption, and achieve the effects of reducing operating costs, ensuring driving safety, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

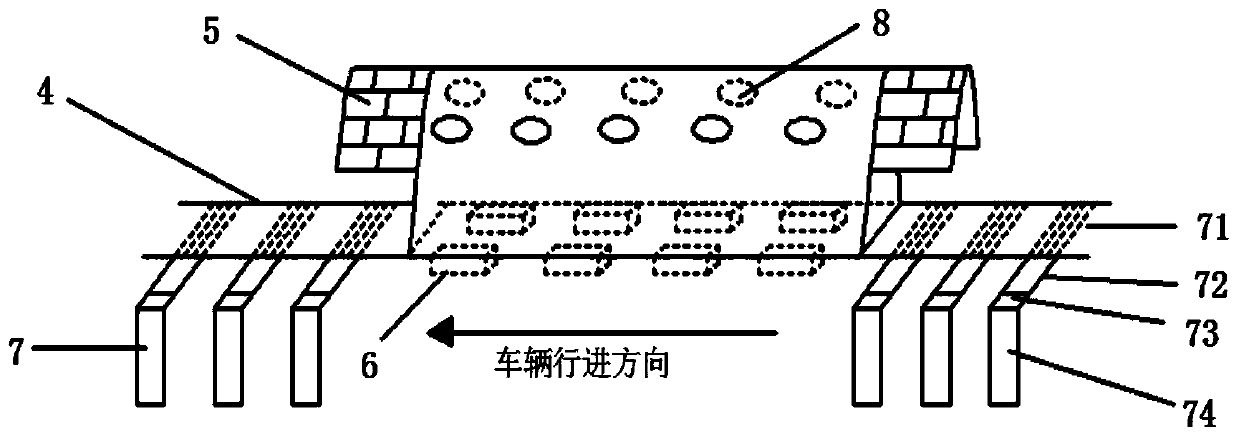

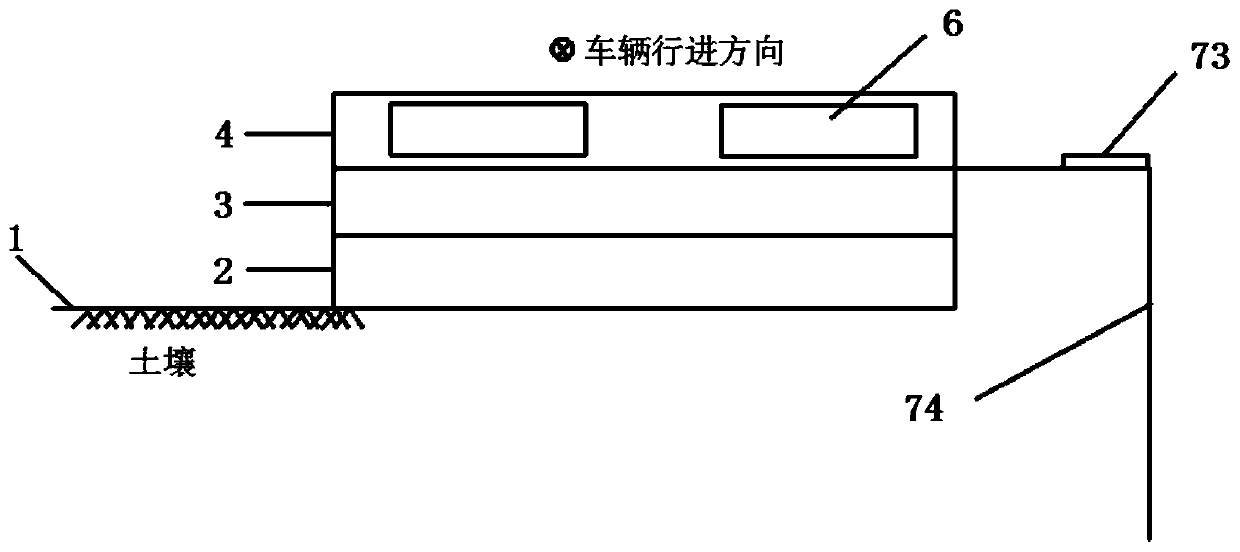

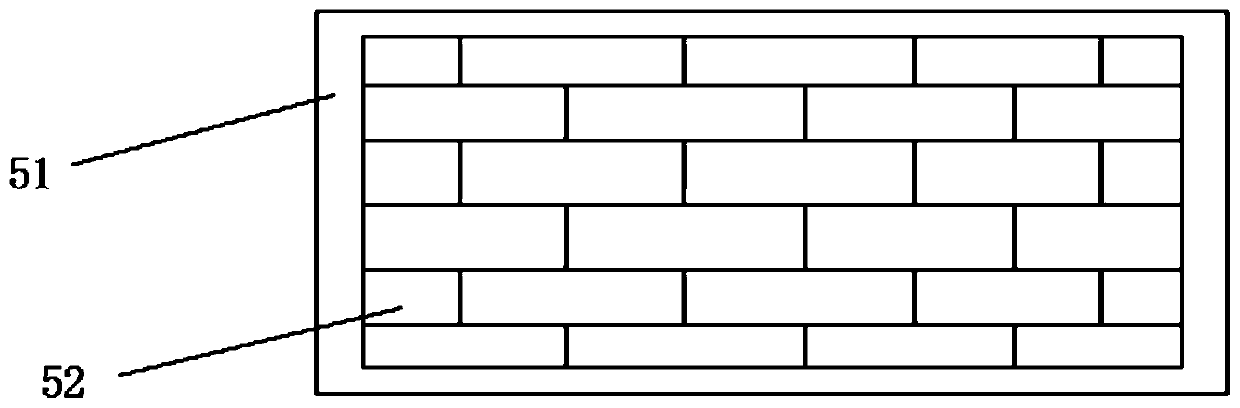

Embodiment 1

[0106] Firstly, excavate the tunnel according to the design drawings and "Technical Specifications for Construction of Highway Tunnels" (JTG F60-2009), mainly including the construction of the entrance section and the portal, tunnel excavation construction, primary support construction, tunnel waterproof and drainage construction, secondary lining construction, etc. Process: After the tunnel construction is completed, the arched beam is constructed at the tunnel entrance. First, the steel frame is welded, the formwork is installed, and then the cement concrete is poured. After the cement concrete is solidified, the formwork is removed and the steel frame structure is installed. The steel bars are connected to form a network structure; epoxy resin bonding materials are prepared at the construction site, and the prepared epoxy resin is coated on the steel frame structure and the back of the solar power generation panel to bond the solar power generation panel to the steel frame st...

Embodiment 2

[0109] Firstly, excavate the tunnel according to the design drawings and "Technical Specifications for Construction of Highway Tunnels" (JTG F60-2009), mainly including the construction of the entrance section and the portal, tunnel excavation construction, primary support construction, tunnel waterproof and drainage construction, secondary lining construction, etc. Process: After the tunnel construction is completed, the arched beam is constructed at the tunnel entrance. First, the steel frame is welded, the formwork is installed, and then the cement concrete is poured. After the cement concrete is solidified, the formwork is removed and the steel frame structure is installed. The steel bars are connected to form a network structure; epoxy resin bonding materials are prepared at the construction site, and the prepared epoxy resin is coated on the steel frame structure and the back of the solar power generation panel to bond the solar power generation panel to the steel frame st...

Embodiment 3

[0112] Firstly, excavate the tunnel according to the design drawings and "Technical Specifications for Construction of Highway Tunnels" (JTG F60-2009), mainly including the construction of the entrance section and the portal, tunnel excavation construction, primary support construction, tunnel waterproof and drainage construction, secondary lining construction, etc. Process: After the tunnel construction is completed, the arched beam is constructed at the tunnel entrance. First, the steel frame is welded, the formwork is installed, and then the cement concrete is poured. After the cement concrete is solidified, the formwork is removed and the steel frame structure is installed. The steel bars are connected to form a network structure; the polyurethane bonding material is prepared on the construction site, and the prepared polyurethane is coated on the steel frame structure and the back of the solar power panel to bond the solar power panel to the steel frame structure to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com