Construction method and structure of embedded unit glass curtain wall in super high-rise

A construction method and glass curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve unrealistic, large glass unit plates are not easy to put into window openings, glass plate adjustment and positioning difficulties, etc., to achieve aerial work The effects of quantity reduction, complete quality control system, and avoiding the influence of technical level differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

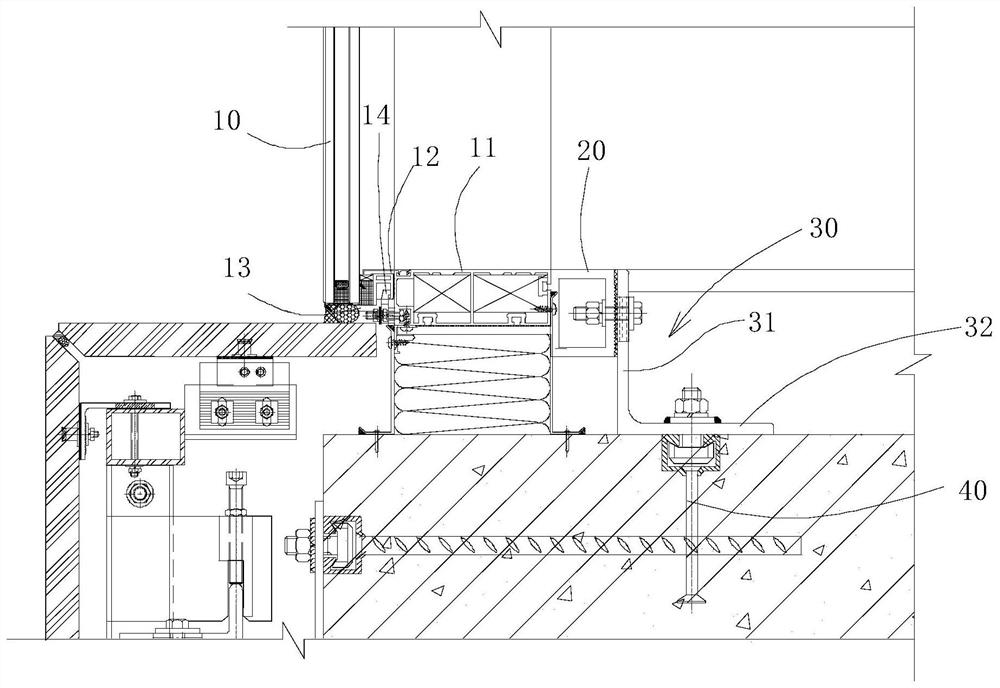

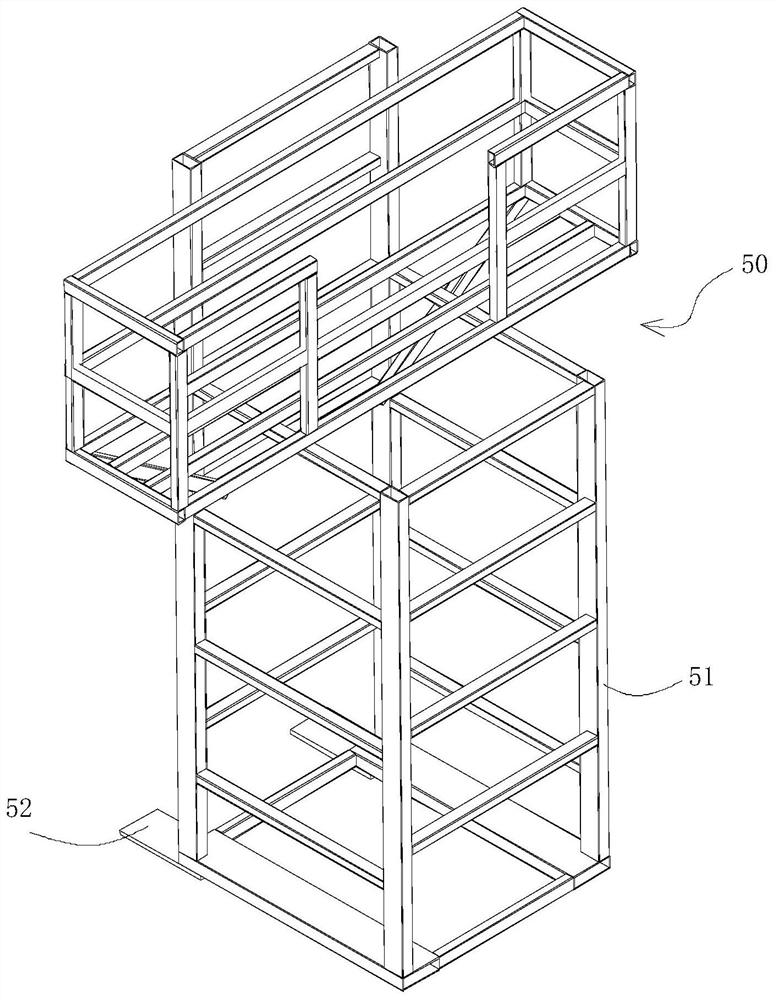

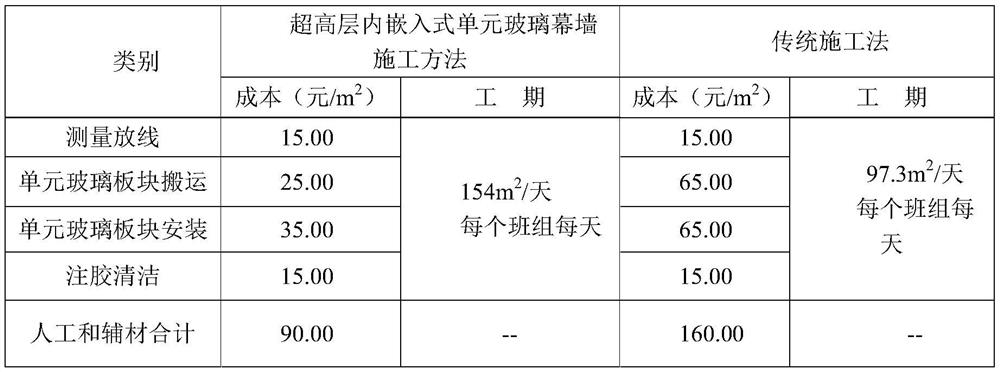

[0027] The invention relates to a construction method for a super-high-rise embedded unit glass curtain wall, comprising the following steps:

[0028] Step 1. Construction preparation

[0029] Material preparation: According to the drawings and engineering conditions, prepare a detailed material order supply plan.

[0030] Preparation of construction machinery and tools: inspect the machinery and tools used to ensure their good performance, especially the forklifts and supporting facilities used to move the unit glass plates.

[0031] Personnel preparation: Organize relevant technical personnel to familiarize themselves with the actual situation of the construction site, provide technical training to technical workers, and make technical disclosures.

[0032] Technical preparation: Familiar with the construction drawings, and prepare the construction organization design scheme, quality acceptance standards and forms used for engineering data.

[0033] Step 2, measuring and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com