Water-based paint drying system and drying method

A drying system and water-based paint technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of waste of energy consumption, large hidden dangers, easy combustion of paint, etc., to reduce energy consumption Energy consumption, clear technological process, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

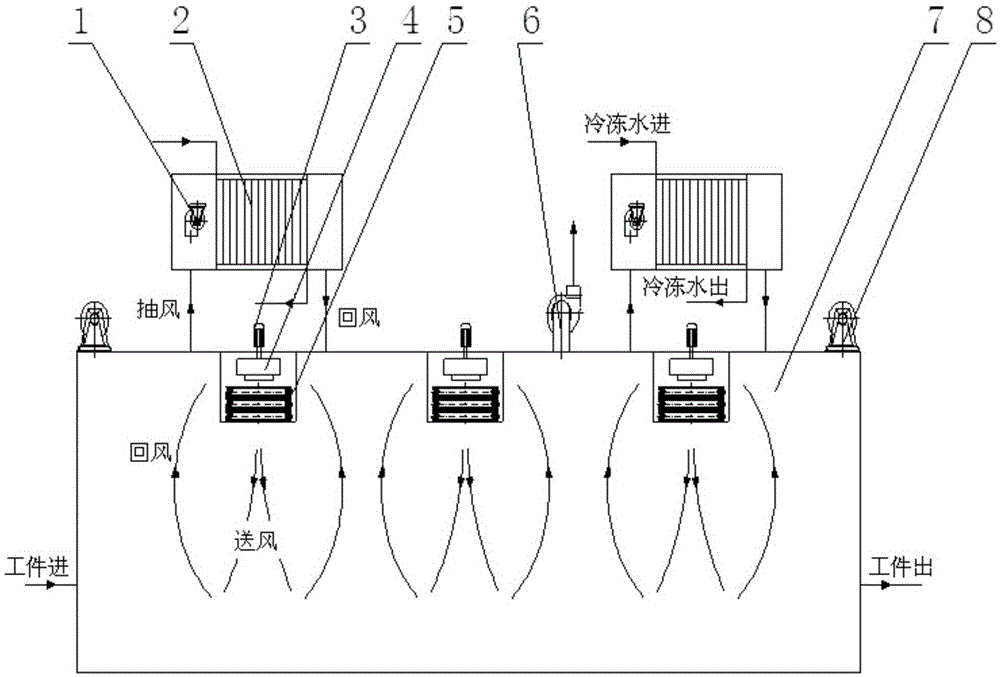

[0027] As shown in the figure, the water-based paint drying system in the present invention includes a drying chamber 7, a hot air circulation heating device arranged in the drying chamber 7, a dehumidification device arranged outside the drying chamber 7, and a device for monitoring and controlling The temperature and humidity control system in the drying room; the hot air circulation heating device is mainly composed of a heating coil 5, a circulation fan 4 and a motor 3 connected to the circulation fan 4, and the heating coil 5 uses hot water for heat exchange. Specifically, the hot water in the heating coil 5 exchanges heat with the air in the drying chamber 7, and the internal circulation is formed by the circulating fan 4 to heat the workpiece, so that the water-based paint on the surface of the workpiece is released in time. The hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com