Shock ring rubber assembly for EPS electronic power steering engine and preparation method thereof

A technology of electronic power steering and shock absorbing ring, which is applied in the field of automobile steering gear, and can solve problems such as large load, affecting the comfort and service life of the vehicle, and poor dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

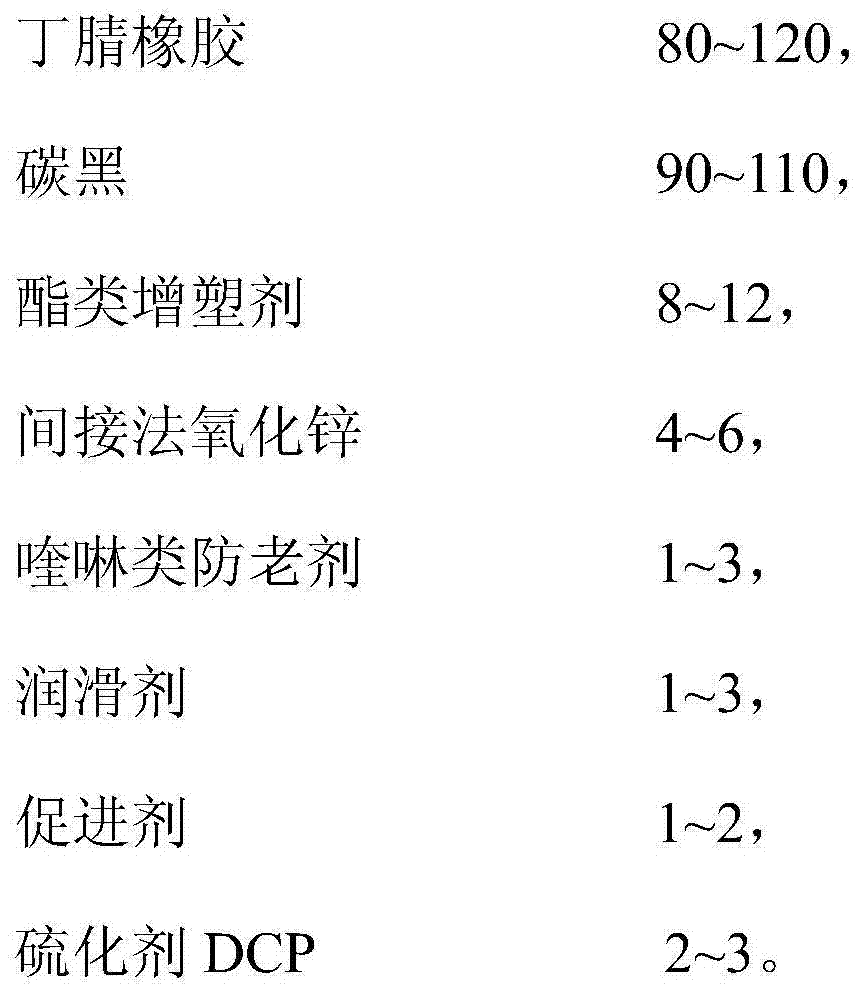

[0057] The EPS electronic power steering shock absorber rubber assembly of this embodiment consists of the following components in parts by weight:

[0058]

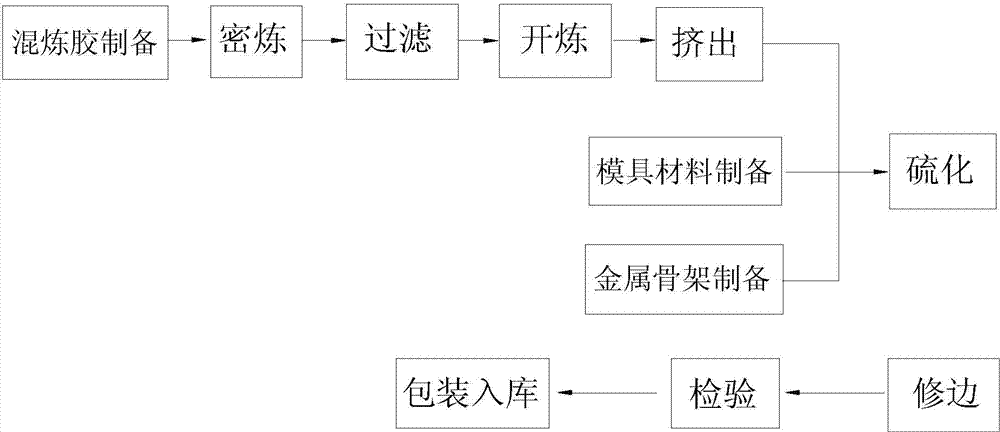

[0059] The preparation method of the EPS electronic power steering shock absorber rubber assembly of the present embodiment includes the following steps:

[0060] a. preparation of synthetic rubber, adding the above-mentioned raw materials in parts by weight into an internal mixer, mixing, and filtering to obtain synthetic rubber;

[0061] b. The molding and vulcanization of rubber, the synthetic rubber obtained in step a is extruded after being uniformly heated by an open mill, and then the extruded rubber strip is injected into the mold in the vulcanization equipment, and the pressure is 170Kgf / cm 2 , the temperature was raised to 175° C., and the vulcanization treatment was carried out for 180 seconds, that is, the temperature of the vulcanization treatment was 175° C., and the time of the vulcanization treatment w...

Embodiment 2

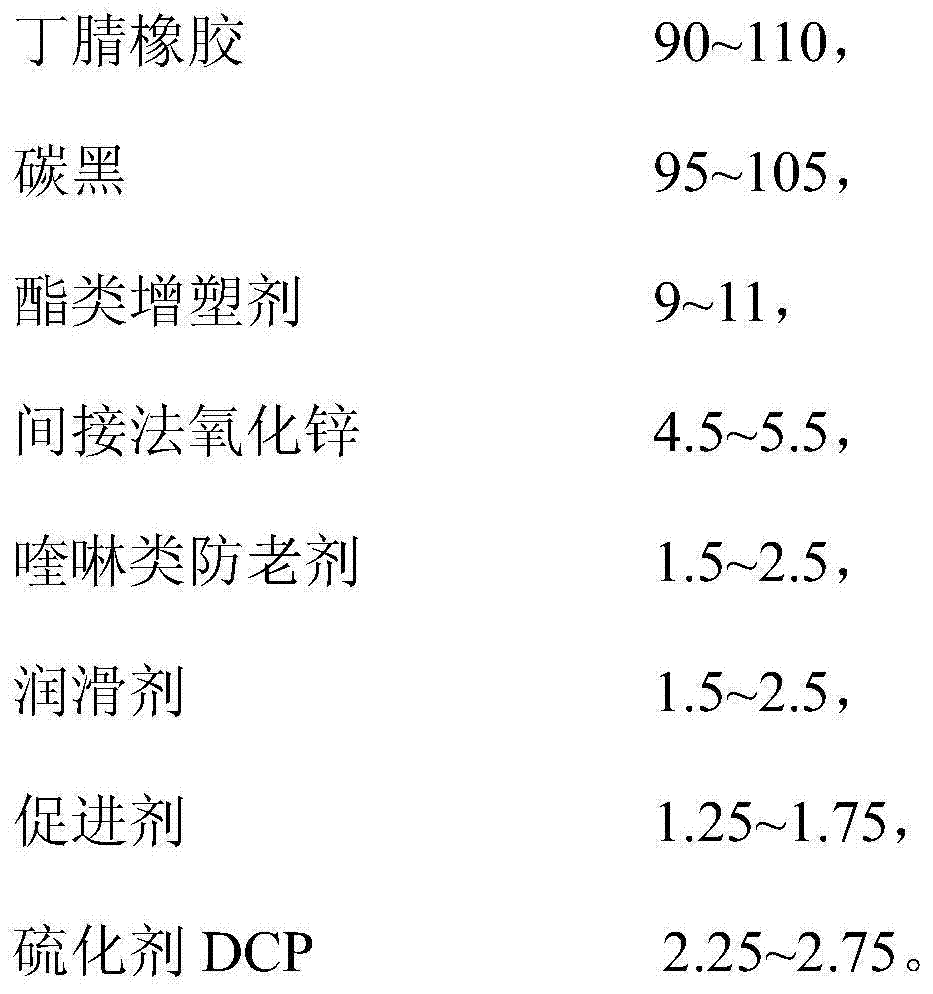

[0063] The EPS electronic power steering shock absorber rubber assembly of this embodiment consists of the following components in parts by weight:

[0064]

[0065] Compared with Embodiment 1, the preparation method of the EPS electronic power steering shock absorber rubber assembly of this embodiment differs in that:

[0066] In step b, pressurize 190Kgf / cm 2 , the temperature of the vulcanization treatment is 165° C., and the time of the vulcanization treatment is 300 seconds.

Embodiment 3

[0068] The EPS electronic power steering shock absorber rubber assembly of this embodiment consists of the following components in parts by weight:

[0069]

[0070] Compared with Example 1, the preparation method of the EPS electronic power steering shock absorber rubber assembly of this embodiment is different in that: in step b, the pressure is 180Kgf / cm2, the temperature of vulcanization treatment is 171°C, and the time of vulcanization treatment for 240 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com