Industrial pilot test performance testing device and industrial pilot test performance testing method for SCR (selective catalytic reduction) denitration catalyst

A denitration catalyst and testing device technology, applied in the field of thermal power generation, can solve the problems of catalyst damage, catalyst life reduction, difficulty in meeting the predetermined denitration requirements, etc., and achieve the effect of clear process flow and small amount of construction work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

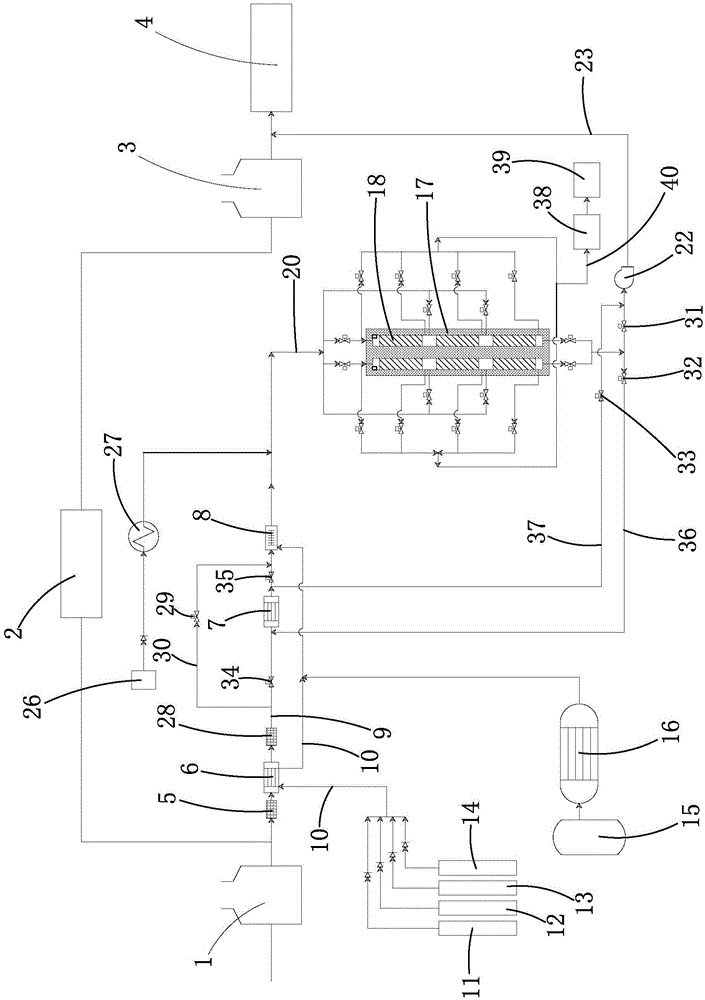

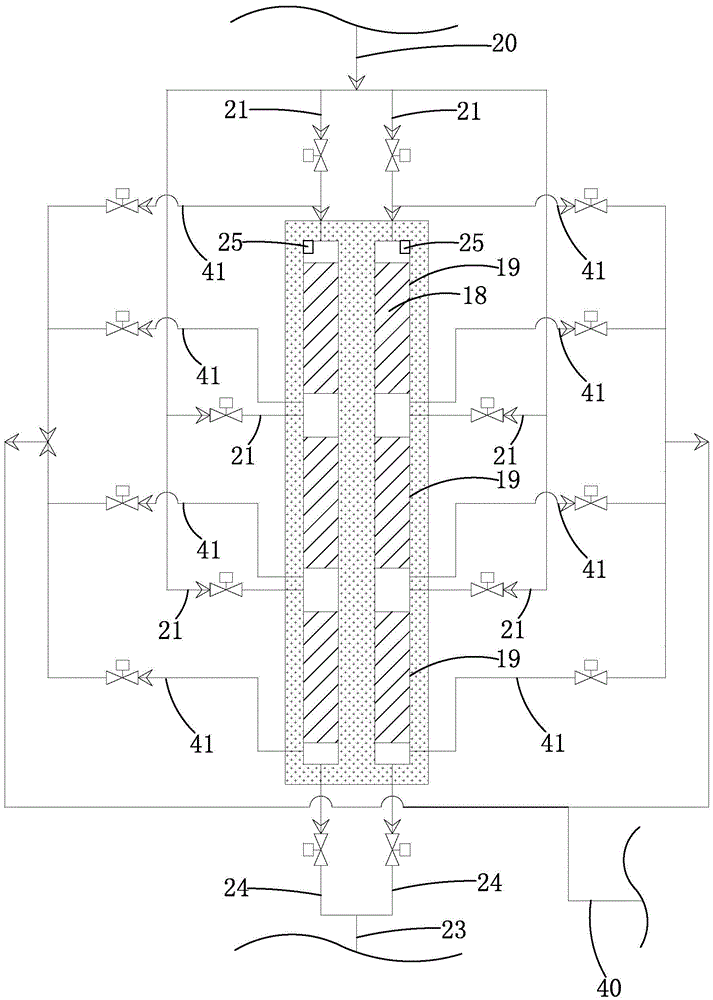

[0026] Such as figure 1 The industrial pilot test performance test device for SCR denitrification catalyst shown is composed of a test device connected to the boiler tail gas pipeline. The boiler tail gas pipeline includes an economizer 1, a selective catalytic reduction reactor connected in series 2. The air preheater 3 and the dust remover 4 are characterized in that the test device includes a gas distribution part connected with the gas outlet of the economizer 1, and a gas distribution part connected with the gas outlet of the air preheater 3. The reaction part and a measurement part arranged on the reaction part, the test device realizes the gas distribution and reaction of the boiler tail gas through the gas distribution part and the reaction part, and the sample gas collection and analysis are carried out thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com