Precast slab formwork nesting connection structure and construction method

A technology of nested connection and prefabricated panels, which is applied in basic structure engineering, construction, etc., can solve problems such as low work efficiency and complex support structure, and achieve the effects of high work efficiency, shortened construction period, and convenient and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

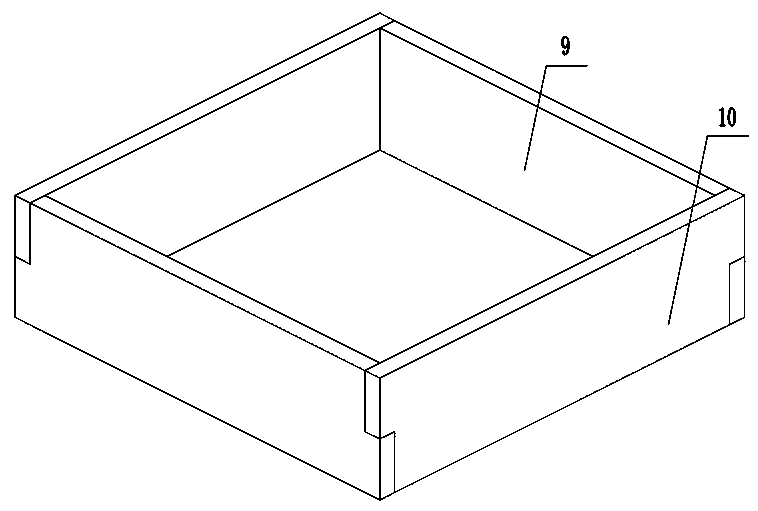

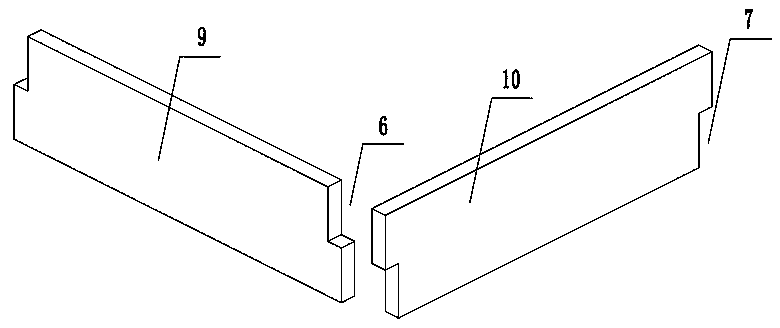

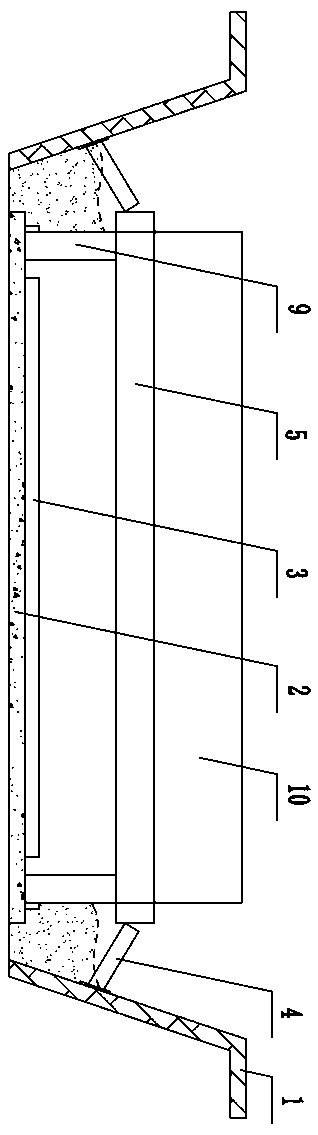

[0034] Such as Figure 1~Figure 4 As shown, a prefabricated slab membrane nested connection structure includes a foundation pit 1, a cushion layer 2 arranged at the bottom of the foundation pit 1, and a platform foundation arranged on the cushion layer 2, which is located on the surrounding sides of the platform foundation. , The upper plane of the cushion layer 2 is provided with a U-shaped card slot 3;

[0035] The U-shaped slots 3 on both sides of the foundation length and width direction of the platform are respectively provided with a prefabricated panel 9 and a prefabricated panel 2 10, and the adjacent prefabricated panels 9 and 2 are embedded with each other. Cover to form a board membrane, and the sides of the board membrane are horizontally provided with square wood 5 to clamp the prefabricated board one 9 and the prefabricated board two 10;

[0036] A steel pipe 4 is arranged between the square timber 5 and the side wall of the foundation pit 1 for support.

[003...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, and the similarities will not be described again. The difference is that the steel pipe 4 is not provided in this embodiment, and the square wood 5 can be directly used to support the board membrane.

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that square wood 5 is not provided in this embodiment, and steel pipe 4 can be directly used to support the board membrane, that is, one end of steel pipe 4 rests on the On the prefabricated slab, the other end is against the side wall of the foundation pit 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com