Patents

Literature

32results about How to "Save engineering expenses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

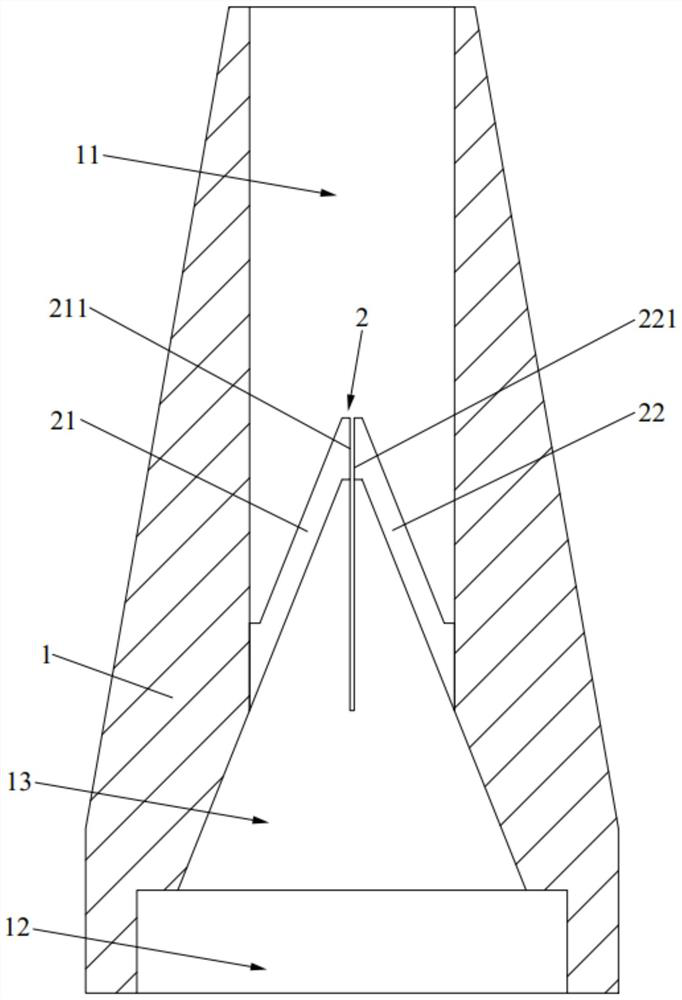

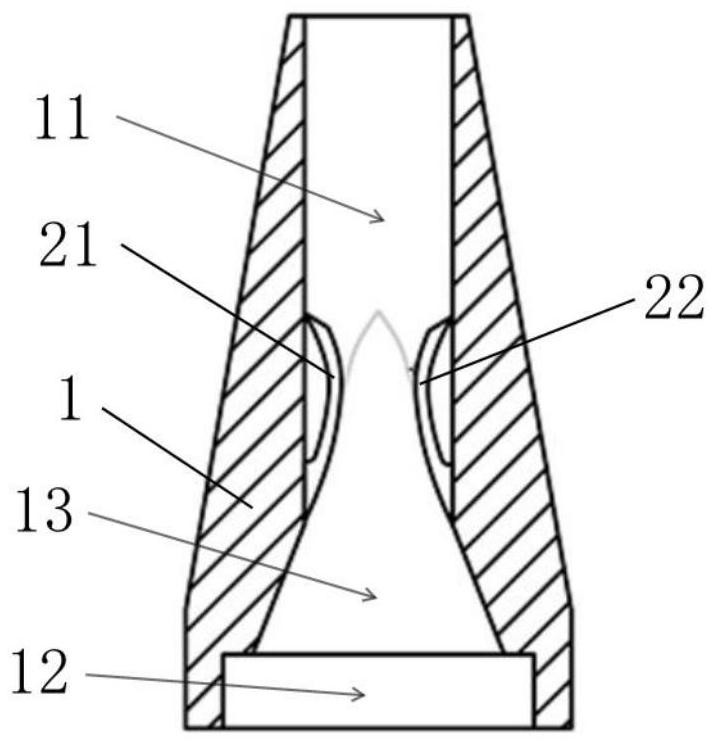

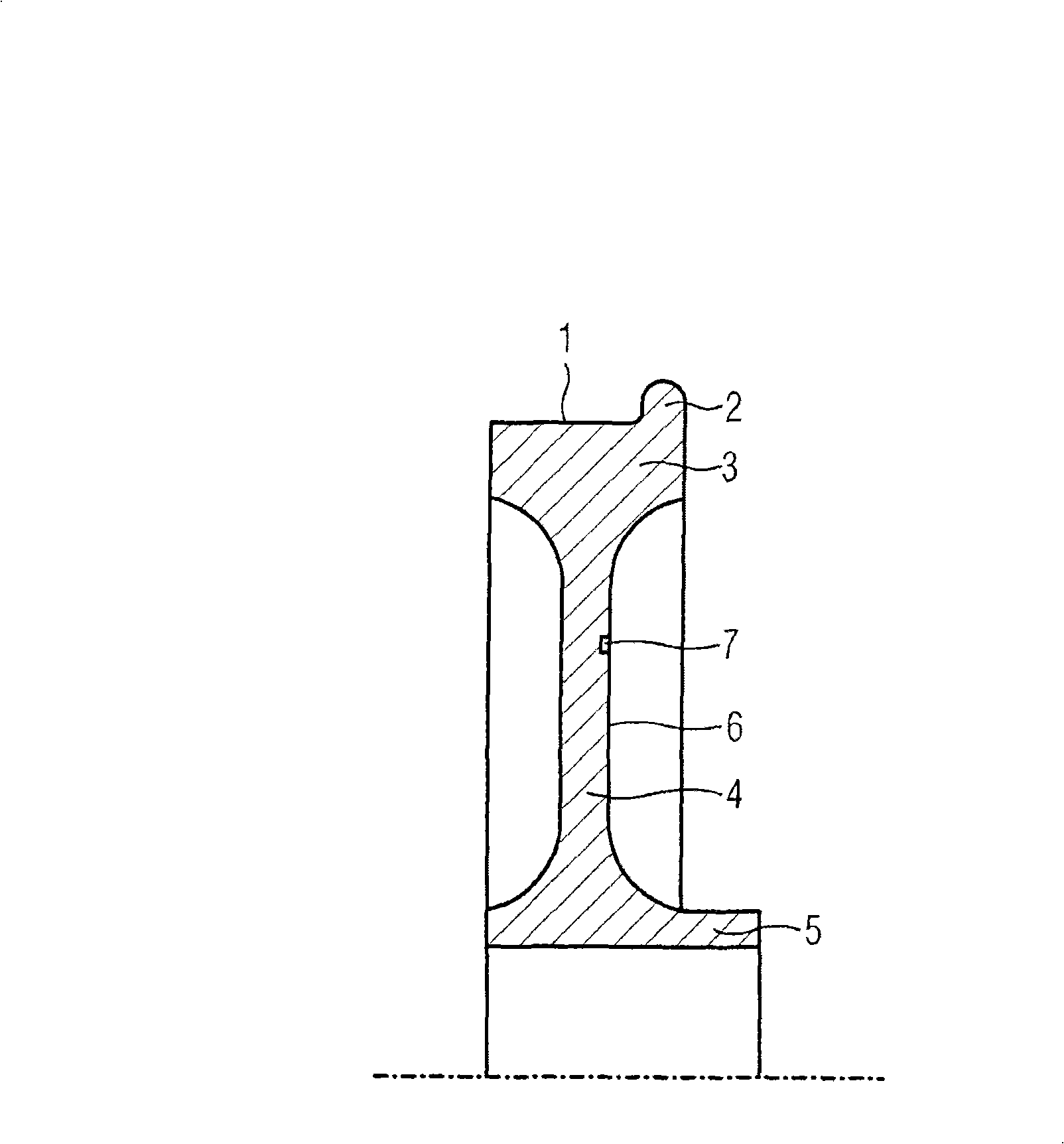

Glue-sizing double R groove shaped conductive thread expanding pulley

ActiveCN101364717AAvoid Squeeze CollisionsExtended service lifeApparatus for overhead lines/cablesArchitectural engineeringShort radius

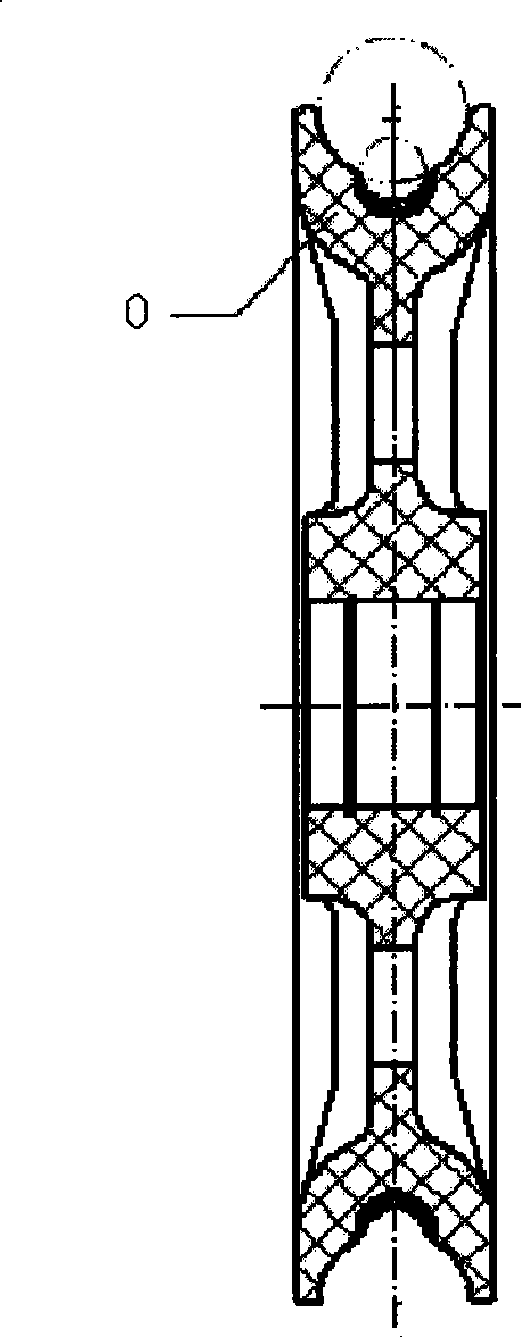

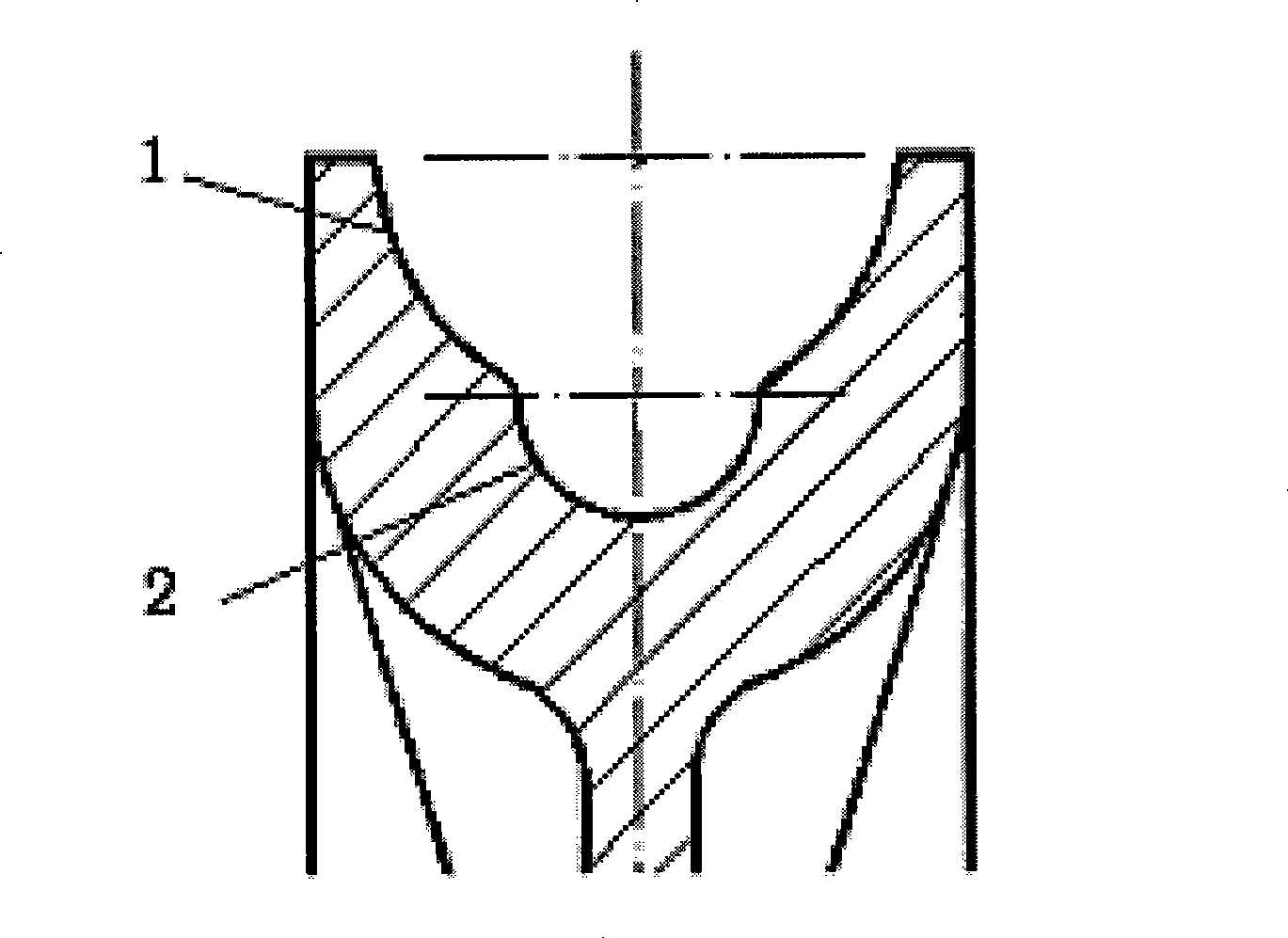

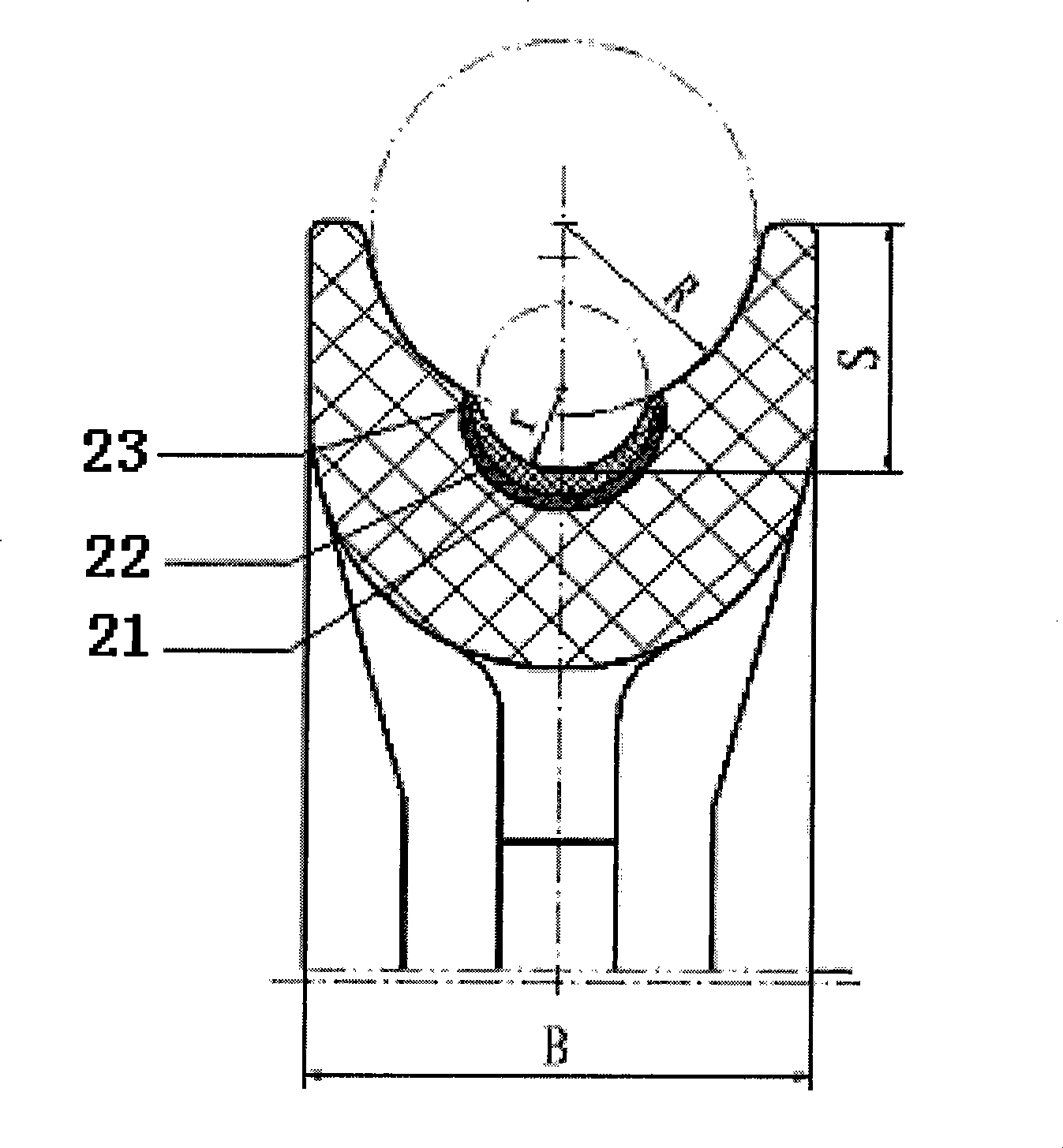

The invention relates to a cementing double-R groove-shaped lead stringing pulley with a double-R groove-shaped pulley groove selection, which is composed of two types of circular arc with different radii. One circular-arc-shaped groove with a short radius is formed at the bottom of the arc-shaped groove with a large radius and a cementing layer is arranged on at least the internal surface of the arc-shaped groove with small radius. Cementing plays a certain role in protecting the lead. The service life of the lead stringing pulley is prolonged. The radii of the big and the small circular arcs are respectively matched with the radii of a connecting pipe protecting device and the lead, thereby enlarging the contact area between the lead and the pulley groove of the lead stringing pulley when the lead passes through a connecting pipe protecting device, and reducing the wear of the lead. At the same time, the small arc-shaped groove has a depth enough to avoid construction accident caused by the lead which leaves out of the pulley groove of the pulley during the stringing process. Therefore, the lead stringing pulley has the advantages that the wear of the lead is reduced, the service life of the lead stringing pulley is prolonged, the safety of stringing construction is improved and the maintenance cost of engineering is reduced.

Owner:CHINA ELECTRIC POWER RES INST

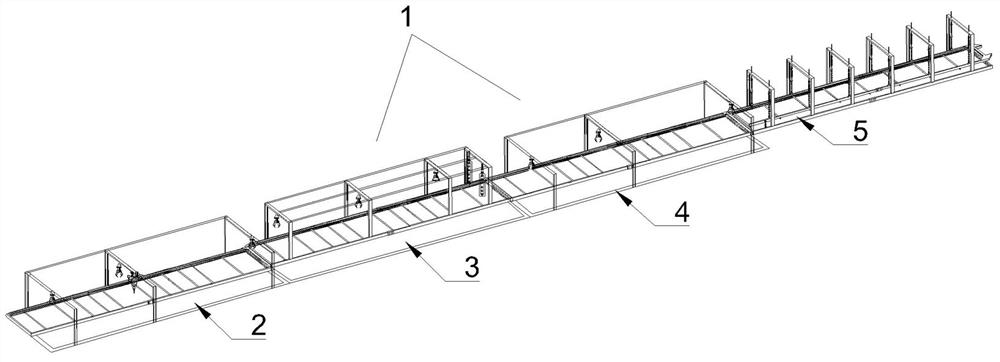

Construction method capable of replacing steel support substitution by full space supports

InactiveCN106567395ASave engineering expensesReduce construction safety risksArtificial islandsCellarsSubway stationEngineering

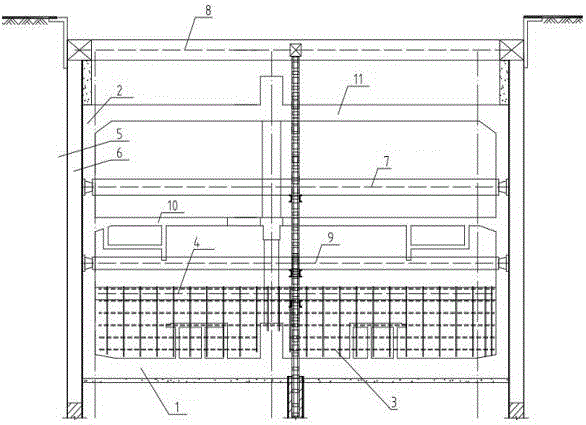

The invention discloses a construction method capable of replacing steel support substitution by full space supports. The construction method particularly comprises the following steps: (1) after the bottom plate construction of a subway station main body structure is finished, constructing side walls at the bottom, utilizing side pressure generated during concrete pouring and auxiliary providing a fastener to guarantee that the horizontal direction of the full space supports to be closely attached and propped tightly, and pouring the side walls and middle plates simultaneously; (3) after the bottom plate and the side walls under the steel support substitution are poured and reach the strength, continuously erecting the full space supports; (3) after erecting the full space supports in the step (2), disassembling third steel supports on part of the full space supports, continuously erecting the full space supports and constructing the middle plates and the side walls of the main body structure; and (4) after the construction of the main body structure is finished and the strength reaches the design requirement, disassembling the full space supports. According to the construction method, the procedures can be simplified, the work efficiency can be improved, the construction period can be shortened, construction safety and convenience are improved, the construction cost is saved and the construction efficiency is improved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD

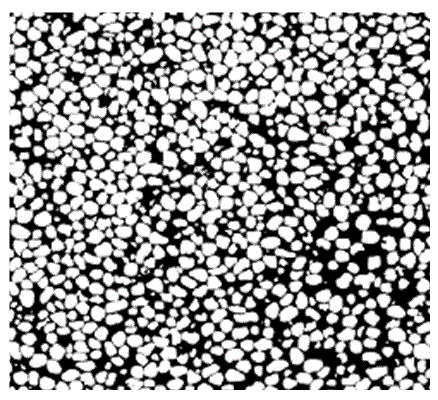

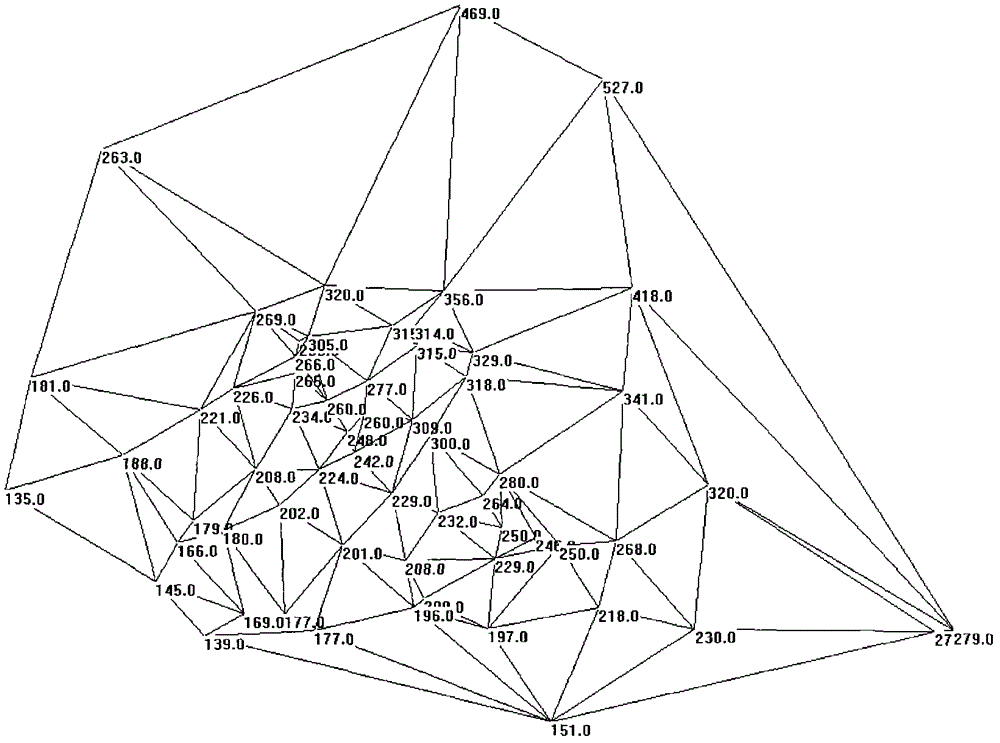

Dike dam riprap density measuring method based on image analysis

InactiveCN102866080ASolve the problem that the particle size is not greater than 0.3 metersAddress leveling requirementsSpecific gravity measurementRough surfaceGranularity

The invention provides a dike dam riprap density measuring method based on image analysis, and the method is characterized in that a two-dimensional image of a riprap accumulation body after being leveled is photographed, a gray processing intermittency detection segmentation technology is adopted for processing the two-dimensional image, the two-dimensional density of the riprap is calculated through the image analysis, and the density of a three-dimensional body of the riprap is calculated by analyzing the two-dimensional density. Due to the adoption of the method, the density of the riprap with the granularity being more than that of an ordinary stone and the density of the riprap with the rough surface difficultly placed with an instrument can be measured, the damage to the riprap dam can be avoided by utilizing the image analysis method, a real nondestructive measurement method is realized, the test cost is low, engineering expense can be saved, and the method can be popularized and used in the dike dam riprap projects.

Owner:CHINA MCC17 GRP

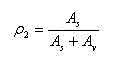

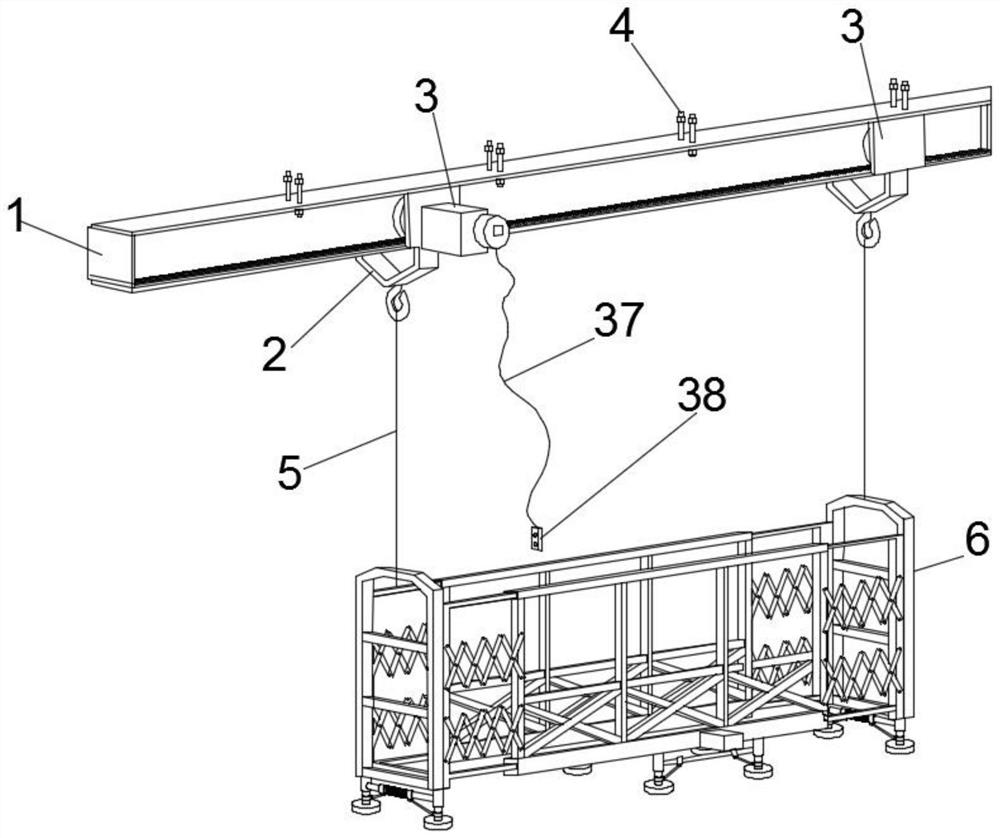

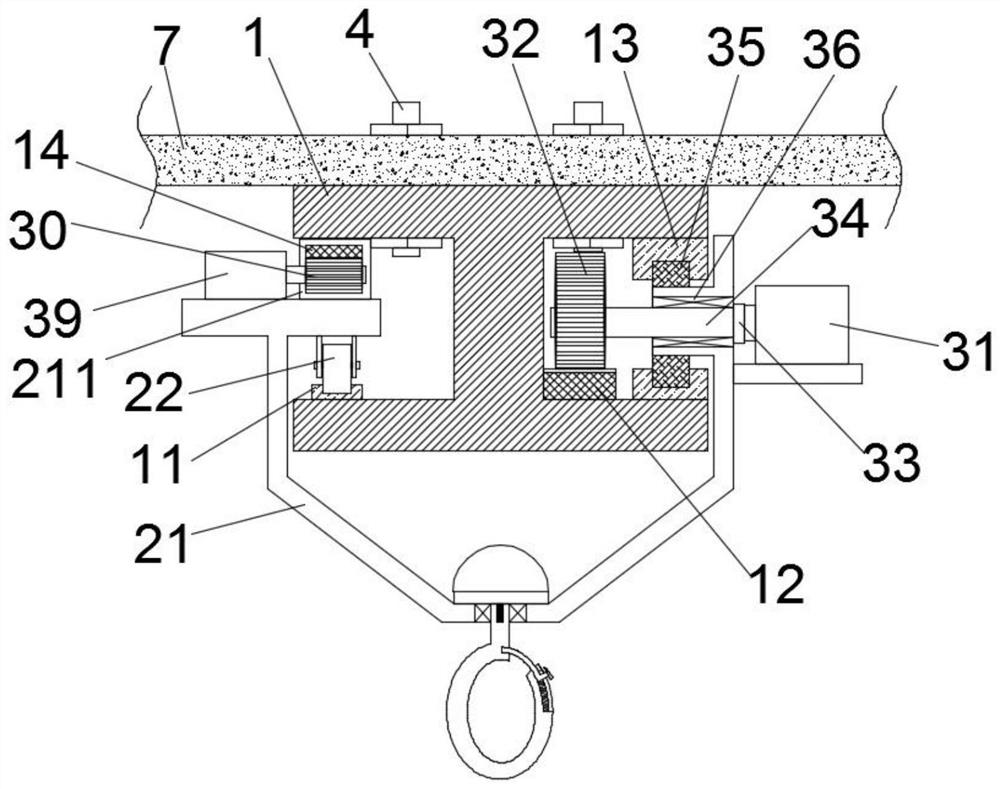

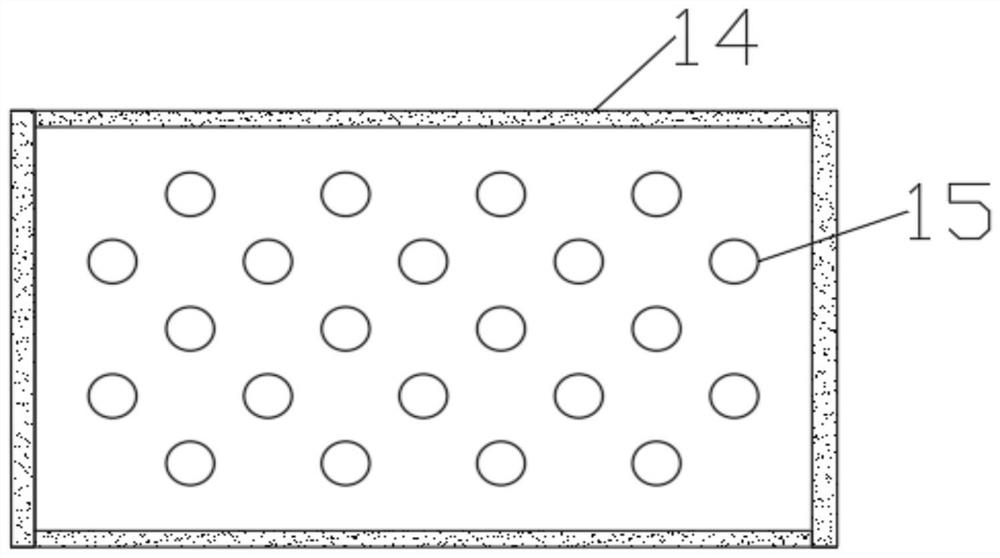

Large-span courtyard side wall sliding rail hanging basket with roof and construction method thereof

ActiveCN113789948AAvoid destructionEasy to operateScaffold accessoriesBuilding support scaffoldsReinforced concreteArchitectural engineering

The invention discloses a large-span courtyard side wall sliding rail hanging basket with a roof and a construction method thereof. The sliding rail hanging basket comprises a guide rail, a hanging piece, a sliding mechanism, a hanging rope and a hanging platform, wherein the guide rail is an I-shaped steel beam and is installed below a reinforced concrete top plate through a fastening installation piece, the hanging piece is installed on the lower side of the guide rail and is in sliding connection with the guide rail through the sliding mechanism, one end of the hanging rope is connected with a hanging hook, the other end of the hanging rope is connected with the hanging platform through a lifting motor, the hanging platform is a telescopic hanging basket and comprises a main basket body and auxiliary basket bodies which are symmetrically arranged on the two sides of the main basket body through telescopic adjusting mechanisms, and damping mechanisms are arranged at the bottoms of the main basket body and the auxiliary basket bodies. During use, the sliding rail hanging basket is used for construction, the problem that a large-span courtyard side wall with the roof is difficult to decorate is effectively solved, the sliding rail hanging basket has the characteristics of convenience and rapidity in construction and easiness in operation by workers, tracking inspection is conducted at any time in the using process, safety accidents are avoided, and the engineering cost is reduced.

Owner:陕西建工第九建设集团有限公司

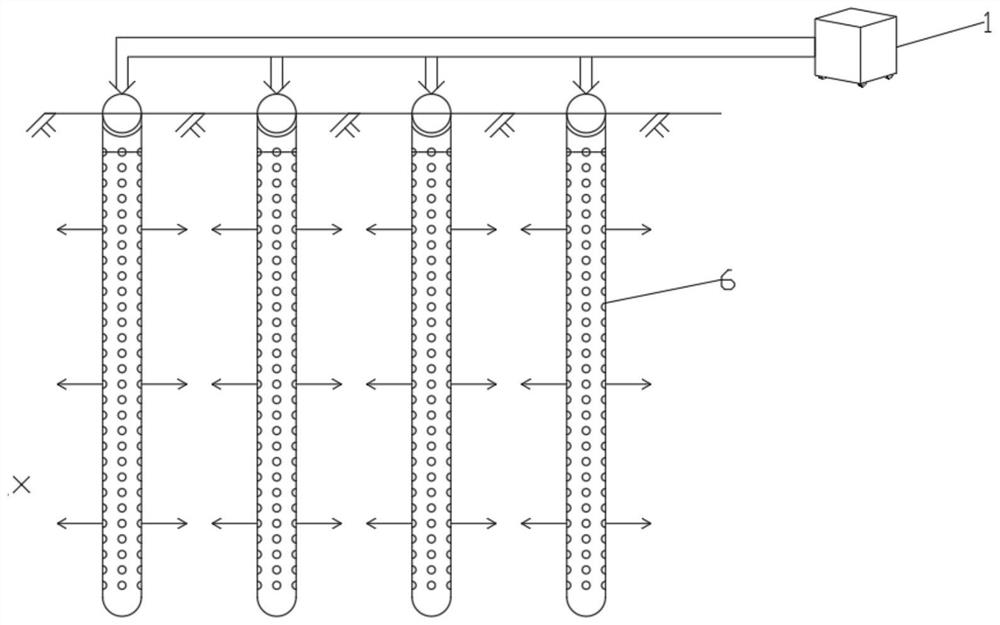

On-site grouting system and method for reinforcing flocculated sludge by combining vacuum preloading and grouting

ActiveCN113322958ACutting costsGuarantee the construction qualitySoil preservationFlocculationSoil science

The invention discloses an on-site grouting system and a method for reinforcing flocculated sludge by combining vacuum preloading and grouting. The on-site grouting system is composed of an engineering mechanical vehicle, a grouting pipe, a vertical drainage plate, a control electric box, a foam plate, a flocculant pump, a vacuum pump and some conveying pipelines. According to the method for reinforcing the flocculated sludge by combining vacuum preloading and grouting, lime pipe grouting is used as a main process, traditional vacuum preloading is improved through an electrical control technology, modern mechanical equipment is adopted for construction, and therefore, the high efficiency and refinement of construction are achieved, the construction process is simplified, manpower participation is reduced, the safety coefficient of labor is increased, and the working efficiency is greatly improved; and the requirement of traditional vacuum preloading on a site is reduced through a lime grouting mode, the flocculation effect in a soil body is improved, the application range of vacuum preloading is widened, the flocculation effect in the soil body is improved, and the construction period is greatly shortened.

Owner:WENZHOU UNIVERSITY

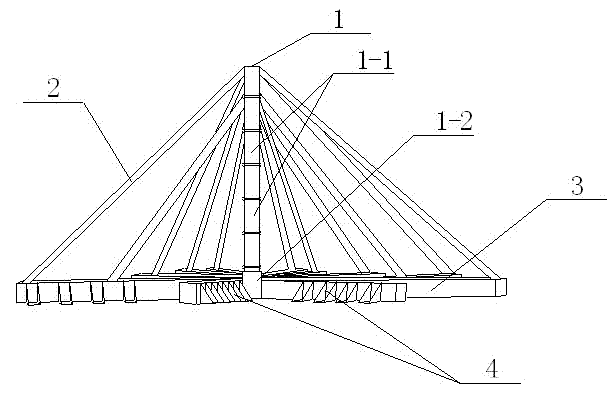

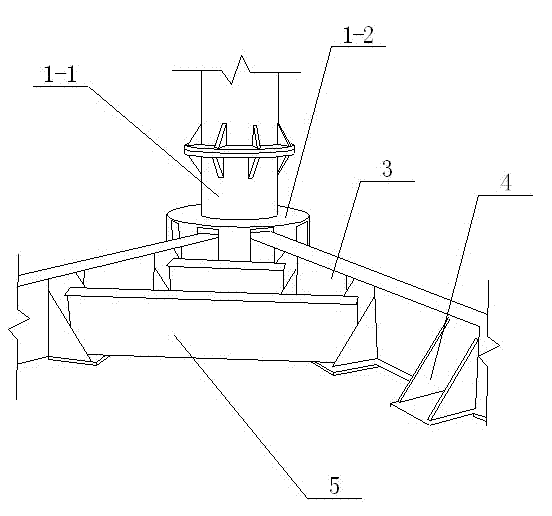

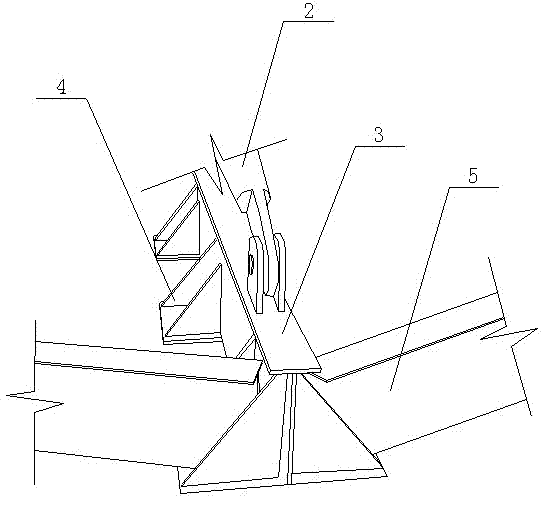

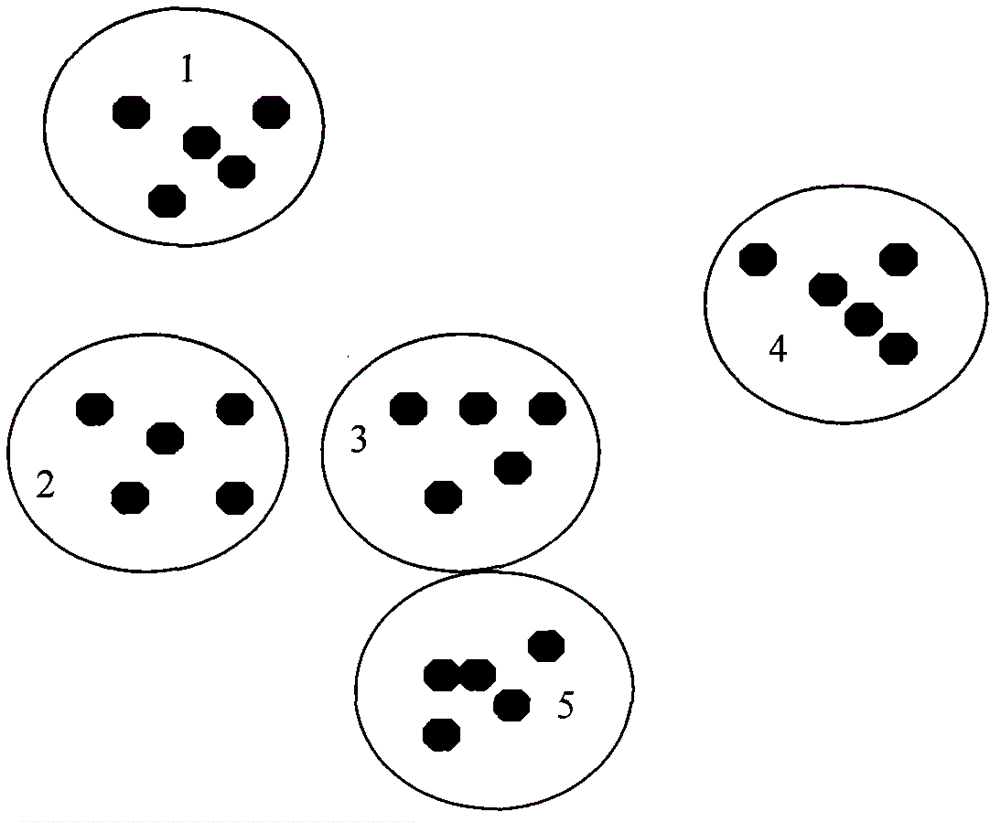

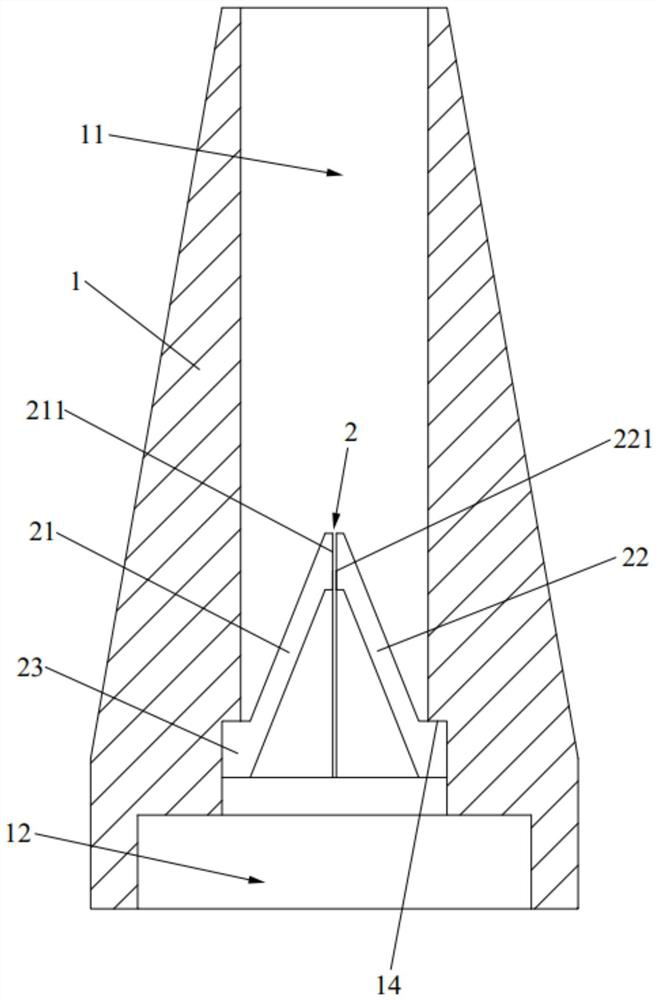

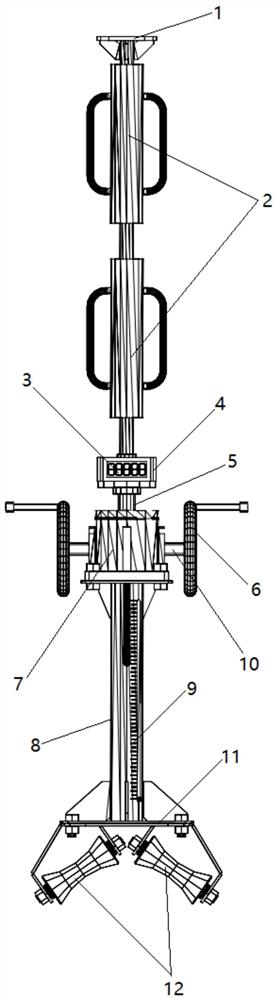

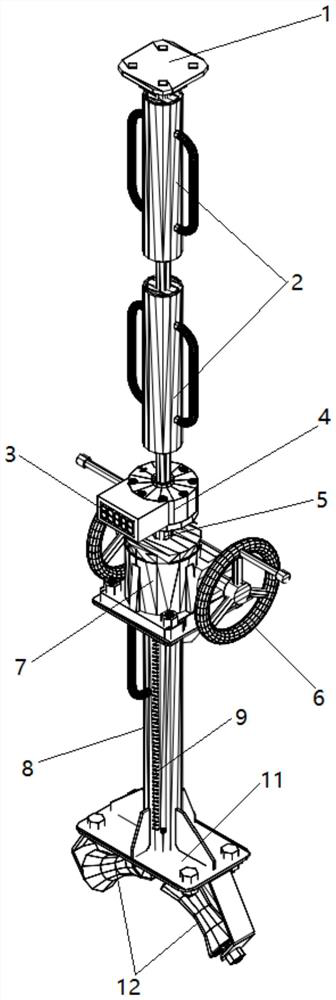

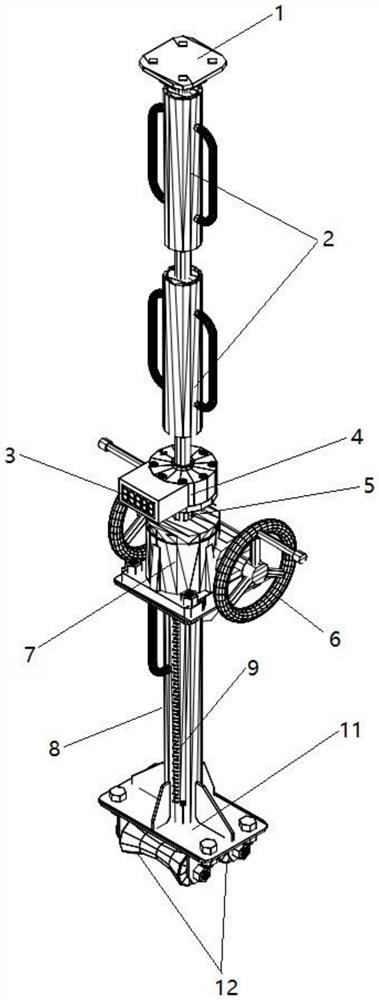

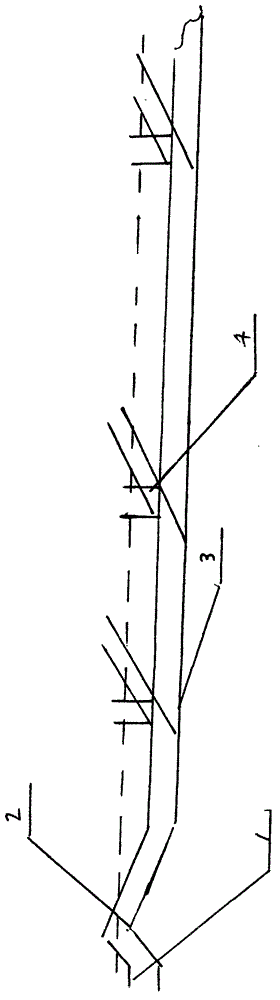

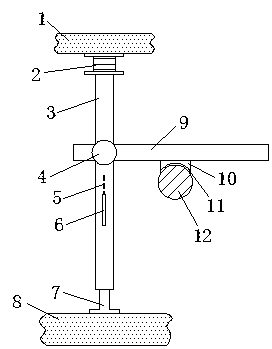

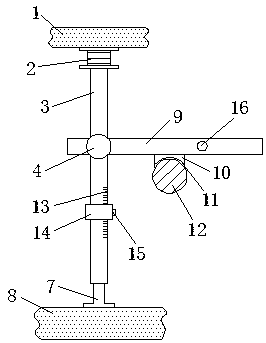

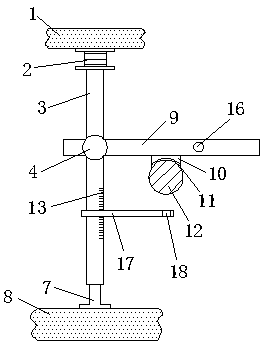

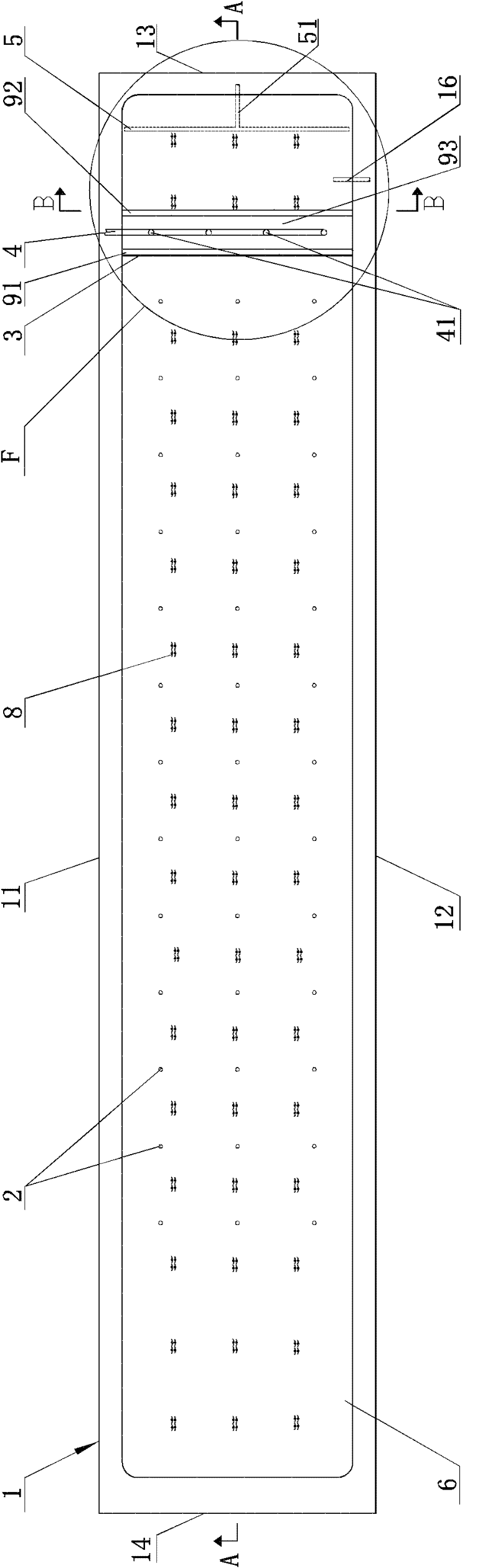

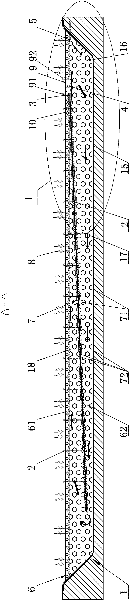

Umbrella type platform static load test equipment

The invention discloses umbrella type platform static load test equipment and relates to the field of engineering machinery processing and manufacturing. The umbrella type platform static load test equipment comprises a main beam (1), pull rods (2), auxiliary beams (3), supports (4) and joist steel (5), wherein the main beam (1) is formed by individual circular steel cylinders (1-1) which are vertically and mutually superposed and fixed; a clamping cap (1-2) is fixed at the lowest end of the main beam (1); one ends of the auxiliary beams (3) are fixed with the clamping cap (1-2), stretches towards all around with a same angle with the clamping cap (1-2) as the center of a circle and fixedly connected with the main beam (1) through the pull rods (2); the supports (4) are uniformly arranged at two sides of each auxiliary beam (3); and two ends of the joist steel (5) are placed on the corresponding supports (4). The umbrella type platform static load test equipment has the advantages that the work efficiency is increased; the work time is saved; and the engineering expense is saved to a large extent while the potential safety hazard in operation process is greatly reduced.

Owner:云南锐索建设工程质量检测有限公司

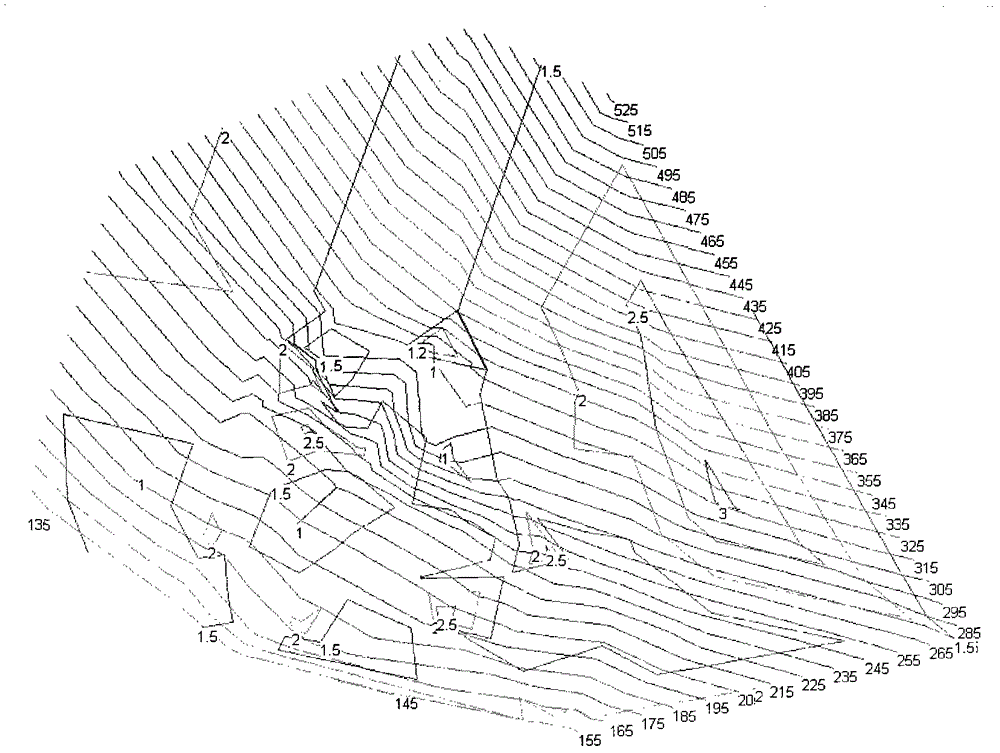

Method for acquiring density of rock fill object by using additive mass method and digital template chart

ActiveCN102175567BRealize dynamicHigh precisionSpecific gravity measurementMethod testDynamic stiffness

The invention provides a method for acquiring density of a rock fill object by using an additive mass method and a digital template chart. The method comprises the following steps: randomly choosing a set of basic measuring points from the rock fill object; performing the additive mass method test and the pit measuring method test on each measuring point and establishing the digital template chart; at different points of the same rock fill object, calculating a natural vibration angular frequency Omega-2 by utilizing a mass of vibration m0 and a dynamic stiffness K acquired by using the additive mass method test; searching for the corresponding volume of vibration V0 from the digital template chart and a moisture content eta 2 on the template chart, by utilizing the K and the Omega-2; and acquiring the density according to a formula. The template chart can be continuously revised and the revised result is continuously converged, thereby increasing the precision of calculating the density of a rock fill object. The method has portability or applicability and can be applied to other engineering, thereby reducing the quantity of pit measuring method and saving the engineering cost.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +2

Hoisting method using three traveling cranes with unequal loads

InactiveCN102976198AReduce dependencySpeed up the construction periodTrolleysEngineeringBuilding construction

Owner:MCC TIANGONG GROUP

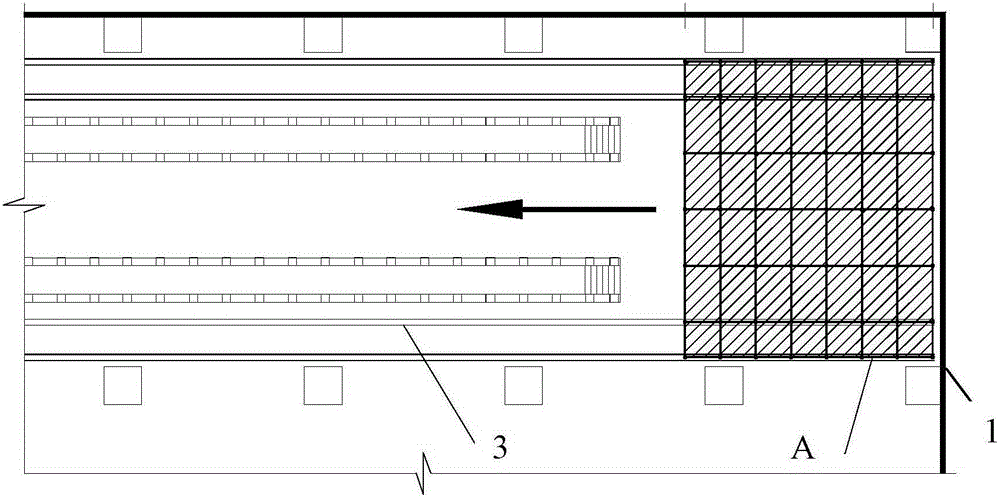

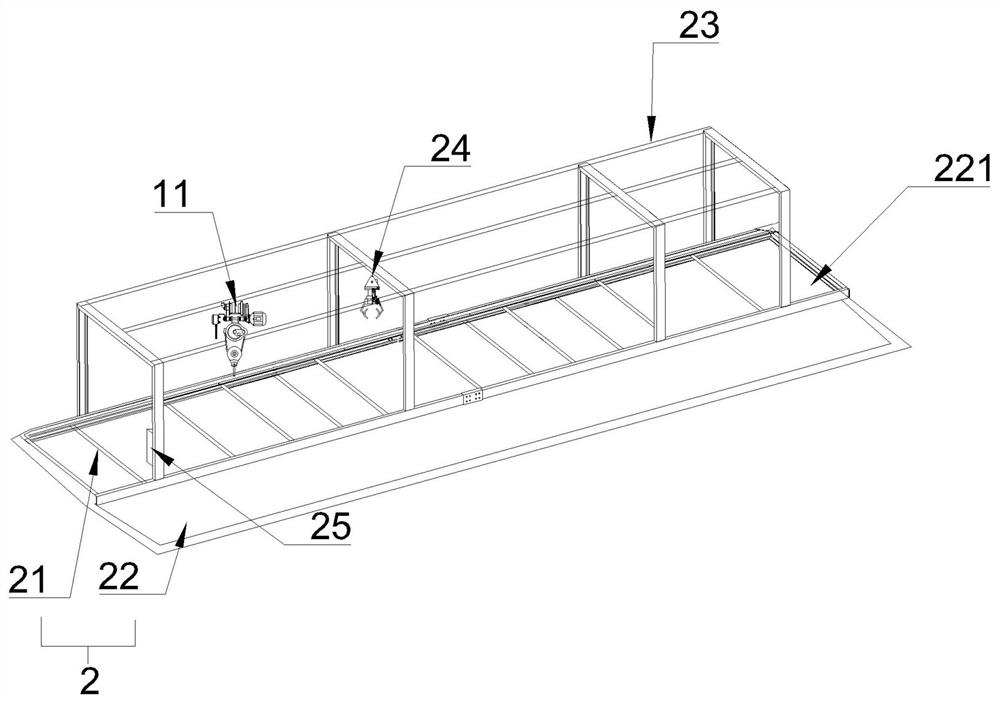

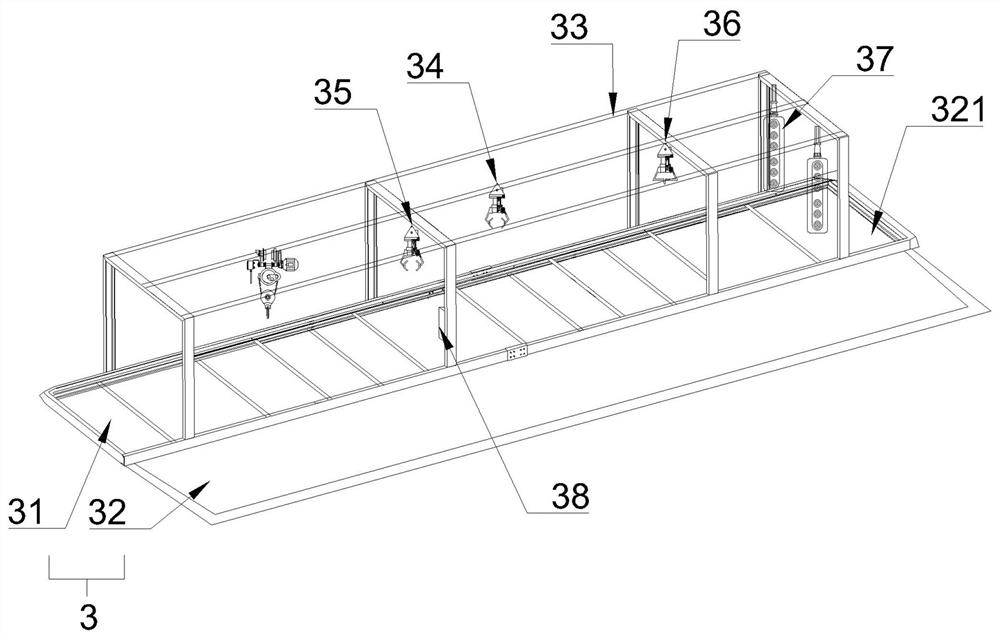

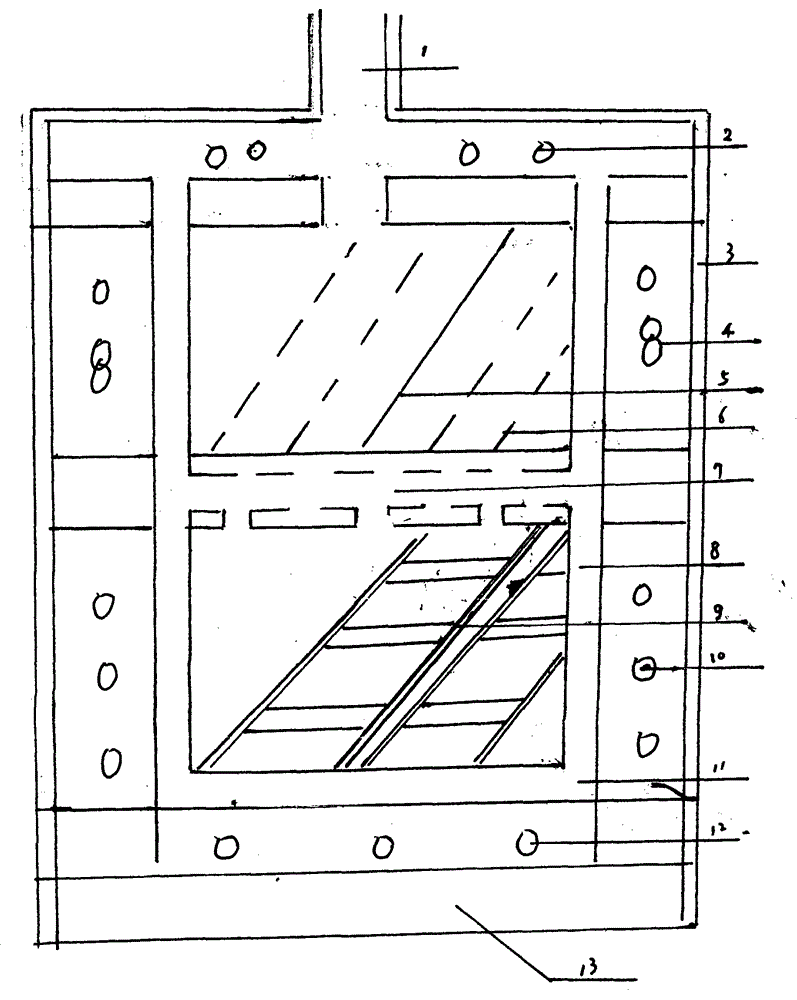

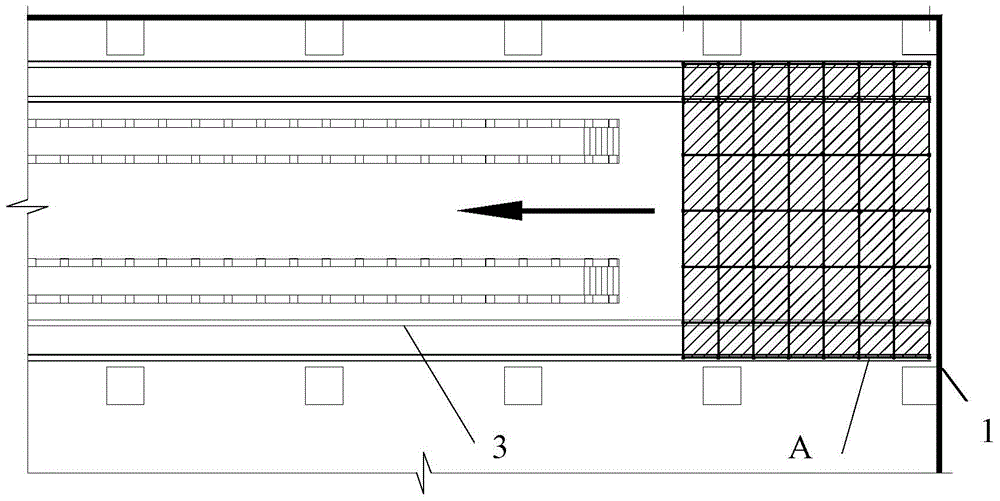

Method for jointly decorating maintenance storehouses and installing and constructing pipelines by aid of movable scaffolds

ActiveCN105220878AEasy and fast set upEasy and quick disassemblyBuilding material handlingBuilding scaffoldsFalseworkArchitectural engineering

The invention discloses a method for jointly decorating maintenance storehouses and installing and constructing pipelines by the aid of movable scaffolds. The method includes constructing first and second inspection pits in the built storehouses; filling the peripheries of the first and second inspection pits with earth in the storehouses; laying two guide rails on the backfilled earth on two sides of each of the first and second inspection pits, sequentially erecting the first, second, third and fourth scaffolds on the guide rail on the outer side of an end of each of the first and second inspection pits, carrying out ceiling plastering, putty applying and paint coating on the scaffolds, and installing the various pipelines, lamps, the firefighting pipelines and electrical equipment on the scaffolds until complete decorating and pipeline installing and constructing procedures are completed in the storehouses. Rollers are respectively installed at the bottoms of the first, second, third and fourth scaffolds. The method has the advantages that indoor ground structural engineering and overhead pipeline and equipment installation engineering such as ceiling decoration engineering, electrical installation engineering, water supply and drainage engineering, firefighting engineering, heating and ventilation engineering can be sequentially constructed in an assembly line manner, accordingly, various construction tasks in profession can be quickly completed, the construction periods can be greatly shortened, and effects of yielding twice the result with half the effort can be realized.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

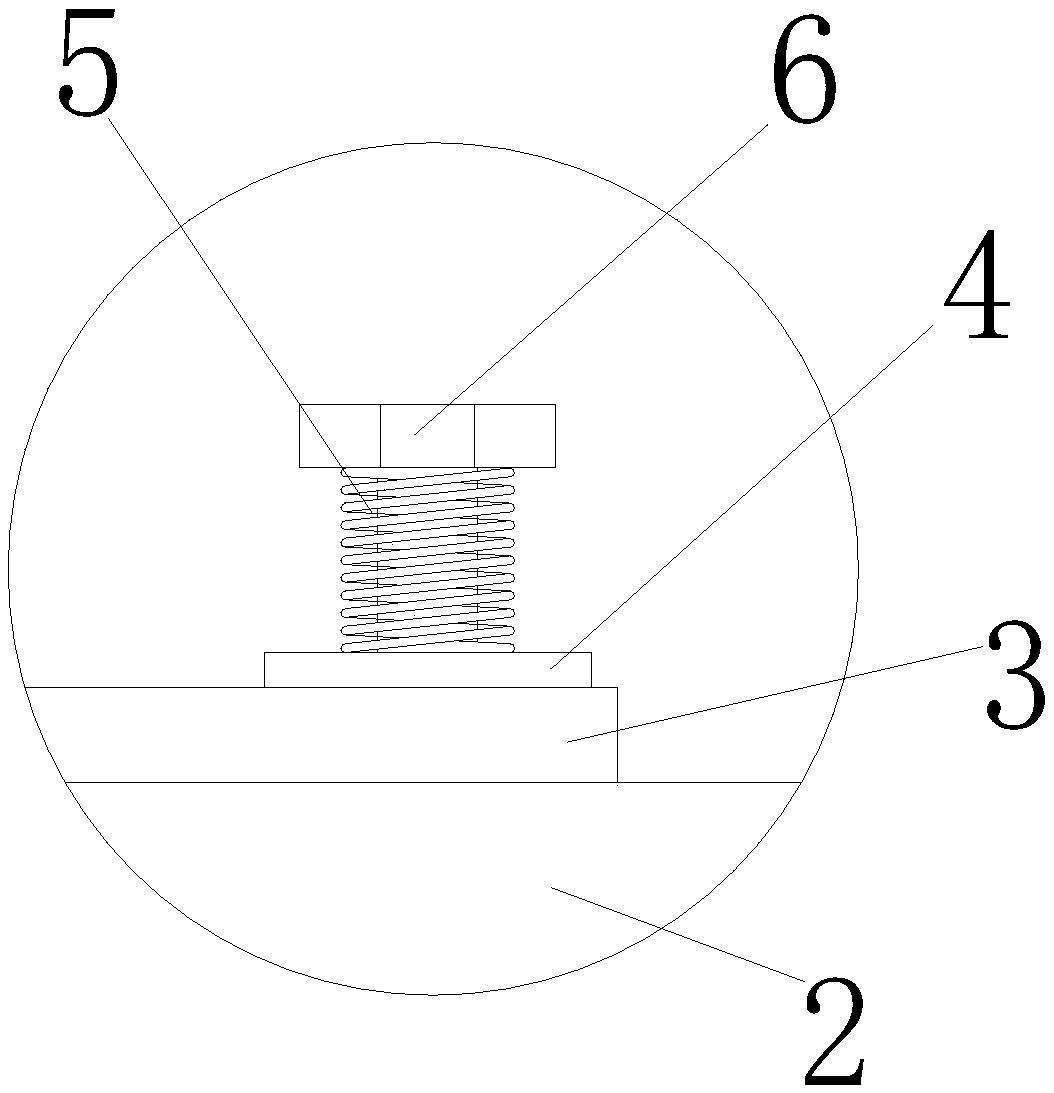

Reinforcing steel bar sleeve grouting device

PendingCN113266109APrevent Backflow LeakagePrevent leakageBuilding reinforcementsArchitectural engineeringSlurry

The invention belongs to the technical field of building construction, and discloses a reinforcing steel bar sleeve grouting device. The reinforcing steel bar sleeve grouting device comprises a grouting pipe plug, wherein a non-return structure is arranged on the inner wall of the grouting pipe plug, when grouting equipment is used for grouting a reinforcing steel bar sleeve, the non-return structure is in an open state, so that concrete slurry in the grouting equipment smoothly passes through an inner cavity of the grouting pipe plug, concrete slurry can entering the reinforcing steel bar sleeve, when the reinforcing steel bar sleeve is filled with concrete slurry, the grouting end of the grouting equipment is moved away from the grouting pipe plug, at the moment, the non-return structure automatically recovers to the closed state, so that the concrete slurry in the reinforcing steel bar sleeve is prevented from flowing back and leaking through the inner cavity of the grouting pipe plug, it is guaranteed that the compactness of the slurry in the reinforcing steel bar sleeve is good, the connecting strength between the components is effectively improved, and the building construction quality and the safety in the building use process are ensured. The non-return structure can timely block the grouting channel after the grouting is stopped, a wooden plug does not need to be additionally inserted or a closable valve does not need to be arranged, the construction process is simplified, and the project cost is reduced.

Owner:SHANGHAI SIPAI AUTOMATION INSTR ENGCO

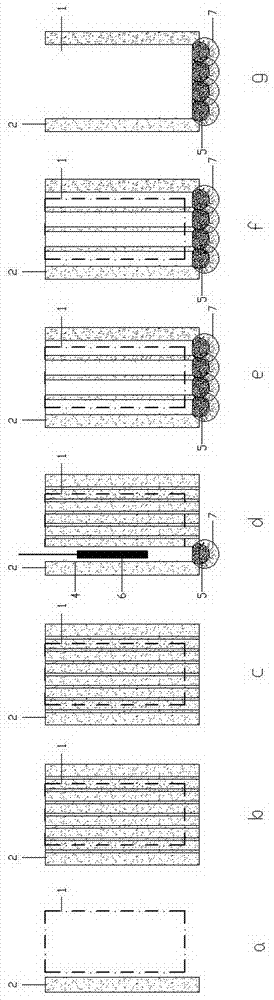

Construction method of water sealing system of deep foundation

The invention provides a construction method of a water sealing system of a deep foundation. The construction method comprises the following steps: 1) constructing continuous piles or walls at the periphery of the deep foundation to be constructed, wherein the depth of the continuous piles or walls is not less than that of the deep foundation to be constructed; 2) continuously performing the operation in step 1) to form an outer closed circle around the deep foundation to be constructed through the continuous piles or walls; 3) reinforcing earth below the deep foundation to be constructed within the closed circle in a filler tamping and compacting and / or injecting and grouting manner; 4) continuously performing the operation in step 3) until all the soil in the closed circle is reinforced and a bottom closed layer is formed, wherein the bottom closed layer and the outer closed circle form a barrel-shaped water sealing system which encircles the deep foundation to be constructed; and 5) performing dewatering and earth excavating to form the deep foundation. With the adoption of the method, the formed water sealing system is stable in structure, and good in water insulation effect; large-area and long-time dewatering is avoided; the natural soil is fully utilized in the construction; the method is high in efficiency, low in cost, environmentally friendly, and free from pollution.

Owner:王继忠

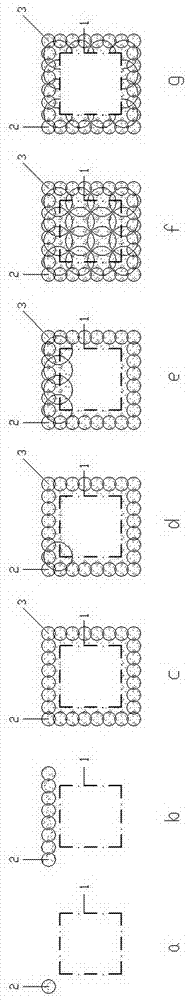

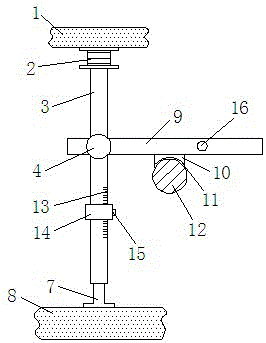

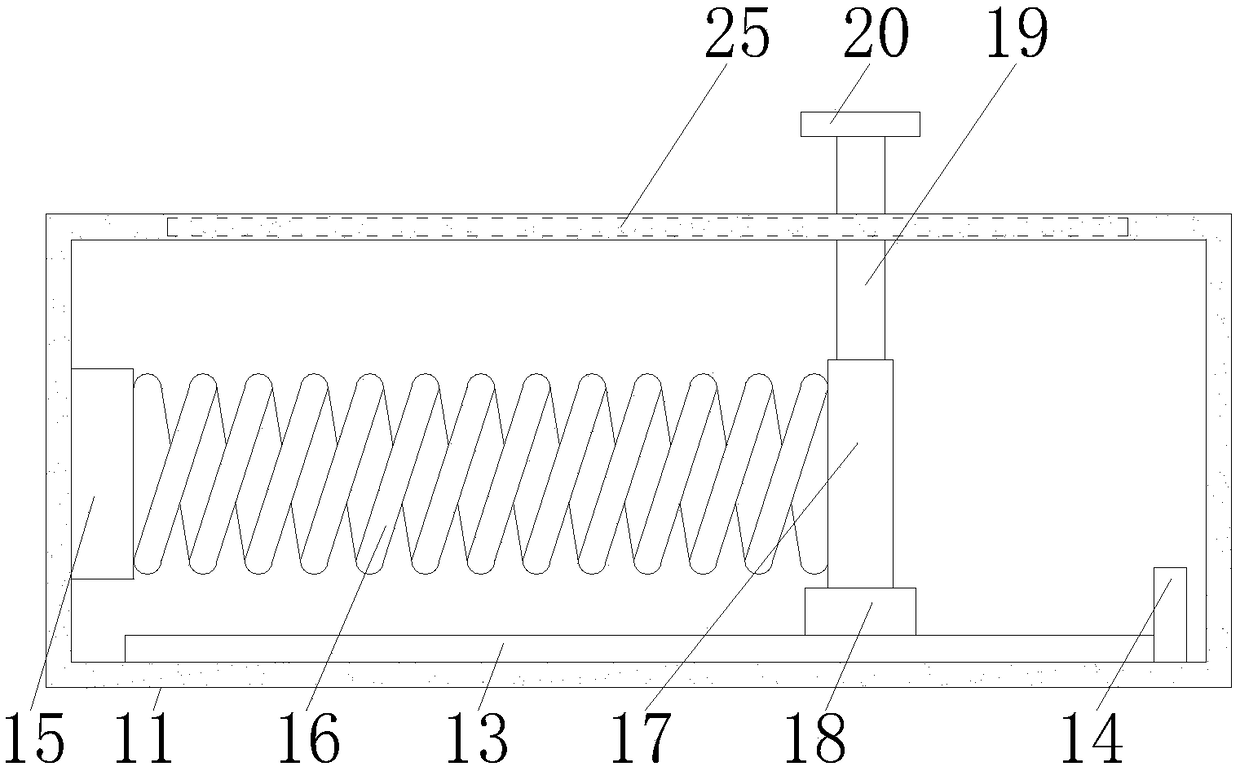

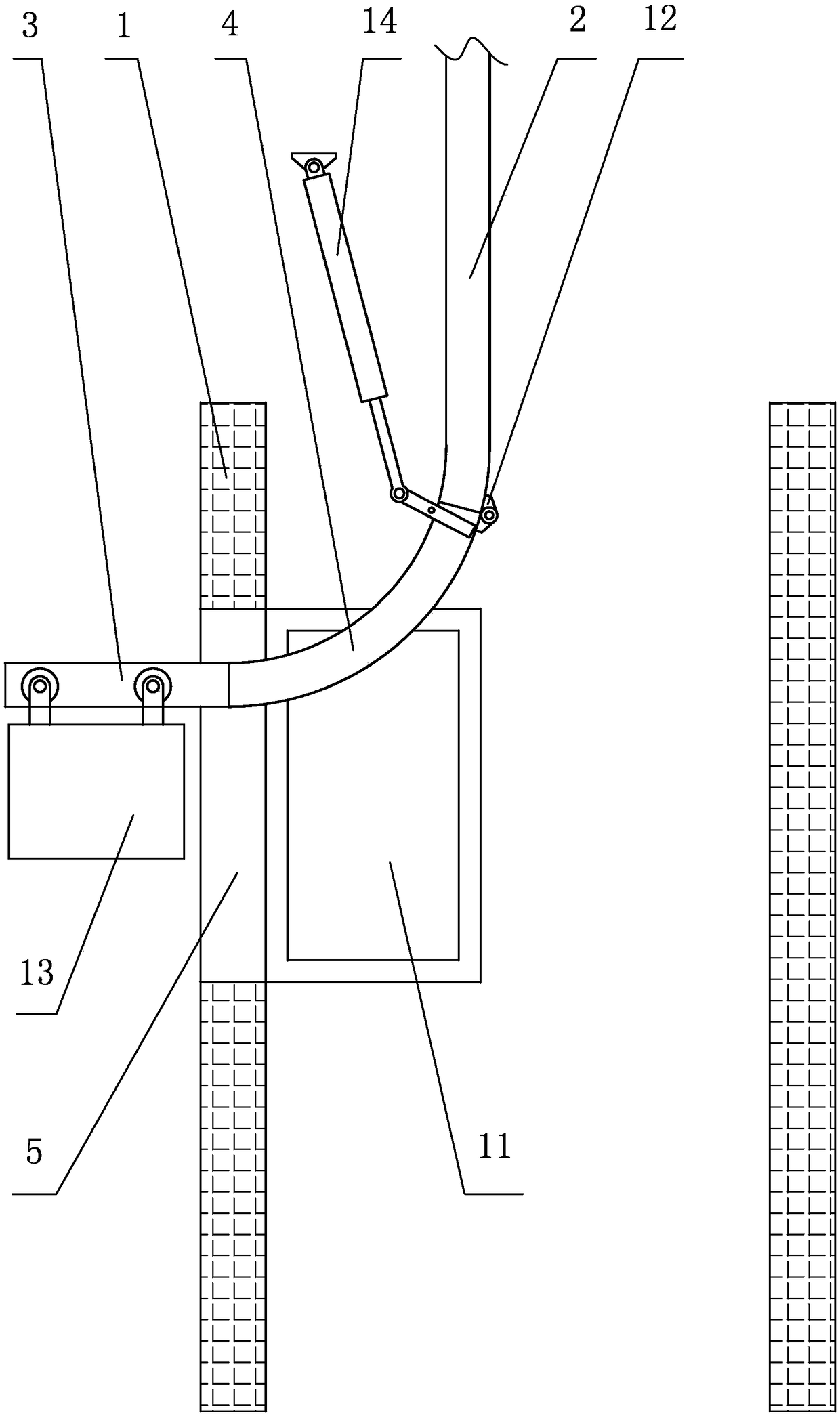

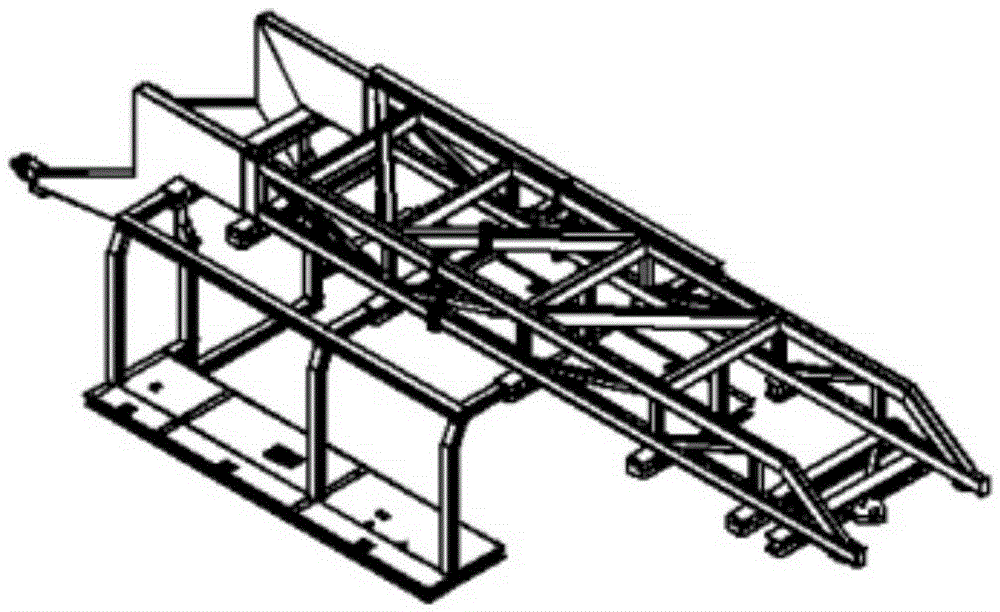

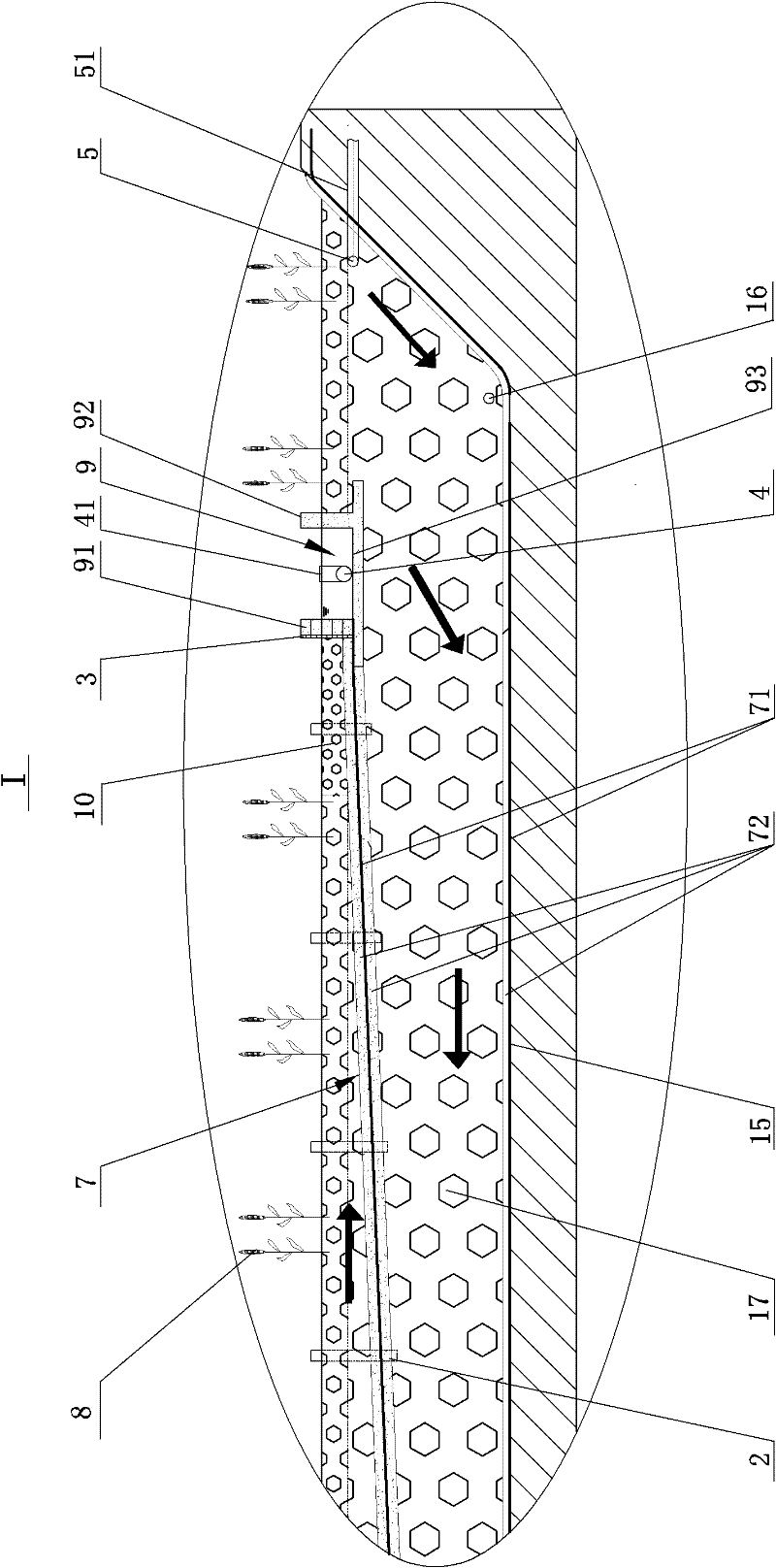

Bending device for snakelike laying of large-section power cables

ActiveCN106345942ATo ensure the quality of laying a qualified rateReduce investmentApparatus for laying cablesPower cableUniversal joint

The invention discloses a bending device for snakelike laying of large-section power cables. The bending device comprises a support rod and a pressure rod, wherein a universal joint and a range identifying device are arranged on the support rod; a support seat is arranged at the bottom end of the support rod, and a telescopic joint is arranged at the top end of the support rod; the pressure rod is connected with the support rod through the universal joint; an arc-shaped curved plate is arranged on the pressure rod. Damage of lateral stress and axial stress of the cables during bending to the cables and an operator is effectively eliminated, and personal safety and cable laying in the construction process of engineering are ensured; the bending device can form perpendicular snakelike bends through one-hand operation, input of construction workers is reduced, the working efficiency is effectively improved, the engineering cost is reduced, snakelike laying of the cables meets the technical requirements, and the first pass yield of cable laying quality reaches 100%.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Device for braking a rail vehicle

InactiveCN101312834ASave engineering expensesSmall braking effectRail-engaging wheelsBraking discsMechanical engineeringEngineering

Owner:SIEMENS AG

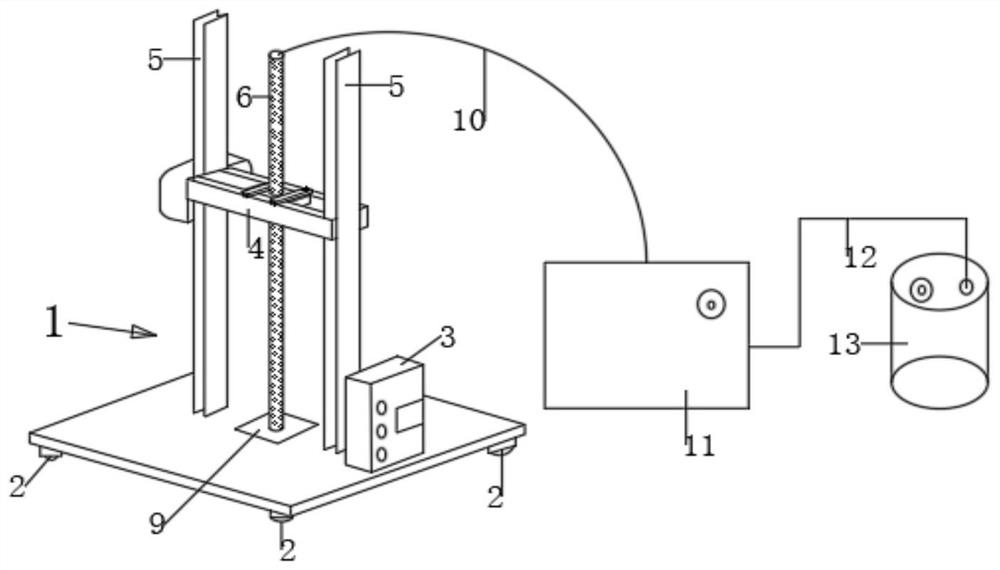

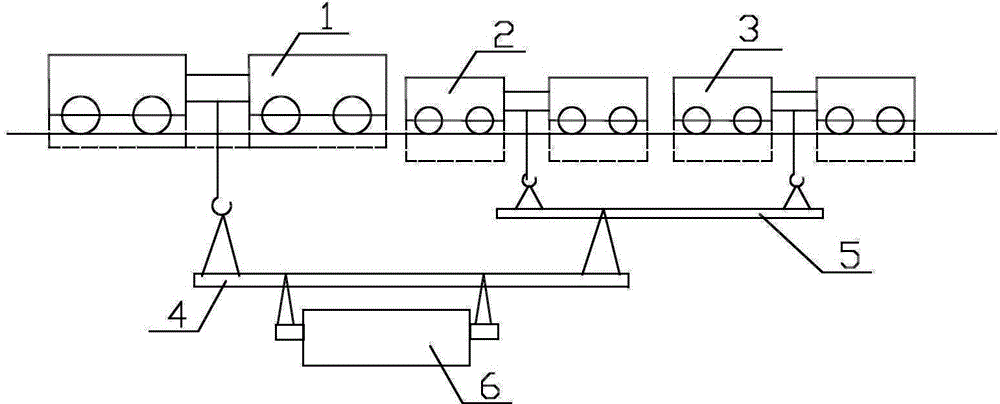

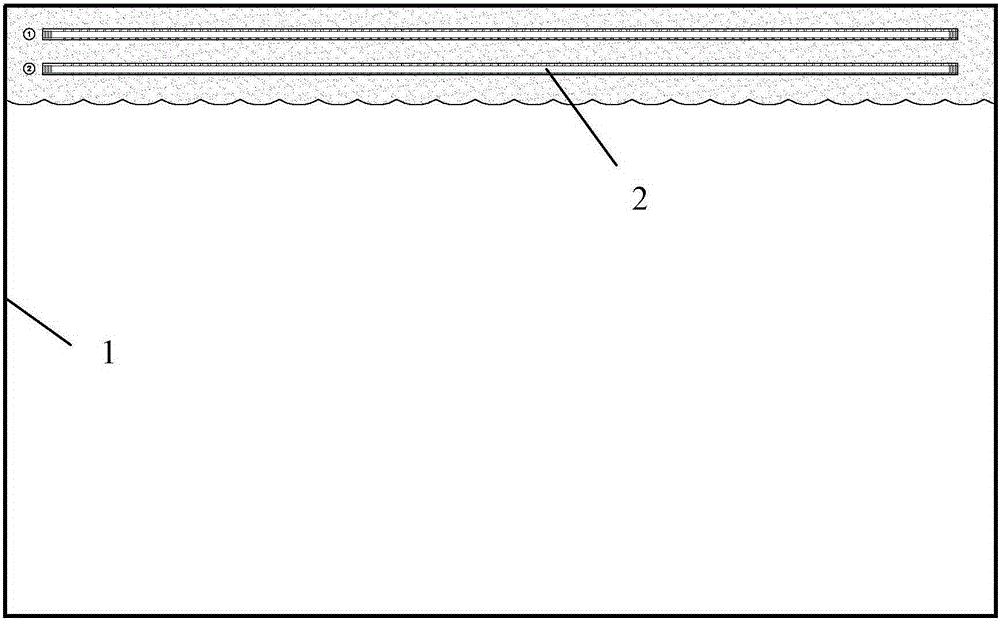

Novel drain board vacuum preloading method geotextile construction equipment and construction method thereof

PendingCN111691396AIncrease productivityReduce manufacturing costLaminationLamination apparatusArchitectural engineeringMachining

The invention discloses novel drain board vacuum preloading method geotextile construction equipment. According to the key points of the technical scheme, the construction equipment comprises a sewingflowing water assembly which comprises first equipment, second equipment, third equipment and fourth equipment; the first equipment comprises first conveying equipment and a first holding groove forholding geotextile and a drain board; the second equipment comprises second conveying equipment and a second holding groove for holding an external hand-shaped joint, a drain pipe and a buckle; the third equipment comprises third conveying equipment and a third holding groove for holding geotextile; the fourth equipment comprises a fourth conveying belt, a frame rod and a sewing device; the purpose lies in that the periphery of the horizontal drain board is coated with a layer of geotextile, and the problem that the drain board is liable to clogging is solved; an automatic machining mode is adopted for material manufacturing, manpower participation is reduced, product refinement can be improved through machining, high-precision guiding, locating and adjustment are achieved, and labor productivity is increased substantially.

Owner:WENZHOU UNIVERSITY

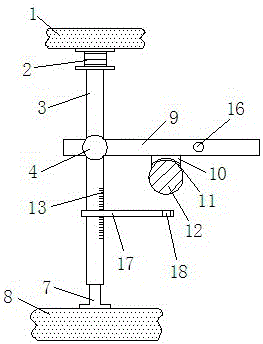

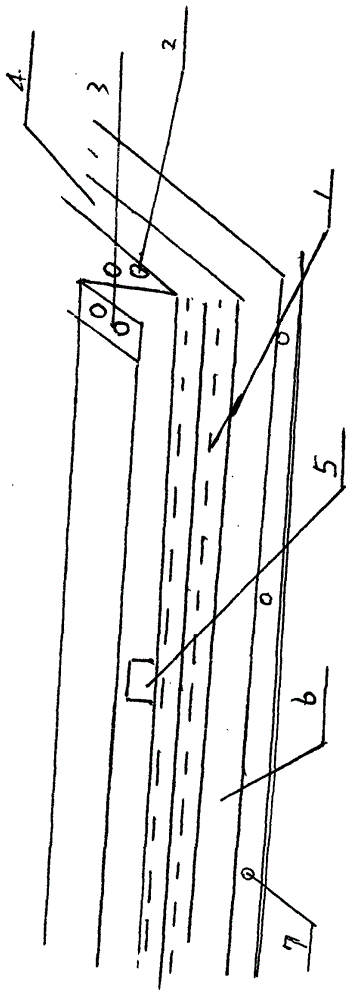

Cable snakelike bending machine

PendingCN113241680AAccurate display of pressureAccurate display of magnitudeApparatus for laying cablesGear wheelMachine

The invention discloses a cable snakelike bending machine. The cable snakelike bending machine comprises a back shore, a stress supporting tool, a pressure sensor, a jacking mechanism, a rack mechanism and a bending roller which are sequentially connected from head to tail, wherein the jacking mechanism comprises a lead screw, a turbine mechanism, a hand-cranking wheel and a rocking wheel input shaft; the lead screw is vertically arranged in the turbine mechanism in a penetrating mode, the rocking wheel wheel input shaft is transversely arranged in the turbine mechanism, and the lead screw and the rocking wheel input shaft are meshed together through a gear; the hand-cranking wheel is located on the outer side of the turbine mechanism and connected with the rocking wheel input shaft; and the upper end of the lead screw is connected with the pressure sensor, and the lower end of the lead screw extends into the rack mechanism. According to the method, the working efficiency is effectively improved, and the project expenditure is reduced; and the cable laying quality is improved, and the S-shaped laying of the cable is ensured to meet the technical requirements. According to the invention, the pressure borne by the cable and the snake-shaped wave amplitude during bending can be accurately displayed, the construction standard can be conveniently formulated, and the installation precision and the maintenance convenience are also guaranteed.

Owner:上海慧沣智能科技有限公司

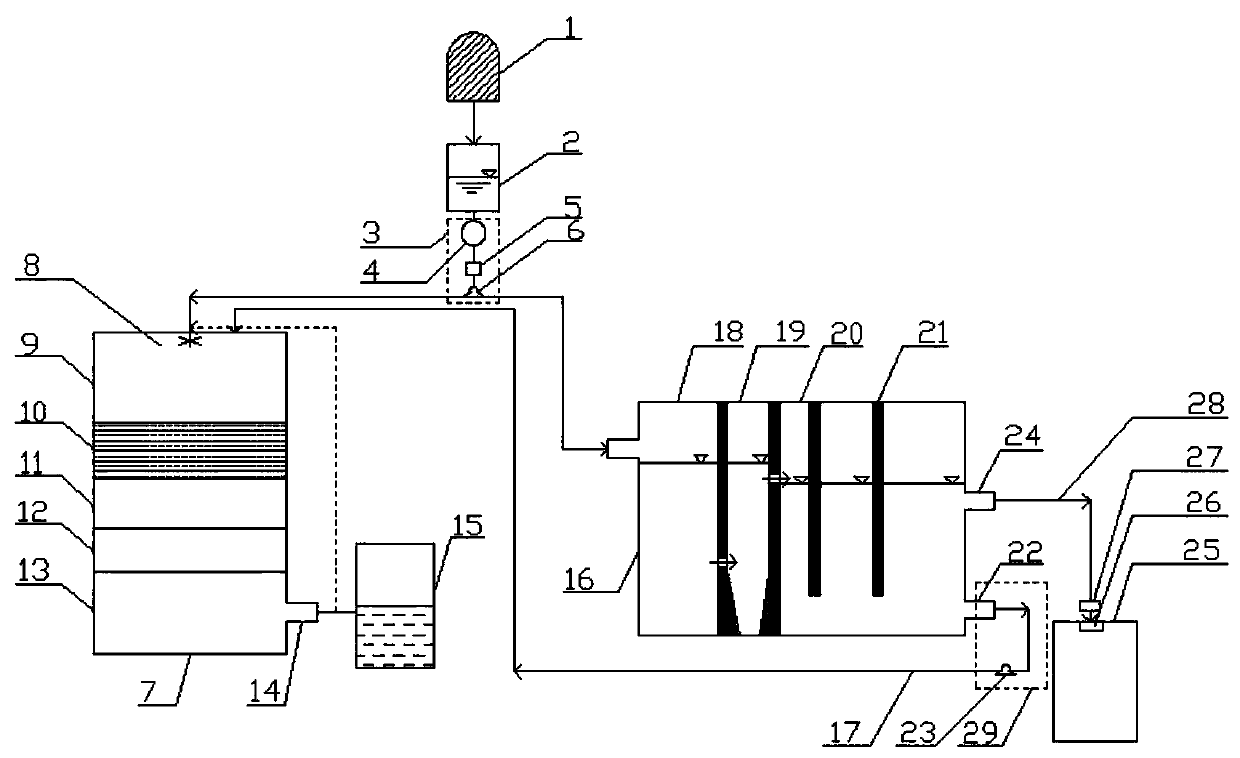

Earthworm based rural decentralized sewage treatment system

PendingCN111217498AProlong and extend the biological metabolic chainRealize "Zero Emissions"Multistage water/sewage treatmentTreatment involving sedimentationCold seasonSludge

The invention relates to an earthworm based rural decentralized sewage treatment system. The system is composed of a grille, an adjusting tank is arranged below the grille, the adjusting tank is connected to an earthworm biofilter and an improved SBR system suitable for decentralized sewage treatment through a temperature sensing system; the earthworm biofilter is used in warm seasons, by utilizing biodegradation of earthworms, the problems that a traditional biofilter is easily blocked by sludge and the sewage treatment effect is gradually reduced are solved, the sludge discharge amount is also greatly reduced, the improved SBR system suitable for decentralized sewage treatment is used in cold seasons, the technological process is short, the investment and operation cost is low, the impact resistance is high, and the water quality is stable; the two processes are alternately used in warm and cold seasons, so that the power consumption and sludge discharge of the device in the use process are effectively reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:ANHUI UNIV OF SCI & TECH

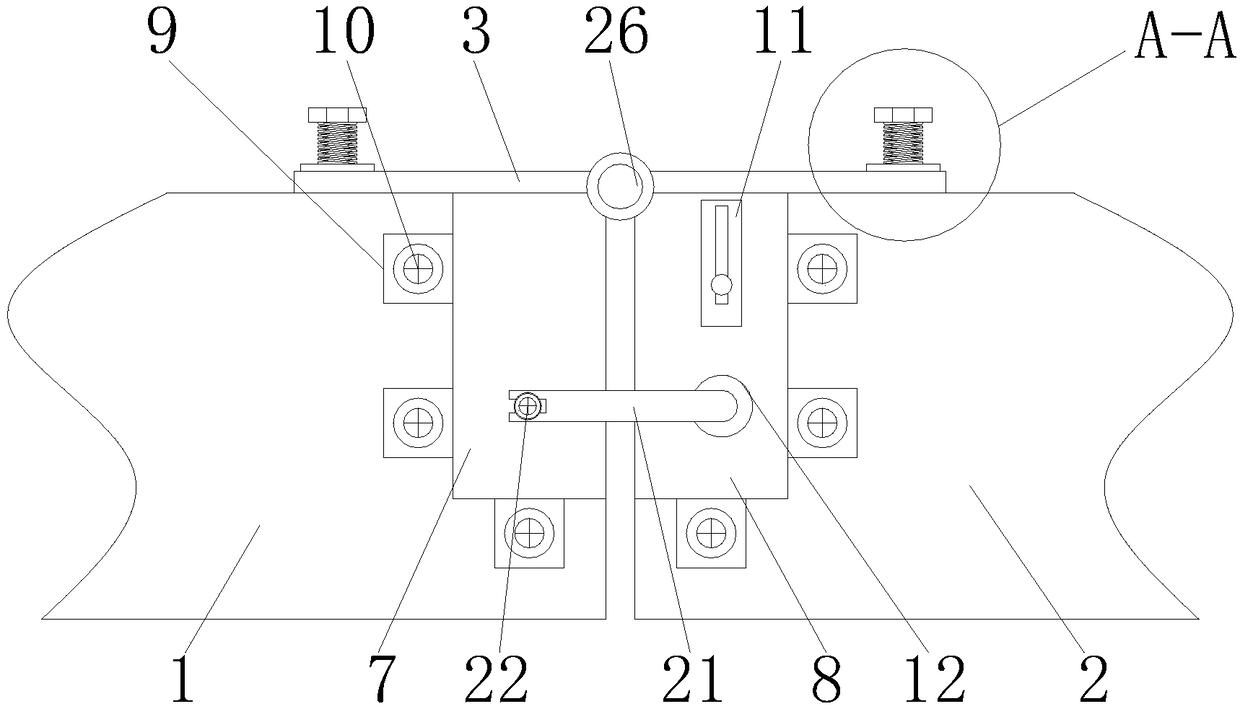

A connection and fixing device for channel steel

The invention discloses a connecting and fixing device for channel steel. The connecting and fixing device comprises a first panel and a second panel. Supporting plates are installed on the top of the first panel and the top of the second panel correspondingly. The supporting plates are movably connected through a rotating shaft. Buffer pads are symmetrically installed on the tops of the supporting plates. Buffer springs are installed on the tops of the buffer pads. Strength bolts are installed on the tops of the buffer springs. The first panel and the second panel are fixedly connected with the supporting plates through the strength bolts correspondingly. A first connection block is installed on one side of the front surface of the first panel. According to the connecting and fixing device for the channel steel, by arranging the first connection block, a second connection block, a position clamping device and a clamping rod, the first panel and the second panel can be stably connected, folding of the channel steel is facilitated, the use capacity of the channel steel is effectively improved, meanwhile, transportation is facilitated for people, the work time of work staff is shortened, and use is facilitated for people.

Owner:湖北立晋钢铁集团有限公司

Method for building and constructing facilities of roadway tunnel and line

The invention relates to a method for building and constructing the facilities of a road tunnel and a line. A road, a railroad and a line are constructed underground, the construction of the existing viaducts is totally changed into underground construction, and ground ditching expressway implementation is carried out; and the construction of expressway and railroads is totally changed into underground construction, a point type underground drainage channel is arranged below a roadbed, high voltage line facility devices are arranged on two sides of the tunnel, illuminating line devices are arranged above the tunnel, a tunnel flood prevention water return bend is arranged at the place 20-200 meters from the access of the tunnel, a vehicle entrance is arranged in the tunnel, and a fire control passage and a safety exit are arranged every three kilometers in the tunnel. The existing roadbed of the tunnel road constructed according to the method for building and constructing the facilities of a road tunnel and a line is changed into fertile farmland, the land is restored, the engineering cost is saved by 30 percent above, and the method disclosed by the invention brings about a big road transformation due to no occupation of land.

Owner:李尚喜

The construction method of joint maintenance warehouse decoration and pipeline installation by using mobile scaffolding

ActiveCN105220878BImprove mobilityMeet a wide range of job requirementsBuilding material handlingBuilding scaffoldsFalseworkArchitectural engineering

The invention discloses a method for jointly decorating maintenance storehouses and installing and constructing pipelines by the aid of movable scaffolds. The method includes constructing first and second inspection pits in the built storehouses; filling the peripheries of the first and second inspection pits with earth in the storehouses; laying two guide rails on the backfilled earth on two sides of each of the first and second inspection pits, sequentially erecting the first, second, third and fourth scaffolds on the guide rail on the outer side of an end of each of the first and second inspection pits, carrying out ceiling plastering, putty applying and paint coating on the scaffolds, and installing the various pipelines, lamps, the firefighting pipelines and electrical equipment on the scaffolds until complete decorating and pipeline installing and constructing procedures are completed in the storehouses. Rollers are respectively installed at the bottoms of the first, second, third and fourth scaffolds. The method has the advantages that indoor ground structural engineering and overhead pipeline and equipment installation engineering such as ceiling decoration engineering, electrical installation engineering, water supply and drainage engineering, firefighting engineering, heating and ventilation engineering can be sequentially constructed in an assembly line manner, accordingly, various construction tasks in profession can be quickly completed, the construction periods can be greatly shortened, and effects of yielding twice the result with half the effort can be realized.

Owner:CHINA RAILWAY SIXTH GRP TIANJIN RAILWAY CONSTR +1

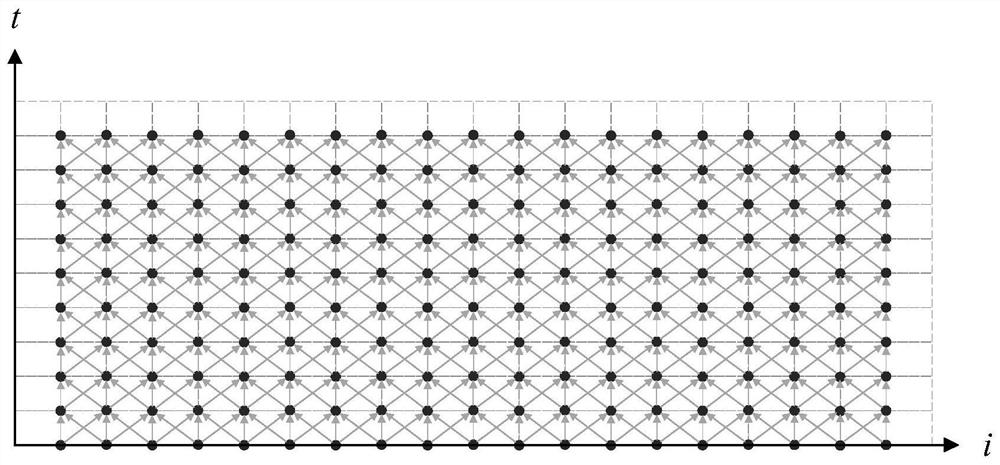

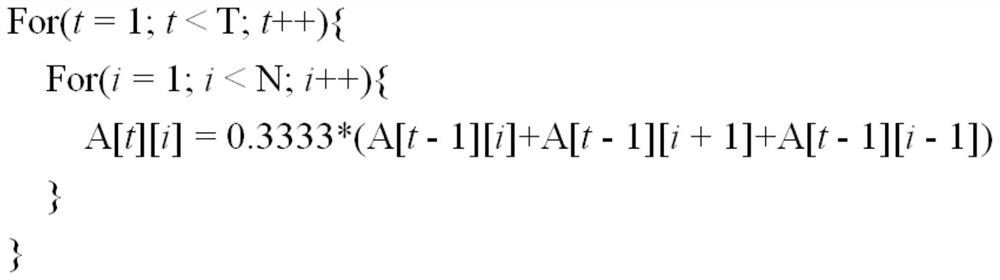

Performance-driven multi-FPGA Jacobian template calculation optimal deployment method and system

PendingCN113255269AReduce runtimeReduce energy consumptionConstraint-based CADCAD circuit designModelSimParallel computing

The invention discloses a performance-driven multi-FPGA Jacobian template calculation optimal deployment method and system, and the method comprises the steps: carrying out the hexagonal partitioning of Jacobian template calculation, and enabling the data between blocks to be subjected to parallel calculation; carrying out formalized description on N FPGA chips running Jacobian template calculation, and expressing various attributes of different FPGA chips by using mathematics; performing mathematical modeling by using the hexagonal blocks and the formalized description content, determining constraint conditions of the model, and determining a target function according to the total cost, resource occupation and the total time consumption of the FPGA chip model; and writing the attributes of the Jacobian hexagon blocks, the formalized description content of the FPGA chip, various constraint conditions and the target function content, generating a model file, performing optimizing to obtain an optimal result, and realizing an optimal placement strategy by using the optimal result. According to the method and system, the optimal placement of the template calculation on the multiple FPGA chips is realized, the resource waste of the FPGA chips is effectively reduced, the efficient operation of the template calculation is realized, and the engineering expenditure of the template calculation is further saved.

Owner:XI AN JIAOTONG UNIV

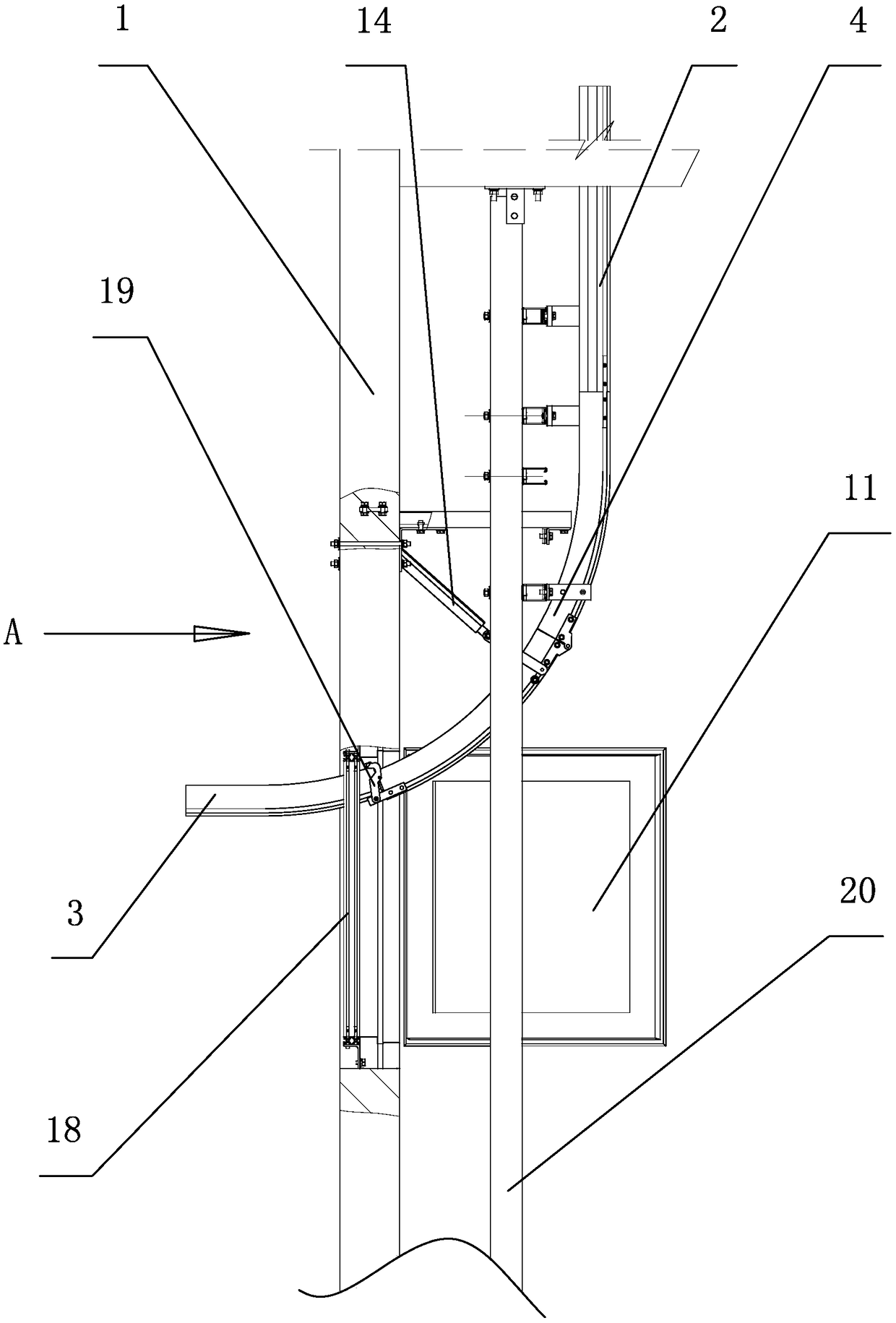

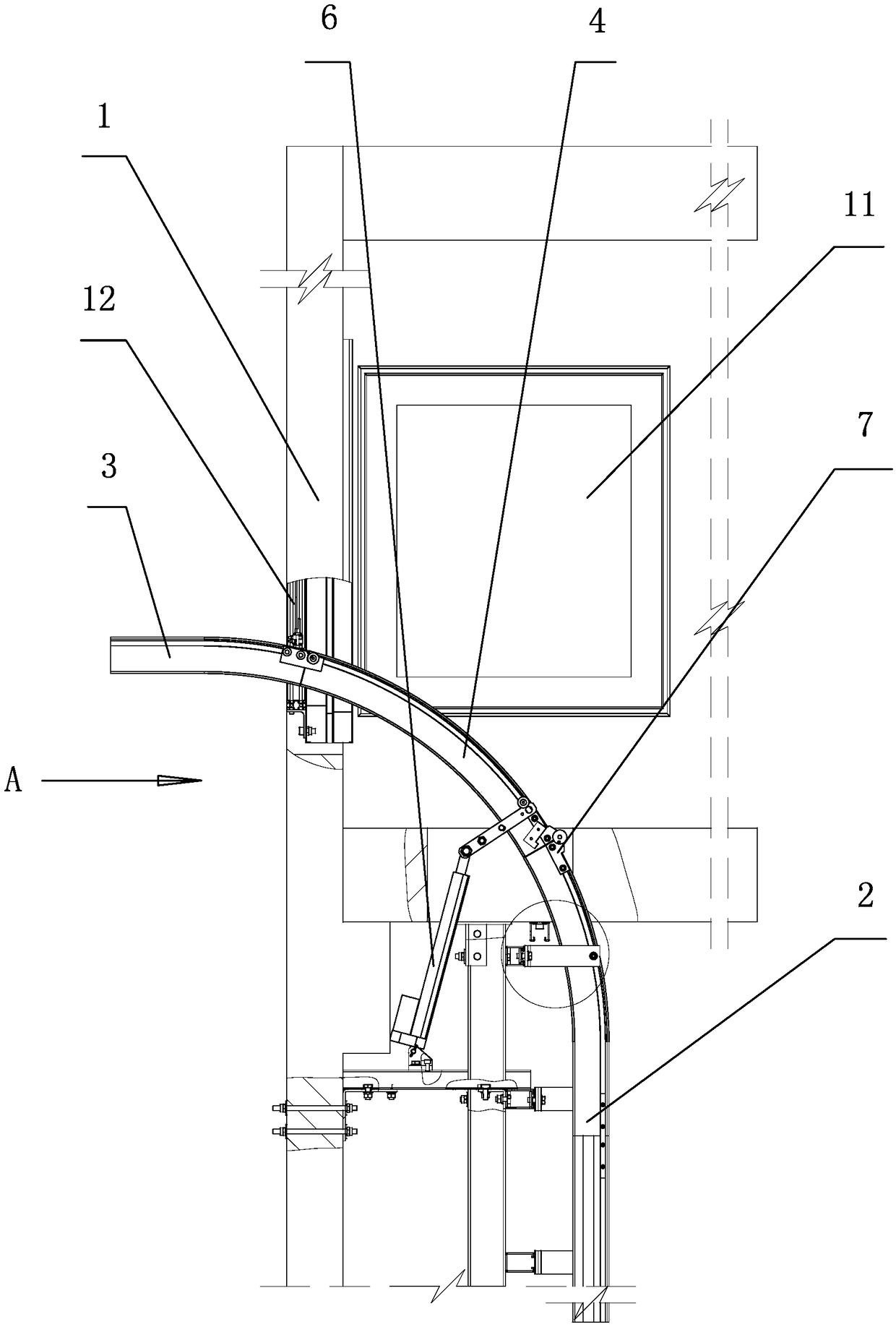

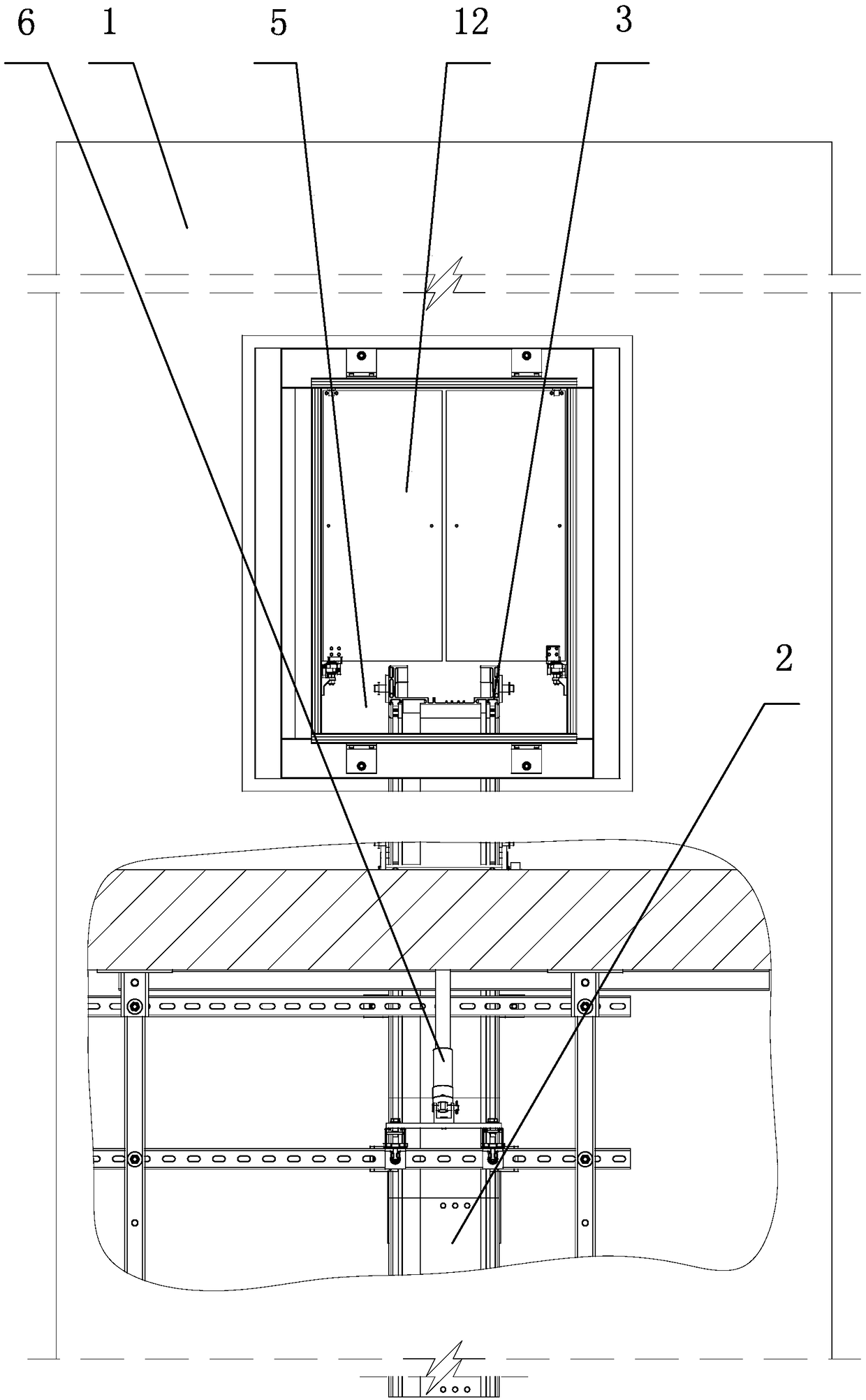

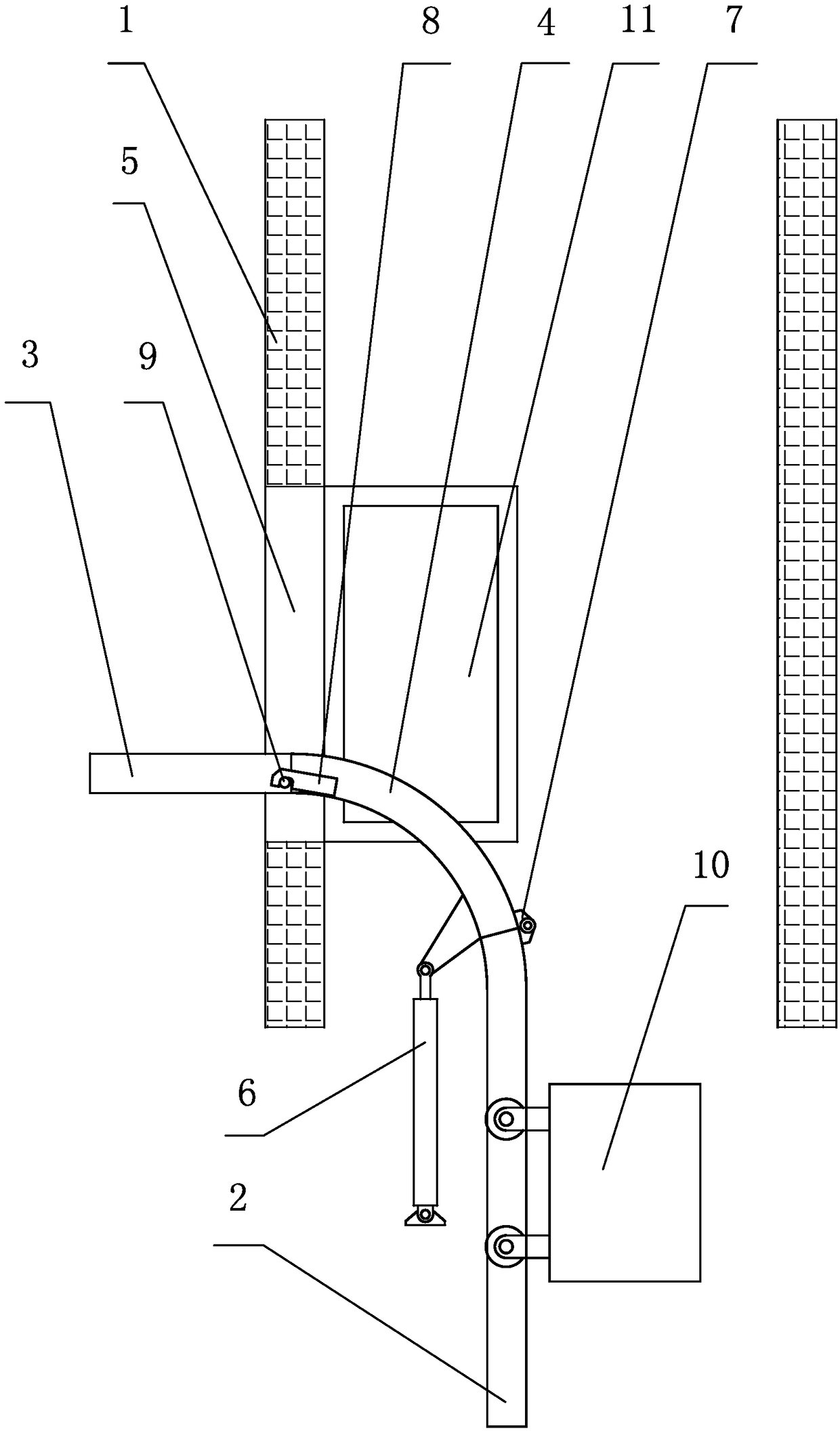

Wind-proof and fire-proof device for outer rail bender on a vertical shaft of logistics track

InactiveCN109178033ASmall space constructionSave engineering expensesElectric devices for scotch-blocksFluid-pressure devices for scotch-blocksLogistics managementLocking mechanism

The invention discloses a wind-proof and fire-proof device of an outer rail bender on a vertical shaft of a logistics track. The wind-proof and fire-proof device comprises a plurality of vertical fixed rails arranged in the shaft corresponding to each floor and a single or double horizontal fixed rails arranged in each floor, and a 90-degree movable bending rail corresponding to each horizontal fixed rail is arranged in the shaft of each corresponding floor, and the front and lower ends of the movable bending rail are connected with the horizontal fixed rail in the window hole of the front wall of the vertical shaft, and the rear and upper ends are hinged with the lower ends of the corresponding vertical fixed rails, and the vertical shaft above the movable bending rail is provided with anoverturning mechanism for overturning the movable bending rail, and the connection end of the movable bending rail and the horizontal fixed rail is provided with a locking mechanism for locking the return position of the movable bending rail; smoke prevention and fire prevention flat windows with closed windows are arranged in the vertical shaft; windshields are provided in the window openings under the single or double horizontal fixed rails. As the rail break is arranged in the vertical shaft, the indoor environment is beautiful and simplify, and the space of the vertical shaft can be builtsmaller, and the construction cost can be reduced.

Owner:GUANGXI MANCHEBISI AUTOMATION EQUIP

A bending device for serpentine laying of large cross-section power cables

ActiveCN106345942BTo ensure the quality of laying a qualified rateReduce investmentApparatus for laying cablesPower cableUniversal joint

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

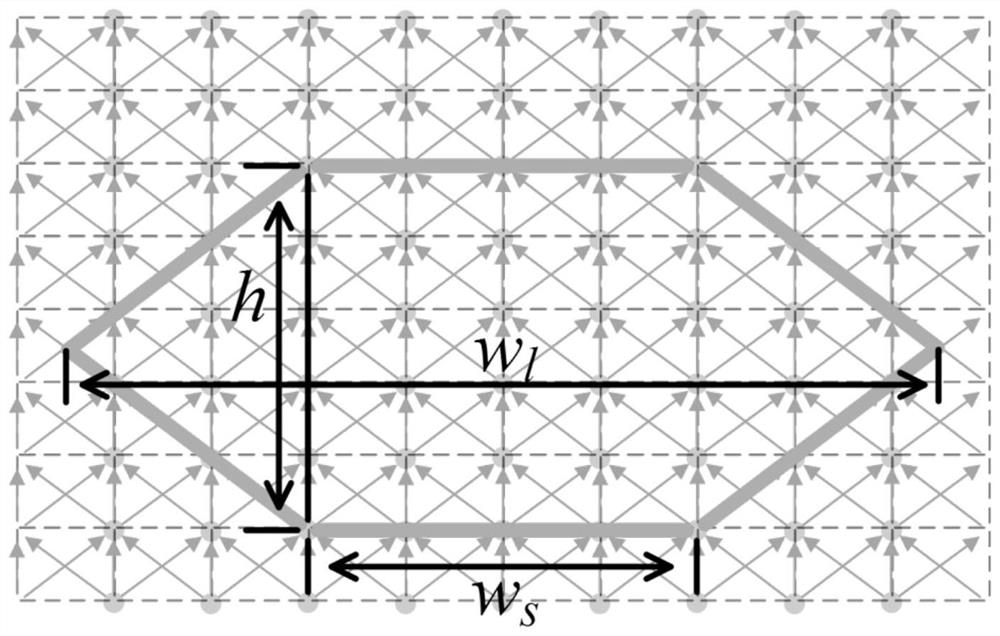

A Non-rectangular Layout Method of FPGA Reconfigurable Resources Based on Clipping Method

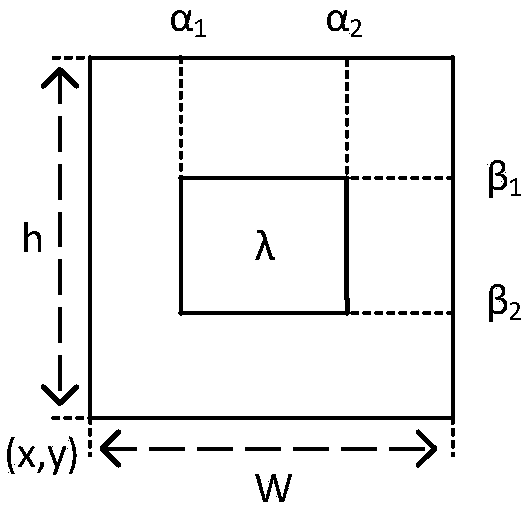

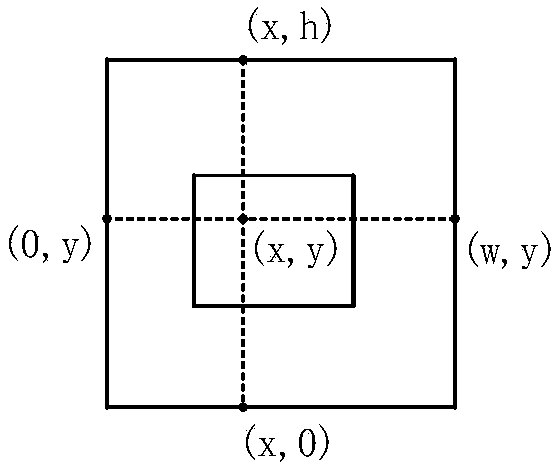

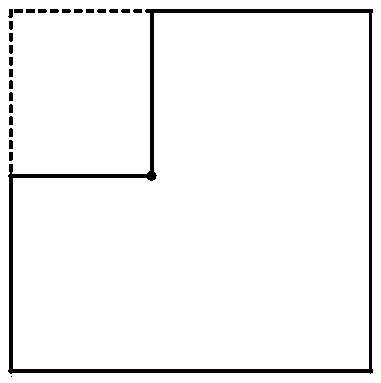

ActiveCN107256281BAvoid problemsReduce complexityComputer aided designSpecial data processing applicationsParallel computingLayout

The invention discloses an FPGA (Field Programmable Gate Array) reconfigurable resource non-rectangular layout method based on a cutting method. According to the method, firstly, n logic function layout requiring region sets N are defined; a cutting range lambda is determined; all points in the lambda are traversed; the protection of each point in the horizontal and vertical directions is calculated; the rectangle is divided into four parts to be cut so as to obtain a layout requiring logic function non-rectangular description model; then, FPGA chip reconfigurable resources are divided according to lines according to the layout requiring logic function non-rectangular description model; and the reconfigurable resource non-rectangular layout method is defined through chip reconfigurable resource data preprocessing and logic function layout requiring region data preprocessing. A region division method is used, so that the occurrence of an extreme shape model is effectively avoided; the layout failure rate is reduced; through the setting of a cutting range threshold value and the introduction of data preprocessing before the layout, the useless workload is effectively avoided; the time consumption of a layout algorithm is reduced; and the work expenditure of an embedded system is further reduced.

Owner:XI AN JIAOTONG UNIV

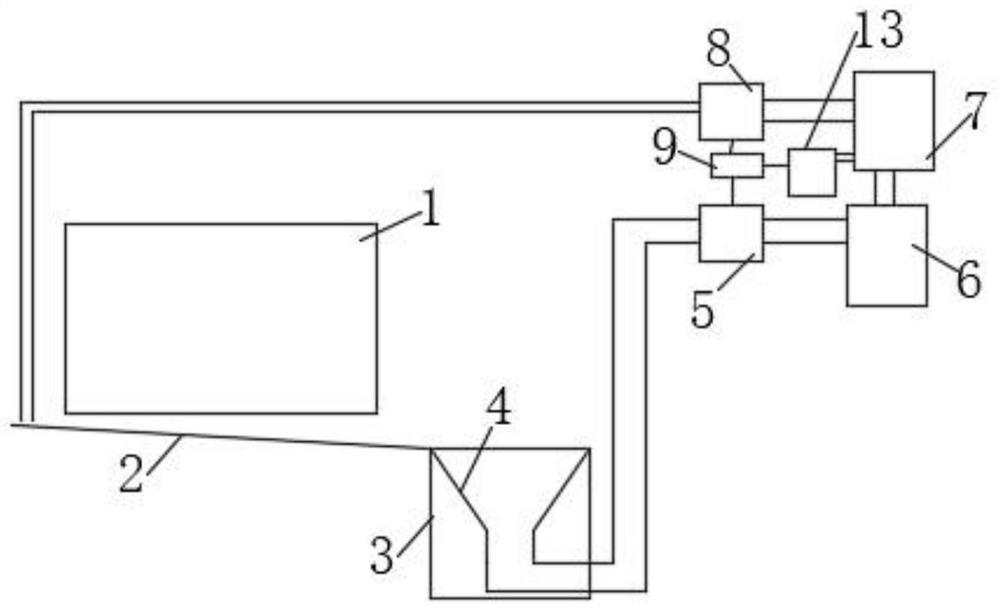

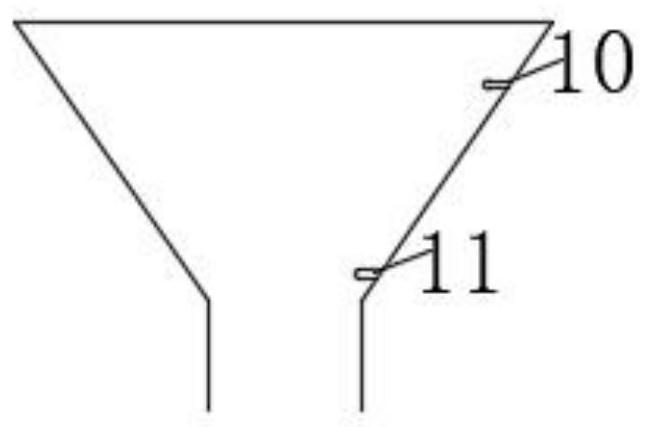

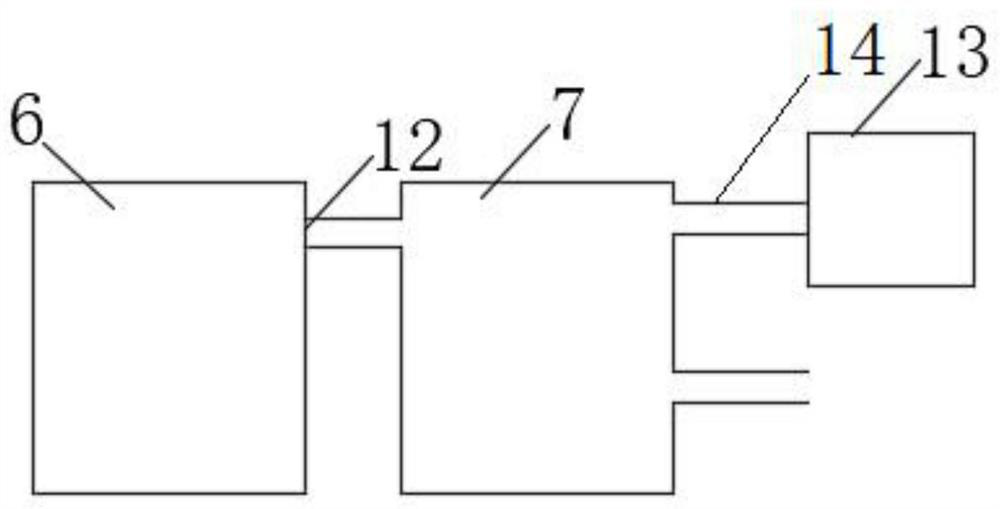

A water-stop curtain grouting production sewage recycling control system and method

ActiveCN110847180BReduce wasteReduce condensationFatty/oily/floating substances removal devicesSewerage structuresWater useControl system

The invention belongs to the technical field of sewage treatment, and discloses a water-stop curtain grouting production sewage recycling control system and method. The water-collecting funnel is arranged in the water-collecting well, and one end of the top of the water-collecting funnel is connected to a drainage channel, and the bottom of the water-collecting funnel is connected through a pipeline. The first water pump, the first water pump is connected to the sedimentation tank through the pipeline, the sedimentation tank is connected to the water collection tank through the pipeline, the water collection tank is respectively connected to the clean water tank and the second water pump through the pipeline, the second water pump, the first water pump and the third water pump, the second water pump is passed through The pipe is connected to the source of the drain. The invention reduces the waste of water resources and reduces engineering expenses by recycling water. The present invention is simple in structure, easy to implement, and suitable for popularization and use. By using the cement retarder to slow down the coagulation speed of cement, the cement coagulates in the sedimentation tank, reduces the coagulation of cement in other equipment, and reduces the cleaning workload. The low-temperature waterproof coating used, It can make the sedimentation tank clean the sedimented cement thoroughly, with high efficiency and saving labor cost.

Owner:SINOHYDRO BUREAU 1 CO LTD

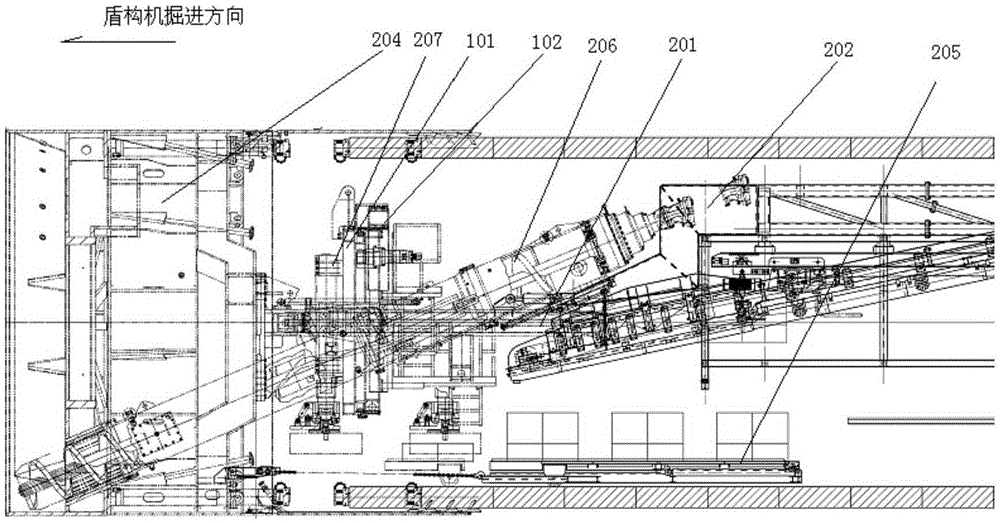

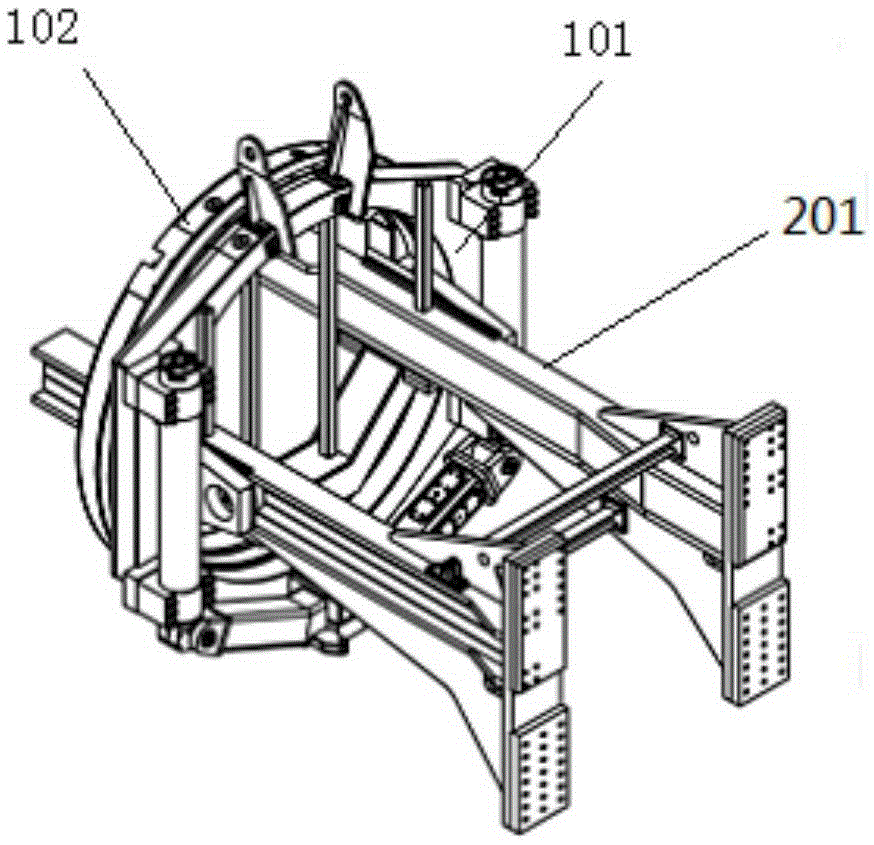

Downhole Replacement Method of Main Bearing of Shield Machine Assembly Machine

The invention discloses a method for underground replacement of an erector main bearing of a shield tunneling machine. The method comprises the following steps: firstly transporting the bulk parts of a hoisting trolley to a crane span structure, mounting a bearing hoisting tool and a new erector main bearing and conveying to the front part of the crane span structure, and fixedly connecting the front part of the crane span structure with a vertical support of a bearing transportation vehicle; dismantling all pipes and moving the crane span structure backwards; assembling the hoisting trolley and dismounting an erector main bearing mounting seat and a damaged erector main bearing connection bolt; hoisting the damaged erector main bearing by using the hoisting trolley and dismounting an erector rotation ring and the damaged erector main bearing connection bolt; hoisting a new erector main bearing to be assembled with the erector rotation ring, and hoisting the erector main bearing mounting seat to assemble with the main bearing; finally recovering the damaged bearing and connecting the pipes. The method for underground replacement of the erector main bearing of the shield tunneling machine is capable of avoiding silo digging on ground, so that lots of of construction is eliminated, the project progress is greatly improved, and the project expense is reduced.

Owner:JIANGSU KAIGONG TUNNEL MACHINERY

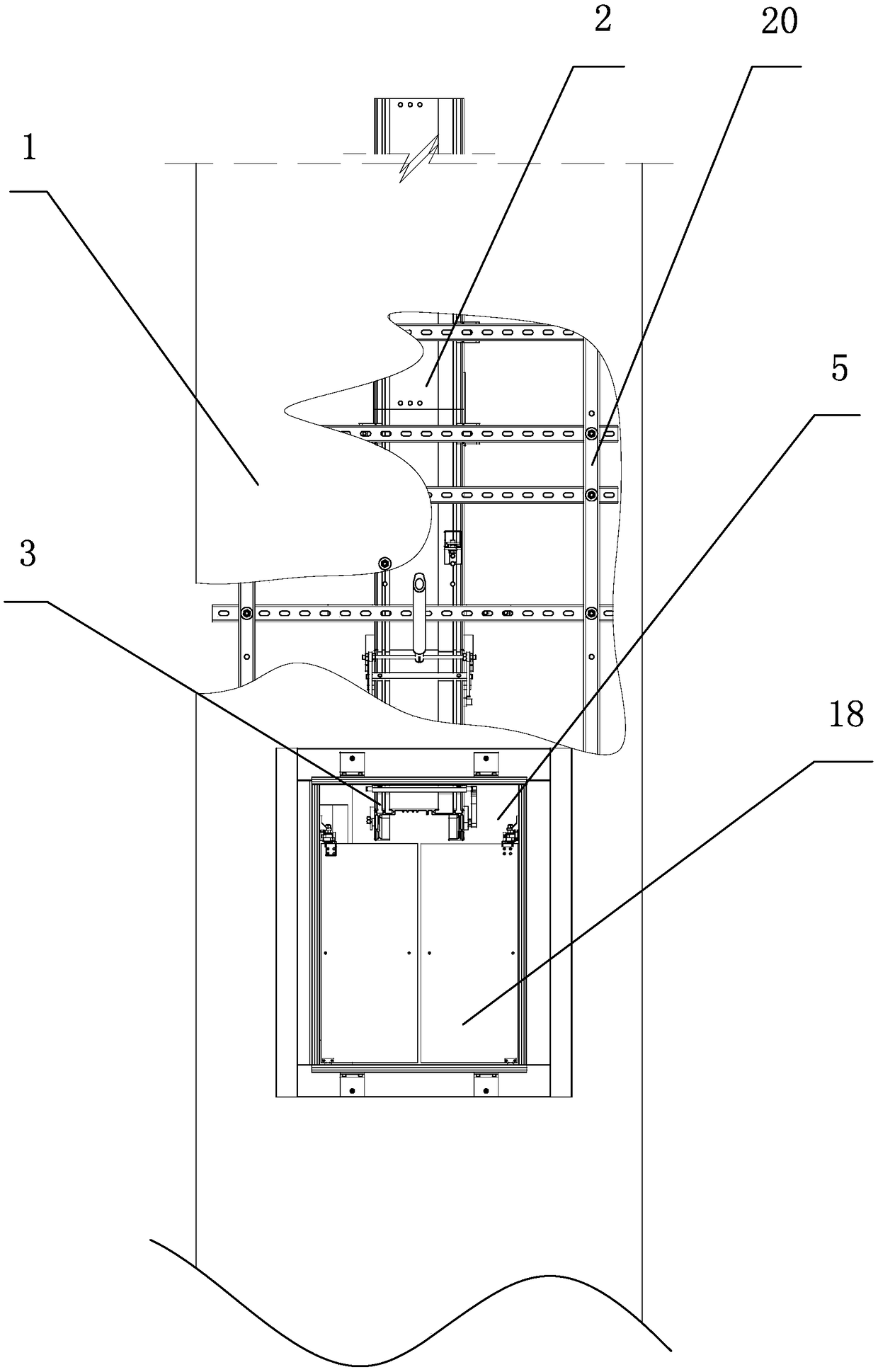

Wind-proof and fire-proof facilities for external rail bender under vertical shaft of logistics track

InactiveCN109178034ASmall space constructionSave engineering expensesElectric devices for scotch-blocksFluid-pressure devices for scotch-blocksLogistics managementWindow opening

The invention discloses a wind-proof and fire-proof device for an external rail bender under a vertical shaft of a logistics track. The wind-proof and fire-proof device includes vertical fixed rails corresponding to each floor arranged in the shaft and horizontal fixed rails arranged at the bottom of each floor, and a 90-degree movable bending rail arranged in the shaft of each corresponding floorcorresponding to the horizontal fixed rail, and the front upper end of the movable bending rail is connected with the horizontal fixed rail in the window hole of the front wall of the vertical shaft,and the rear lower end is hinged with the upper end of the vertical fixed rail, and the vertical shaft is provided with an overturning mechanism for overturning the movable bending rail, and the connecting end of the movable bending rail and the horizontal fixed rail is provided with a support mechanism; smoke prevention and fire prevention flat windows with closed windows are arranged in the vertical shaft; windshields are provided in the window openings above the horizontally fixed rails. The invention changes the scheme of installing the rail breaker in the indoor into installing the railbreaker in the vertical shaft, which not only simplifies the indoor environment but also reduces the space of the vertical shaft and the engineering cost of the building.

Owner:GUANGXI MANCHEBISI AUTOMATION EQUIP

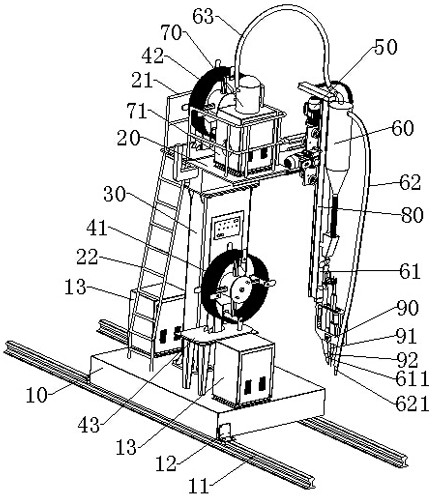

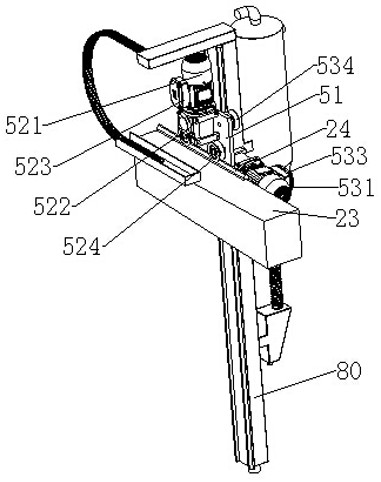

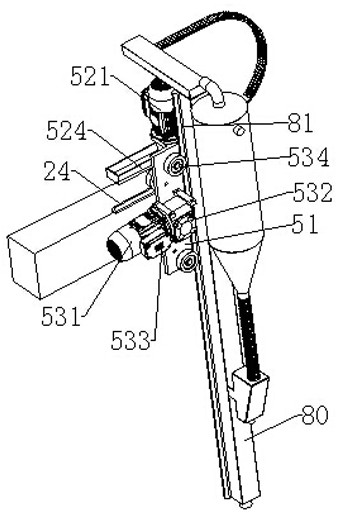

Double-wire welding machine

The invention discloses a double-wire welding machine in the technical field of welding equipment. The double-wire welding machine comprises a base and an upper platform, wherein the base slides alongguide rails front and back, a first welding wire coil is arranged on the base, a second welding wire coil is fixed on the upper platform, an adjusting mechanism is arranged on an adjusting table extending outwards from the side surface of the upper platform and drives a welding flux storage tank to slide along the adjusting table left and right, an adjusting stand column drives the welding flux storage tank to slide up and down, the lower end of the welding flux storage tank is connected with a first welding flux guide pipe, the upper end of the welding flux storage tank is connected with a second welding flux guide pipe, and welding heads are arranged at the end parts of the two welding flux guide pipes. According to the double-wire welding machine, by means of front-and-back movement ofthe base and left-and-right and up-and-down movement of the welding adjusting stand column, 360-degree adjustment of the welding position is realized, so that the adjustable range of the whole double-wire welding machine is increased, besides, the accurate control for the welding position is guaranteed, and welding quality of the whole product is ensured.

Owner:CHINA 19TH METALLURGICAL CORP

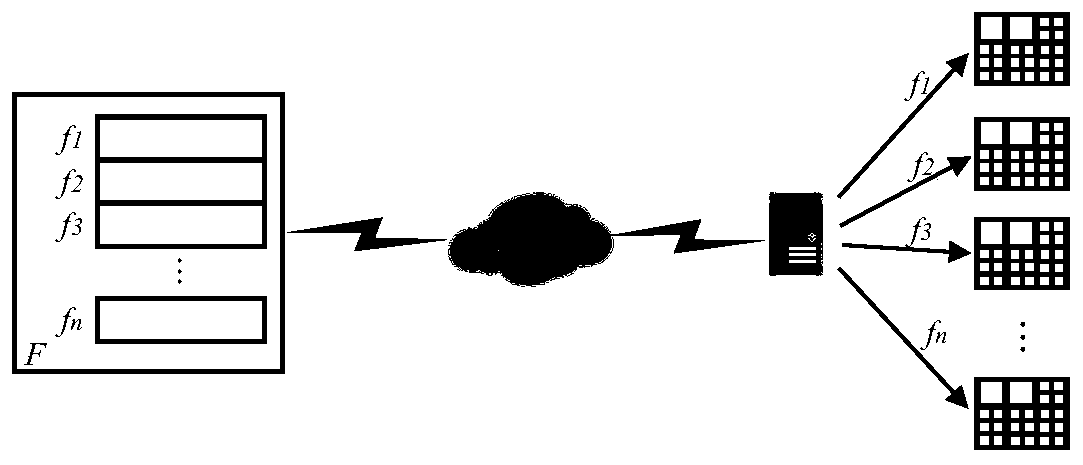

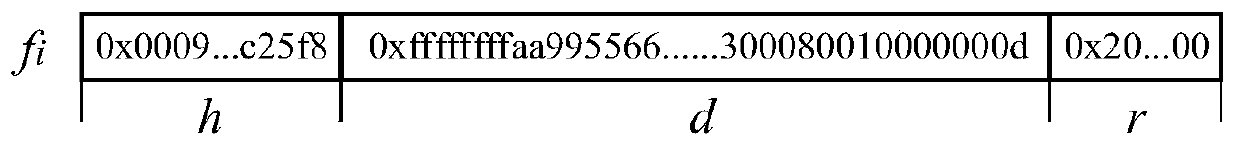

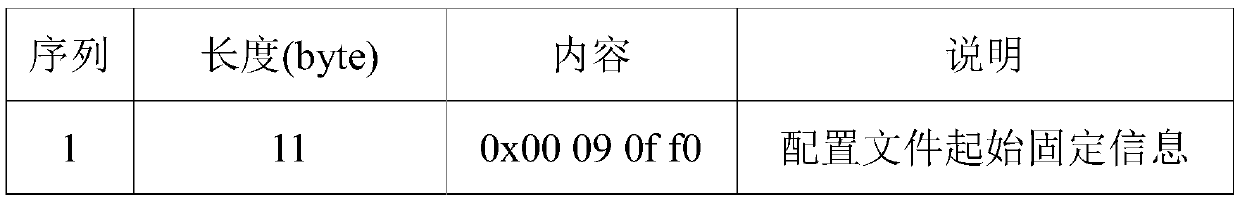

FPGA configuration file compression and decompression method based on partition reference technology

ActiveCN111427857ASolve the problem that the transfer process takes too longSave engineering expensesDigital data information retrievalSpecial data processing applicationsComputer hardwareComputer architecture

The invention discloses an FPGA configuration file compression and decompression method based on a partition reference technology, and the method comprises the steps of defining an FPGA configurationfile fi = (h, d, r), i = 1, 2, 3,..., n, and enabling head information h to comprise a project name, compiling time and target chip model information, wherein the configuration data information d comprises binary codes of various resources in the target chip, wherein the tail redundant information r comprises a plurality of null instruction operations, and partitioning the FPGA configuration file;and performing compression and decompression operation on the head information h, the configuration data information d and the tail redundant information r by adopting different compression strategies. According to the method, the FPGA configuration files are partitioned according to functions; corresponding compression and decompression strategies are designed for different partitions; the application scenarios of the multiple FPGA configuration files need to be transmitted at a time during large-scale neural network cooperative processing; repeated information among the configuration filesis analyzed; and the compression rate is further increased by adopting a reference compression method.

Owner:XI AN JIAOTONG UNIV

Compound underflow constructed wetland system

InactiveCN101993150BDelayed clogging timeGuaranteed temperatureTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandSurface layer

The invention relates to a compound underflow constructed wetland system, comprising a wetland pool and a wetland bed body. The surface layer of the wetland bed body is covered with small size filler layers. Big size filler layers are arranged from the surface layer to the pool bottom. The wetland bed body is provided with a water inlet pipe and a water collecting tank. The water collecting side of the water collecting tank is a water collecting tracery wall to connect a fine grid, and a water outlet pipe is arranged in the water collecting tank. Wetland plants are distributed on the surface of the wetland bed body. The system is characterized in that a water inlet end and a water outlet end are arranged on the same end of the wetland bed body; the water inlet pipe is a perforated pipe horizontally arranged between the big size filler layers and the small size filler layers along the direction of a short side dam; the water collecting tank and the water inlet pipe are arranged on one side of the water inlet pipe far from the short side dam; a waterproof layer is arranged at the lower inclined part of the wetland bed body along a long side dam; the upper end of the waterproof layeris connected with the bottom of the water collecting tracery wall; the lower end and the back end short side dam and the pool bottom keep a distance; long sides on the two sides are connected with the dam; and the wetland bed body is provided with a gas relief pipe. The system has the advantages that the removal of total nitrogen is improved, the wetland blockage is delayed, the occupation area is reduced, and the high treatment efficiency is realized during operation at a low temperature or in winter.

Owner:天津市天水环保设计工程有限公司

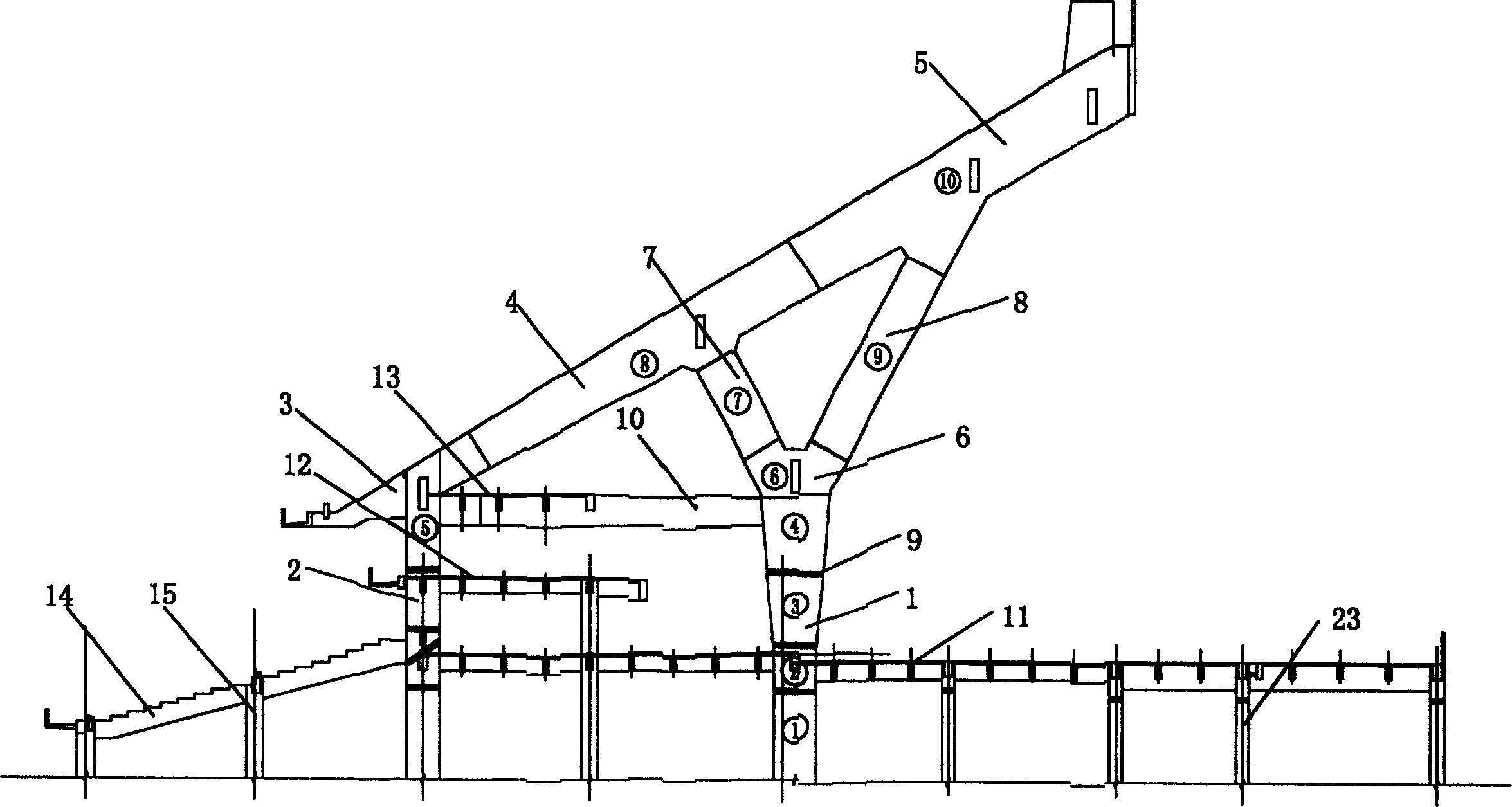

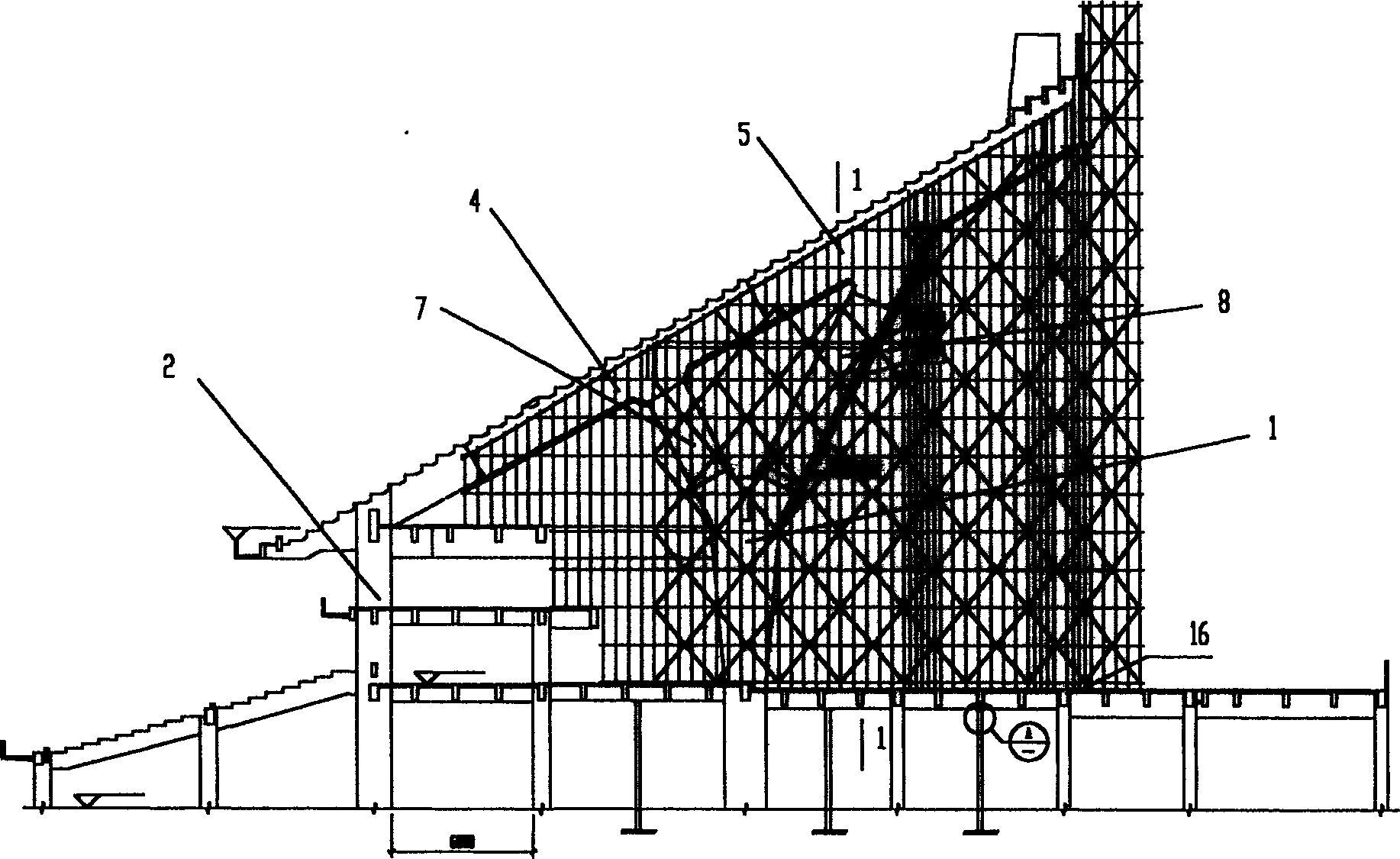

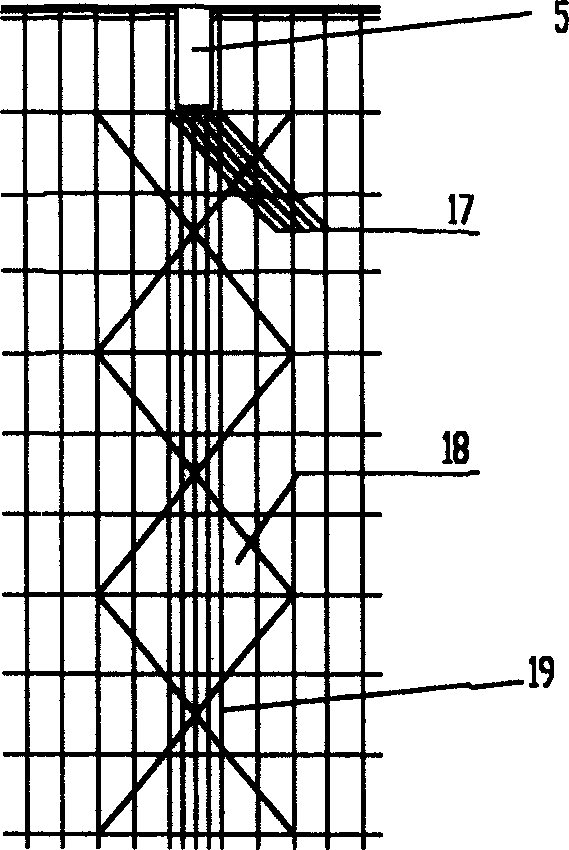

Method for constructing Y shape pillar and suspended declined beam

InactiveCN1215236CGuaranteed quality and reliabilityGuarantee safe and reliable performanceForms/shuttering/falseworksFalseworkFloor slab

A construction method for Y-shaped column and overhung great inclined beam features that the Y-shaped column and the overhung great inclined beam are segmented and each segment is constructed along with its connected floor slab, beam, column and other concrete structure by concreting at same time to integrate them as a whole to bear the axial pressure and horizontal push force generated by the dead weight of said great inclined beam. Its scaffold is the combination of multifunctional one and ordinary one.

Owner:中国建筑第八工程局中南公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com