Method for constructing Y shape pillar and suspended declined beam

A construction method and oblique beam technology, which is applied to formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve the problems of difficult construction of sports venues, low safety factor, high cost, etc., and achieve a solution Small subsidence and displacement, saving engineering expenses, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

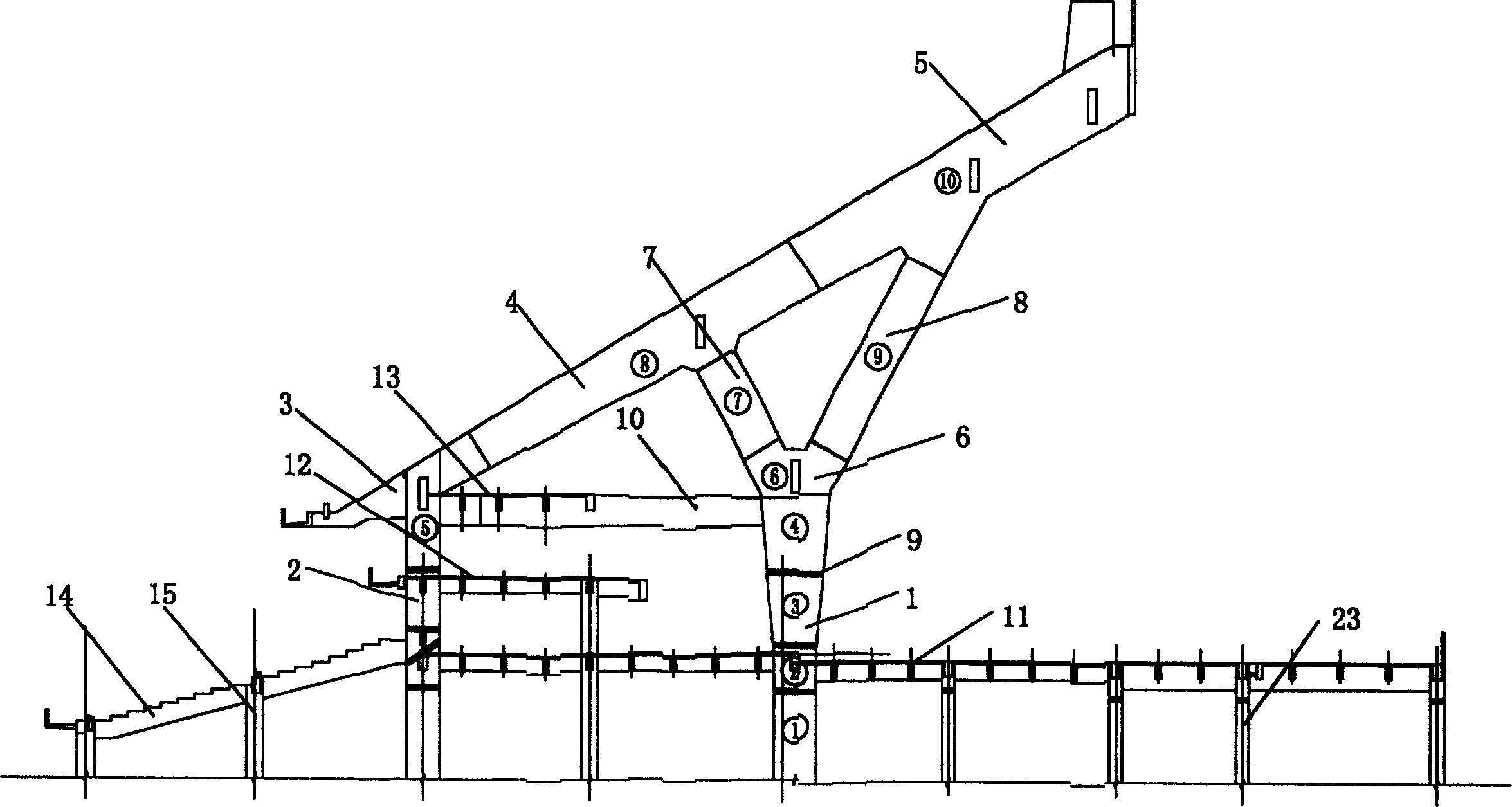

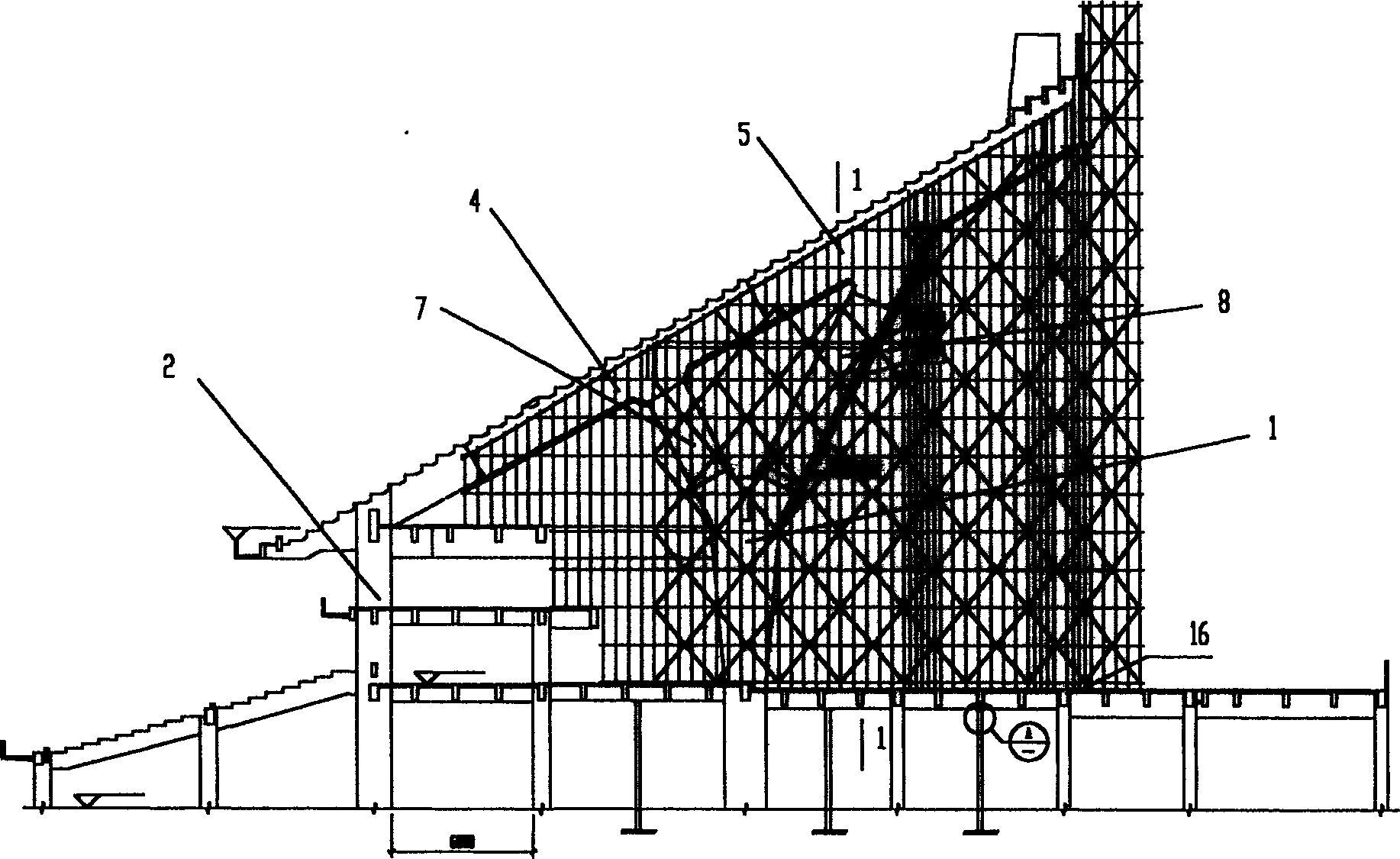

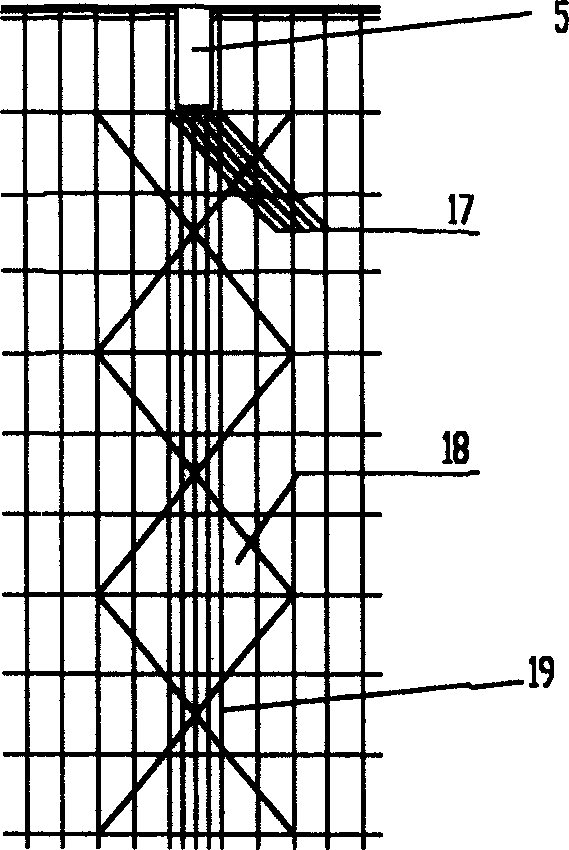

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. A stadium project is the third largest project in the country, and its project uses Y-shaped columns and stepped large inclined beams as the main structural support system. As shown in attached drawings 1-4, the vertical section of the Y-shaped column is 13.7m high, the elevations at the oblique forks are 20.5m and 27.9m respectively, and the maximum cross-section of the column is 1000×5618mm. 56 concrete columns support all stands through stepped inclined beams And the upper structure, the oblique beam is 40m long in the axial direction, is a variable cross-section beam, and its maximum cross-section is 1200×2840mm, the lowest point of the oblique beam is 12.70m, the highest point is 37.03m, the inclination angle is 33.13 degrees, the cantilever length It is 8.68m.

[0025] The first difficulty in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com