Patents

Literature

256results about How to "Precise proportion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

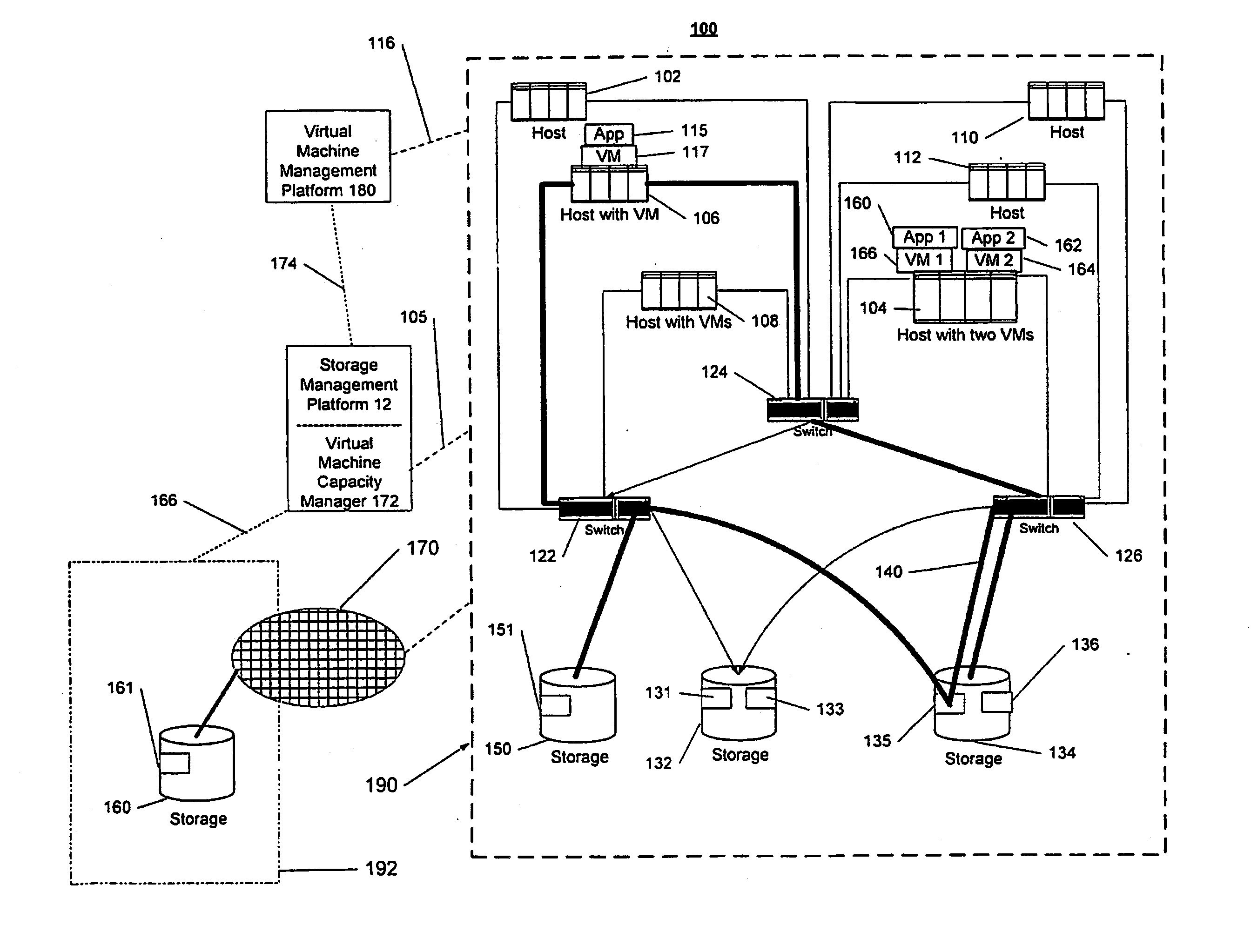

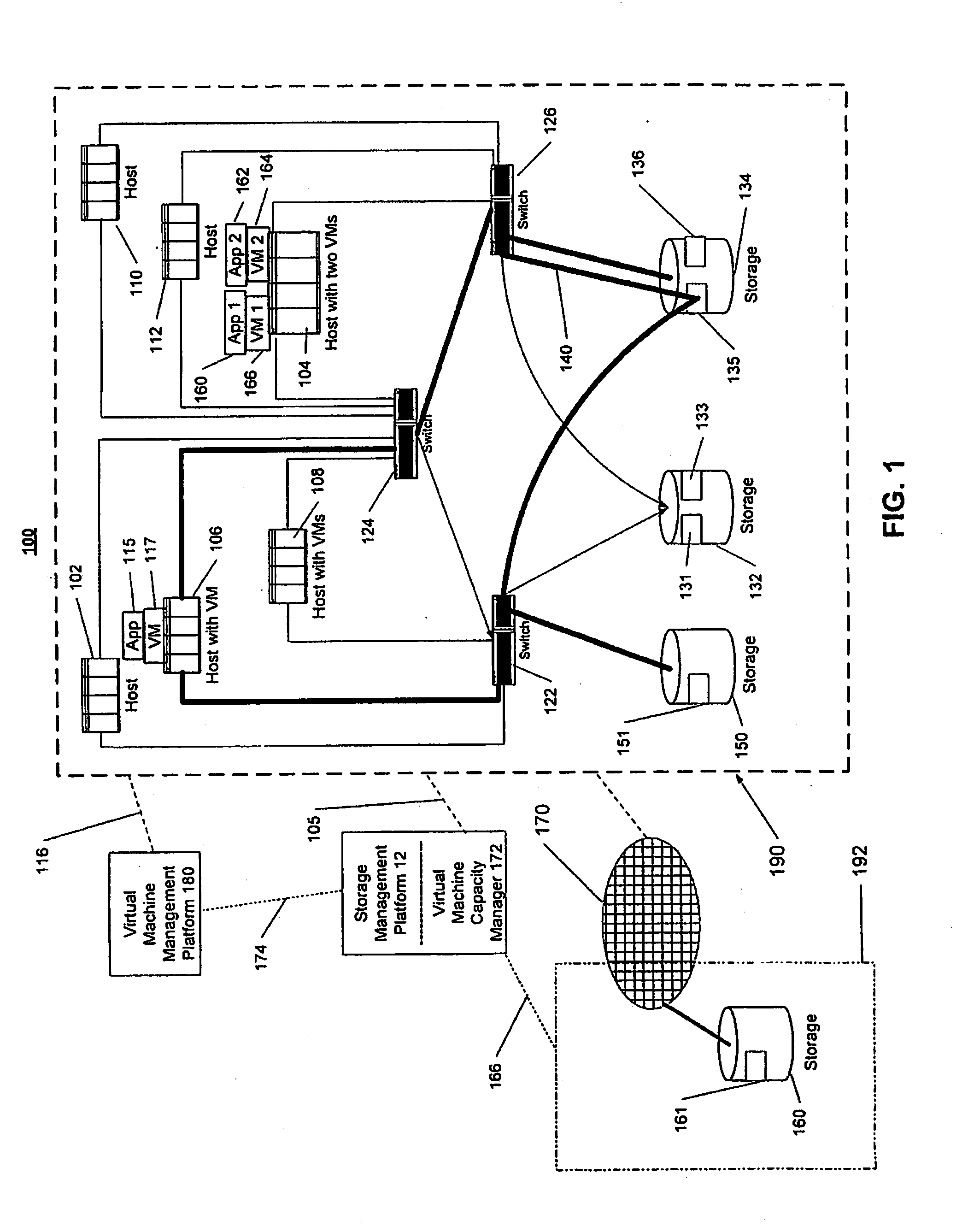

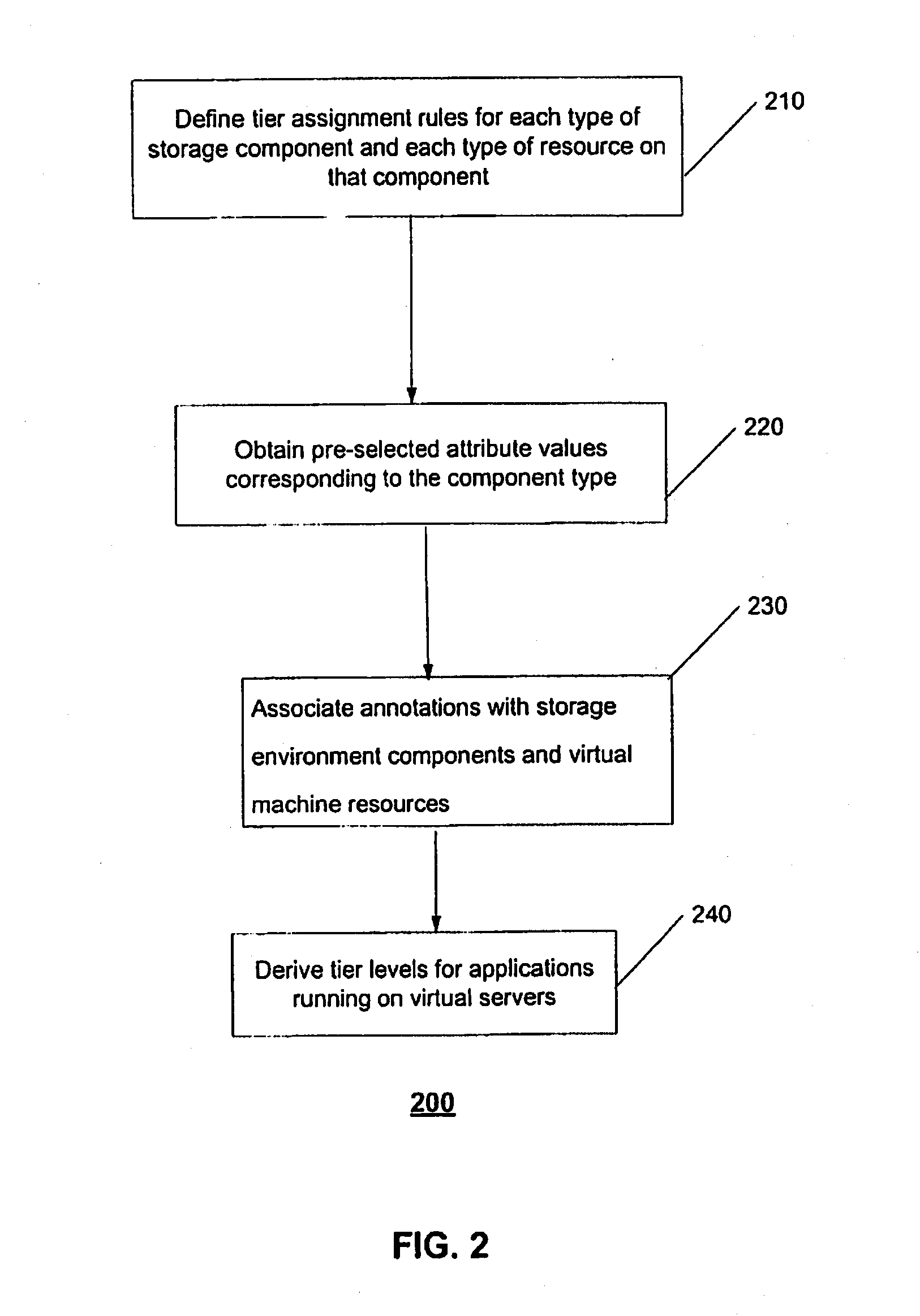

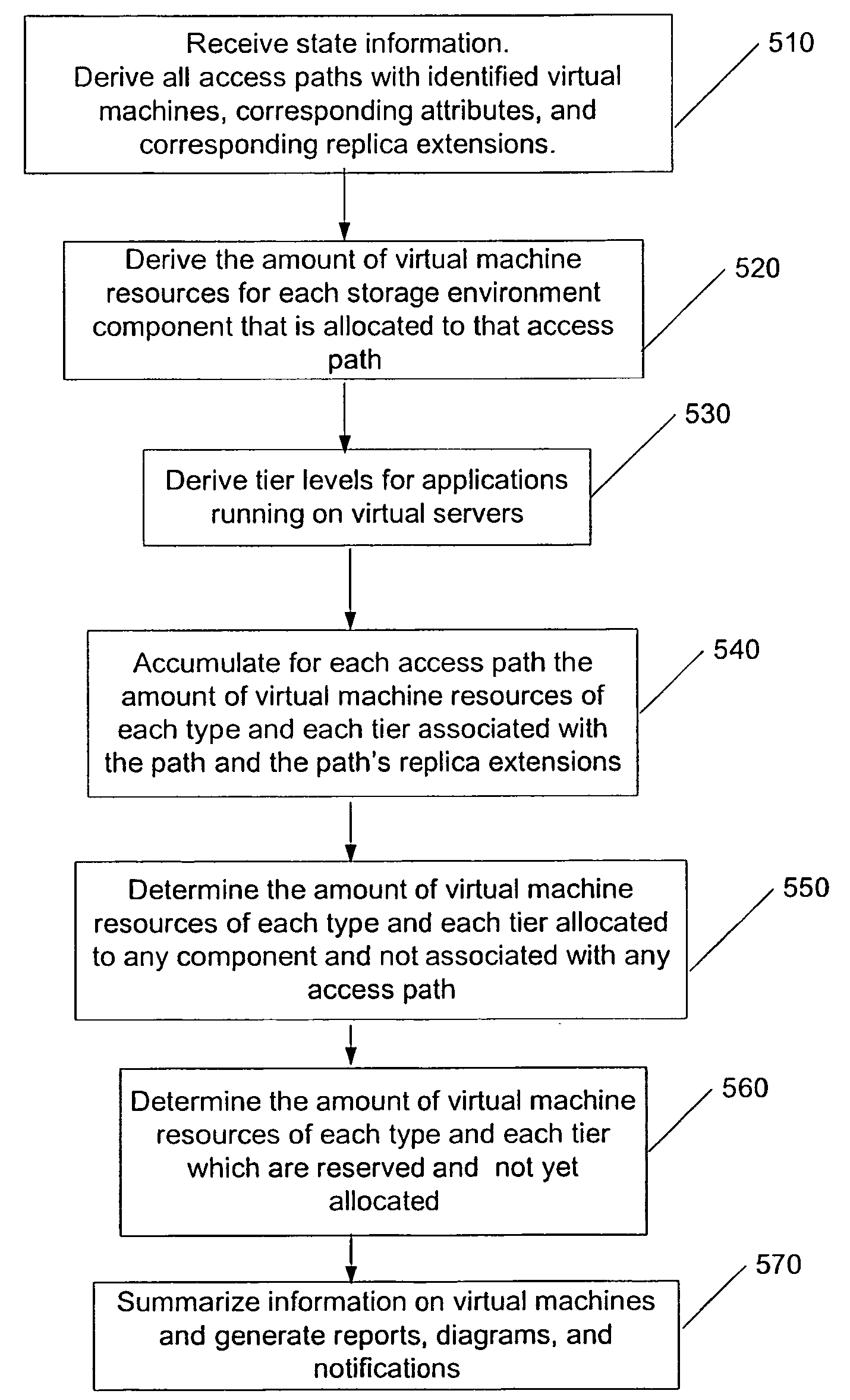

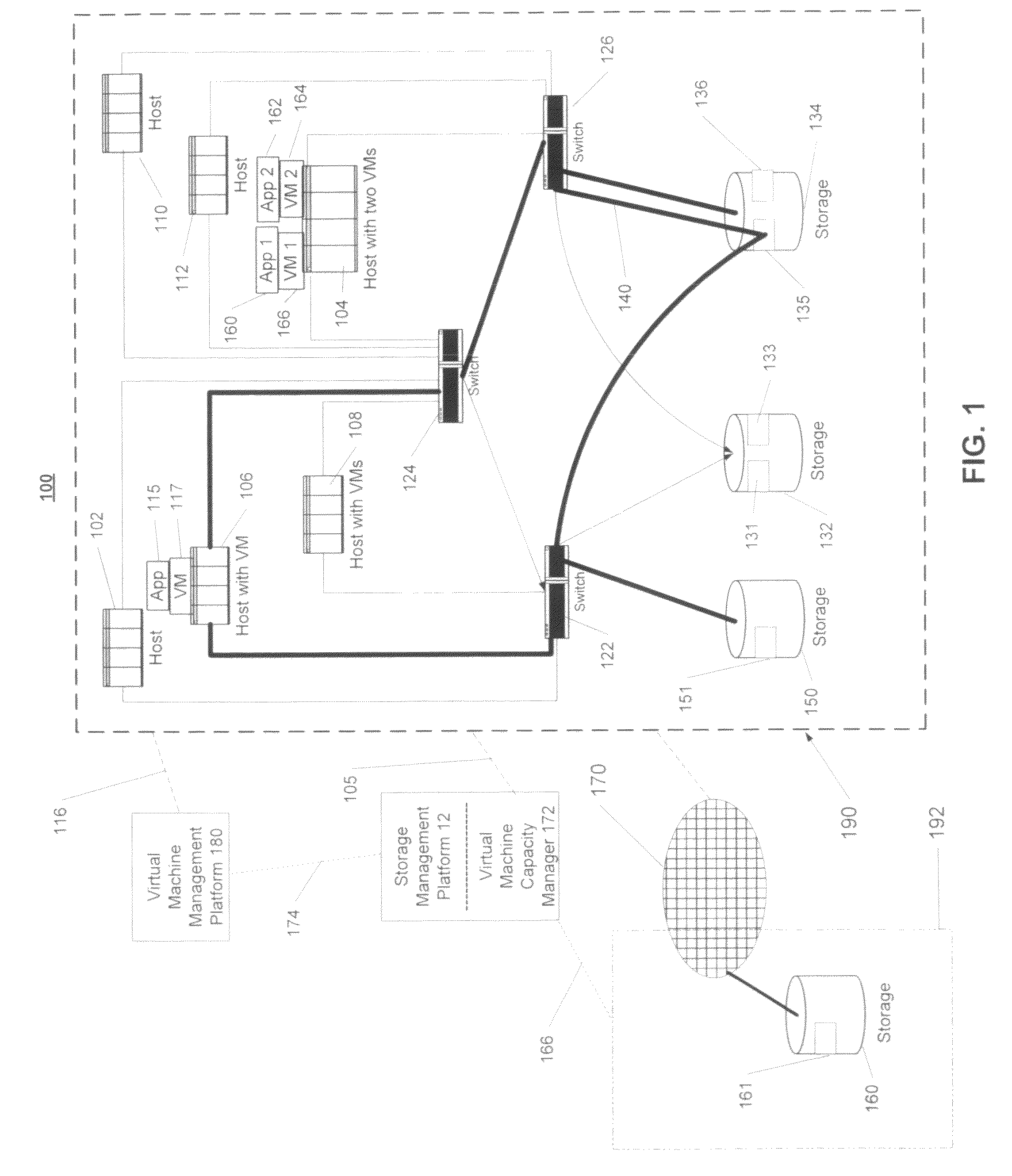

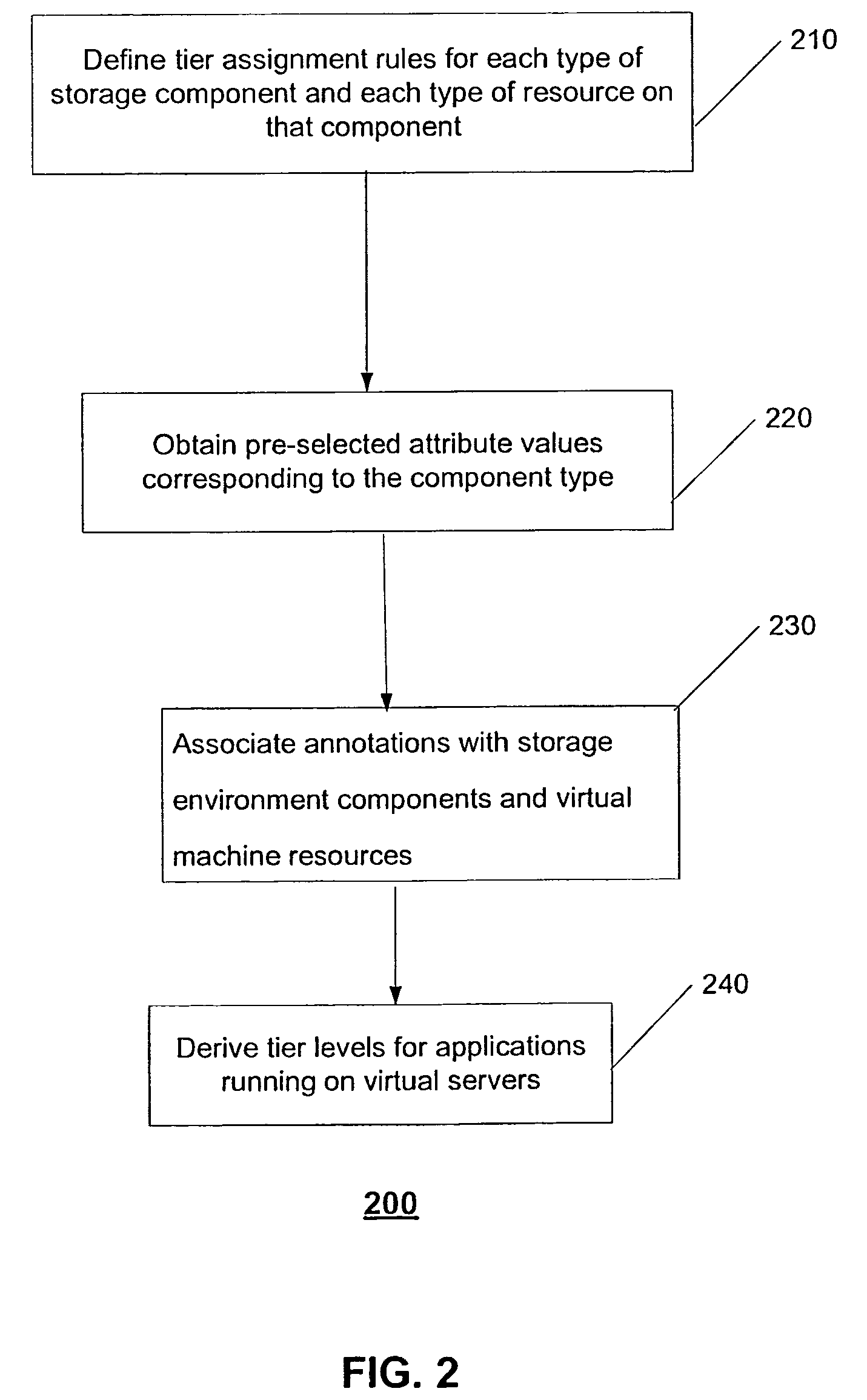

Systems and methods for path-based management of virtual servers in storage network environments

ActiveUS20140019972A1Risk minimizationMaximizationData processing applicationsResource allocationResource consumptionApplication software

Systems and methods for analyzing the service and performance levels associated with virtual machines in a storage network environment for compliance with a resource capacity policy are provided. Component configuration and connectivity information from components in the network environment is collected without using host agents on the virtual machines. Access paths defining end-to-end access relationships between an application on a virtual machine and storage data objects associated with the virtual machine in the network environment are derived. Access paths comprise sequences of components configured to enable information flow between an application residing on a virtual machine and a data object on a respective storage device. Access path resource consumption is computed and virtual machines with resource consumptions that violate the resource capacity policy are identified.

Owner:NETWORK APPLIANCE INC

Systems and methods for path-based management of virtual servers in storage network environments

ActiveUS8560671B1Minimize riskRisk minimizationData processing applicationsError detection/correctionWeb environmentApplication software

Systems and methods for analyzing the service and performance levels associated with virtual machines in a storage network environment for compliance with a resource capacity policy are provided. Component configuration and connectivity information from components in the network environment is collected without using host agents on the virtual machines. Access paths defining end-to-end access relationships between an application on a virtual machine and storage data objects associated with the virtual machine in the network environment are derived. Access paths comprise sequences of components configured to enable information flow between an application residing on a virtual machine and a data object on a respective storage device. Access path resource consumption is computed and virtual machines with resource consumptions that violate the resource capacity policy are identified.

Owner:NETWORK APPLIANCE INC

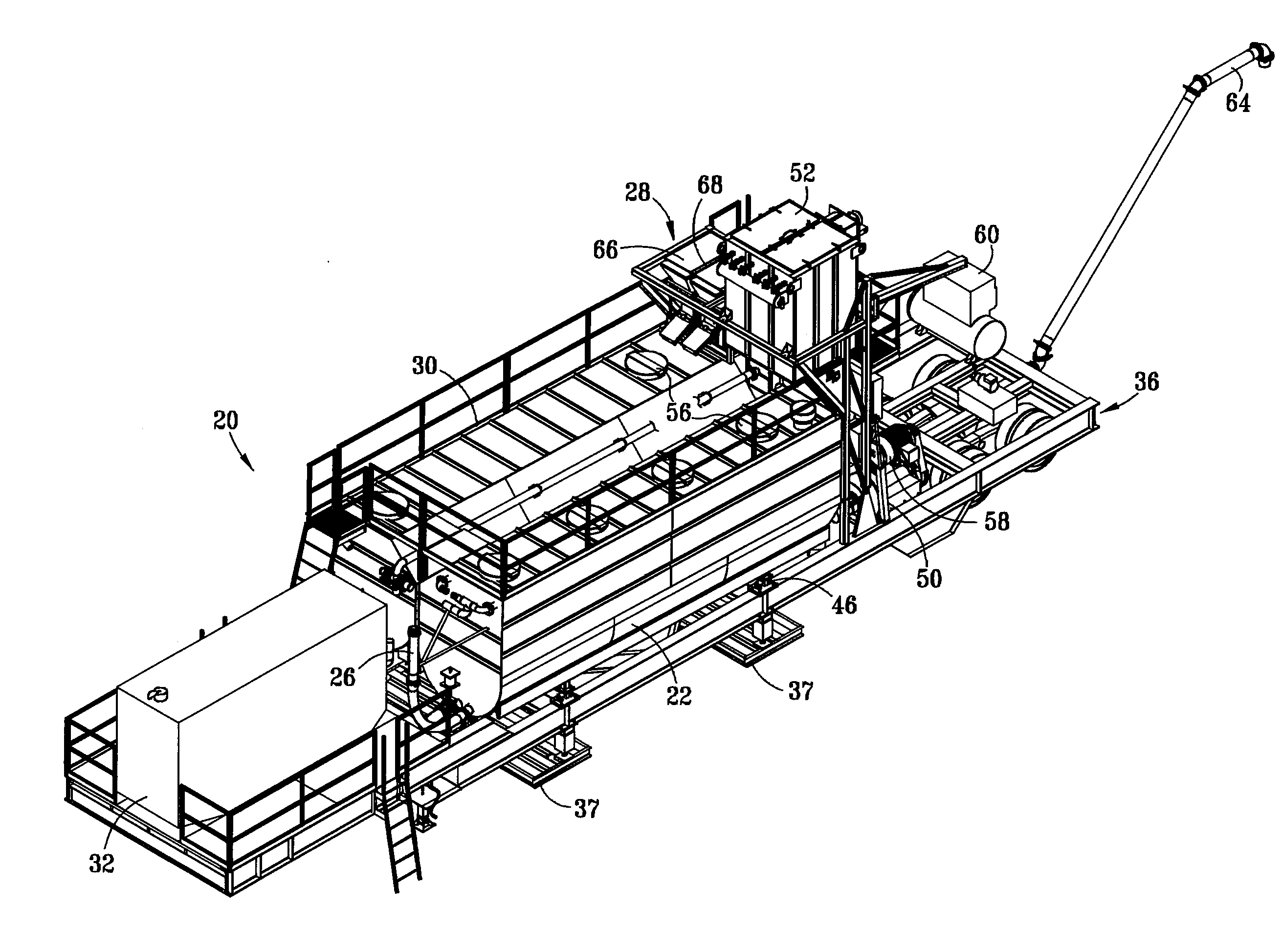

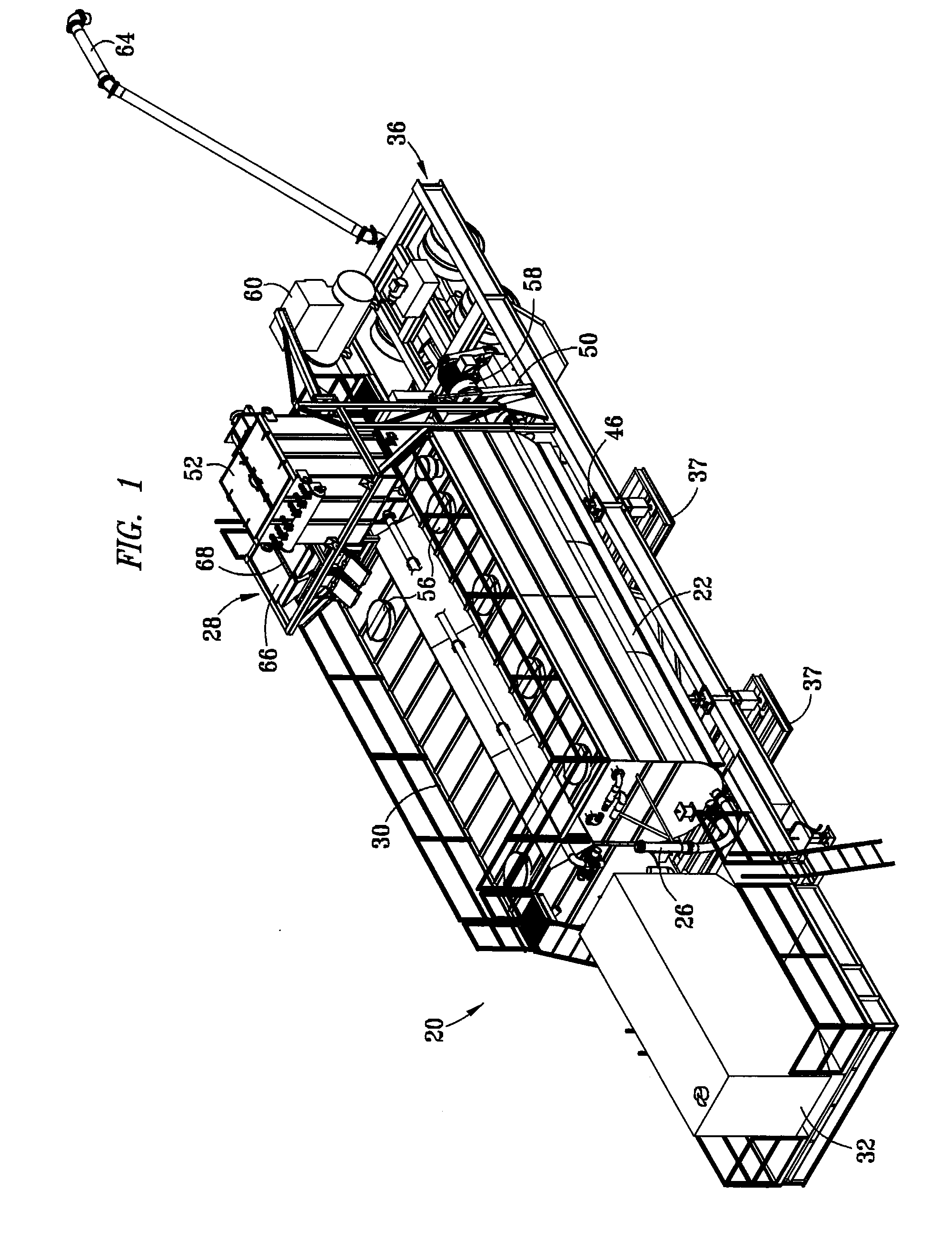

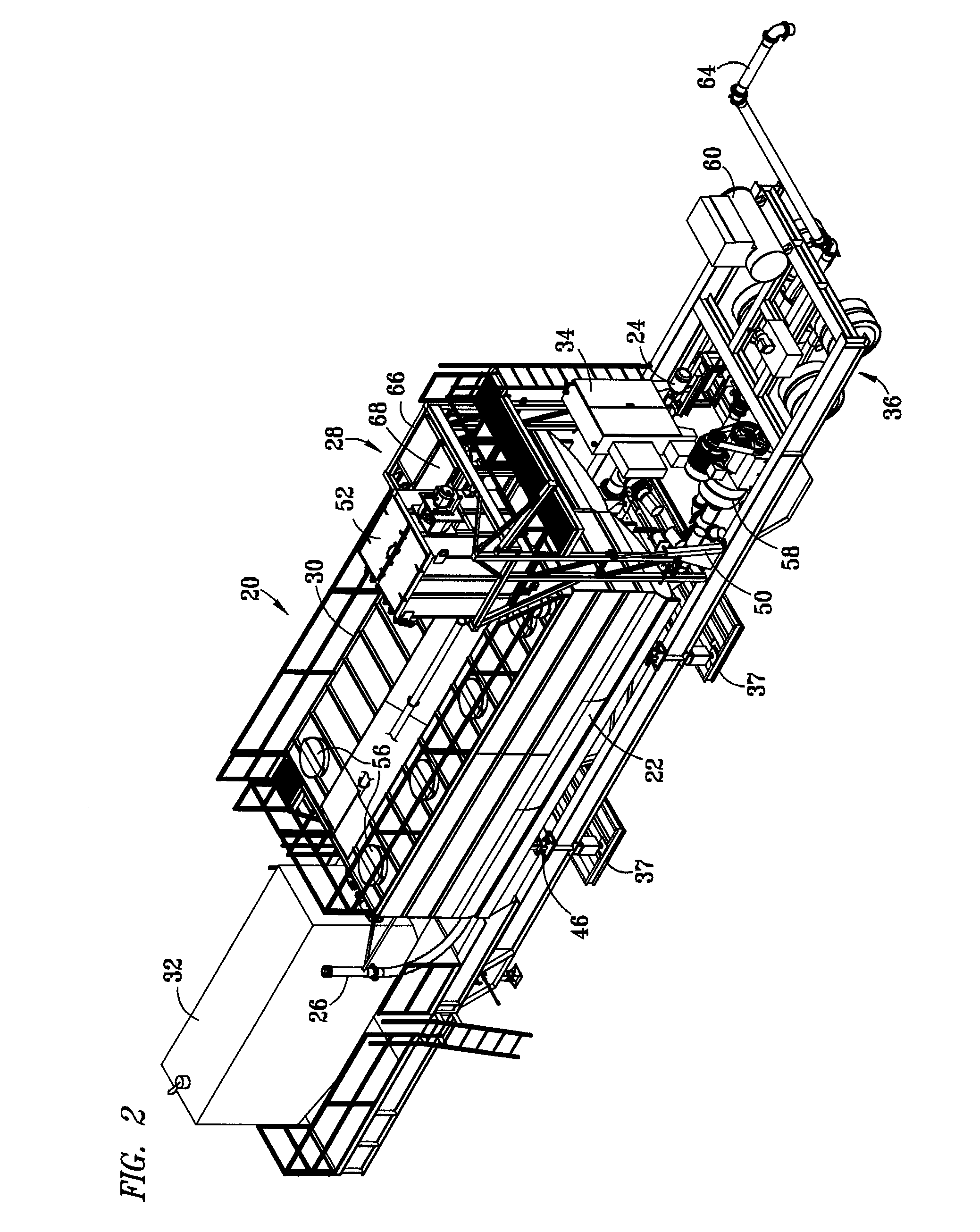

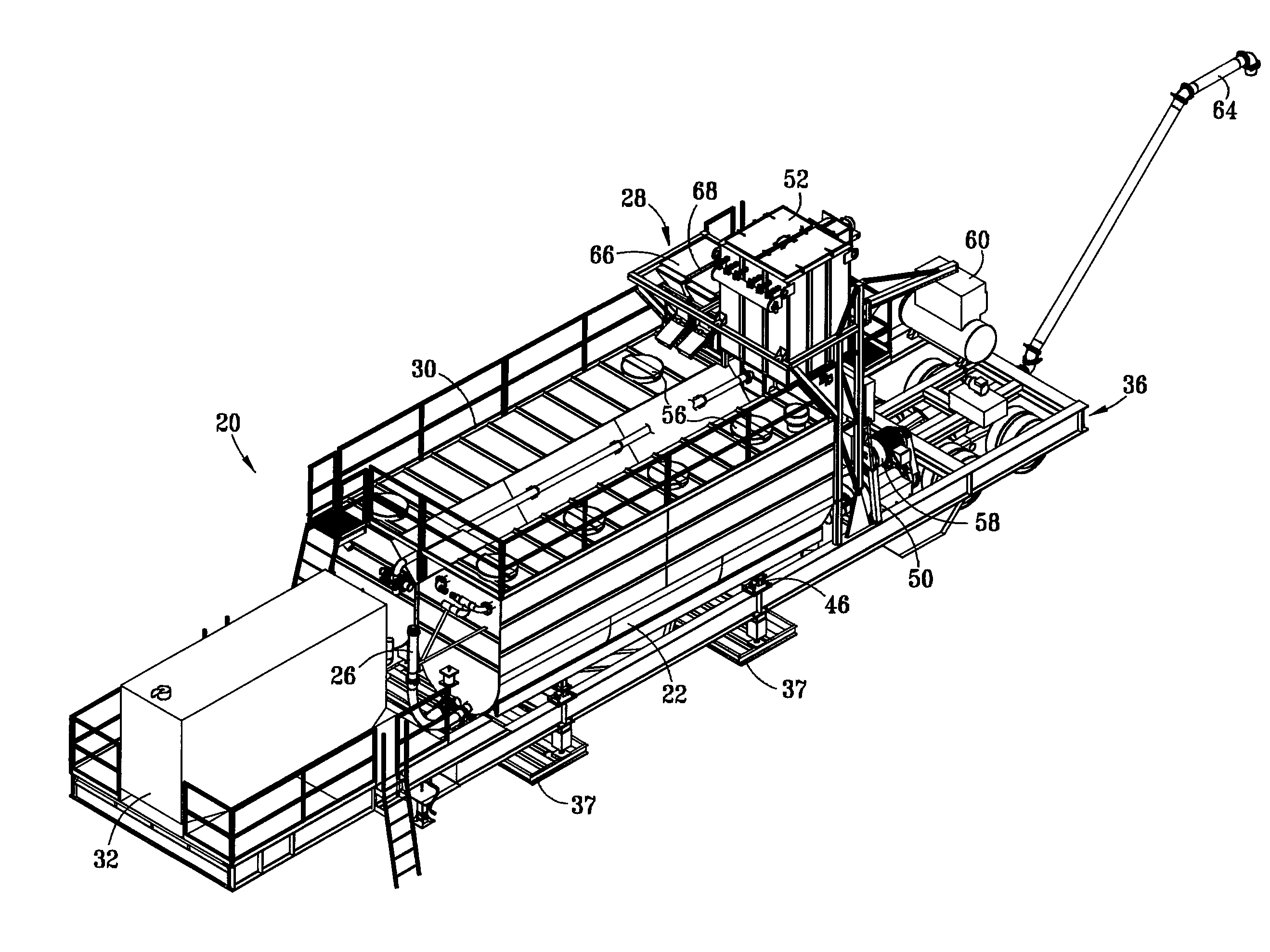

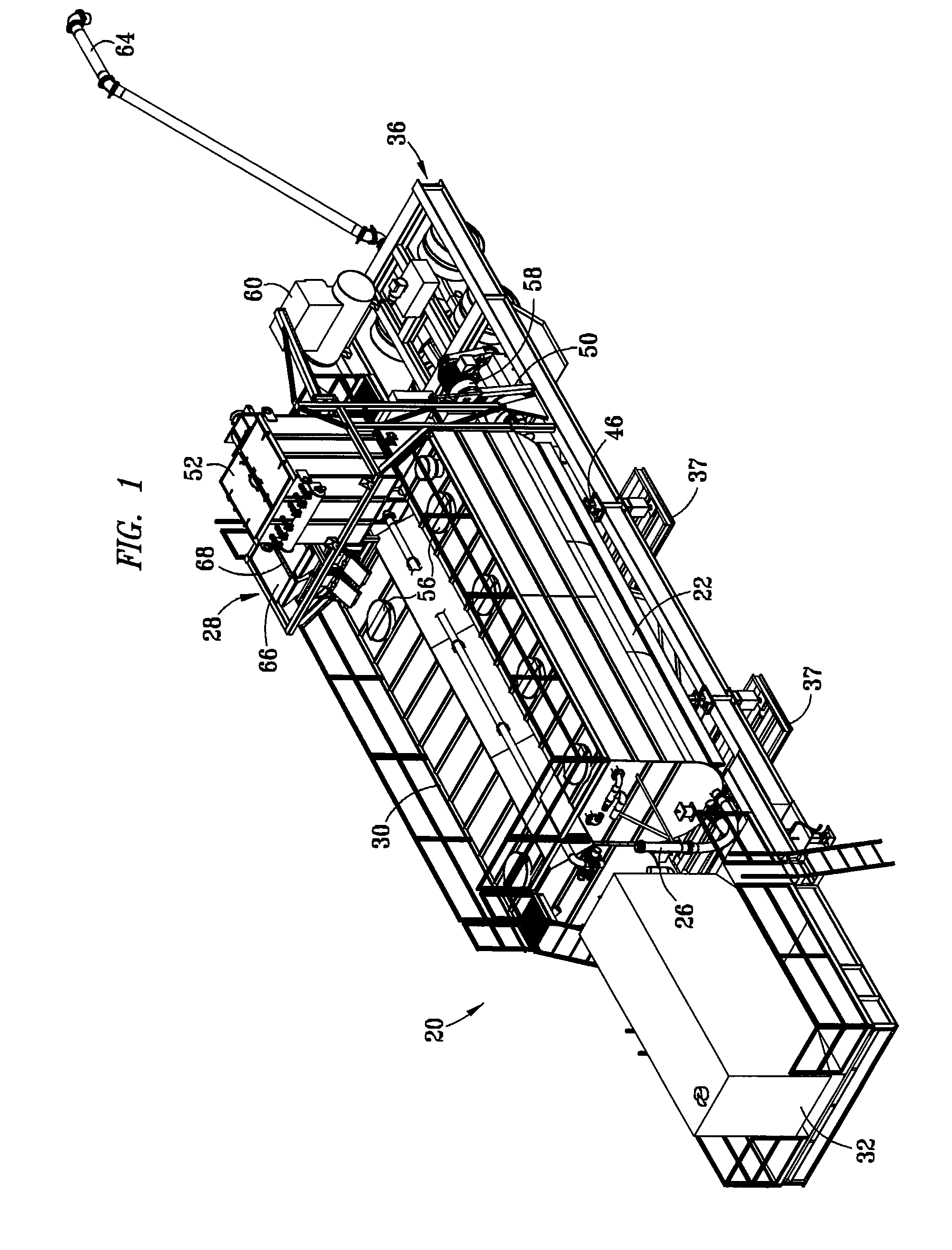

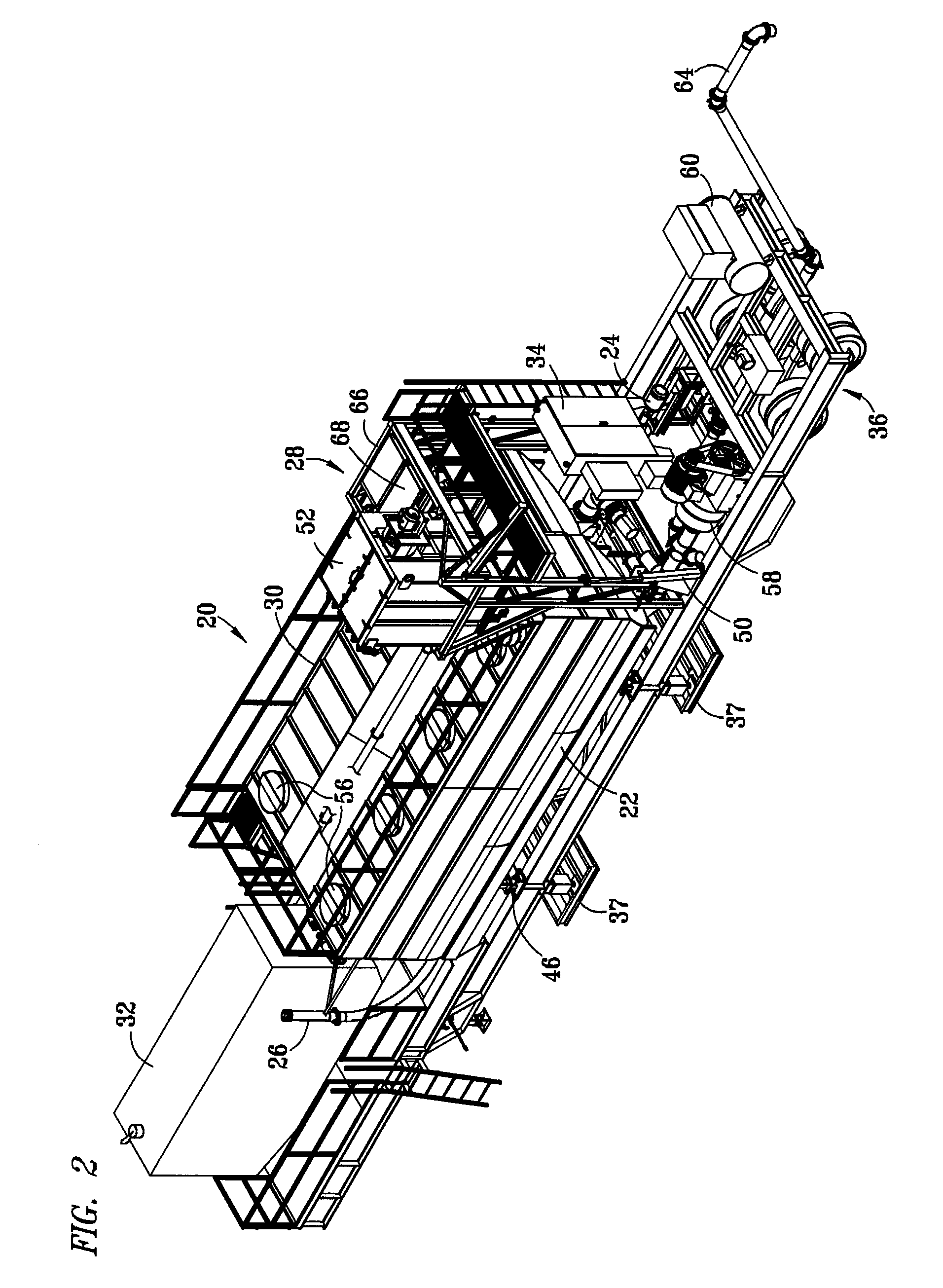

Cement Stabilization of Soils Using a Proportional Cement Slurry

ActiveUS20090044726A1Composition is stableAvoid settingSolid waste managementCement mixing apparatusChemical treatmentCellulose

A novel cement slurry composed of cement and water that can be used in cement stabilization applications. The cement slurry compound itself is chemically treated, by means of a cellulosic or other thixotropic thickening agent(s) to create a thixotropic system wherein the wetted cement remains in suspension and does not settle out prior to use even without further mixing. A chemical retarder / stabilizer is also used to prevent the slurry from prematurely setting during shipping. A novel apparatus and method for mixing the novel cement slurry is disclosed to insure the exact proportioning of all ingredients and the proper wetting of the cement.

Owner:TEXAS INDUSTRIES

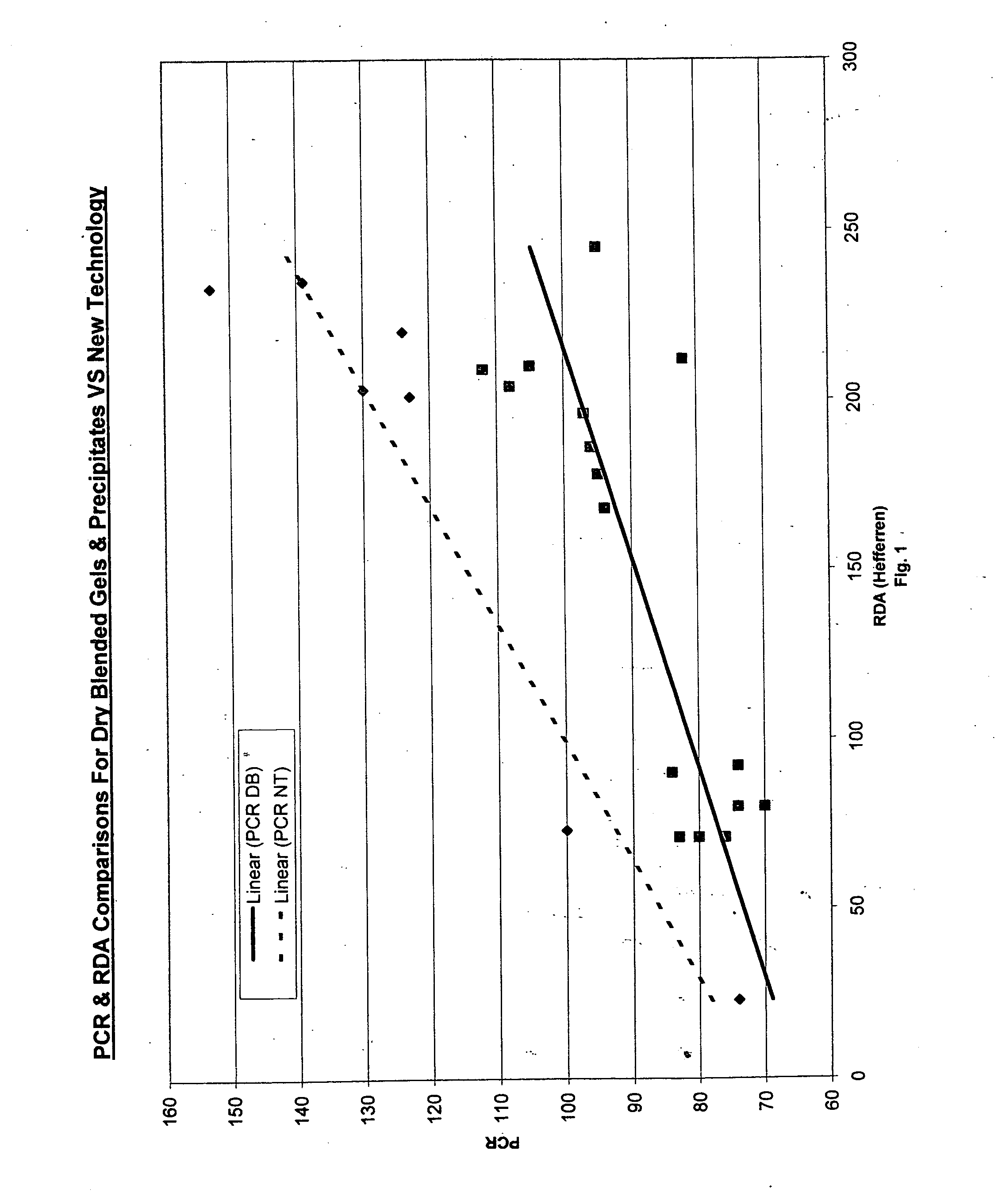

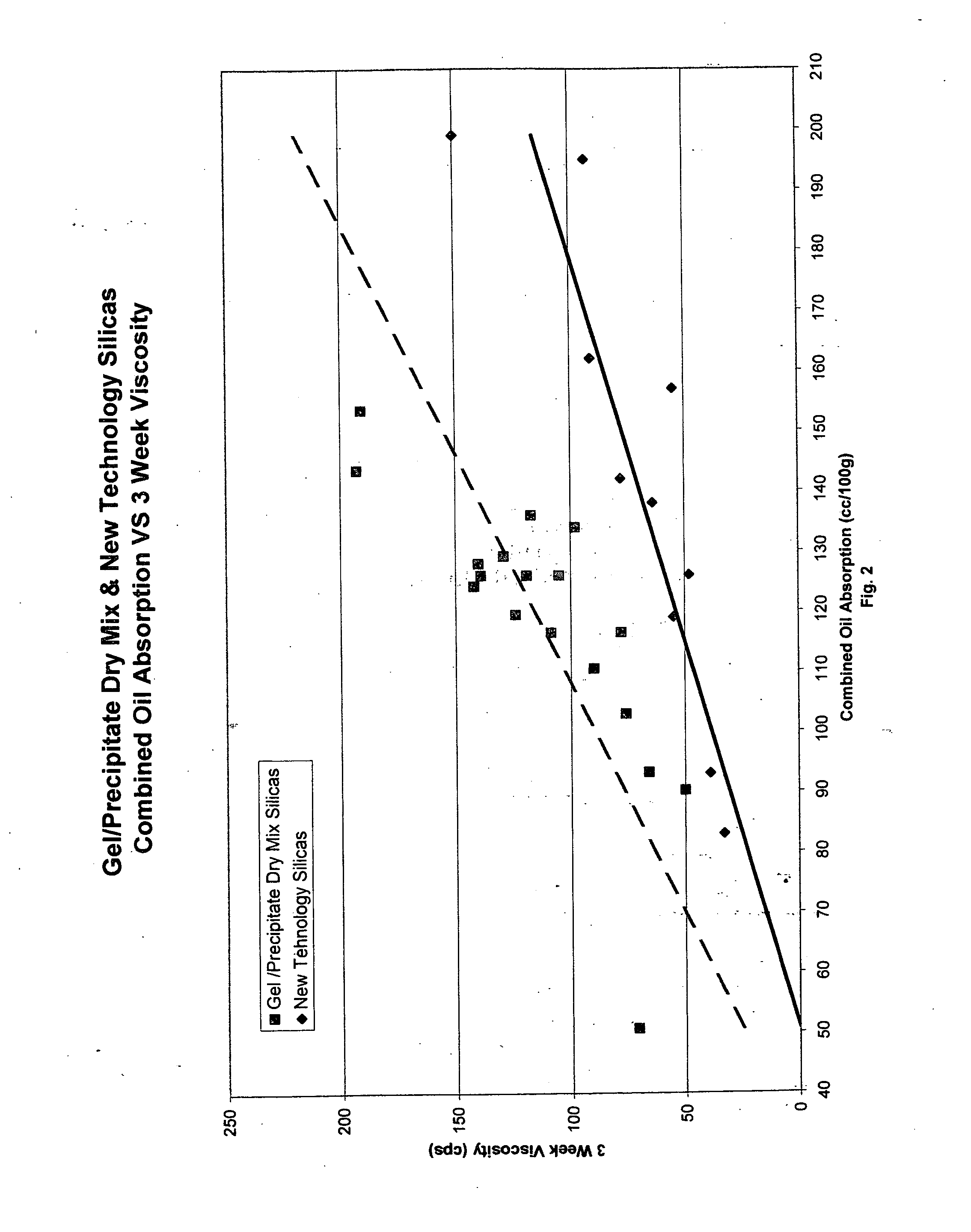

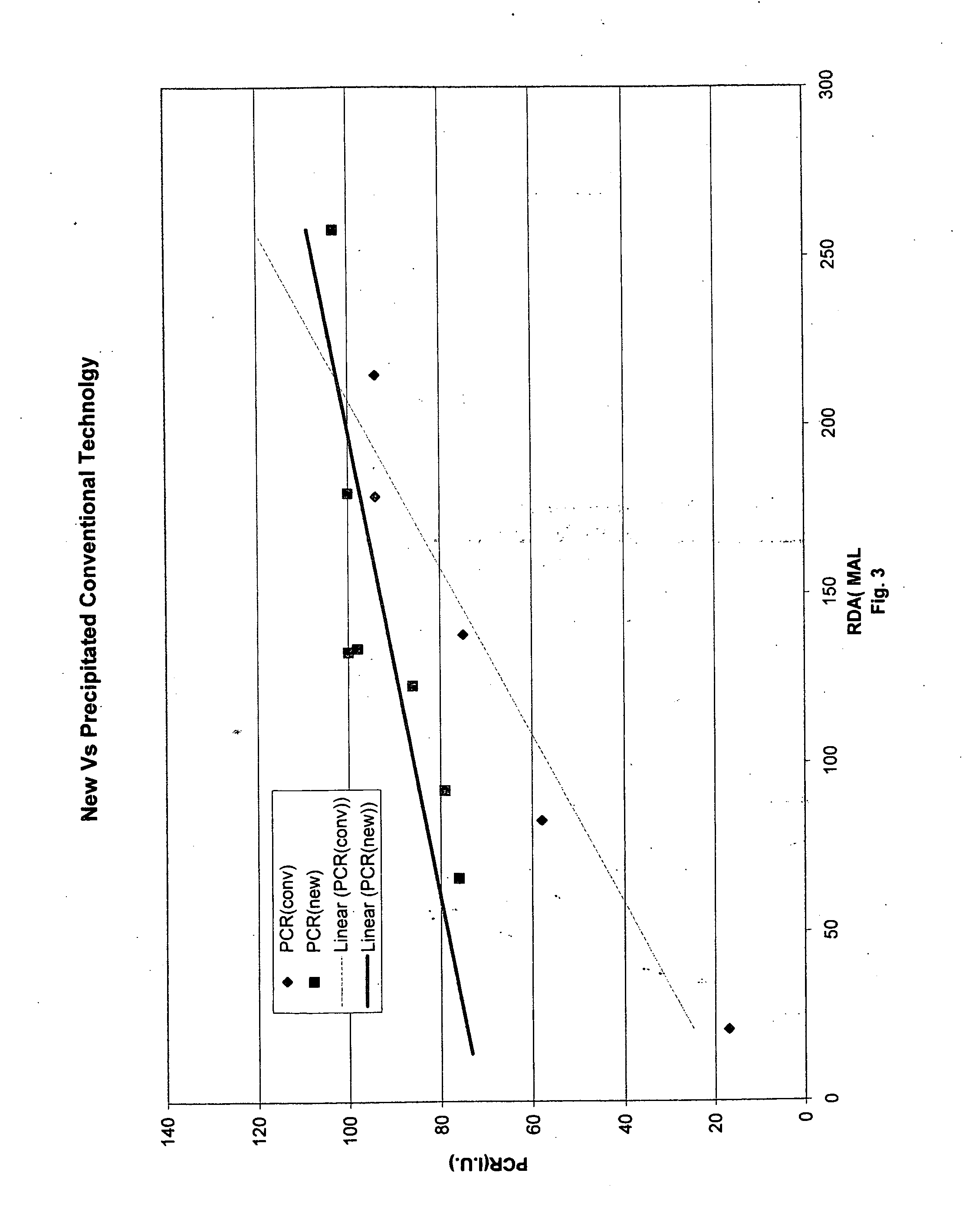

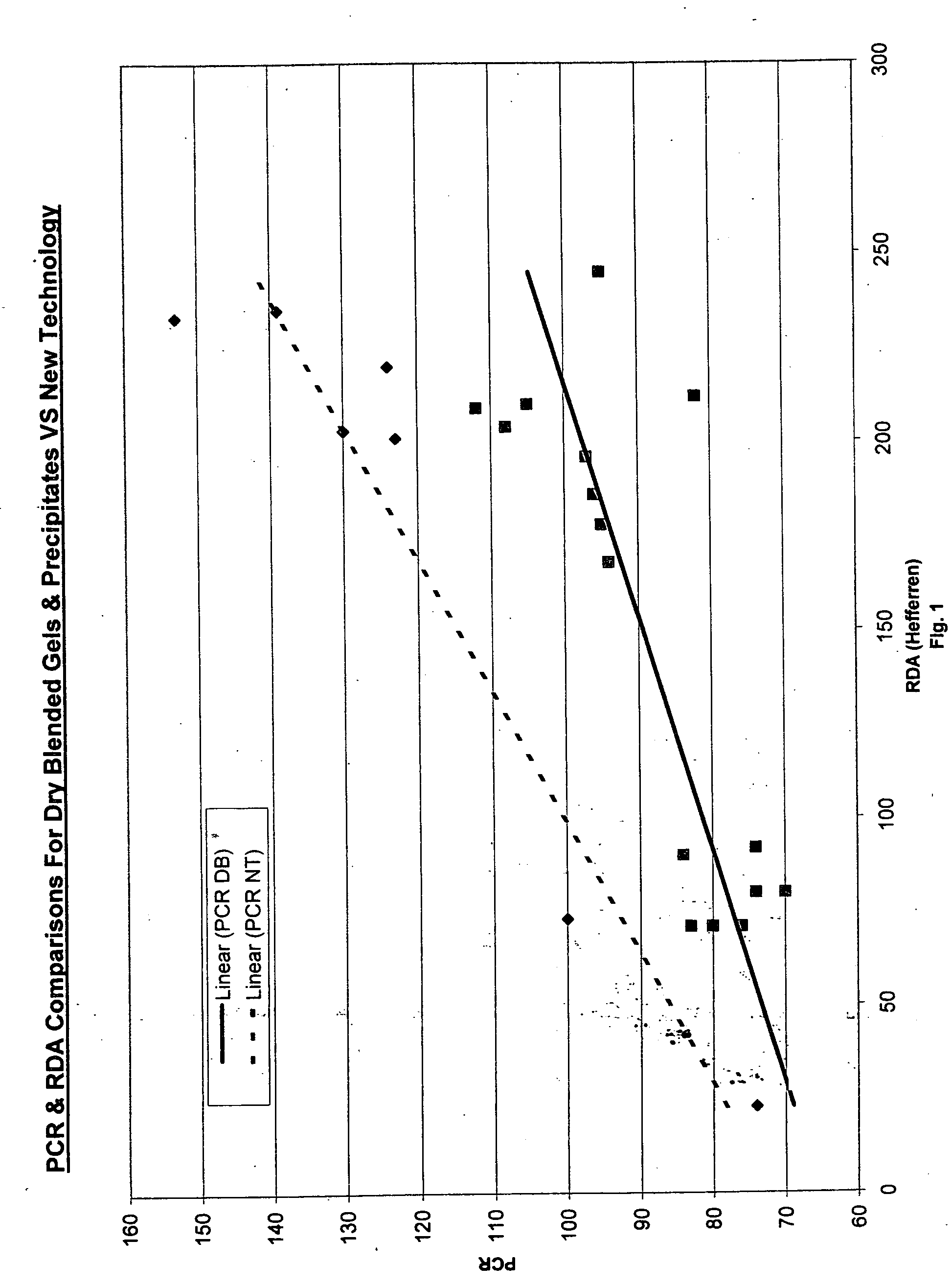

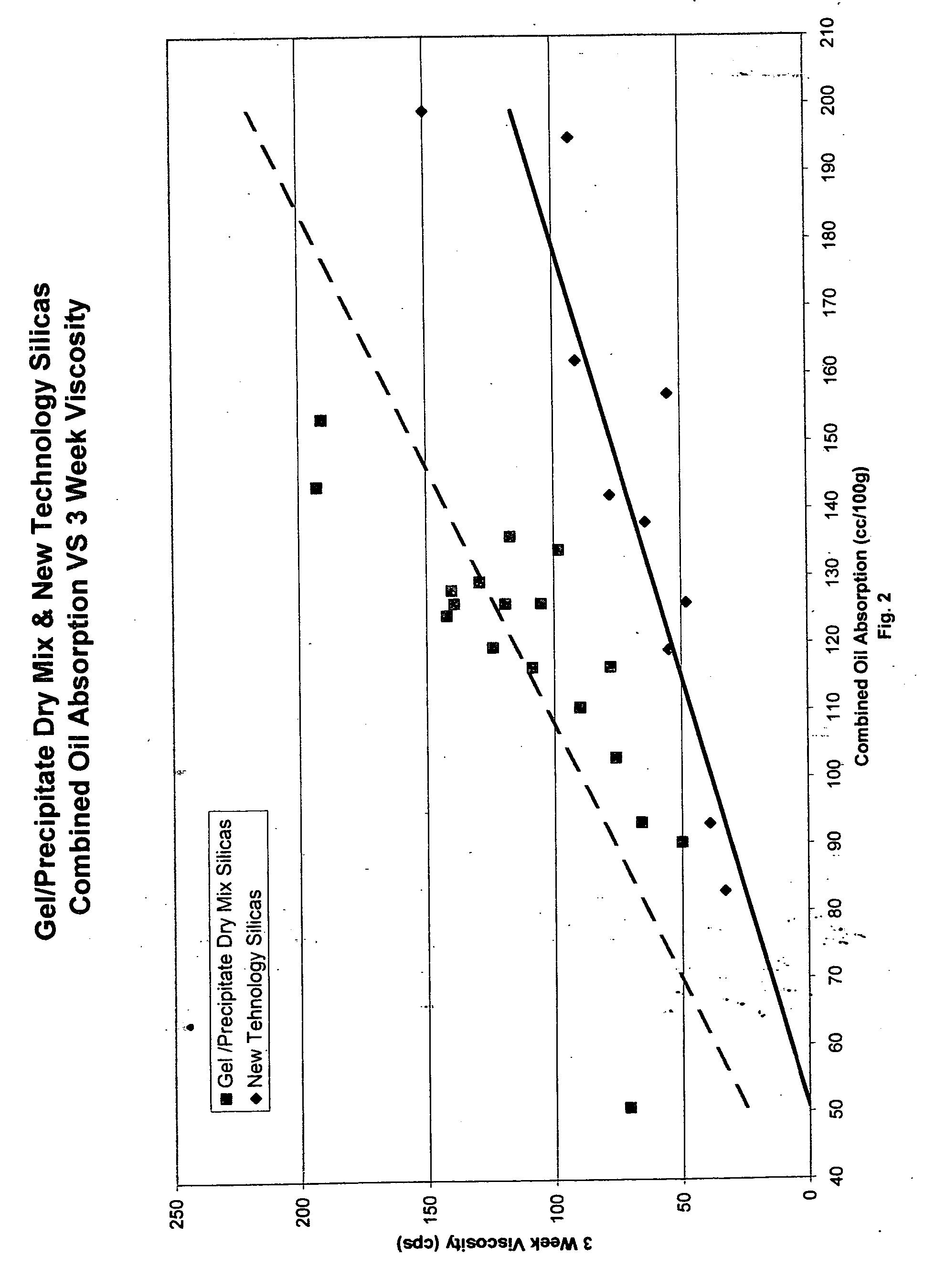

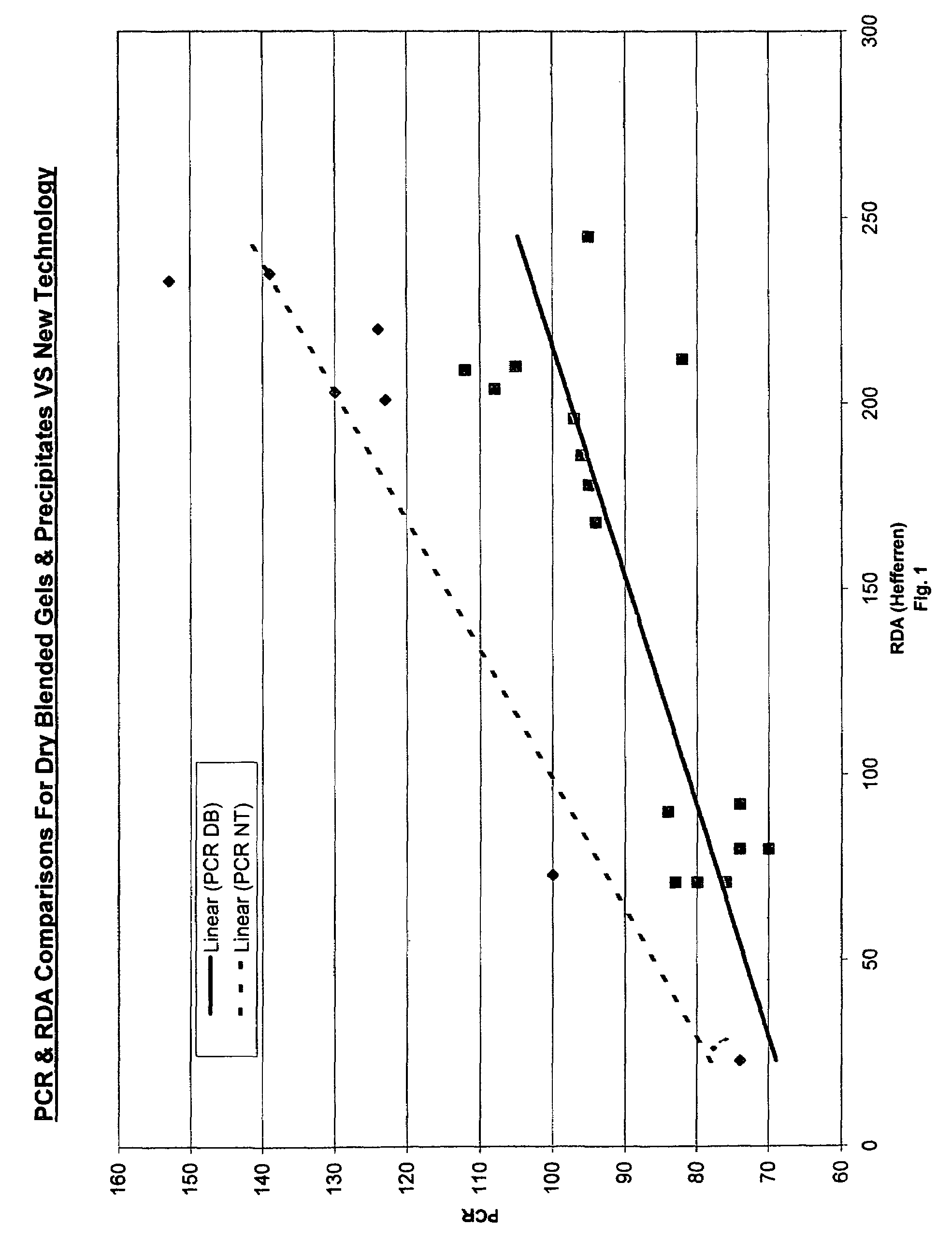

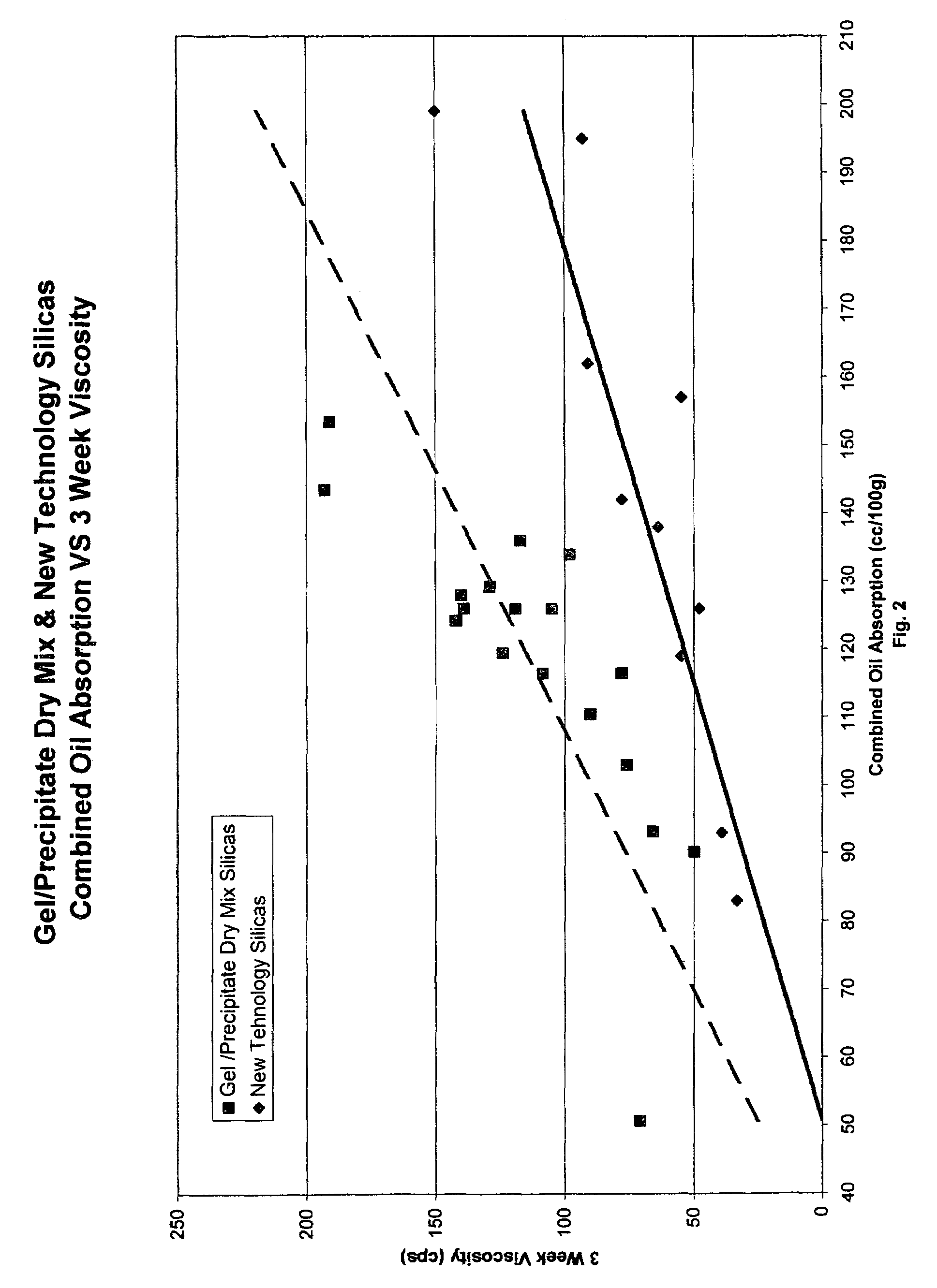

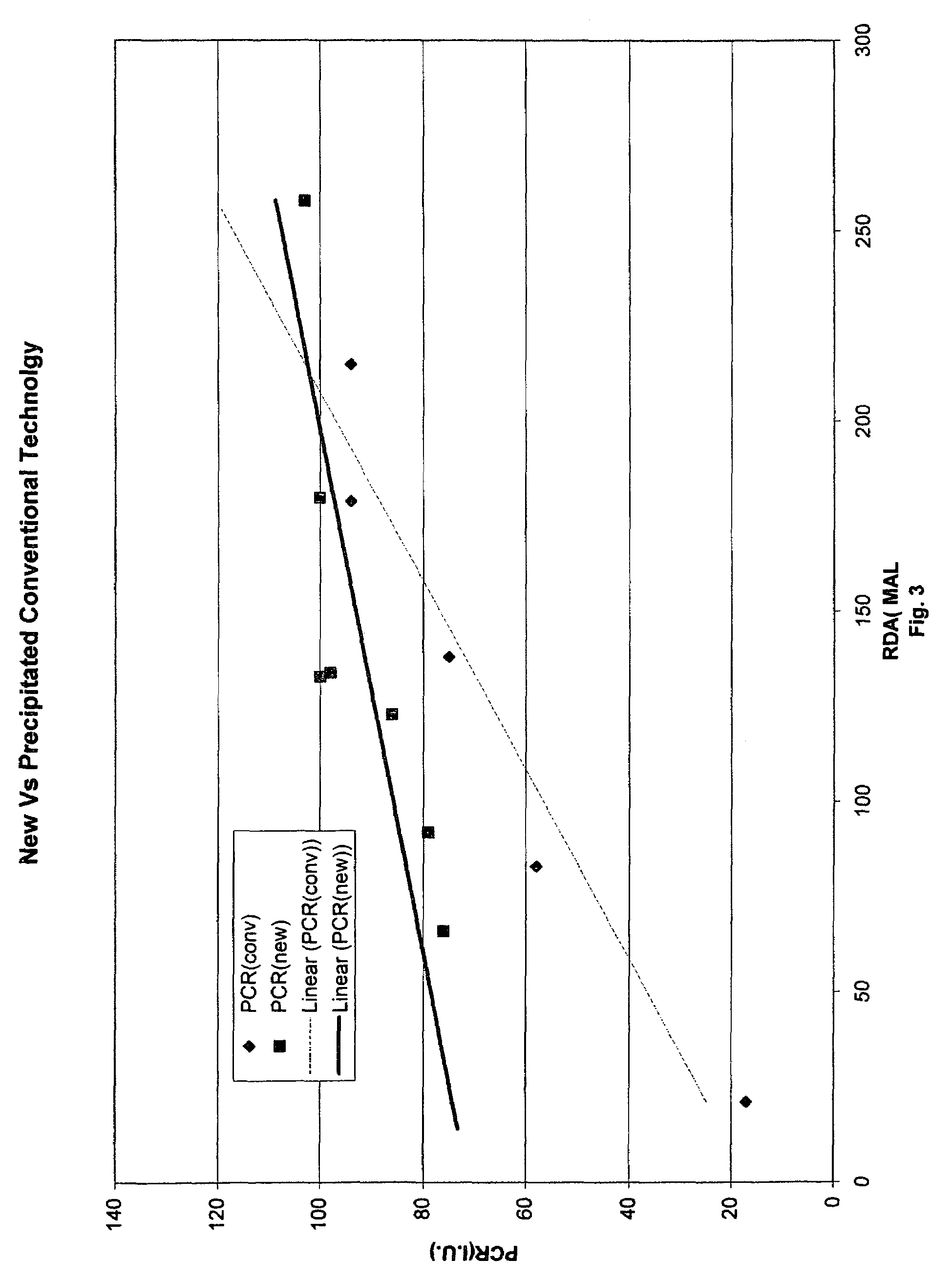

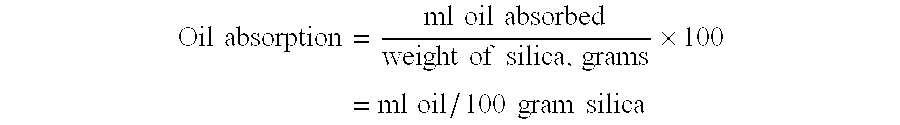

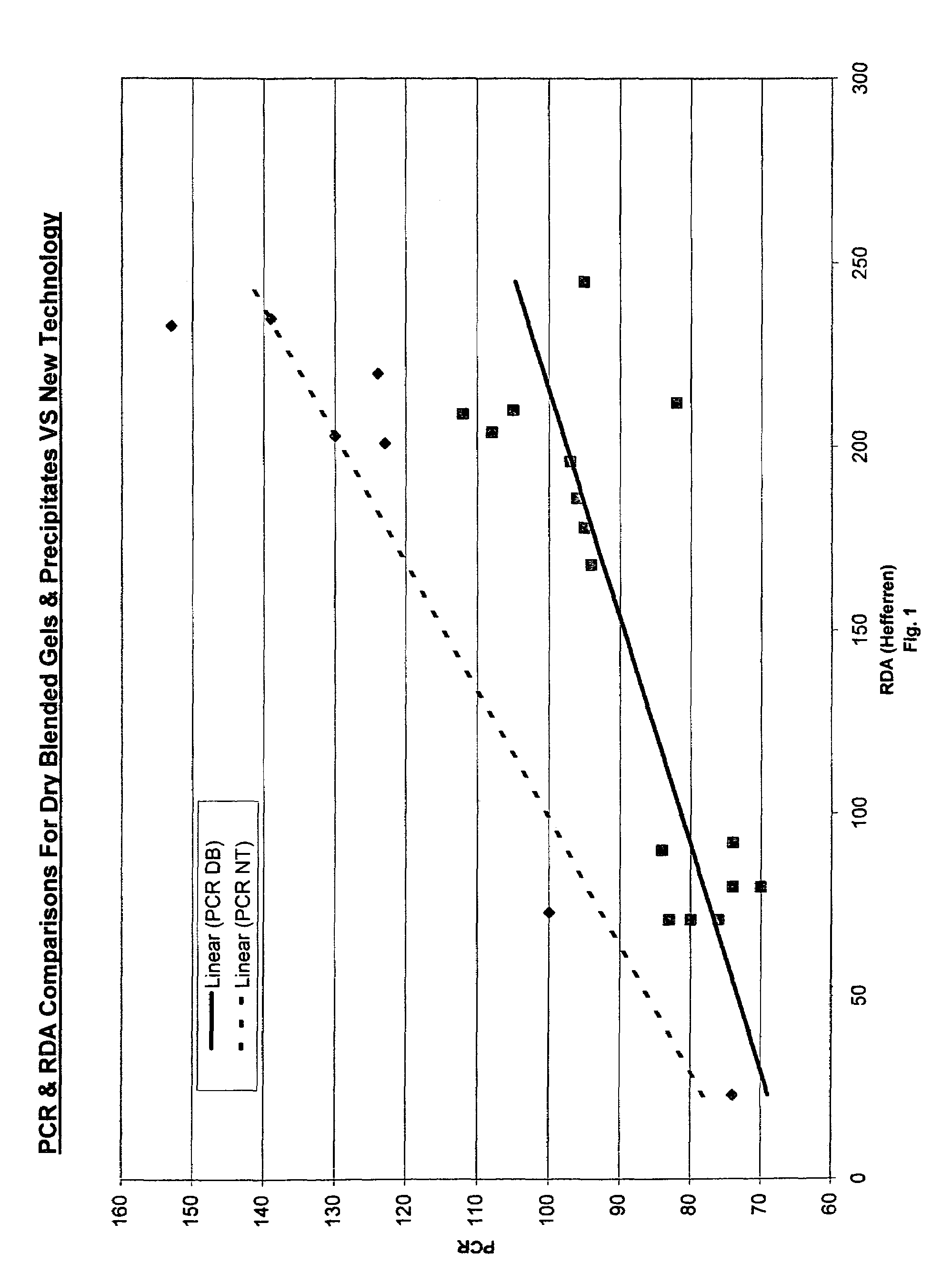

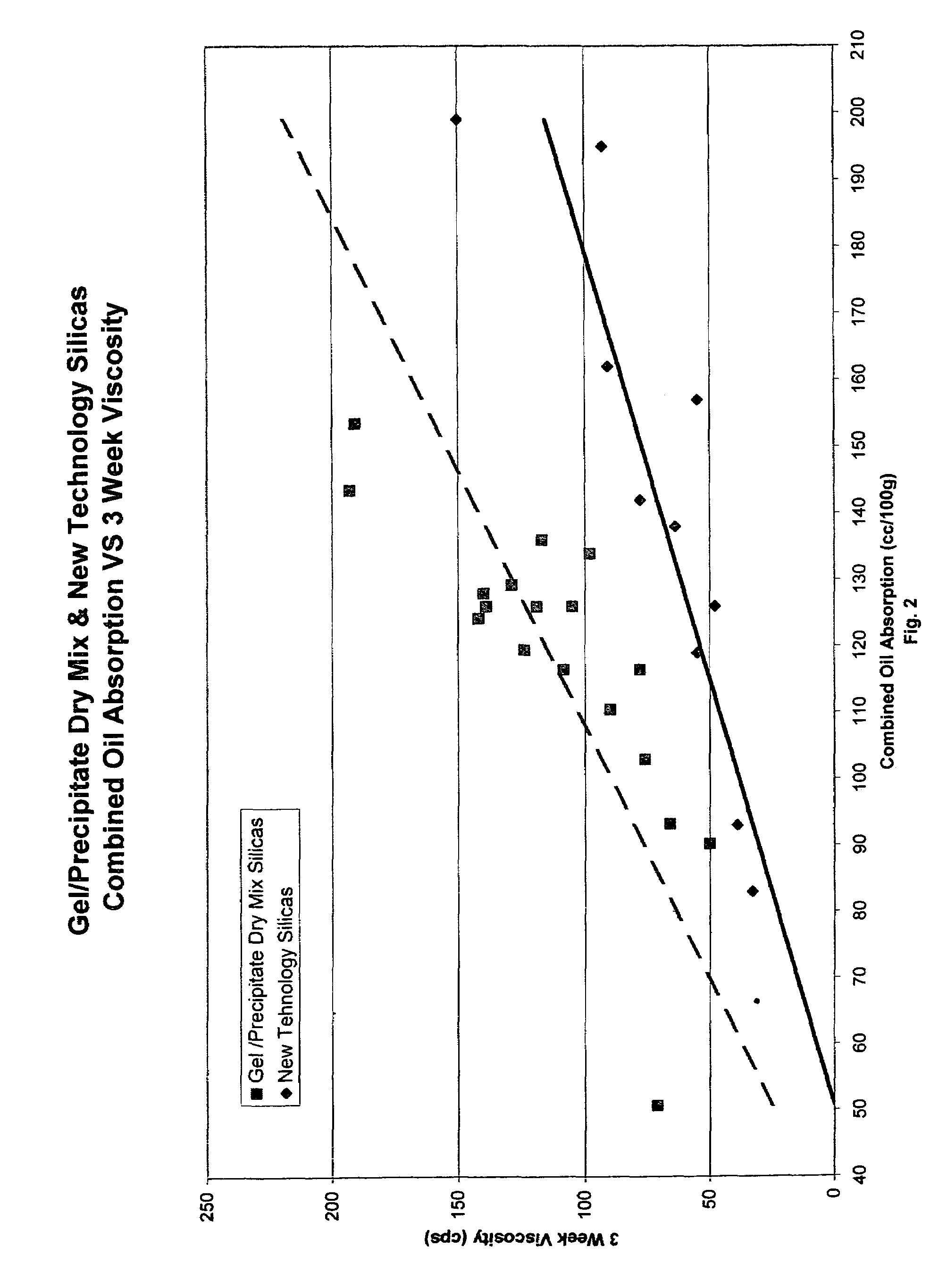

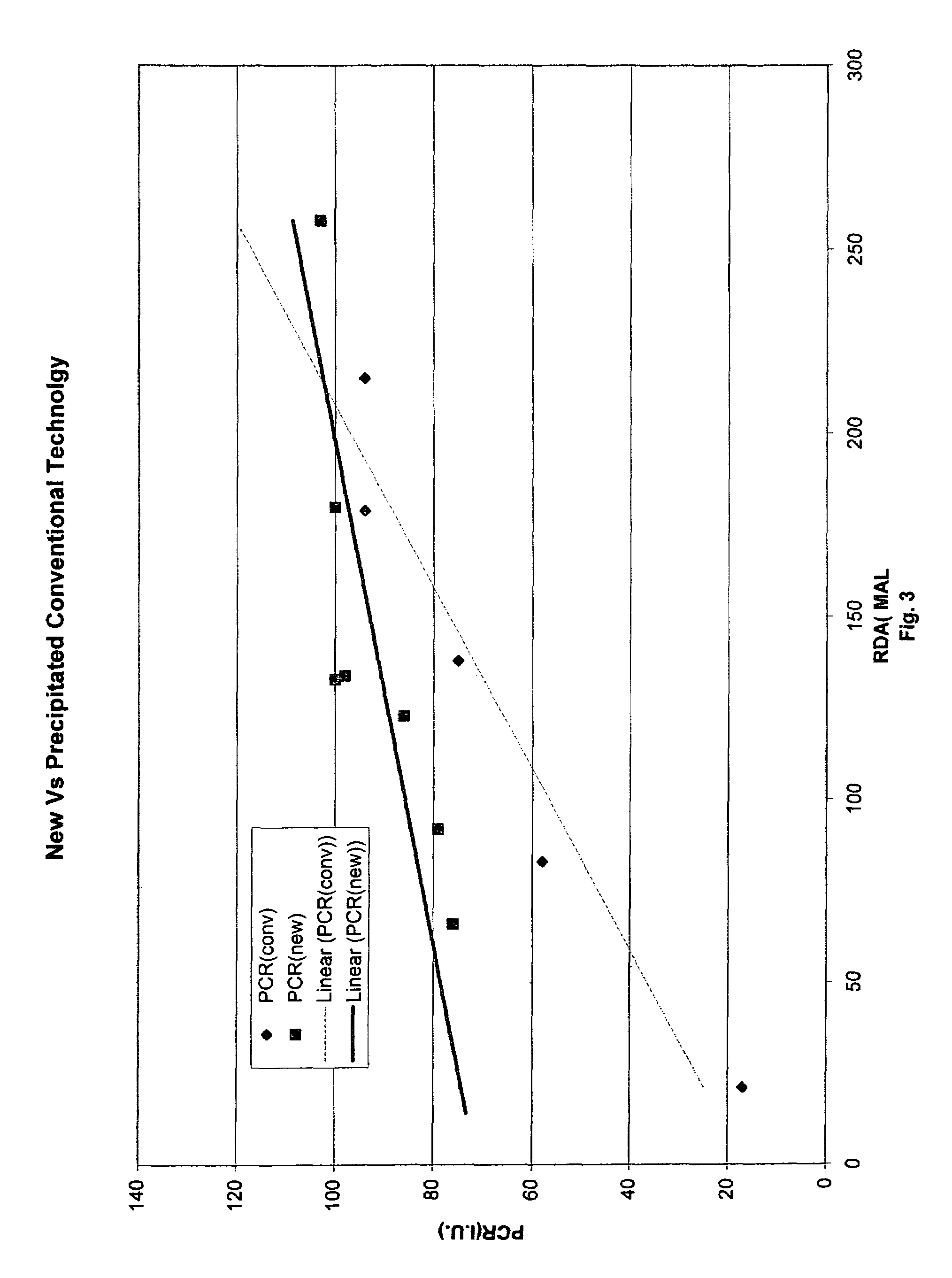

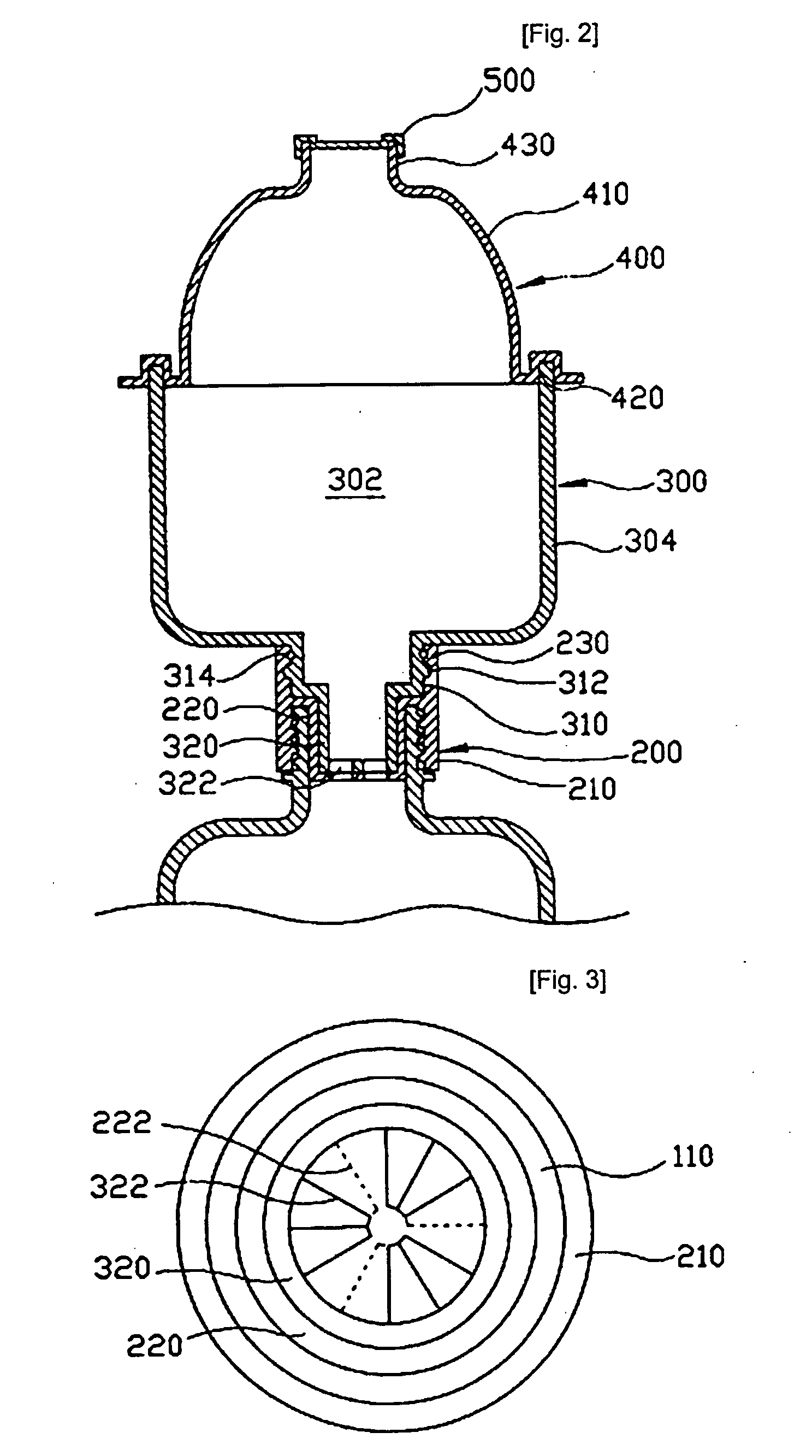

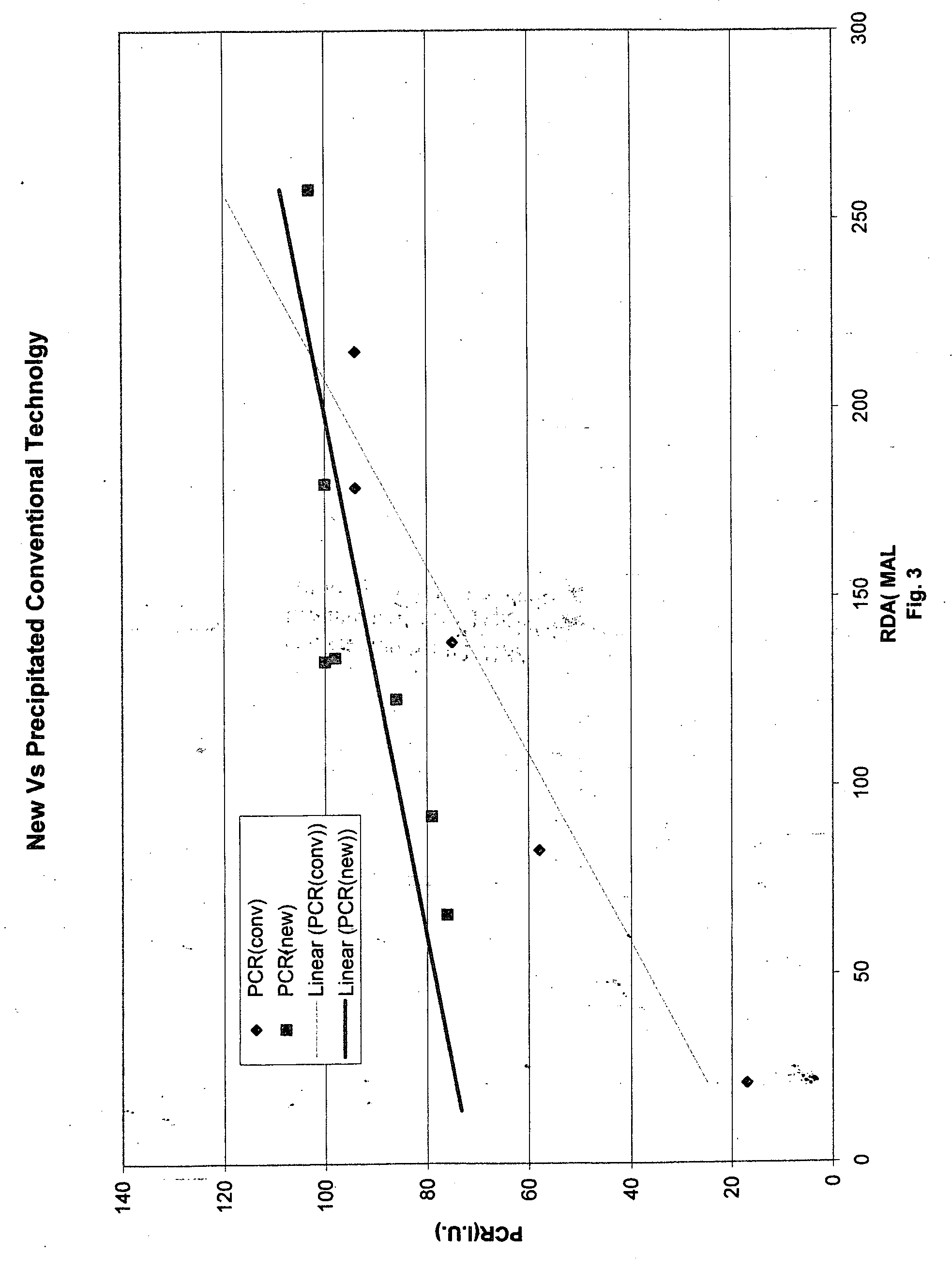

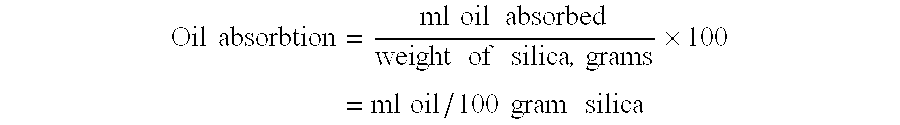

High-cleaning silica materials made via product morphology control and dentifrice containing such

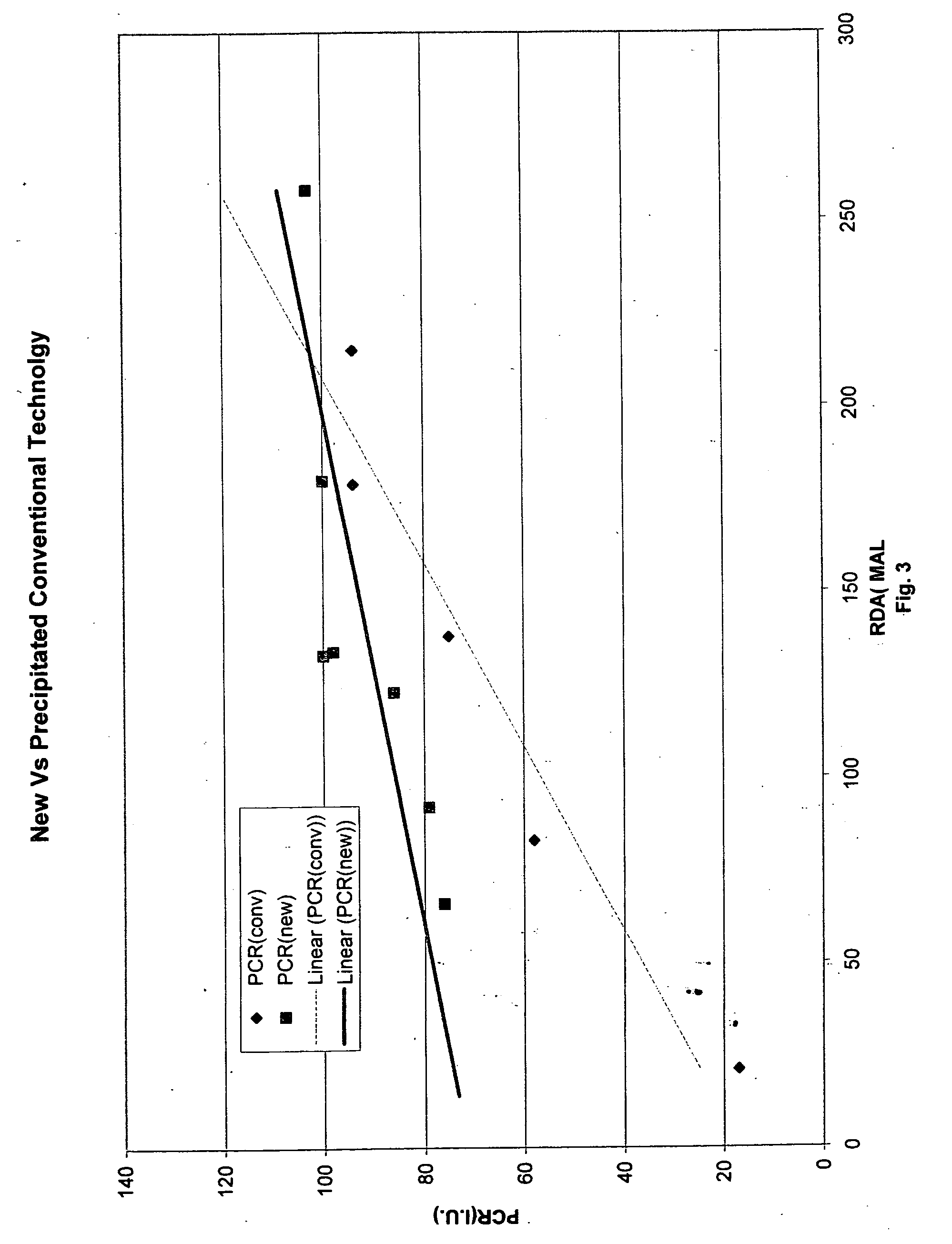

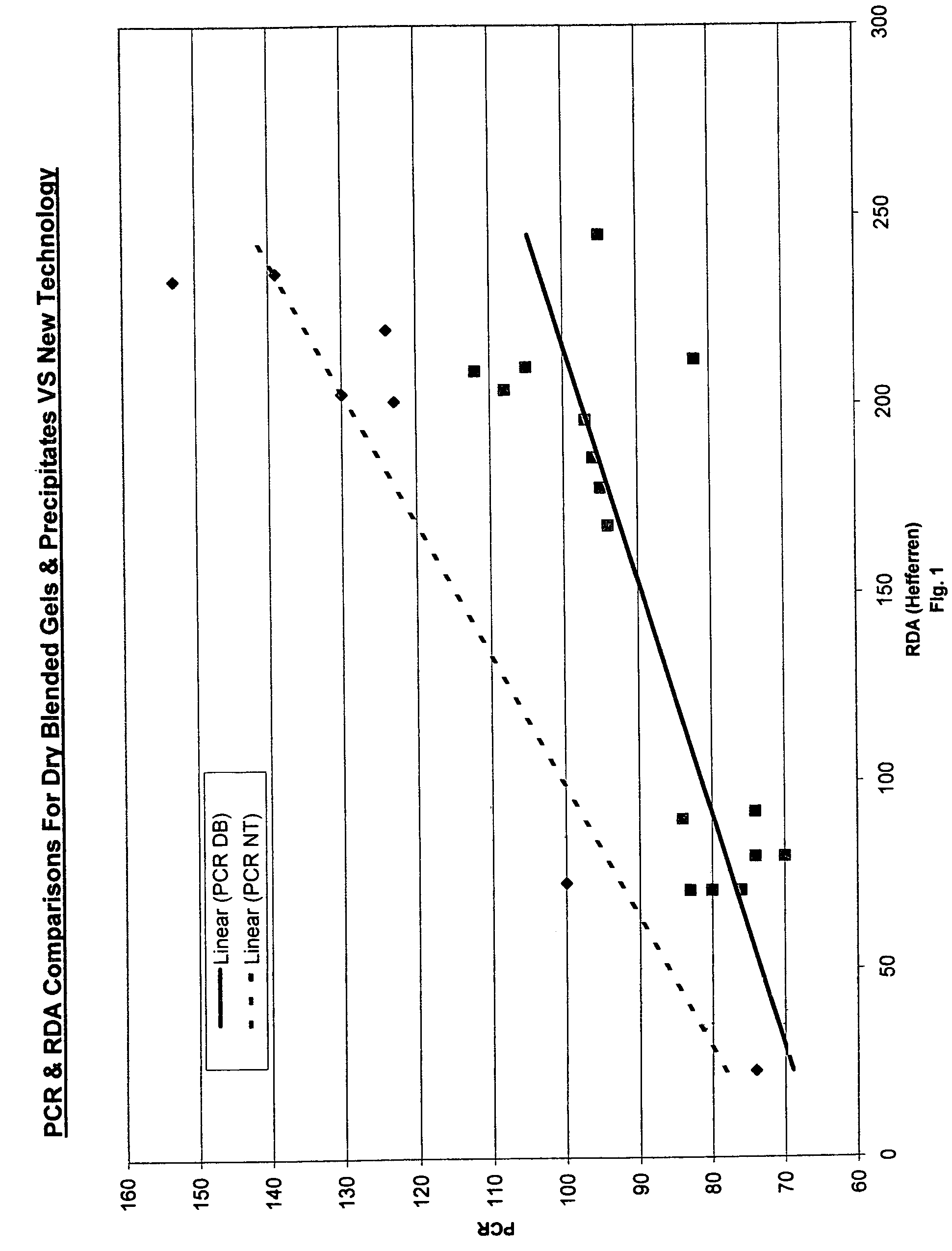

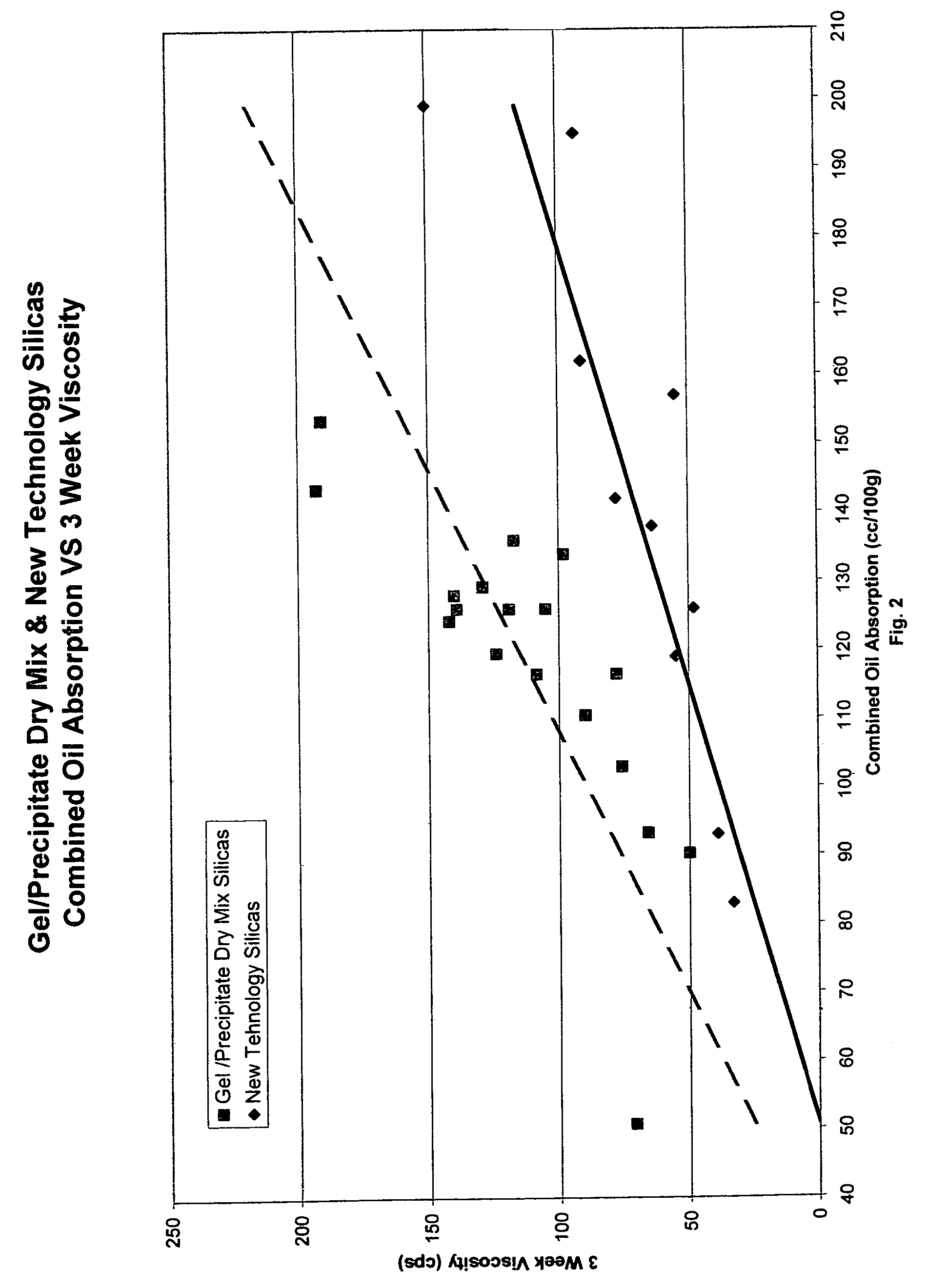

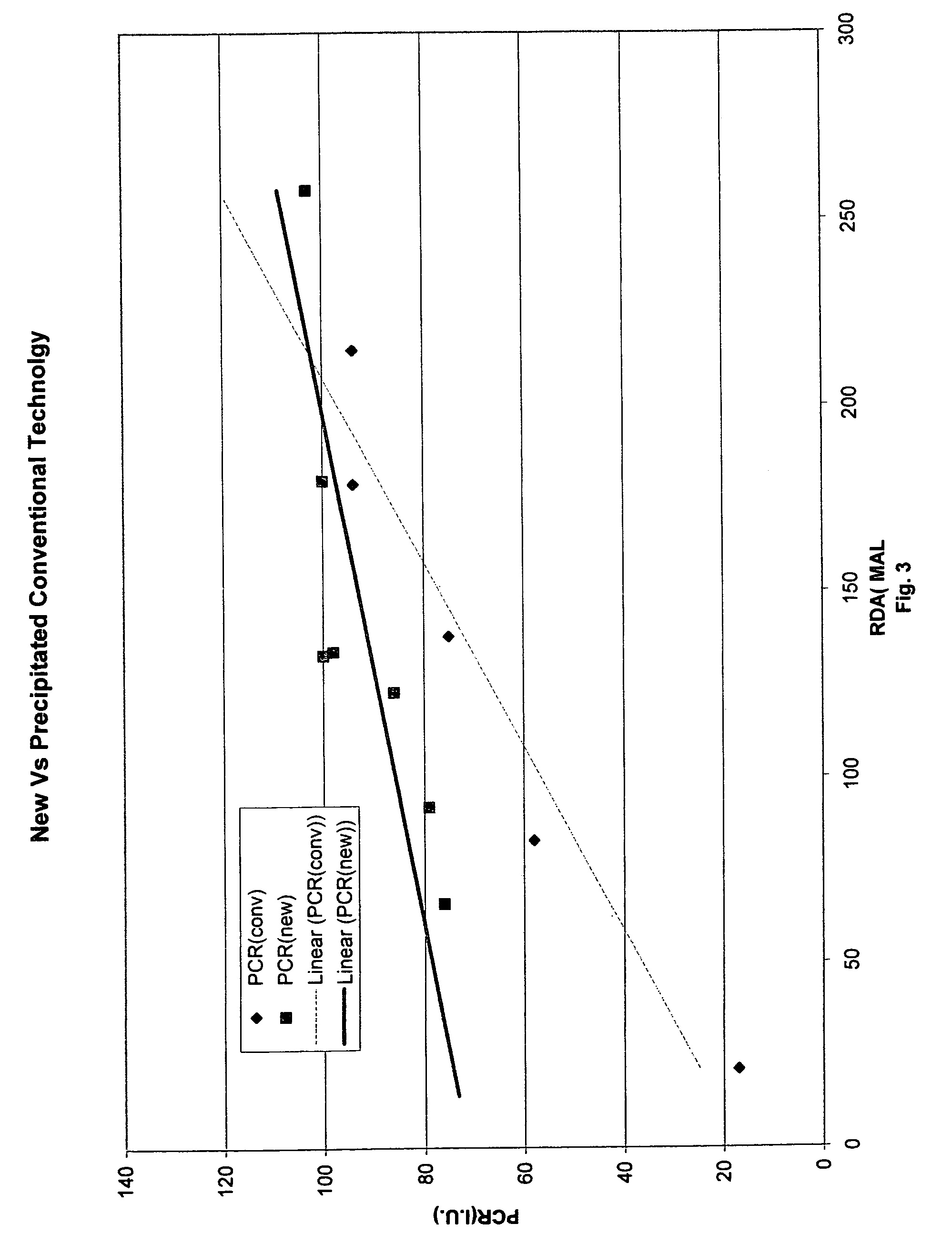

InactiveUS20060110307A1Excellent thickening propertyDesirable abrasivePigmenting treatmentCosmetic preparationsClean teethViscosity

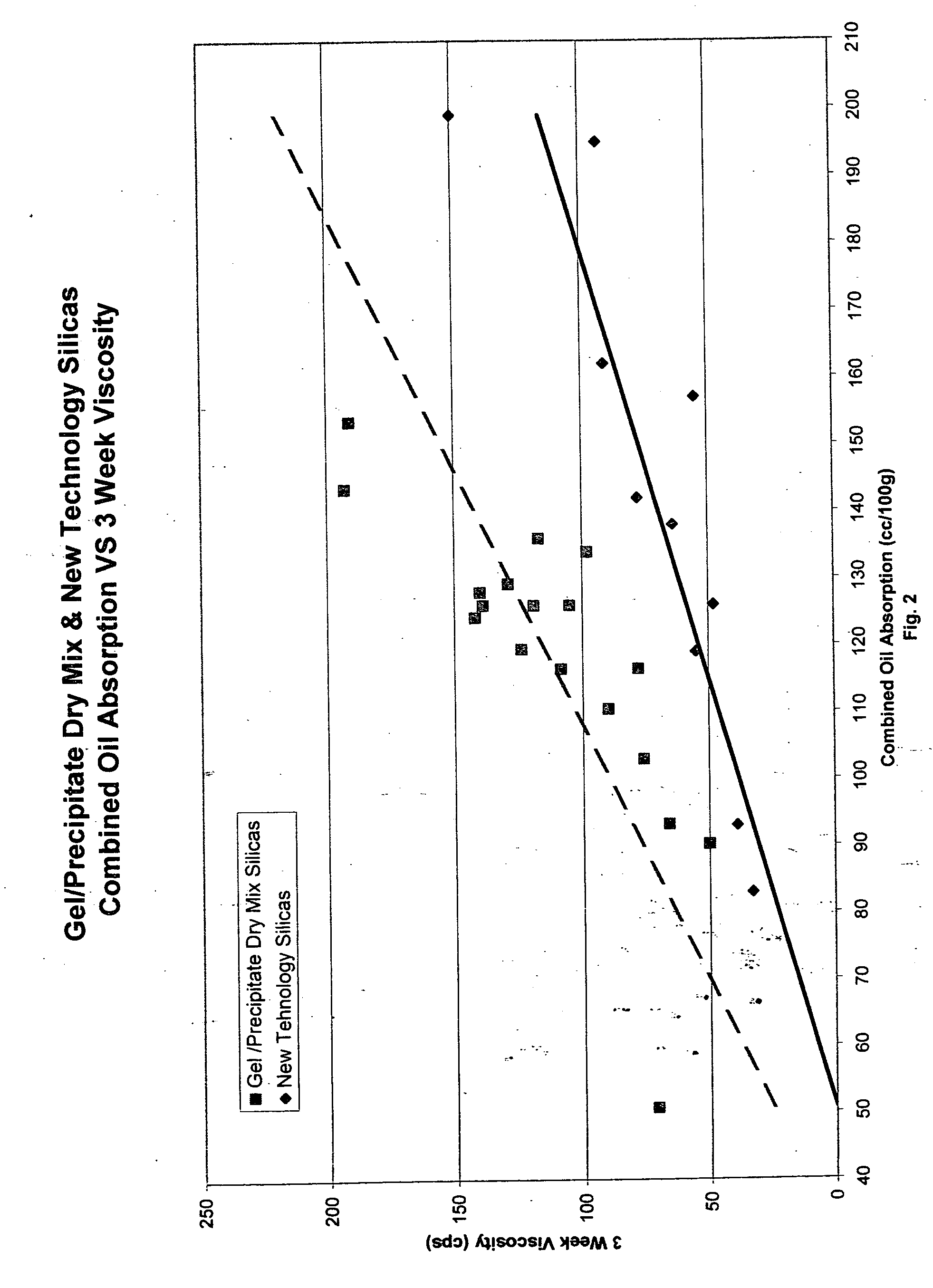

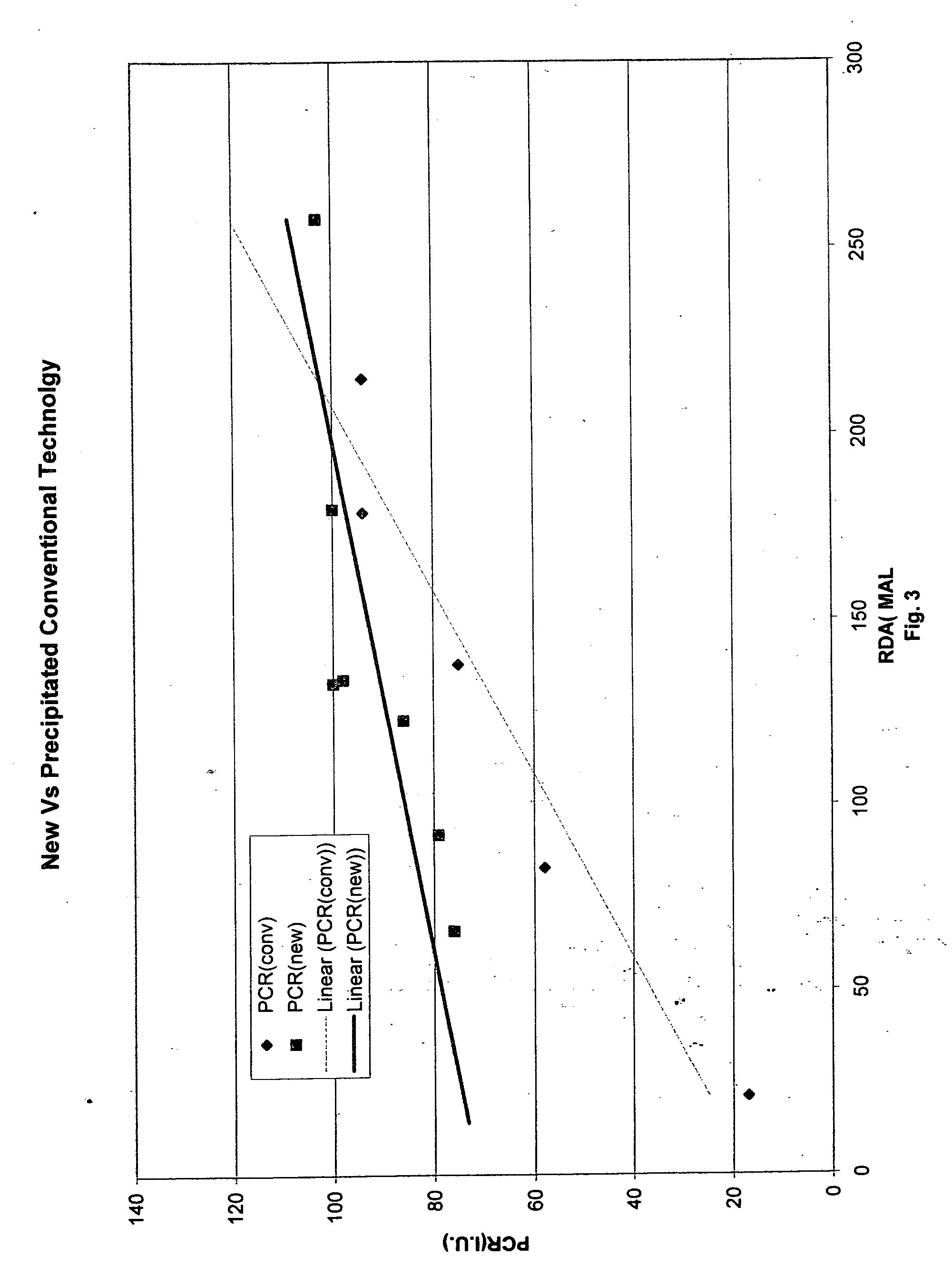

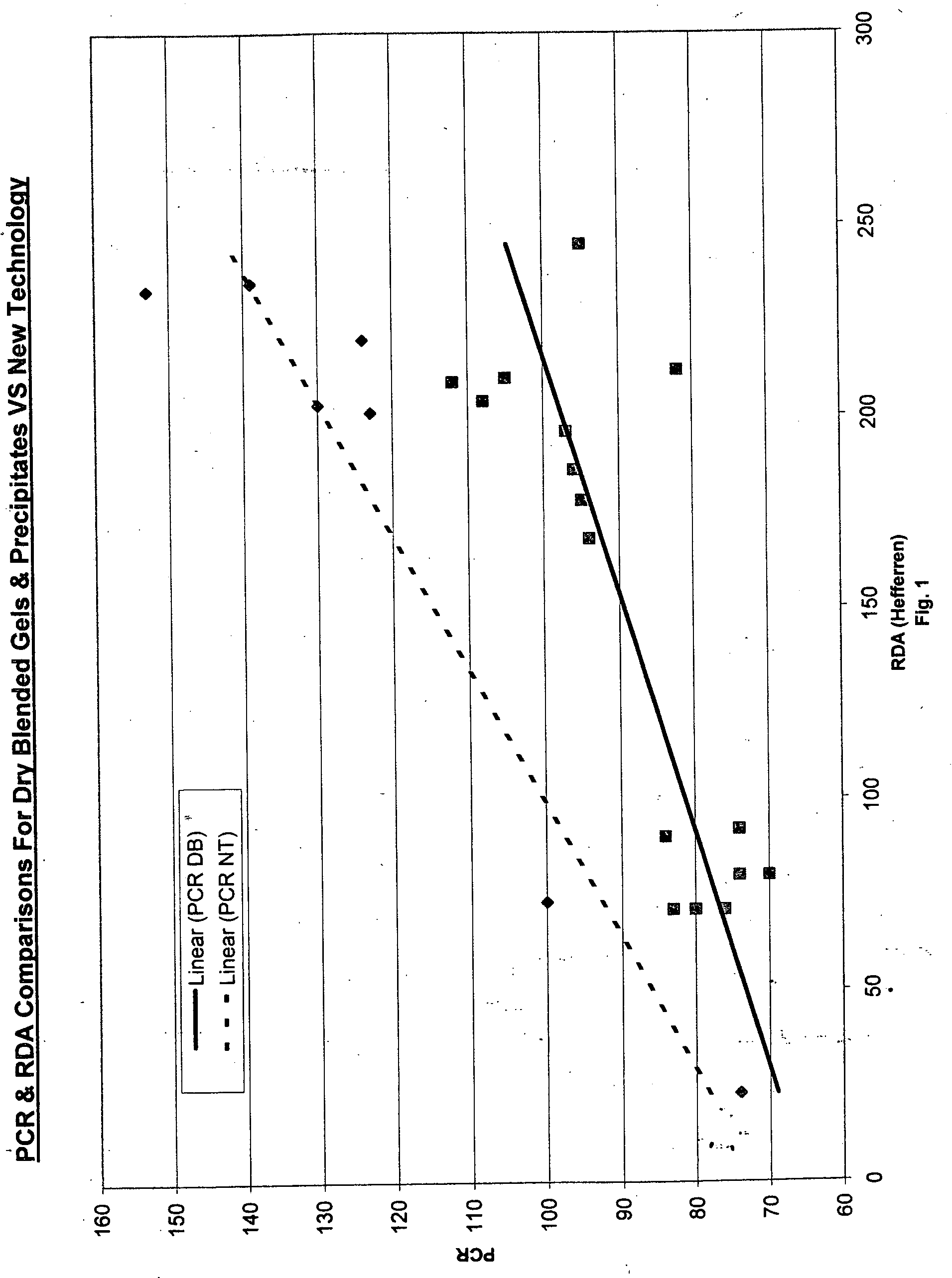

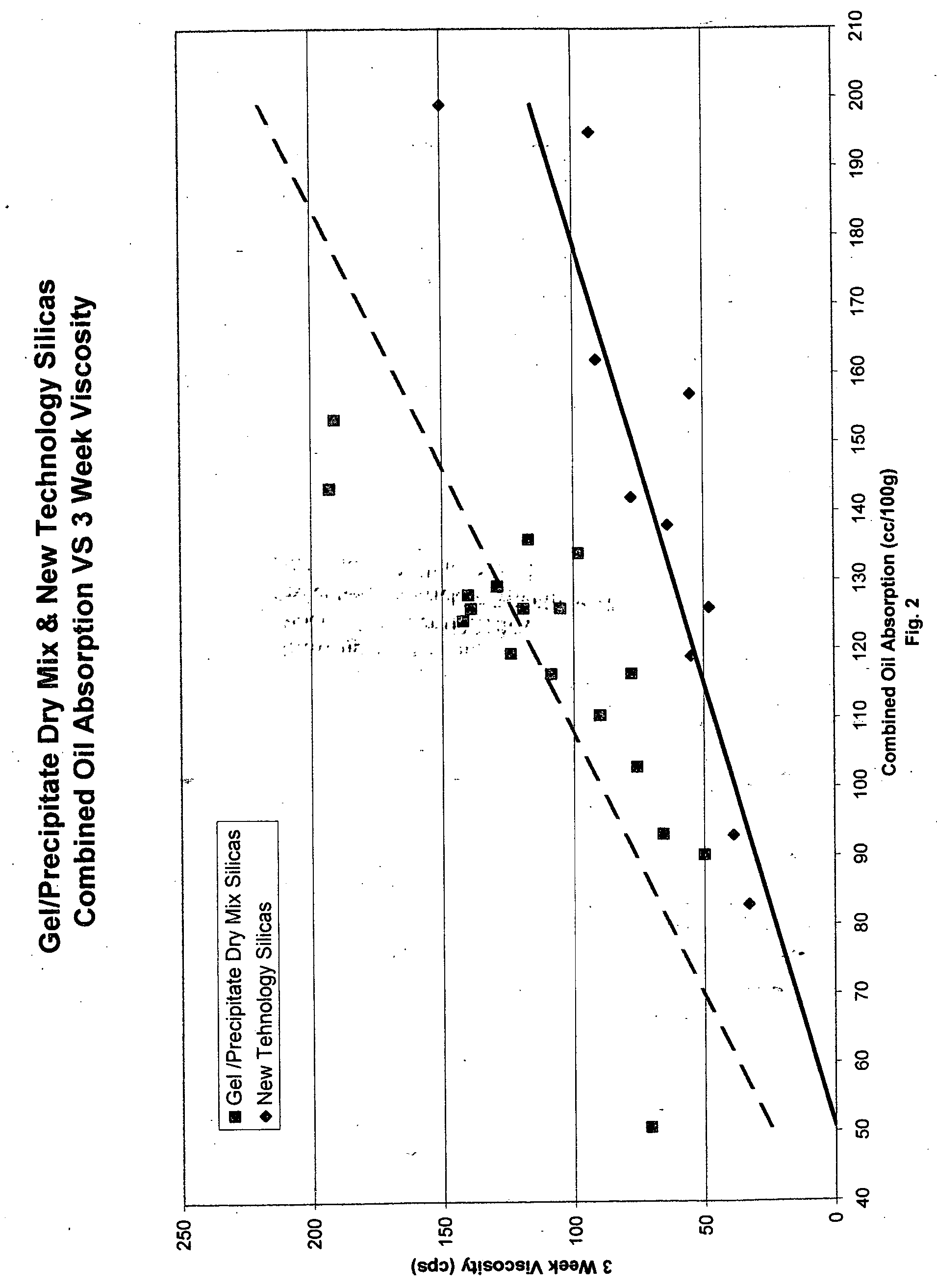

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

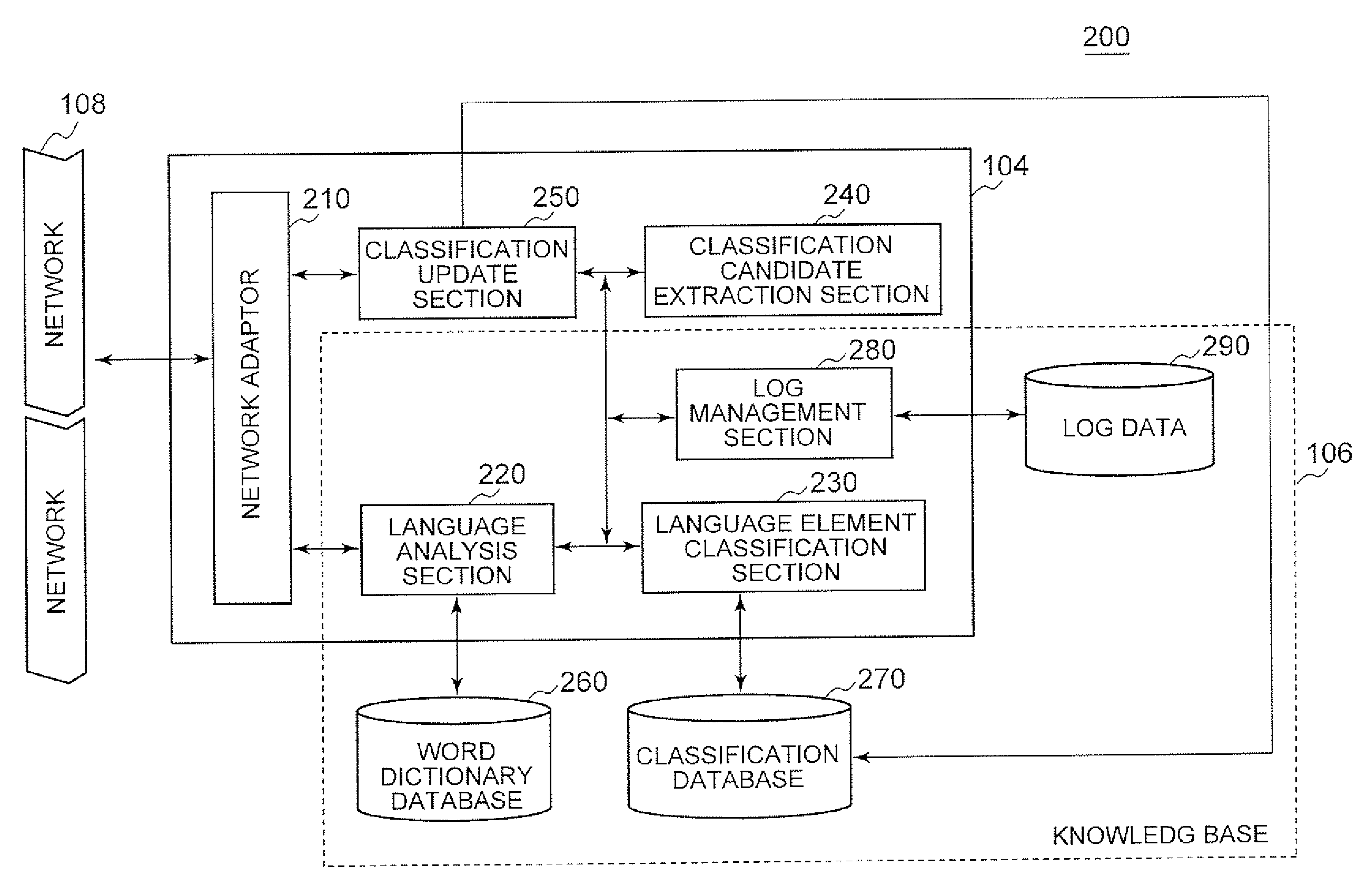

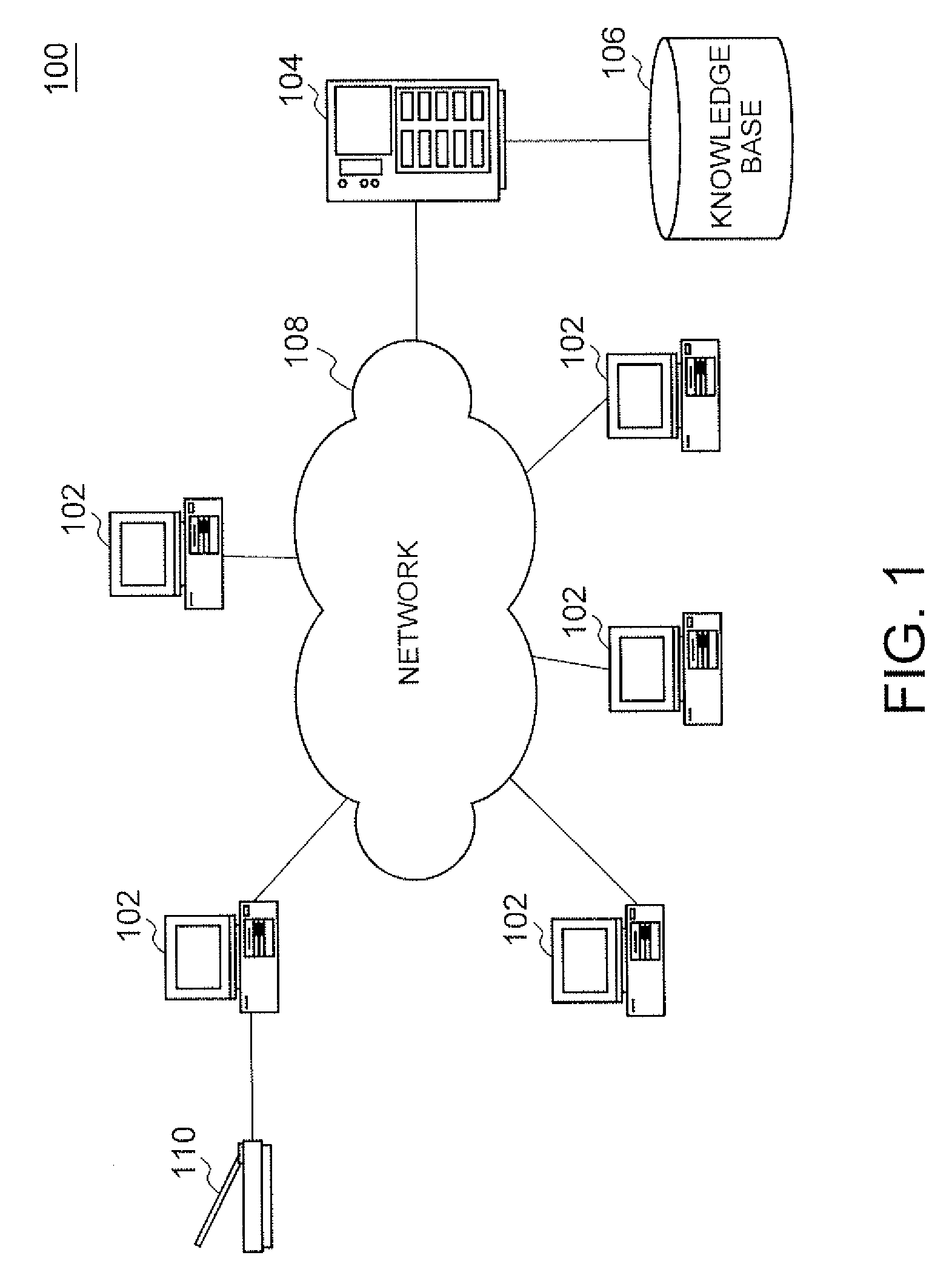

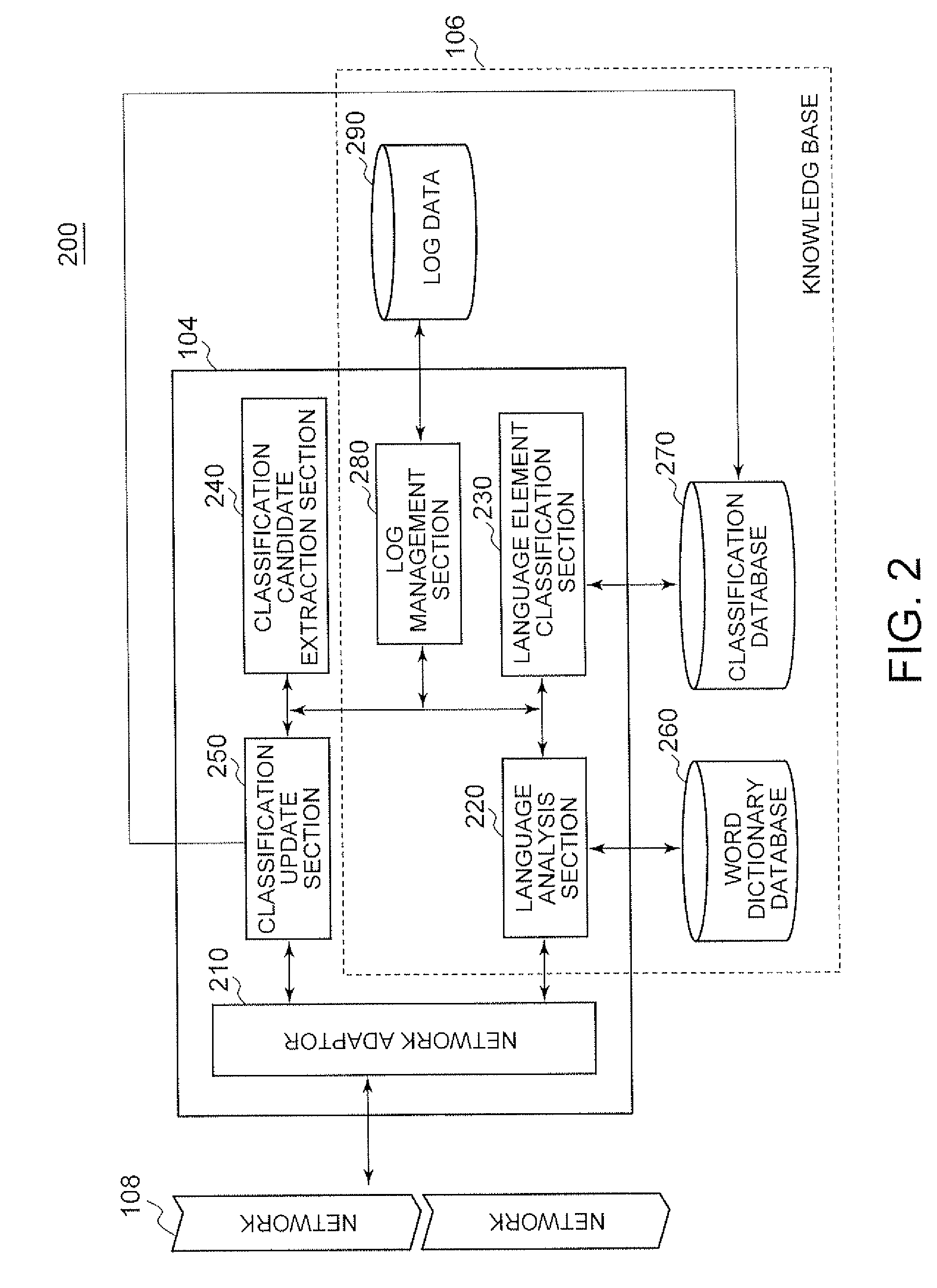

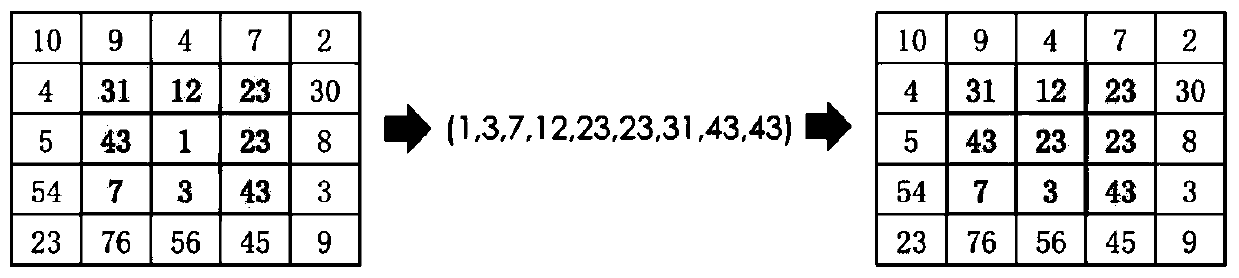

Information classification system, information processing apparatus, information classification method and program

ActiveUS20090248671A1Appropriately extractedPrecise proportionDigital data information retrievalDigital computer detailsInformation processingClassification methods

An information classification system includes a server that includes a knowledge base that receives classification information to be classified, conducts language analysis of the classification information to acquire a plurality of keywords and classify the plurality of keywords into elements made up of a classification target word and a related word that modifies the classification target word, and conduct a search with the related word being for a judgment condition for decision of the classification while separating the classification target word from the related word, so as to assign a classification identification value to the information; a classification candidate extraction section that extracts the classification identification value that the knowledge base assigns to generate an automatic classification result; and a classification update section that receives the automatic classification result, displays a GUI for classification confirmation allowing confirmation of correctness of the automatic classification result, and corrects registered items in the knowledge base with a correction value received through the GUI for classification confirmation while referring to log data that is a processing history about automatic classification for the language analysis and the element classification.

Owner:IBM CORP

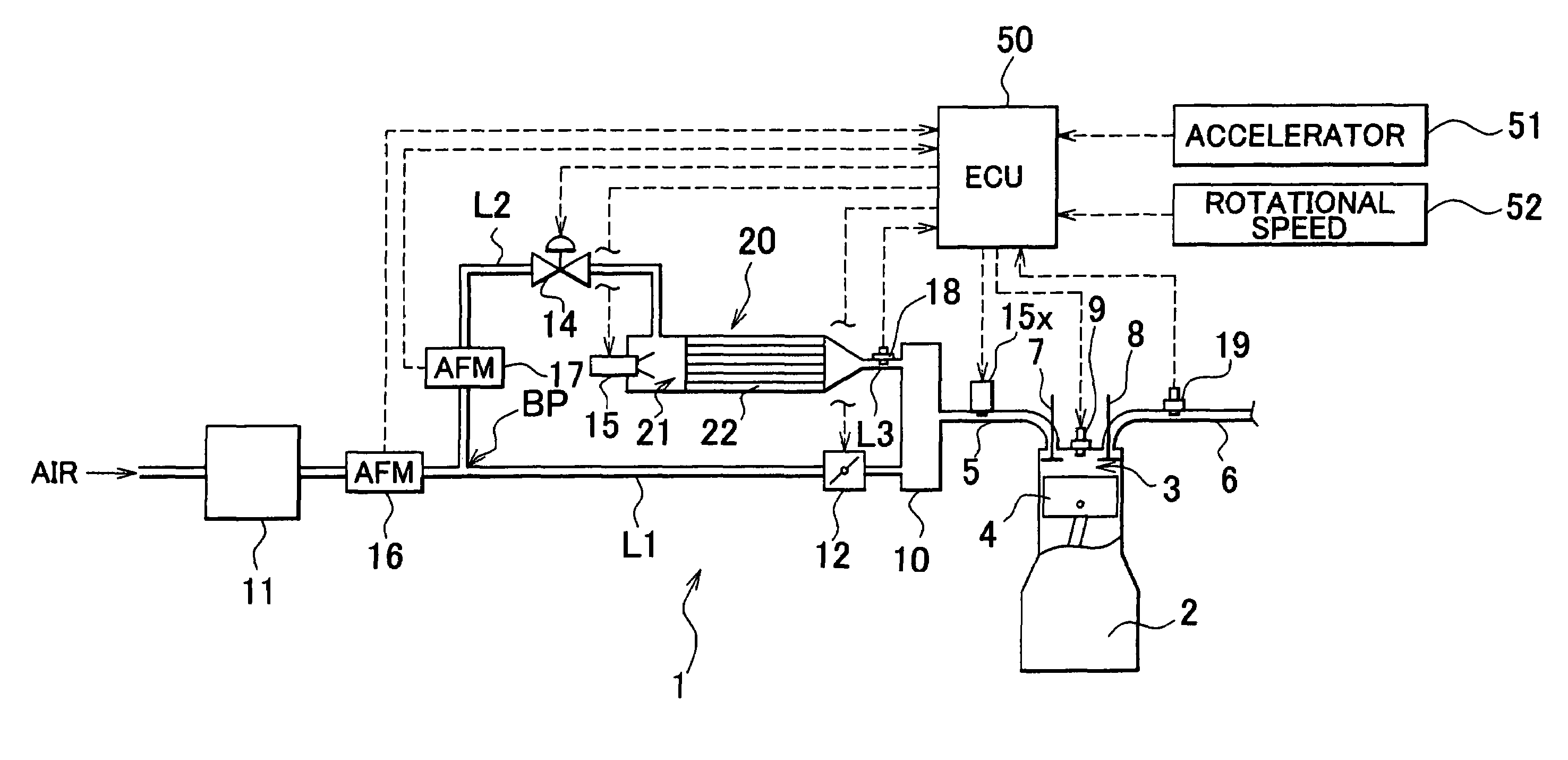

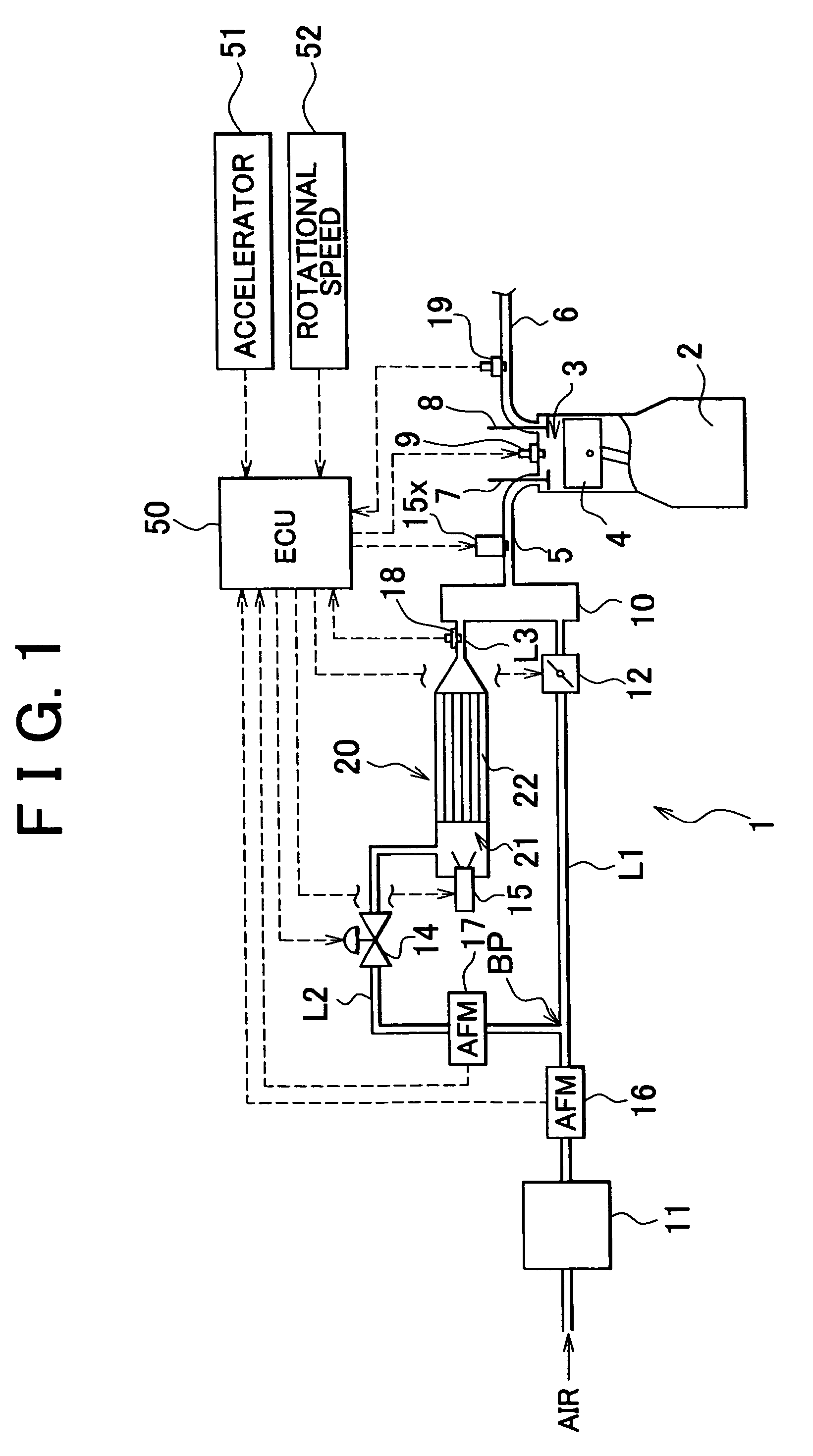

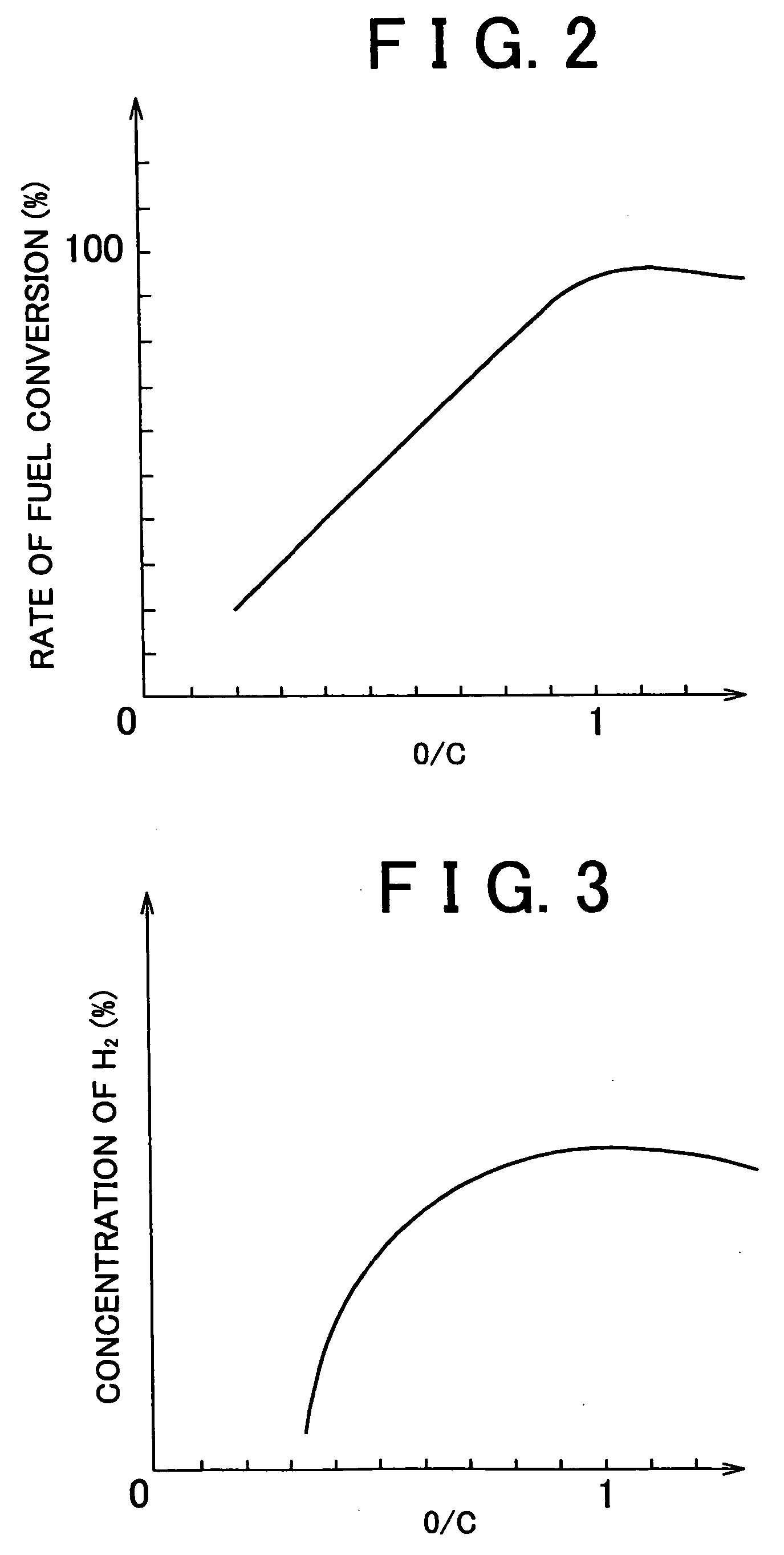

Internal combustion engine and method of operating internal combustion engine

InactiveUS6997142B2Accurate graspPrecise proportionHydrogenElectrical controlCombustion chamberAir–fuel ratio

An internal combustion engine in accordance with one aspect of the invention is characterized by comprising a combustion chamber, a reformer, and a control portion. A predetermined fuel component is burnt in the combustion chamber. The reformer has a reforming catalyst, and that produces a reformed gas which contains the fuel component obtained by reforming a mixture of fuel and air and which supplied to the combustion chamber. The control portion sets an air-fuel ratio of the mixture in the reformer such that a reforming efficiency of the reformer is held within a predetermined range, and sets an amount of the mixture supplied to the reformer such that an actual output torque of the internal combustion engine coincides with a target torque.

Owner:TOYOTA JIDOSHA KK

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS7267814B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning/moderate abrasive silica materials and dentifrice containing such materials

InactiveUS7306788B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaLinseed oilSilica gel

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

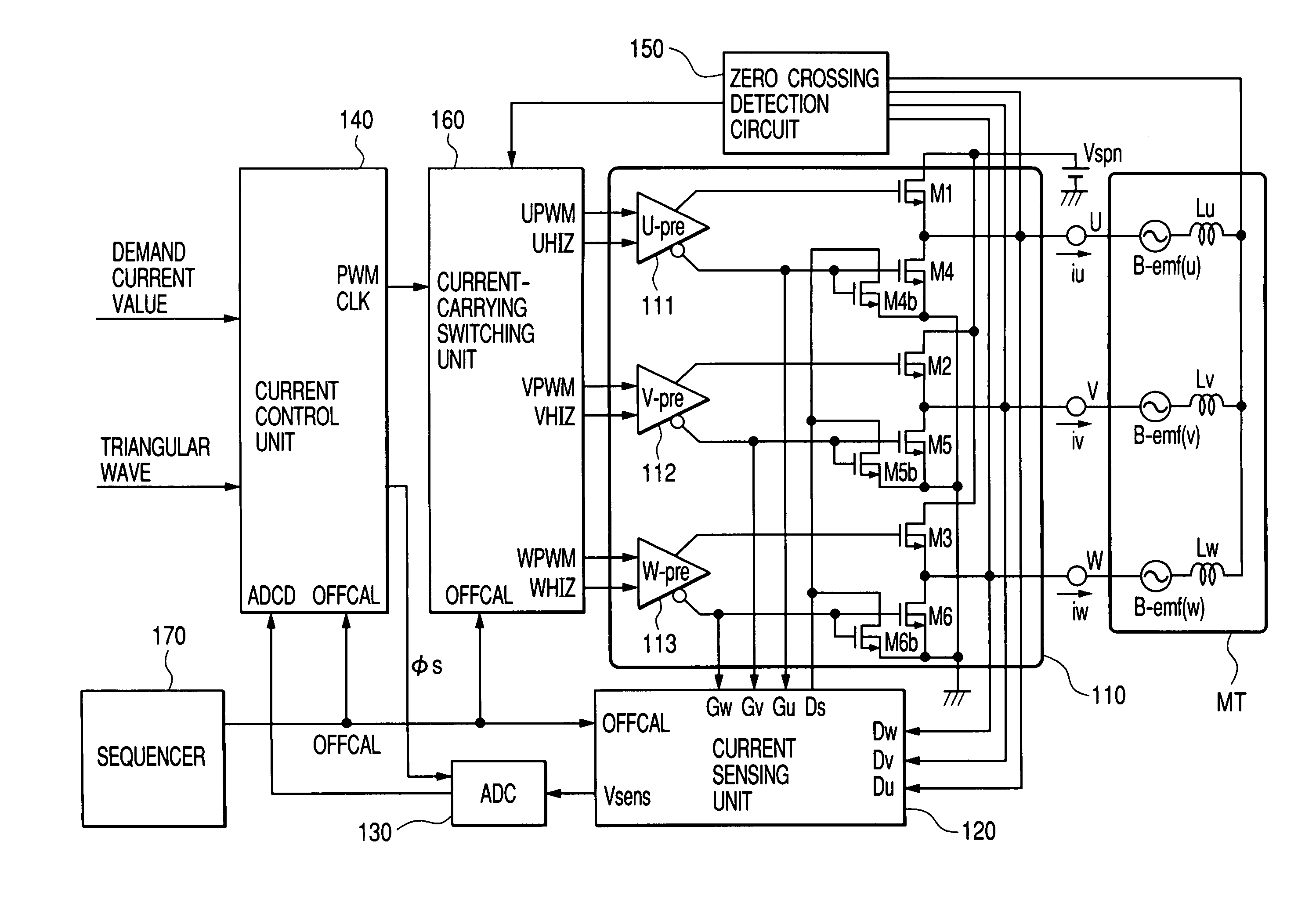

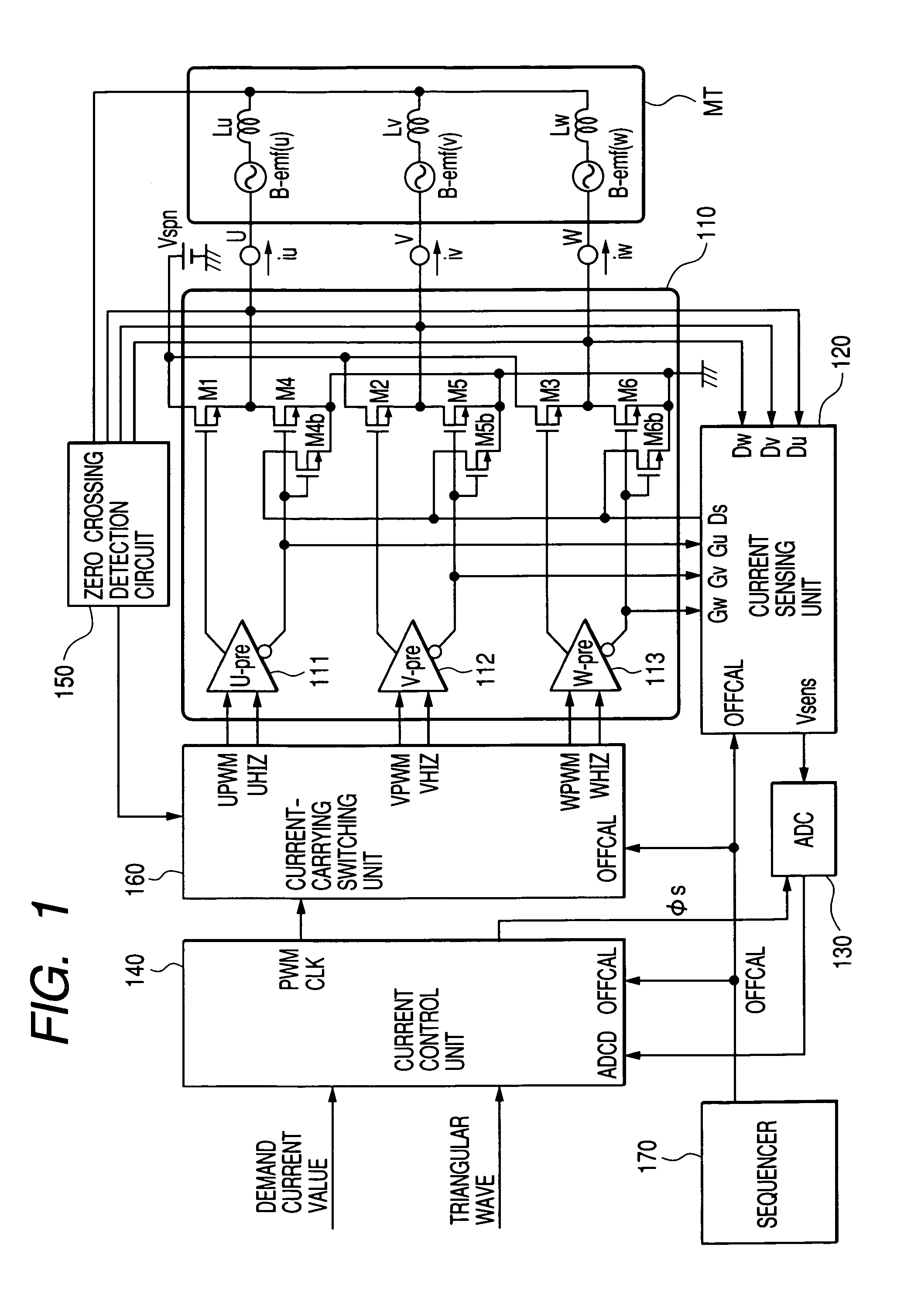

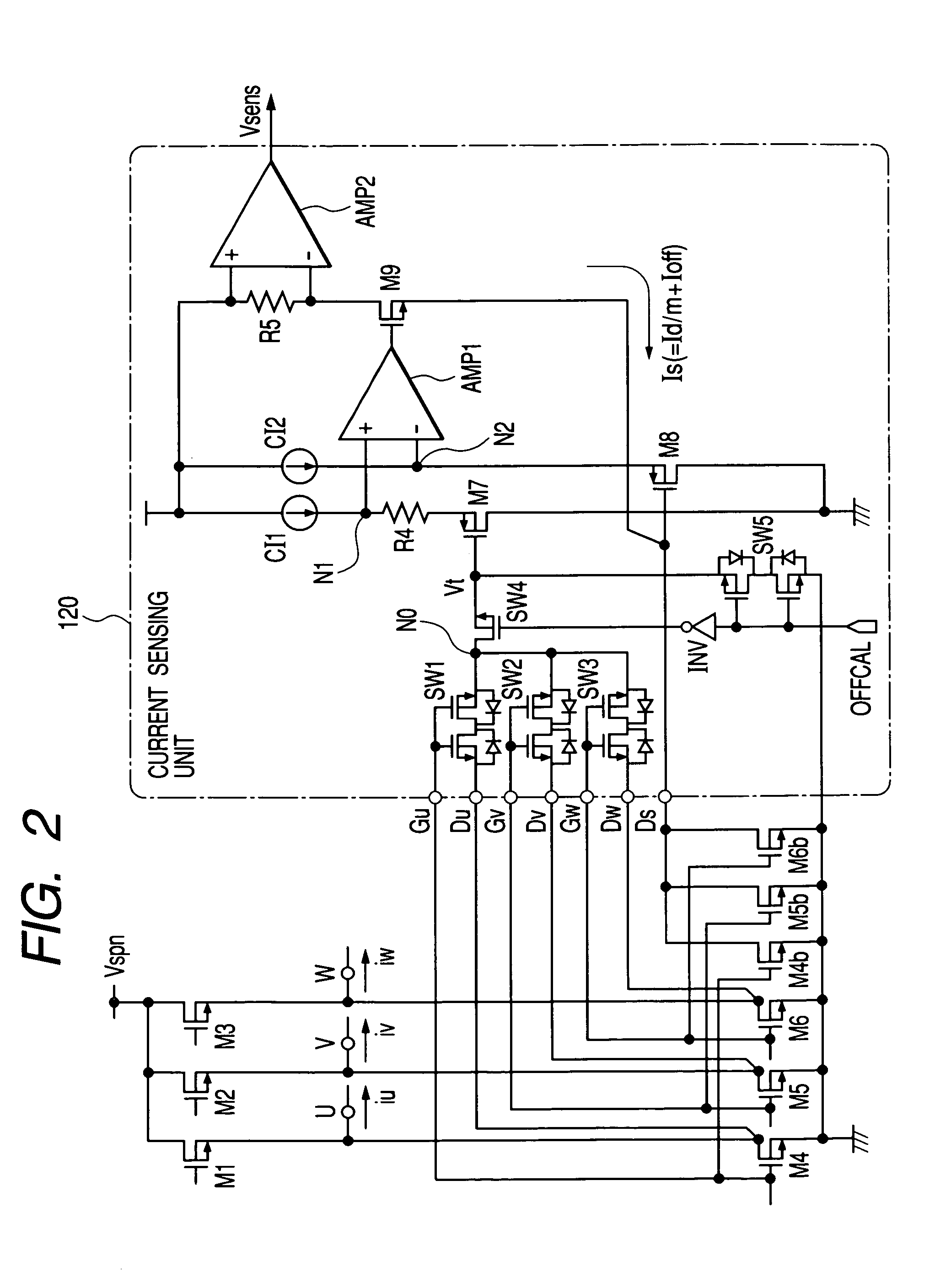

Drive control device for direct current motor, rotation drive system for direct current motor and semiconductor integrated circuit for driving coil

InactiveUS7119508B2High accuracyImprove accuracySingle-phase induction motor startersSynchronous motors startersIntegrated circuitSemiconductor

A dc motor drive system with a PWM control system permits a high-accuracy rotation drive control while detecting the currents flowing into the coils without using shunt resistors. The system drives output MOS transistors by the PWM control to make the currents flow into the coils, and drives to rotate the dc motor. The system includes current sensing MOS transistors having a predetermined size ratio 1 / m (M>1) to the output MOS transistors that make the currents flow into the coils. The current sensing MOS transistors are capable of making flow reduced currents proportional to the currents of the output MOS transistors.

Owner:RENESAS TECH CORP

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

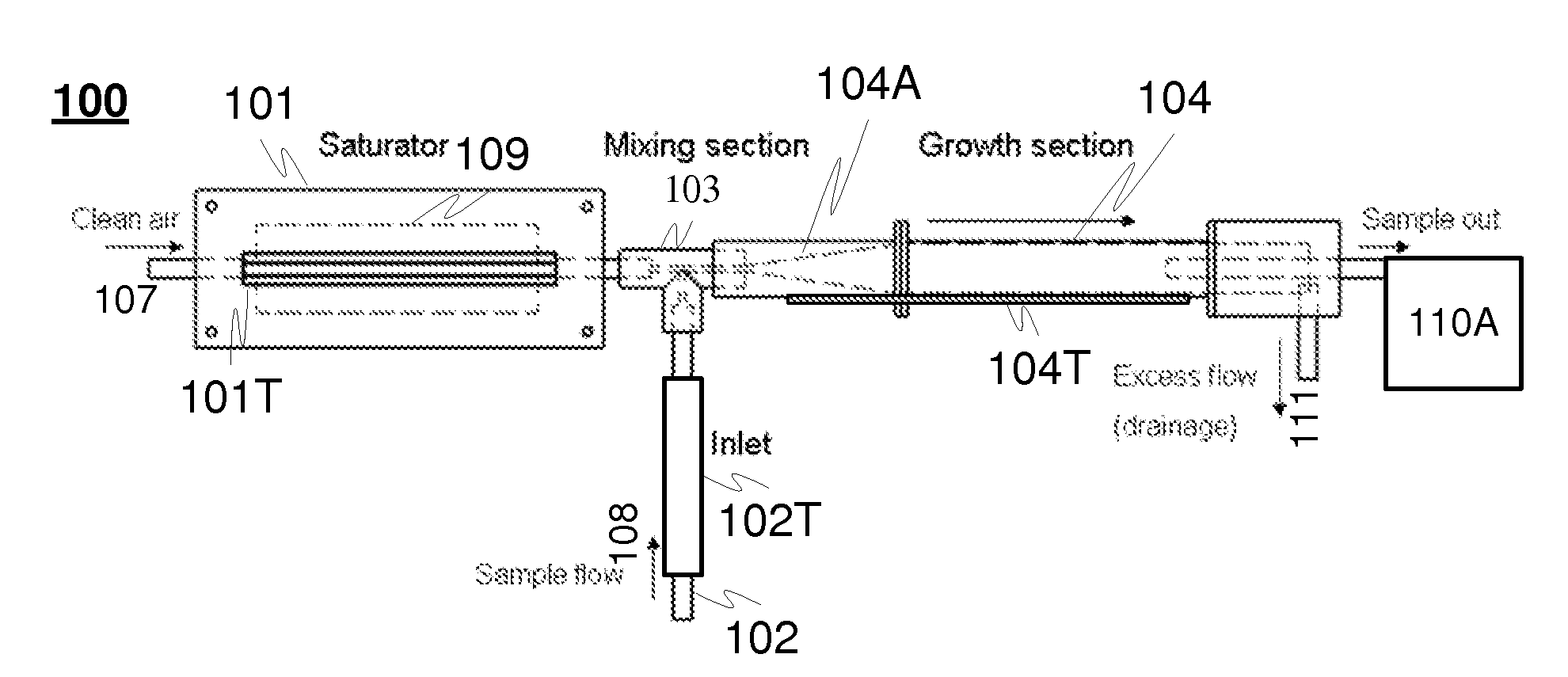

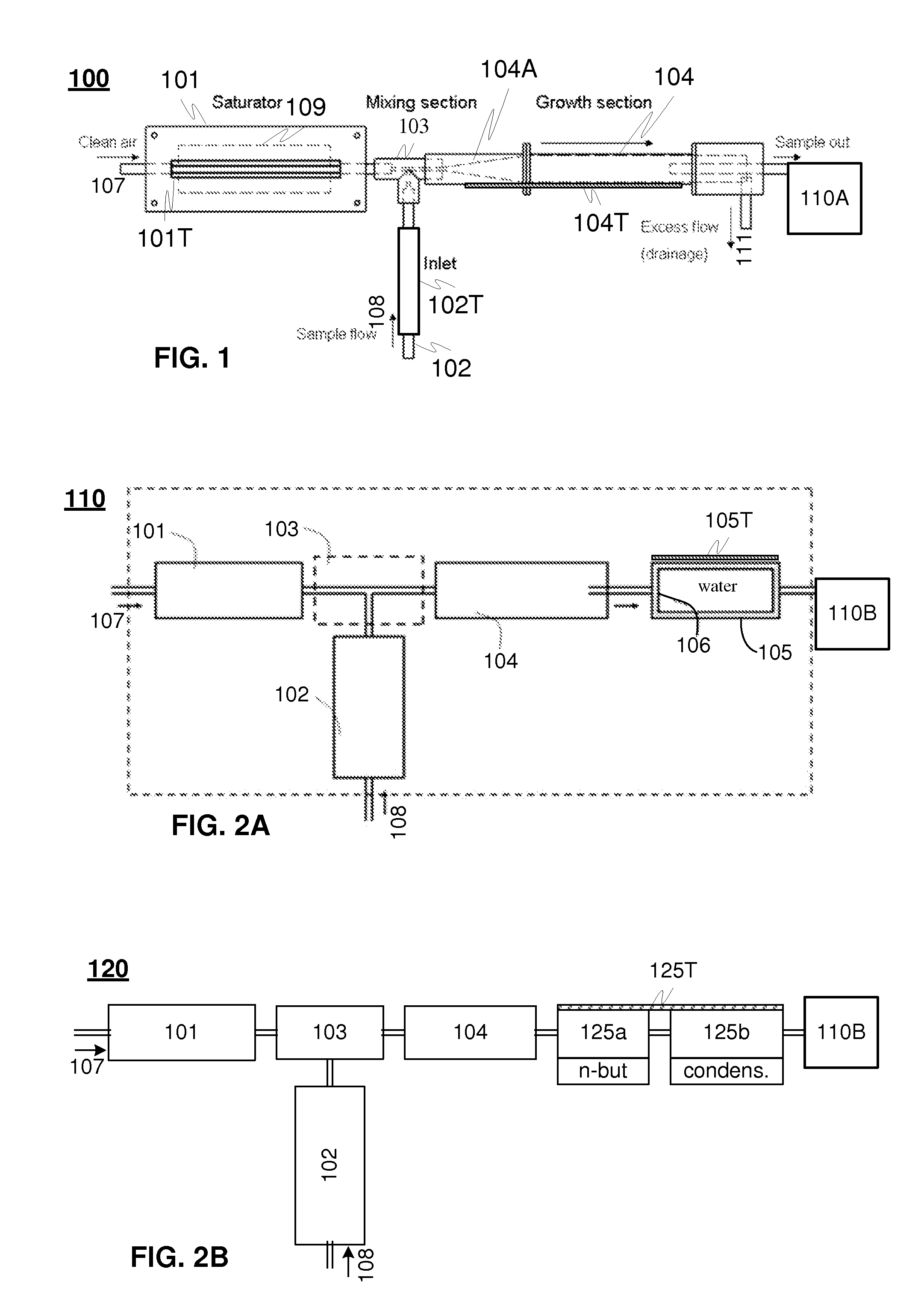

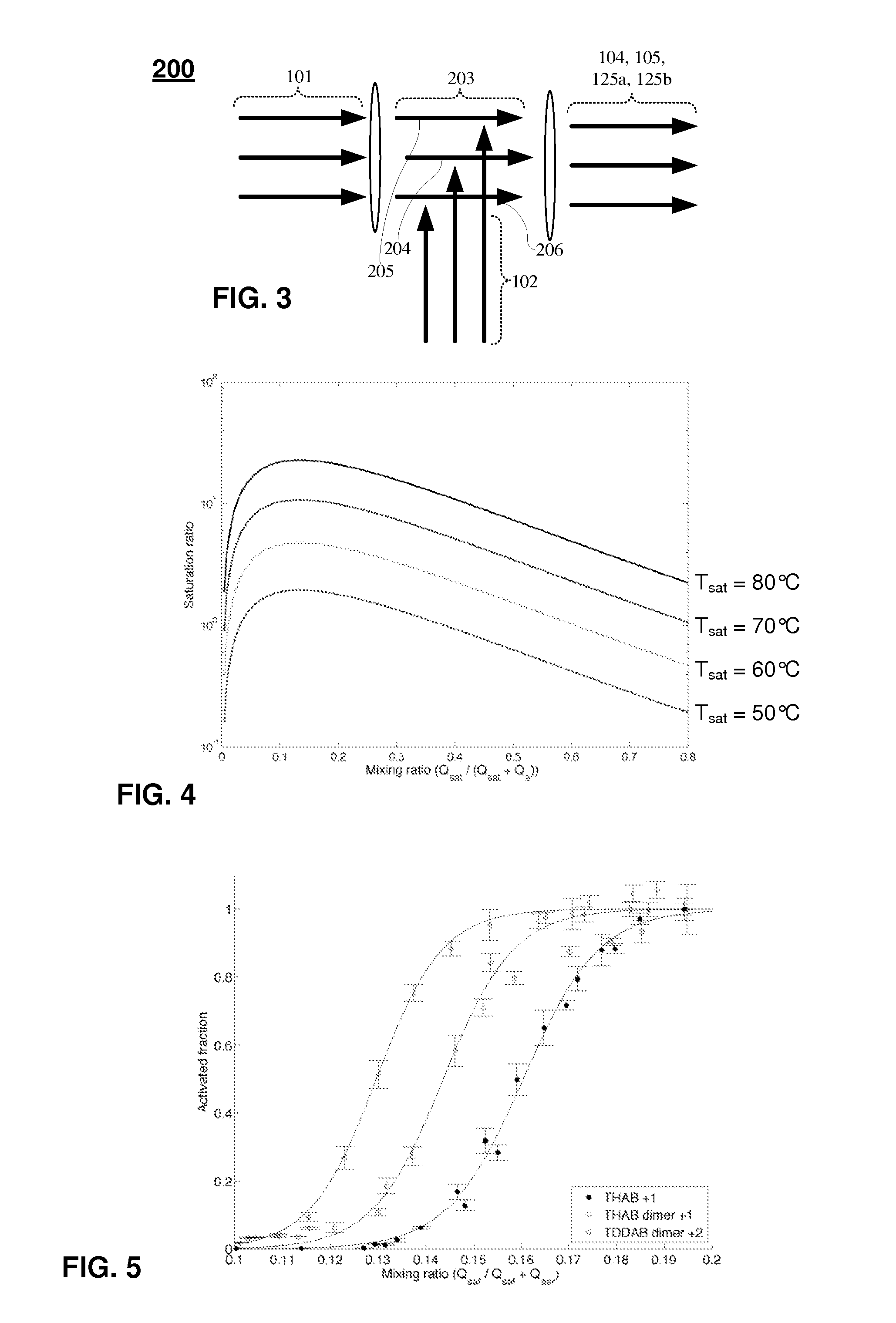

Method and device for detecting aerosol particles

ActiveUS20120131989A1Growth correctionSmall sizeNanoparticle analysisParticle size analysisParticle flowPrill

Sizes or size distribution of aerosol particles of an aerosol gas stream is detected. A particle-free carrier flow is saturated in a saturator by a first condensing medium, after which, the carrier flow is mixed in a mixing section turbulently with aerosol particle flow. Advantageously, a plurality of separate mixtures with different saturation ratios are provided and introduced to the first condensing environment in order to condensate the condensing medium onto the aerosol particles. Depending on the saturation ratio, the particles with different lowest original size are activated and grown in a growing section and / or in the condensing environment. After activation and growing, the particles are detected by a detecting means.

Owner:AIRMODUS

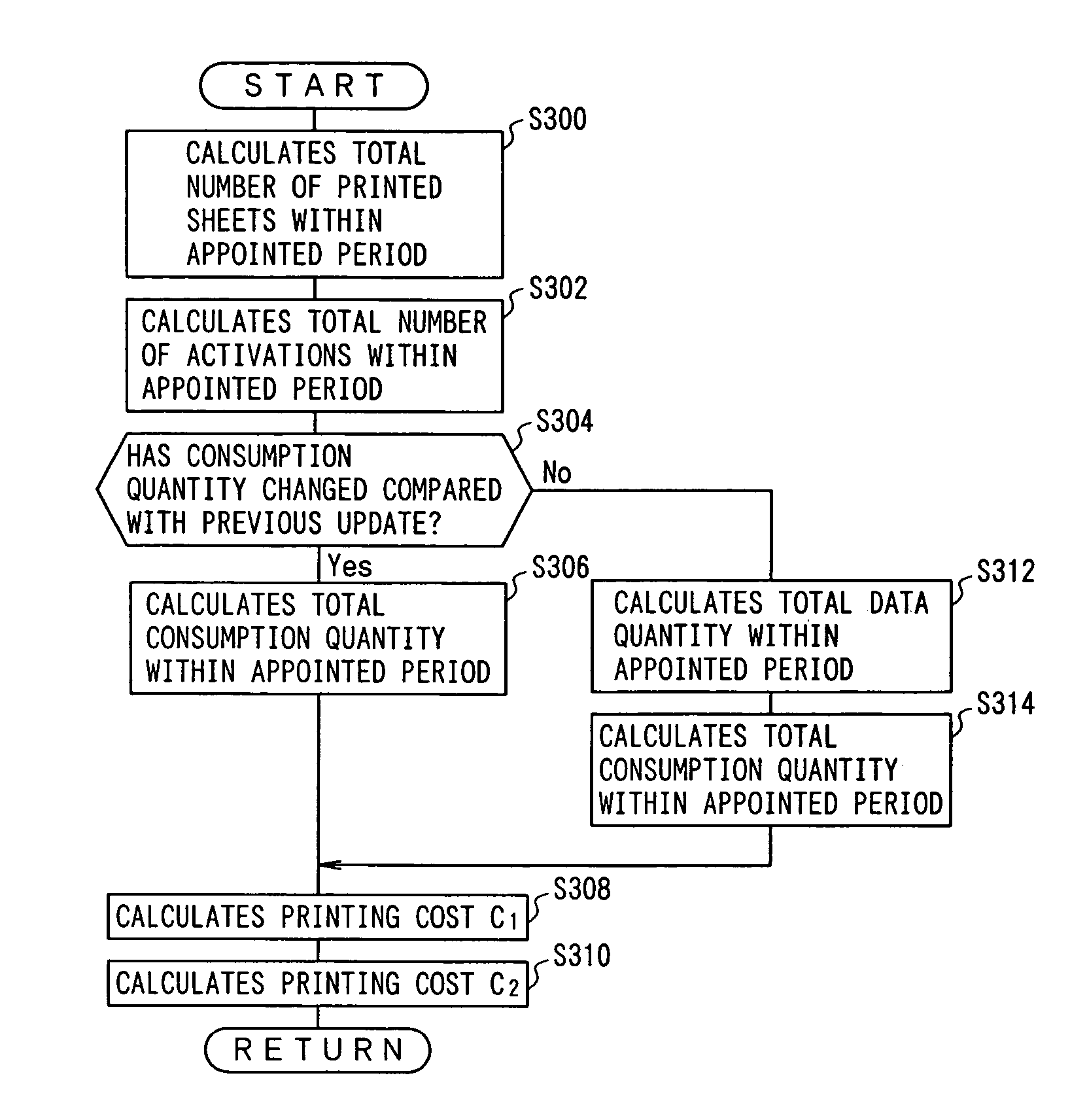

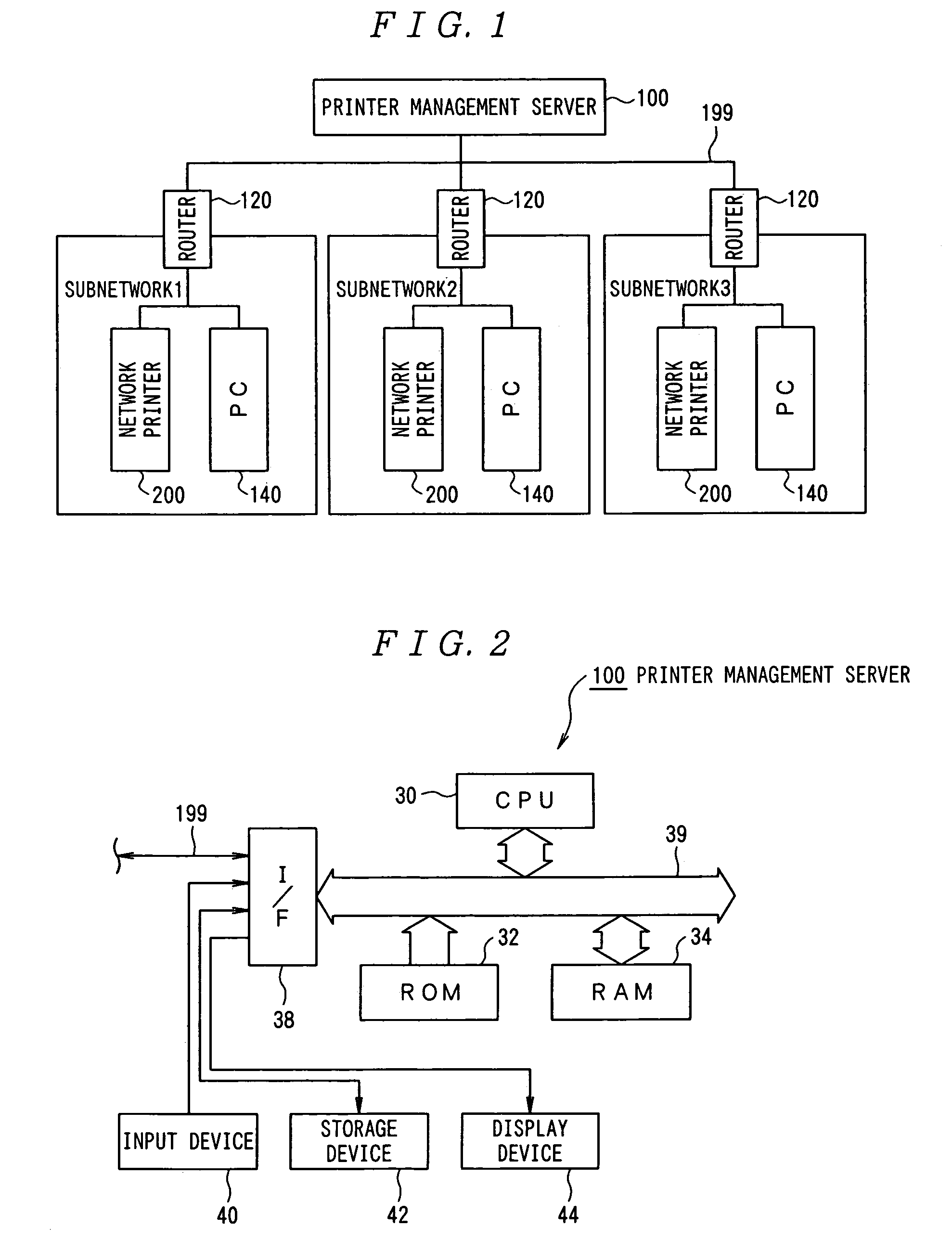

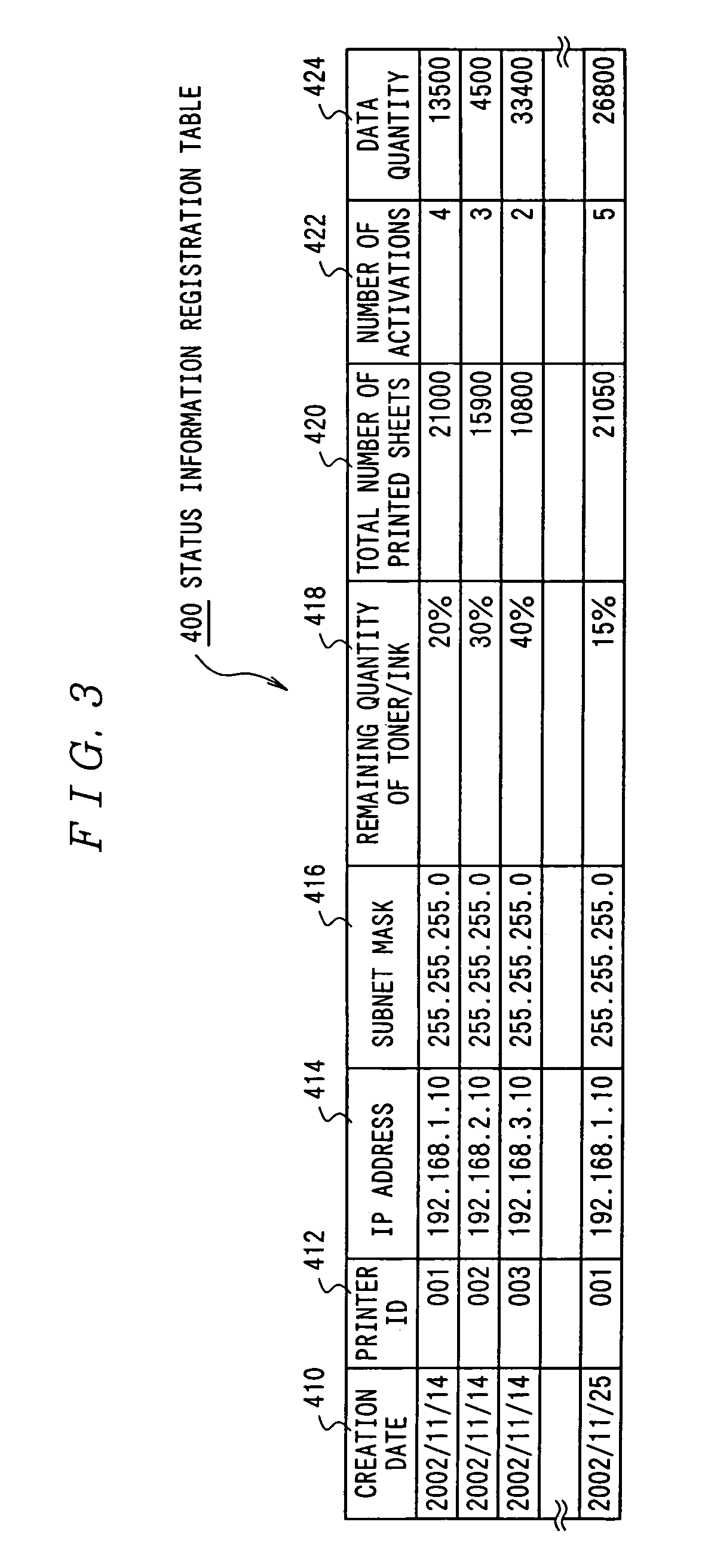

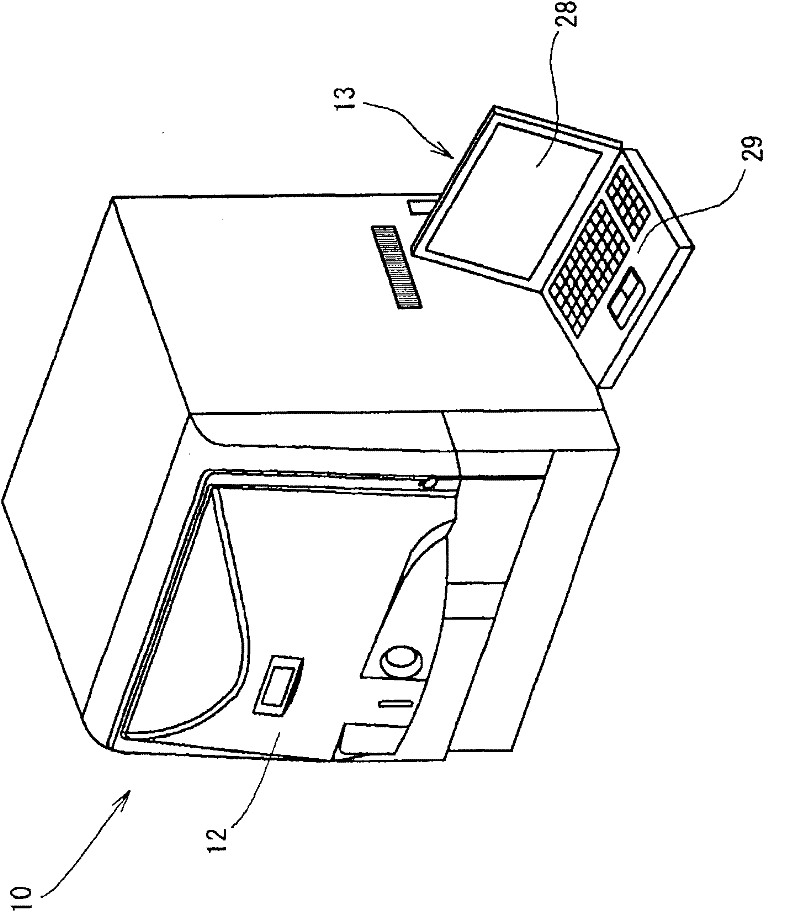

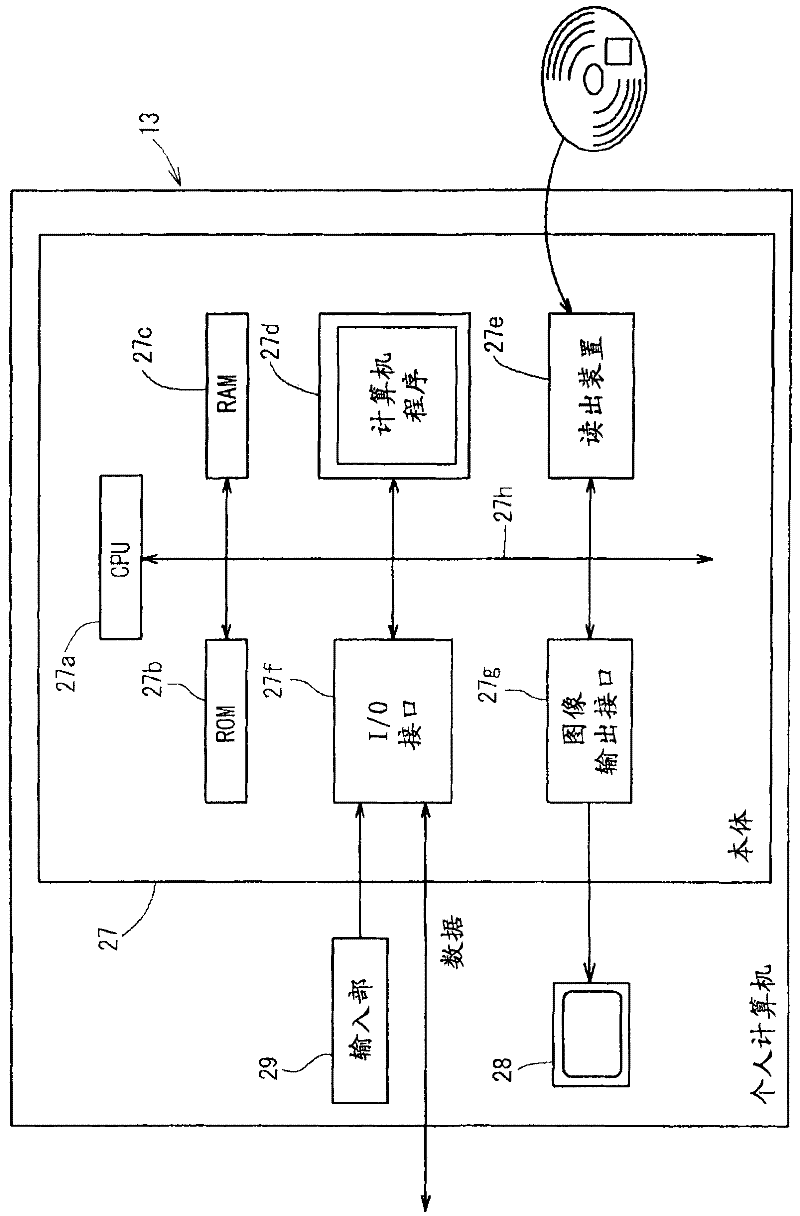

Device management system, printer management system, printer management terminal, network printer, program for terminal and program for printer, and device management method

ActiveUS7085503B2Accurate calculationAccuracy of detecting consumptionElectrographic process apparatusResourcesEngineeringComputer terminal

There is provided a device management system suitable for accurately calculating an average consumption quantity of toner and the like per print sheet and thereby accurately calculating a printing cost depending on use environments. A network printer 200 detects a remaining quantity of toner and the like, a total number of printed sheets and a total number of activations, and send status information including the detection results to a printer management server 100. When receiving the status information, the printer management server 100 registers the received status information with a status information registration table 400, and calculates an average consumption quantity by calculating the total consumption quantity of toner and the like, the total number of printed sheets and the total number of activations within an appointed period based on the status information registration table 400, multiplying the total number of activations by the consumption-quantity-during-activation calculation coefficient k1 and dividing the multiplication result added to the total consumption quantity of toner and the like by the total number of printed sheets.

Owner:SEIKO EPSON CORP

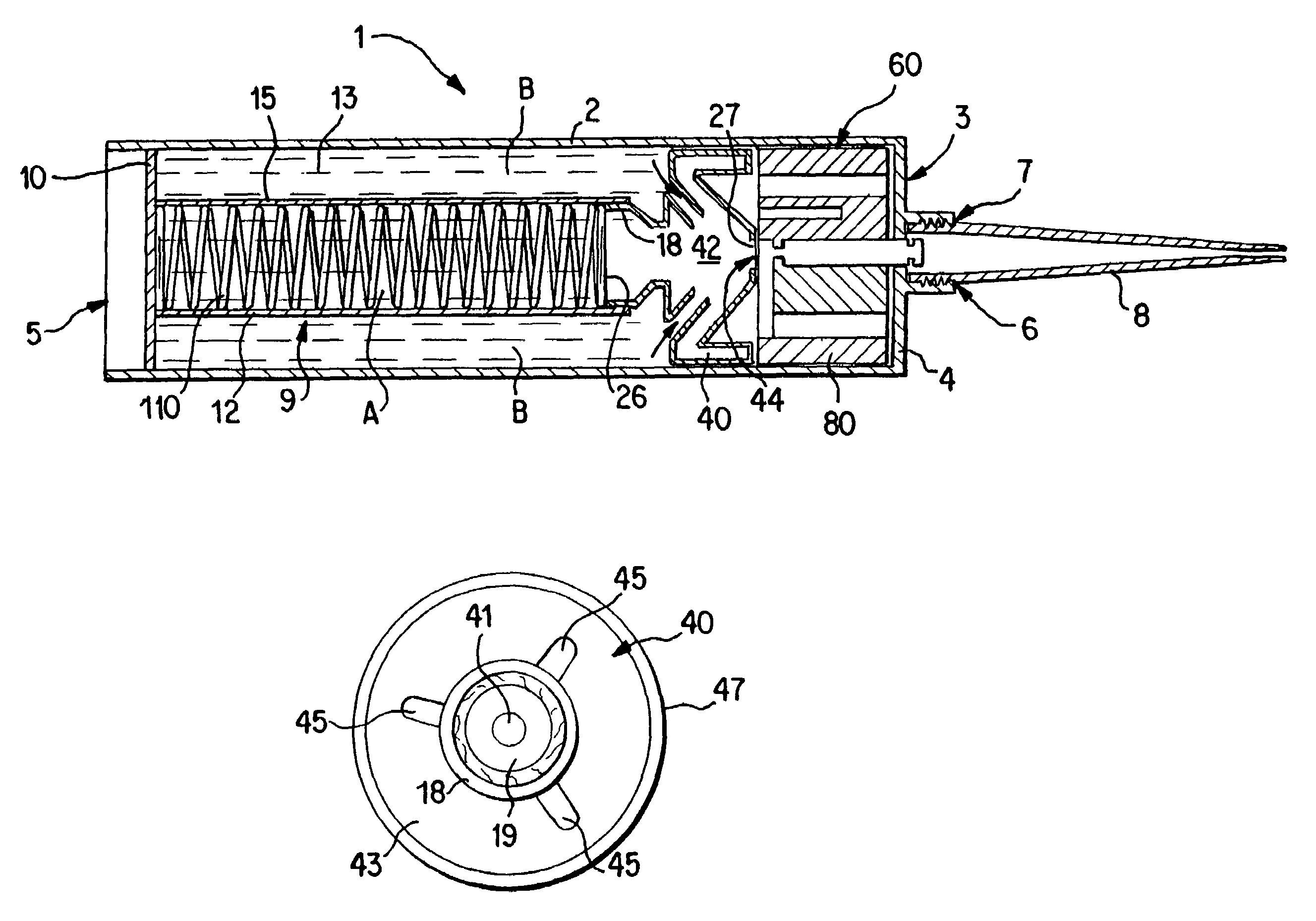

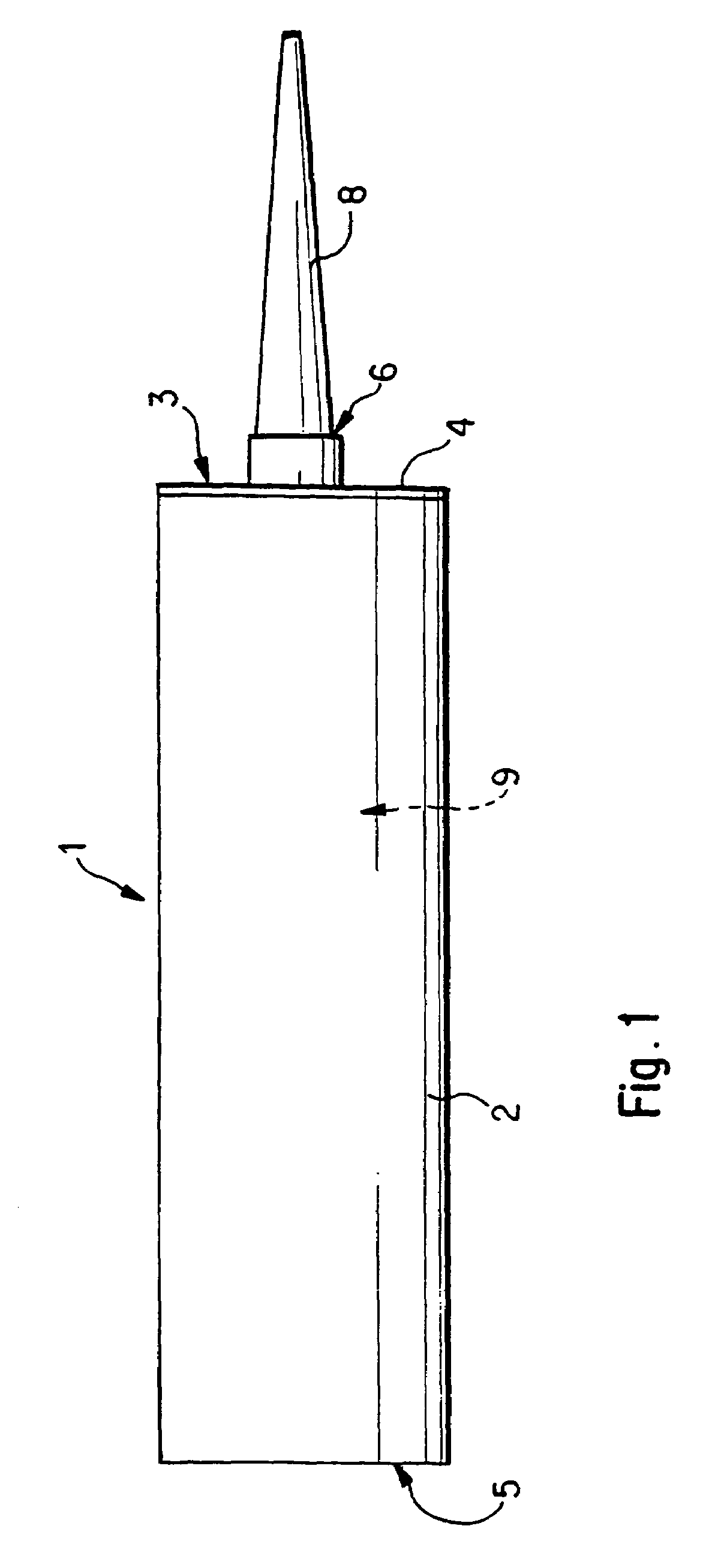

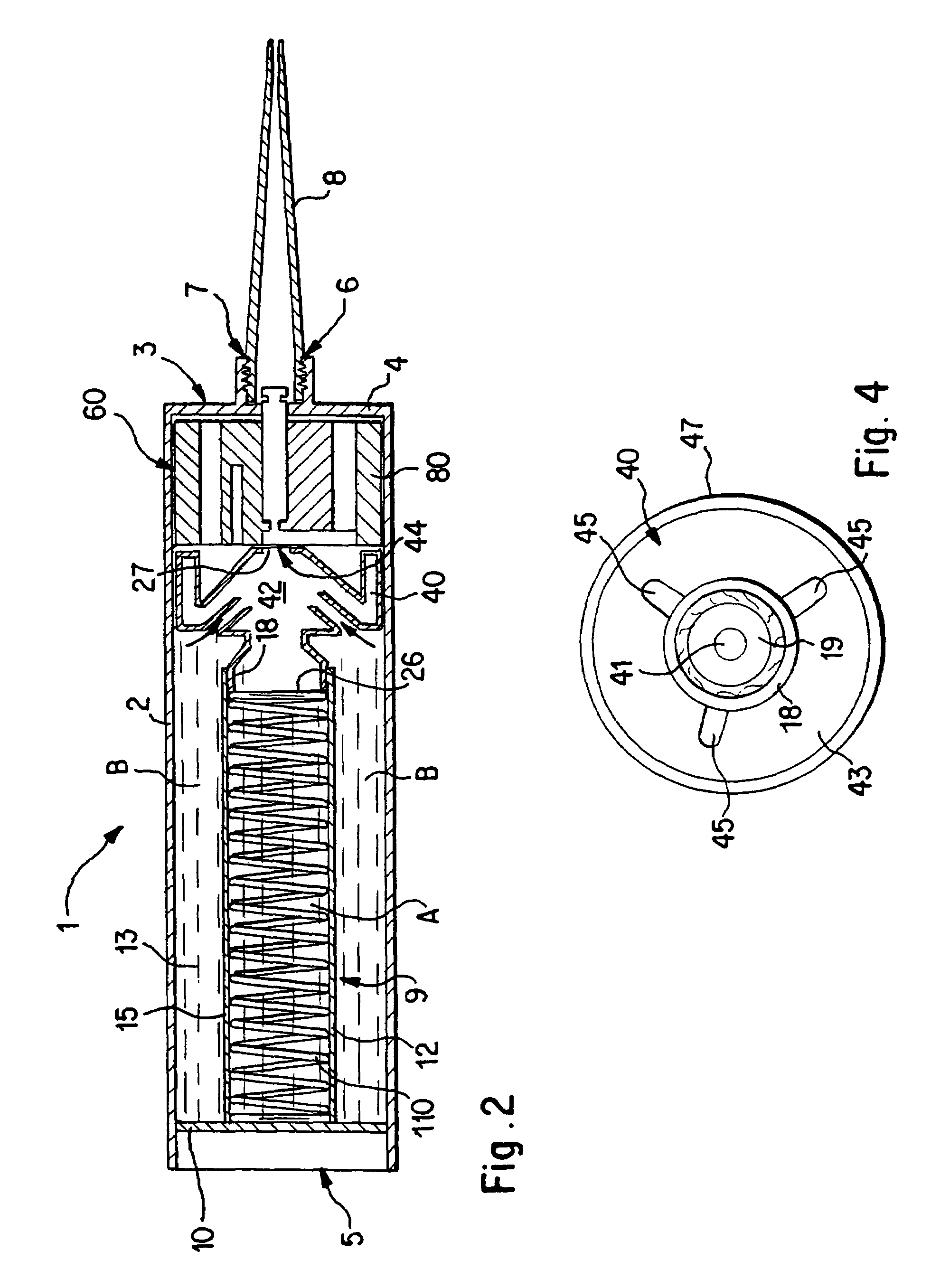

Apparatus and method for mixing and dispensing components of a composition

InactiveUS6971787B2Precise proportionEfficient mixingLiquid surface applicatorsFlow mixersEngineeringNozzle

A cartridge assembly used with a conventional caulking gun for mixing and dispensing components of a material. The cartridge assembly includes a component carrying body that has a plurality of separate component reservoirs and a component flow directing housing at a forward end of the reservoirs. A mixing unit extends between the component flow directing housing and a discharge nozzle secured to the front end of the carrying body. The mixing unit mixes the components and delivers them to the discharge nozzle. The mixing unit includes a plurality of mixing cylinders that each have a longitudinal axis that extends substantially parallel to the longitudinal axis of the component carrying body. The mixing cylinders and guiding channels that extend between them form at least a portion of a component mixing path. The mixing cylinders can each include one or more mixing elements.

Owner:ROYAL ADHESIVES & SEALANTS CANADA

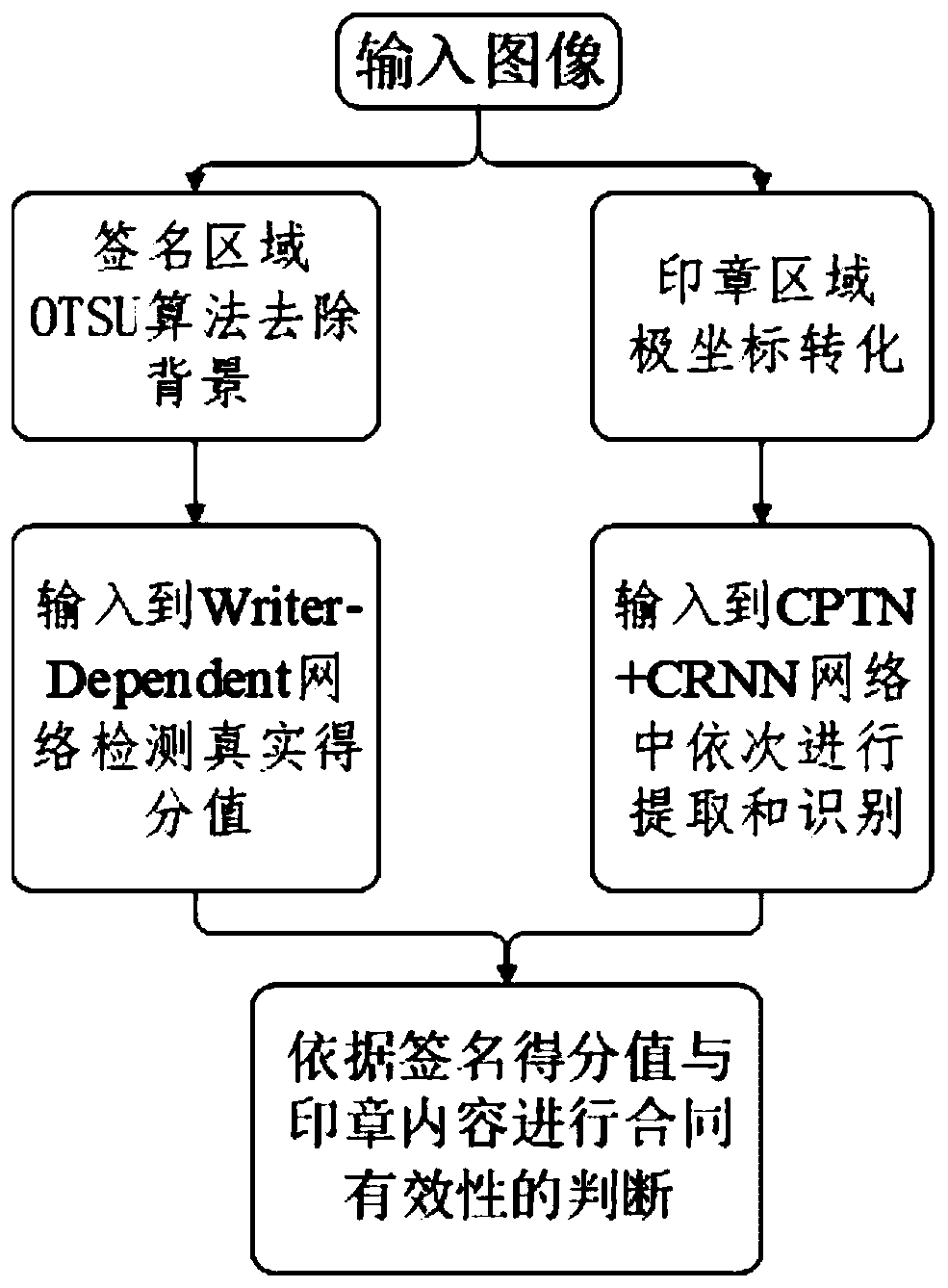

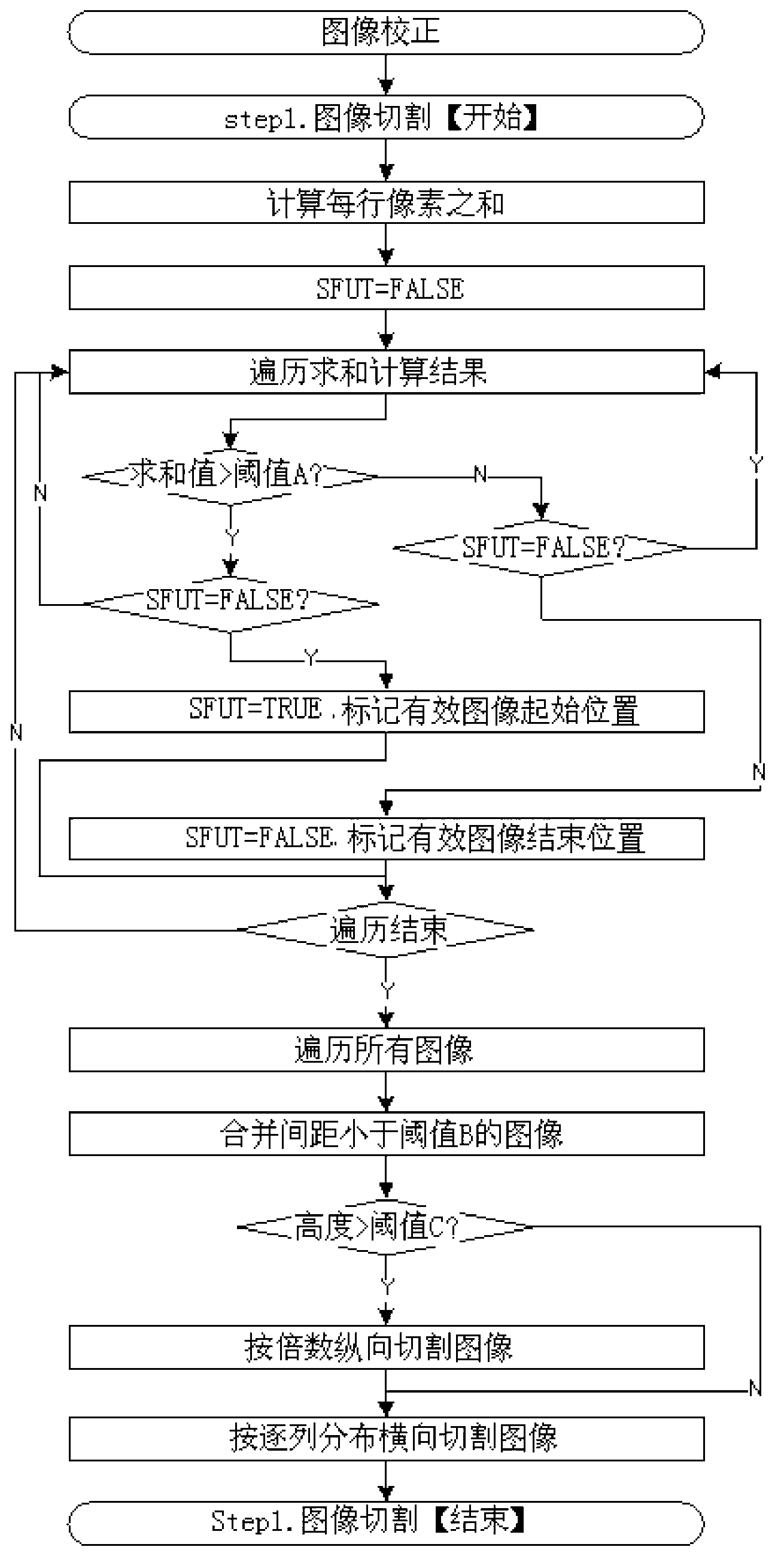

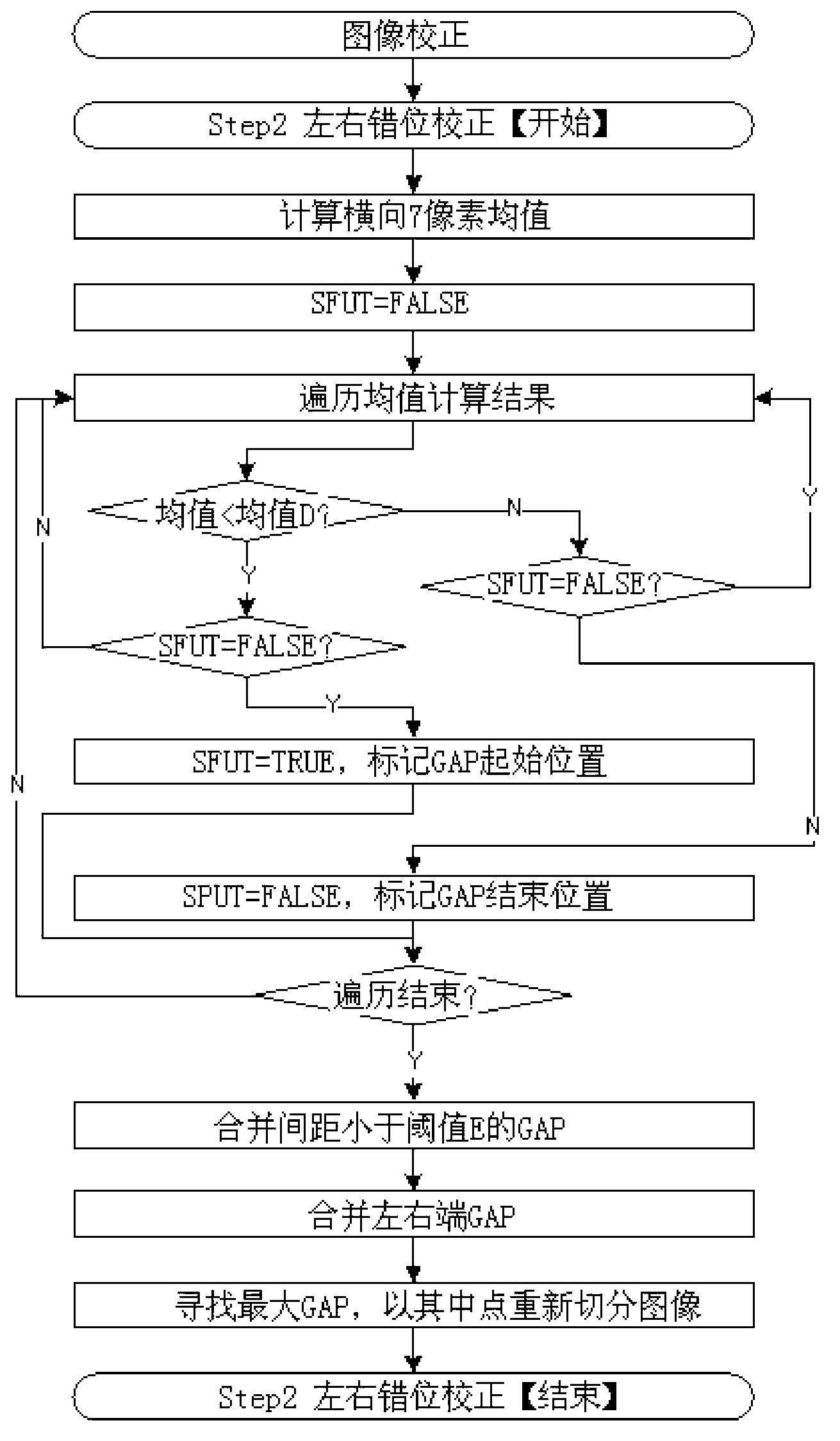

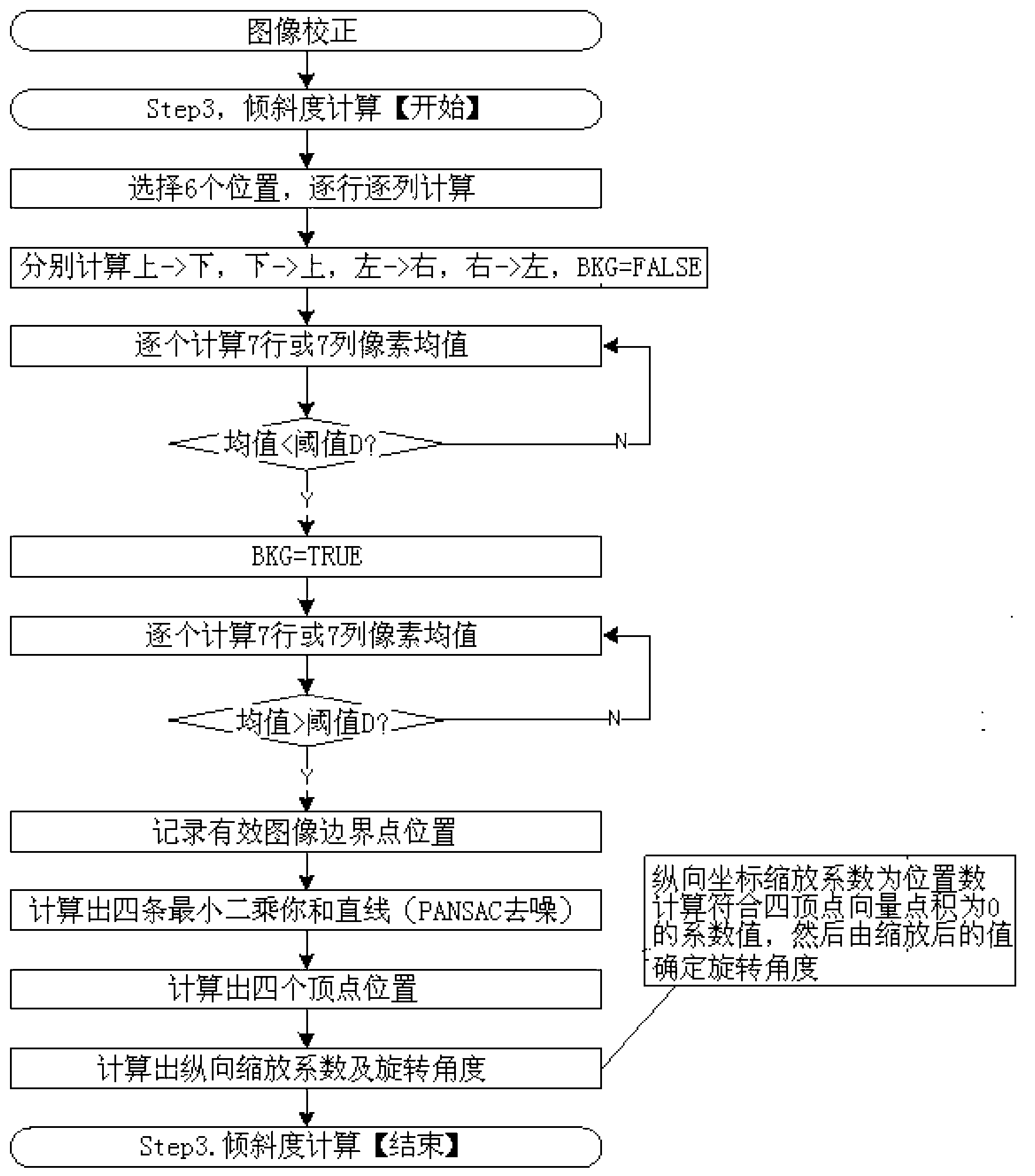

Method for extracting and identifying graphic and text information of scanned document

PendingCN111401372AFast and Efficient DetectabilityFast and efficient identificationCharacter and pattern recognitionPattern recognitionSvm classifier

The invention relates to a method for extracting and identifying graphic and text information of a scanned document, which comprises the following steps of: 1) preprocessing a scanned document image,carrying out layout segmentation on the preprocessed image, and selecting items, including but not limited to, a signature and a seal; (2) preprocessing the signature extracted in the step (1), removing a background by adopting an OTSU algorithm, inputting the signature into a Writer-Dependent network to extract a characteristic value of the signature, and inputting the characteristic value into an SVM classifier obtained by using real signature training to obtain the authenticity of the signature; (3) conducting polar coordinate transformation on the seal extracted in the step (1) after preprocessing, so that annular characters in the seal are expanded into transversely-arranged characters, inputting the expanded characters into a CPTN + CRNN network to be sequentially extracted and recognized, and outputting the character content of the seal; 4) judging the validity of the document. The method can replace manual work to analyze and judge the document.

Owner:STATE GRID CORP OF CHINA +1

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS7303742B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

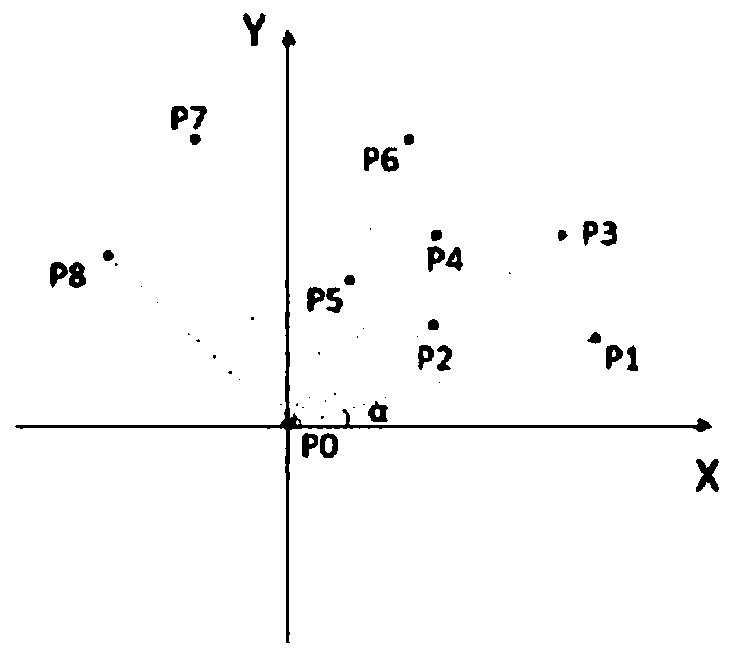

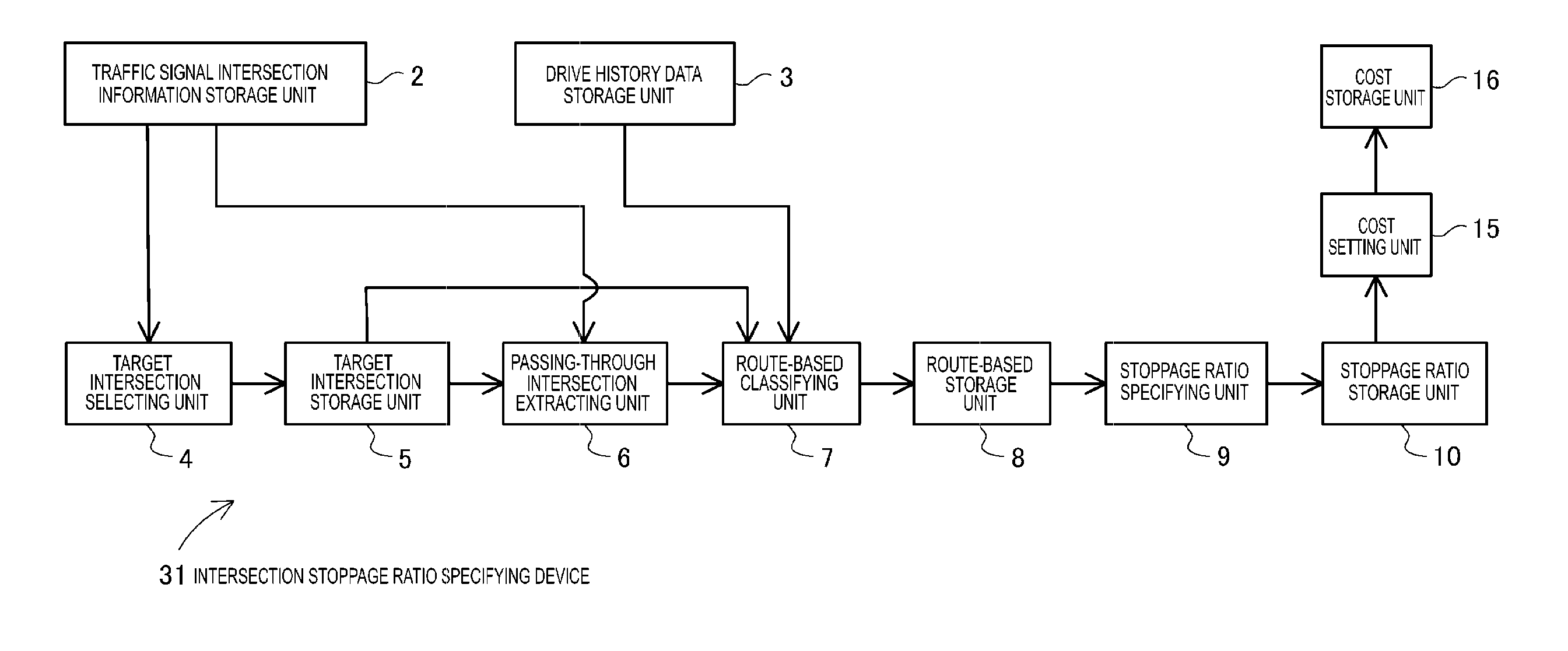

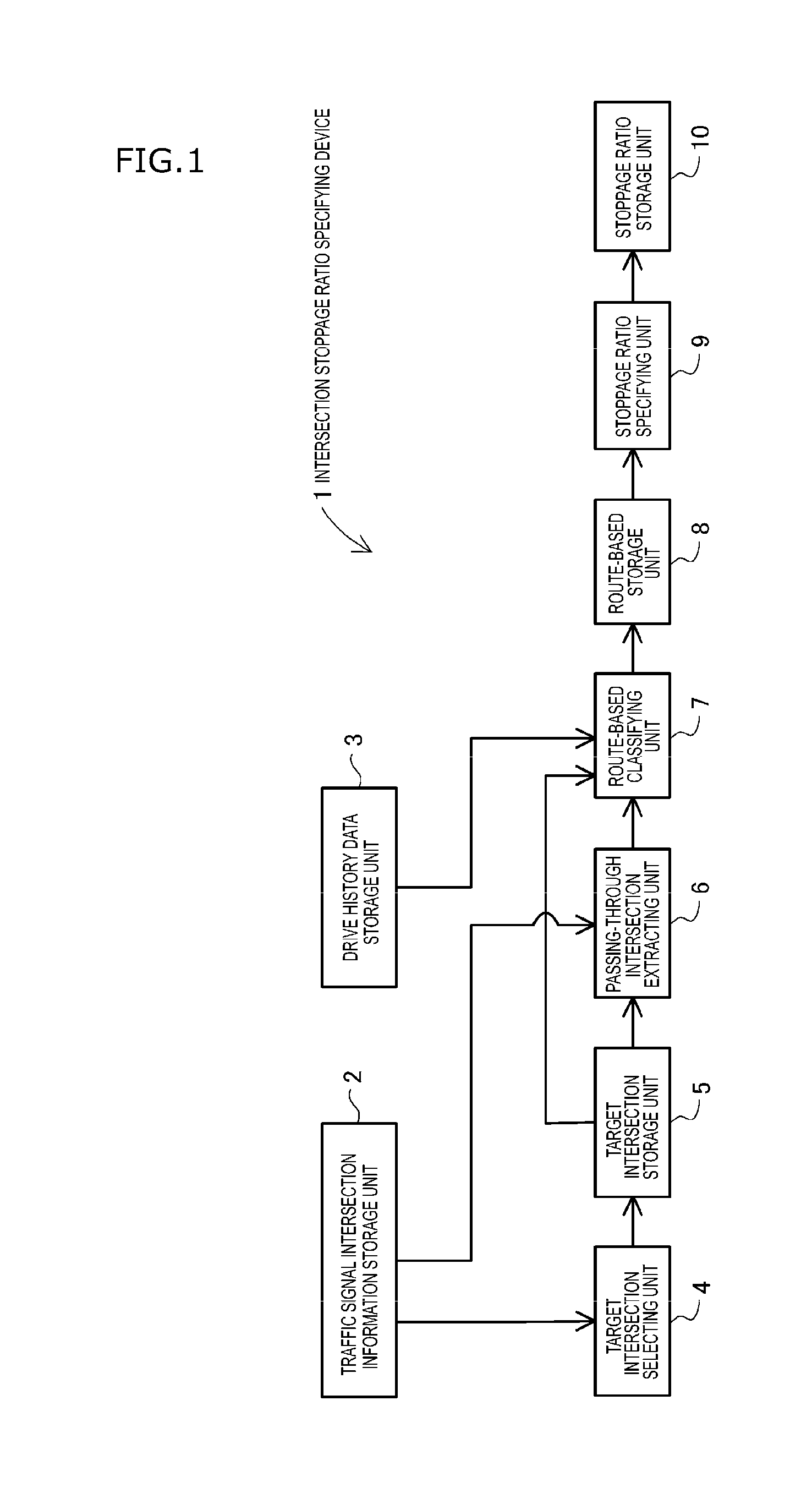

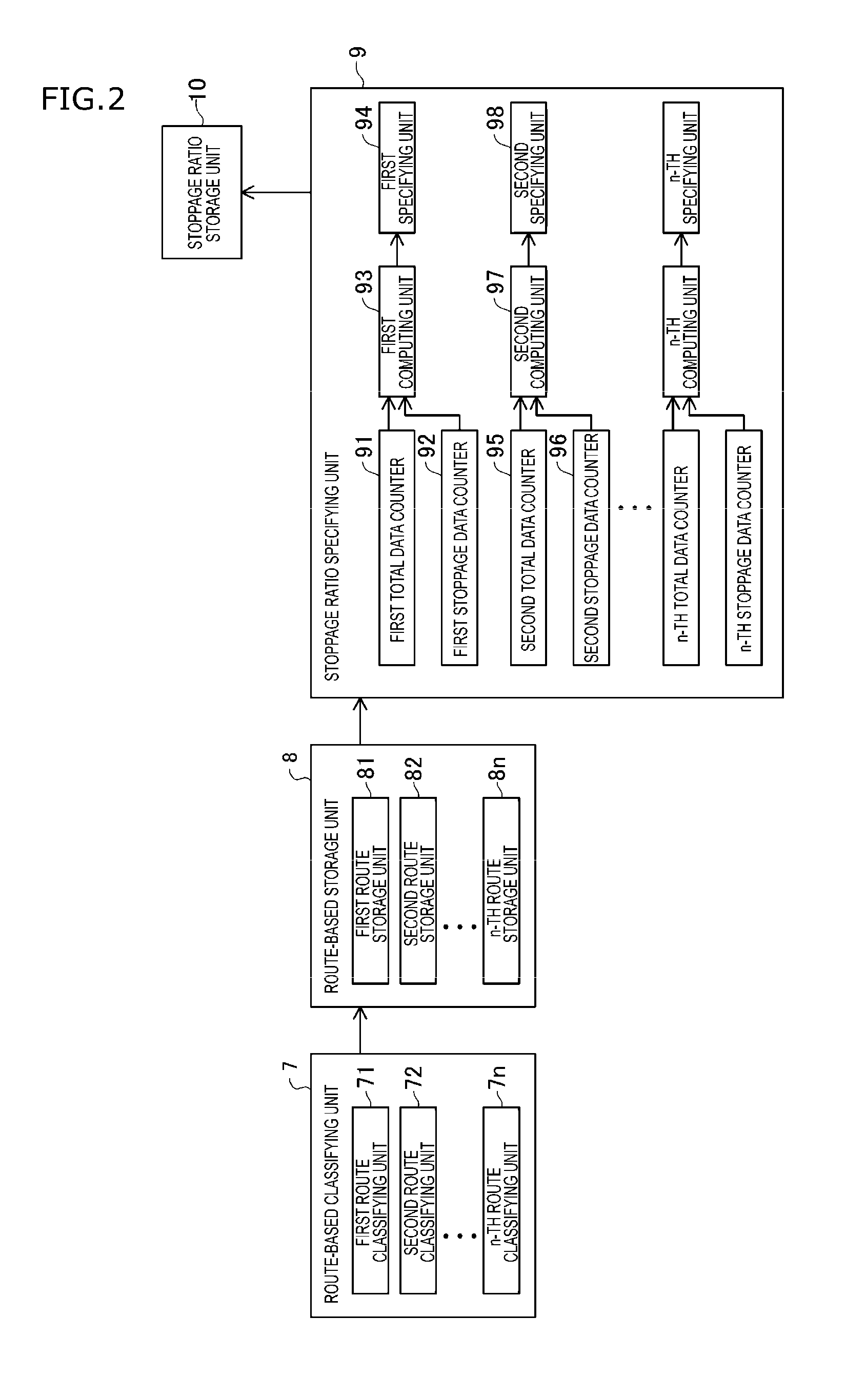

Intersection-Stopping-Rate Specifying Apparatus, Navigation Apparatus, Computer Program for Specifying Intersection-Stopping-Rate, Computer Program for Conducting Navigation

InactiveUS20130006508A1Inform practical stoppage ratioRelieve stressAnalogue computers for vehiclesInstruments for road network navigationComputer scienceMarine navigation

Provided is an apparatus and method for automatically creating stopping rates of vehicles at signal-equipped intersections. A signal-equipped intersection to be subjected to specifying of stopping rates at signal-equipped intersections is selected from a signal-equipped-intersection information storage unit as a target intersection, a pass-through-intersection extraction that extracts a signal-equipped intersection that was passed-through just before reaching the target intersection as a pass-through intersection is conducted according to a prescribed rule, driving-history data of a probe car is classified for each of the routes that start from the pass-through intersection and pass through the target intersection, and the rate at which the probe car stopped at the target intersection is specified as a stopping rate, for each of the classified routes.

Owner:TOYOTA MAPMASTER +1

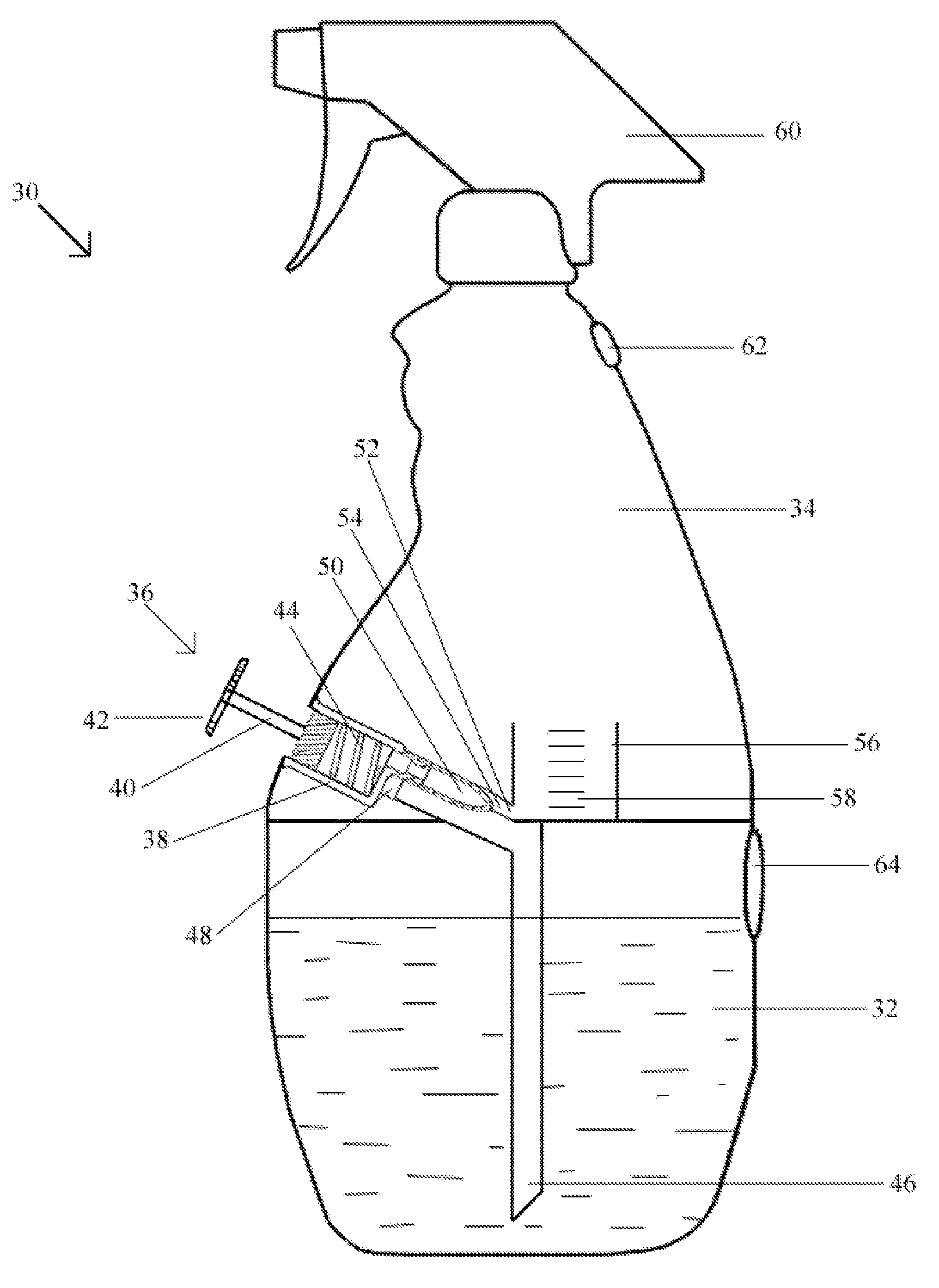

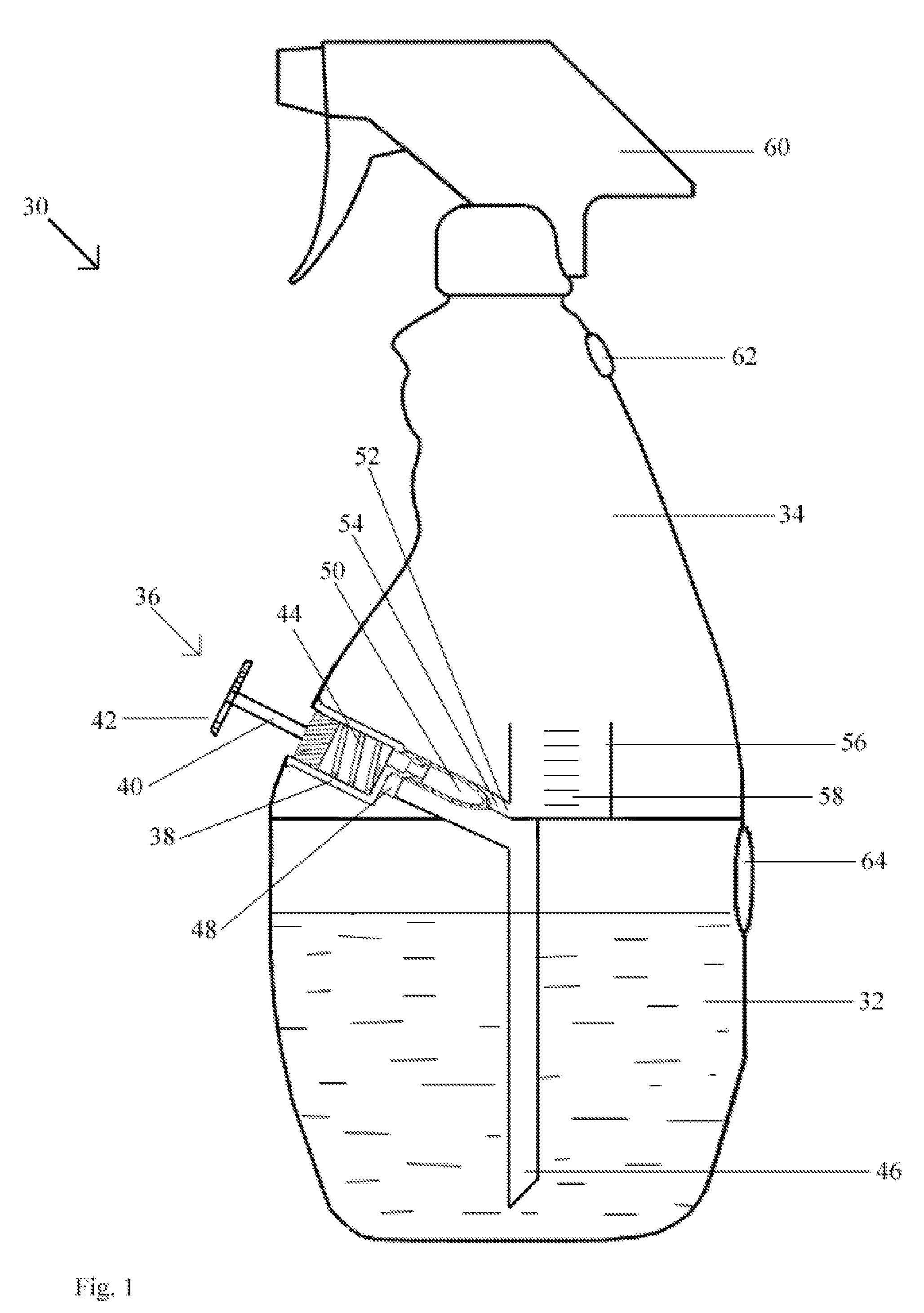

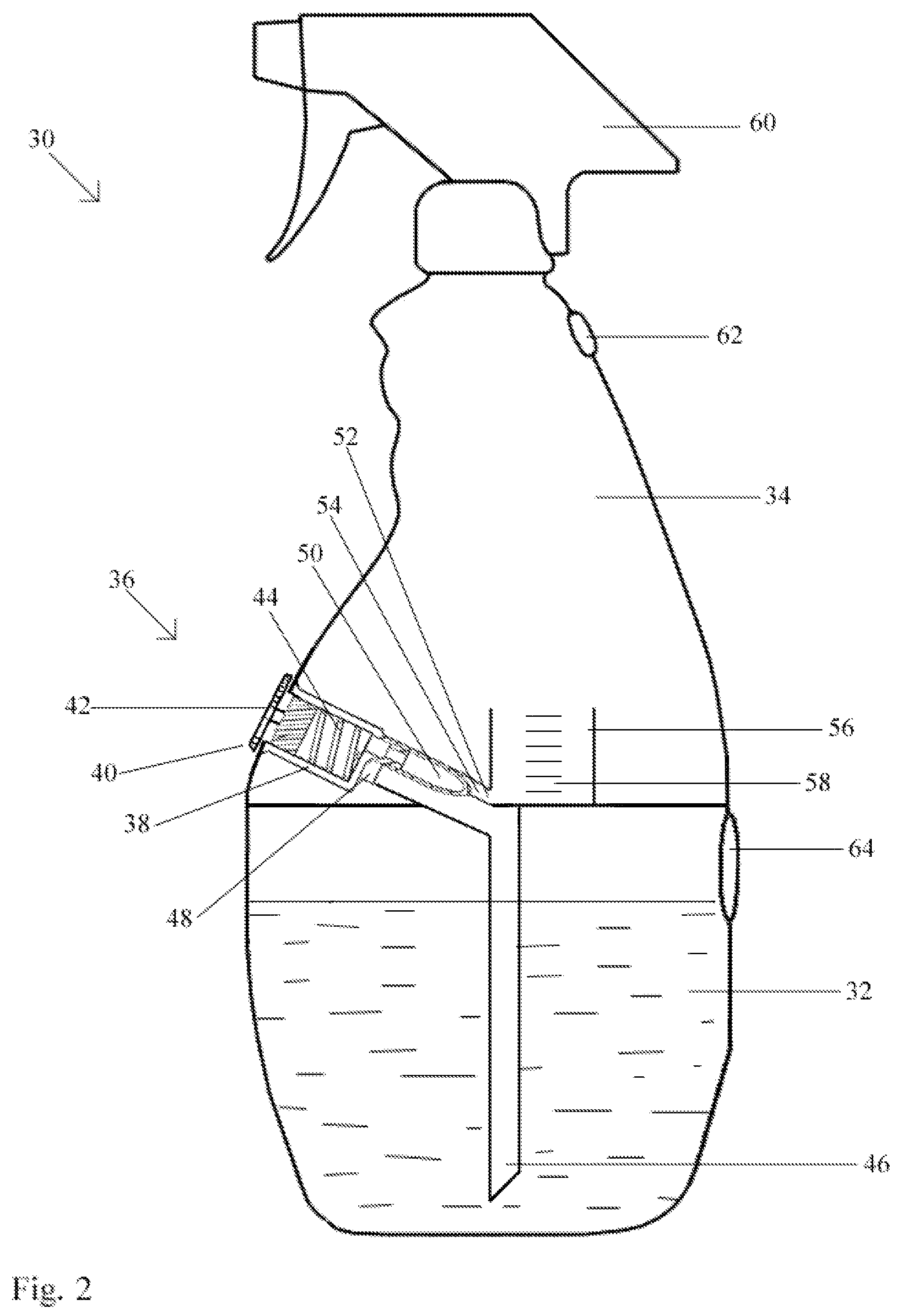

Refillable/reusable mixer bottle

ActiveUS7565988B2Easy to manufactureEasy to useLiquid transferring devicesSingle-unit apparatusEngineeringBottle

Owner:REPLENISH BOTTLING

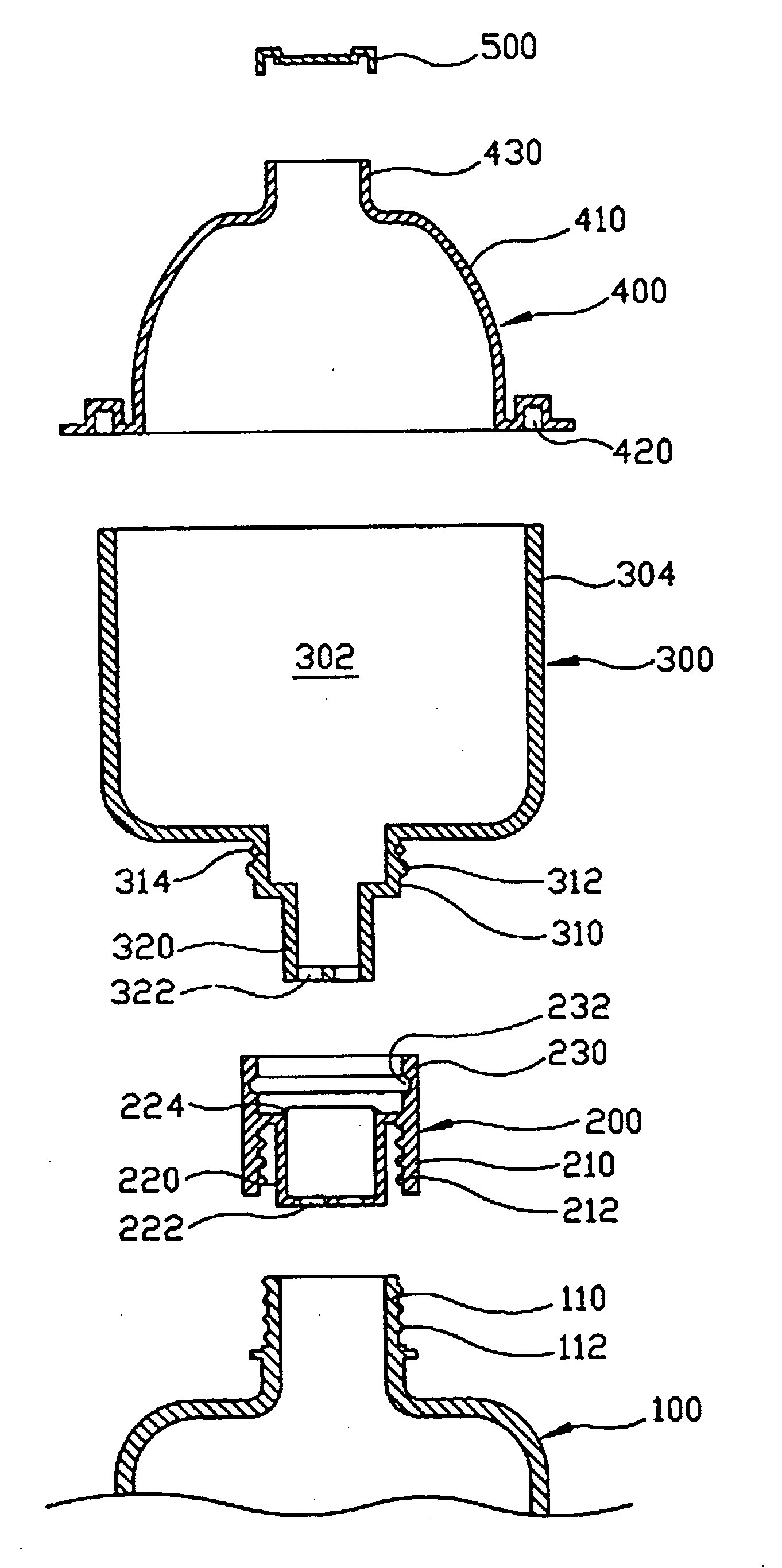

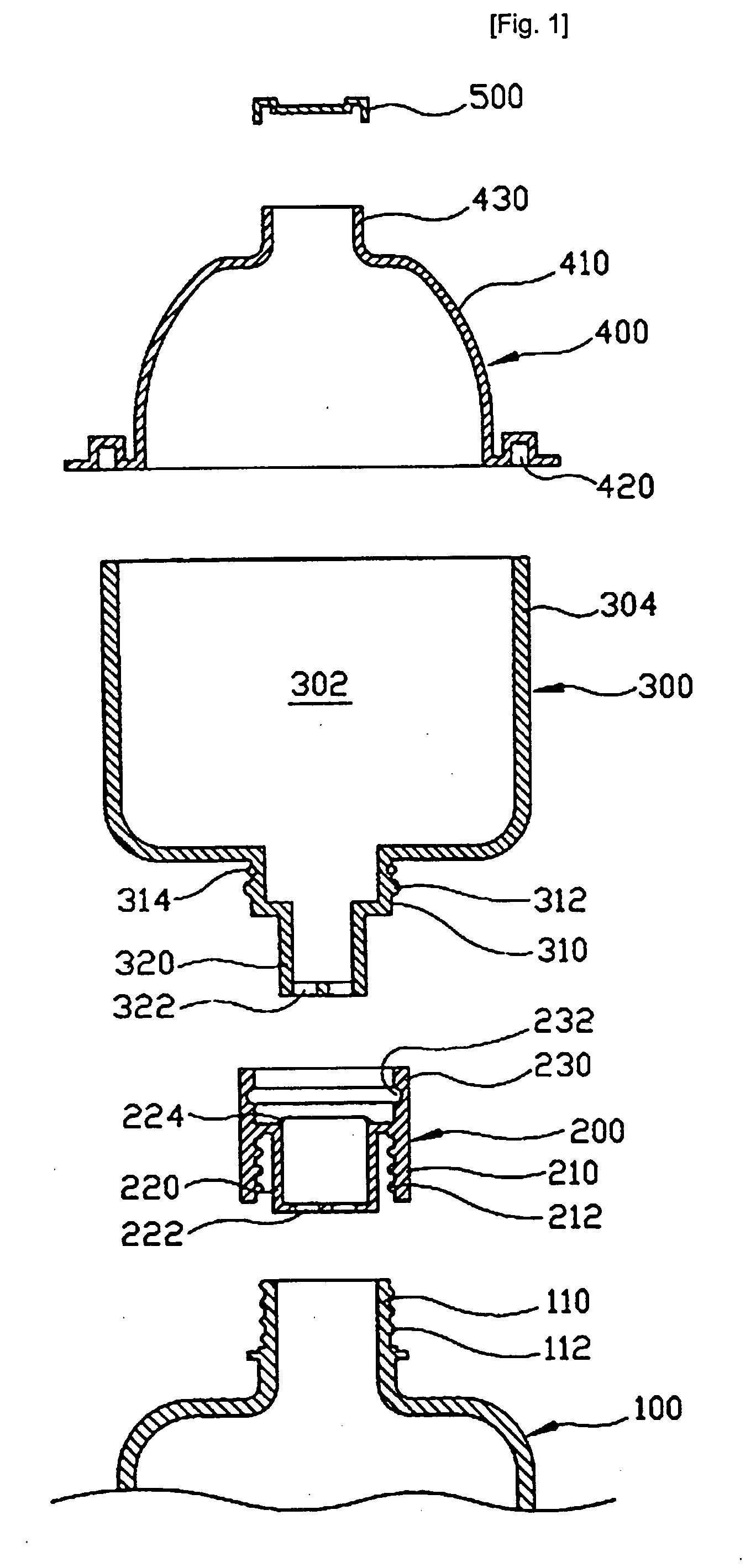

Bottle

InactiveUS20070119727A1Efficient mixingPrecise proportionClosure with auxillary devicesRigid containersEngineeringBottle

Disclosed herein is a bottle capable of storing or mixing two or more different materials. The bottle results from the combination of a general bottle body with a mixing means including an openable additive container. The bottle body may be separated from the additive container so that different materials can be separately stored and then combined with each other upon use. Thus, the bottle can open new markets due to its greatly enhanced storage performance and economical advantages.

Owner:CHO YOUNG KOOK

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS20060110339A1Desirable abrasiveGood thickening effectCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning silica materials and dentifrice containing such

InactiveUS20060110336A1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsToilet preparationsCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

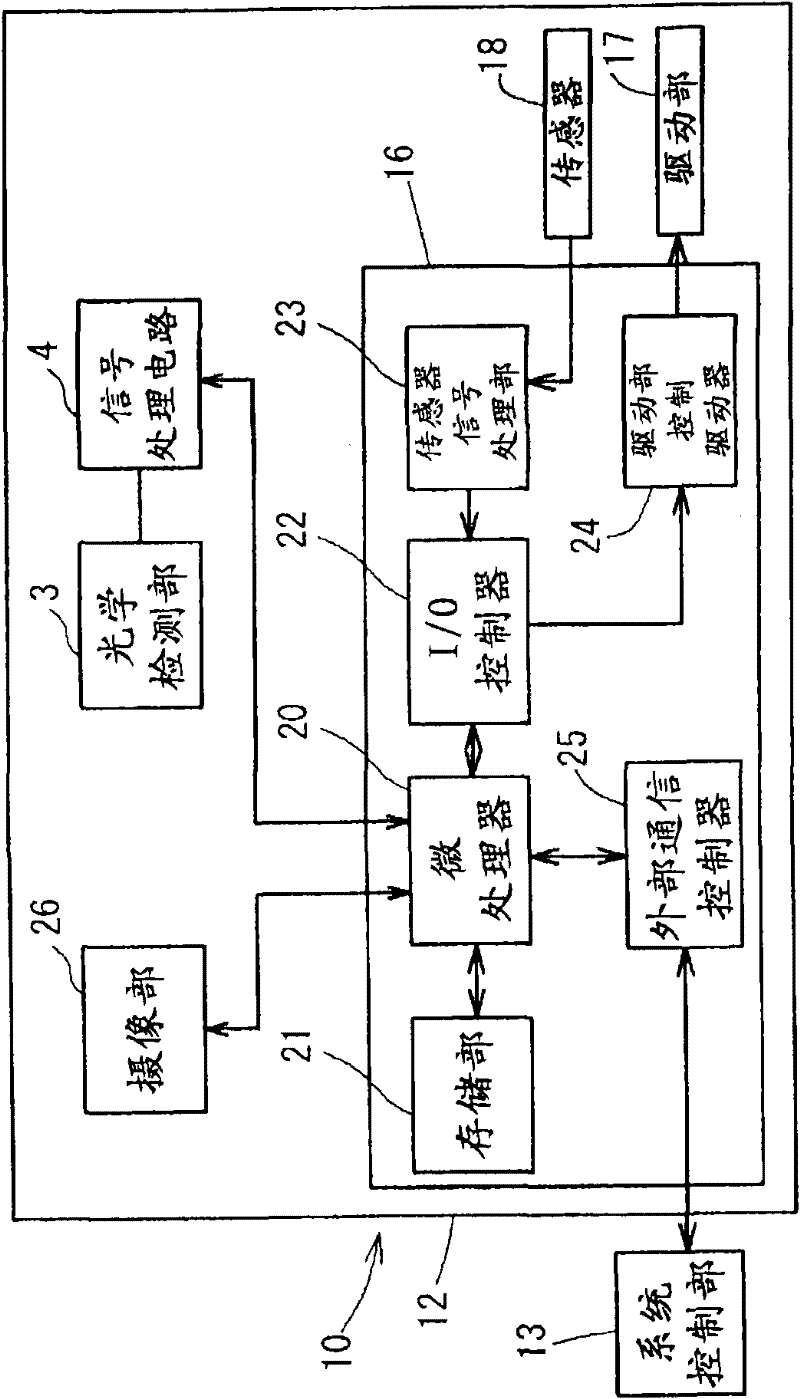

Cell analyzing apparatus and cell analyzing method

InactiveCN102053057AImprove reliabilityAccurate identificationIndividual particle analysisAnalysis methodComputer science

A cell analyzing apparatus, comprising: a parameter obtaining section for obtaining a characteristic parameter from a cell in a measurement sample; an imaging section for capturing an image of the cell in the measurement sample; an analyzing section for counting a cell in which the characteristic parameter meets a predetermined requirement among the cells in the measurement sample as a counting target and generating output data based on a counting result; a display section for displaying an image of the cell meeting the predetermined requirement and the output data; and an input section for receiving an instruction to specify the image displayed on the display section, wherein the analyzing section excludes a cell relevant to the specified image from the counting target and regenerates the output data is disclosed. A cell analyzing method is also disclosed.

Owner:SYSMEX CORP

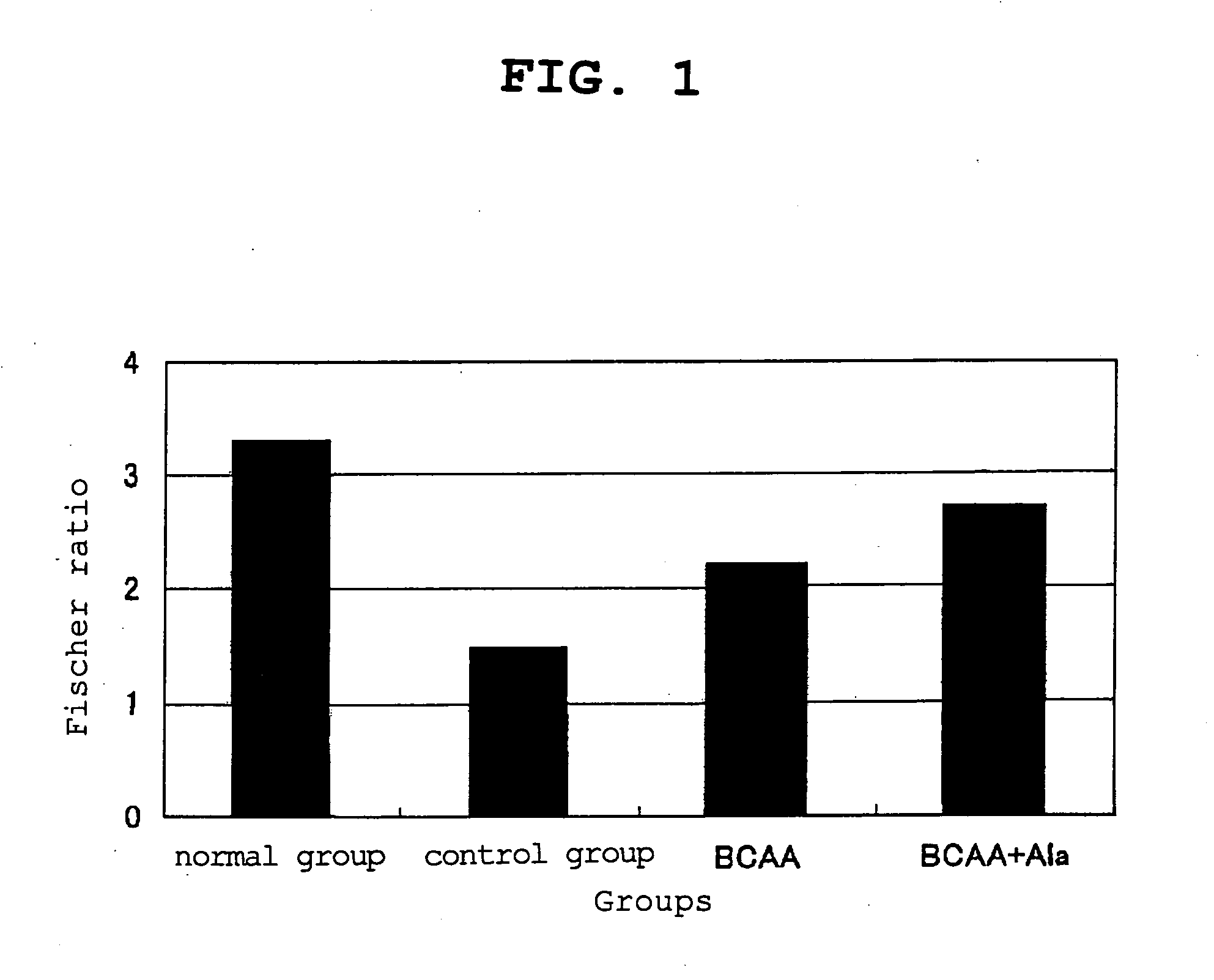

Therapeutic agent for hepatic disease

InactiveUS20050197398A1Good effectEffective treatmentBiocideOrganic active ingredientsDiseaseTherapeutic effect

Pharmaceutical compositions which contain isoleucine, leucine, valine, and alanine as active ingredients, are useful for treating liver diseases such as hepatitis, liver cirrhosis, liver cancer, and the like via maintenance and improvement of albumin level in blood. In preferred embodiments, the mass ratio of isoleucine:leucine:valine is 1:1.9 to 2.2:1.1 to 1.3; the mass ratio of the total mass of isoleucine, leucine and valine: alanine is 1:0.05 to 10; and a daily dose per person contains isoleucine in an amount of 0.2-30.0 g, leucine in an amount of 0.2-30.0 g, valine in an amount of 0.2-30.0 g, and alanine in an amount of 0.2-50.0 g.

Owner:AJINOMOTO CO INC

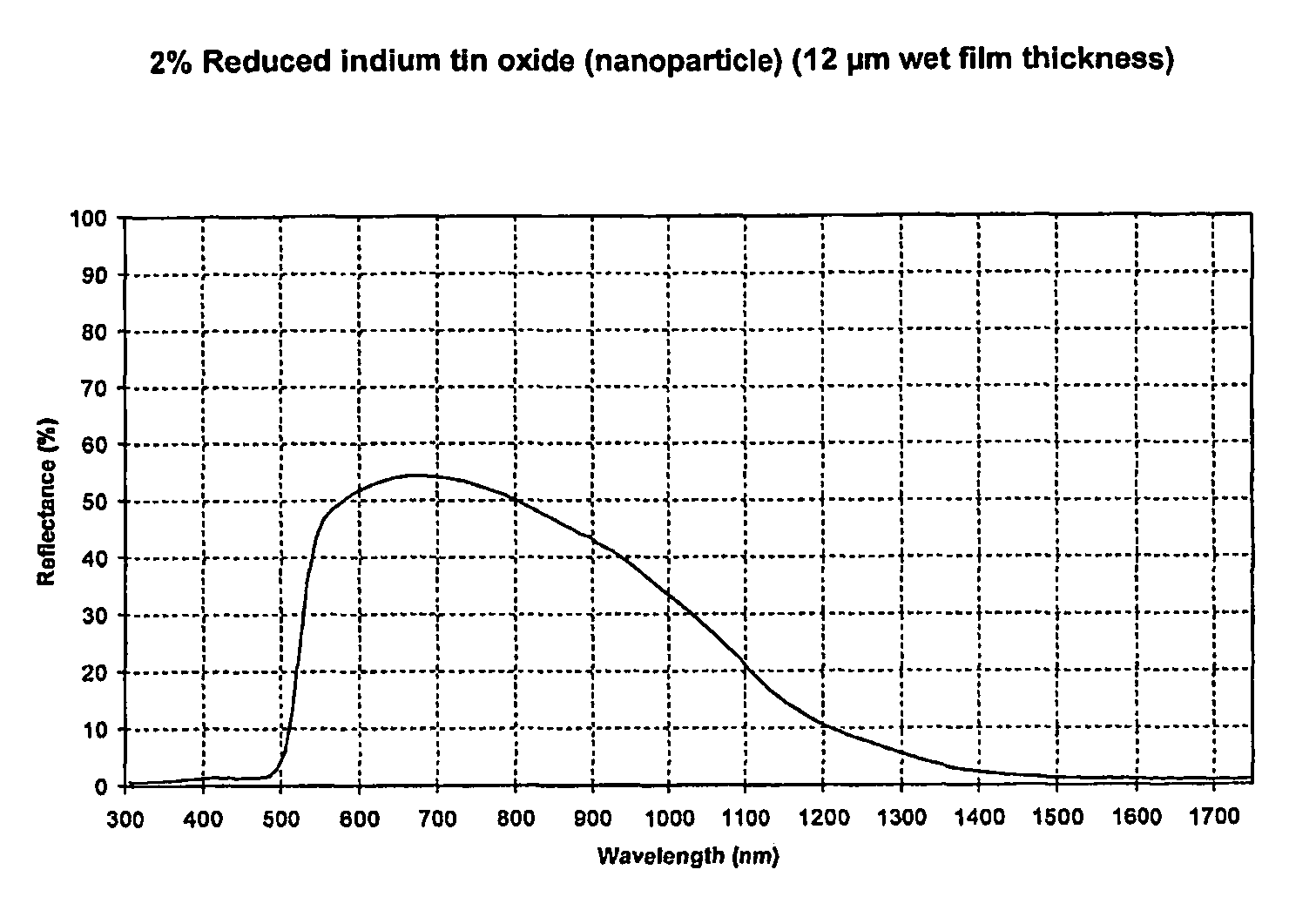

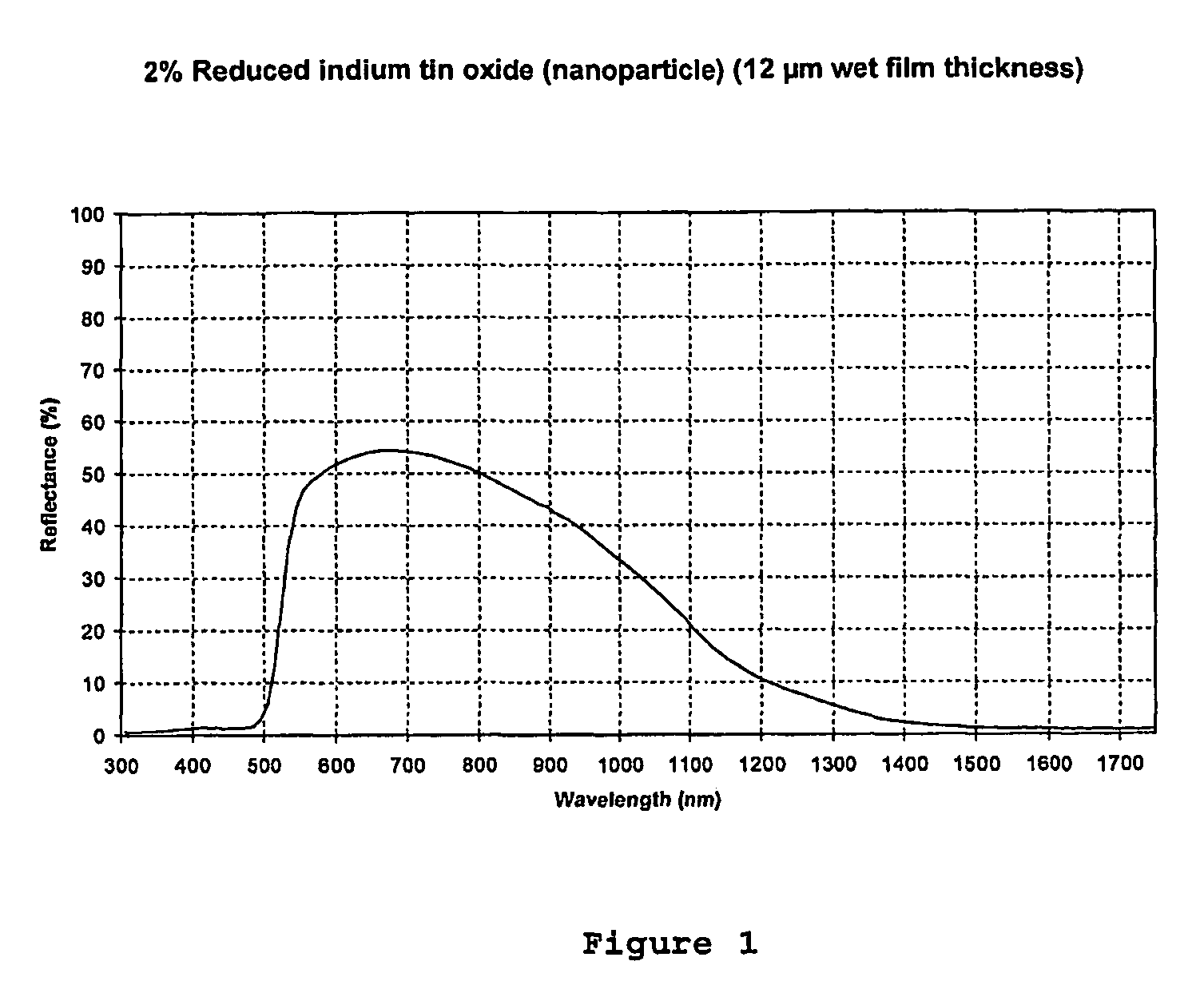

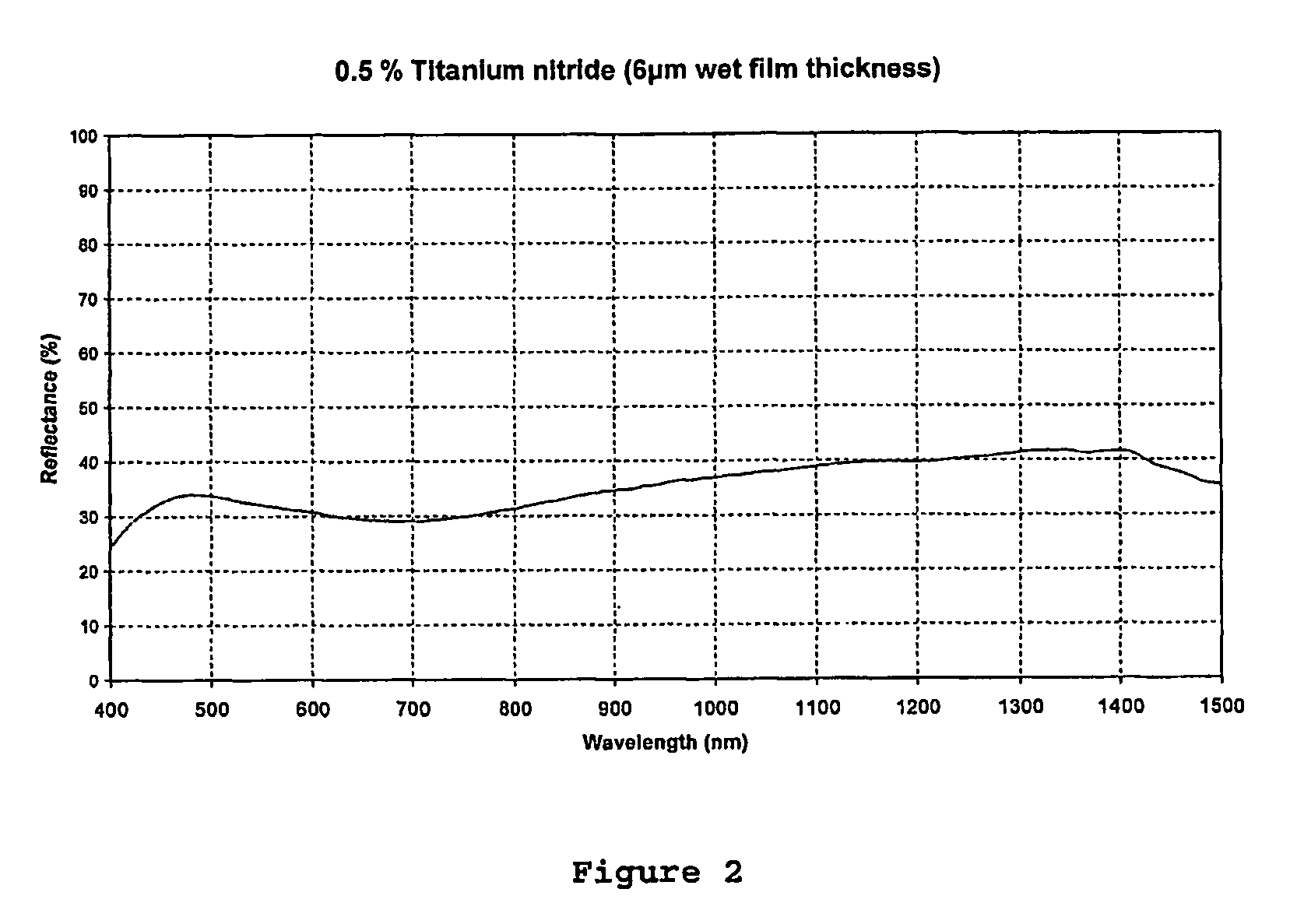

Security inks containing infrared absorbing metal compounds

ActiveUS8157905B2Easy to detectNot easy to detectNon-fibrous pulp additionLayered productsNeodymium chlorideLanthanum hexaboride

Composition including an oleophilic base ink composition having dispersed therein particles of an infrared-absorbing material wherein the infrared-absorbing material is selected from reduced indium tin oxide, titanium nitride, zirconium nitride, molybdenum metal, copper chromate, lanthanum hexaboride, neodymium oxide, neodymium chloride, dysprosium oxide and praseodymium oxide.

Owner:INOVINK

Method for cutting and correcting dislocation of paper note image

ActiveCN102831422APrecise proportionAccurate locationCharacter and pattern recognitionComputer scienceDislocation

The invention discloses a method for cutting and correcting dislocation of paper money images. The method comprises the following steps: paper notes are arranged on a conveyer belt; images on the positive sides and the back sides of the paper notes are scanned by using a CIS (corporate identity system) scanning device respectively; continuous full-size paper note images are obtained by the scanning device; the continuous paper note images are cut into single pieces of paper note images; the dislocation correction is carried out on the positive side images and the back side images respectively; and the inclination level correction is carried out on the positive side images and the back side images of the paper notes respectively. With the adoption of the method, paper note images with correct ratios and accurate positions can be provided.

Owner:杭州九聚科技有限公司

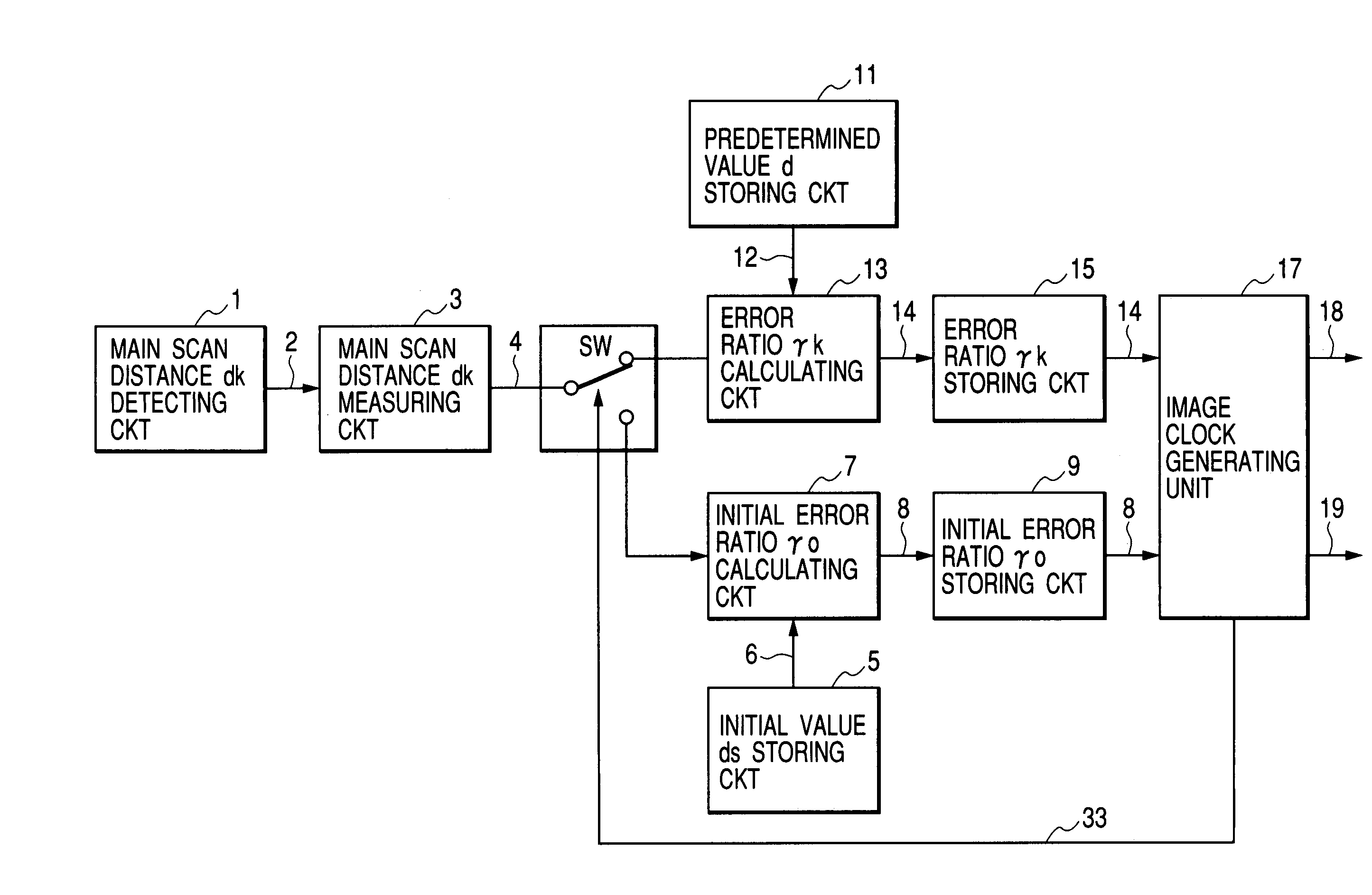

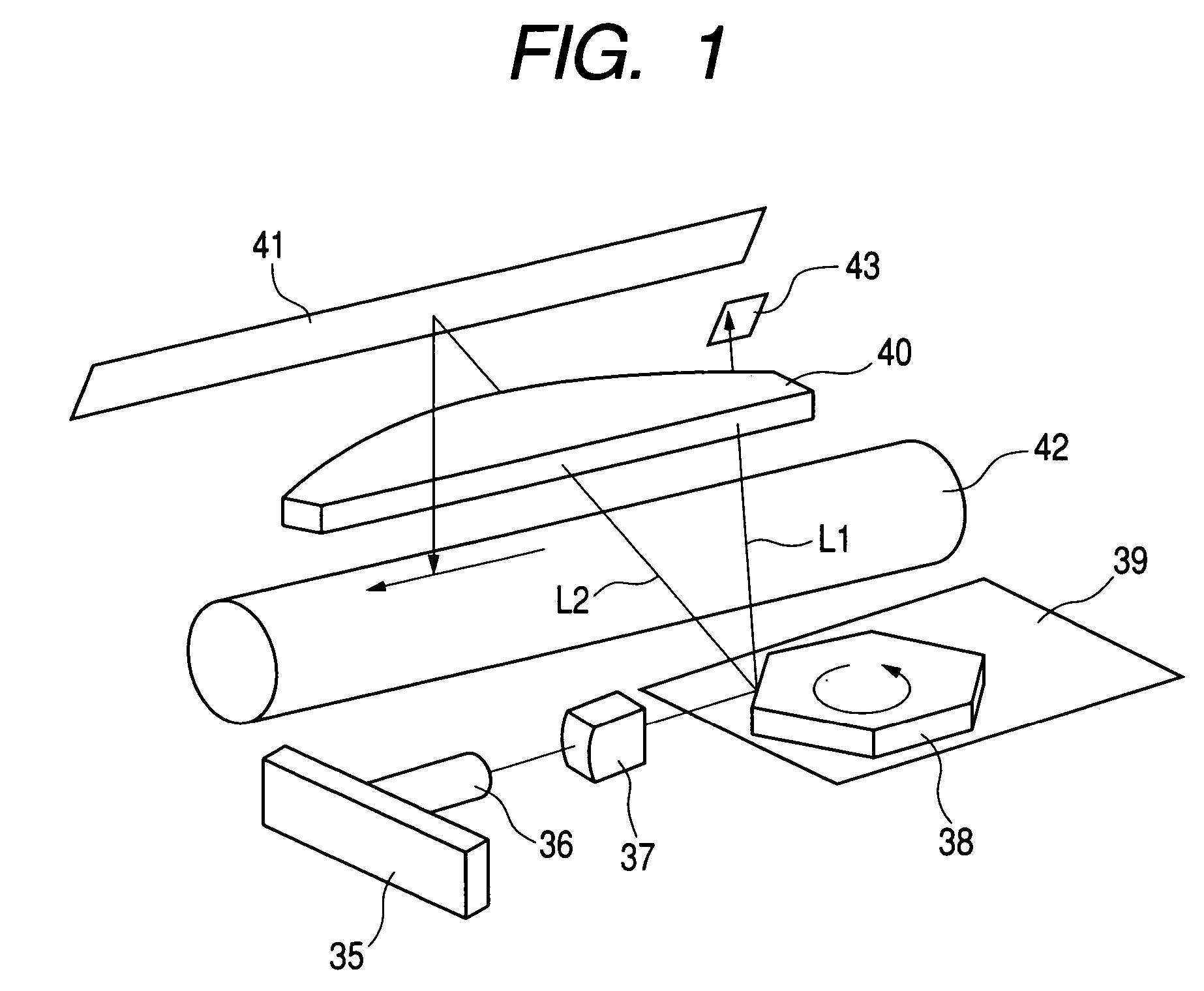

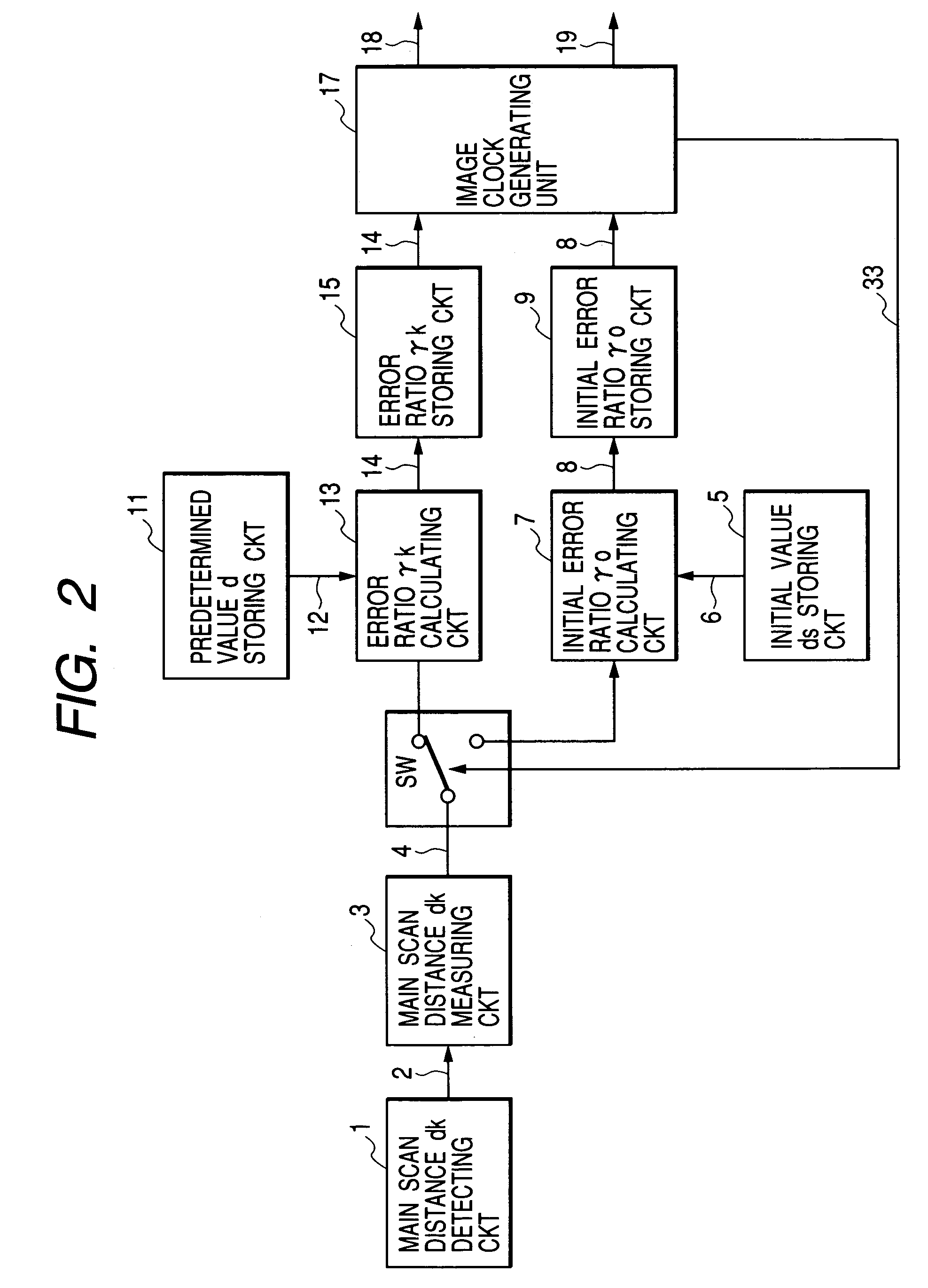

Frequency modulation apparatus and frequency modulation method

InactiveUS7129967B2Improve printing qualityImprove accuracyChestsBuilding locksScan lineMagnification

Disclosed are a frequency modulation apparatus and a frequency modulation method for generating an image clock that is used for turning on / off a laser beam that scans an image bearing member, such as a photosensitive drum. The frequency modulation apparatus divides, into a plurality of segments for each pixel, a main scan line on an image bearing member, and calculates auxiliary clock periods based on a reference clock period and variable-magnification coefficients corresponding to the segments. Then, the frequency modulation apparatus generates image clocks for the respective segments based on an initial predesignated period value and the obtained auxiliary clock periods. Furthermore, the frequency modulation apparatus includes a detecting device for detecting a difference between a reference value stored in a memory and an actual laser irradiation location, and corrects a shift in the laser irradiation location in accordance with the detection results obtained by the detecting device.

Owner:CANON KK

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS7270803B1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

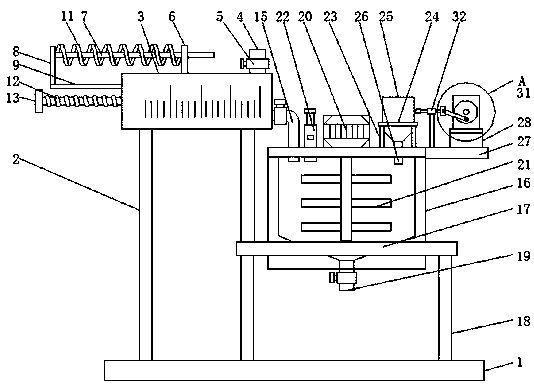

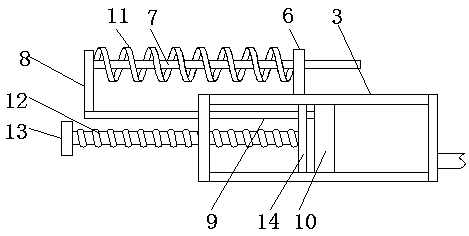

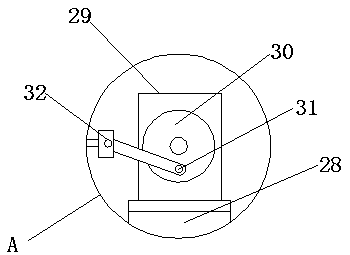

Dialysate preparing device for nephrology department

InactiveCN108283737AAffect the treatment effectPrecise proportionRotary stirring mixersTransportation and packagingEngineeringTherapeutic effect

The inventio relates to the field of medical devices, and discloses a dialysate preparing device for the nephrology department. The dialysate preparing device comprises a base, wherein support rods are fixedly mounted on the side face of the top of the base, four support rods are available, for the four support rods, each two support rods form one group, the support rods are symmetrically distributed on the base, the top ends of the four support rods are fixedly connected with a liquid guide box, and a water inlet pipe fixedly sleeves one side of the top of the liquid guide box. For the dialysate preparing device for the nephrology department provided by the invention, dialysate preparing dry powder is added into a feeding box and enters a stirring box through a material guide pipe, a threaded rod drives a baffle to move, in match with scale lines on the liquid guide box, the water amount needing to be added is controlled, through extruding of a piston, water enters the stirring box tobe mixed with the dry powder, thus the ratio of water to the dry powder is accurate, so that the problem that during artificial preparation, the water adding amount has errors, consequently, the concentration of the dialysate is not accurate, and the treatment effect of the dialysate is influenced, is solved.

Owner:鄢海军

Cement stabilization of soils using a proportional cement slurry

ActiveUS7993451B2Composition is stableAvoid settingSolid waste managementCement mixing apparatusCelluloseChemical treatment

A novel cement slurry composed of cement and water that can be used in cement stabilization applications. The cement slurry compound itself is chemically treated, by means of a cellulosic or other thixotropic thickening agent(s) to create a thixotropic system wherein the wetted cement remains in suspension and does not settle out prior to use even without further mixing. A chemical retarder / stabilizer is also used to prevent the slurry from prematurely setting during shipping. A novel apparatus and method for mixing the novel cement slurry is disclosed to insure the exact proportioning of all ingredients and the proper wetting of the cement.

Owner:TEXAS INDUSTRIES

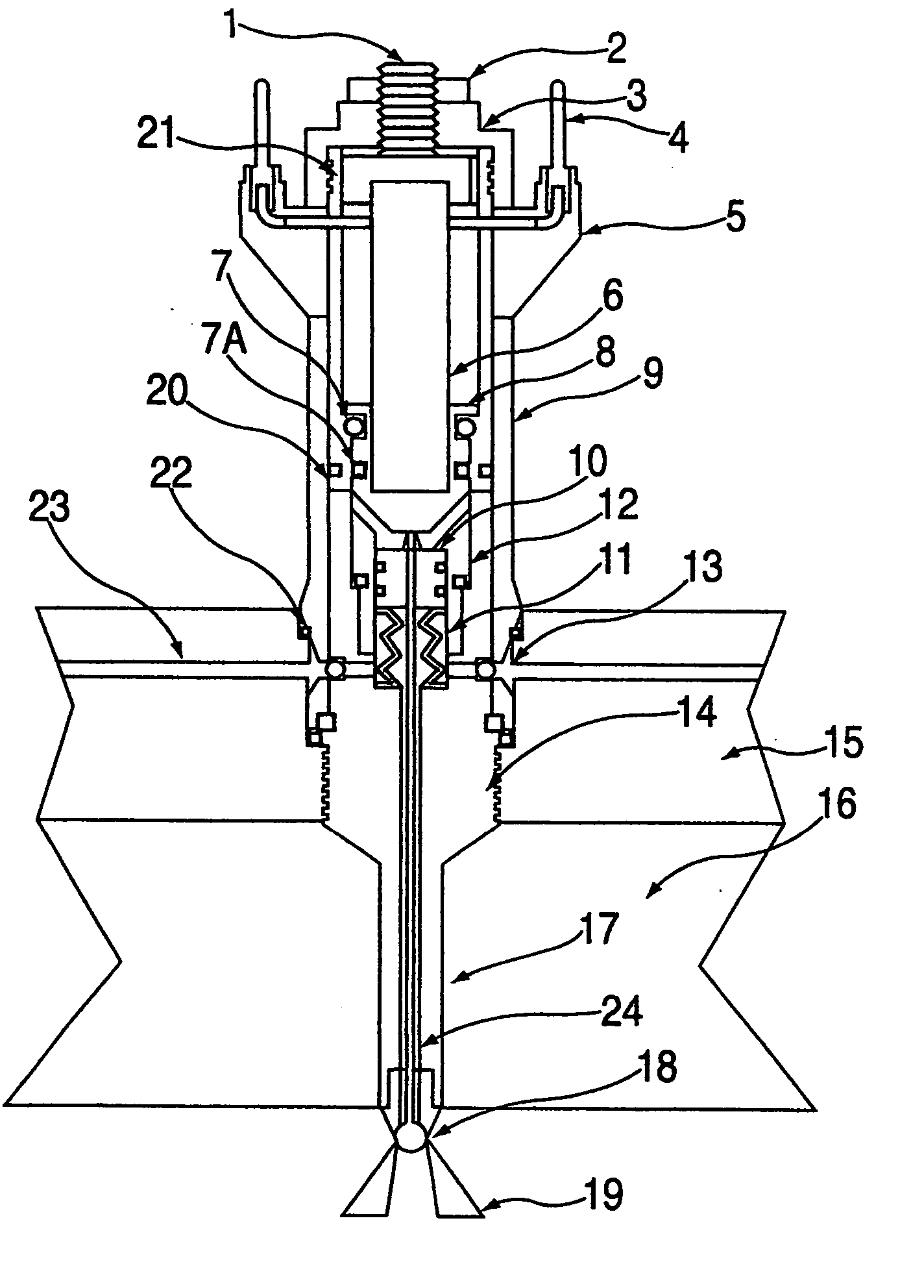

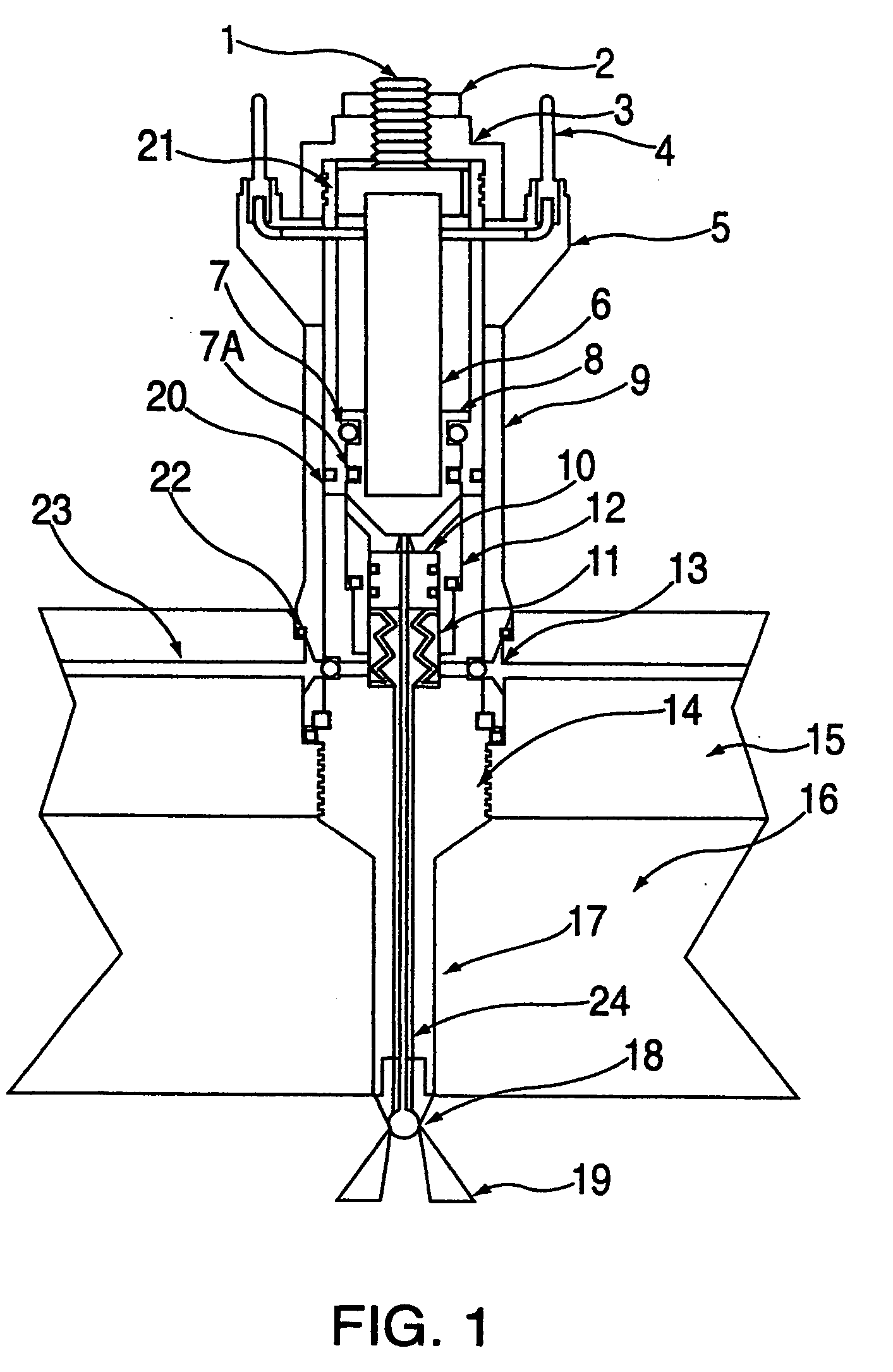

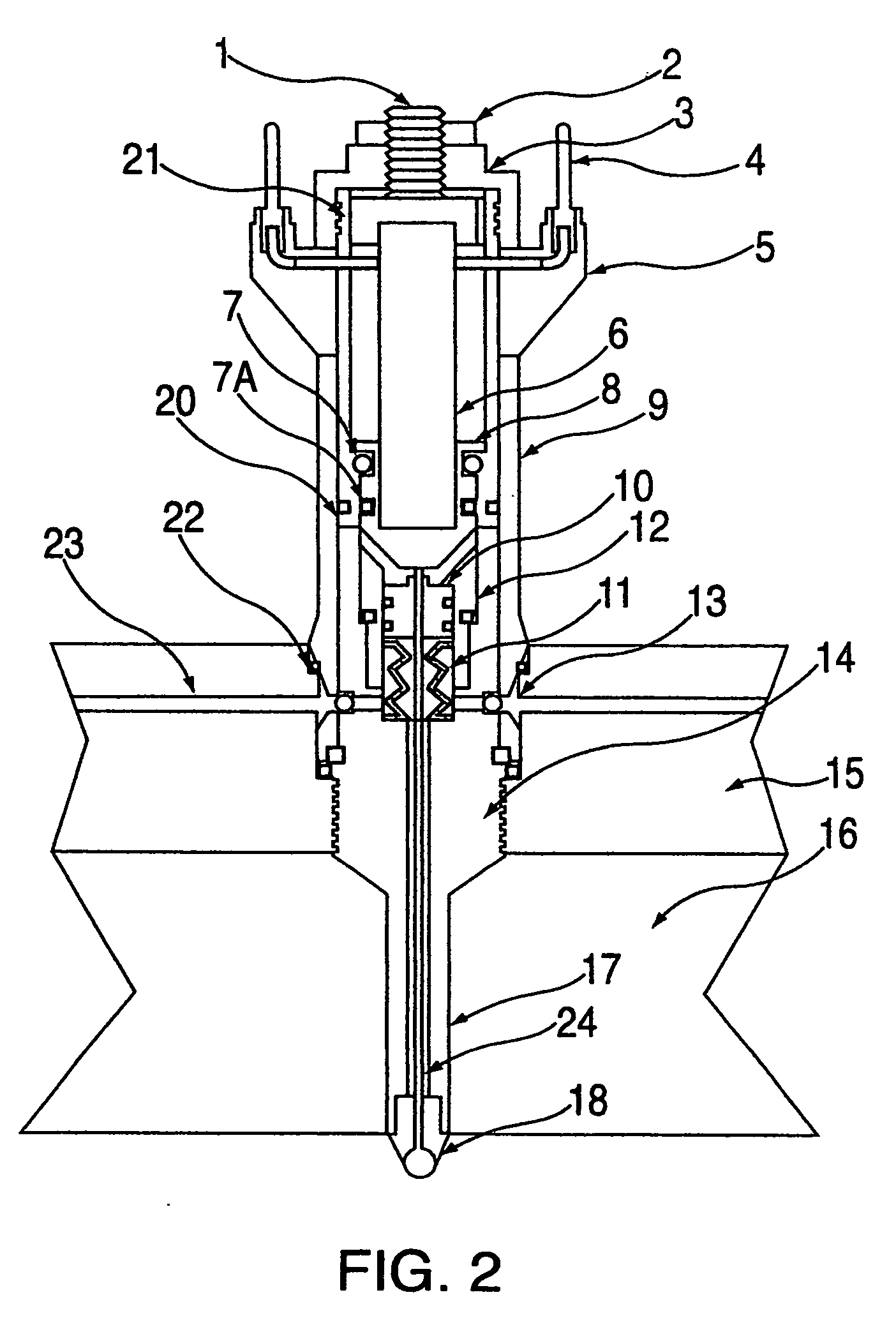

Piezoelectric liquid injector

InactiveUS20070069043A1Amount of fuel be smallSimple to buildLiquid surface applicatorsSelf-acting watering devicesInjectorNeedle valve

A fuel or liquid injector includes a needle valve and a piezoelectric actuator that bears a hydraulic acceleration piston on its distal end. The actuator expands moving the piston toward the needle valve. The needle valve has a ball end, restrained against the valve seat by a spring, sealing the valve until the spring force is overcome by mechanical and hydraulic forces on the piston. When closed, the piston rests against the needle valve. Expansion of the piezoelectric actuator mechanically actuates the piston, and then increases the hydraulic pressure, which closes the fuel check valve, and accelerates the forward movement of the piston attached to the needle valve. When the restraining force on the needle valve is overcome, the ball end of the needle valve is unseated, and compressed fluid in the lower hydraulic chamber is released in a high velocity spray.

Owner:AXIAL VECTOR ENGINE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com